engine DAEWOO NUBIRA 2004 Service Repair Manual

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: NUBIRA, Model: DAEWOO NUBIRA 2004Pages: 2643, PDF Size: 80.54 MB

Page 148 of 2643

1C2 – 28I1.8L DOHC ENGINE MECHANICAL

DAEWOO V–121 BL4

TIMING BELT

Removal Procedure

1. Disconnect the negative battery cable.

2. Disconnect the manifold air temperature (MAT)

sensor connector.

3. Disconnect the air cleaner outlet hose from the

throttle body.

4. Disconnect the breather tube from the camshaft

cover.

5. Remove the air cleaner housing bolts.

6. Remove the air cleaner housing.

7. Remove the right front wheel. Refer to Section 2E,

Tires and Wheels.

8. Remove the right front wheel well splash shield.

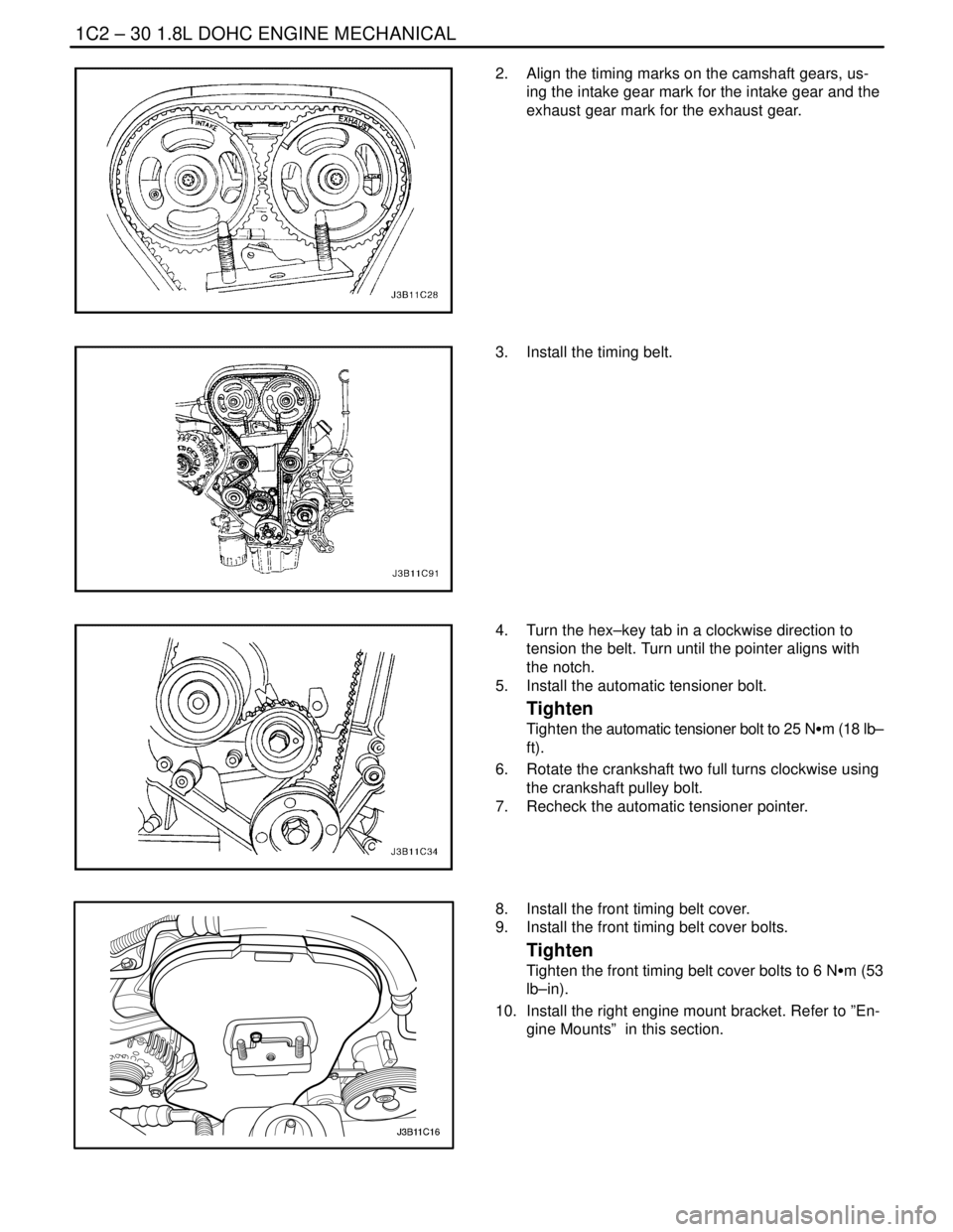

9. Remove the serpentine accessory drive belt. Refer

to Section 6B, Power Steering Pump.

10. Remove the crankshaft pulley bolts.

11. Remove the crankshaft pulley.

12. Remove the right engine mount bracket. Refer to

”Engine Mount” in this section.

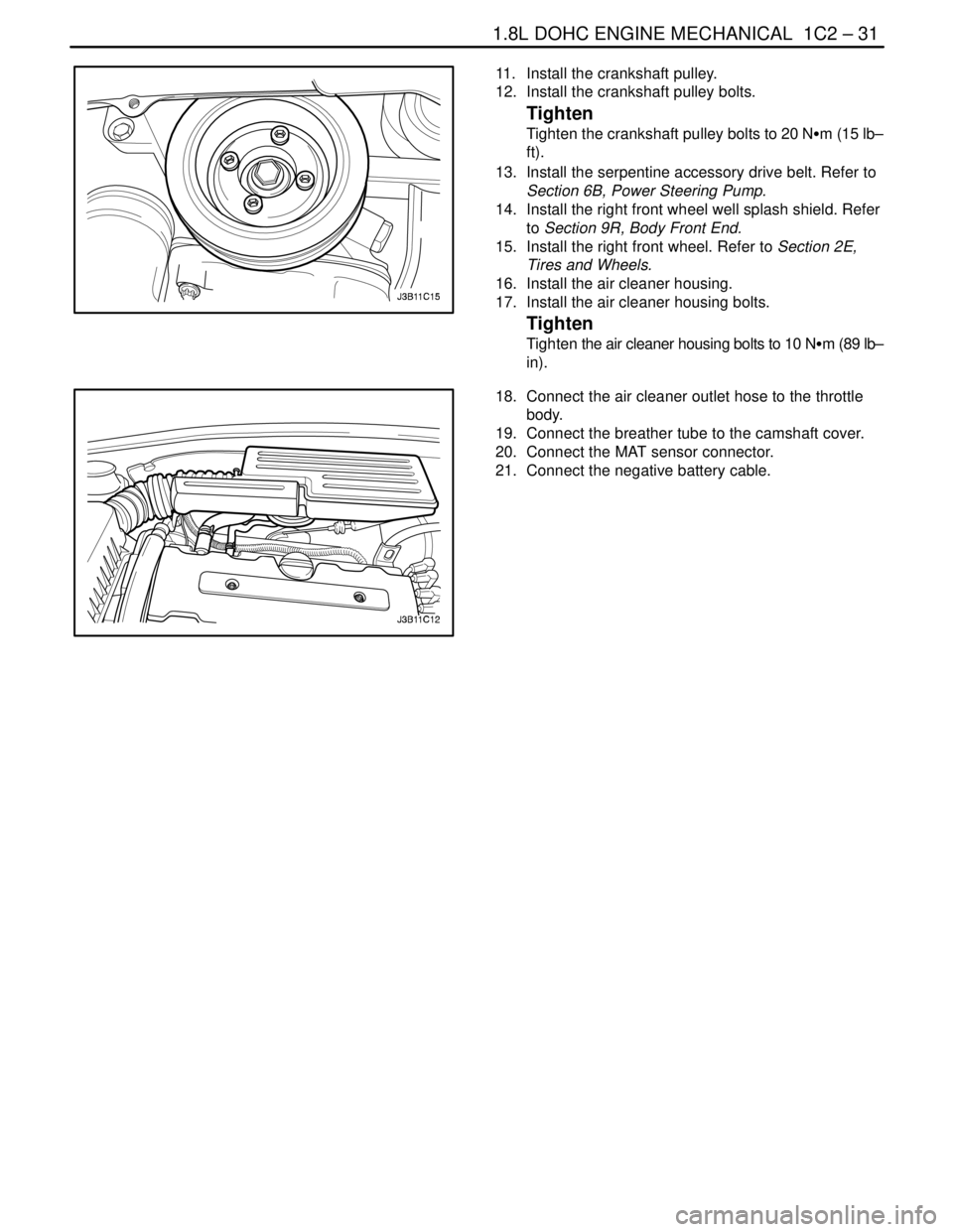

13. Remove the front timing belt cover bolts.

14. Remove the front timing belt cover.

Page 149 of 2643

1.8L DOHC ENGINE MECHANICAL 1C2 – 29

DAEWOO V–121 BL4

15. Using the crankshaft gear bolt, rotate the crank-

shaft clockwise until the timing mark on the crank-

shaft gear is aligned with the notch at the bottom of

the rear timing belt cover.

Notice : The camshaft gears must align with the notch on

the camshaft cover or damage to the engine could result.

16. Align the camshaft gears with the notch on the

camshaft cover.

Important : Use the intake gear mark for the intake cam-

shaft gear and the exhaust gear mark for the exhaust cam-

shaft gear since both gears are interchangeable.

17. Remove the timing belt.

18. Loosen the automatic tensioner bolt. Turn the hex–

key tab to relieve belt tension.

Installation Procedure

1. Align the timing mark on the crankshaft gear with

the notch on the bottom of the rear timing belt cov-

er.

Page 150 of 2643

1C2 – 30I1.8L DOHC ENGINE MECHANICAL

DAEWOO V–121 BL4

2. Align the timing marks on the camshaft gears, us-

ing the intake gear mark for the intake gear and the

exhaust gear mark for the exhaust gear.

3. Install the timing belt.

4. Turn the hex–key tab in a clockwise direction to

tension the belt. Turn until the pointer aligns with

the notch.

5. Install the automatic tensioner bolt.

Tighten

Tighten the automatic tensioner bolt to 25 NSm (18 lb–

ft).

6. Rotate the crankshaft two full turns clockwise using

the crankshaft pulley bolt.

7. Recheck the automatic tensioner pointer.

8. Install the front timing belt cover.

9. Install the front timing belt cover bolts.

Tighten

Tighten the front timing belt cover bolts to 6 NSm (53

lb–in).

10. Install the right engine mount bracket. Refer to ”En-

gine Mounts” in this section.

Page 151 of 2643

1.8L DOHC ENGINE MECHANICAL 1C2 – 31

DAEWOO V–121 BL4

11. Install the crankshaft pulley.

12. Install the crankshaft pulley bolts.

Tighten

Tighten the crankshaft pulley bolts to 20 NSm (15 lb–

ft).

13. Install the serpentine accessory drive belt. Refer to

Section 6B, Power Steering Pump.

14. Install the right front wheel well splash shield. Refer

to Section 9R, Body Front End.

15. Install the right front wheel. Refer to Section 2E,

Tires and Wheels.

16. Install the air cleaner housing.

17. Install the air cleaner housing bolts.

Tighten

Tighten the air cleaner housing bolts to 10 NSm (89 lb–

in).

18. Connect the air cleaner outlet hose to the throttle

body.

19. Connect the breather tube to the camshaft cover.

20. Connect the MAT sensor connector.

21. Connect the negative battery cable.

Page 152 of 2643

1C2 – 32I1.8L DOHC ENGINE MECHANICAL

DAEWOO V–121 BL4

OIL PAN

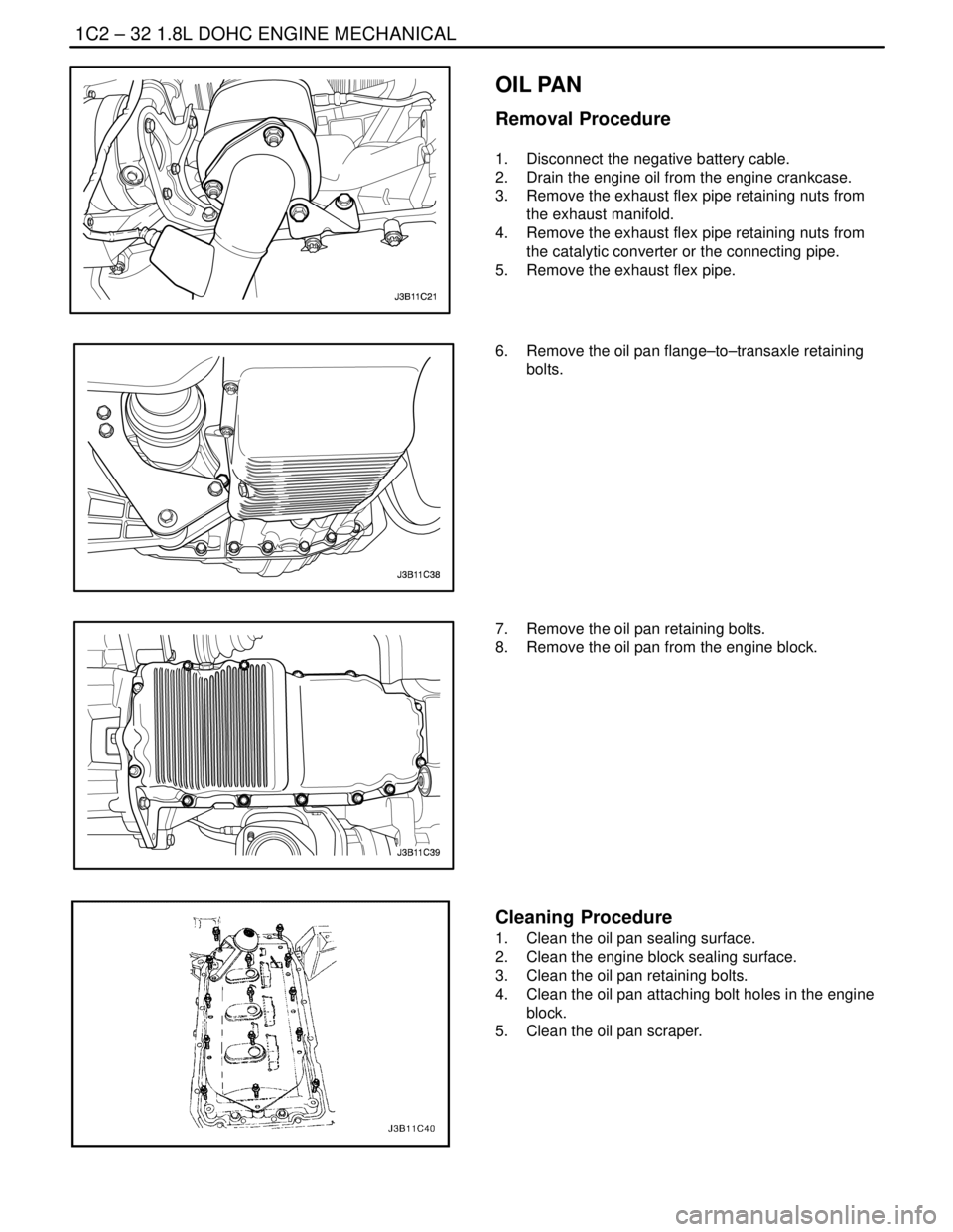

Removal Procedure

1. Disconnect the negative battery cable.

2. Drain the engine oil from the engine crankcase.

3. Remove the exhaust flex pipe retaining nuts from

the exhaust manifold.

4. Remove the exhaust flex pipe retaining nuts from

the catalytic converter or the connecting pipe.

5. Remove the exhaust flex pipe.

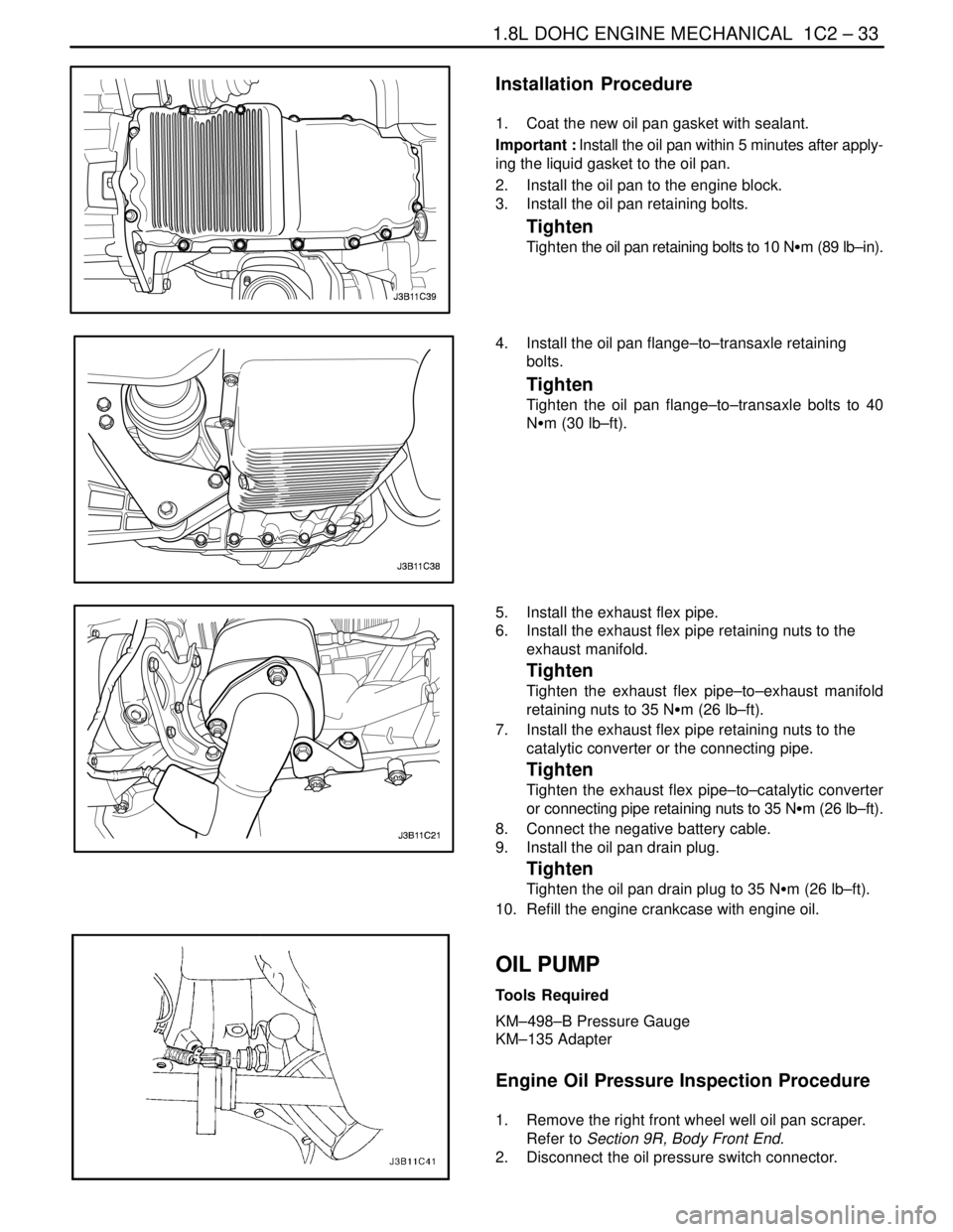

6. Remove the oil pan flange–to–transaxle retaining

bolts.

7. Remove the oil pan retaining bolts.

8. Remove the oil pan from the engine block.

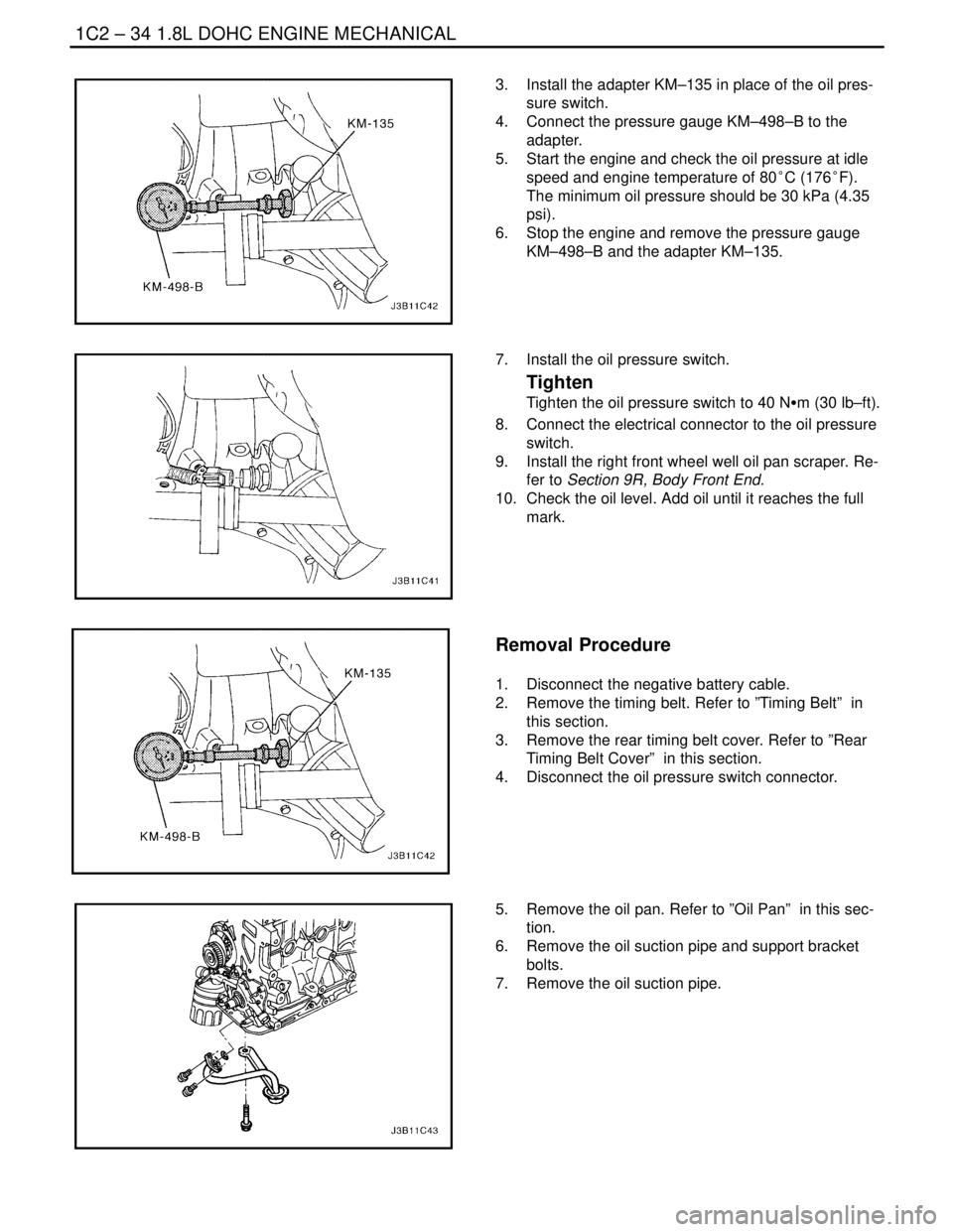

Cleaning Procedure

1. Clean the oil pan sealing surface.

2. Clean the engine block sealing surface.

3. Clean the oil pan retaining bolts.

4. Clean the oil pan attaching bolt holes in the engine

block.

5. Clean the oil pan scraper.

Page 153 of 2643

1.8L DOHC ENGINE MECHANICAL 1C2 – 33

DAEWOO V–121 BL4

Installation Procedure

1. Coat the new oil pan gasket with sealant.

Important : Install the oil pan within 5 minutes after apply-

ing the liquid gasket to the oil pan.

2. Install the oil pan to the engine block.

3. Install the oil pan retaining bolts.

Tighten

Tighten the oil pan retaining bolts to 10 NSm (89 lb–in).

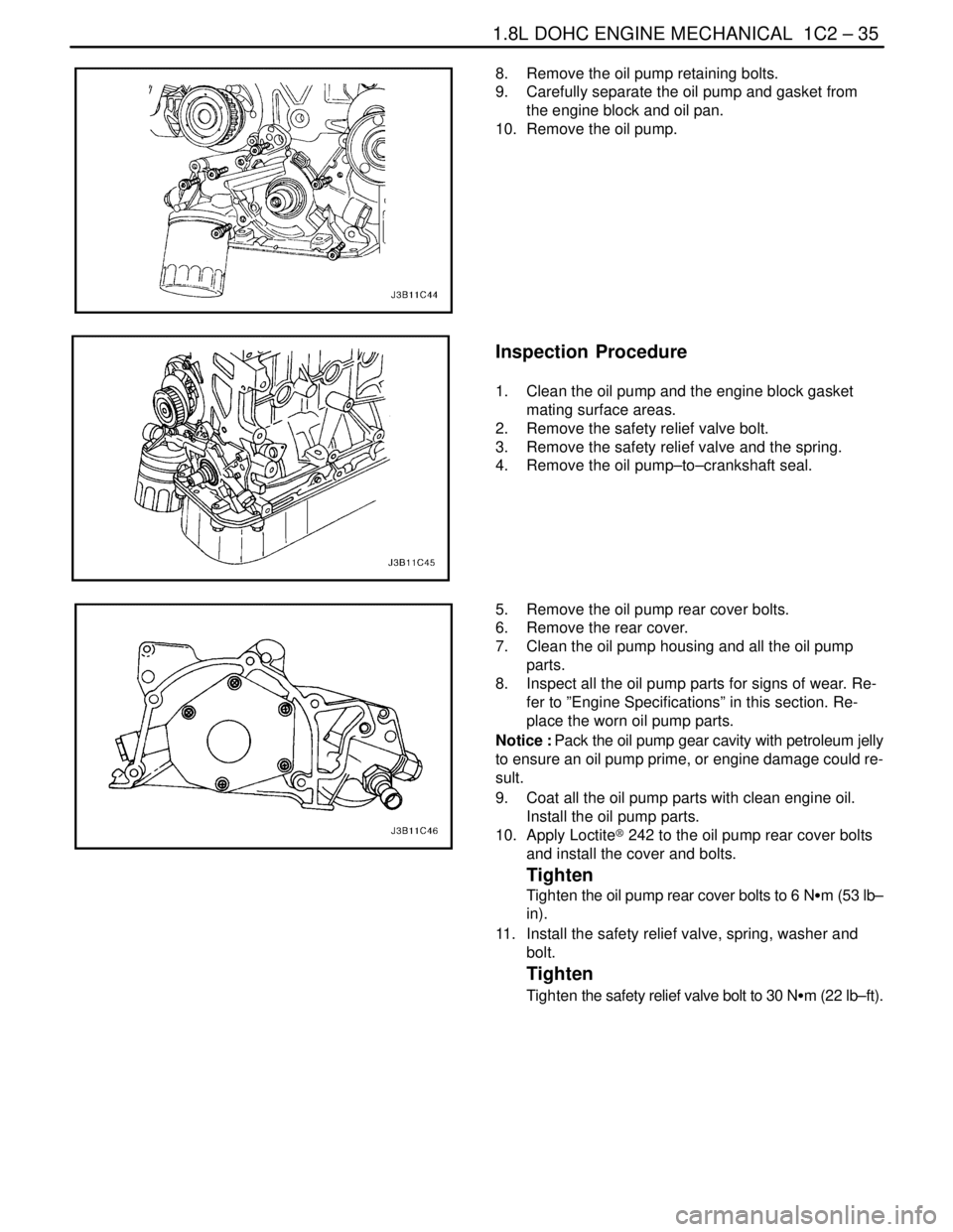

4. Install the oil pan flange–to–transaxle retaining

bolts.

Tighten

Tighten the oil pan flange–to–transaxle bolts to 40

NSm (30 lb–ft).

5. Install the exhaust flex pipe.

6. Install the exhaust flex pipe retaining nuts to the

exhaust manifold.

Tighten

Tighten the exhaust flex pipe–to–exhaust manifold

retaining nuts to 35 NSm (26 lb–ft).

7. Install the exhaust flex pipe retaining nuts to the

catalytic converter or the connecting pipe.

Tighten

Tighten the exhaust flex pipe–to–catalytic converter

or connecting pipe retaining nuts to 35 NSm (26 lb–ft).

8. Connect the negative battery cable.

9. Install the oil pan drain plug.

Tighten

Tighten the oil pan drain plug to 35 NSm (26 lb–ft).

10. Refill the engine crankcase with engine oil.

OIL PUMP

Tools Required

KM–498–B Pressure Gauge

KM–135 Adapter

Engine Oil Pressure Inspection Procedure

1. Remove the right front wheel well oil pan scraper.

Refer to Section 9R, Body Front End.

2. Disconnect the oil pressure switch connector.

Page 154 of 2643

1C2 – 34I1.8L DOHC ENGINE MECHANICAL

DAEWOO V–121 BL4

3. Install the adapter KM–135 in place of the oil pres-

sure switch.

4. Connect the pressure gauge KM–498–B to the

adapter.

5. Start the engine and check the oil pressure at idle

speed and engine temperature of 80°C (176°F).

The minimum oil pressure should be 30 kPa (4.35

psi).

6. Stop the engine and remove the pressure gauge

KM–498–B and the adapter KM–135.

7. Install the oil pressure switch.

Tighten

Tighten the oil pressure switch to 40 NSm (30 lb–ft).

8. Connect the electrical connector to the oil pressure

switch.

9. Install the right front wheel well oil pan scraper. Re-

fer to Section 9R, Body Front End.

10. Check the oil level. Add oil until it reaches the full

mark.

Removal Procedure

1. Disconnect the negative battery cable.

2. Remove the timing belt. Refer to ”Timing Belt” in

this section.

3. Remove the rear timing belt cover. Refer to ”Rear

Timing Belt Cover” in this section.

4. Disconnect the oil pressure switch connector.

5. Remove the oil pan. Refer to ”Oil Pan” in this sec-

tion.

6. Remove the oil suction pipe and support bracket

bolts.

7. Remove the oil suction pipe.

Page 155 of 2643

1.8L DOHC ENGINE MECHANICAL 1C2 – 35

DAEWOO V–121 BL4

8. Remove the oil pump retaining bolts.

9. Carefully separate the oil pump and gasket from

the engine block and oil pan.

10. Remove the oil pump.

Inspection Procedure

1. Clean the oil pump and the engine block gasket

mating surface areas.

2. Remove the safety relief valve bolt.

3. Remove the safety relief valve and the spring.

4. Remove the oil pump–to–crankshaft seal.

5. Remove the oil pump rear cover bolts.

6. Remove the rear cover.

7. Clean the oil pump housing and all the oil pump

parts.

8. Inspect all the oil pump parts for signs of wear. Re-

fer to ”Engine Specifications” in this section. Re-

place the worn oil pump parts.

Notice : Pack the oil pump gear cavity with petroleum jelly

to ensure an oil pump prime, or engine damage could re-

sult.

9. Coat all the oil pump parts with clean engine oil.

Install the oil pump parts.

10. Apply Loctite® 242 to the oil pump rear cover bolts

and install the cover and bolts.

Tighten

Tighten the oil pump rear cover bolts to 6 NSm (53 lb–

in).

11. Install the safety relief valve, spring, washer and

bolt.

Tighten

Tighten the safety relief valve bolt to 30 NSm (22 lb–ft).

Page 156 of 2643

1C2 – 36I1.8L DOHC ENGINE MECHANICAL

DAEWOO V–121 BL4

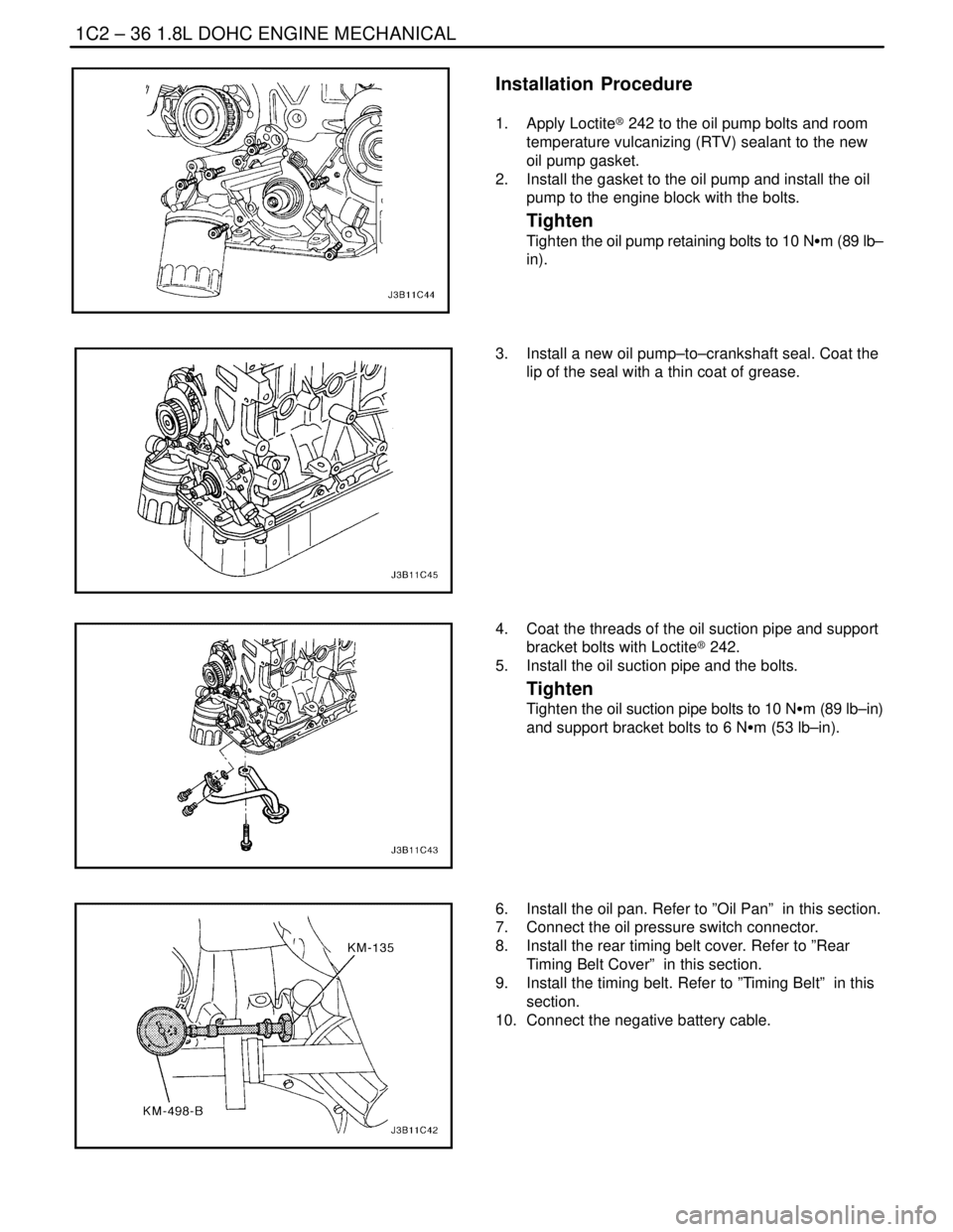

Installation Procedure

1. Apply Loctite® 242 to the oil pump bolts and room

temperature vulcanizing (RTV) sealant to the new

oil pump gasket.

2. Install the gasket to the oil pump and install the oil

pump to the engine block with the bolts.

Tighten

Tighten the oil pump retaining bolts to 10 NSm (89 lb–

in).

3. Install a new oil pump–to–crankshaft seal. Coat the

lip of the seal with a thin coat of grease.

4. Coat the threads of the oil suction pipe and support

bracket bolts with Loctite® 242.

5. Install the oil suction pipe and the bolts.

Tighten

Tighten the oil suction pipe bolts to 10 NSm (89 lb–in)

and support bracket bolts to 6 NSm (53 lb–in).

6. Install the oil pan. Refer to ”Oil Pan” in this section.

7. Connect the oil pressure switch connector.

8. Install the rear timing belt cover. Refer to ”Rear

Timing Belt Cover” in this section.

9. Install the timing belt. Refer to ”Timing Belt” in this

section.

10. Connect the negative battery cable.

Page 157 of 2643

1.8L DOHC ENGINE MECHANICAL 1C2 – 37

DAEWOO V–121 BL4

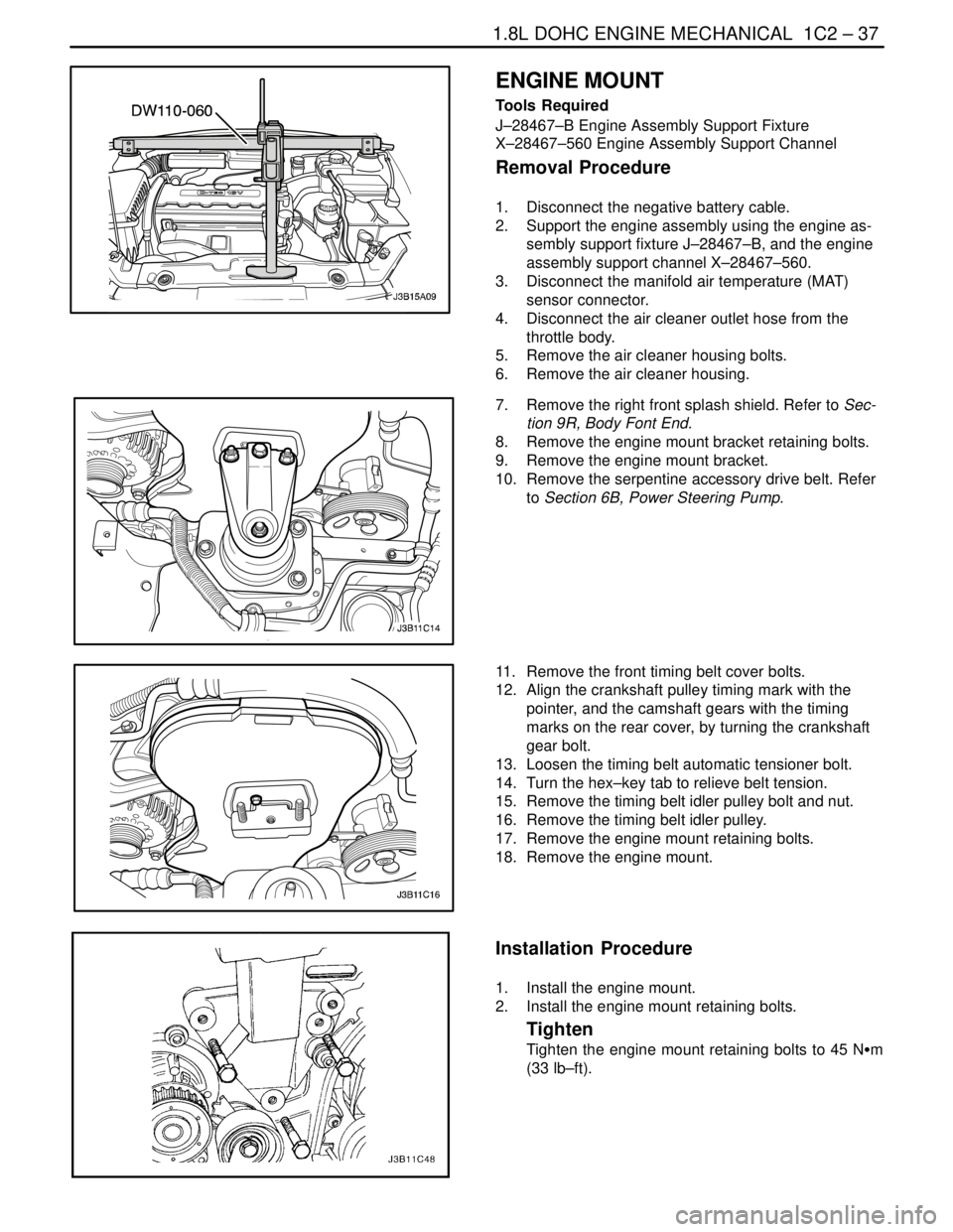

ENGINE MOUNT

Tools Required

J–28467–B Engine Assembly Support Fixture

X–28467–560 Engine Assembly Support Channel

Removal Procedure

1. Disconnect the negative battery cable.

2. Support the engine assembly using the engine as-

sembly support fixture J–28467–B, and the engine

assembly support channel X–28467–560.

3. Disconnect the manifold air temperature (MAT)

sensor connector.

4. Disconnect the air cleaner outlet hose from the

throttle body.

5. Remove the air cleaner housing bolts.

6. Remove the air cleaner housing.

7. Remove the right front splash shield. Refer to Sec-

tion 9R, Body Font End.

8. Remove the engine mount bracket retaining bolts.

9. Remove the engine mount bracket.

10. Remove the serpentine accessory drive belt. Refer

to Section 6B, Power Steering Pump.

11. Remove the front timing belt cover bolts.

12. Align the crankshaft pulley timing mark with the

pointer, and the camshaft gears with the timing

marks on the rear cover, by turning the crankshaft

gear bolt.

13. Loosen the timing belt automatic tensioner bolt.

14. Turn the hex–key tab to relieve belt tension.

15. Remove the timing belt idler pulley bolt and nut.

16. Remove the timing belt idler pulley.

17. Remove the engine mount retaining bolts.

18. Remove the engine mount.

Installation Procedure

1. Install the engine mount.

2. Install the engine mount retaining bolts.

Tighten

Tighten the engine mount retaining bolts to 45 NSm

(33 lb–ft).