ECU DAEWOO NUBIRA 2004 Service Repair Manual

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: NUBIRA, Model: DAEWOO NUBIRA 2004Pages: 2643, PDF Size: 80.54 MB

Page 951 of 2643

REAR SUSPENSION 2D – 9

DAEWOO V–121 BL4

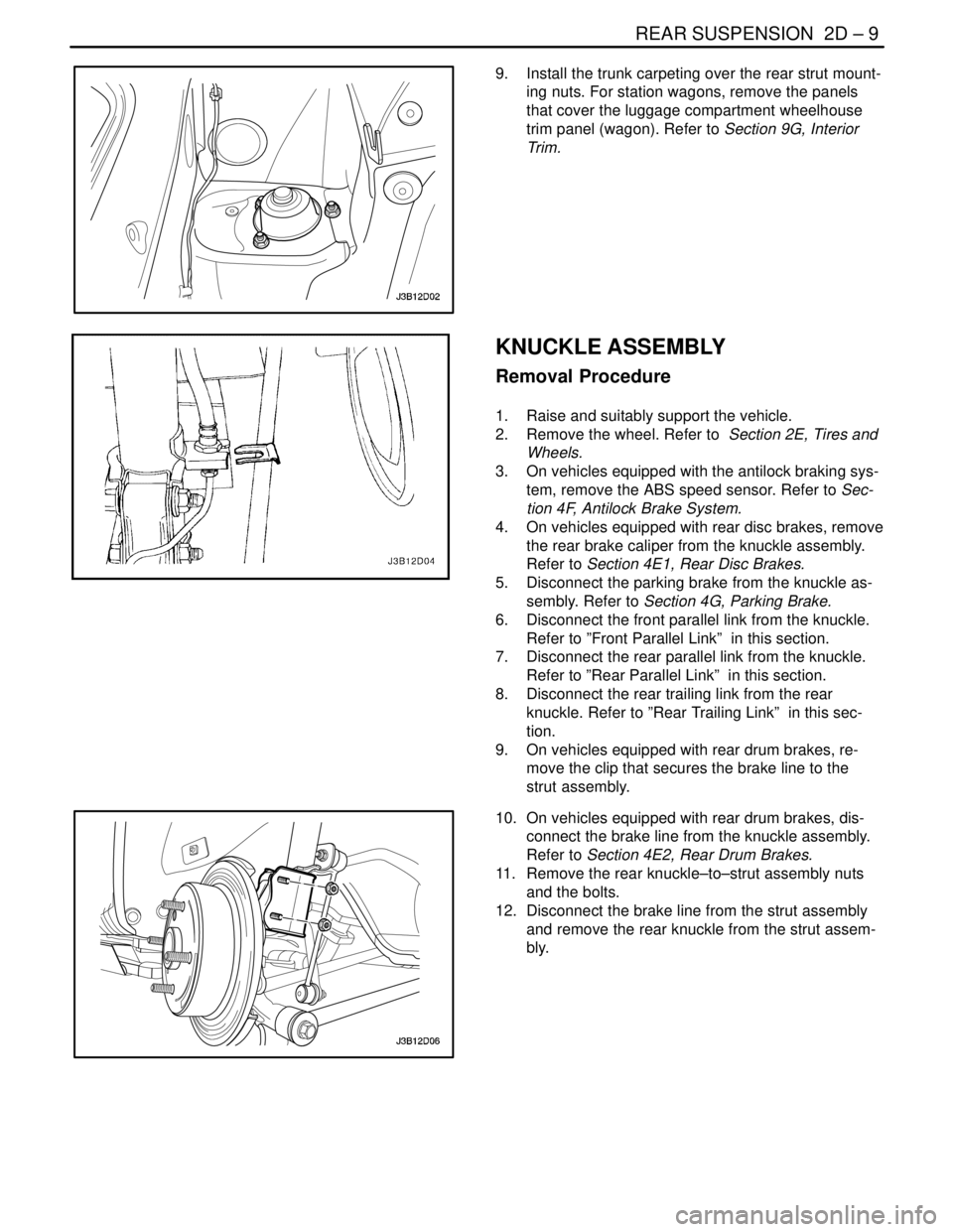

9. Install the trunk carpeting over the rear strut mount-

ing nuts. For station wagons, remove the panels

that cover the luggage compartment wheelhouse

trim panel (wagon). Refer to Section 9G, Interior

Trim.

KNUCKLE ASSEMBLY

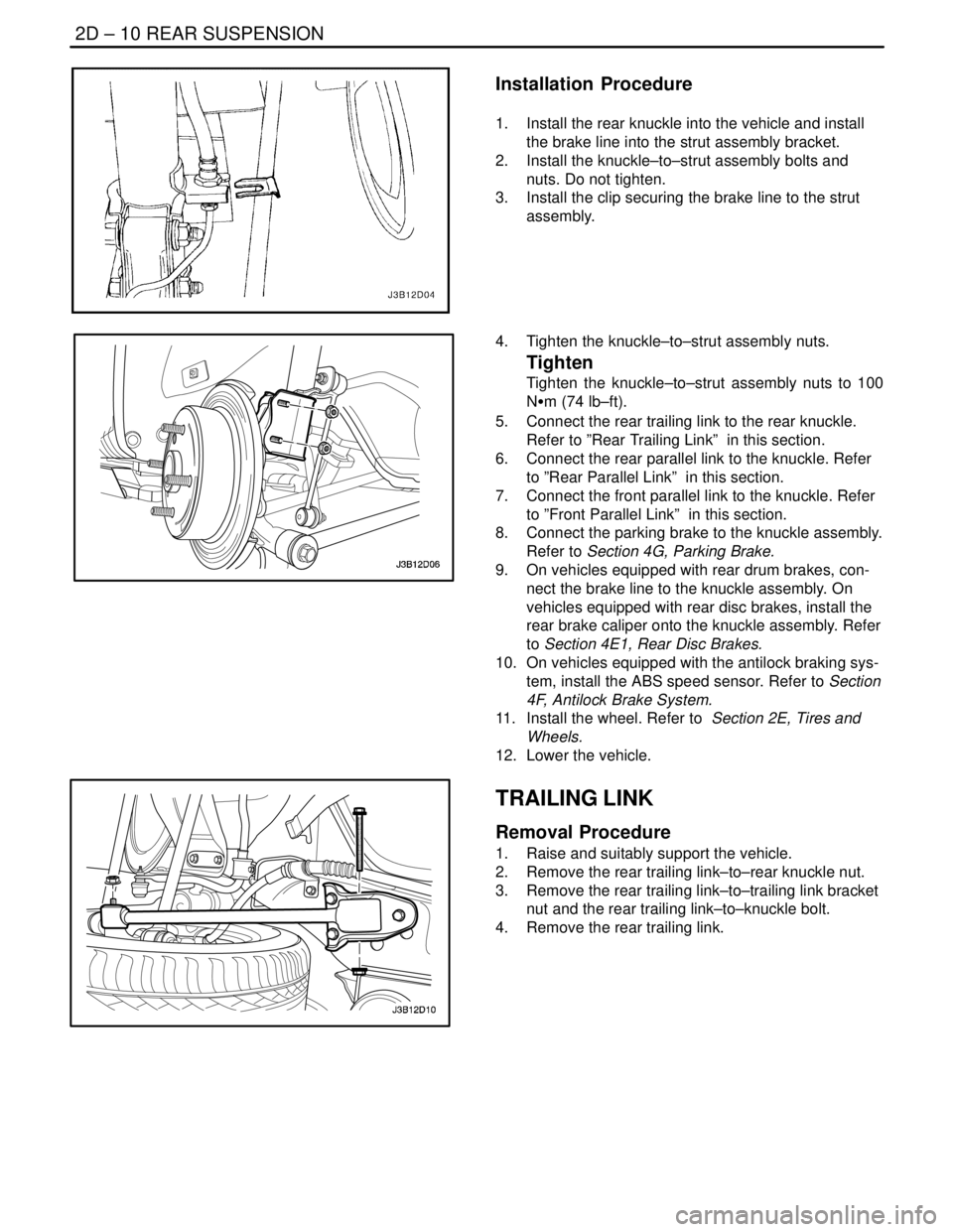

Removal Procedure

1. Raise and suitably support the vehicle.

2. Remove the wheel. Refer to Section 2E, Tires and

Wheels.

3. On vehicles equipped with the antilock braking sys-

tem, remove the ABS speed sensor. Refer to Sec-

tion 4F, Antilock Brake System.

4. On vehicles equipped with rear disc brakes, remove

the rear brake caliper from the knuckle assembly.

Refer to Section 4E1, Rear Disc Brakes.

5. Disconnect the parking brake from the knuckle as-

sembly. Refer to Section 4G, Parking Brake.

6. Disconnect the front parallel link from the knuckle.

Refer to ”Front Parallel Link” in this section.

7. Disconnect the rear parallel link from the knuckle.

Refer to ”Rear Parallel Link” in this section.

8. Disconnect the rear trailing link from the rear

knuckle. Refer to ”Rear Trailing Link” in this sec-

tion.

9. On vehicles equipped with rear drum brakes, re-

move the clip that secures the brake line to the

strut assembly.

10. On vehicles equipped with rear drum brakes, dis-

connect the brake line from the knuckle assembly.

Refer to Section 4E2, Rear Drum Brakes.

11. Remove the rear knuckle–to–strut assembly nuts

and the bolts.

12. Disconnect the brake line from the strut assembly

and remove the rear knuckle from the strut assem-

bly.

Page 952 of 2643

2D – 10IREAR SUSPENSION

DAEWOO V–121 BL4

Installation Procedure

1. Install the rear knuckle into the vehicle and install

the brake line into the strut assembly bracket.

2. Install the knuckle–to–strut assembly bolts and

nuts. Do not tighten.

3. Install the clip securing the brake line to the strut

assembly.

4. Tighten the knuckle–to–strut assembly nuts.

Tighten

Tighten the knuckle–to–strut assembly nuts to 100

NSm (74 lb–ft).

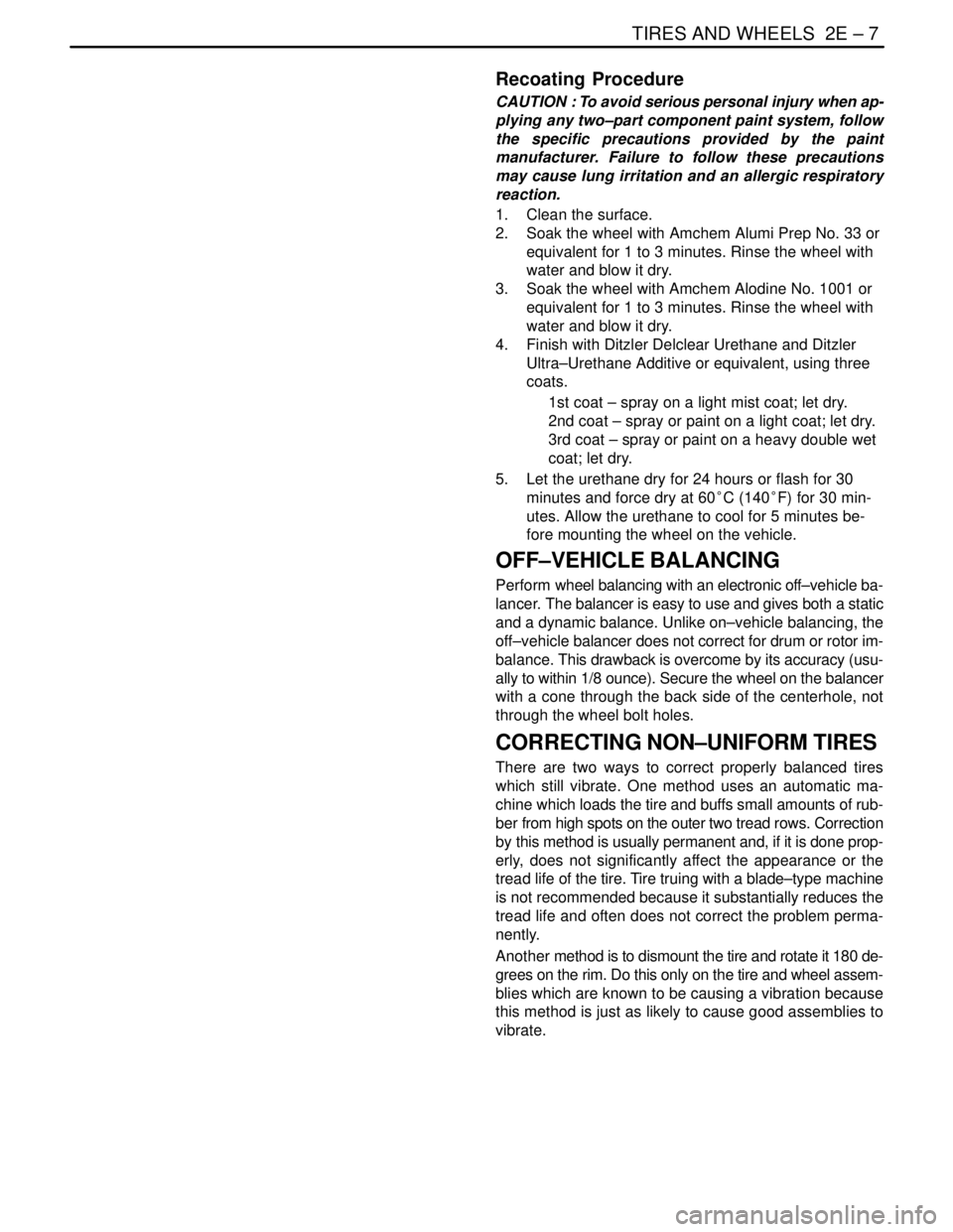

5. Connect the rear trailing link to the rear knuckle.

Refer to ”Rear Trailing Link” in this section.

6. Connect the rear parallel link to the knuckle. Refer

to ”Rear Parallel Link” in this section.

7. Connect the front parallel link to the knuckle. Refer

to ”Front Parallel Link” in this section.

8. Connect the parking brake to the knuckle assembly.

Refer to Section 4G, Parking Brake.

9. On vehicles equipped with rear drum brakes, con-

nect the brake line to the knuckle assembly. On

vehicles equipped with rear disc brakes, install the

rear brake caliper onto the knuckle assembly. Refer

to Section 4E1, Rear Disc Brakes.

10. On vehicles equipped with the antilock braking sys-

tem, install the ABS speed sensor. Refer to Section

4F, Antilock Brake System.

11. Install the wheel. Refer to Section 2E, Tires and

Wheels.

12. Lower the vehicle.

TRAILING LINK

Removal Procedure

1. Raise and suitably support the vehicle.

2. Remove the rear trailing link–to–rear knuckle nut.

3. Remove the rear trailing link–to–trailing link bracket

nut and the rear trailing link–to–knuckle bolt.

4. Remove the rear trailing link.

Page 969 of 2643

TIRES AND WHEELS 2E – 7

DAEWOO V–121 BL4

Recoating Procedure

CAUTION : To avoid serious personal injury when ap-

plying any two–part component paint system, follow

the specific precautions provided by the paint

manufacturer. Failure to follow these precautions

may cause lung irritation and an allergic respiratory

reaction.

1. Clean the surface.

2. Soak the wheel with Amchem Alumi Prep No. 33 or

equivalent for 1 to 3 minutes. Rinse the wheel with

water and blow it dry.

3. Soak the wheel with Amchem Alodine No. 1001 or

equivalent for 1 to 3 minutes. Rinse the wheel with

water and blow it dry.

4. Finish with Ditzler Delclear Urethane and Ditzler

Ultra–Urethane Additive or equivalent, using three

coats.

1st coat – spray on a light mist coat; let dry.

2nd coat – spray or paint on a light coat; let dry.

3rd coat – spray or paint on a heavy double wet

coat; let dry.

5. Let the urethane dry for 24 hours or flash for 30

minutes and force dry at 60°C (140°F) for 30 min-

utes. Allow the urethane to cool for 5 minutes be-

fore mounting the wheel on the vehicle.

OFF–VEHICLE BALANCING

Perform wheel balancing with an electronic off–vehicle ba-

lancer. The balancer is easy to use and gives both a static

and a dynamic balance. Unlike on–vehicle balancing, the

off–vehicle balancer does not correct for drum or rotor im-

balance. This drawback is overcome by its accuracy (usu-

ally to within 1/8 ounce). Secure the wheel on the balancer

with a cone through the back side of the centerhole, not

through the wheel bolt holes.

CORRECTING NON–UNIFORM TIRES

There are two ways to correct properly balanced tires

which still vibrate. One method uses an automatic ma-

chine which loads the tire and buffs small amounts of rub-

ber from high spots on the outer two tread rows. Correction

by this method is usually permanent and, if it is done prop-

erly, does not significantly affect the appearance or the

tread life of the tire. Tire truing with a blade–type machine

is not recommended because it substantially reduces the

tread life and often does not correct the problem perma-

nently.

Another method is to dismount the tire and rotate it 180 de-

grees on the rim. Do this only on the tire and wheel assem-

blies which are known to be causing a vibration because

this method is just as likely to cause good assemblies to

vibrate.

Page 971 of 2643

TIRES AND WHEELS 2E – 9

DAEWOO V–121 BL4

GENERAL DESCRIPTION

AND SYSTEM OPERATION

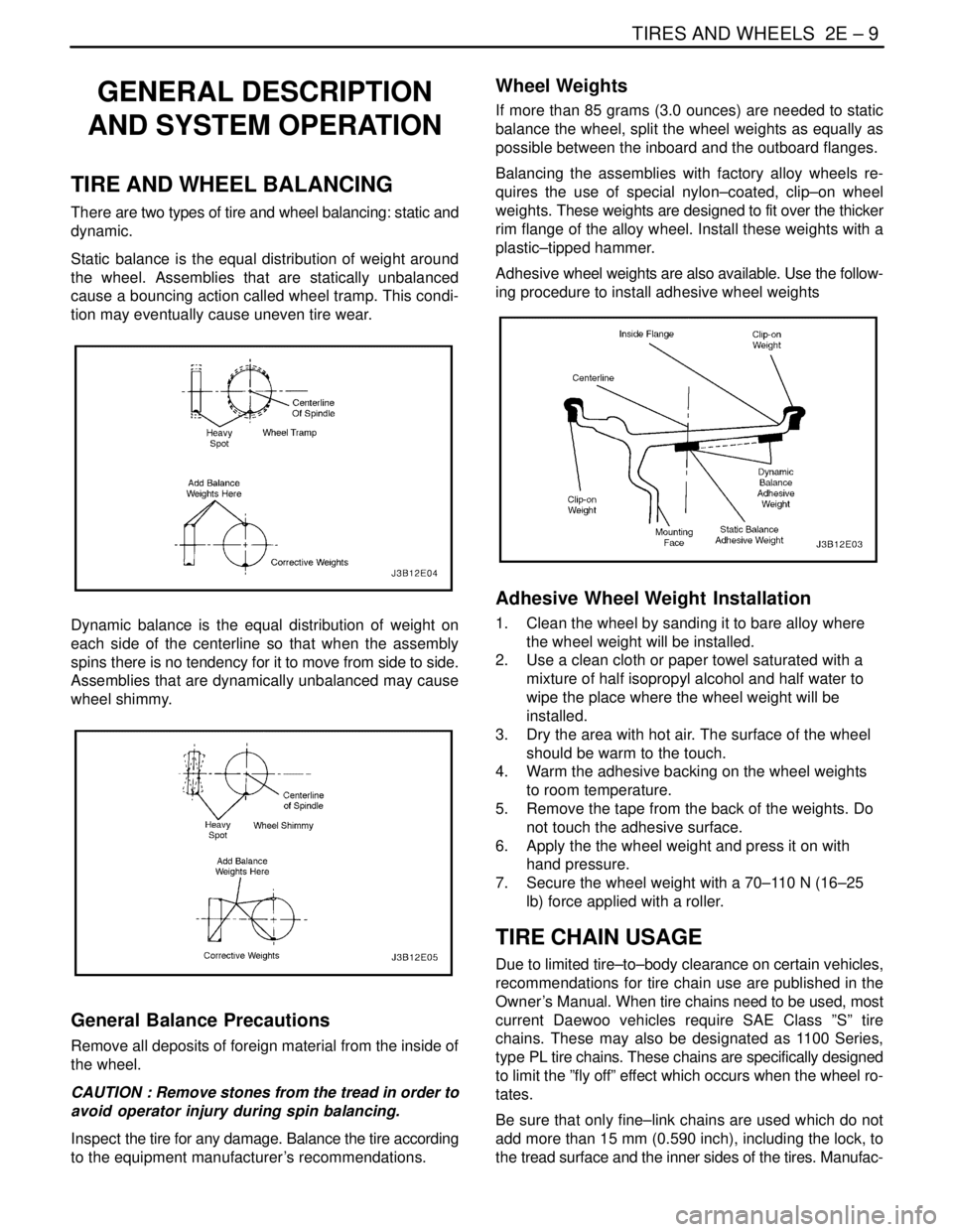

TIRE AND WHEEL BALANCING

There are two types of tire and wheel balancing: static and

dynamic.

Static balance is the equal distribution of weight around

the wheel. Assemblies that are statically unbalanced

cause a bouncing action called wheel tramp. This condi-

tion may eventually cause uneven tire wear.

Dynamic balance is the equal distribution of weight on

each side of the centerline so that when the assembly

spins there is no tendency for it to move from side to side.

Assemblies that are dynamically unbalanced may cause

wheel shimmy.

General Balance Precautions

Remove all deposits of foreign material from the inside of

the wheel.

CAUTION : Remove stones from the tread in order to

avoid operator injury during spin balancing.

Inspect the tire for any damage. Balance the tire according

to the equipment manufacturer’s recommendations.

Wheel Weights

If more than 85 grams (3.0 ounces) are needed to static

balance the wheel, split the wheel weights as equally as

possible between the inboard and the outboard flanges.

Balancing the assemblies with factory alloy wheels re-

quires the use of special nylon–coated, clip–on wheel

weights. These weights are designed to fit over the thicker

rim flange of the alloy wheel. Install these weights with a

plastic–tipped hammer.

Adhesive wheel weights are also available. Use the follow-

ing procedure to install adhesive wheel weights

Adhesive Wheel Weight Installation

1. Clean the wheel by sanding it to bare alloy where

the wheel weight will be installed.

2. Use a clean cloth or paper towel saturated with a

mixture of half isopropyl alcohol and half water to

wipe the place where the wheel weight will be

installed.

3. Dry the area with hot air. The surface of the wheel

should be warm to the touch.

4. Warm the adhesive backing on the wheel weights

to room temperature.

5. Remove the tape from the back of the weights. Do

not touch the adhesive surface.

6. Apply the the wheel weight and press it on with

hand pressure.

7. Secure the wheel weight with a 70–110 N (16–25

lb) force applied with a roller.

TIRE CHAIN USAGE

Due to limited tire–to–body clearance on certain vehicles,

recommendations for tire chain use are published in the

Owner ’s Manual. When tire chains need to be used, most

current Daewoo vehicles require SAE Class ”S” tire

chains. These may also be designated as 1100 Series,

type PL tire chains. These chains are specifically designed

to limit the ”fly off” effect which occurs when the wheel ro-

tates.

Be sure that only fine–link chains are used which do not

add more than 15 mm (0.590 inch), including the lock, to

the tread surface and the inner sides of the tires. Manufac-

Page 1051 of 2643

FRONT DISC BRAKES 4D – 3

DAEWOO V–121 BL4

MAINTENANCE AND REPAIR

ON–VEHICLE SERVICE

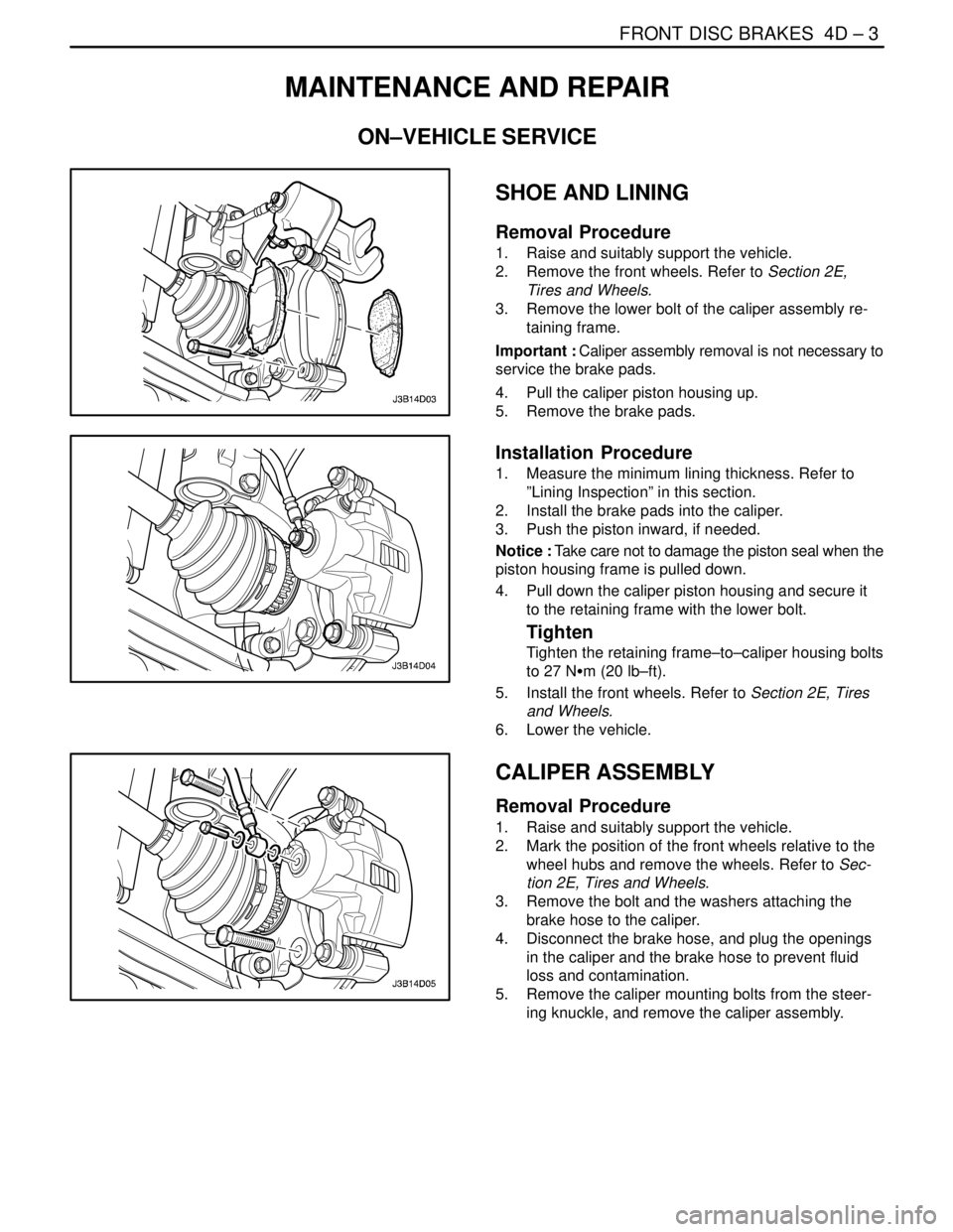

SHOE AND LINING

Removal Procedure

1. Raise and suitably support the vehicle.

2. Remove the front wheels. Refer to Section 2E,

Tires and Wheels.

3. Remove the lower bolt of the caliper assembly re-

taining frame.

Important : Caliper assembly removal is not necessary to

service the brake pads.

4. Pull the caliper piston housing up.

5. Remove the brake pads.

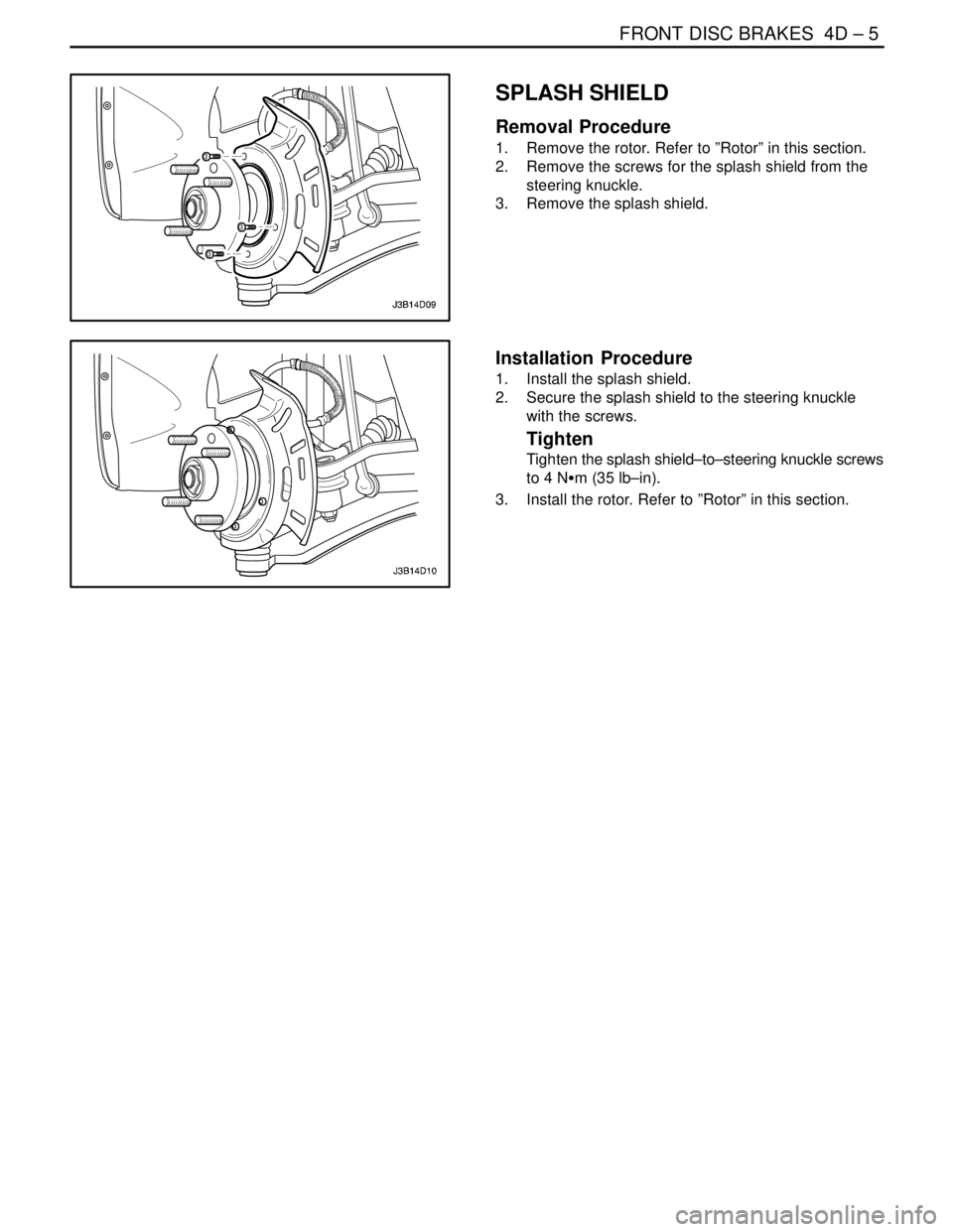

Installation Procedure

1. Measure the minimum lining thickness. Refer to

”Lining Inspection” in this section.

2. Install the brake pads into the caliper.

3. Push the piston inward, if needed.

Notice : Take care not to damage the piston seal when the

piston housing frame is pulled down.

4. Pull down the caliper piston housing and secure it

to the retaining frame with the lower bolt.

Tighten

Tighten the retaining frame–to–caliper housing bolts

to 27 NSm (20 lb–ft).

5. Install the front wheels. Refer to Section 2E, Tires

and Wheels.

6. Lower the vehicle.

CALIPER ASSEMBLY

Removal Procedure

1. Raise and suitably support the vehicle.

2. Mark the position of the front wheels relative to the

wheel hubs and remove the wheels. Refer to Sec-

tion 2E, Tires and Wheels.

3. Remove the bolt and the washers attaching the

brake hose to the caliper.

4. Disconnect the brake hose, and plug the openings

in the caliper and the brake hose to prevent fluid

loss and contamination.

5. Remove the caliper mounting bolts from the steer-

ing knuckle, and remove the caliper assembly.

Page 1053 of 2643

FRONT DISC BRAKES 4D – 5

DAEWOO V–121 BL4

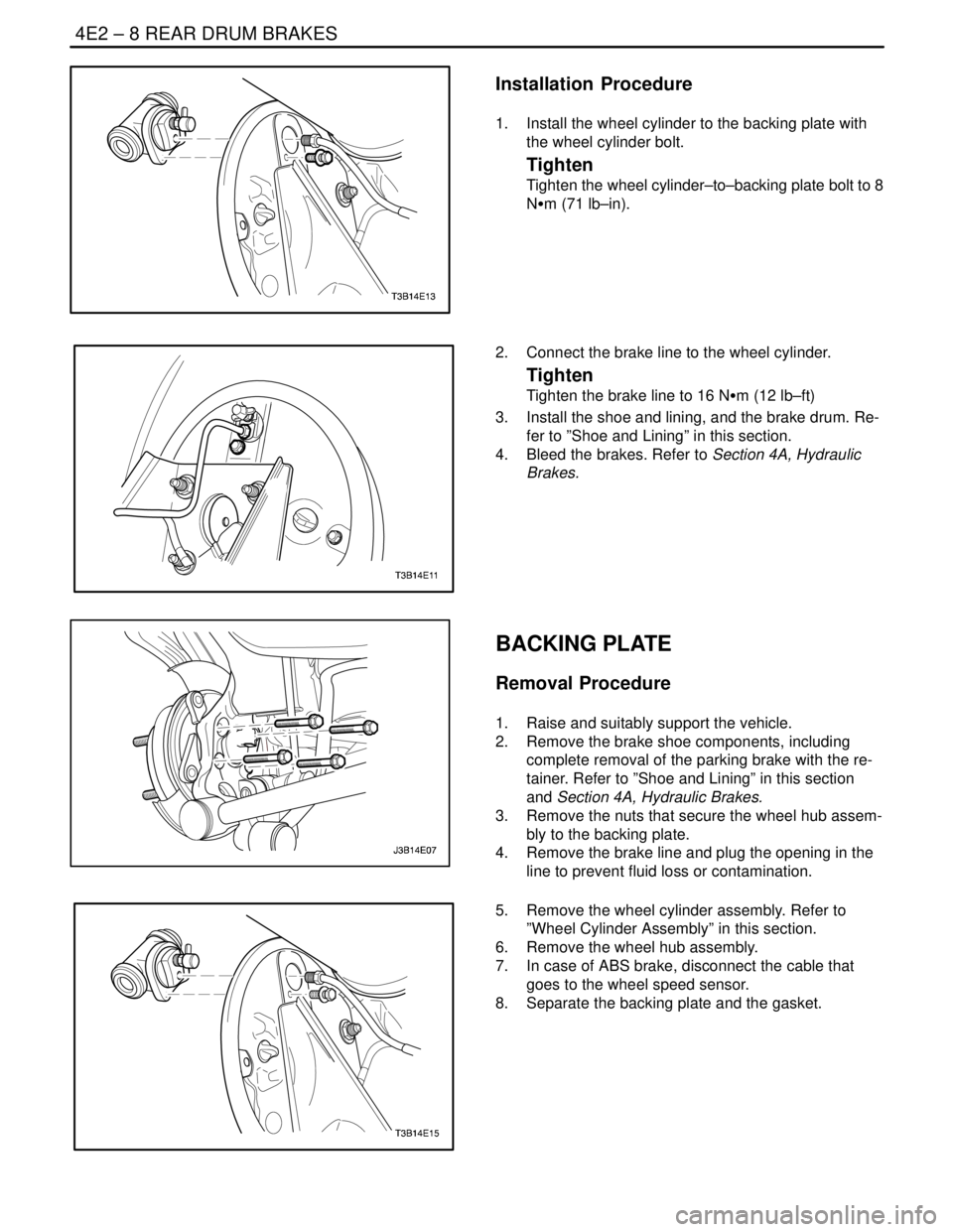

SPLASH SHIELD

Removal Procedure

1. Remove the rotor. Refer to ”Rotor” in this section.

2. Remove the screws for the splash shield from the

steering knuckle.

3. Remove the splash shield.

Installation Procedure

1. Install the splash shield.

2. Secure the splash shield to the steering knuckle

with the screws.

Tighten

Tighten the splash shield–to–steering knuckle screws

to 4 NSm (35 lb–in).

3. Install the rotor. Refer to ”Rotor” in this section.

Page 1077 of 2643

4E2 – 8IREAR DRUM BRAKES

DAEWOO V–121 BL4

Installation Procedure

1. Install the wheel cylinder to the backing plate with

the wheel cylinder bolt.

Tighten

Tighten the wheel cylinder–to–backing plate bolt to 8

NSm (71 lb–in).

2. Connect the brake line to the wheel cylinder.

Tighten

Tighten the brake line to 16 NSm (12 lb–ft)

3. Install the shoe and lining, and the brake drum. Re-

fer to ”Shoe and Lining” in this section.

4. Bleed the brakes. Refer to Section 4A, Hydraulic

Brakes.

BACKING PLATE

Removal Procedure

1. Raise and suitably support the vehicle.

2. Remove the brake shoe components, including

complete removal of the parking brake with the re-

tainer. Refer to ”Shoe and Lining” in this section

and Section 4A, Hydraulic Brakes.

3. Remove the nuts that secure the wheel hub assem-

bly to the backing plate.

4. Remove the brake line and plug the opening in the

line to prevent fluid loss or contamination.

5. Remove the wheel cylinder assembly. Refer to

”Wheel Cylinder Assembly” in this section.

6. Remove the wheel hub assembly.

7. In case of ABS brake, disconnect the cable that

goes to the wheel speed sensor.

8. Separate the backing plate and the gasket.

Page 1143 of 2643

4F – 62IANTILOCK BRAKE SYSTEM

DAEWOO V–121 BL4

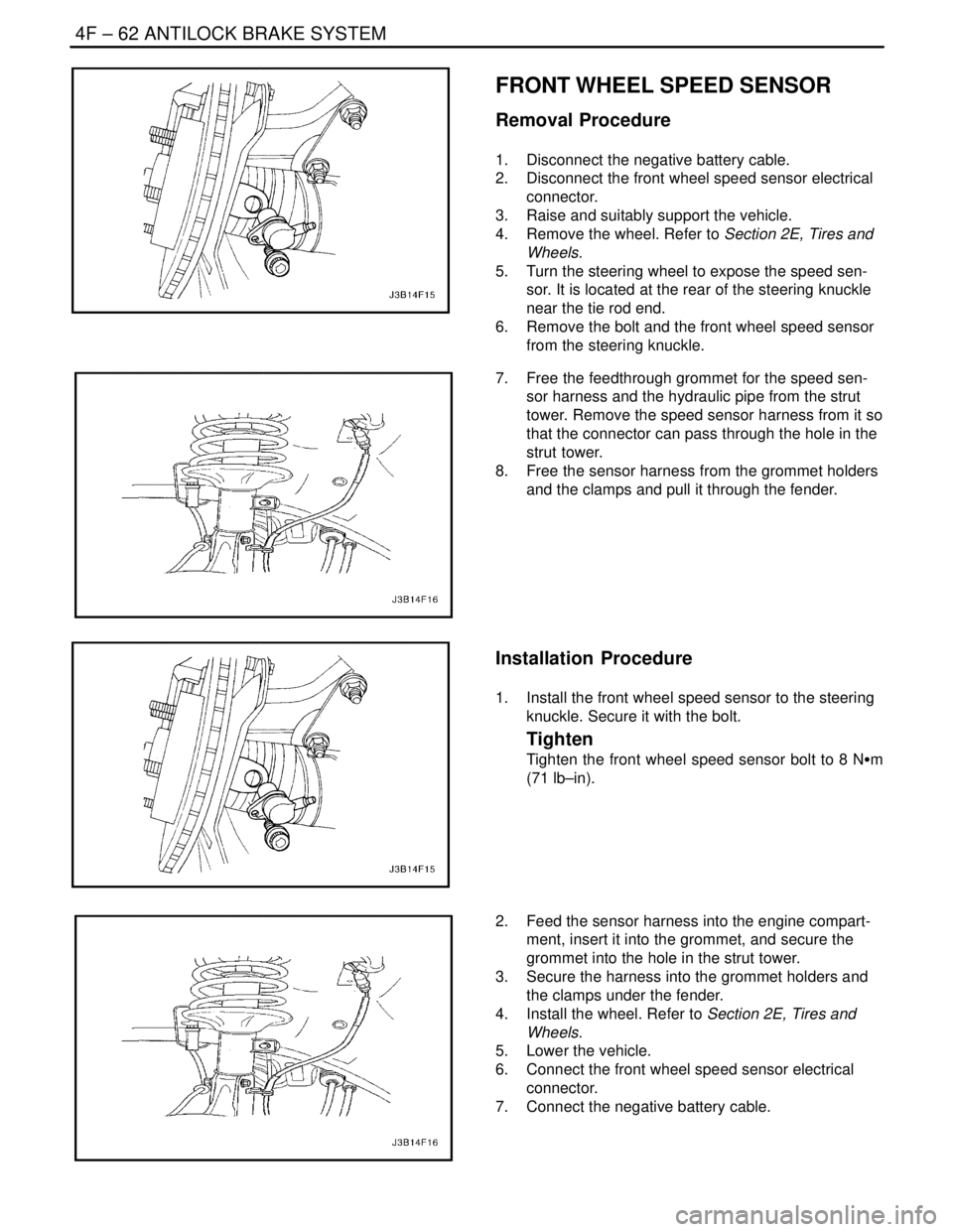

FRONT WHEEL SPEED SENSOR

Removal Procedure

1. Disconnect the negative battery cable.

2. Disconnect the front wheel speed sensor electrical

connector.

3. Raise and suitably support the vehicle.

4. Remove the wheel. Refer to Section 2E, Tires and

Wheels.

5. Turn the steering wheel to expose the speed sen-

sor. It is located at the rear of the steering knuckle

near the tie rod end.

6. Remove the bolt and the front wheel speed sensor

from the steering knuckle.

7. Free the feedthrough grommet for the speed sen-

sor harness and the hydraulic pipe from the strut

tower. Remove the speed sensor harness from it so

that the connector can pass through the hole in the

strut tower.

8. Free the sensor harness from the grommet holders

and the clamps and pull it through the fender.

Installation Procedure

1. Install the front wheel speed sensor to the steering

knuckle. Secure it with the bolt.

Tighten

Tighten the front wheel speed sensor bolt to 8 NSm

(71 lb–in).

2. Feed the sensor harness into the engine compart-

ment, insert it into the grommet, and secure the

grommet into the hole in the strut tower.

3. Secure the harness into the grommet holders and

the clamps under the fender.

4. Install the wheel. Refer to Section 2E, Tires and

Wheels.

5. Lower the vehicle.

6. Connect the front wheel speed sensor electrical

connector.

7. Connect the negative battery cable.

Page 1144 of 2643

ANTILOCK BRAKE SYSTEM 4F – 63

DAEWOO V–121 BL4

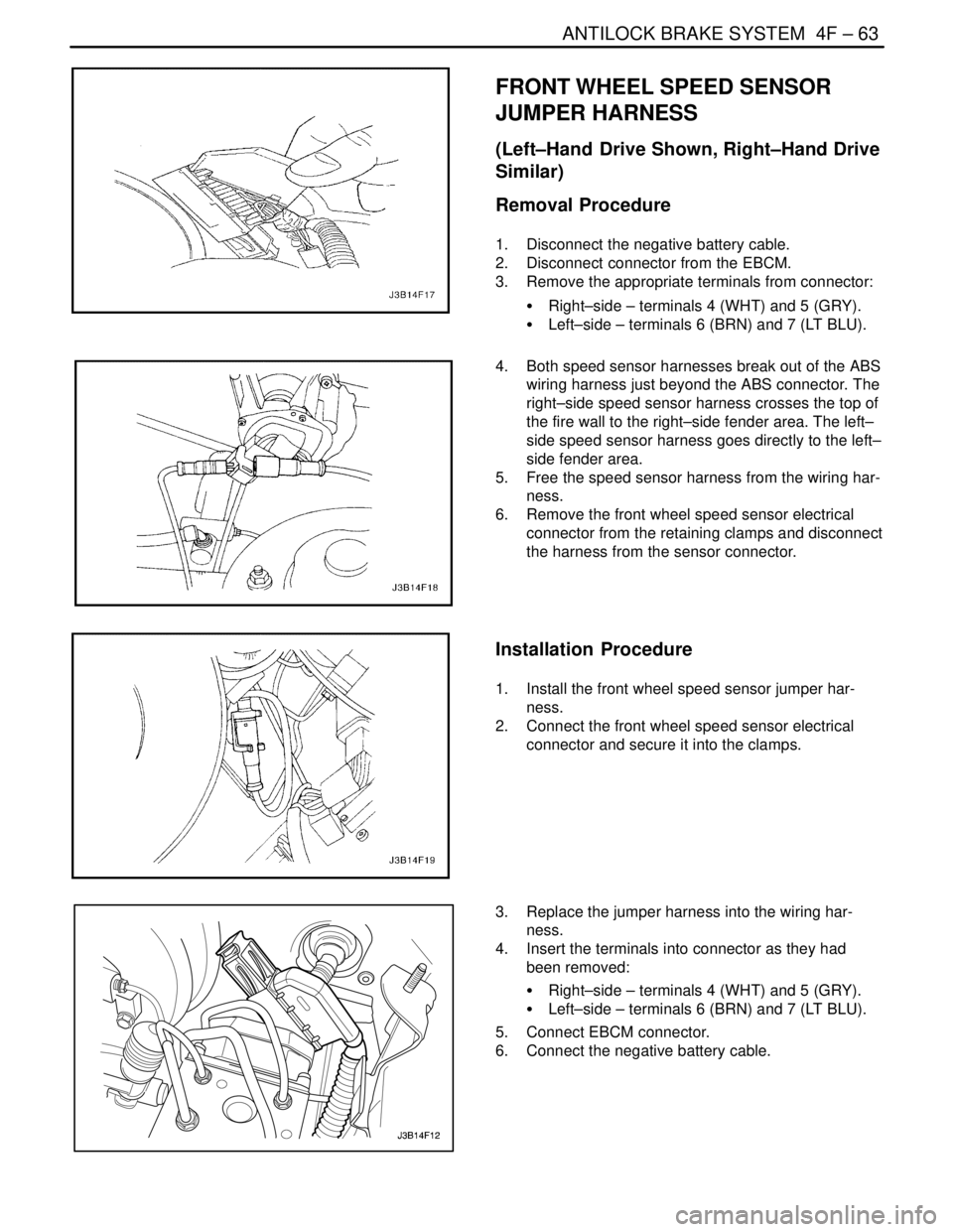

FRONT WHEEL SPEED SENSOR

JUMPER HARNESS

(Left–Hand Drive Shown, Right–Hand Drive

Similar)

Removal Procedure

1. Disconnect the negative battery cable.

2. Disconnect connector from the EBCM.

3. Remove the appropriate terminals from connector:

S Right–side – terminals 4 (WHT) and 5 (GRY).

S Left–side – terminals 6 (BRN) and 7 (LT BLU).

4. Both speed sensor harnesses break out of the ABS

wiring harness just beyond the ABS connector. The

right–side speed sensor harness crosses the top of

the fire wall to the right–side fender area. The left–

side speed sensor harness goes directly to the left–

side fender area.

5. Free the speed sensor harness from the wiring har-

ness.

6. Remove the front wheel speed sensor electrical

connector from the retaining clamps and disconnect

the harness from the sensor connector.

Installation Procedure

1. Install the front wheel speed sensor jumper har-

ness.

2. Connect the front wheel speed sensor electrical

connector and secure it into the clamps.

3. Replace the jumper harness into the wiring har-

ness.

4. Insert the terminals into connector as they had

been removed:

S Right–side – terminals 4 (WHT) and 5 (GRY).

S Left–side – terminals 6 (BRN) and 7 (LT BLU).

5. Connect EBCM connector.

6. Connect the negative battery cable.

Page 1158 of 2643

4G – 6IPARKING BRAKE

DAEWOO V–121 BL4

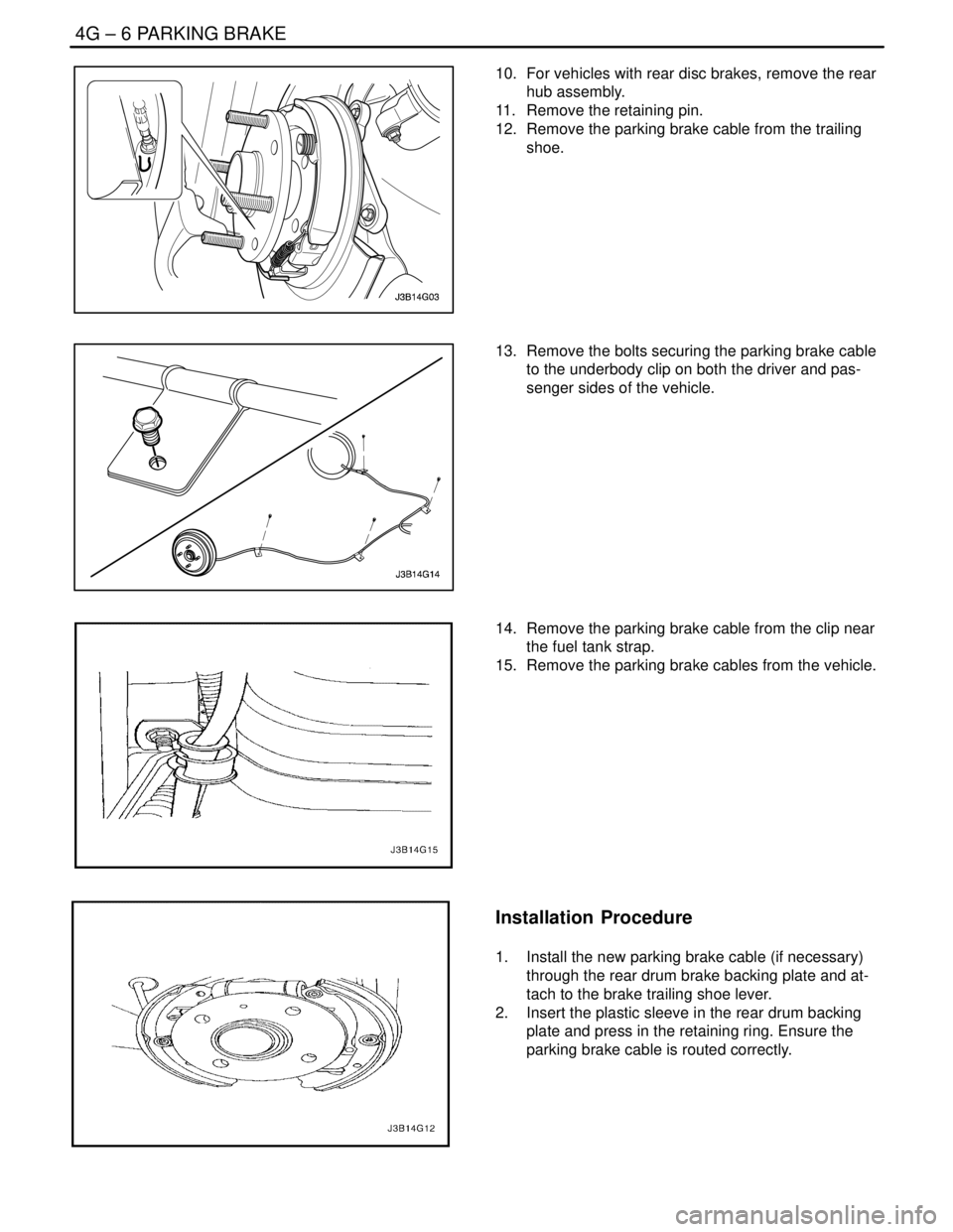

10. For vehicles with rear disc brakes, remove the rear

hub assembly.

11. Remove the retaining pin.

12. Remove the parking brake cable from the trailing

shoe.

13. Remove the bolts securing the parking brake cable

to the underbody clip on both the driver and pas-

senger sides of the vehicle.

14. Remove the parking brake cable from the clip near

the fuel tank strap.

15. Remove the parking brake cables from the vehicle.

Installation Procedure

1. Install the new parking brake cable (if necessary)

through the rear drum brake backing plate and at-

tach to the brake trailing shoe lever.

2. Insert the plastic sleeve in the rear drum backing

plate and press in the retaining ring. Ensure the

parking brake cable is routed correctly.