Lay down DAEWOO NUBIRA 2004 Service User Guide

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: NUBIRA, Model: DAEWOO NUBIRA 2004Pages: 2643, PDF Size: 80.54 MB

Page 1103 of 2643

4F – 22IANTILOCK BRAKE SYSTEM

DAEWOO V–121 BL4

SELF–DIAGNOSTICS

Important : The electronic brake control module (EBCM)

turns the valve relay off when a diagnostic trouble code

(DTC) is set. The scan tool will indicate that the valve relay

is off when it is used to monitor the data list. This is normal

and should not be considered a malfunction.

Important : For safety reasons it is recommended that the

vehicle not be driven with test equipment connected. Ex-

ception : for testing of wheel speeds provided the test reg-

ulations are met.

The EBCM performs system self–diagnostics and can de-

tect and often isolate system malfunctions. When it de-

tects a malfunction, the EBCM sets a DTC that represents

the malfunction, turns ON the ABS and/or the EBD indica-

tors in most instances, and may disable the ABS and/or

the EBD functions as necessary for the duration of the igni-

tion cycle.

Once each ignition cycle, the EBCM performs an automat-

ic test when the vehicle speed > 6 km/h and the brake ped-

al is not actuated or when the vehicle speed > 15 km/h and

the brake pedal is actuated. In the course of this test, the

system cycles each valve solenoid and the pump motor,

along with the necessary relays, to check component op-

eration. If the EBCM detects any malfunctions, it will set

a DTC as described above.

DISPLAYING DTCS

Tools Required

Scan Tool

DTCs can be read through the use of the scan tool.

CLEARING DTCS

Tools Required

Scan Tool

The diagnostic trouble codes (DTCs) in the electronic

brake control module (EBCM) memory are erased:S Use the scan tool ”Clear DTCs” selection.

The method is detailed below. Be sure to verify proper sys-

tem operation and absence of DTCs when the clearing

procedure is completed.

The EBCM will not permit DTC clearing until all DTCs have

been displayed. Also, DTCs cannot be cleared by discon-

necting the EBCM, disconnecting the battery cables, or

turning the ignition switch to LOCK.

Scan Tool Method

The scan tool can clear ABS system DTCs using the mass

storage cartridge.

1. Install the scan tool and the mass storage cartridge.

2. Select ”Fault Memory.”

3. Select ”Clear Fault Memory.”

Clearing the fault memory cannot reset a valve relay which

was shut down when the fault was recognized. Changes

are possible only after the fault has been eliminated and

the next ignition cycle has begun.

INTERMITTENTS AND POOR

CONNECTIONS

As with most electronic systems, intermittent malfunctions

may be difficult to diagnose accurately. The following is a

method to try to isolate an intermittent malfunction, espe-

cially in wheel speed circuitry.

If an ABS malfunction occurs, the ABS indicator will illumi-

nate during the ignition cycle in which the malfunction was

detected. If it is an intermittent problem which seems to

have corrected itself (ABS indicator off), a history DTC will

be stored. Also stored will be the history data of the DTC

at the time the malfunction occurred. Use the scan tool

modular diagnostic system to read ABS history data.

Most intermittents are caused by faulty electrical connec-

tions or wiring, although a sticking relay or solenoid can oc-

casionally be at fault.

Page 1394 of 2643

ZF 4 HP 16 AUTOMATIC TRANSAXLE 5A1 – 45

DAEWOO V–121 BL4

CLUTCH PLATE DIAGNOSIS

Composition Plates

Dry the plate and inspect the plates for the following condi-

tions :

S Pitting

S Flaking

S Wear

S Glazing

S Cracking

S Charring

Chips or metal particles embedded in the lining

Replace a composition plate which shows any of these

conditions.

Steel Plates

Wipe the plates dry and check the plates for heat discolor-

ation. If the surfaces are smooth, even if colorsmear is in-

dicated, you can reuse the plate. If the plate is discolored

with hot spots or if the surface is scuffed, replace the plate.

Important : If the clutch shows evidence or extreme heat

or burning, replace the springs.

Causes of Burned Clutch Plates

The following conditions can result in a burned clutch

plate:

S Incorrect usage of clutch plates.

S Engine coolant in the transaxle fluid.

S A cracked clutch piston.

S Damaged or missing seals.

S Low line pressure.

S Valve problems.

– The valve body face is not flat

– Porosity between channels

– The valve bushing clips are improperly installed.

– The check balls are misplaced.

S The seal rings are worn or damaged

Engine Coolant in Transaxle

Notice : Antifreeze will deteriorate the O–ring seals and

the glue used to bond the clutch material to the pressure

plate. Both conditions may cause transaxle damage.

Perform the following steps if the transaxle oil cooler has

developed a leak, allowing engine coolant to enter the

transaxle:

1. Because the coolant will attach to the seal material

causing leakage, disassemble the transaxle and

replace all rubber type seals.

2. Because the facing material may become sepa-

rated from the steel center portion, replace the

composition faced clutch plate assemblies.

3. Replace all nylon parts including washers.

4. Replace the torque converter.

5. Thoroughly clean and rebuild the transaxle, using

new gaskets and oil filter.6. Flush the cooler lines after you have properly re-

paired or replaced the transaxle.

COOLER FLUSHING AND FLOW

TEST

Notice : You must flush the cooler whenever you receive

a transaxle for service. Cooler flushing is essential for

SRTA installation, major overhaul, whenever you replace

a pump or torque converter, or whenever you suspect that

the fluid has been contaminated.

After filling the transaxle with fluid, start the engine and run

for 30 seconds. This will remove any residual moisture

from the oil cooler. Disconnect the return line at the trans-

axle and observe the flow with the engine running. If the

fluid flow is insufficient, check the fluid flow by disconnect-

ing the feed line at the cooler. Observe the flow with the

engine running.

S If the flow from the cooler return line at the trans-

axle is insufficient, check the flow rate from the feed

line to the cooler. BLockage exists in the transaxle

or the cooler.

S If the flow from the transaxle feed line to the cooler

is insufficient, the transaxle is the cause of the fluid

flow problem.

S If the flow the transaxle feed line to the cooler is

insufficient, but flow from the cooler return line to

the transaxle is insufficient, inspect the cooler pipes

and fittings. Then repeat the cooler flushing proce-

dure. If the flow is still insufficient, replace the cool-

er.

TRANSAXLE FLUID LEVEL SERVICE

PROCEDURE

This procedure is to be used when checking a concern

with the fluid level in a vehicle. A low fluid level will result

in slipping and loss of drive/ reverse or delay on engage-

ment of drive/ reverse when the vehicle is cold.

The vehicle is first checked for transaxle diagnostic mes-

sages on the scan tool. If the oil level is low, it is possible

to register a vehicle speed signal fault.

The vehicle is to be test driven to determine if there is an

abnormal delay when selecting drive or reverse, or loss of

drive. One symptom of low fluid level is a momentary loss

of drive when driving the vehicle around a corner. Also

when the transaxle fluid level is low, a loss of drive may oc-

cur when the transaxle fluid temperature is low.

When adding or changing transaxle fluid use only ESSO

LT 71141 automatic transaxle fluid or other approved

fluids. The use of incorrect fluid will cause the performance

and durability of the transaxle to be severely degraded.

Fluid Level Diagnosis Procedure

1. If the vehicle is at operating temperature allow the

vehicle to cool down for two hours, but no greater

than four hours. Or if the vehicle is at cool status,

start the engine and allow the engine to idle for

approximately 5 minutes (825~875 rpm), if pos-

Page 1566 of 2643

ZF 4 HP 16 AUTOMATIC TRANSAXLE 5A1 – 217

DAEWOO V–121 BL4

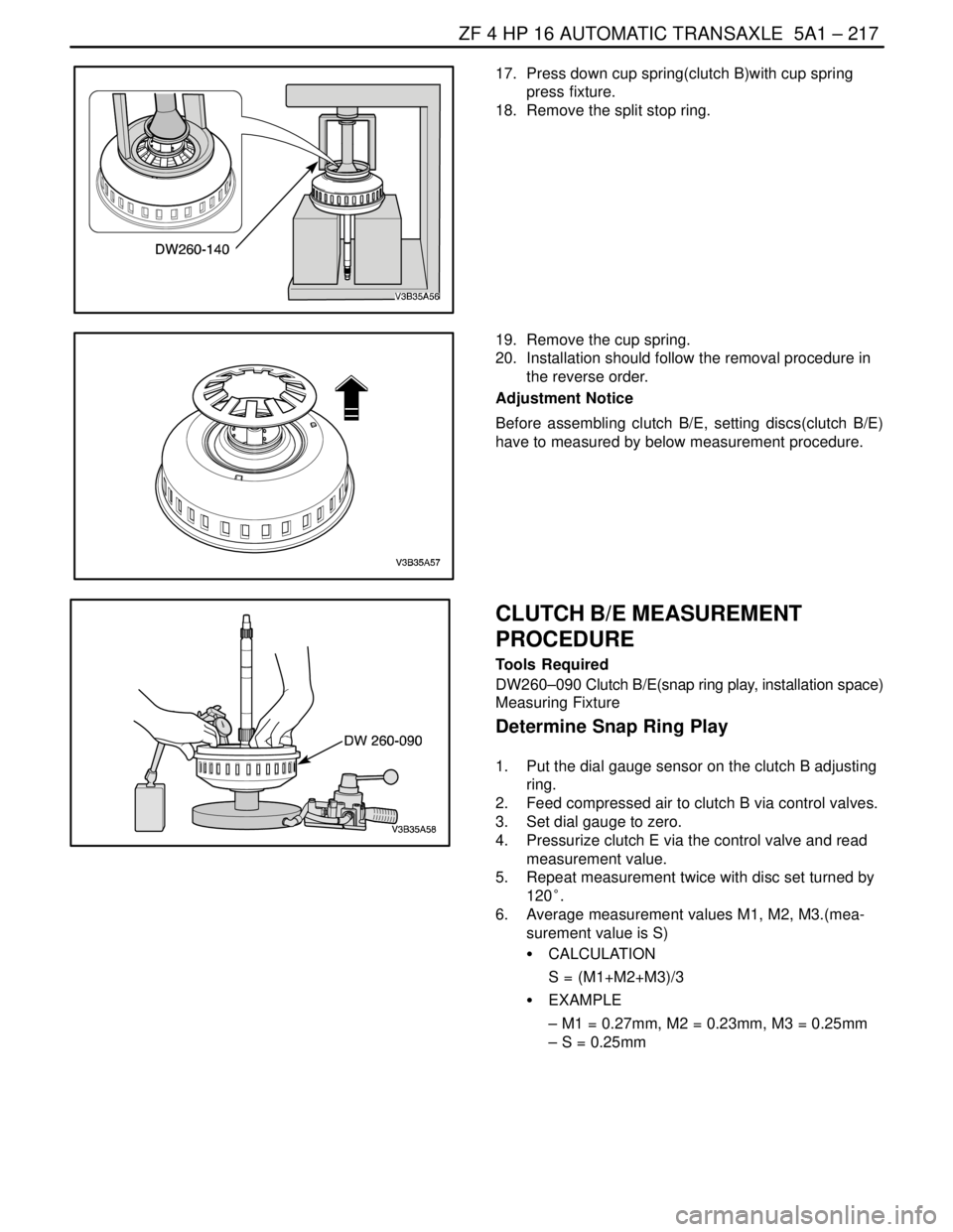

17. Press down cup spring(clutch B)with cup spring

press fixture.

18. Remove the split stop ring.

19. Remove the cup spring.

20. Installation should follow the removal procedure in

the reverse order.

Adjustment Notice

Before assembling clutch B/E, setting discs(clutch B/E)

have to measured by below measurement procedure.

CLUTCH B/E MEASUREMENT

PROCEDURE

Tools Required

DW260–090 Clutch B/E(snap ring play, installation space)

Measuring Fixture

Determine Snap Ring Play

1. Put the dial gauge sensor on the clutch B adjusting

ring.

2. Feed compressed air to clutch B via control valves.

3. Set dial gauge to zero.

4. Pressurize clutch E via the control valve and read

measurement value.

5. Repeat measurement twice with disc set turned by

120°.

6. Average measurement values M1, M2, M3.(mea-

surement value is S)

S CALCULATION

S = (M1+M2+M3)/3

S EXAMPLE

– M1 = 0.27mm, M2 = 0.23mm, M3 = 0.25mm

– S = 0.25mm

Page 1588 of 2643

ZF 4 HP 16 AUTOMATIC TRANSAXLE 5A1 – 239

DAEWOO V–121 BL4

S Excessive transaxle fluid leaking into the connector,

wicking up into the external wiring harness, and

degrading the wire insulation.

S Water/moisture intrusion in the connector.

S Low pin retention in the external connector from

excessive connection and disconnection of the wir-

ing connector assembly.

S Pin corrosion from contamination.

S Broken/cracked connector assembly.

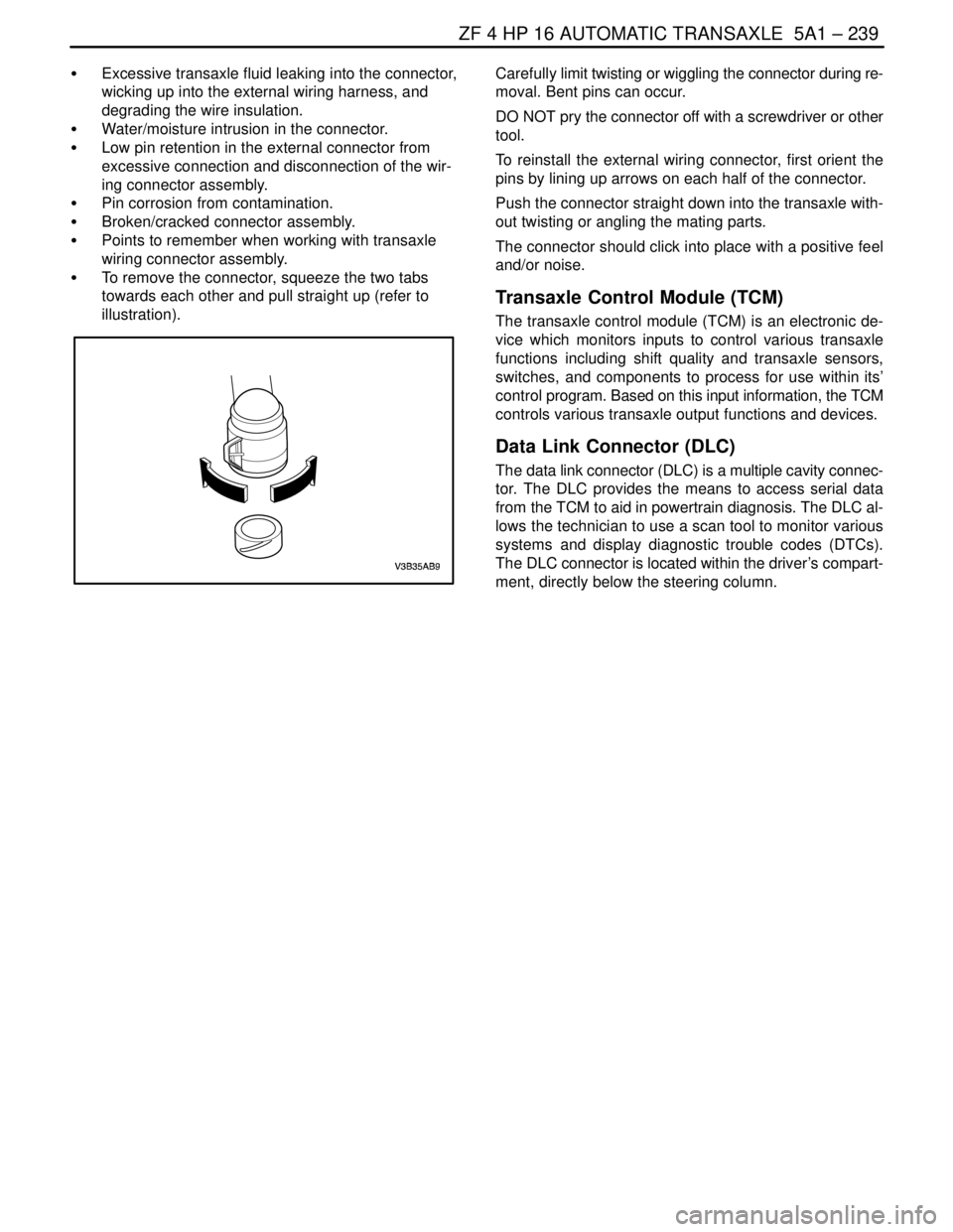

S Points to remember when working with transaxle

wiring connector assembly.

S To remove the connector, squeeze the two tabs

towards each other and pull straight up (refer to

illustration).Carefully limit twisting or wiggling the connector during re-

moval. Bent pins can occur.

DO NOT pry the connector off with a screwdriver or other

tool.

To reinstall the external wiring connector, first orient the

pins by lining up arrows on each half of the connector.

Push the connector straight down into the transaxle with-

out twisting or angling the mating parts.

The connector should click into place with a positive feel

and/or noise.

Transaxle Control Module (TCM)

The transaxle control module (TCM) is an electronic de-

vice which monitors inputs to control various transaxle

functions including shift quality and transaxle sensors,

switches, and components to process for use within its’

control program. Based on this input information, the TCM

controls various transaxle output functions and devices.

Data Link Connector (DLC)

The data link connector (DLC) is a multiple cavity connec-

tor. The DLC provides the means to access serial data

from the TCM to aid in powertrain diagnosis. The DLC al-

lows the technician to use a scan tool to monitor various

systems and display diagnostic trouble codes (DTCs).

The DLC connector is located within the driver’s compart-

ment, directly below the steering column.

Page 1924 of 2643

POWER STEERING GEAR 6C – 7

DAEWOO V–121 BL4

SPEED SENSITIVE POWER STEERING SYSTEM

OPERATING WITH FULL ASSIST AT ALL TIMES

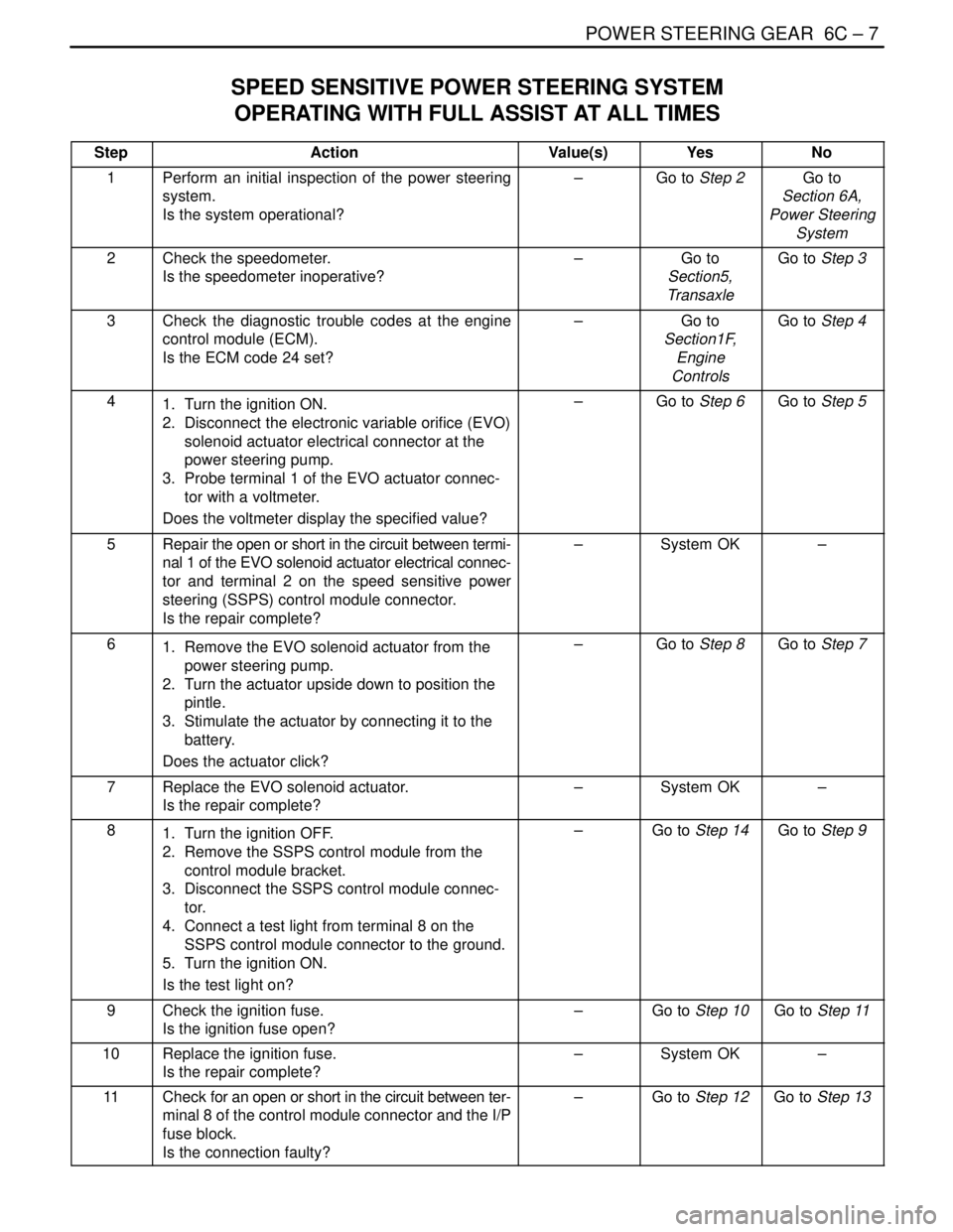

StepActionValue(s)YesNo

1Perform an initial inspection of the power steering

system.

Is the system operational?–Go to Step 2Go to

Section 6A,

Power Steering

System

2Check the speedometer.

Is the speedometer inoperative?–Go to

Section5,

TransaxleGo to Step 3

3Check the diagnostic trouble codes at the engine

control module (ECM).

Is the ECM code 24 set?–Go to

Section1F,

Engine

ControlsGo to Step 4

41. Turn the ignition ON.

2. Disconnect the electronic variable orifice (EVO)

solenoid actuator electrical connector at the

power steering pump.

3. Probe terminal 1 of the EVO actuator connec-

tor with a voltmeter.

Does the voltmeter display the specified value?–Go to Step 6Go to Step 5

5Repair the open or short in the circuit between termi-

nal 1 of the EVO solenoid actuator electrical connec-

tor and terminal 2 on the speed sensitive power

steering (SSPS) control module connector.

Is the repair complete?–System OK–

61. Remove the EVO solenoid actuator from the

power steering pump.

2. Turn the actuator upside down to position the

pintle.

3. Stimulate the actuator by connecting it to the

battery.

Does the actuator click?–Go to Step 8Go to Step 7

7Replace the EVO solenoid actuator.

Is the repair complete?–System OK–

81. Turn the ignition OFF.

2. Remove the SSPS control module from the

control module bracket.

3. Disconnect the SSPS control module connec-

tor.

4. Connect a test light from terminal 8 on the

SSPS control module connector to the ground.

5. Turn the ignition ON.

Is the test light on?–Go to Step 14Go to Step 9

9Check the ignition fuse.

Is the ignition fuse open?–Go to Step 10Go to Step 11

10Replace the ignition fuse.

Is the repair complete?–System OK–

11Check for an open or short in the circuit between ter-

minal 8 of the control module connector and the I/P

fuse block.

Is the connection faulty?–Go to Step 12Go to Step 13

Page 1970 of 2643

6E – 16ISTEERING WHEEL AND COLUMN

DAEWOO V–121 BL4

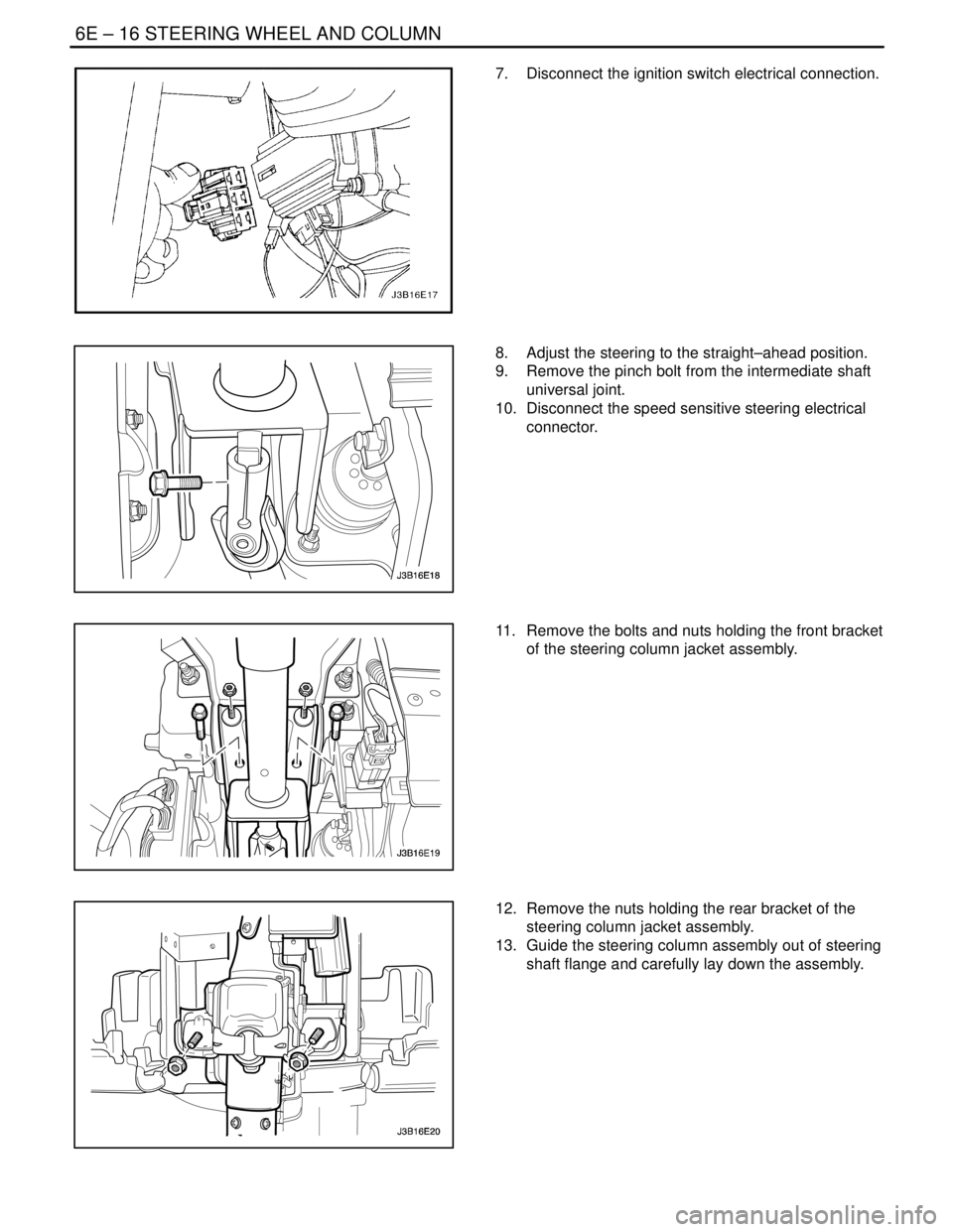

7. Disconnect the ignition switch electrical connection.

8. Adjust the steering to the straight–ahead position.

9. Remove the pinch bolt from the intermediate shaft

universal joint.

10. Disconnect the speed sensitive steering electrical

connector.

11. Remove the bolts and nuts holding the front bracket

of the steering column jacket assembly.

12. Remove the nuts holding the rear bracket of the

steering column jacket assembly.

13. Guide the steering column assembly out of steering

shaft flange and carefully lay down the assembly.

Page 1998 of 2643

7A – 24IHEATING AND VENTILATION SYSTEM

DAEWOO V–121 BL4

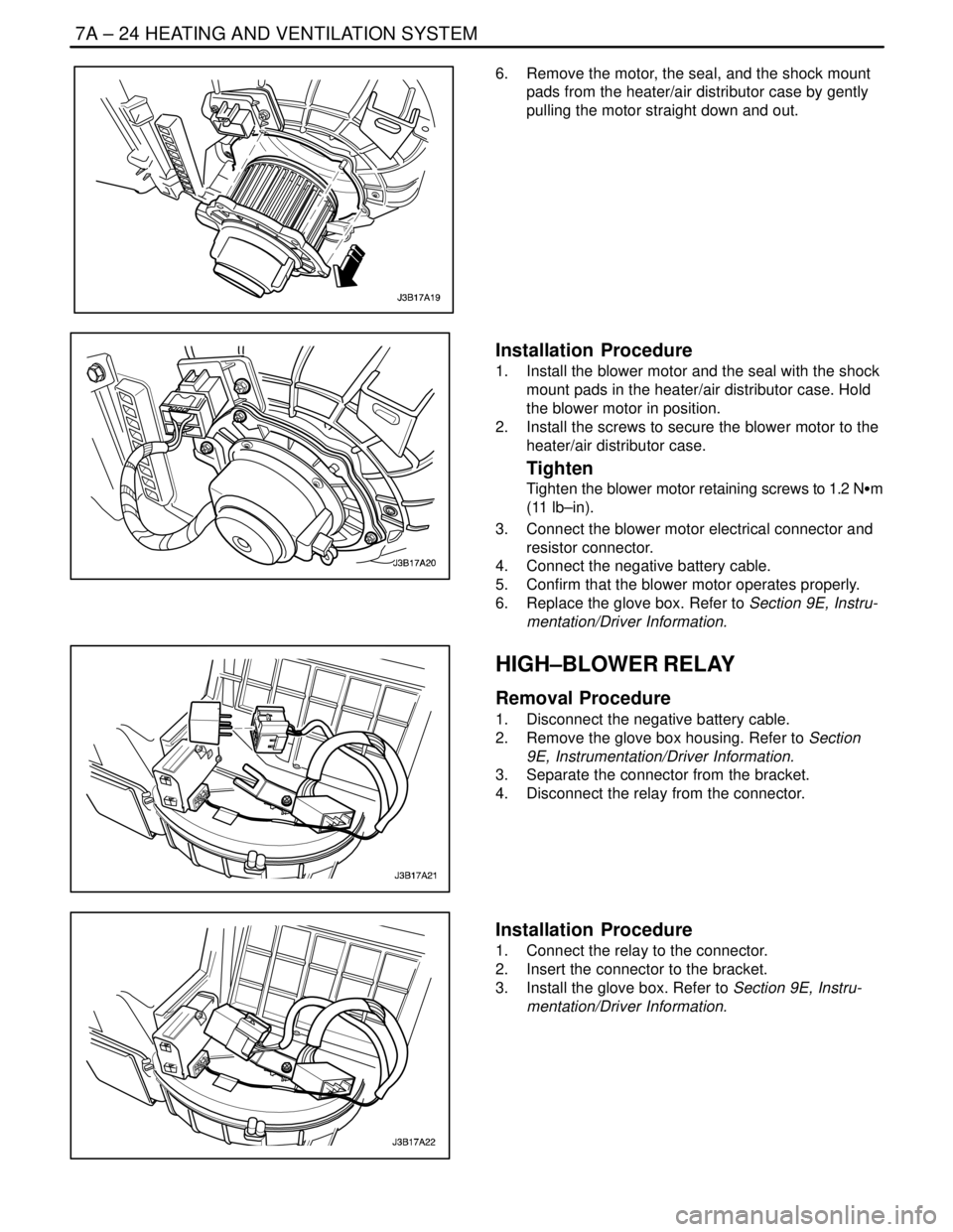

6. Remove the motor, the seal, and the shock mount

pads from the heater/air distributor case by gently

pulling the motor straight down and out.

Installation Procedure

1. Install the blower motor and the seal with the shock

mount pads in the heater/air distributor case. Hold

the blower motor in position.

2. Install the screws to secure the blower motor to the

heater/air distributor case.

Tighten

Tighten the blower motor retaining screws to 1.2 NSm

(11 lb–in).

3. Connect the blower motor electrical connector and

resistor connector.

4. Connect the negative battery cable.

5. Confirm that the blower motor operates properly.

6. Replace the glove box. Refer to Section 9E, Instru-

mentation/Driver Information.

HIGH–BLOWER RELAY

Removal Procedure

1. Disconnect the negative battery cable.

2. Remove the glove box housing. Refer to Section

9E, Instrumentation/Driver Information.

3. Separate the connector from the bracket.

4. Disconnect the relay from the connector.

Installation Procedure

1. Connect the relay to the connector.

2. Insert the connector to the bracket.

3. Install the glove box. Refer to Section 9E, Instru-

mentation/Driver Information.

Page 2095 of 2643

7D – 40IAUTOMATIC TEMPERATURE CONTROL HEATING, VENTILATION, AND AIR CONDITIONING SYSTEM

DAEWOO V–121 BL4

GENERAL DESCRIPTION

AND SYSTEM OPERATION

GENERAL INFORMATION

THE V5 SYSTEM

Refer to Section 7B, Manual Control Heating, Ventilation,

and Air Conditioning System,for general information de-

tails for the following:

S System Components – Functional.

S The V5 A/C System.

S V5 Compressor – Description of Operation.

S V5 Compressor – General Description.

SYSTEM COMPONENTS–CONTROL

Controller

The operation of the A/C system is controlled by the

switches on the control head. This console–mounted

heating and ventilation system contains the following

knobs and display:

Temperature Control Push Knobs

1. Raise the temperature of the air entering the ve-

hicle by pressing the top switch, with the red arrow

pointing upward.

2. Lower the temperature by pressing the bottom

switch, with the blue arrow pointing downward.

3. Actuate the air mix door by an electric motor.

4. Vary the mix of the air passing through the heater

core with the air bypassing the core.

Each press of a switch changes the set temperature by in-

crements of 0.5°C (1°F). This is shown in the temperature

window on the function display.

The Function Display

This is an LCD display indicating the status of the control

settings selected. Starting from the left end of the display,

the sections are as follows:

1. Temperature setting – Indicates the temperature set

with the temperature control knob.

2. Auto status – Indicates whether the system is oper-

ating in the full auto mode or the manual mode.

3. Defroster icon – Indicates manual selection of full

defrost mode.

4. Mode – Indicated by icon, the mode chosen by the

system in auto (or by the operator in manual) is

shown by an illumination arrow indicating the air

path.

5. A/C – A snowflake icon indicating whether the A/C

is ON or OFF.

6. Fan speed – Indicates the fan speed by illuminating

a bar based on the segment at the front, for low

speed, and adding additional segments in order up

to the fifth, for high speed.Eight Additional Push Knobs

1. Full defrost – Causes the mode motors to direct all

air to the windshield and aide window outlets for

maximum defrosting.

2. Air intake – Switches between fresh air intake, the

default, and recirculating air. Airflow arrows on the

display indicate the mode in effect.

3. Full Auto Switch – Maintains the set temperature

automatically. In this mode, the fully automatic tem-

perature control (FATC) system controls the follow-

ing:

S The air mix door motor.

S The mode door motor.

S The blower motor speed.

S The inlet air door motor.

S A/C ON/OFF.

4. OFF Switch – Turns the automatic air conditioning

and fan control off.

5. Mode Switch – Allows manual selection of the air-

flow direction.

S Selection is shown on the function display.

S Each time the mode switch is pressed, the next

function is displayed.

6. A/C Switch – Allows manual selection and control

of the air conditioning function.

7. Fan Control Switch – Allows manual selection

among five fan speeds.

8. Defogger Switch – Turns on the electric defogging

heater in the rear window and the outside rearview

mirrors, if the vehicle is equipped with heated mir-

rors.

Pressure Transducer

Pressure transducer switching incorporates the functions

of the high–pressure and the low–pressure cutout

switches along with the fan cycling switch. The pressure

transducer is located in the high–side liquid refrigerant line

behind the right strut tower, between the right strut tower

and the fire wall. The output from this pressure transducer

goes to the electronic control module (ECM), which con-

trols the compressor function based on the pressure sig-

nal.

Wide–Open Throttle (WOT) Compressor

Cutoff

During full–throttle acceleration, the throttle position sen-

sor (TPS) sends a signal to the ECM, which then controls

the compressor clutch.

High RPM Cutoff

As engine rpm approaches the maximum limit, the ECM

will disengage the compressor clutch until the engine

slows to a lower rpm.

Page 2329 of 2643

9E – 30IINSTRUMENTATION/DRIVER INFORMATION

DAEWOO V–121 BL4

GENERAL DESCRIPTION

AND SYSTEM OPERATION

CIGAR LIGHTER

The cigar lighter is located in the front portion of the floor

console. To use the lighter, push it in completely. When the

lighter is hot, it will release itself from contact with the heat-

ing element. The lighter and the heating element can be

damaged if the lighter is not allowed to release itself fully

from the heating element.

ASHTRAY

The ashtray is located below the audio system. To access

the ashtray, pull it out from the center console. The ashtray

lamp will go on when the parking lamps or the headlamps

are turned on.

INSTRUMENT PANEL VENTS

The center and the side vents in the instrument panel can

be adjusted up and down and from side to side. The side

vents can also be aimed toward the side windows in order

to defog them.

GLOVE BOX

The glove box can be opened by pulling up on the latch

handle. The glove box must be removed in order to gain

access to the passenger’s side airbag module.

DIGTAL CLOCK

The digital clock is located in the instrument panel, above

the audio system. The clock is capable of a 12–hour or a

24–hour display.

INSTRUMENT CLUSTER

The instrument cluster is located above the steering col-

umn and in the instrument cluster trim panel. The instru-

ment cluster contains the instruments that provide the

driver with vehicle performance information. The instru-

ment cluster contains a speedometer, an odometer, a trip

odometer, a temperature gauge, a fuel gauge, and several

indicator lamps. For replacement of the indicator lamp

bulbs contained in the instrument cluster, refer to ”Instru-

ment Cluster Indicator Lamps Specifications” and”Instru-

ment Cluster Indicator Lamps” in this section.

SPEEDOMETER/ODOMETER/TRIP

ODOMETER

The speedometer measures the speed of the vehicle in

km/h (mph in some countries). It consists of an instrument

cluster gauge connected to the vehicle speed sensor

(VSS) on the transaxle output shaft.The odometer measures in kilometers (miles in some

countries) the total distance the vehicle has traveled since

it was manufactured. It consists of an instrument cluster

gauge connected to the VSS on the transaxle output shaft.

The trip odometer measures the distance the vehicle has

traveled since the odometer was last reset. It consists of

an instrument cluster gauge connected to the VSS on the

transaxle output shaft. The trip odometer can be reset to

zero at any time so that the driver can record the distance

traveled from any starting point.

FUEL GAUGE

The fuel gauge consists of an instrument cluster gauge

connected to a sending unit in the fuel tank.

The fuel gauge indicates the quantity of fuel in the tank

only when the ignition switch is turned to ON or ACC.

When the ignition is turned to LOCK or START, the pointer

may come to rest at any position.

TEMPERATURE GAUGE

The temperature gauge consists of an instrument cluster

gauge connected to a temperature sensor that is in con-

tact with the circulating engine coolant.

The temperature gauge indicates the temperature of the

coolant. Prolonged driving or idling in very hot weather

may cause the pointer to move beyond the center of the

gauge. The engine is overheating if the pointer moves into

the red zone at the upper limit of the gauge.

INSTRUMENT CLUSTER INDICATOR

LAMPS

The instrument cluster contains indicator lamps that indi-

cate the functioning of certain systems or the existence of

potential problems with the operation of the vehicle. The

indicator lamps are replaceable. For replacement of the in-

dicator lamps contained in the instrument cluster, refer to

”Instrument Cluster Indicator Lamps Specifications”

and”Instrument Cluster Indicator Lamps” in this section.

CHIME MODULE

The chime module is located above the instrument panel

fuse block and will sound in order to bring attention to one

or more of the following conditions:

S The lamps are on, the door is ajar, and the ignition

switch is not in ACC, ON, or START.

S The seat belt is unbuckled when the ignition switch

is in ON or START.

S The door is open when the ignition switch is in ON

or START.

S The key is left in the ignition switch when the igni-

tion is in LOCK and the door is open.

Page 2488 of 2643

REMOTE KEYLESS ENTRY AND ANTI–THEFT SYSTEM 9T1 – 7

DAEWOO V–121 BL4

REMOTE KEYLESS ENTRY

TRANSMITTER PROGRAMMING

The Remote Keyless Entry System allows for the use of

as many as four(4) transmitters for each vehicle. Replace-

ment Remote Keyless Entry System Transmitters must

first be programmend to specific vehicle using the

Scan100 Secan tool.

This process is completed using serial data communica-

tion between the Scan 100 Scan tool and the Remote Key-

less Entry Control Unit and is the only method available for

programming Transmitters.

Notice : All Transmitters for a specific vehicle must be pro-

grammed at same time.

Notice : Once the programming function of the Remote

Keyless Entry System is activated, any Transmitter(exist-

ing or new) that is not programmed(or reprogrammed)

during the programming procedure will no longer operate

the Remote Keyless Entry System of that vehicle.

Notice : Ensure that the doors, hood and trunk/rear hatch

are closed prior to starting the programming procedure.

1. Connect the Scan 100 Scan Tool to the Data Link

Connector(DLC)

2. Turn the Scan 100 Scan Tool ”ON” by pressing the

”Power” Button, then wait for the MAIN MENU

screen to be displayed.

3. From the MAIN MENU screen, select ”Diagnostics”

by pressing #1 on the Key Pad.

4. From the MODEL YEAR screen, select the ap-

propriate model year of the specific vehicle by ei-

ther scrolling down to the year and pressing ”EN-

TER”, or by pressing the respective item number on

the Key Pad.

5. From the VEHICLE TYPE screen, select the specif-

ic vehicle model by either scrolling down to the

model name and pressing ”ENTER”, or by pressing

the respective item number on the Key Pad.

6. From the SYSTEM SELECTION MENU screen,

select ”Body” by pressing #2 on the Key Pad.

7. From the BODY SELECTION MENU screen, select

”Coding” by pressing #2 on the Key Pad.8. From the CODY SELECTION MENU screen, select

”Coding” by pressing #1 on the Key Pad.

9. From the SECRET NUMBER OF CODINGS

screen, enter for(4) zero’s (0–0–0–0) in the for(4)

boxes labeled ”1–2–3–4–”.

10. From the CODING SYSTEM SELECT screen, se-

lect ”Keyless Entry” by pressing #2 on the Key Pad.

Notice : A slight delay may occur and ”PLEASE WAIT”

may be displayed before the next screen appears.

11. From the KEYLESS ENTRY CODING SYSTEM

screen, select ”Coding Transmitter” by pressing #1

on the Key Pad.

12. When directed by the Scan 100 Scan Tool, press

any Button on the first Transmitter to be pro-

grammed.

CAUTION : Ensure that Transmitters from other ve-

hicles in the immediate area are not activated during

this procedure.

13. Continue programming Transmitters when directed

by the Scan 100 Scan Tool until all Transmitters

have been programmed.

Notice : A maximum of four(4) Transmitters may be pro-

grammed to a vehicle.

14. Once all Transmitters have been programmed,

press the ”ESC” Button on the Key Pad. The dis-

play will confirm the number of Transmitters pro-

grammed. If the number displayed does not match

the number of Transmitters programmed, repeat

the procedure.

15. Turn the Scan 100 Scan Tool ”OFF” by pressing the

”POWER” Button, then disconnect it from the Data

Link Connector.

16. Wait approximately 10 seconds, then test the op-

eration of each programmed Transmitter to ensure

it operates properly.

The control module/receiver leaves the programming

mode automatically and switches to the normal operating

mode when either of the following conditions occurs:

S the scan tool is disconnected from the ALDL.

S Four passwords are recorded in the control module/

receiver.