engine DAEWOO NUBIRA 2004 Service Repair Manual

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: NUBIRA, Model: DAEWOO NUBIRA 2004Pages: 2643, PDF Size: 80.54 MB

Page 178 of 2643

1C2 – 58I1.8L DOHC ENGINE MECHANICAL

DAEWOO V–121 BL4

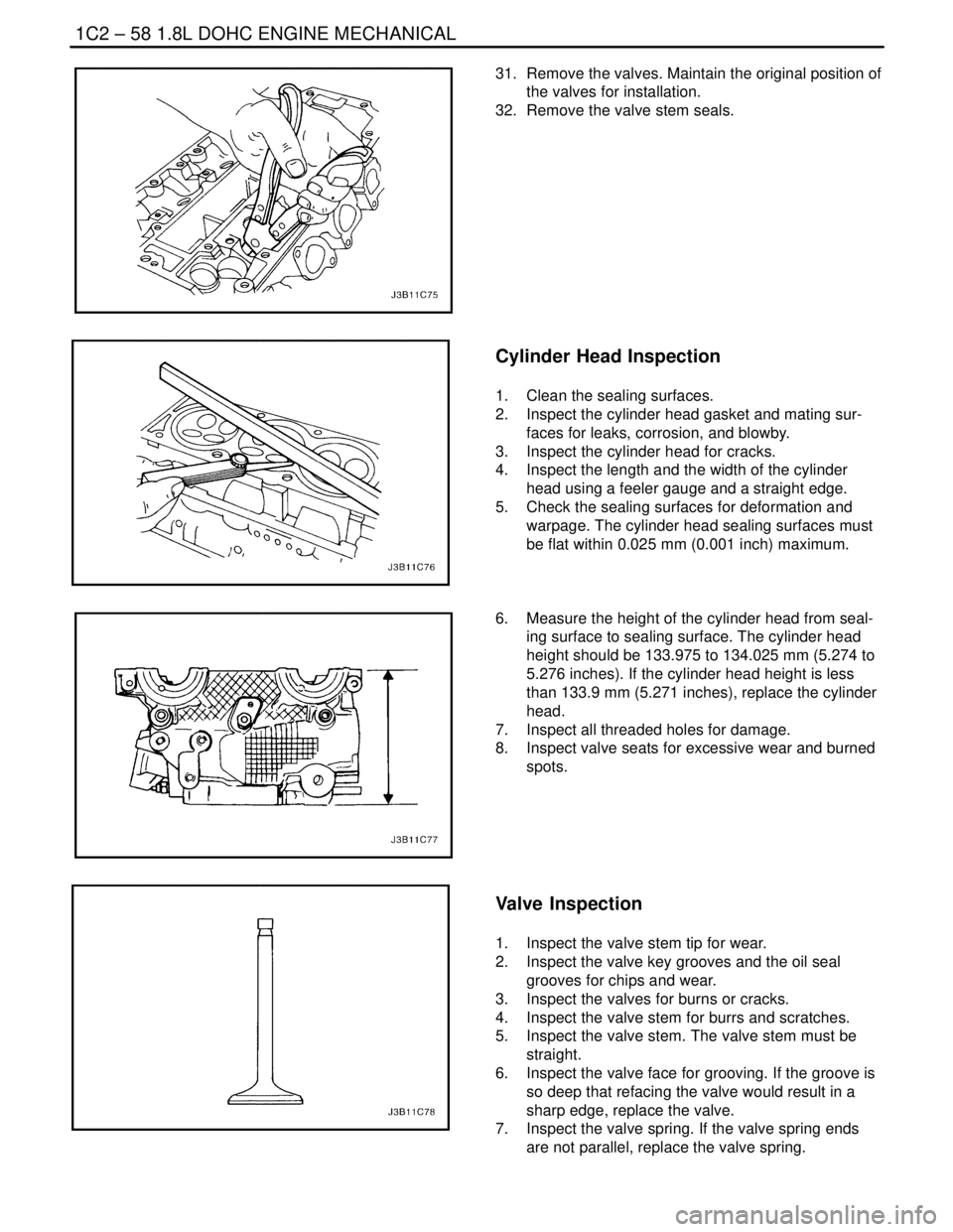

31. Remove the valves. Maintain the original position of

the valves for installation.

32. Remove the valve stem seals.

Cylinder Head Inspection

1. Clean the sealing surfaces.

2. Inspect the cylinder head gasket and mating sur-

faces for leaks, corrosion, and blowby.

3. Inspect the cylinder head for cracks.

4. Inspect the length and the width of the cylinder

head using a feeler gauge and a straight edge.

5. Check the sealing surfaces for deformation and

warpage. The cylinder head sealing surfaces must

be flat within 0.025 mm (0.001 inch) maximum.

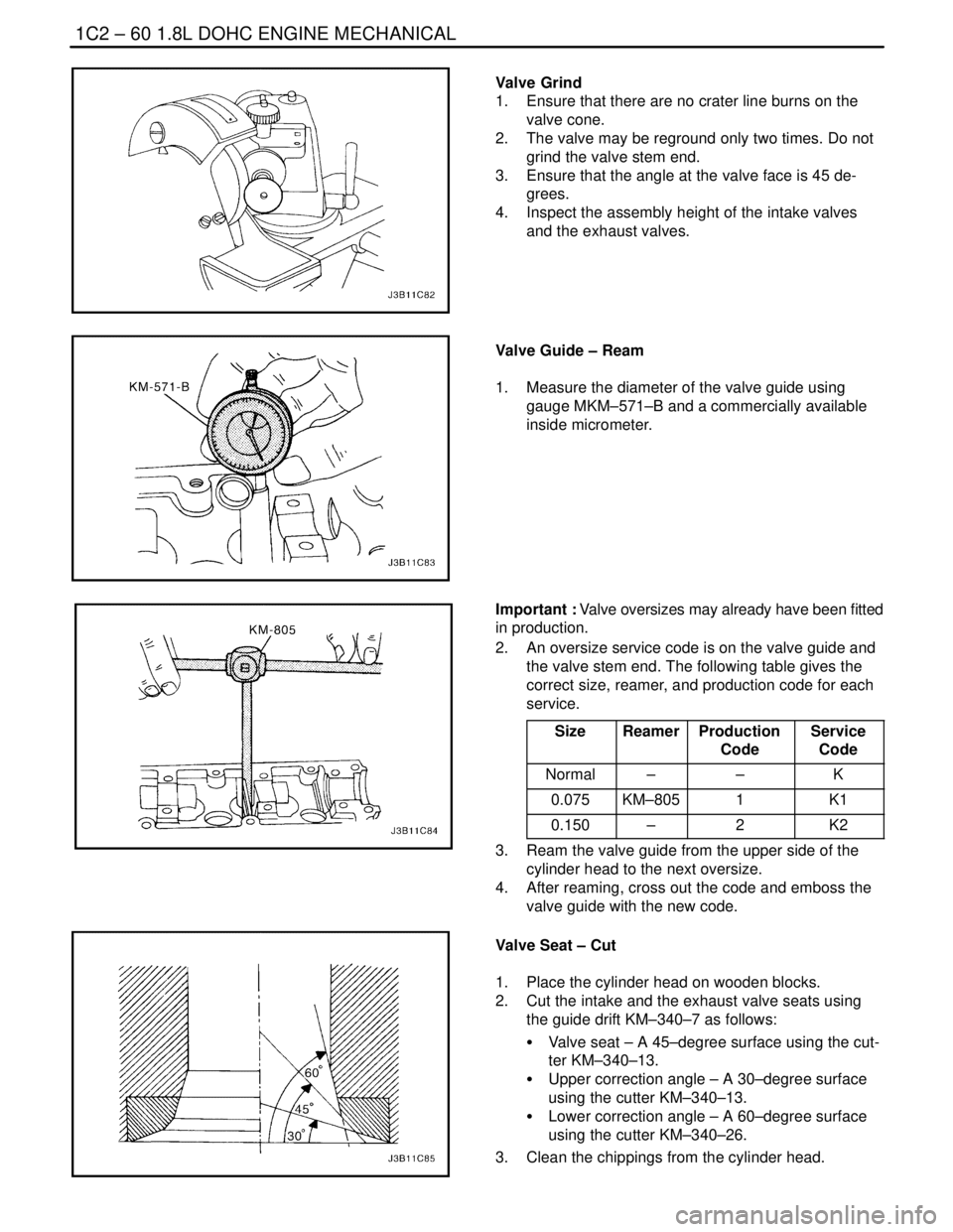

6. Measure the height of the cylinder head from seal-

ing surface to sealing surface. The cylinder head

height should be 133.975 to 134.025 mm (5.274 to

5.276 inches). If the cylinder head height is less

than 133.9 mm (5.271 inches), replace the cylinder

head.

7. Inspect all threaded holes for damage.

8. Inspect valve seats for excessive wear and burned

spots.

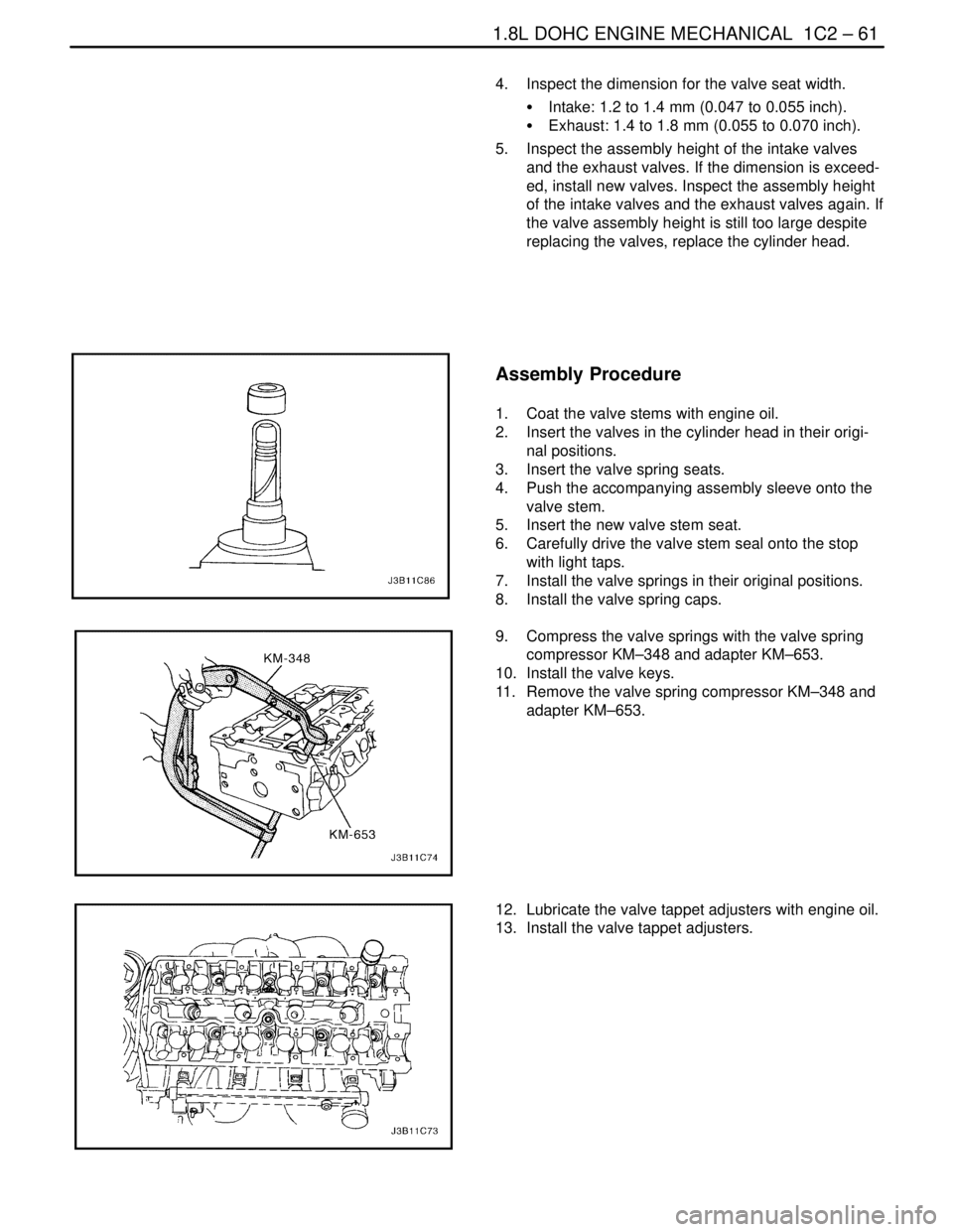

Valve Inspection

1. Inspect the valve stem tip for wear.

2. Inspect the valve key grooves and the oil seal

grooves for chips and wear.

3. Inspect the valves for burns or cracks.

4. Inspect the valve stem for burrs and scratches.

5. Inspect the valve stem. The valve stem must be

straight.

6. Inspect the valve face for grooving. If the groove is

so deep that refacing the valve would result in a

sharp edge, replace the valve.

7. Inspect the valve spring. If the valve spring ends

are not parallel, replace the valve spring.

Page 179 of 2643

1.8L DOHC ENGINE MECHANICAL 1C2 – 59

DAEWOO V–121 BL4

8. Inspect the valve spring seating surface of the

valve rotators for wear or gouges. Replace as re-

quired.

Cleaning Procedure

1. Clean the cylinder head.

2. Clean the valve guides.

3. Clean all of the threaded holes.

4. Clean the valves of carbon, oil, and varnish.

Cylinder Head Overhaul

Valve Grind–in

1. Lubricate the valve seat using a fine–grained paste.

2. Lift the valve rhythmically from the seat with a com-

mercially available valve grinding tool in order to

distribute the paste.

3. Check the contact pattern on the valve head and in

the cylinder head.

4. Clean the valves the valve guides and the cylinder

head.

Page 180 of 2643

1C2 – 60I1.8L DOHC ENGINE MECHANICAL

DAEWOO V–121 BL4

Valve Grind

1. Ensure that there are no crater line burns on the

valve cone.

2. The valve may be reground only two times. Do not

grind the valve stem end.

3. Ensure that the angle at the valve face is 45 de-

grees.

4. Inspect the assembly height of the intake valves

and the exhaust valves.

Valve Guide – Ream

1. Measure the diameter of the valve guide using

gauge MKM–571–B and a commercially available

inside micrometer.

Important : Valve oversizes may already have been fitted

in production.

2. An oversize service code is on the valve guide and

the valve stem end. The following table gives the

correct size, reamer, and production code for each

service.

Size

ReamerProduction

CodeService

Code

Normal––K

0.075KM–8051K1

0.150–2K2

3. Ream the valve guide from the upper side of the

cylinder head to the next oversize.

4. After reaming, cross out the code and emboss the

valve guide with the new code.

Valve Seat – Cut

1. Place the cylinder head on wooden blocks.

2. Cut the intake and the exhaust valve seats using

the guide drift KM–340–7 as follows:

S Valve seat – A 45–degree surface using the cut-

ter KM–340–13.

S Upper correction angle – A 30–degree surface

using the cutter KM–340–13.

S Lower correction angle – A 60–degree surface

using the cutter KM–340–26.

3. Clean the chippings from the cylinder head.

Page 181 of 2643

1.8L DOHC ENGINE MECHANICAL 1C2 – 61

DAEWOO V–121 BL4

4. Inspect the dimension for the valve seat width.

S Intake: 1.2 to 1.4 mm (0.047 to 0.055 inch).

S Exhaust: 1.4 to 1.8 mm (0.055 to 0.070 inch).

5. Inspect the assembly height of the intake valves

and the exhaust valves. If the dimension is exceed-

ed, install new valves. Inspect the assembly height

of the intake valves and the exhaust valves again. If

the valve assembly height is still too large despite

replacing the valves, replace the cylinder head.

Assembly Procedure

1. Coat the valve stems with engine oil.

2. Insert the valves in the cylinder head in their origi-

nal positions.

3. Insert the valve spring seats.

4. Push the accompanying assembly sleeve onto the

valve stem.

5. Insert the new valve stem seat.

6. Carefully drive the valve stem seal onto the stop

with light taps.

7. Install the valve springs in their original positions.

8. Install the valve spring caps.

9. Compress the valve springs with the valve spring

compressor KM–348 and adapter KM–653.

10. Install the valve keys.

11. Remove the valve spring compressor KM–348 and

adapter KM–653.

12. Lubricate the valve tappet adjusters with engine oil.

13. Install the valve tappet adjusters.

Page 182 of 2643

1C2 – 62I1.8L DOHC ENGINE MECHANICAL

DAEWOO V–121 BL4

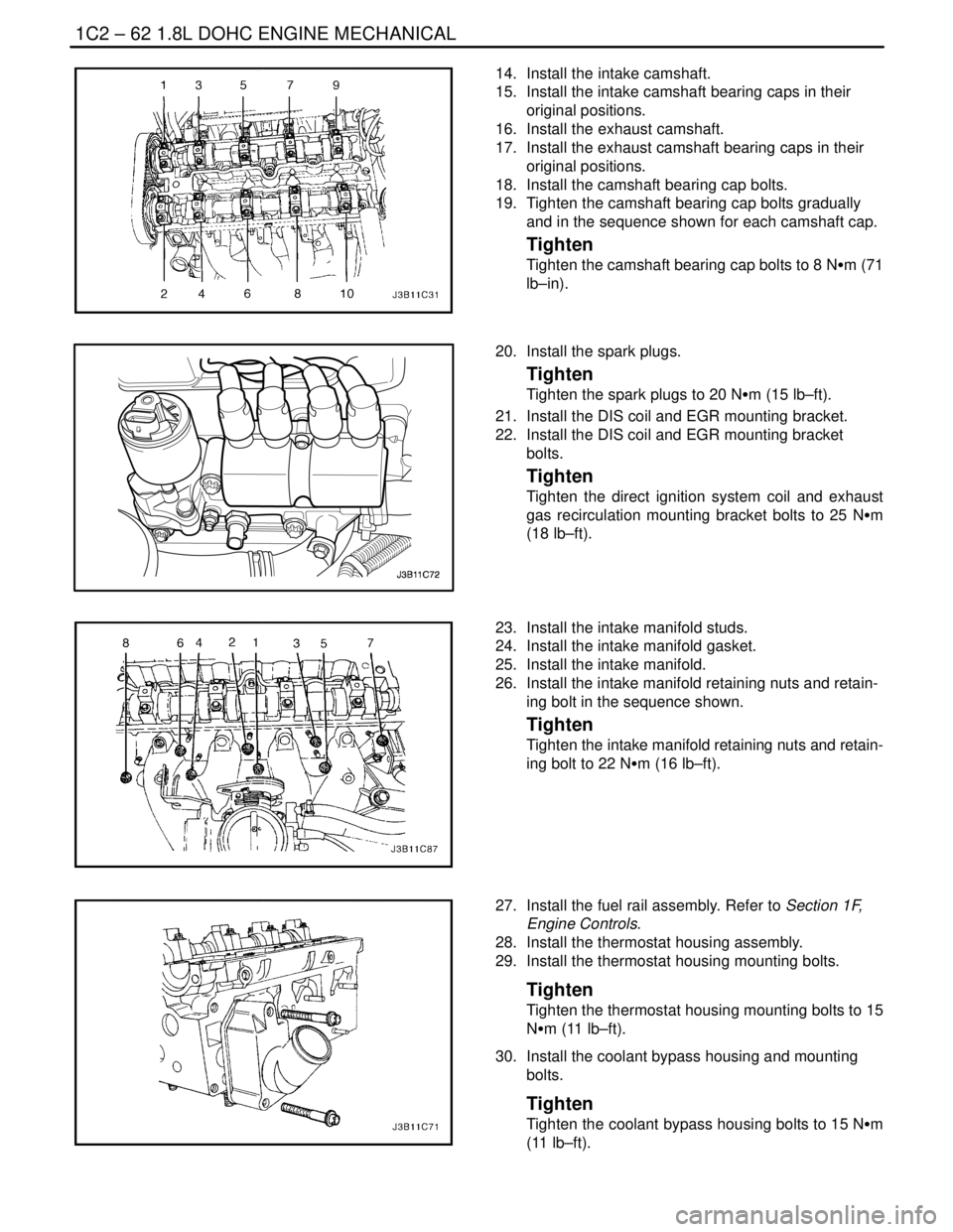

14. Install the intake camshaft.

15. Install the intake camshaft bearing caps in their

original positions.

16. Install the exhaust camshaft.

17. Install the exhaust camshaft bearing caps in their

original positions.

18. Install the camshaft bearing cap bolts.

19. Tighten the camshaft bearing cap bolts gradually

and in the sequence shown for each camshaft cap.

Tighten

Tighten the camshaft bearing cap bolts to 8 NSm (71

lb–in).

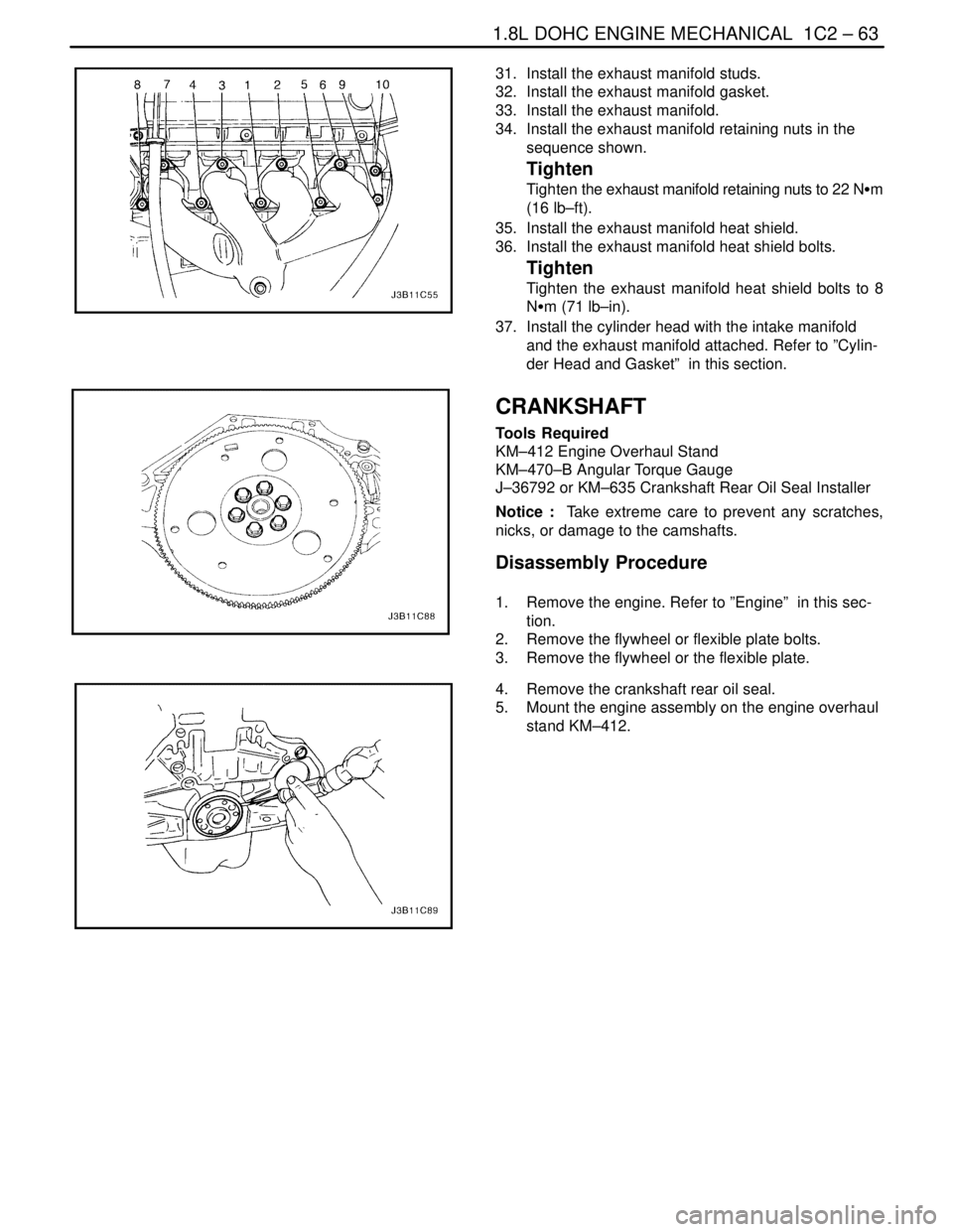

20. Install the spark plugs.

Tighten

Tighten the spark plugs to 20 NSm (15 lb–ft).

21. Install the DIS coil and EGR mounting bracket.

22. Install the DIS coil and EGR mounting bracket

bolts.

Tighten

Tighten the direct ignition system coil and exhaust

gas recirculation mounting bracket bolts to 25 NSm

(18 lb–ft).

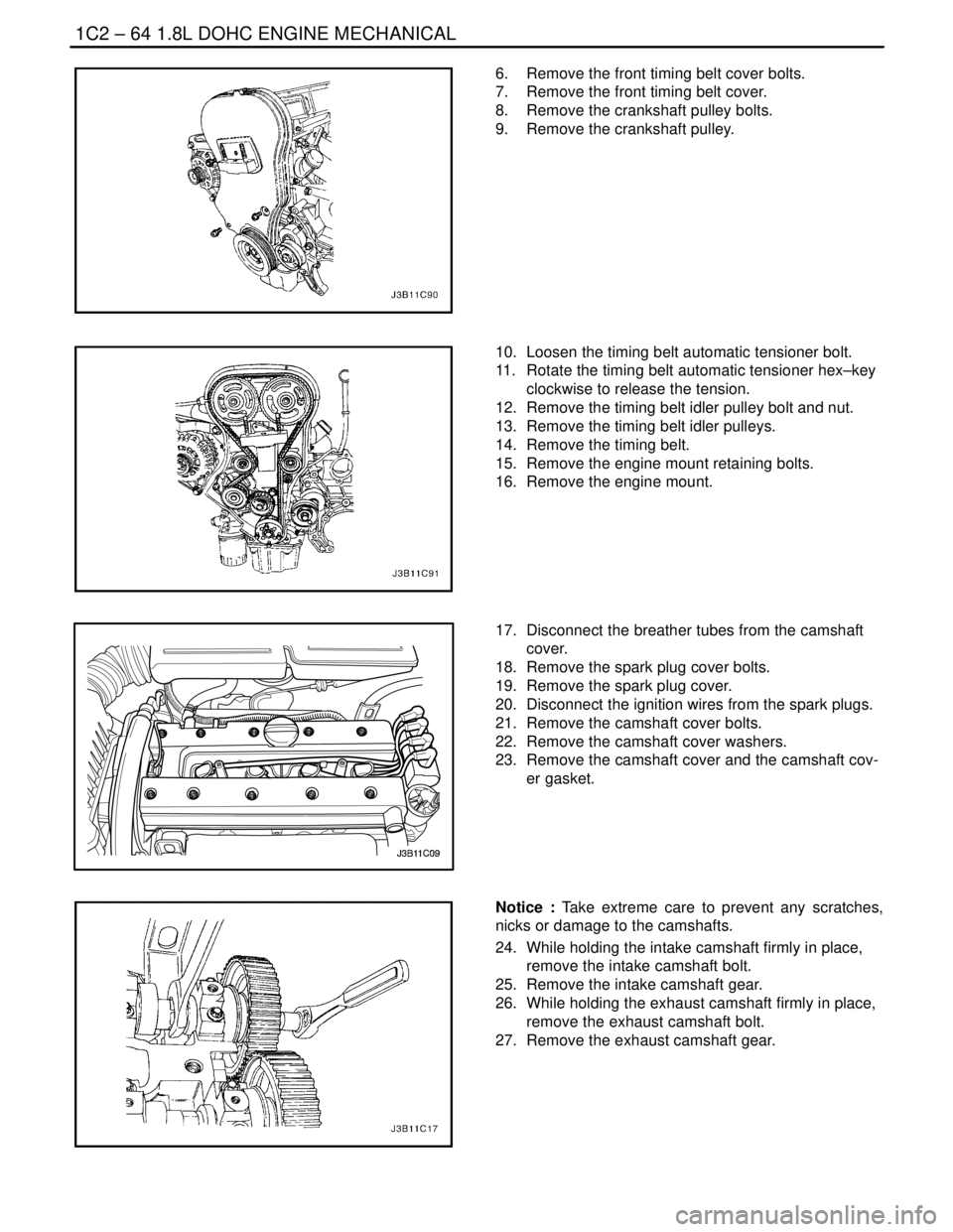

23. Install the intake manifold studs.

24. Install the intake manifold gasket.

25. Install the intake manifold.

26. Install the intake manifold retaining nuts and retain-

ing bolt in the sequence shown.

Tighten

Tighten the intake manifold retaining nuts and retain-

ing bolt to 22 NSm (16 lb–ft).

27. Install the fuel rail assembly. Refer to Section 1F,

Engine Controls.

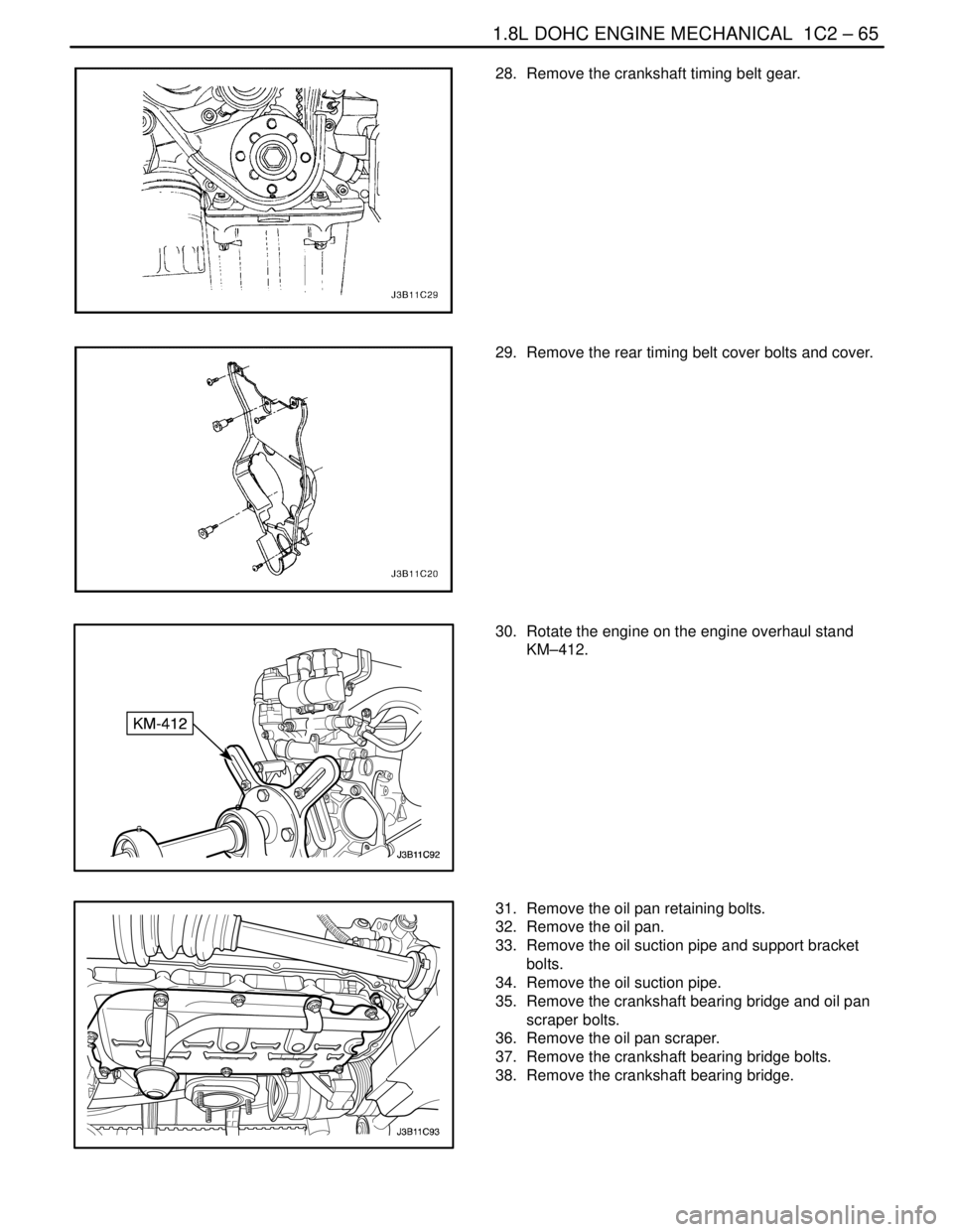

28. Install the thermostat housing assembly.

29. Install the thermostat housing mounting bolts.

Tighten

Tighten the thermostat housing mounting bolts to 15

NSm (11 lb–ft).

30. Install the coolant bypass housing and mounting

bolts.

Tighten

Tighten the coolant bypass housing bolts to 15 NSm

(11 lb–ft).

Page 183 of 2643

1.8L DOHC ENGINE MECHANICAL 1C2 – 63

DAEWOO V–121 BL4

31. Install the exhaust manifold studs.

32. Install the exhaust manifold gasket.

33. Install the exhaust manifold.

34. Install the exhaust manifold retaining nuts in the

sequence shown.

Tighten

Tighten the exhaust manifold retaining nuts to 22 NSm

(16 lb–ft).

35. Install the exhaust manifold heat shield.

36. Install the exhaust manifold heat shield bolts.

Tighten

Tighten the exhaust manifold heat shield bolts to 8

NSm (71 lb–in).

37. Install the cylinder head with the intake manifold

and the exhaust manifold attached. Refer to ”Cylin-

der Head and Gasket” in this section.

CRANKSHAFT

Tools Required

KM–412 Engine Overhaul Stand

KM–470–B Angular Torque Gauge

J–36792 or KM–635 Crankshaft Rear Oil Seal Installer

Notice : Take extreme care to prevent any scratches,

nicks, or damage to the camshafts.

Disassembly Procedure

1. Remove the engine. Refer to ”Engine” in this sec-

tion.

2. Remove the flywheel or flexible plate bolts.

3. Remove the flywheel or the flexible plate.

4. Remove the crankshaft rear oil seal.

5. Mount the engine assembly on the engine overhaul

stand KM–412.

Page 184 of 2643

1C2 – 64I1.8L DOHC ENGINE MECHANICAL

DAEWOO V–121 BL4

6. Remove the front timing belt cover bolts.

7. Remove the front timing belt cover.

8. Remove the crankshaft pulley bolts.

9. Remove the crankshaft pulley.

10. Loosen the timing belt automatic tensioner bolt.

11. Rotate the timing belt automatic tensioner hex–key

clockwise to release the tension.

12. Remove the timing belt idler pulley bolt and nut.

13. Remove the timing belt idler pulleys.

14. Remove the timing belt.

15. Remove the engine mount retaining bolts.

16. Remove the engine mount.

17. Disconnect the breather tubes from the camshaft

cover.

18. Remove the spark plug cover bolts.

19. Remove the spark plug cover.

20. Disconnect the ignition wires from the spark plugs.

21. Remove the camshaft cover bolts.

22. Remove the camshaft cover washers.

23. Remove the camshaft cover and the camshaft cov-

er gasket.

Notice : Take extreme care to prevent any scratches,

nicks or damage to the camshafts.

24. While holding the intake camshaft firmly in place,

remove the intake camshaft bolt.

25. Remove the intake camshaft gear.

26. While holding the exhaust camshaft firmly in place,

remove the exhaust camshaft bolt.

27. Remove the exhaust camshaft gear.

Page 185 of 2643

1.8L DOHC ENGINE MECHANICAL 1C2 – 65

DAEWOO V–121 BL4

28. Remove the crankshaft timing belt gear.

29. Remove the rear timing belt cover bolts and cover.

30. Rotate the engine on the engine overhaul stand

KM–412.

31. Remove the oil pan retaining bolts.

32. Remove the oil pan.

33. Remove the oil suction pipe and support bracket

bolts.

34. Remove the oil suction pipe.

35. Remove the crankshaft bearing bridge and oil pan

scraper bolts.

36. Remove the oil pan scraper.

37. Remove the crankshaft bearing bridge bolts.

38. Remove the crankshaft bearing bridge.

Page 186 of 2643

1C2 – 66I1.8L DOHC ENGINE MECHANICAL

DAEWOO V–121 BL4

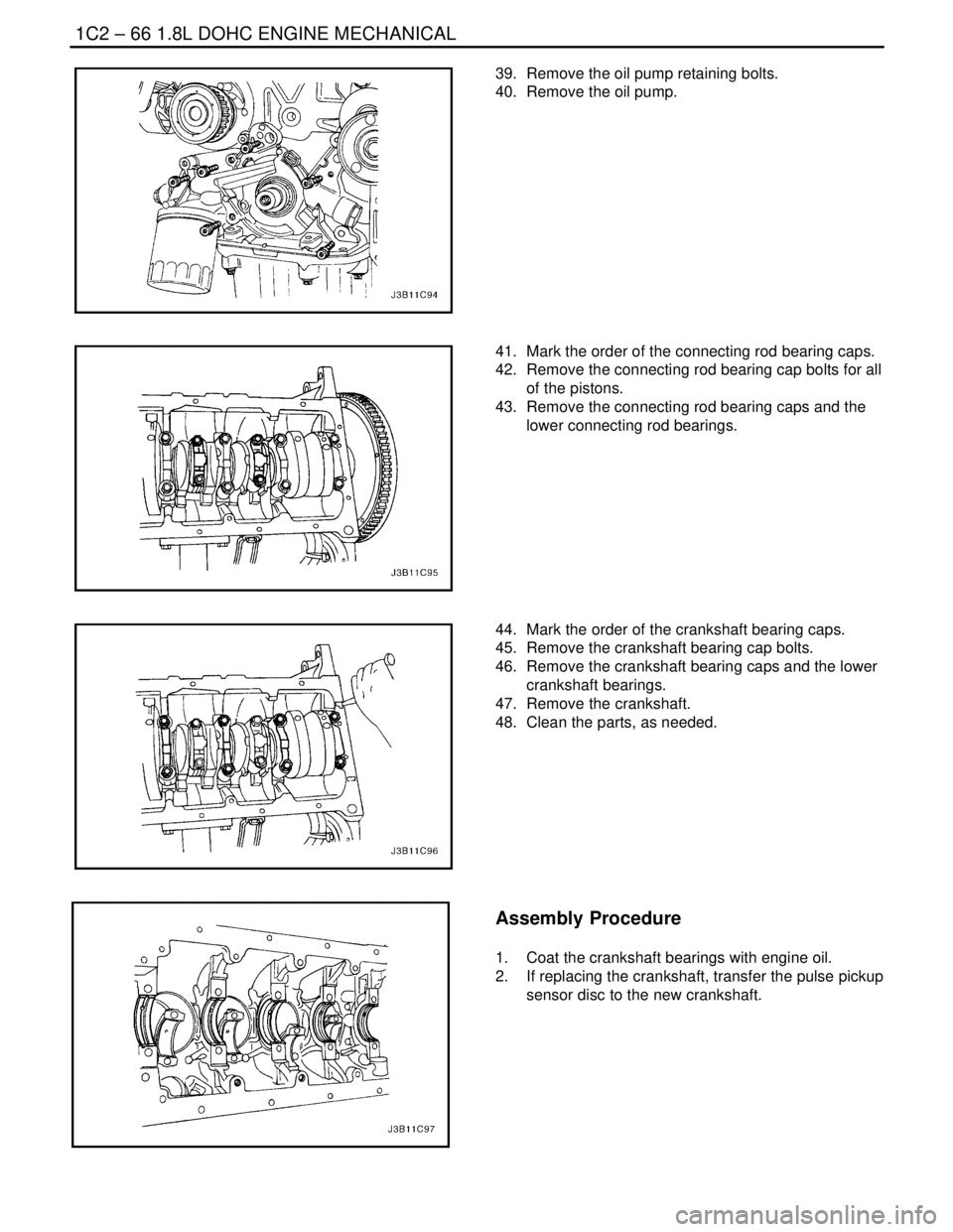

39. Remove the oil pump retaining bolts.

40. Remove the oil pump.

41. Mark the order of the connecting rod bearing caps.

42. Remove the connecting rod bearing cap bolts for all

of the pistons.

43. Remove the connecting rod bearing caps and the

lower connecting rod bearings.

44. Mark the order of the crankshaft bearing caps.

45. Remove the crankshaft bearing cap bolts.

46. Remove the crankshaft bearing caps and the lower

crankshaft bearings.

47. Remove the crankshaft.

48. Clean the parts, as needed.

Assembly Procedure

1. Coat the crankshaft bearings with engine oil.

2. If replacing the crankshaft, transfer the pulse pickup

sensor disc to the new crankshaft.

Page 187 of 2643

1.8L DOHC ENGINE MECHANICAL 1C2 – 67

DAEWOO V–121 BL4

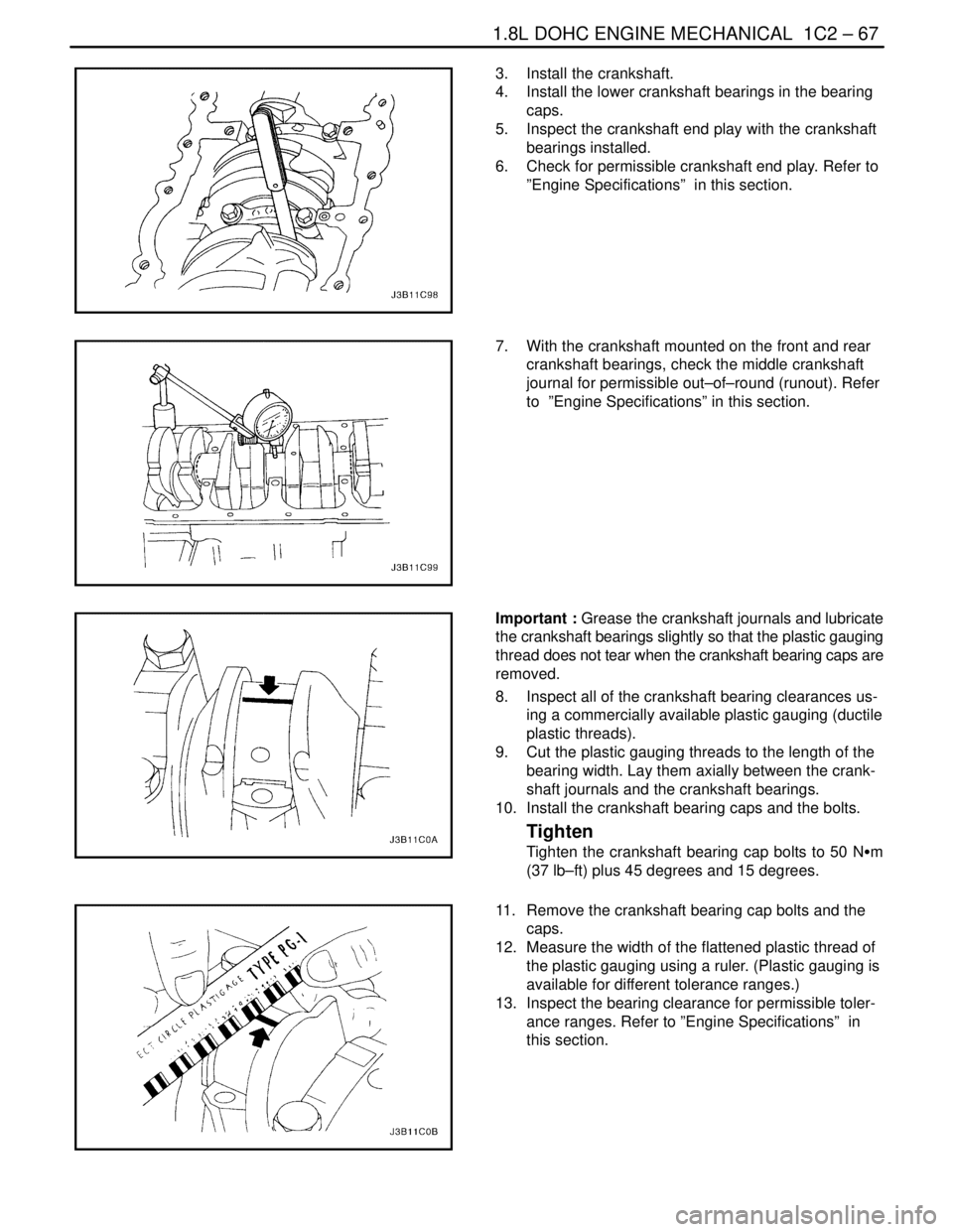

3. Install the crankshaft.

4. Install the lower crankshaft bearings in the bearing

caps.

5. Inspect the crankshaft end play with the crankshaft

bearings installed.

6. Check for permissible crankshaft end play. Refer to

”Engine Specifications” in this section.

7. With the crankshaft mounted on the front and rear

crankshaft bearings, check the middle crankshaft

journal for permissible out–of–round (runout). Refer

to ”Engine Specifications” in this section.

Important : Grease the crankshaft journals and lubricate

the crankshaft bearings slightly so that the plastic gauging

thread does not tear when the crankshaft bearing caps are

removed.

8. Inspect all of the crankshaft bearing clearances us-

ing a commercially available plastic gauging (ductile

plastic threads).

9. Cut the plastic gauging threads to the length of the

bearing width. Lay them axially between the crank-

shaft journals and the crankshaft bearings.

10. Install the crankshaft bearing caps and the bolts.

Tighten

Tighten the crankshaft bearing cap bolts to 50 NSm

(37 lb–ft) plus 45 degrees and 15 degrees.

11. Remove the crankshaft bearing cap bolts and the

caps.

12. Measure the width of the flattened plastic thread of

the plastic gauging using a ruler. (Plastic gauging is

available for different tolerance ranges.)

13. Inspect the bearing clearance for permissible toler-

ance ranges. Refer to ”Engine Specifications” in

this section.