ECU DAEWOO NUBIRA 2004 Service Repair Manual

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: NUBIRA, Model: DAEWOO NUBIRA 2004Pages: 2643, PDF Size: 80.54 MB

Page 2476 of 2643

BODY REAR END 9S – 5

DAEWOO V–121 BL4

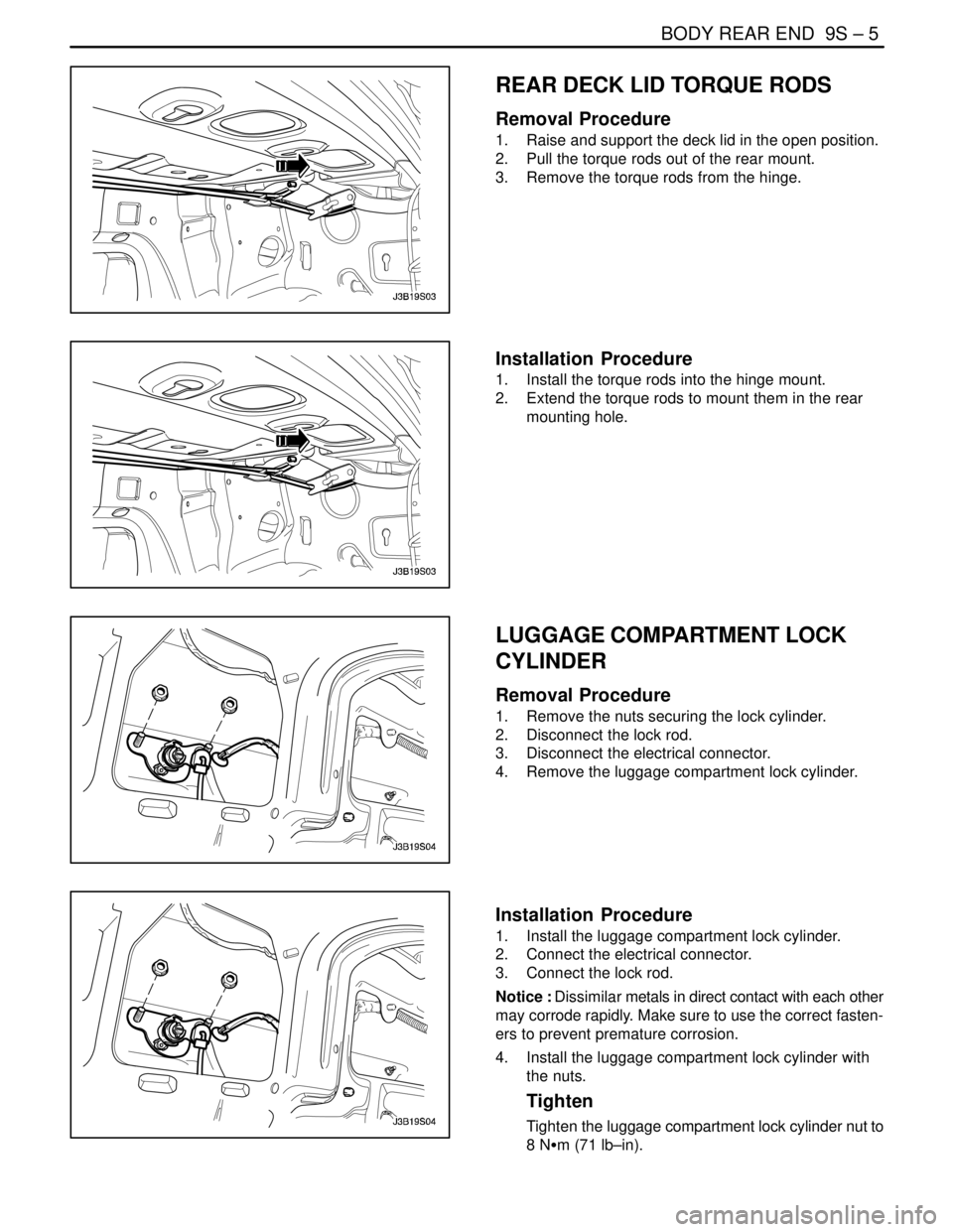

REAR DECK LID TORQUE RODS

Removal Procedure

1. Raise and support the deck lid in the open position.

2. Pull the torque rods out of the rear mount.

3. Remove the torque rods from the hinge.

Installation Procedure

1. Install the torque rods into the hinge mount.

2. Extend the torque rods to mount them in the rear

mounting hole.

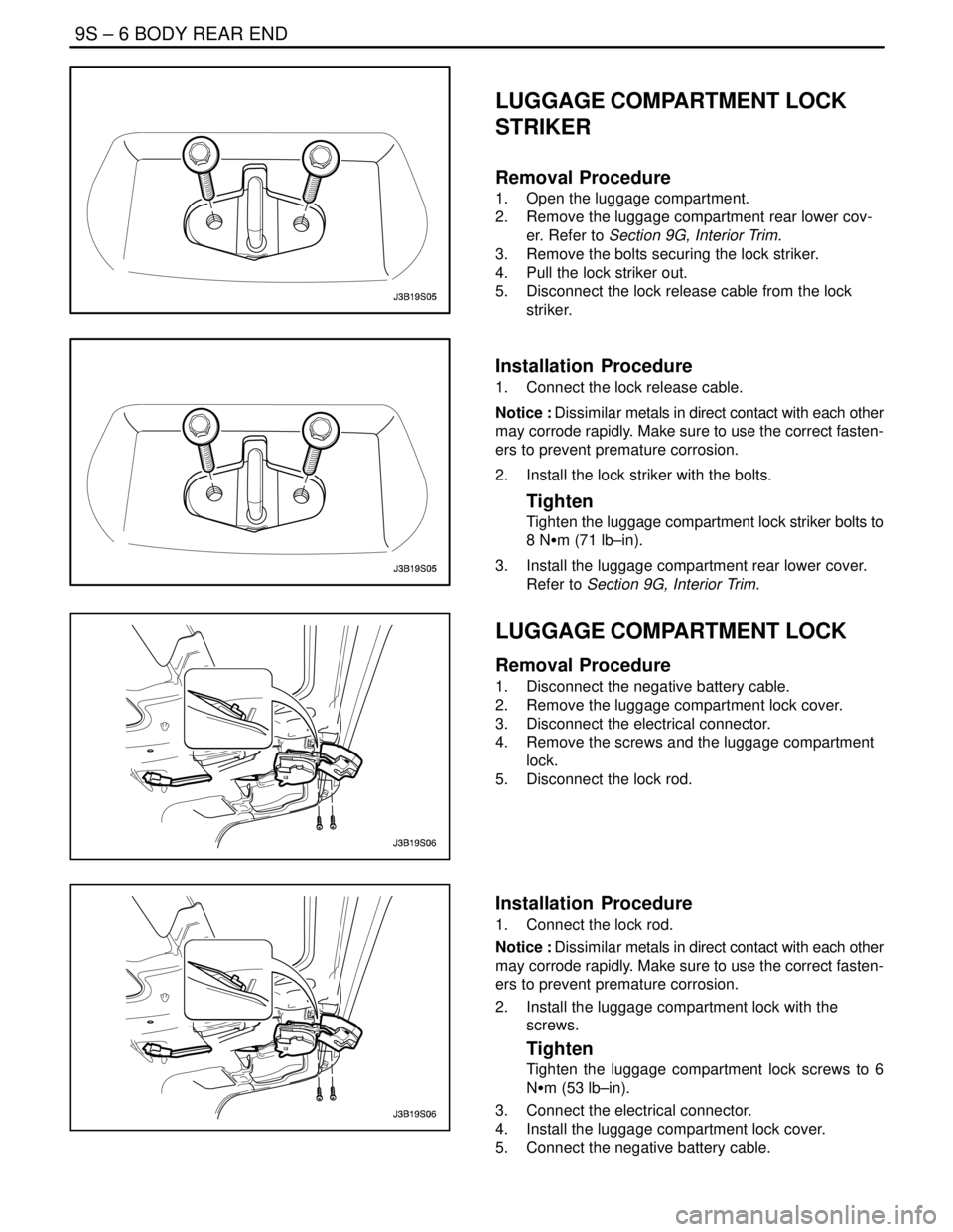

LUGGAGE COMPARTMENT LOCK

CYLINDER

Removal Procedure

1. Remove the nuts securing the lock cylinder.

2. Disconnect the lock rod.

3. Disconnect the electrical connector.

4. Remove the luggage compartment lock cylinder.

Installation Procedure

1. Install the luggage compartment lock cylinder.

2. Connect the electrical connector.

3. Connect the lock rod.

Notice : Dissimilar metals in direct contact with each other

may corrode rapidly. Make sure to use the correct fasten-

ers to prevent premature corrosion.

4. Install the luggage compartment lock cylinder with

the nuts.

Tighten

Tighten the luggage compartment lock cylinder nut to

8 NSm (71 lb–in).

Page 2477 of 2643

9S – 6IBODY REAR END

DAEWOO V–121 BL4

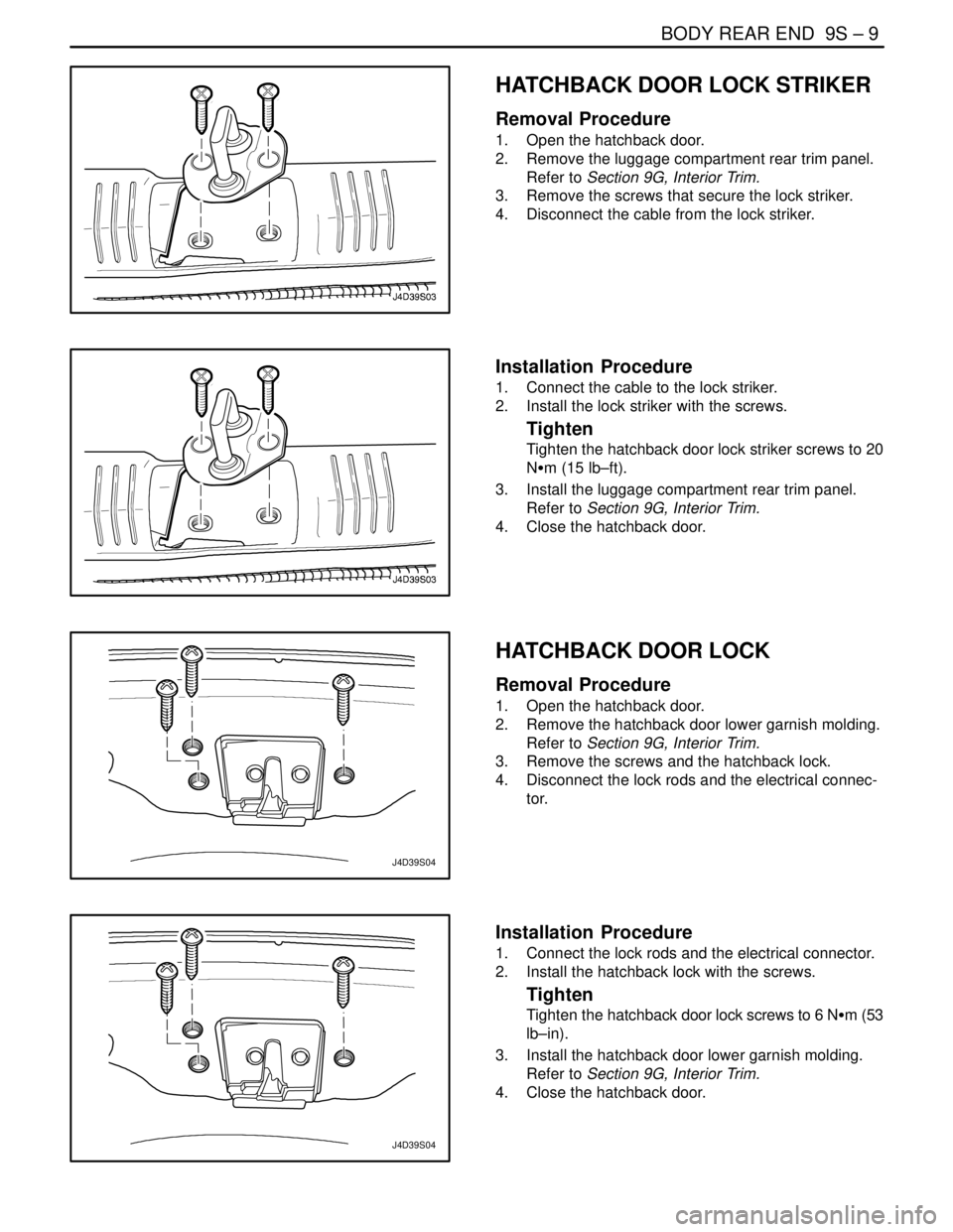

LUGGAGE COMPARTMENT LOCK

STRIKER

Removal Procedure

1. Open the luggage compartment.

2. Remove the luggage compartment rear lower cov-

er. Refer to Section 9G, Interior Trim.

3. Remove the bolts securing the lock striker.

4. Pull the lock striker out.

5. Disconnect the lock release cable from the lock

striker.

Installation Procedure

1. Connect the lock release cable.

Notice : Dissimilar metals in direct contact with each other

may corrode rapidly. Make sure to use the correct fasten-

ers to prevent premature corrosion.

2. Install the lock striker with the bolts.

Tighten

Tighten the luggage compartment lock striker bolts to

8 NSm (71 lb–in).

3. Install the luggage compartment rear lower cover.

Refer to Section 9G, Interior Trim.

LUGGAGE COMPARTMENT LOCK

Removal Procedure

1. Disconnect the negative battery cable.

2. Remove the luggage compartment lock cover.

3. Disconnect the electrical connector.

4. Remove the screws and the luggage compartment

lock.

5. Disconnect the lock rod.

Installation Procedure

1. Connect the lock rod.

Notice : Dissimilar metals in direct contact with each other

may corrode rapidly. Make sure to use the correct fasten-

ers to prevent premature corrosion.

2. Install the luggage compartment lock with the

screws.

Tighten

Tighten the luggage compartment lock screws to 6

NSm (53 lb–in).

3. Connect the electrical connector.

4. Install the luggage compartment lock cover.

5. Connect the negative battery cable.

Page 2480 of 2643

BODY REAR END 9S – 9

DAEWOO V–121 BL4

HATCHBACK DOOR LOCK STRIKER

Removal Procedure

1. Open the hatchback door.

2. Remove the luggage compartment rear trim panel.

Refer to Section 9G, Interior Trim.

3. Remove the screws that secure the lock striker.

4. Disconnect the cable from the lock striker.

Installation Procedure

1. Connect the cable to the lock striker.

2. Install the lock striker with the screws.

Tighten

Tighten the hatchback door lock striker screws to 20

NSm (15 lb–ft).

3. Install the luggage compartment rear trim panel.

Refer to Section 9G, Interior Trim.

4. Close the hatchback door.

J4D39S04

HATCHBACK DOOR LOCK

Removal Procedure

1. Open the hatchback door.

2. Remove the hatchback door lower garnish molding.

Refer to Section 9G, Interior Trim.

3. Remove the screws and the hatchback lock.

4. Disconnect the lock rods and the electrical connec-

tor.

J4D39S04

Installation Procedure

1. Connect the lock rods and the electrical connector.

2. Install the hatchback lock with the screws.

Tighten

Tighten the hatchback door lock screws to 6 NSm (53

lb–in).

3. Install the hatchback door lower garnish molding.

Refer to Section 9G, Interior Trim.

4. Close the hatchback door.

Page 2482 of 2643

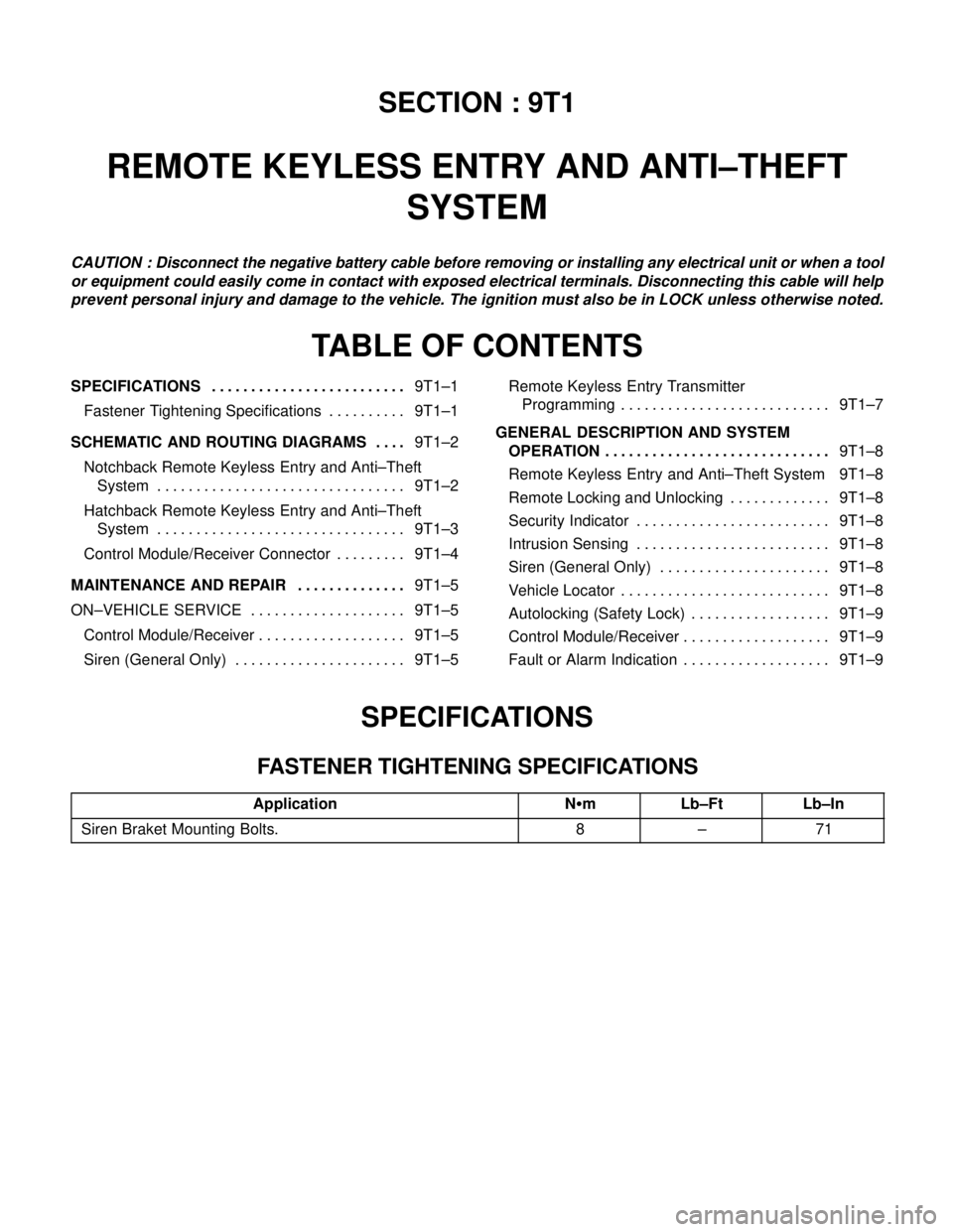

SECTION : 9T1

REMOTE KEYLESS ENTRY AND ANTI–THEFT

SYSTEM

CAUTION : Disconnect the negative battery cable before removing or installing any electrical unit or when a tool

or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable will help

prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwise noted.

TABLE OF CONTENTS

SPECIFICATIONS 9T1–1 . . . . . . . . . . . . . . . . . . . . . . . . .

Fastener Tightening Specifications 9T1–1. . . . . . . . . .

SCHEMATIC AND ROUTING DIAGRAMS9T1–2 . . . .

Notchback Remote Keyless Entry and Anti–Theft

System 9T1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hatchback Remote Keyless Entry and Anti–Theft

System 9T1–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Control Module/Receiver Connector 9T1–4. . . . . . . . .

MAINTENANCE AND REPAIR9T1–5 . . . . . . . . . . . . . .

ON–VEHICLE SERVICE 9T1–5. . . . . . . . . . . . . . . . . . . .

Control Module/Receiver 9T1–5. . . . . . . . . . . . . . . . . . .

Siren (General Only) 9T1–5. . . . . . . . . . . . . . . . . . . . . . Remote Keyless Entry Transmitter

Programming 9T1–7. . . . . . . . . . . . . . . . . . . . . . . . . . .

GENERAL DESCRIPTION AND SYSTEM

OPERATION9T1–8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Remote Keyless Entry and Anti–Theft System 9T1–8

Remote Locking and Unlocking 9T1–8. . . . . . . . . . . . .

Security Indicator 9T1–8. . . . . . . . . . . . . . . . . . . . . . . . .

Intrusion Sensing 9T1–8. . . . . . . . . . . . . . . . . . . . . . . . .

Siren (General Only) 9T1–8. . . . . . . . . . . . . . . . . . . . . .

Vehicle Locator 9T1–8. . . . . . . . . . . . . . . . . . . . . . . . . . .

Autolocking (Safety Lock) 9T1–9. . . . . . . . . . . . . . . . . .

Control Module/Receiver 9T1–9. . . . . . . . . . . . . . . . . . .

Fault or Alarm Indication 9T1–9. . . . . . . . . . . . . . . . . . .

SPECIFICATIONS

FASTENER TIGHTENING SPECIFICATIONS

ApplicationNSmLb–FtLb–In

Siren Braket Mounting Bolts.8–71

Page 2485 of 2643

9T1 – 4IREMOTE KEYLESS ENTRY AND ANTI–THEFT SYSTEM

DAEWOO V–121 BL4

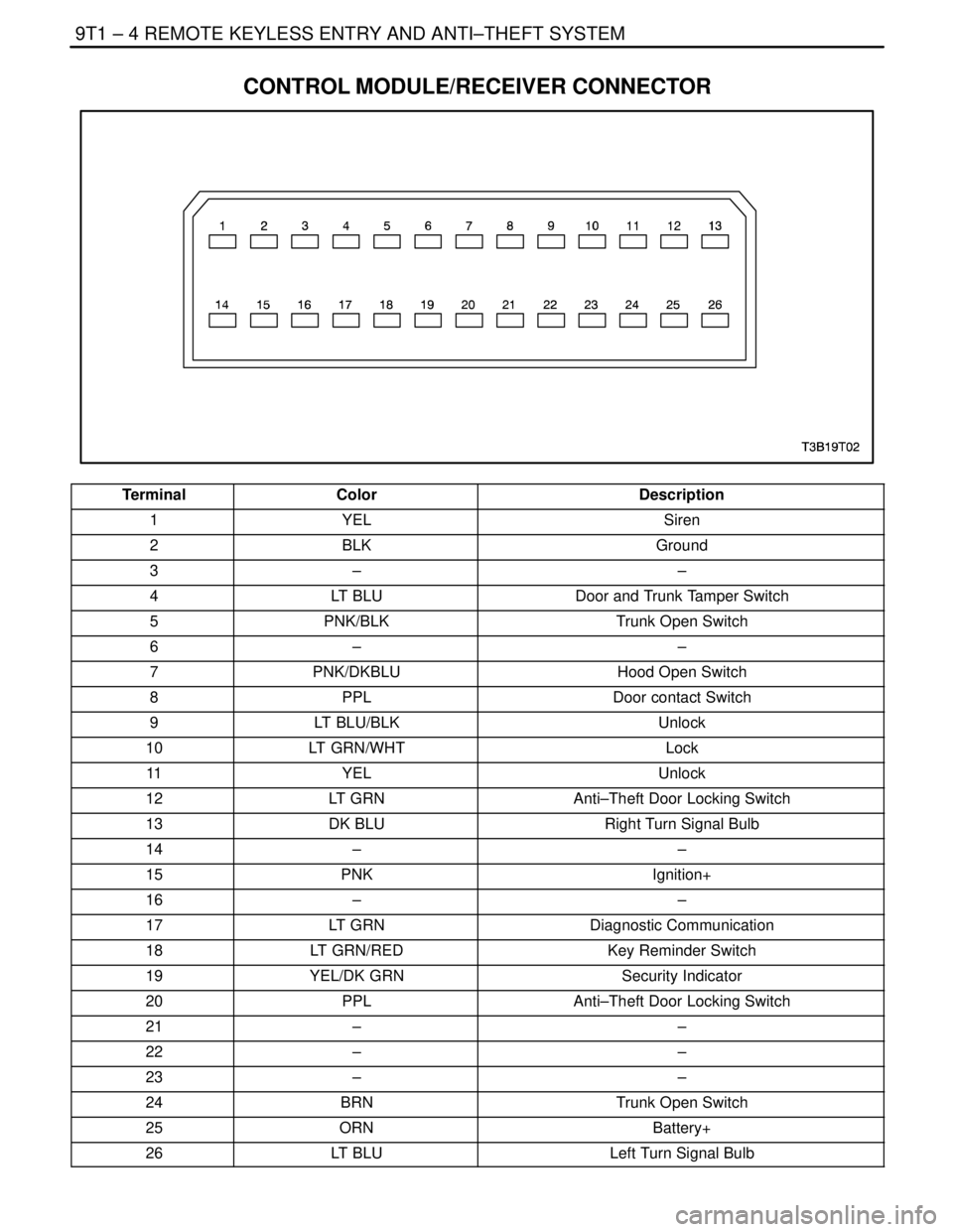

CONTROL MODULE/RECEIVER CONNECTOR

TerminalColorDescription

1YELSiren

2BLKGround

3––

4LT BLUDoor and Trunk Tamper Switch

5PNK/BLKTrunk Open Switch

6––

7PNK/DKBLUHood Open Switch

8PPLDoor contact Switch

9LT BLU/BLKUnlock

10LT GRN/WHTLock

11YELUnlock

12LT GRNAnti–Theft Door Locking Switch

13DK BLURight Turn Signal Bulb

14––

15PNKIgnition+

16––

17LT GRNDiagnostic Communication

18LT GRN/REDKey Reminder Switch

19YEL/DK GRNSecurity Indicator

20PPLAnti–Theft Door Locking Switch

21––

22––

23––

24BRNTrunk Open Switch

25ORNBattery+

26LT BLULeft Turn Signal Bulb

Page 2489 of 2643

9T1 – 8IREMOTE KEYLESS ENTRY AND ANTI–THEFT SYSTEM

DAEWOO V–121 BL4

GENERAL DESCRIPTION

AND SYSTEM OPERATION

REMOTE KEYLESS ENTRY AND

ANTI–THEFT SYSTEM

The remote keyless entry and anti–theft system can per-

form the following functions:

S Remotely lock and unlock the vehicle doors by

means of a hand–held, high–frequency transmitter.

S Sense intrusion into the vehicle.

S Activate a warning in the event of an intrusion.

S Help the driver find the vehicle in a parking area.

S Automatically re–lock the doors if the door or the

trunk is not opened within 30 seconds after the ve-

hicle has been unlocked by the remote keyless

entry.

S Communicate serial data to a scan tool to help

diagnose system faults.

The remote keyless entry and anti–theft system consists

of the following components:

S Keyless entry and anti–theft control module/receiv-

er.

S Security indicator.

S Trunk open switch (NOTCHBACK).

S Trunk tamper switch (NOTCHBACK).

S Front door tamper switches.

S Door contact switches.

S Central door lock relay.

S Turn signal bulbs.

S Siren.

S Hood open switch.

REMOTE LOCKING AND UNLOCKING

The hand–held transmitter locks and unlocks the vehicle

doors by sending radio waves to the control module/re-

ceiver in the vehicle. The effective range of the transmitter

varies between 5 and 10 meters, (approximately 16 to 32

feet), depending on whether or not objects, such as other

vehicles are blocking the path of the radio waves.

The transmitter has a LOCK button and an UNLOCK but-

ton which only function when the ignition is OFF. Pressing

the UNLOCK button has the following effects:

S The doors are unlocked.

S The turn signal bulbs flash twice.

S The control module is disarmed.

Pressing the LOCK button has the following effects:

S The doors are locked.

S The turn signal bulbs flash once.

S The control module is armed.

The transmitter has a replaceable battery. The battery is

designed to last at least two years before replacement is

necessary.

SECURITY INDICATOR

There is a security indicator on the instrument panel. After

the LOCK button of the transmitter is pressed, the module

is placed in the armed mode, and the security indicator

flashes. The security indicator turns ON for 0.1 second

and OFF for 0.7 second. It then flashes at that frequency

until the control module/receiver is disarmed.

INTRUSION SENSING

The anti–theft function is armed if the transmitter sends

the LOCK message to the control module/receiver when

the ignition is OFF. When the hood, door, or trunk is

opened, the hood open, door contact, or trunk open switch

sends a ”ground” signal to the control module/receiver.

Unless the control module/receiver is disarmed, the siren

will be activated when the ”ground” signal is received from

the trunk open, hood open, or door contact switches.

The following actions disarm the anti–theft system:

S An UNLOCK message is received from the trans-

mitter.

S Key operation is detected by the tamper switches.

(The tamper switches are operated by the lock cyl-

inders in the front doors and trunk.)

The alarm will also be activated if the control module/re-

ceiver detects voltage from the ignition before either of the

following conditions occur:

S An UNLOCK message is received from the trans-

mitter.

S Key operation is indicated by the tamper switches.

SIREN (GENERAL ONLY)

The remote keyless entry system is armed when the

LOCK message is received from the transmitter when the

ignition is OFF. When the system is armed, it will activate

the siren and flash the turn signals for 28 seconds if any

of the following conditions occur:

S Close all the windows.

S Turn the ignition key to LOCK and remove the key.

S Have all passengers get out of the vehicle.

S Close all doors, the hood and the turnk lid.

S The control module/receiver detects ignition voltage

while the system is armed.

The siren will not operate if any of the following conditions

occur after the system has been armed:

S The door is opened with the key.

S The trunk is opened with the key.

S The UNLOCK or LOCK button on the remote trans-

mitter is pressed within 2 seconds after the siren is

activated.

VEHICLE LOCATOR

The remote keyless entry system assists the driver in lo-

cating the vehicle. When the vehicle is unlocked with the

remote control, the turn signals flash twice to indicate the

location of the vehicle. The duration of the flashes and the

Page 2501 of 2643

IMMOBILIZER ANTI–THEFT SYSTEM 9T2 – 11

DAEWOO V–121 BL4

GENERAL DESCRIPTION

AND SYSTEM OPERATION

IMMOBILIZER SYSTEM

The purpose of the Immobilizer system is to provide addi-

tional theft deterrence to the vehicle in which it is installed

and to prevent it from being stolen or driven by unautho-

rized users.

The verification of the user authorization is done by an igni-

tion key with integrated transponder.

The external LED displays the Immobilizer status and has

an additional theft deterrence function.

To secure the communication, the status is exchanged be-

tween the Immobilizer and the ECM in a 5 byte of encoded

data.

These 5 bytes are composed by a mixture of random data

and two types of fixed code

S a vehicle model identification number : MIN

S a vehicle specific identification : VIN

The MIN is known from the first supply of the system.

The VIN is realized by ICU on the special order from the

key coding (reading of transponder code and storing it as

valid key code in Immobilizer EEPROM).

A different random data is computed at each key transi-

tion.

All the immobilization communication between the ECM

and ICU is made on K–line (K line : Serial data line ’7’).

Due to the learning of the Vehicle specific identification

Number, both ICU and ECM can stay in 3 stable modes

S Virgin mode (VIN not learnt)

S Learnt mode (VIN learnt)

S Neutral mode (for a new VIN learning)

In case of using valid key, the release message commu-

nication with the ECM take place and the LED displays the

Immobilizer status valid key In case of using invalid key,

the ECM disables the fuel injector circuit with coded inter-

vention and sets DTC(Diagnostic Trouble Code)

The above conditions are maintained until the ignition is

switched off.

An ECM without an immobilizer control unit cannot be in-

terchanged for an ECM that is used with an immobilizer

control unit system. The Immobilizer control unit and ECM

must have a matching ID code. ID coding and key coding

are accomplished by using Scanner–100

The Immobilizer system consists of

S a maximum or 5 ignition keys with integrated trans-

ponder

S the toroidal coil (Detection coil) for energizing and

reading the transponder mounted at the ignition

lock.S the Immobilizer control unit(ICU) with :

– power supply

– ignition input circuit

– transponder modulation and demodulation unit

– EEPROM

– driver electronic for the external status LED

– serial data link hardware

S the external status LED for displaying the Immobi-

lizer status

S the serial data link between Immobilizer and ECM

ELECTRONICALLY CODED KEYS

Each valid ignition key has an internal transponder which

is a read /write transponder.

The transponder contains an implementation of a crypto–

algorithm with 96 bits of user configurable s cret–key con-

tained in EEPROM and transmits data to the ICU by mod-

ulating the amplitude of the ele tromagnetic field, and

receives data and commands in a similar way.

DETECTION COIL

The toroidal coil is mounted at the ignition lock in front of

the key barrel.

It is connected to the ICU with a four terminal connector

fixed at the body of the coil.

The length of the connection between coil and Immobilizer

is restricted to 50cm. The correct placement on the ignition

lock and the exact electrical data is very important for the

reading distance of transponder.

he toroidal coil and receiving coil inside the transponder

built a transformer. During the readingprocess the coil in-

duces energy into the transponder. The transponder

charges the field and generates an amplitude modulated

signal with the manchester coded data. This charge of the

field is demodulated inside the Immobilizer.

The Immobilizer contains the coil driver hardware for di-

rect connection of the toroidal coil.

IMMOBILIZER CONTROL UNIT

The function of the Immobilizer System is shared between

the ICU and the ECM.

The task of the Immobilizer Electronic Control unit (ICU)

are:

S Reading of the input information ”ignition ON/OFF”

S Controlling the states LED

S Controlling the transponder read/write process

(modulation, demodulation, decoding, comparison

of the read code with the code of the valid keys).

S Communication with the ECM after ignition ON (re-

ceiving of the ECM–request and transmission of

release message).

S Special functions for calculation and handling of the

VIN–code.

The VIN code is calculated by the Immobilizer using a ran-

dom generator.

Page 2502 of 2643

9T2 – 12IIMMOBILIZER ANTI–THEFT SYSTEM

DAEWOO V–121 BL4

The VIN code is transmitted from the Immobilizer in the re-

lease message communication only incase of using an au-

thorized key. Without an authorized key it is not possible

to getthe system VIN code.In case of ECM internal state

is in Virgin mode or neutral mode the ECM learns the sys-

tem VIN code automatically after receiving the first release

response message.

To get a synchronized Immobilizer system (same VIN–

code in Immobilizer and ECM,authorized key) the DLC

test equipment has to be used for authorization of the

keys(first key coding). The usage of this test equipment is

restricted to authorized persons.

S Communication with the DLC–test equipment. Main

functions are the key coding procedure, the VIN–

code handling and the support for system test func-

tions.

S Handling of the software watchdog

Operation

In the active mode of immobilizer (engine OFF, IG key

OFF) the status LED isblinking as mode A. When ignition

is turned ON, the system wakes up and tries to read out

the transponder.

In case of the detection of a valid key , The release mes-

sage communication with the ECM takes place. The sta-

tus LED displays the Immobilizer state ”valid key”.

After turning off the ignition(ignition OFF detection similar

to the ECM ignition OFF detection), the Immobilizer

changes to the active mode. The status LED is blinking as

Mode A.

Data Link Connector (DLC) Mode

When the ignition is on, a scan tool can switch the immobi-

lizer control unit to the DLC mode for diagnostics, key cod-

ing and ID coding.

S The status LED is turned off during DLC–mode

S The Immobilizer will answer all correct messages,

which are defined as Immobilizer messages.

ID Code Handling

One of 65,535 VIN codes is stored in the immobilizer EE-

PROM.

The VIN code can be erased by using ”Reset VIN code”

command of the scan tool.

When the immobilizer control unit calculates a new VIN

code, ECM VIN code should be reset to get identical with

the immobilizer control unit’s.

During diagnostic procedures, the VIN code can be read

for comparison with the ECM VIN code by using the scan

tool’s ”Read immobilizer control unit VIN code” command.

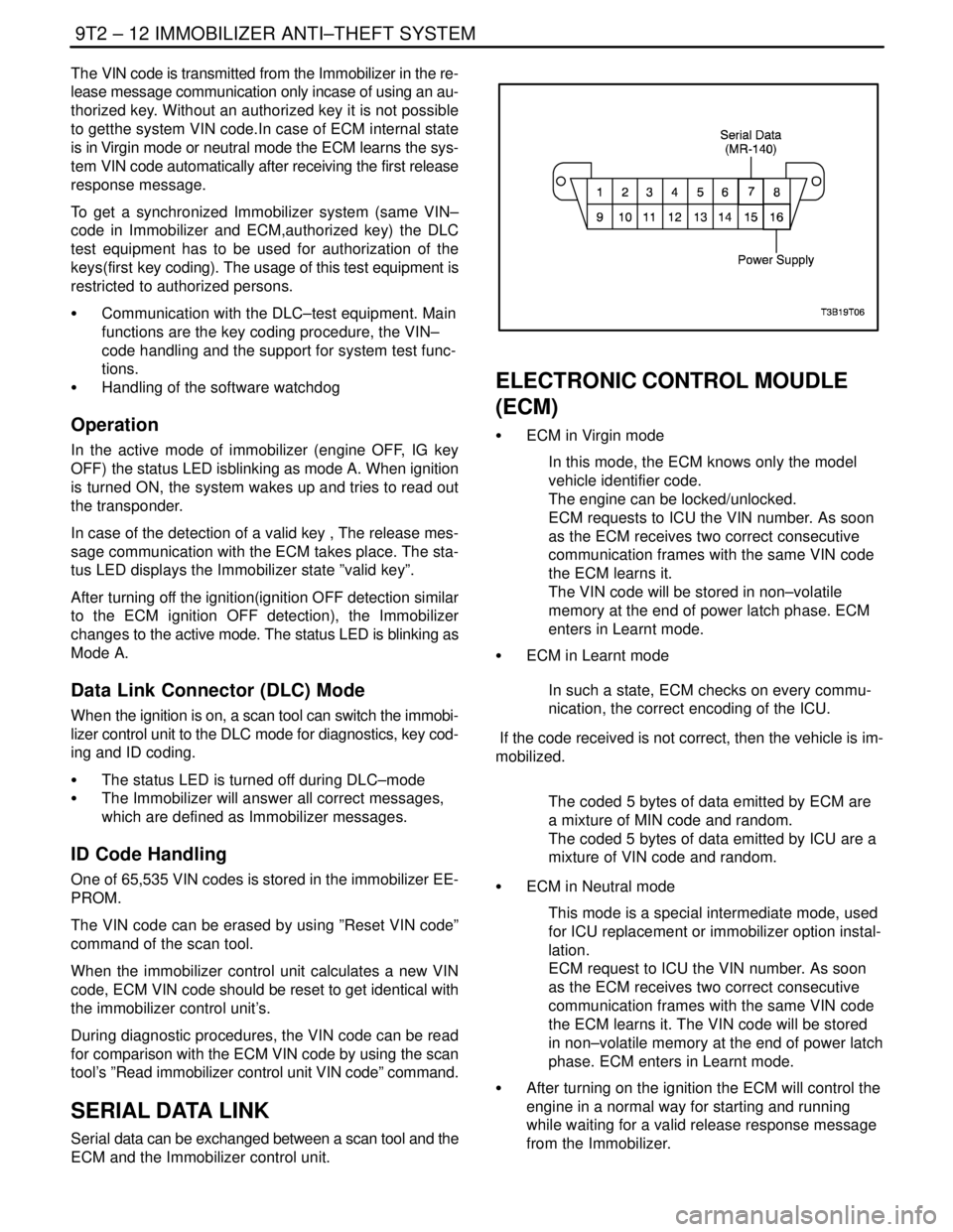

SERIAL DATA LINK

Serial data can be exchanged between a scan tool and the

ECM and the Immobilizer control unit.

ELECTRONIC CONTROL MOUDLE

(ECM)

S ECM in Virgin mode

In this mode, the ECM knows only the model

vehicle identifier code.

The engine can be locked/unlocked.

ECM requests to ICU the VIN number. As soon

as the ECM receives two correct consecutive

communication frames with the same VIN code

the ECM learns it.

The VIN code will be stored in non–volatile

memory at the end of power latch phase. ECM

enters in Learnt mode.

S ECM in Learnt mode

In such a state, ECM checks on every commu-

nication, the correct encoding of the ICU.

If the code received is not correct, then the vehicle is im-

mobilized.

The coded 5 bytes of data emitted by ECM are

a mixture of MIN code and random.

The coded 5 bytes of data emitted by ICU are a

mixture of VIN code and random.

S ECM in Neutral mode

This mode is a special intermediate mode, used

for ICU replacement or immobilizer option instal-

lation.

ECM request to ICU the VIN number. As soon

as the ECM receives two correct consecutive

communication frames with the same VIN code

the ECM learns it. The VIN code will be stored

in non–volatile memory at the end of power latch

phase. ECM enters in Learnt mode.

S After turning on the ignition the ECM will control the

engine in a normal way for starting and running

while waiting for a valid release response message

from the Immobilizer.

Page 2537 of 2643

NUBIRA/LACETTIFRONT 4–3

1–2. REPAIR PROCEDURE

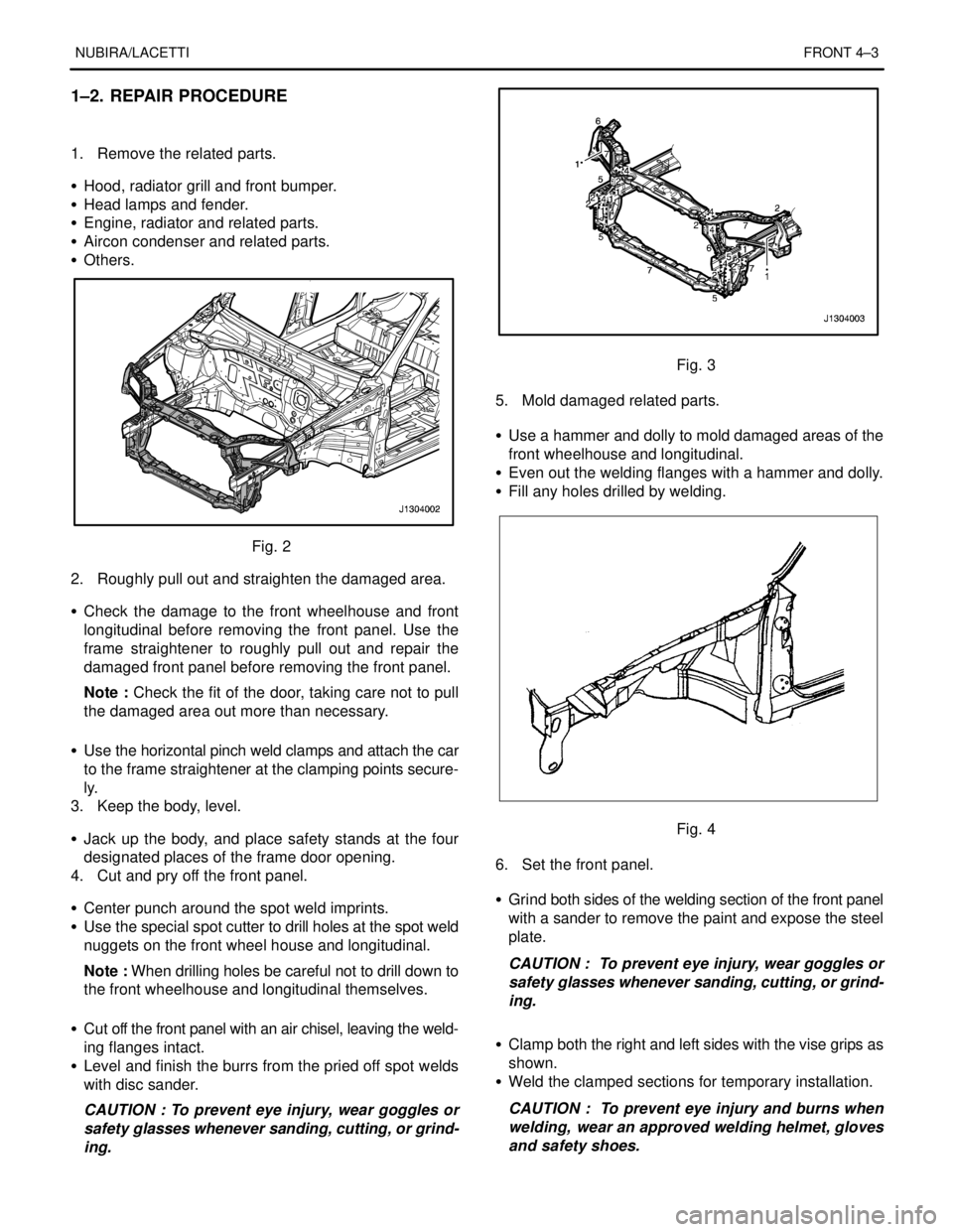

1. Remove the related parts.

S Hood, radiator grill and front bumper.

S Head lamps and fender.

S Engine, radiator and related parts.

S Aircon condenser and related parts.

S Others.

Fig. 2

2. Roughly pull out and straighten the damaged area.

S Check the damage to the front wheelhouse and front

longitudinal before removing the front panel. Use the

frame straightener to roughly pull out and repair the

damaged front panel before removing the front panel.

Note : Check the fit of the door, taking care not to pull

the damaged area out more than necessary.

S Use the horizontal pinch weld clamps and attach the car

to the frame straightener at the clamping points secure-

ly.

3. Keep the body, level.

S Jack up the body, and place safety stands at the four

designated places of the frame door opening.

4. Cut and pry off the front panel.

S Center punch around the spot weld imprints.

S Use the special spot cutter to drill holes at the spot weld

nuggets on the front wheel house and longitudinal.

Note : When drilling holes be careful not to drill down to

the front wheelhouse and longitudinal themselves.

S Cut off the front panel with an air chisel, leaving the weld-

ing flanges intact.

S Level and finish the burrs from the pried off spot welds

with disc sander.

CAUTION : To prevent eye injury, wear goggles or

safety glasses whenever sanding, cutting, or grind-

ing.

Fig. 3

5. Mold damaged related parts.

S Use a hammer and dolly to mold damaged areas of the

front wheelhouse and longitudinal.

S Even out the welding flanges with a hammer and dolly.

S Fill any holes drilled by welding.

Fig. 4

6. Set the front panel.

S Grind both sides of the welding section of the front panel

with a sander to remove the paint and expose the steel

plate.

CAUTION : To prevent eye injury, wear goggles or

safety glasses whenever sanding, cutting, or grind-

ing.

S Clamp both the right and left sides with the vise grips as

shown.

S Weld the clamped sections for temporary installation.

CAUTION : To prevent eye injury and burns when

welding, wear an approved welding helmet, gloves

and safety shoes.

Page 2561 of 2643

NUBIRA/LACETTI ROOF, BACK PANEL AND REAR FLOOR PANEL 5–9

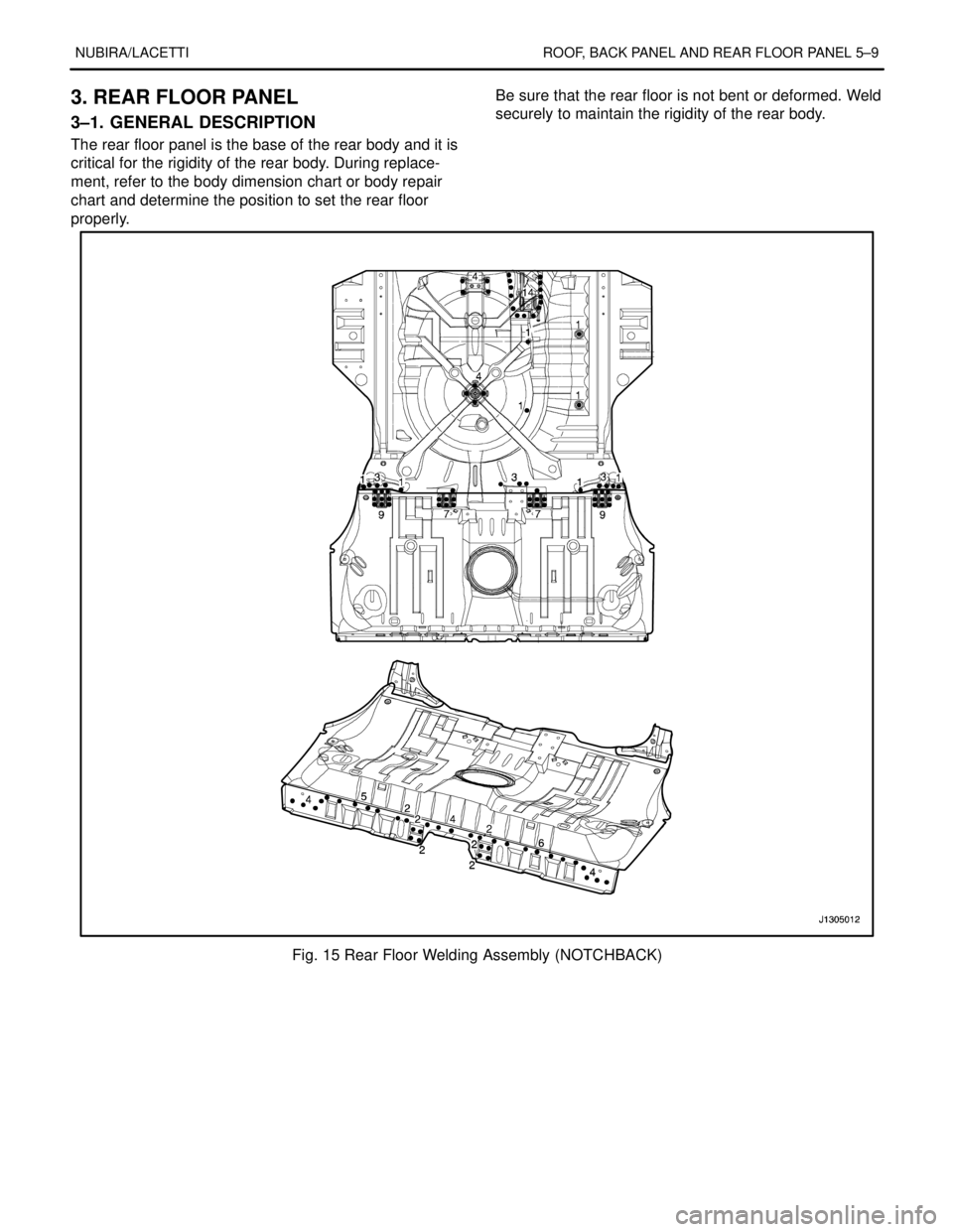

3. REAR FLOOR PANEL

3–1. GENERAL DESCRIPTION

The rear floor panel is the base of the rear body and it is

critical for the rigidity of the rear body. During replace-

ment, refer to the body dimension chart or body repair

chart and determine the position to set the rear floor

properly.Be sure that the rear floor is not bent or deformed. Weld

securely to maintain the rigidity of the rear body.

2

Fig. 15 Rear Floor Welding Assembly (NOTCHBACK)