automatic transaxle DAEWOO NUBIRA 2004 Service Repair Manual

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: NUBIRA, Model: DAEWOO NUBIRA 2004Pages: 2643, PDF Size: 80.54 MB

Page 1565 of 2643

5A1 – 216IZF 4 HP 16 AUTOMATIC TRANSAXLE

DAEWOO V–121 BL4

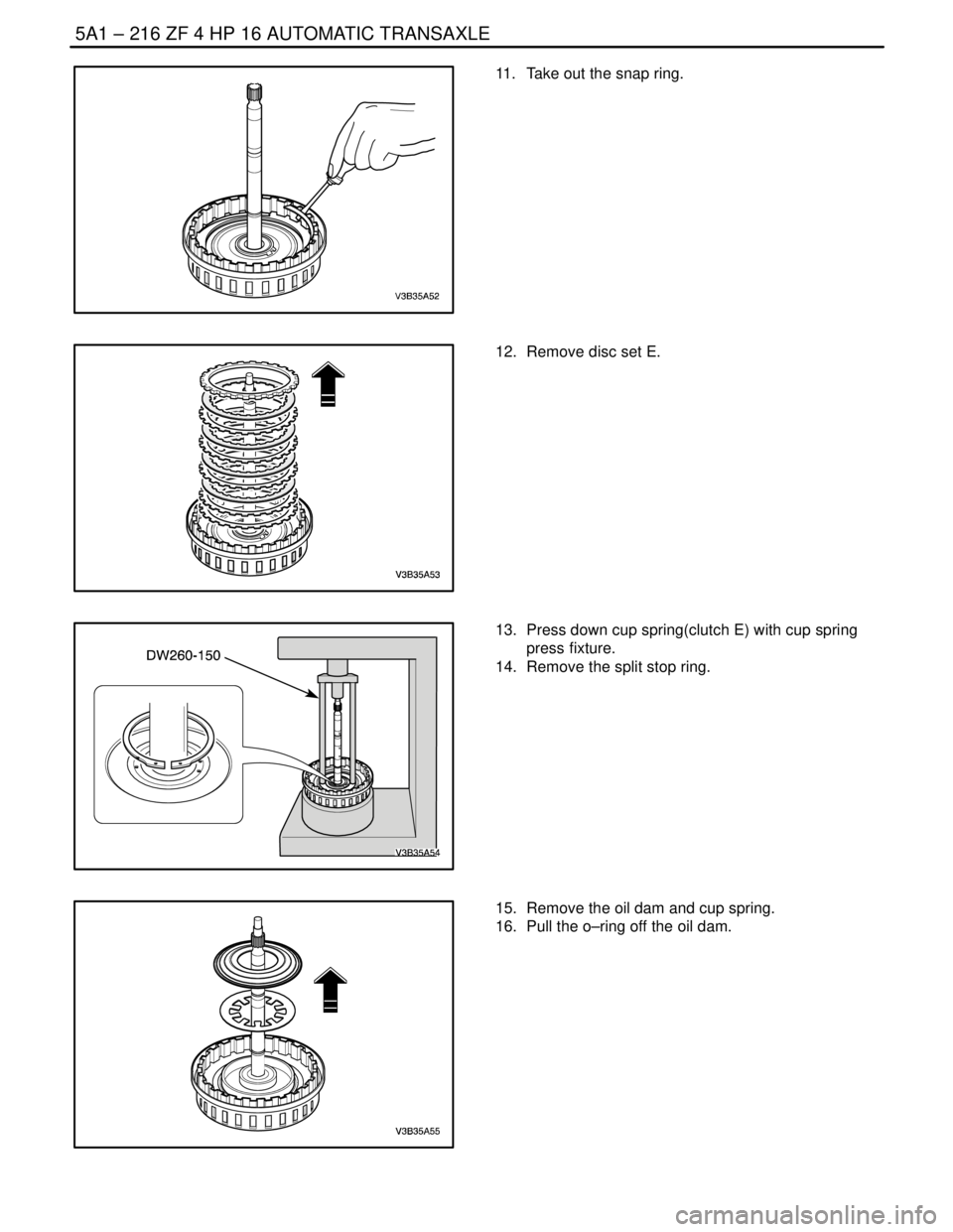

11. Take out the snap ring.

12. Remove disc set E.

13. Press down cup spring(clutch E) with cup spring

press fixture.

14. Remove the split stop ring.

15. Remove the oil dam and cup spring.

16. Pull the o–ring off the oil dam.

Page 1566 of 2643

ZF 4 HP 16 AUTOMATIC TRANSAXLE 5A1 – 217

DAEWOO V–121 BL4

17. Press down cup spring(clutch B)with cup spring

press fixture.

18. Remove the split stop ring.

19. Remove the cup spring.

20. Installation should follow the removal procedure in

the reverse order.

Adjustment Notice

Before assembling clutch B/E, setting discs(clutch B/E)

have to measured by below measurement procedure.

CLUTCH B/E MEASUREMENT

PROCEDURE

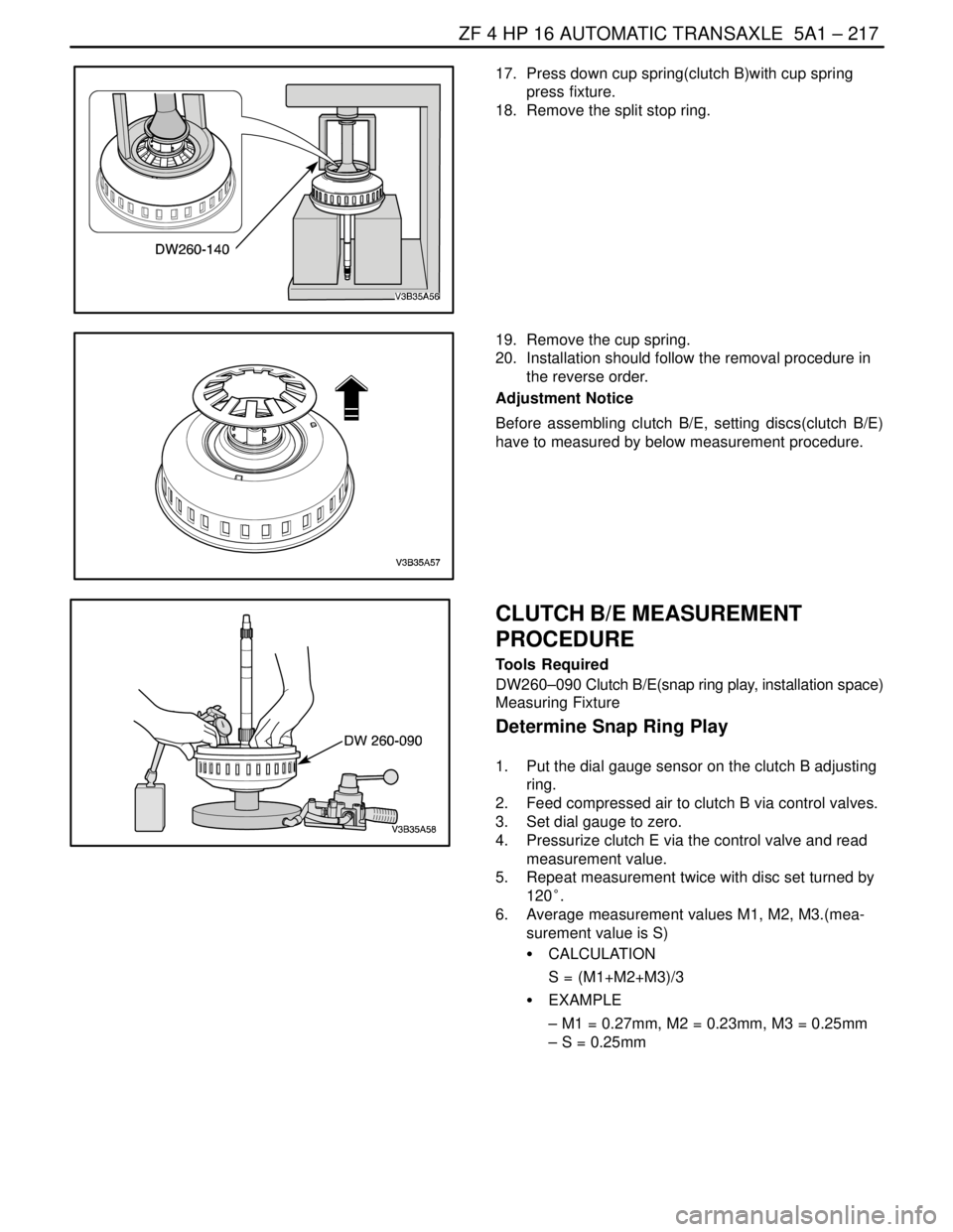

Tools Required

DW260–090 Clutch B/E(snap ring play, installation space)

Measuring Fixture

Determine Snap Ring Play

1. Put the dial gauge sensor on the clutch B adjusting

ring.

2. Feed compressed air to clutch B via control valves.

3. Set dial gauge to zero.

4. Pressurize clutch E via the control valve and read

measurement value.

5. Repeat measurement twice with disc set turned by

120°.

6. Average measurement values M1, M2, M3.(mea-

surement value is S)

S CALCULATION

S = (M1+M2+M3)/3

S EXAMPLE

– M1 = 0.27mm, M2 = 0.23mm, M3 = 0.25mm

– S = 0.25mm

Page 1567 of 2643

5A1 – 218IZF 4 HP 16 AUTOMATIC TRANSAXLE

DAEWOO V–121 BL4

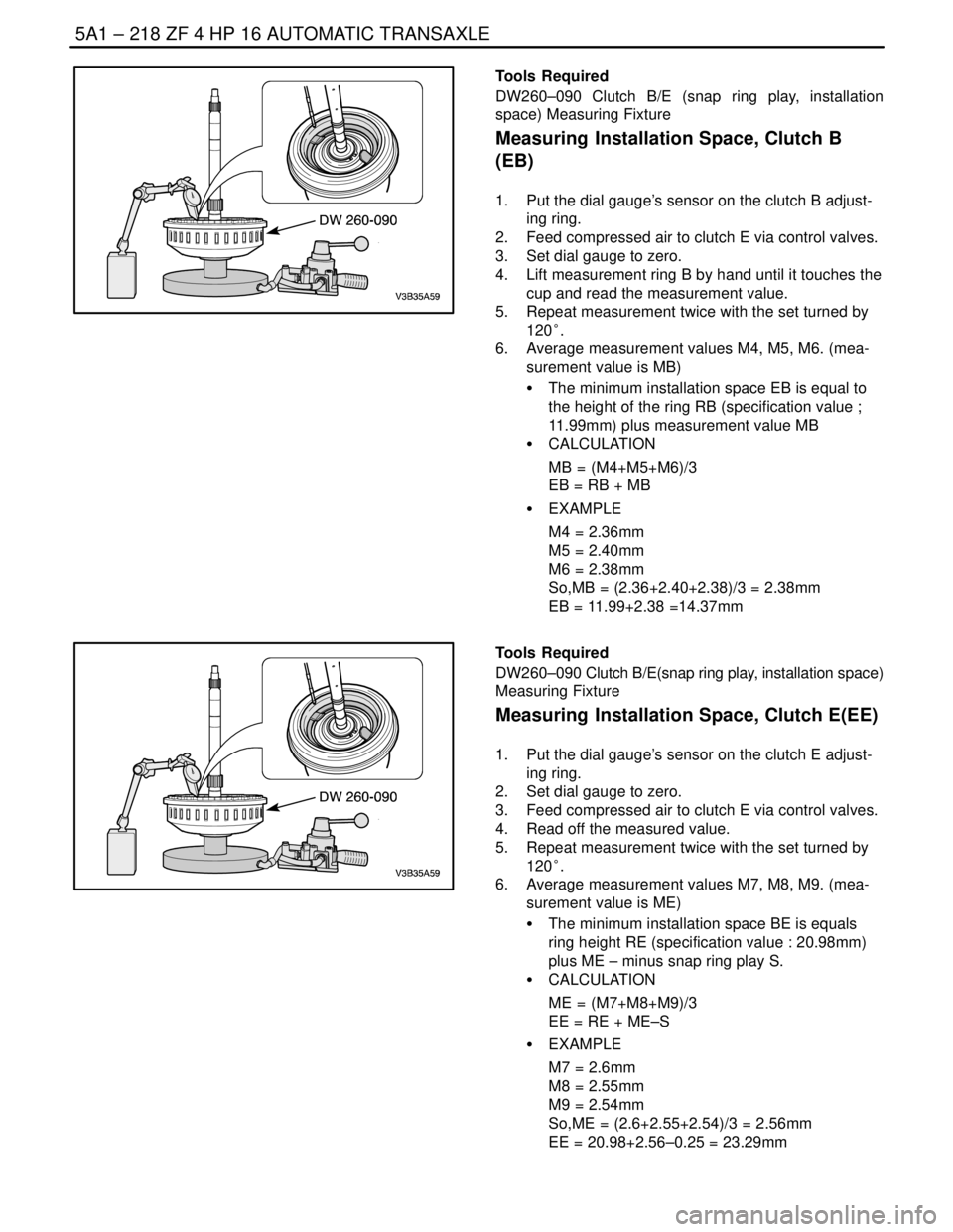

Tools Required

DW260–090 Clutch B/E (snap ring play, installation

space) Measuring Fixture

Measuring Installation Space, Clutch B

(EB)

1. Put the dial gauge’s sensor on the clutch B adjust-

ing ring.

2. Feed compressed air to clutch E via control valves.

3. Set dial gauge to zero.

4. Lift measurement ring B by hand until it touches the

cup and read the measurement value.

5. Repeat measurement twice with the set turned by

120°.

6. Average measurement values M4, M5, M6. (mea-

surement value is MB)

S The minimum installation space EB is equal to

the height of the ring RB (specification value ;

11.99mm) plus measurement value MB

S CALCULATION

MB = (M4+M5+M6)/3

EB = RB + MB

S EXAMPLE

M4 = 2.36mm

M5 = 2.40mm

M6 = 2.38mm

So,MB = (2.36+2.40+2.38)/3 = 2.38mm

EB = 11.99+2.38 =14.37mm

Tools Required

DW260–090 Clutch B/E(snap ring play, installation space)

Measuring Fixture

Measuring Installation Space, Clutch E(EE)

1. Put the dial gauge’s sensor on the clutch E adjust-

ing ring.

2. Set dial gauge to zero.

3. Feed compressed air to clutch E via control valves.

4. Read off the measured value.

5. Repeat measurement twice with the set turned by

120°.

6. Average measurement values M7, M8, M9. (mea-

surement value is ME)

S The minimum installation space BE is equals

ring height RE (specification value : 20.98mm)

plus ME – minus snap ring play S.

S CALCULATION

ME = (M7+M8+M9)/3

EE = RE + ME–S

S EXAMPLE

M7 = 2.6mm

M8 = 2.55mm

M9 = 2.54mm

So,ME = (2.6+2.55+2.54)/3 = 2.56mm

EE = 20.98+2.56–0.25 = 23.29mm

Page 1568 of 2643

ZF 4 HP 16 AUTOMATIC TRANSAXLE 5A1 – 219

DAEWOO V–121 BL4

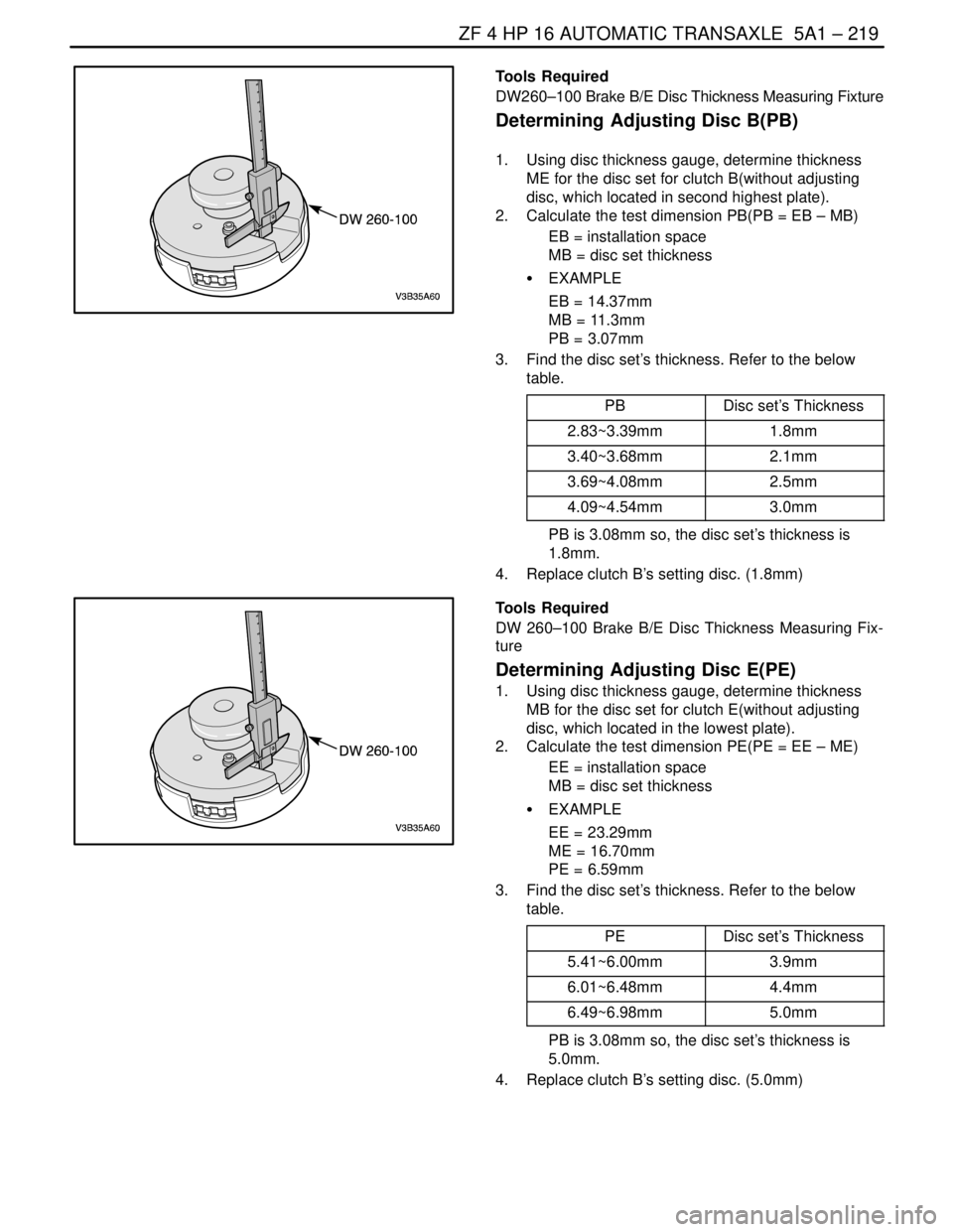

Tools Required

DW260–100 Brake B/E Disc Thickness Measuring Fixture

Determining Adjusting Disc B(PB)

1. Using disc thickness gauge, determine thickness

ME for the disc set for clutch B(without adjusting

disc, which located in second highest plate).

2. Calculate the test dimension PB(PB = EB – MB)

EB = installation space

MB = disc set thickness

S EXAMPLE

EB = 14.37mm

MB = 11.3mm

PB = 3.07mm

3. Find the disc set’s thickness. Refer to the below

table.

PB

Disc set’s Thickness

2.83~3.39mm1.8mm

3.40~3.68mm2.1mm

3.69~4.08mm2.5mm

4.09~4.54mm3.0mm

PB is 3.08mm so, the disc set’s thickness is

1.8mm.

4. Replace clutch B’s setting disc. (1.8mm)

Tools Required

DW 260–100 Brake B/E Disc Thickness Measuring Fix-

ture

Determining Adjusting Disc E(PE)

1. Using disc thickness gauge, determine thickness

MB for the disc set for clutch E(without adjusting

disc, which located in the lowest plate).

2. Calculate the test dimension PE(PE = EE – ME)

EE = installation space

MB = disc set thickness

S EXAMPLE

EE = 23.29mm

ME = 16.70mm

PE = 6.59mm

3. Find the disc set’s thickness. Refer to the below

table.

PE

Disc set’s Thickness

5.41~6.00mm3.9mm

6.01~6.48mm4.4mm

6.49~6.98mm5.0mm

PB is 3.08mm so, the disc set’s thickness is

5.0mm.

4. Replace clutch B’s setting disc. (5.0mm)

Page 1569 of 2643

5A1 – 220IZF 4 HP 16 AUTOMATIC TRANSAXLE

DAEWOO V–121 BL4

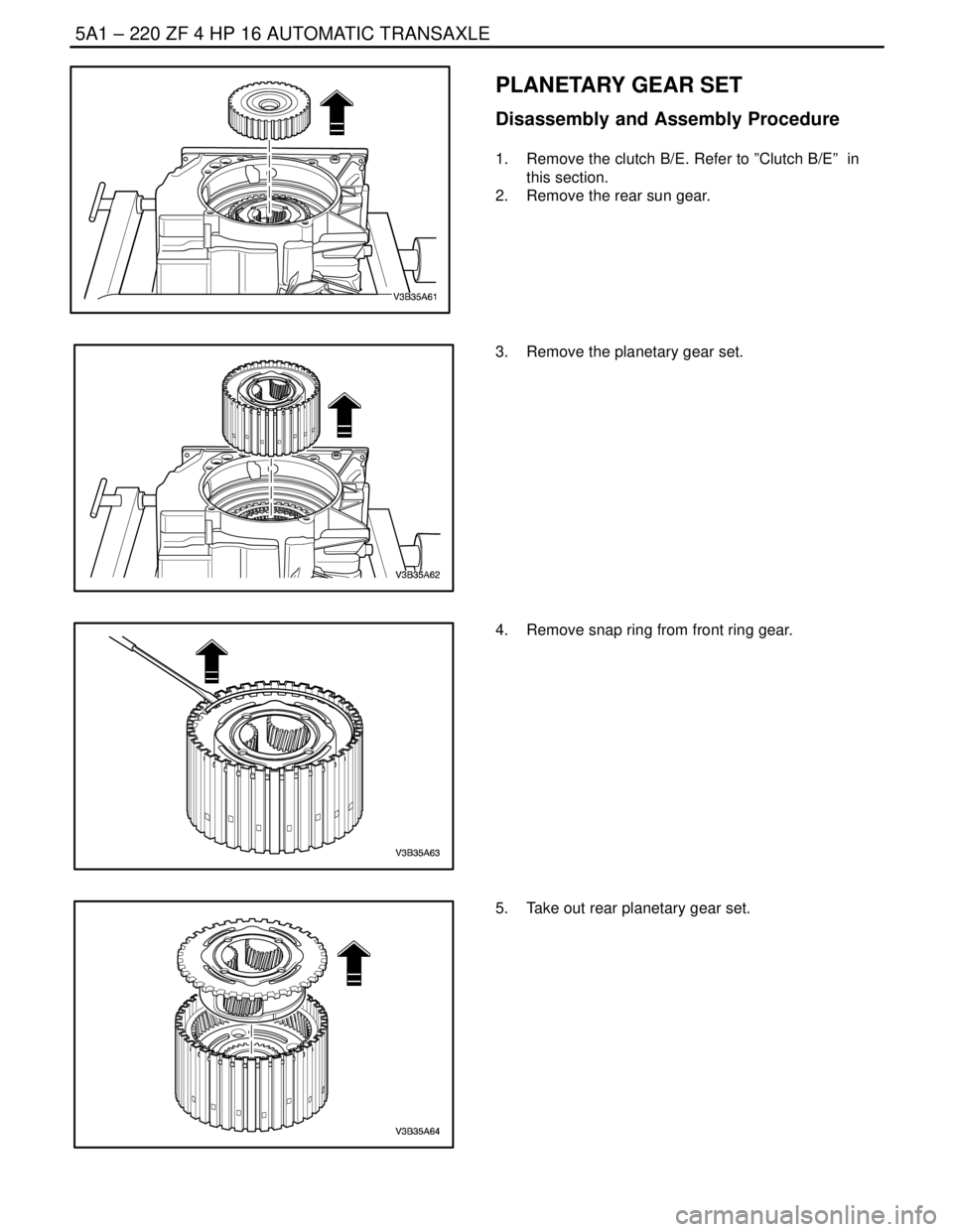

PLANETARY GEAR SET

Disassembly and Assembly Procedure

1. Remove the clutch B/E. Refer to ”Clutch B/E” in

this section.

2. Remove the rear sun gear.

3. Remove the planetary gear set.

4. Remove snap ring from front ring gear.

5. Take out rear planetary gear set.

Page 1570 of 2643

ZF 4 HP 16 AUTOMATIC TRANSAXLE 5A1 – 221

DAEWOO V–121 BL4

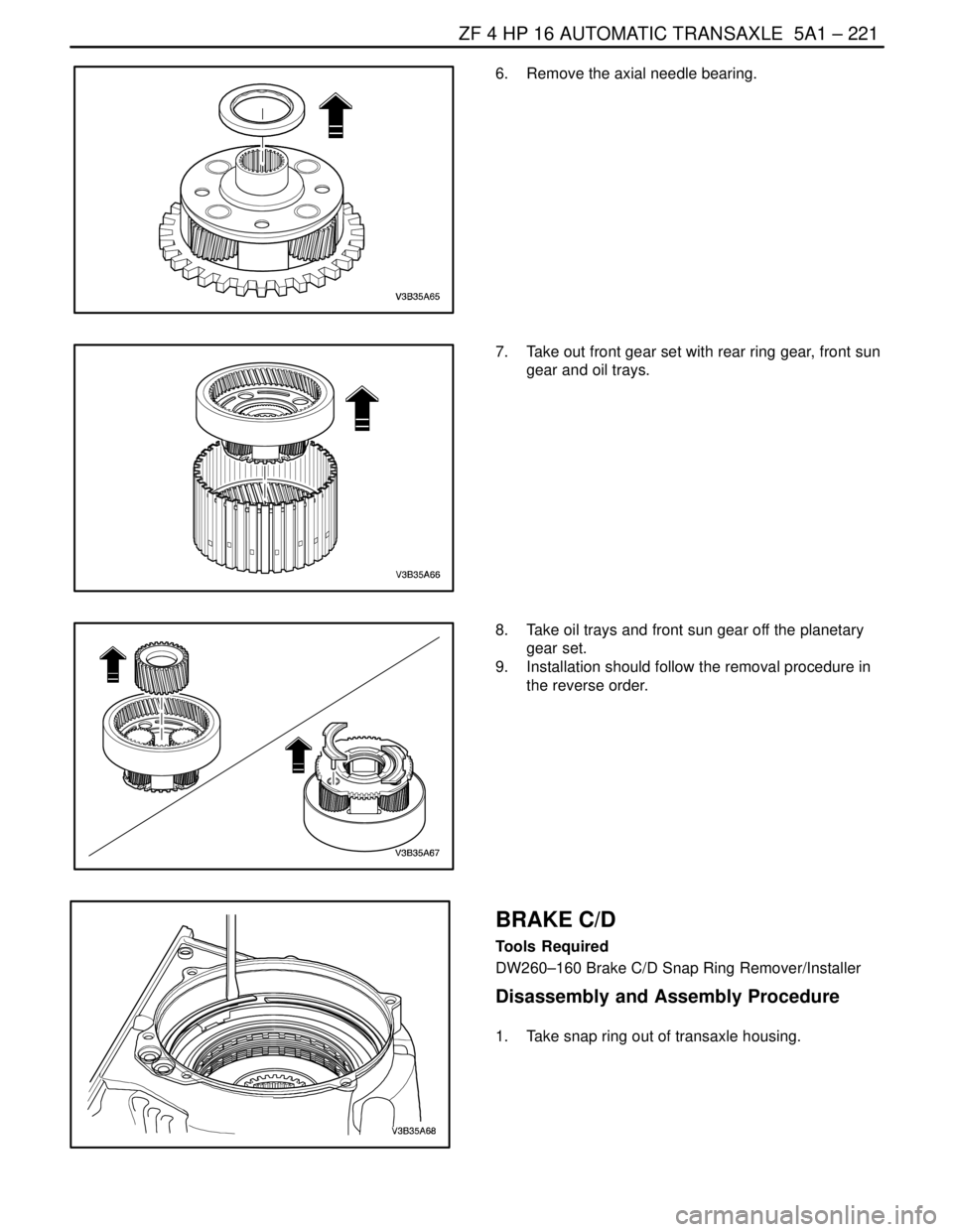

6. Remove the axial needle bearing.

7. Take out front gear set with rear ring gear, front sun

gear and oil trays.

8. Take oil trays and front sun gear off the planetary

gear set.

9. Installation should follow the removal procedure in

the reverse order.

BRAKE C/D

Tools Required

DW260–160 Brake C/D Snap Ring Remover/Installer

Disassembly and Assembly Procedure

1. Take snap ring out of transaxle housing.

Page 1571 of 2643

5A1 – 222IZF 4 HP 16 AUTOMATIC TRANSAXLE

DAEWOO V–121 BL4

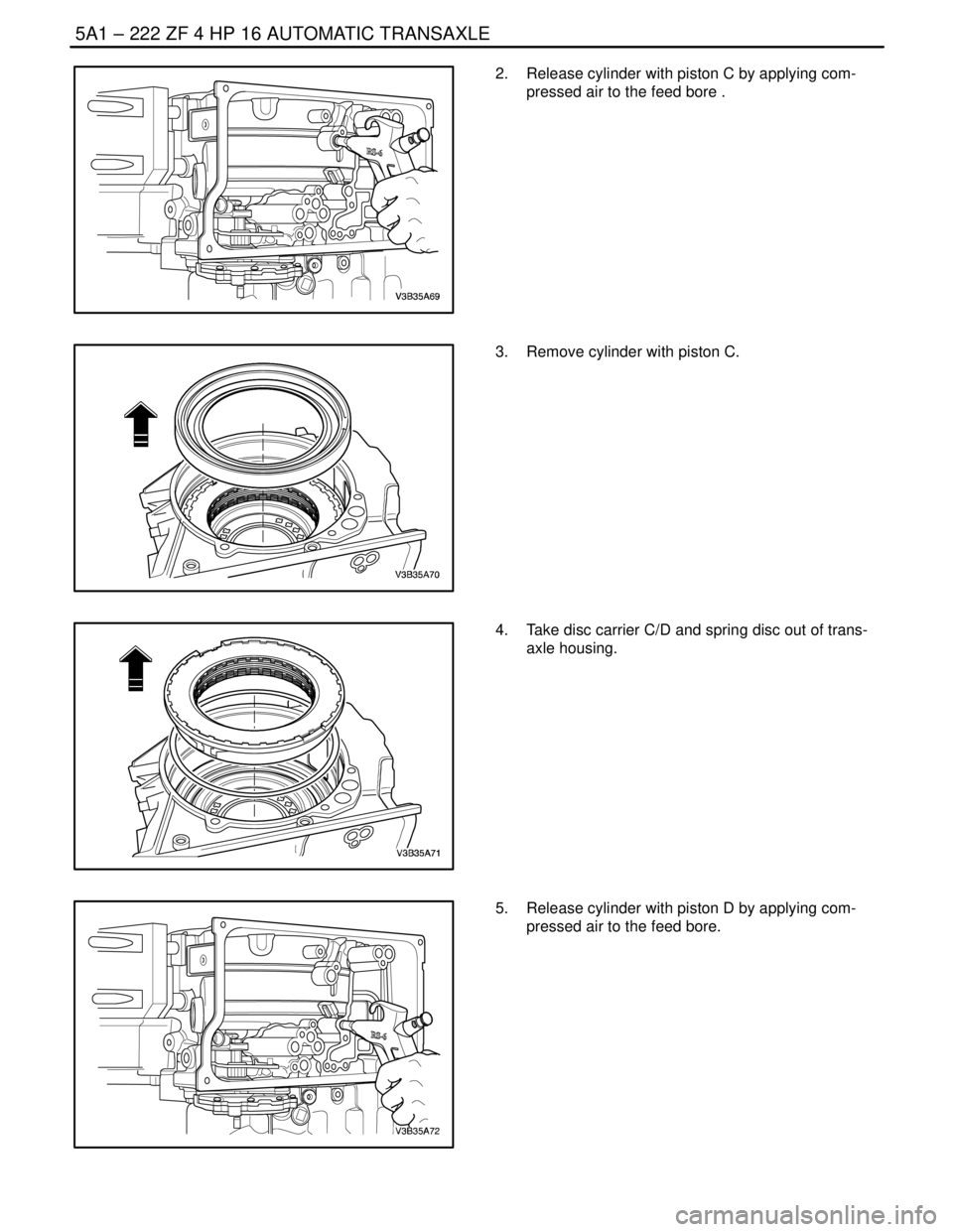

2. Release cylinder with piston C by applying com-

pressed air to the feed bore .

3. Remove cylinder with piston C.

4. Take disc carrier C/D and spring disc out of trans-

axle housing.

5. Release cylinder with piston D by applying com-

pressed air to the feed bore.

Page 1572 of 2643

ZF 4 HP 16 AUTOMATIC TRANSAXLE 5A1 – 223

DAEWOO V–121 BL4

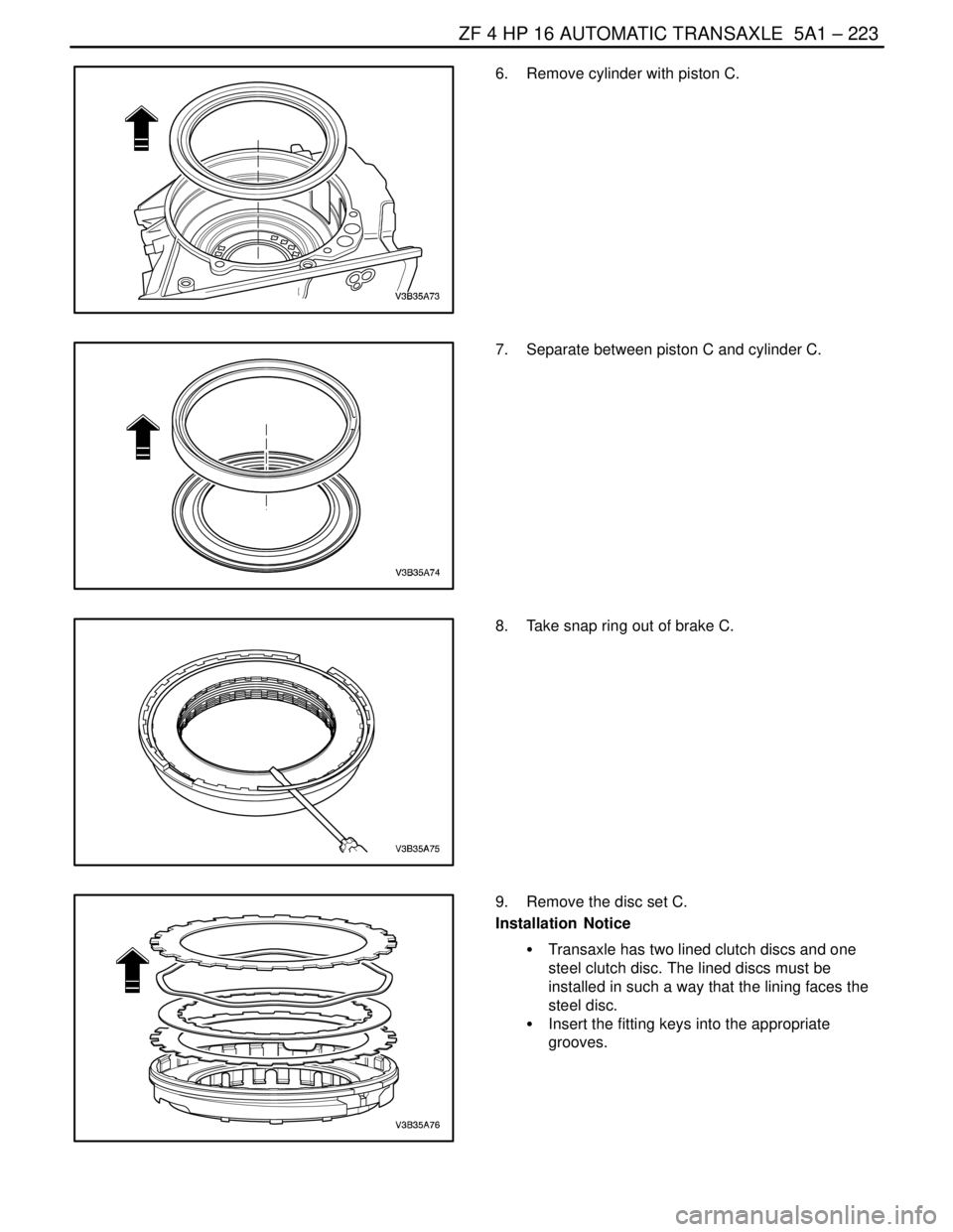

6. Remove cylinder with piston C.

7. Separate between piston C and cylinder C.

8. Take snap ring out of brake C.

9. Remove the disc set C.

Installation Notice

S Transaxle has two lined clutch discs and one

steel clutch disc. The lined discs must be

installed in such a way that the lining faces the

steel disc.

S Insert the fitting keys into the appropriate

grooves.

Page 1573 of 2643

5A1 – 224IZF 4 HP 16 AUTOMATIC TRANSAXLE

DAEWOO V–121 BL4

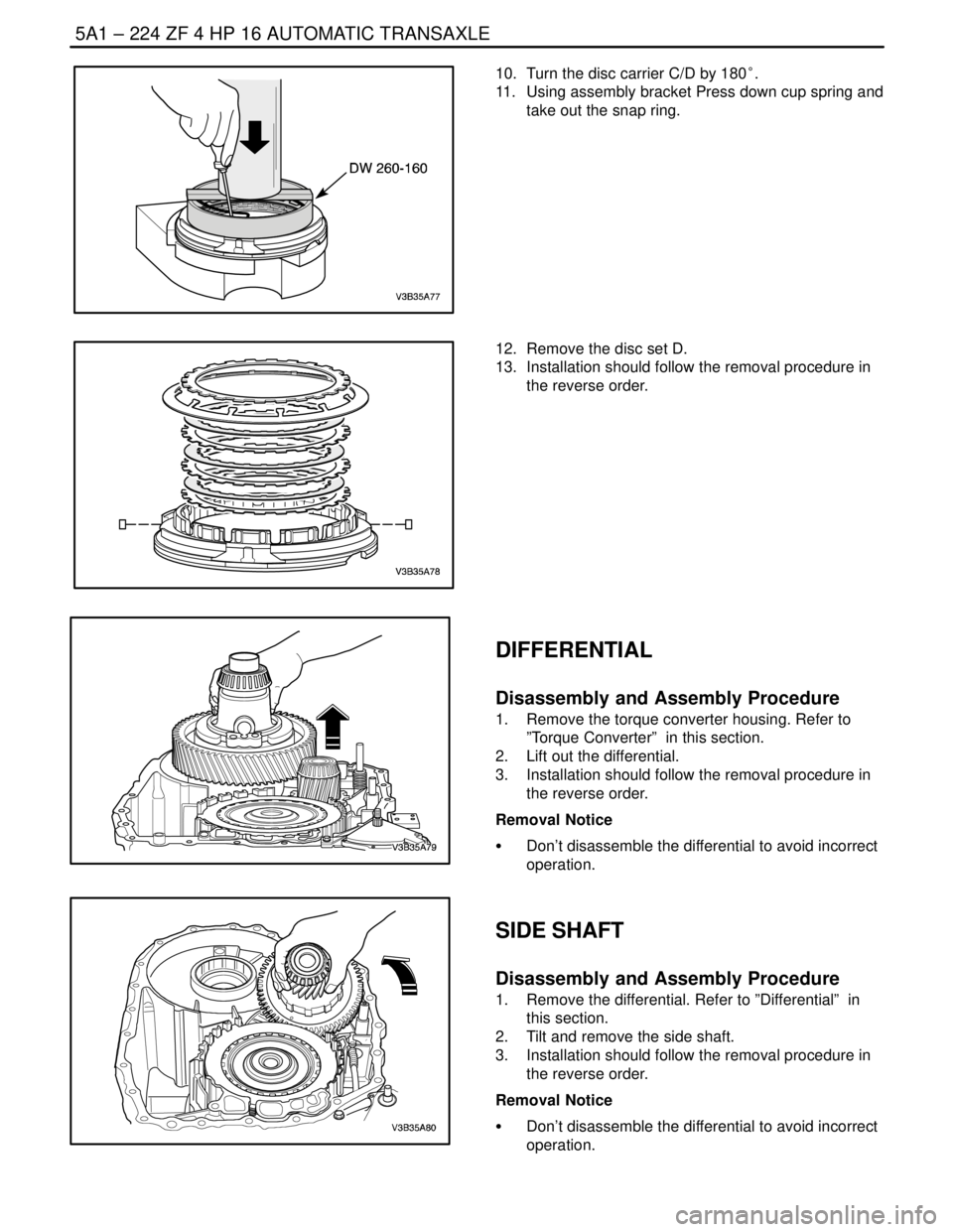

10. Turn the disc carrier C/D by 180°.

11. Using assembly bracket Press down cup spring and

take out the snap ring.

12. Remove the disc set D.

13. Installation should follow the removal procedure in

the reverse order.

DIFFERENTIAL

Disassembly and Assembly Procedure

1. Remove the torque converter housing. Refer to

”Torque Converter” in this section.

2. Lift out the differential.

3. Installation should follow the removal procedure in

the reverse order.

Removal Notice

S Don’t disassemble the differential to avoid incorrect

operation.

SIDE SHAFT

Disassembly and Assembly Procedure

1. Remove the differential. Refer to ”Differential” in

this section.

2. Tilt and remove the side shaft.

3. Installation should follow the removal procedure in

the reverse order.

Removal Notice

S Don’t disassemble the differential to avoid incorrect

operation.

Page 1574 of 2643

ZF 4 HP 16 AUTOMATIC TRANSAXLE 5A1 – 225

DAEWOO V–121 BL4

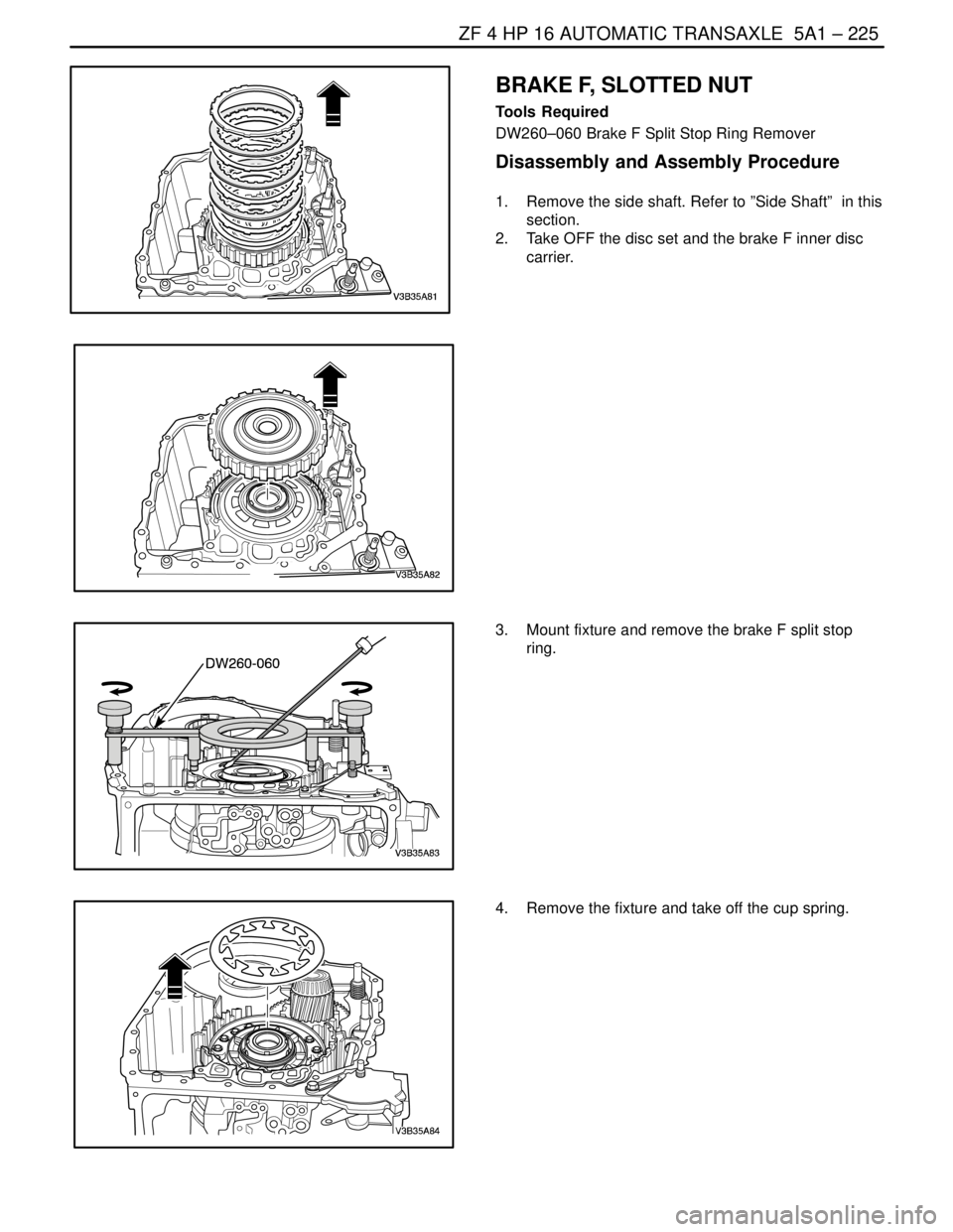

BRAKE F, SLOTTED NUT

Tools Required

DW260–060 Brake F Split Stop Ring Remover

Disassembly and Assembly Procedure

1. Remove the side shaft. Refer to ”Side Shaft” in this

section.

2. Take OFF the disc set and the brake F inner disc

carrier.

3. Mount fixture and remove the brake F split stop

ring.

4. Remove the fixture and take off the cup spring.