ignition DAEWOO NUBIRA 2004 Service Repair Manual

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: NUBIRA, Model: DAEWOO NUBIRA 2004Pages: 2643, PDF Size: 80.54 MB

Page 344 of 2643

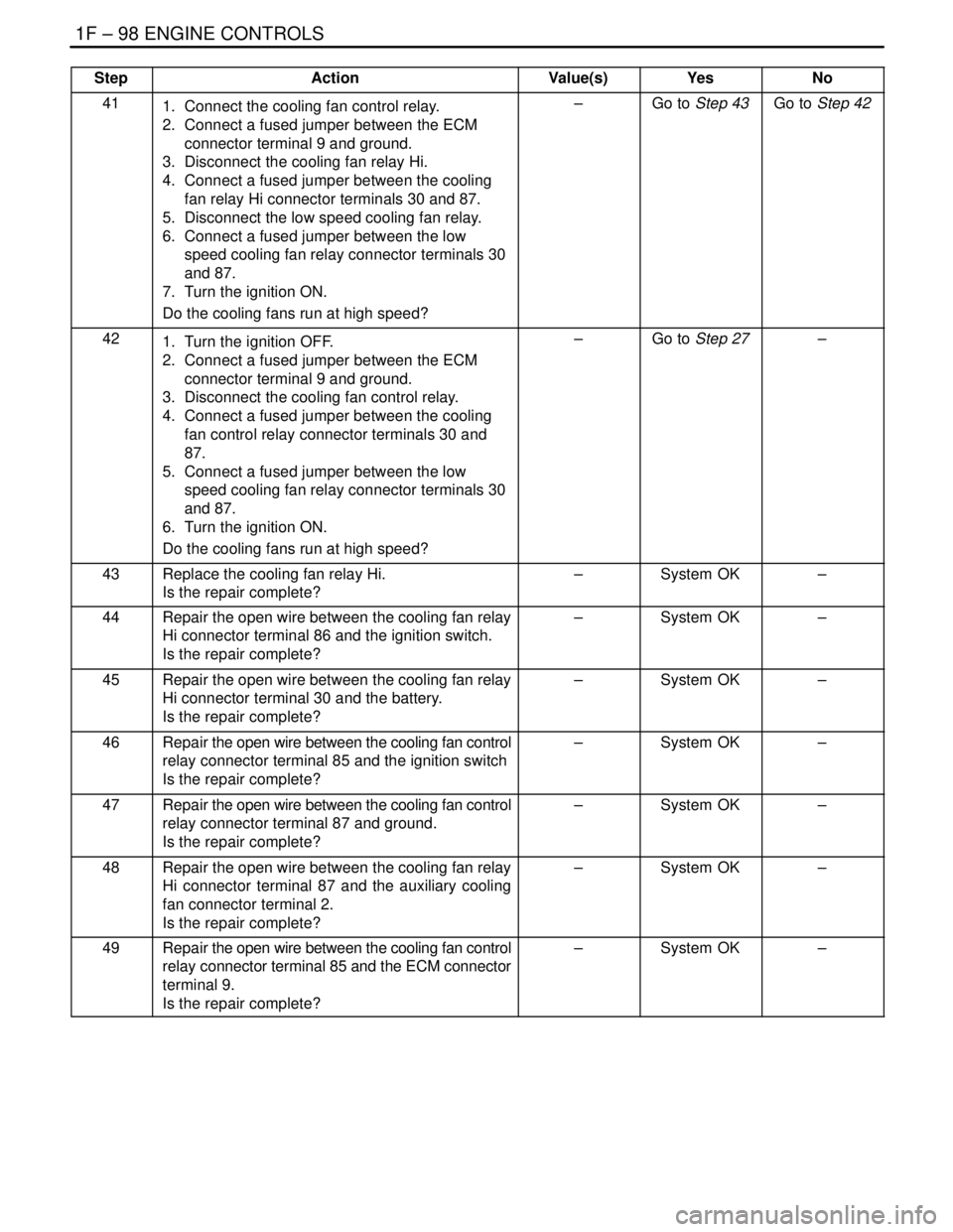

1F – 98IENGINE CONTROLS

DAEWOO V–121 BL4

StepNo Yes Value(s) Action

411. Connect the cooling fan control relay.

2. Connect a fused jumper between the ECM

connector terminal 9 and ground.

3. Disconnect the cooling fan relay Hi.

4. Connect a fused jumper between the cooling

fan relay Hi connector terminals 30 and 87.

5. Disconnect the low speed cooling fan relay.

6. Connect a fused jumper between the low

speed cooling fan relay connector terminals 30

and 87.

7. Turn the ignition ON.

Do the cooling fans run at high speed?–Go to Step 43Go to Step 42

421. Turn the ignition OFF.

2. Connect a fused jumper between the ECM

connector terminal 9 and ground.

3. Disconnect the cooling fan control relay.

4. Connect a fused jumper between the cooling

fan control relay connector terminals 30 and

87.

5. Connect a fused jumper between the low

speed cooling fan relay connector terminals 30

and 87.

6. Turn the ignition ON.

Do the cooling fans run at high speed?–Go to Step 27–

43Replace the cooling fan relay Hi.

Is the repair complete?–System OK–

44Repair the open wire between the cooling fan relay

Hi connector terminal 86 and the ignition switch.

Is the repair complete?–System OK–

45Repair the open wire between the cooling fan relay

Hi connector terminal 30 and the battery.

Is the repair complete?–System OK–

46Repair the open wire between the cooling fan control

relay connector terminal 85 and the ignition switch

Is the repair complete?–System OK–

47Repair the open wire between the cooling fan control

relay connector terminal 87 and ground.

Is the repair complete?–System OK–

48Repair the open wire between the cooling fan relay

Hi connector terminal 87 and the auxiliary cooling

fan connector terminal 2.

Is the repair complete?–System OK–

49Repair the open wire between the cooling fan control

relay connector terminal 85 and the ECM connector

terminal 9.

Is the repair complete?–System OK–

Page 346 of 2643

1F – 100IENGINE CONTROLS

DAEWOO V–121 BL4

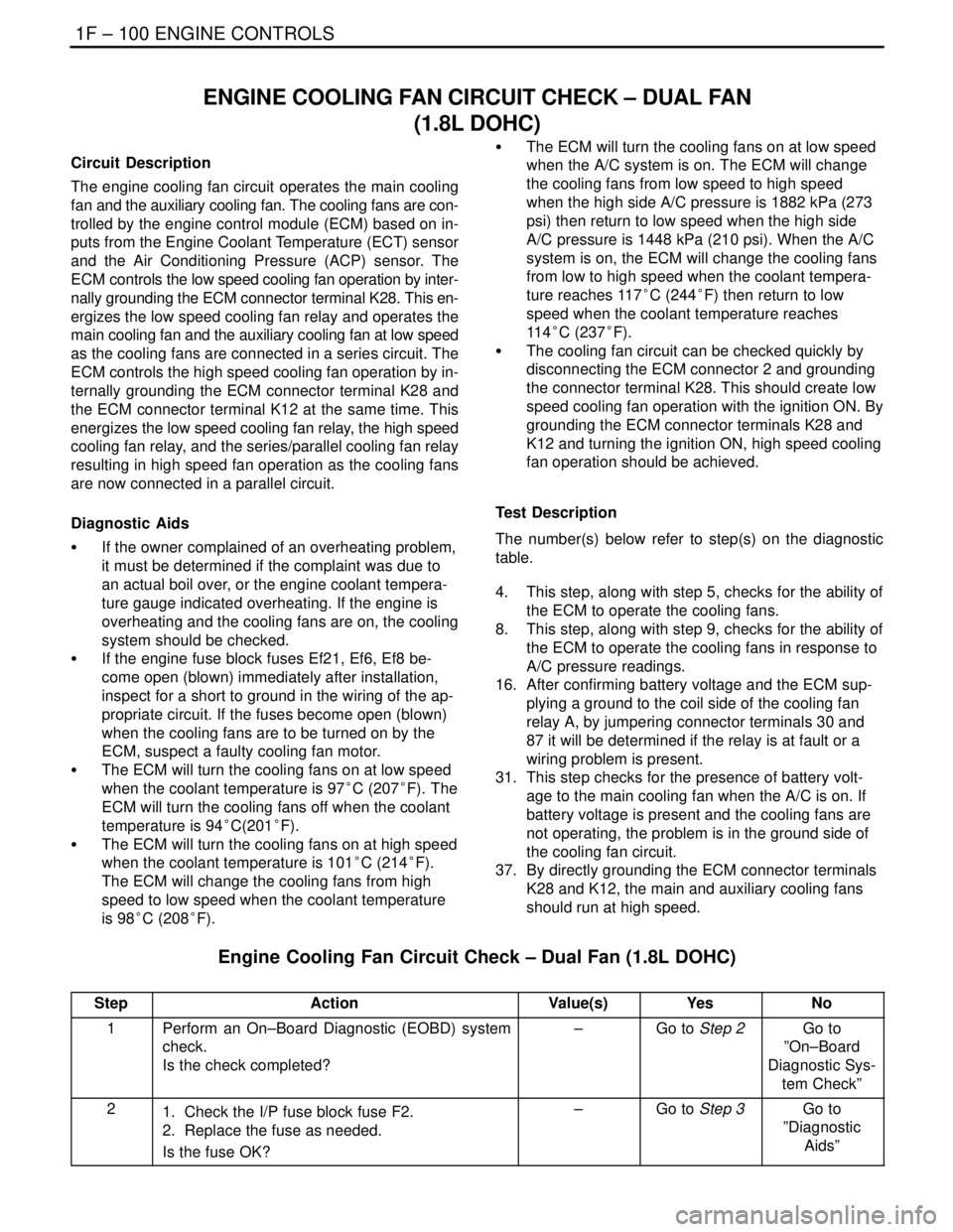

ENGINE COOLING FAN CIRCUIT CHECK – DUAL FAN

(1.8L DOHC)

Circuit Description

The engine cooling fan circuit operates the main cooling

fan and the auxiliary cooling fan. The cooling fans are con-

trolled by the engine control module (ECM) based on in-

puts from the Engine Coolant Temperature (ECT) sensor

and the Air Conditioning Pressure (ACP) sensor. The

ECM controls the low speed cooling fan operation by inter-

nally grounding the ECM connector terminal K28. This en-

ergizes the low speed cooling fan relay and operates the

main cooling fan and the auxiliary cooling fan at low speed

as the cooling fans are connected in a series circuit. The

ECM controls the high speed cooling fan operation by in-

ternally grounding the ECM connector terminal K28 and

the ECM connector terminal K12 at the same time. This

energizes the low speed cooling fan relay, the high speed

cooling fan relay, and the series/parallel cooling fan relay

resulting in high speed fan operation as the cooling fans

are now connected in a parallel circuit.

Diagnostic Aids

S If the owner complained of an overheating problem,

it must be determined if the complaint was due to

an actual boil over, or the engine coolant tempera-

ture gauge indicated overheating. If the engine is

overheating and the cooling fans are on, the cooling

system should be checked.

S If the engine fuse block fuses Ef21, Ef6, Ef8 be-

come open (blown) immediately after installation,

inspect for a short to ground in the wiring of the ap-

propriate circuit. If the fuses become open (blown)

when the cooling fans are to be turned on by the

ECM, suspect a faulty cooling fan motor.

S The ECM will turn the cooling fans on at low speed

when the coolant temperature is 97°C (207°F). The

ECM will turn the cooling fans off when the coolant

temperature is 94°C(201°F).

S The ECM will turn the cooling fans on at high speed

when the coolant temperature is 101°C (214°F).

The ECM will change the cooling fans from high

speed to low speed when the coolant temperature

is 98°C (208°F).S The ECM will turn the cooling fans on at low speed

when the A/C system is on. The ECM will change

the cooling fans from low speed to high speed

when the high side A/C pressure is 1882 kPa (273

psi) then return to low speed when the high side

A/C pressure is 1448 kPa (210 psi). When the A/C

system is on, the ECM will change the cooling fans

from low to high speed when the coolant tempera-

ture reaches 117°C (244°F) then return to low

speed when the coolant temperature reaches

11 4°C (237°F).

S The cooling fan circuit can be checked quickly by

disconnecting the ECM connector 2 and grounding

the connector terminal K28. This should create low

speed cooling fan operation with the ignition ON. By

grounding the ECM connector terminals K28 and

K12 and turning the ignition ON, high speed cooling

fan operation should be achieved.

Test Description

The number(s) below refer to step(s) on the diagnostic

table.

4. This step, along with step 5, checks for the ability of

the ECM to operate the cooling fans.

8. This step, along with step 9, checks for the ability of

the ECM to operate the cooling fans in response to

A/C pressure readings.

16. After confirming battery voltage and the ECM sup-

plying a ground to the coil side of the cooling fan

relay A, by jumpering connector terminals 30 and

87 it will be determined if the relay is at fault or a

wiring problem is present.

31. This step checks for the presence of battery volt-

age to the main cooling fan when the A/C is on. If

battery voltage is present and the cooling fans are

not operating, the problem is in the ground side of

the cooling fan circuit.

37. By directly grounding the ECM connector terminals

K28 and K12, the main and auxiliary cooling fans

should run at high speed.

Engine Cooling Fan Circuit Check – Dual Fan (1.8L DOHC)

StepActionValue(s)YesNo

1Perform an On–Board Diagnostic (EOBD) system

check.

Is the check completed?–Go to Step 2Go to

”On–Board

Diagnostic Sys-

tem Check”

21. Check the I/P fuse block fuse F2.

2. Replace the fuse as needed.

Is the fuse OK?–Go to Step 3Go to

”Diagnostic

Aids”

Page 347 of 2643

ENGINE CONTROLS 1F – 101

DAEWOO V–121 BL4

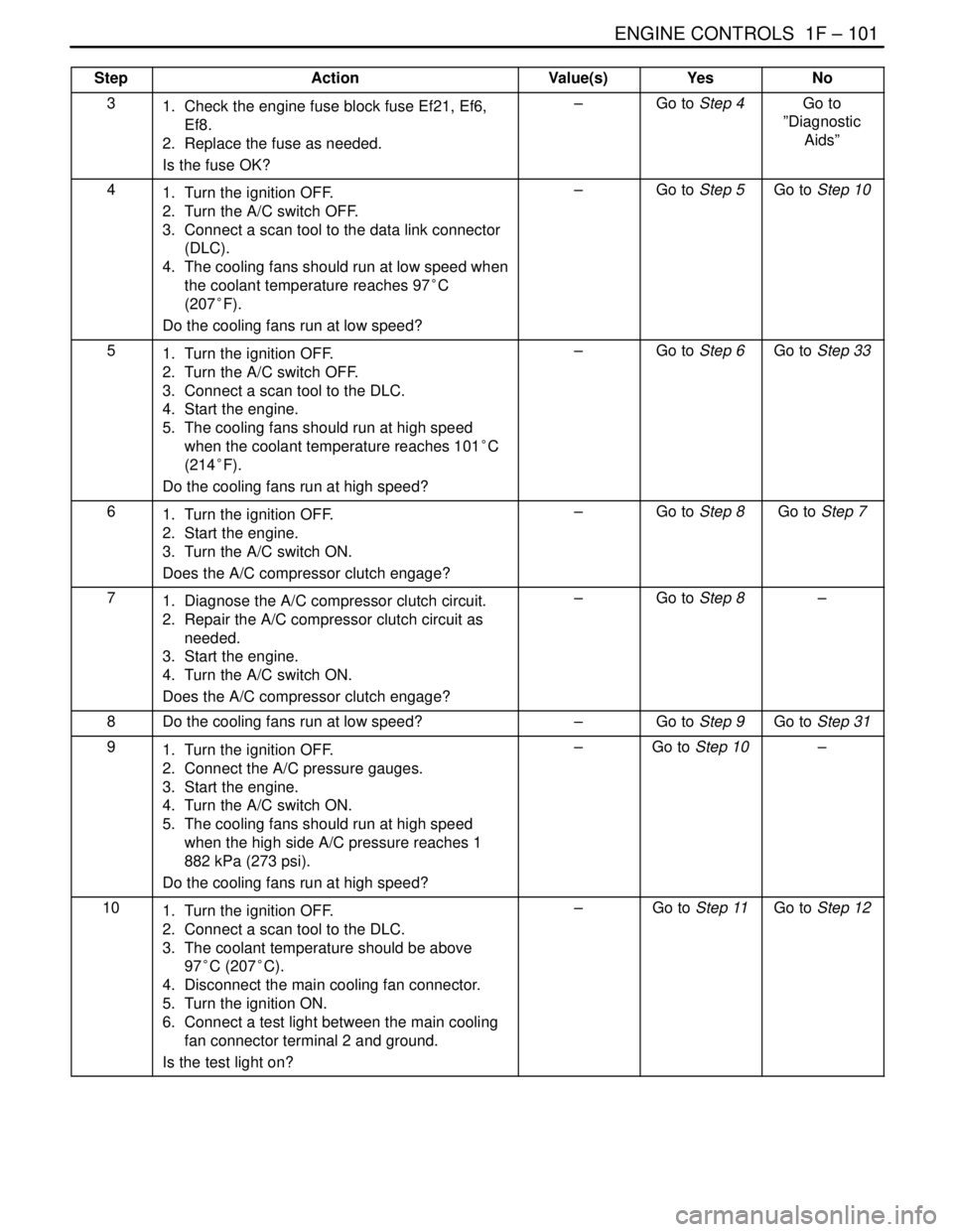

StepNo Yes Value(s) Action

31. Check the engine fuse block fuse Ef21, Ef6,

Ef8.

2. Replace the fuse as needed.

Is the fuse OK?–Go to Step 4Go to

”Diagnostic

Aids”

41. Turn the ignition OFF.

2. Turn the A/C switch OFF.

3. Connect a scan tool to the data link connector

(DLC).

4. The cooling fans should run at low speed when

the coolant temperature reaches 97°C

(207°F).

Do the cooling fans run at low speed?–Go to Step 5Go to Step 10

51. Turn the ignition OFF.

2. Turn the A/C switch OFF.

3. Connect a scan tool to the DLC.

4. Start the engine.

5. The cooling fans should run at high speed

when the coolant temperature reaches 101°C

(214°F).

Do the cooling fans run at high speed?–Go to Step 6Go to Step 33

61. Turn the ignition OFF.

2. Start the engine.

3. Turn the A/C switch ON.

Does the A/C compressor clutch engage?–Go to Step 8Go to Step 7

71. Diagnose the A/C compressor clutch circuit.

2. Repair the A/C compressor clutch circuit as

needed.

3. Start the engine.

4. Turn the A/C switch ON.

Does the A/C compressor clutch engage?–Go to Step 8–

8Do the cooling fans run at low speed?–Go to Step 9Go to Step 31

91. Turn the ignition OFF.

2. Connect the A/C pressure gauges.

3. Start the engine.

4. Turn the A/C switch ON.

5. The cooling fans should run at high speed

when the high side A/C pressure reaches 1

882 kPa (273 psi).

Do the cooling fans run at high speed?–Go to Step 10–

101. Turn the ignition OFF.

2. Connect a scan tool to the DLC.

3. The coolant temperature should be above

97°C (207°C).

4. Disconnect the main cooling fan connector.

5. Turn the ignition ON.

6. Connect a test light between the main cooling

fan connector terminal 2 and ground.

Is the test light on?–Go to Step 11Go to Step 12

Page 348 of 2643

1F – 102IENGINE CONTROLS

DAEWOO V–121 BL4

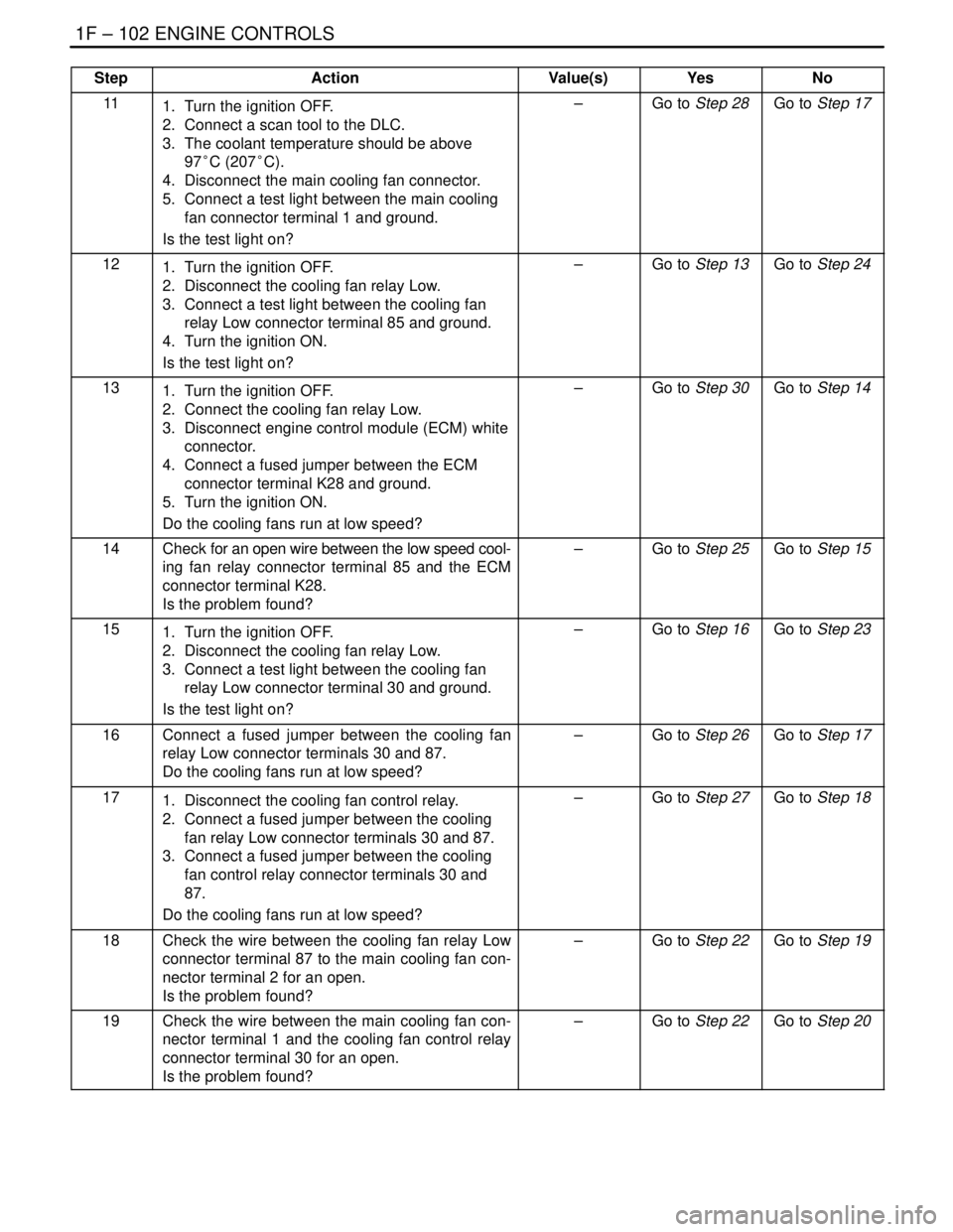

StepNo Yes Value(s) Action

111. Turn the ignition OFF.

2. Connect a scan tool to the DLC.

3. The coolant temperature should be above

97°C (207°C).

4. Disconnect the main cooling fan connector.

5. Connect a test light between the main cooling

fan connector terminal 1 and ground.

Is the test light on?–Go to Step 28Go to Step 17

121. Turn the ignition OFF.

2. Disconnect the cooling fan relay Low.

3. Connect a test light between the cooling fan

relay Low connector terminal 85 and ground.

4. Turn the ignition ON.

Is the test light on?–Go to Step 13Go to Step 24

131. Turn the ignition OFF.

2. Connect the cooling fan relay Low.

3. Disconnect engine control module (ECM) white

connector.

4. Connect a fused jumper between the ECM

connector terminal K28 and ground.

5. Turn the ignition ON.

Do the cooling fans run at low speed?–Go to Step 30Go to Step 14

14Check for an open wire between the low speed cool-

ing fan relay connector terminal 85 and the ECM

connector terminal K28.

Is the problem found?–Go to Step 25Go to Step 15

151. Turn the ignition OFF.

2. Disconnect the cooling fan relay Low.

3. Connect a test light between the cooling fan

relay Low connector terminal 30 and ground.

Is the test light on?–Go to Step 16Go to Step 23

16Connect a fused jumper between the cooling fan

relay Low connector terminals 30 and 87.

Do the cooling fans run at low speed?–Go to Step 26Go to Step 17

171. Disconnect the cooling fan control relay.

2. Connect a fused jumper between the cooling

fan relay Low connector terminals 30 and 87.

3. Connect a fused jumper between the cooling

fan control relay connector terminals 30 and

87.

Do the cooling fans run at low speed?–Go to Step 27Go to Step 18

18Check the wire between the cooling fan relay Low

connector terminal 87 to the main cooling fan con-

nector terminal 2 for an open.

Is the problem found?–Go to Step 22Go to Step 19

19Check the wire between the main cooling fan con-

nector terminal 1 and the cooling fan control relay

connector terminal 30 for an open.

Is the problem found?–Go to Step 22Go to Step 20

Page 349 of 2643

ENGINE CONTROLS 1F – 103

DAEWOO V–121 BL4

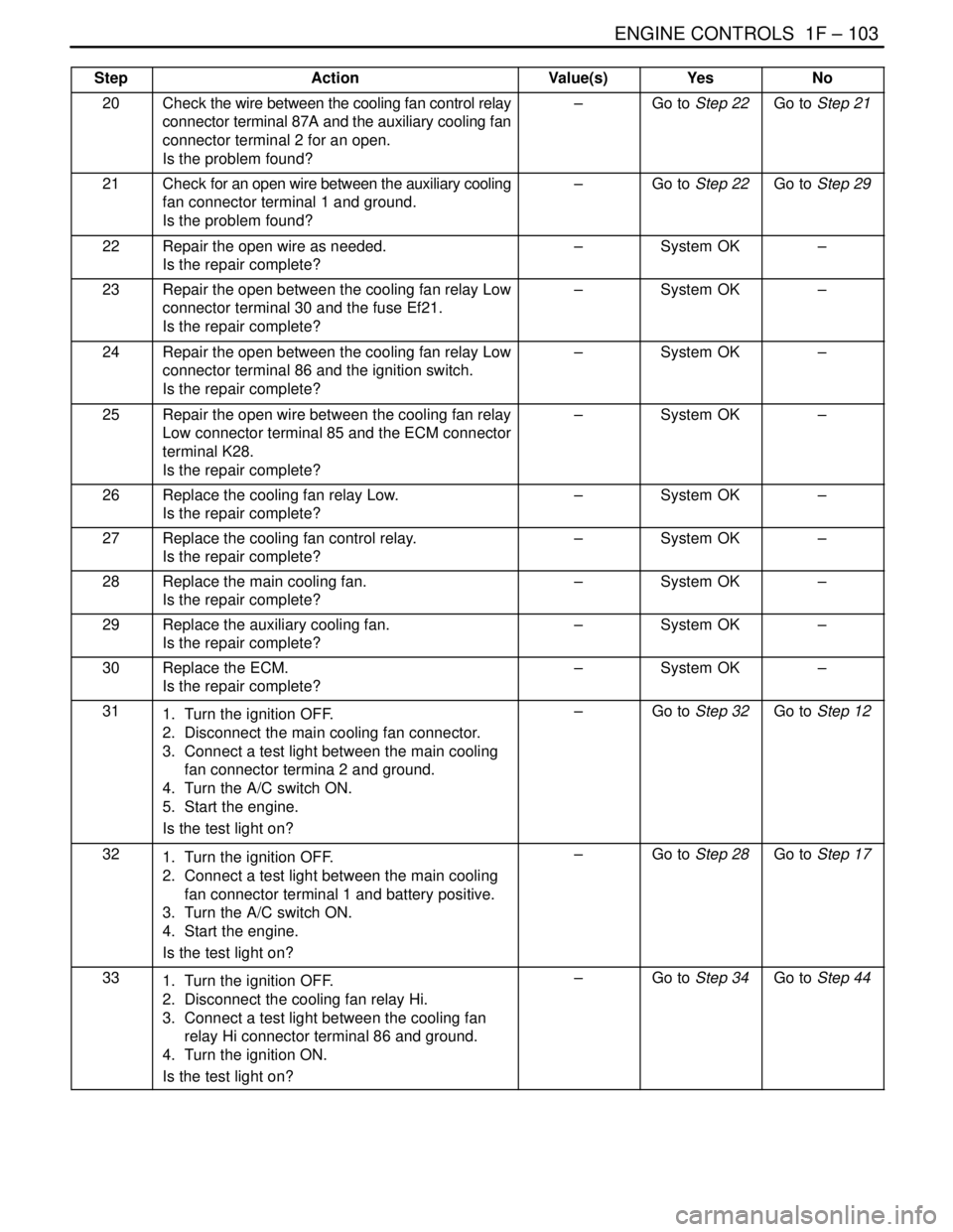

StepNo Yes Value(s) Action

20Check the wire between the cooling fan control relay

connector terminal 87A and the auxiliary cooling fan

connector terminal 2 for an open.

Is the problem found?–Go to Step 22Go to Step 21

21Check for an open wire between the auxiliary cooling

fan connector terminal 1 and ground.

Is the problem found?–Go to Step 22Go to Step 29

22Repair the open wire as needed.

Is the repair complete?–System OK–

23Repair the open between the cooling fan relay Low

connector terminal 30 and the fuse Ef21.

Is the repair complete?–System OK–

24Repair the open between the cooling fan relay Low

connector terminal 86 and the ignition switch.

Is the repair complete?–System OK–

25Repair the open wire between the cooling fan relay

Low connector terminal 85 and the ECM connector

terminal K28.

Is the repair complete?–System OK–

26Replace the cooling fan relay Low.

Is the repair complete?–System OK–

27Replace the cooling fan control relay.

Is the repair complete?–System OK–

28Replace the main cooling fan.

Is the repair complete?–System OK–

29Replace the auxiliary cooling fan.

Is the repair complete?–System OK–

30Replace the ECM.

Is the repair complete?–System OK–

311. Turn the ignition OFF.

2. Disconnect the main cooling fan connector.

3. Connect a test light between the main cooling

fan connector termina 2 and ground.

4. Turn the A/C switch ON.

5. Start the engine.

Is the test light on?–Go to Step 32Go to Step 12

321. Turn the ignition OFF.

2. Connect a test light between the main cooling

fan connector terminal 1 and battery positive.

3. Turn the A/C switch ON.

4. Start the engine.

Is the test light on?–Go to Step 28Go to Step 17

331. Turn the ignition OFF.

2. Disconnect the cooling fan relay Hi.

3. Connect a test light between the cooling fan

relay Hi connector terminal 86 and ground.

4. Turn the ignition ON.

Is the test light on?–Go to Step 34Go to Step 44

Page 350 of 2643

1F – 104IENGINE CONTROLS

DAEWOO V–121 BL4

StepNo Yes Value(s) Action

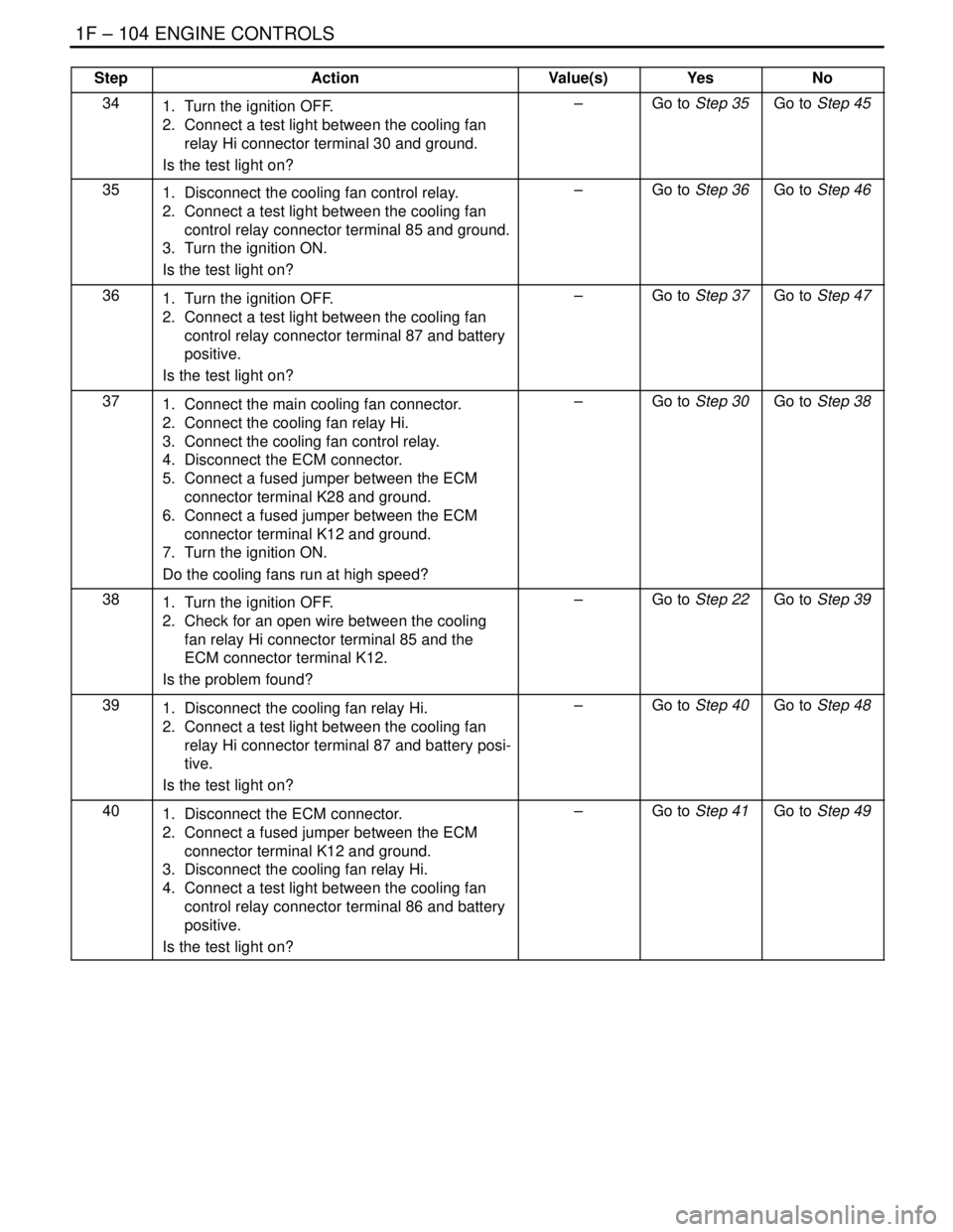

341. Turn the ignition OFF.

2. Connect a test light between the cooling fan

relay Hi connector terminal 30 and ground.

Is the test light on?–Go to Step 35Go to Step 45

351. Disconnect the cooling fan control relay.

2. Connect a test light between the cooling fan

control relay connector terminal 85 and ground.

3. Turn the ignition ON.

Is the test light on?–Go to Step 36Go to Step 46

361. Turn the ignition OFF.

2. Connect a test light between the cooling fan

control relay connector terminal 87 and battery

positive.

Is the test light on?–Go to Step 37Go to Step 47

371. Connect the main cooling fan connector.

2. Connect the cooling fan relay Hi.

3. Connect the cooling fan control relay.

4. Disconnect the ECM connector.

5. Connect a fused jumper between the ECM

connector terminal K28 and ground.

6. Connect a fused jumper between the ECM

connector terminal K12 and ground.

7. Turn the ignition ON.

Do the cooling fans run at high speed?–Go to Step 30Go to Step 38

381. Turn the ignition OFF.

2. Check for an open wire between the cooling

fan relay Hi connector terminal 85 and the

ECM connector terminal K12.

Is the problem found?–Go to Step 22Go to Step 39

391. Disconnect the cooling fan relay Hi.

2. Connect a test light between the cooling fan

relay Hi connector terminal 87 and battery posi-

tive.

Is the test light on?–Go to Step 40Go to Step 48

401. Disconnect the ECM connector.

2. Connect a fused jumper between the ECM

connector terminal K12 and ground.

3. Disconnect the cooling fan relay Hi.

4. Connect a test light between the cooling fan

control relay connector terminal 86 and battery

positive.

Is the test light on?–Go to Step 41Go to Step 49

Page 351 of 2643

ENGINE CONTROLS 1F – 105

DAEWOO V–121 BL4

StepNo Yes Value(s) Action

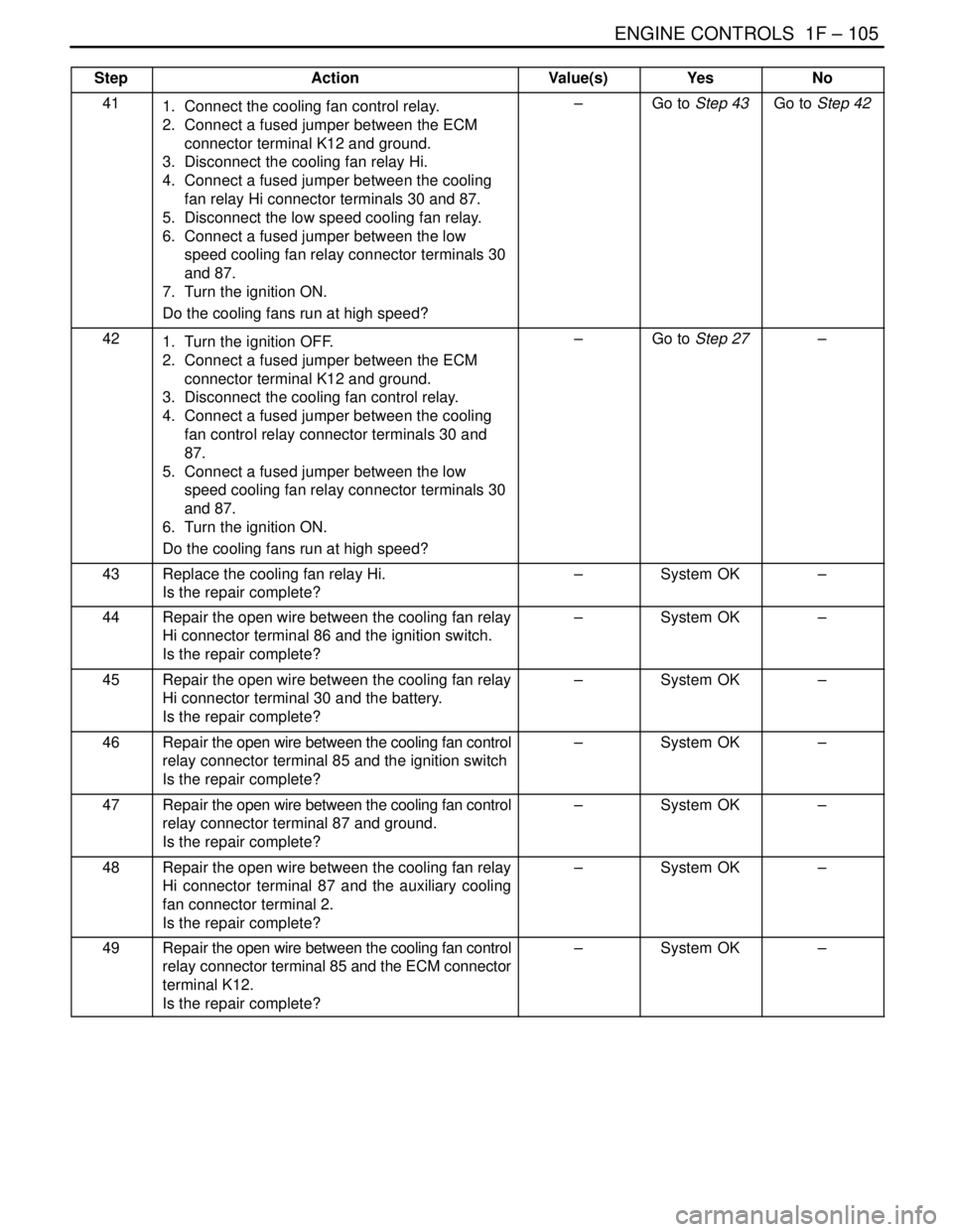

411. Connect the cooling fan control relay.

2. Connect a fused jumper between the ECM

connector terminal K12 and ground.

3. Disconnect the cooling fan relay Hi.

4. Connect a fused jumper between the cooling

fan relay Hi connector terminals 30 and 87.

5. Disconnect the low speed cooling fan relay.

6. Connect a fused jumper between the low

speed cooling fan relay connector terminals 30

and 87.

7. Turn the ignition ON.

Do the cooling fans run at high speed?–Go to Step 43Go to Step 42

421. Turn the ignition OFF.

2. Connect a fused jumper between the ECM

connector terminal K12 and ground.

3. Disconnect the cooling fan control relay.

4. Connect a fused jumper between the cooling

fan control relay connector terminals 30 and

87.

5. Connect a fused jumper between the low

speed cooling fan relay connector terminals 30

and 87.

6. Turn the ignition ON.

Do the cooling fans run at high speed?–Go to Step 27–

43Replace the cooling fan relay Hi.

Is the repair complete?–System OK–

44Repair the open wire between the cooling fan relay

Hi connector terminal 86 and the ignition switch.

Is the repair complete?–System OK–

45Repair the open wire between the cooling fan relay

Hi connector terminal 30 and the battery.

Is the repair complete?–System OK–

46Repair the open wire between the cooling fan control

relay connector terminal 85 and the ignition switch

Is the repair complete?–System OK–

47Repair the open wire between the cooling fan control

relay connector terminal 87 and ground.

Is the repair complete?–System OK–

48Repair the open wire between the cooling fan relay

Hi connector terminal 87 and the auxiliary cooling

fan connector terminal 2.

Is the repair complete?–System OK–

49Repair the open wire between the cooling fan control

relay connector terminal 85 and the ECM connector

terminal K12.

Is the repair complete?–System OK–

Page 353 of 2643

ENGINE CONTROLS 1F – 107

DAEWOO V–121 BL4

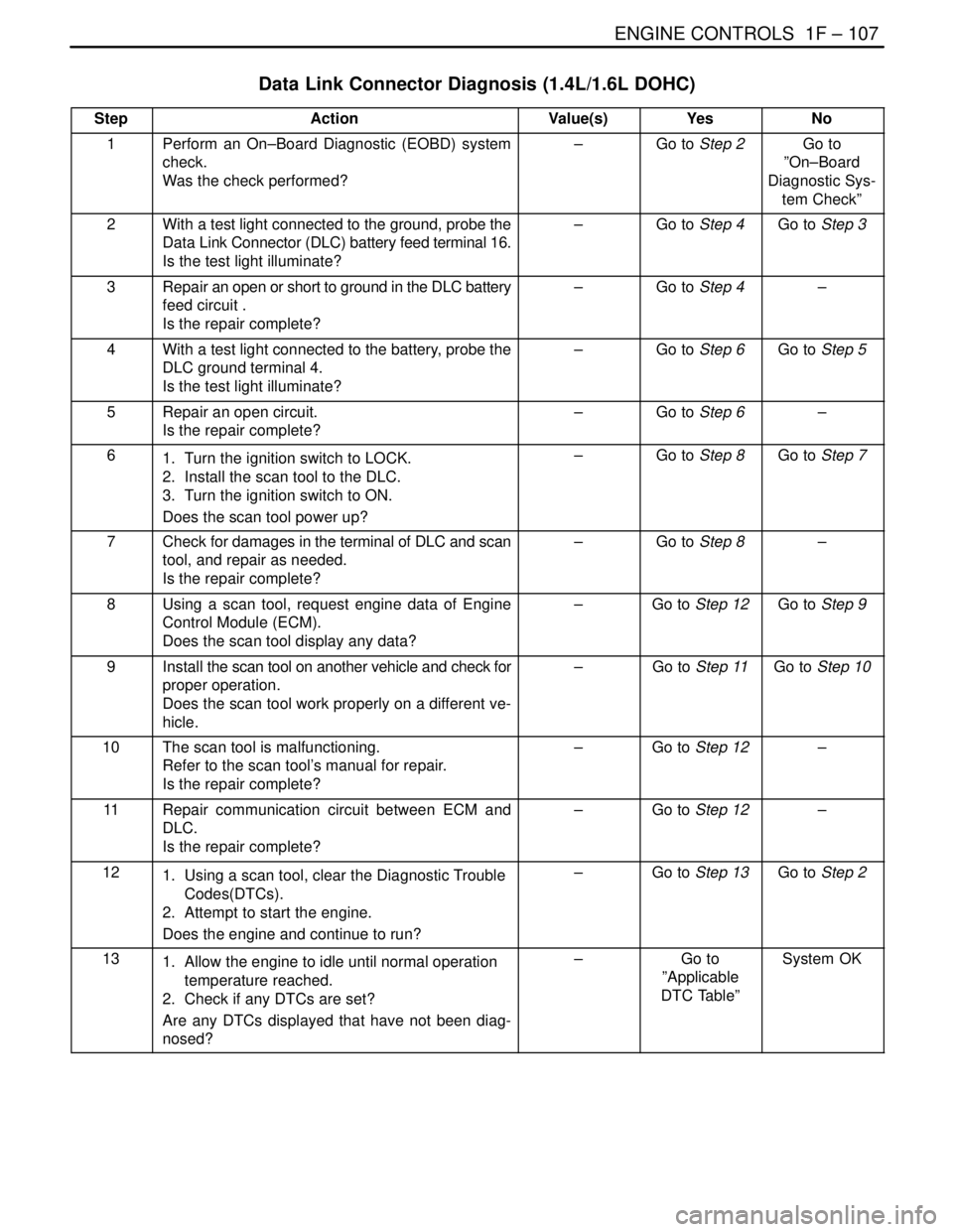

Data Link Connector Diagnosis (1.4L/1.6L DOHC)

StepActionValue(s)YesNo

1Perform an On–Board Diagnostic (EOBD) system

check.

Was the check performed?–Go to Step 2Go to

”On–Board

Diagnostic Sys-

tem Check”

2With a test light connected to the ground, probe the

Data Link Connector (DLC) battery feed terminal 16.

Is the test light illuminate?–Go to Step 4Go to Step 3

3Repair an open or short to ground in the DLC battery

feed circuit .

Is the repair complete?–Go to Step 4–

4With a test light connected to the battery, probe the

DLC ground terminal 4.

Is the test light illuminate?–Go to Step 6Go to Step 5

5Repair an open circuit.

Is the repair complete?–Go to Step 6–

61. Turn the ignition switch to LOCK.

2. Install the scan tool to the DLC.

3. Turn the ignition switch to ON.

Does the scan tool power up?–Go to Step 8Go to Step 7

7Check for damages in the terminal of DLC and scan

tool, and repair as needed.

Is the repair complete?–Go to Step 8–

8Using a scan tool, request engine data of Engine

Control Module (ECM).

Does the scan tool display any data?–Go to Step 12Go to Step 9

9Install the scan tool on another vehicle and check for

proper operation.

Does the scan tool work properly on a different ve-

hicle.–Go to Step 11Go to Step 10

10The scan tool is malfunctioning.

Refer to the scan tool’s manual for repair.

Is the repair complete?–Go to Step 12–

11Repair communication circuit between ECM and

DLC.

Is the repair complete?–Go to Step 12–

121. Using a scan tool, clear the Diagnostic Trouble

Codes(DTCs).

2. Attempt to start the engine.

Does the engine and continue to run?–Go to Step 13Go to Step 2

131. Allow the engine to idle until normal operation

temperature reached.

2. Check if any DTCs are set?

Are any DTCs displayed that have not been diag-

nosed?–Go to

”Applicable

DTC Table”System OK

Page 355 of 2643

ENGINE CONTROLS 1F – 109

DAEWOO V–121 BL4

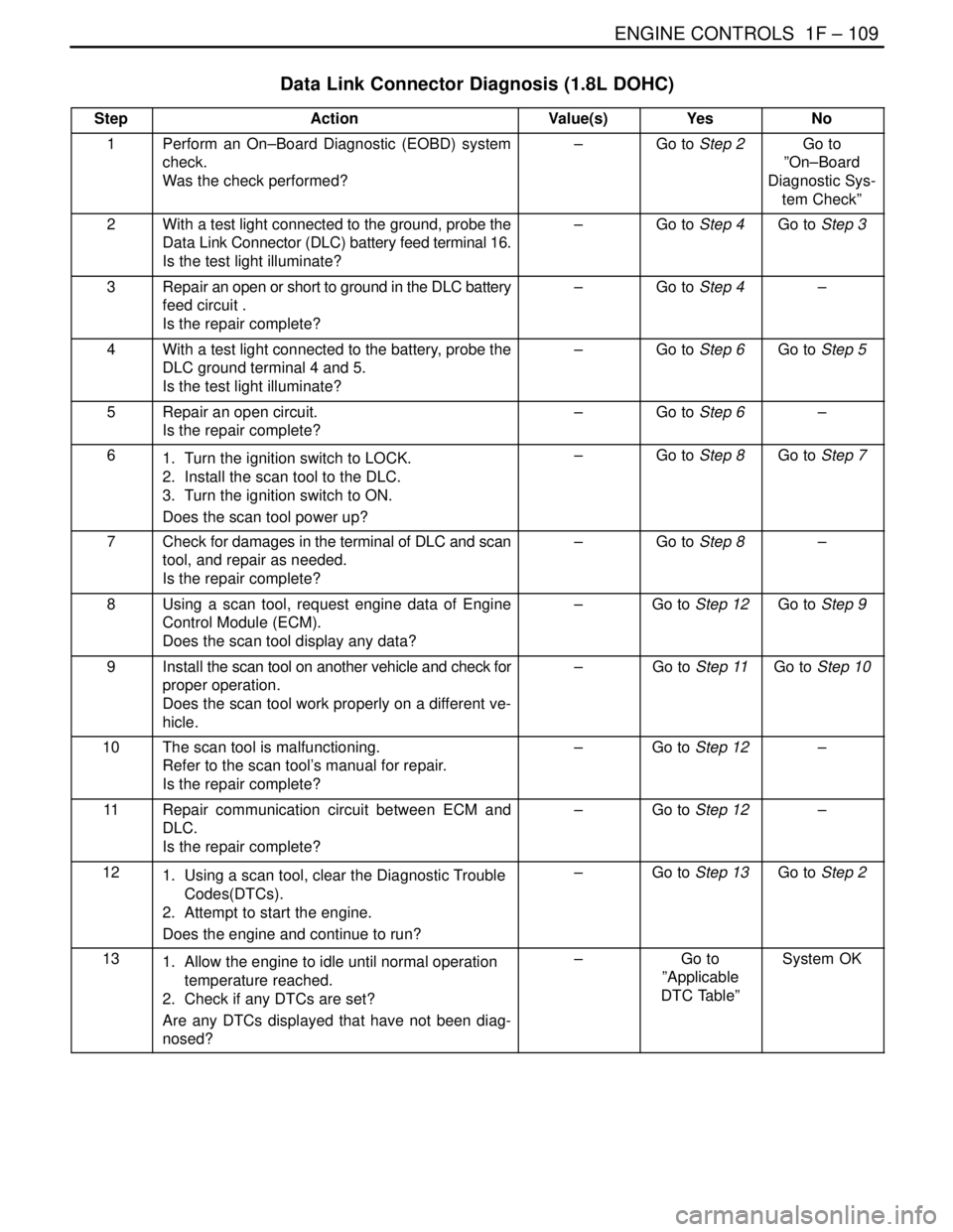

Data Link Connector Diagnosis (1.8L DOHC)

StepActionValue(s)YesNo

1Perform an On–Board Diagnostic (EOBD) system

check.

Was the check performed?–Go to Step 2Go to

”On–Board

Diagnostic Sys-

tem Check”

2With a test light connected to the ground, probe the

Data Link Connector (DLC) battery feed terminal 16.

Is the test light illuminate?–Go to Step 4Go to Step 3

3Repair an open or short to ground in the DLC battery

feed circuit .

Is the repair complete?–Go to Step 4–

4With a test light connected to the battery, probe the

DLC ground terminal 4 and 5.

Is the test light illuminate?–Go to Step 6Go to Step 5

5Repair an open circuit.

Is the repair complete?–Go to Step 6–

61. Turn the ignition switch to LOCK.

2. Install the scan tool to the DLC.

3. Turn the ignition switch to ON.

Does the scan tool power up?–Go to Step 8Go to Step 7

7Check for damages in the terminal of DLC and scan

tool, and repair as needed.

Is the repair complete?–Go to Step 8–

8Using a scan tool, request engine data of Engine

Control Module (ECM).

Does the scan tool display any data?–Go to Step 12Go to Step 9

9Install the scan tool on another vehicle and check for

proper operation.

Does the scan tool work properly on a different ve-

hicle.–Go to Step 11Go to Step 10

10The scan tool is malfunctioning.

Refer to the scan tool’s manual for repair.

Is the repair complete?–Go to Step 12–

11Repair communication circuit between ECM and

DLC.

Is the repair complete?–Go to Step 12–

121. Using a scan tool, clear the Diagnostic Trouble

Codes(DTCs).

2. Attempt to start the engine.

Does the engine and continue to run?–Go to Step 13Go to Step 2

131. Allow the engine to idle until normal operation

temperature reached.

2. Check if any DTCs are set?

Are any DTCs displayed that have not been diag-

nosed?–Go to

”Applicable

DTC Table”System OK

Page 356 of 2643

1F – 110IENGINE CONTROLS

DAEWOO V–121 BL4

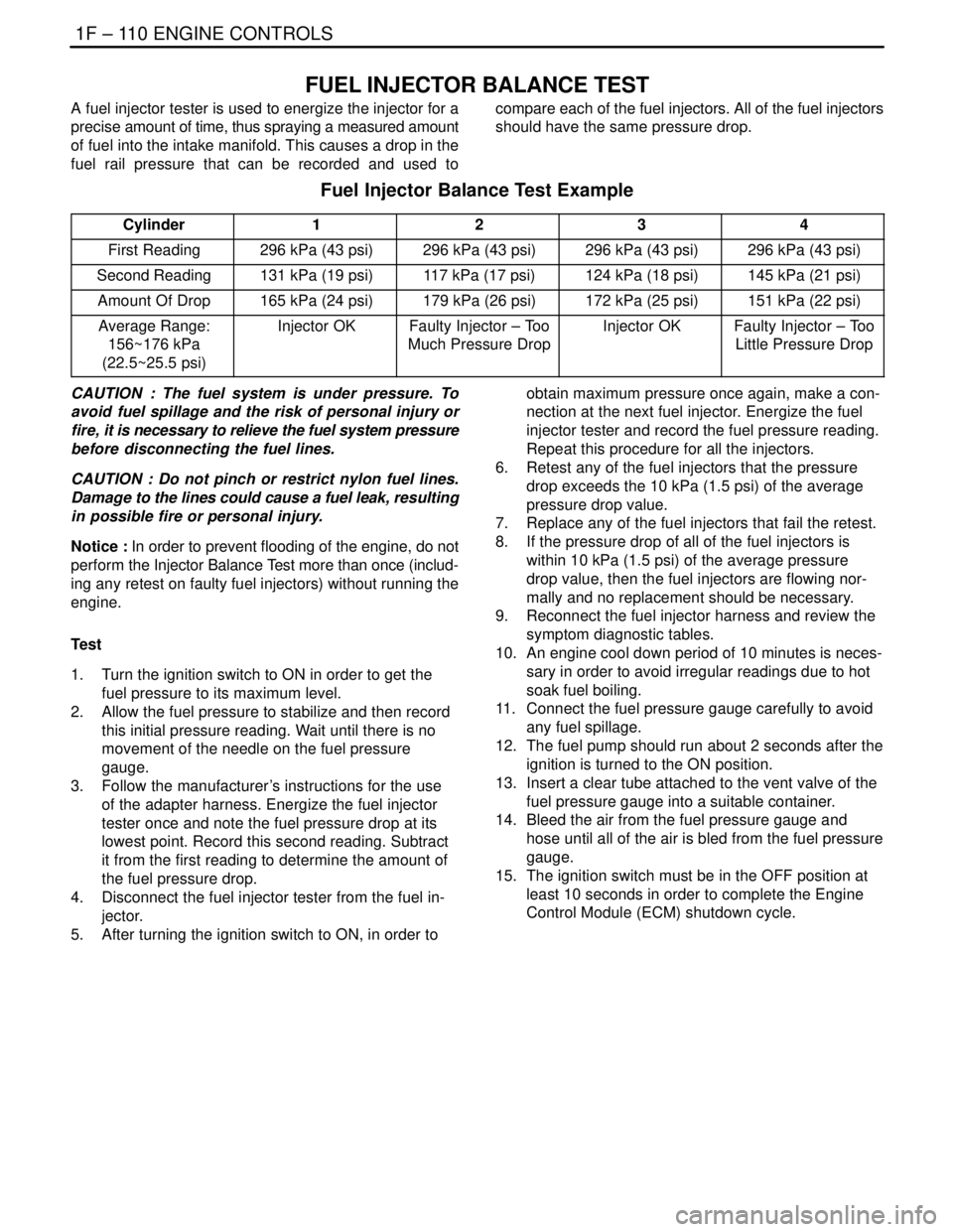

FUEL INJECTOR BALANCE TEST

A fuel injector tester is used to energize the injector for a

precise amount of time, thus spraying a measured amount

of fuel into the intake manifold. This causes a drop in the

fuel rail pressure that can be recorded and used tocompare each of the fuel injectors. All of the fuel injectors

should have the same pressure drop.

Fuel Injector Balance Test Example

Cylinder1234

First Reading296 kPa (43 psi)296 kPa (43 psi)296 kPa (43 psi)296 kPa (43 psi)

Second Reading131 kPa (19 psi)117 kPa (17 psi)124 kPa (18 psi)145 kPa (21 psi)

Amount Of Drop165 kPa (24 psi)179 kPa (26 psi)172 kPa (25 psi)151 kPa (22 psi)

Average Range:

156~176 kPa

(22.5~25.5 psi)Injector OKFaulty Injector – Too

Much Pressure DropInjector OKFaulty Injector – Too

Little Pressure Drop

CAUTION : The fuel system is under pressure. To

avoid fuel spillage and the risk of personal injury or

fire, it is necessary to relieve the fuel system pressure

before disconnecting the fuel lines.

CAUTION : Do not pinch or restrict nylon fuel lines.

Damage to the lines could cause a fuel leak, resulting

in possible fire or personal injury.

Notice : In order to prevent flooding of the engine, do not

perform the Injector Balance Test more than once (includ-

ing any retest on faulty fuel injectors) without running the

engine.

Test

1. Turn the ignition switch to ON in order to get the

fuel pressure to its maximum level.

2. Allow the fuel pressure to stabilize and then record

this initial pressure reading. Wait until there is no

movement of the needle on the fuel pressure

gauge.

3. Follow the manufacturer’s instructions for the use

of the adapter harness. Energize the fuel injector

tester once and note the fuel pressure drop at its

lowest point. Record this second reading. Subtract

it from the first reading to determine the amount of

the fuel pressure drop.

4. Disconnect the fuel injector tester from the fuel in-

jector.

5. After turning the ignition switch to ON, in order toobtain maximum pressure once again, make a con-

nection at the next fuel injector. Energize the fuel

injector tester and record the fuel pressure reading.

Repeat this procedure for all the injectors.

6. Retest any of the fuel injectors that the pressure

drop exceeds the 10 kPa (1.5 psi) of the average

pressure drop value.

7. Replace any of the fuel injectors that fail the retest.

8. If the pressure drop of all of the fuel injectors is

within 10 kPa (1.5 psi) of the average pressure

drop value, then the fuel injectors are flowing nor-

mally and no replacement should be necessary.

9. Reconnect the fuel injector harness and review the

symptom diagnostic tables.

10. An engine cool down period of 10 minutes is neces-

sary in order to avoid irregular readings due to hot

soak fuel boiling.

11. Connect the fuel pressure gauge carefully to avoid

any fuel spillage.

12. The fuel pump should run about 2 seconds after the

ignition is turned to the ON position.

13. Insert a clear tube attached to the vent valve of the

fuel pressure gauge into a suitable container.

14. Bleed the air from the fuel pressure gauge and

hose until all of the air is bled from the fuel pressure

gauge.

15. The ignition switch must be in the OFF position at

least 10 seconds in order to complete the Engine

Control Module (ECM) shutdown cycle.