Lamp fuse DAEWOO NUBIRA 2004 Service Owner's Manual

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: NUBIRA, Model: DAEWOO NUBIRA 2004Pages: 2643, PDF Size: 80.54 MB

Page 1016 of 2643

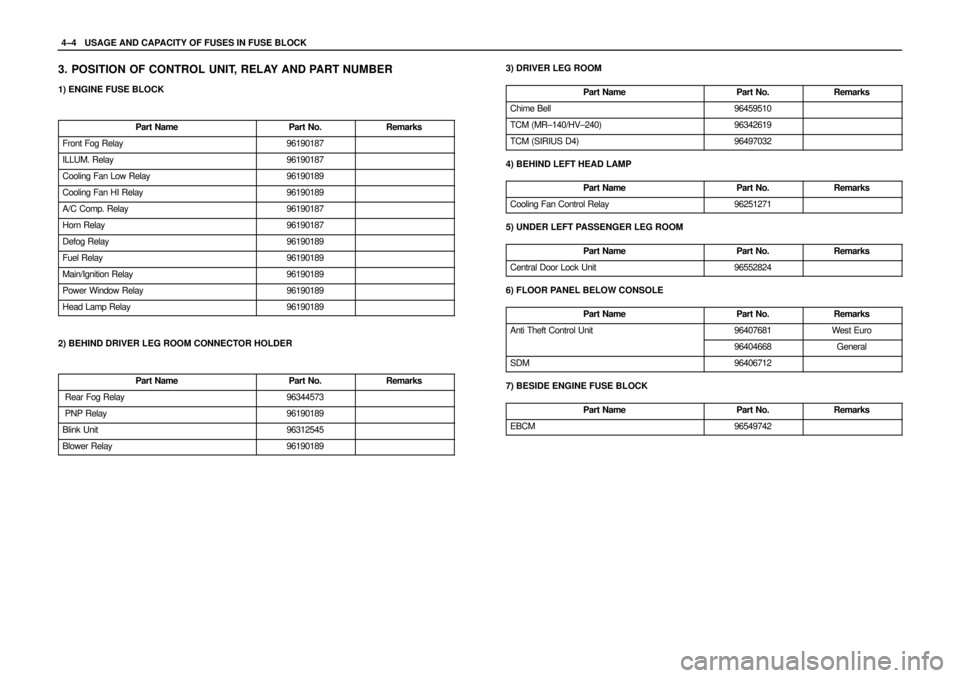

4–4WUSAGE AND CAPACITY OF FUSES IN FUSE BLOCK

3. POSITION OF CONTROL UNIT, RELAY AND PART NUMBER

1) ENGINE FUSE BLOCK

Part Name

Part No.Remarks

Front Fog Relay96190187

ILLUM. Relay96190187

Cooling Fan Low Relay96190189

Cooling Fan HI Relay96190189

A/C Comp. Relay96190187

Horn Relay96190187

Defog Relay96190189

Fuel Relay96190189

Main/Ignition Relay96190189

Power Window Relay96190189

Head Lamp Relay96190189

2) BEHIND DRIVER LEG ROOM CONNECTOR HOLDER

Part Name

Part No.Remarks

Rear Fog Relay96344573

PNP Relay96190189

Blink Unit96312545

Blower Relay96190189

3) DRIVER LEG ROOM

Part Name

Part No.Remarks

Chime Bell96459510

TCM (MR–140/HV–240)96342619

TCM (SIRIUS D4)96497032

4) BEHIND LEFT HEAD LAMP

Part Name

Part No.Remarks

Cooling Fan Control Relay96251271

5) UNDER LEFT PASSENGER LEG ROOM

Part Name

Part No.Remarks

Central Door Lock Unit96552824

6) FLOOR PANEL BELOW CONSOLE

Part Name

Part No.Remarks

Anti Theft Control Unit96407681Wes t Euro

96404668General

SDM96406712

7) BESIDE ENGINE FUSE BLOCK

Part Name

Part No.Remarks

EBCM96549742

Page 1022 of 2643

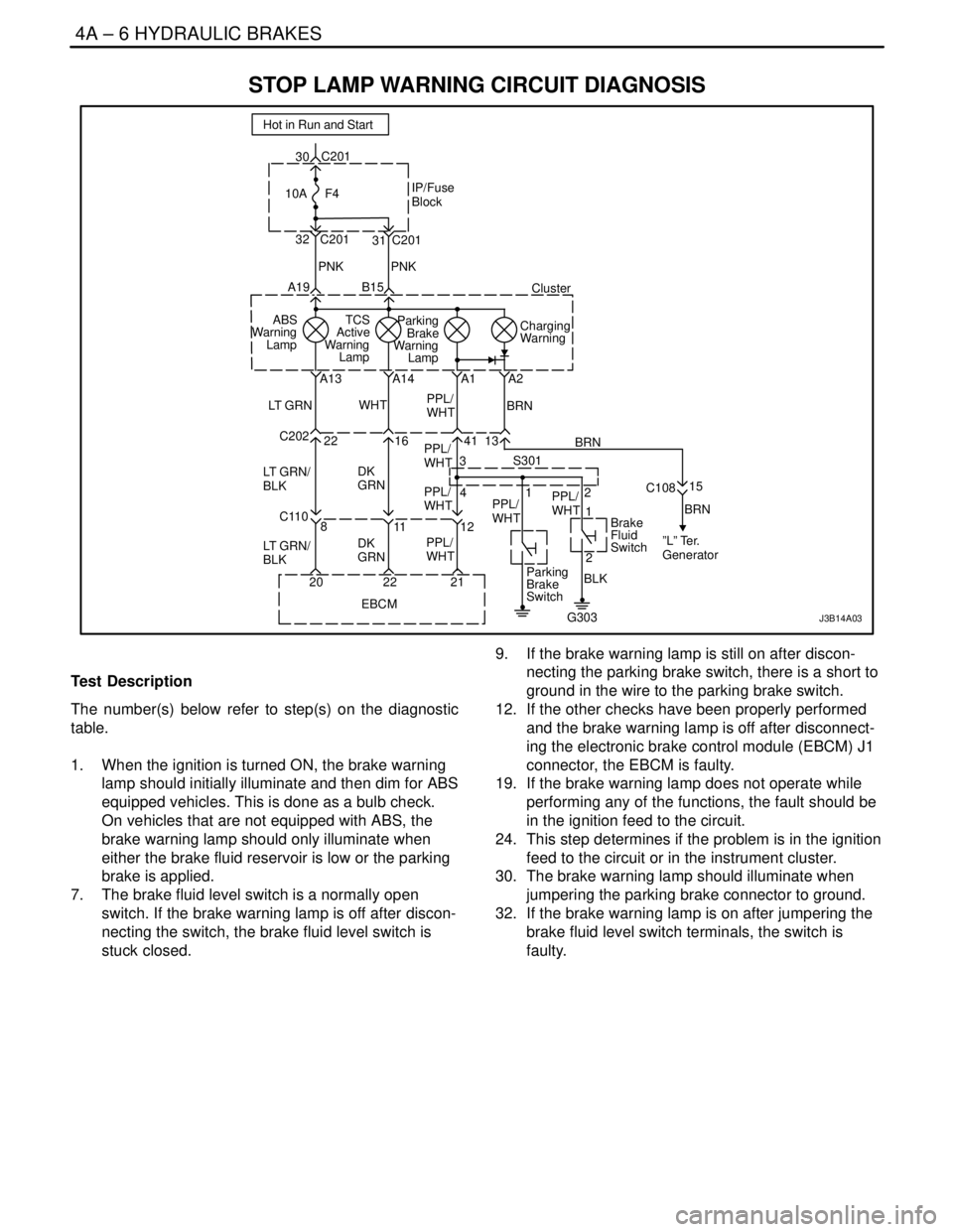

4A – 6IHYDRAULIC BRAKES

DAEWOO V–121 BL4

STOP LAMP WARNING CIRCUIT DIAGNOSIS

J3B14A03

10A30

F4

32

A19

A13 A14 A1 A2B15 C201

31C201IP/Fuse

Block C201

C202

C110C108 S301 WHT

BRN

BRN

Parking

Brake

SwitchBrake

Fluid

Switch

BLKBRN LT GRN

DK

GRN

DK

GRN LT GRN/

BLK

LT GRN/

BLKPPL/

WHT

PPL/

WHT

PPL/

WHTPPL/

WHT PPL/

WHT

PPL/

WHT ABS

Warning

Lamp TCS

Active

Warning

Lamp Parking

Brake

Warning

Lamp Charging

Warning

Hot in Run and Start

PNK

Cluster PNK

EBCM”L” Ter.

Generator 1 12

2

20 2222 16 41 13

3

4

11 1 215

8

21

G303

Test Description

The number(s) below refer to step(s) on the diagnostic

table.

1. When the ignition is turned ON, the brake warning

lamp should initially illuminate and then dim for ABS

equipped vehicles. This is done as a bulb check.

On vehicles that are not equipped with ABS, the

brake warning lamp should only illuminate when

either the brake fluid reservoir is low or the parking

brake is applied.

7. The brake fluid level switch is a normally open

switch. If the brake warning lamp is off after discon-

necting the switch, the brake fluid level switch is

stuck closed.9. If the brake warning lamp is still on after discon-

necting the parking brake switch, there is a short to

ground in the wire to the parking brake switch.

12. If the other checks have been properly performed

and the brake warning lamp is off after disconnect-

ing the electronic brake control module (EBCM) J1

connector, the EBCM is faulty.

19. If the brake warning lamp does not operate while

performing any of the functions, the fault should be

in the ignition feed to the circuit.

24. This step determines if the problem is in the ignition

feed to the circuit or in the instrument cluster.

30. The brake warning lamp should illuminate when

jumpering the parking brake connector to ground.

32. If the brake warning lamp is on after jumpering the

brake fluid level switch terminals, the switch is

faulty.

Page 1024 of 2643

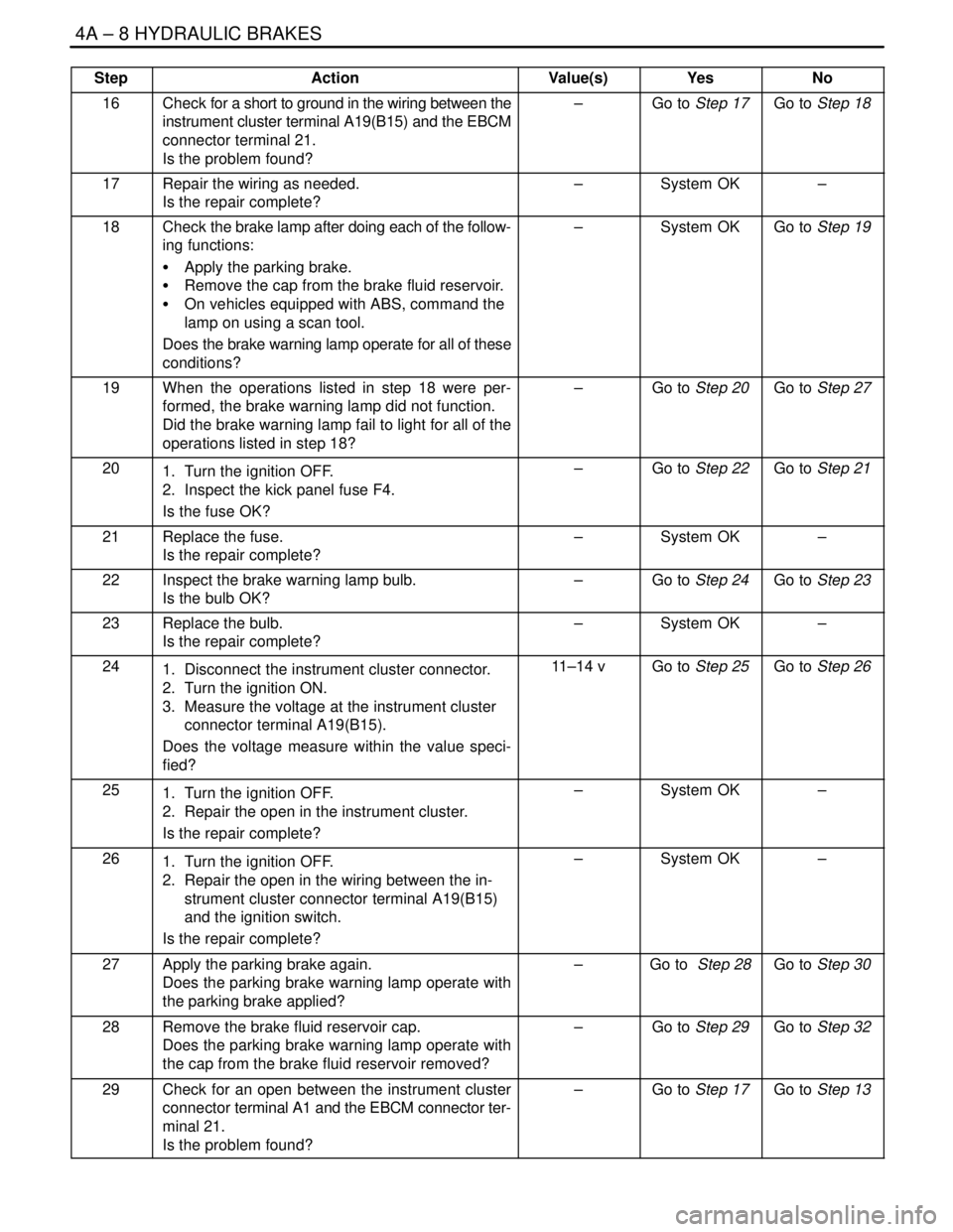

4A – 8IHYDRAULIC BRAKES

DAEWOO V–121 BL4

StepNo Yes Value(s) Action

16Check for a short to ground in the wiring between the

instrument cluster terminal A19(B15) and the EBCM

connector terminal 21.

Is the problem found?–Go to Step 17Go to Step 18

17Repair the wiring as needed.

Is the repair complete?–System OK–

18Check the brake lamp after doing each of the follow-

ing functions:

S Apply the parking brake.

S Remove the cap from the brake fluid reservoir.

S On vehicles equipped with ABS, command the

lamp on using a scan tool.

Does the brake warning lamp operate for all of these

conditions?–System OKGo to Step 19

19When the operations listed in step 18 were per-

formed, the brake warning lamp did not function.

Did the brake warning lamp fail to light for all of the

operations listed in step 18?–Go to Step 20Go to Step 27

201. Turn the ignition OFF.

2. Inspect the kick panel fuse F4.

Is the fuse OK?–Go to Step 22Go to Step 21

21Replace the fuse.

Is the repair complete?–System OK–

22Inspect the brake warning lamp bulb.

Is the bulb OK?–Go to Step 24Go to Step 23

23Replace the bulb.

Is the repair complete?–System OK–

241. Disconnect the instrument cluster connector.

2. Turn the ignition ON.

3. Measure the voltage at the instrument cluster

connector terminal A19(B15).

Does the voltage measure within the value speci-

fied?11–14 vGo to Step 25Go to Step 26

251. Turn the ignition OFF.

2. Repair the open in the instrument cluster.

Is the repair complete?–System OK–

261. Turn the ignition OFF.

2. Repair the open in the wiring between the in-

strument cluster connector terminal A19(B15)

and the ignition switch.

Is the repair complete?–System OK–

27Apply the parking brake again.

Does the parking brake warning lamp operate with

the parking brake applied?–Go to Step 28Go to Step 30

28Remove the brake fluid reservoir cap.

Does the parking brake warning lamp operate with

the cap from the brake fluid reservoir removed?–Go to Step 29Go to Step 32

29Check for an open between the instrument cluster

connector terminal A1 and the EBCM connector ter-

minal 21.

Is the problem found?–Go to Step 17Go to Step 13

Page 1085 of 2643

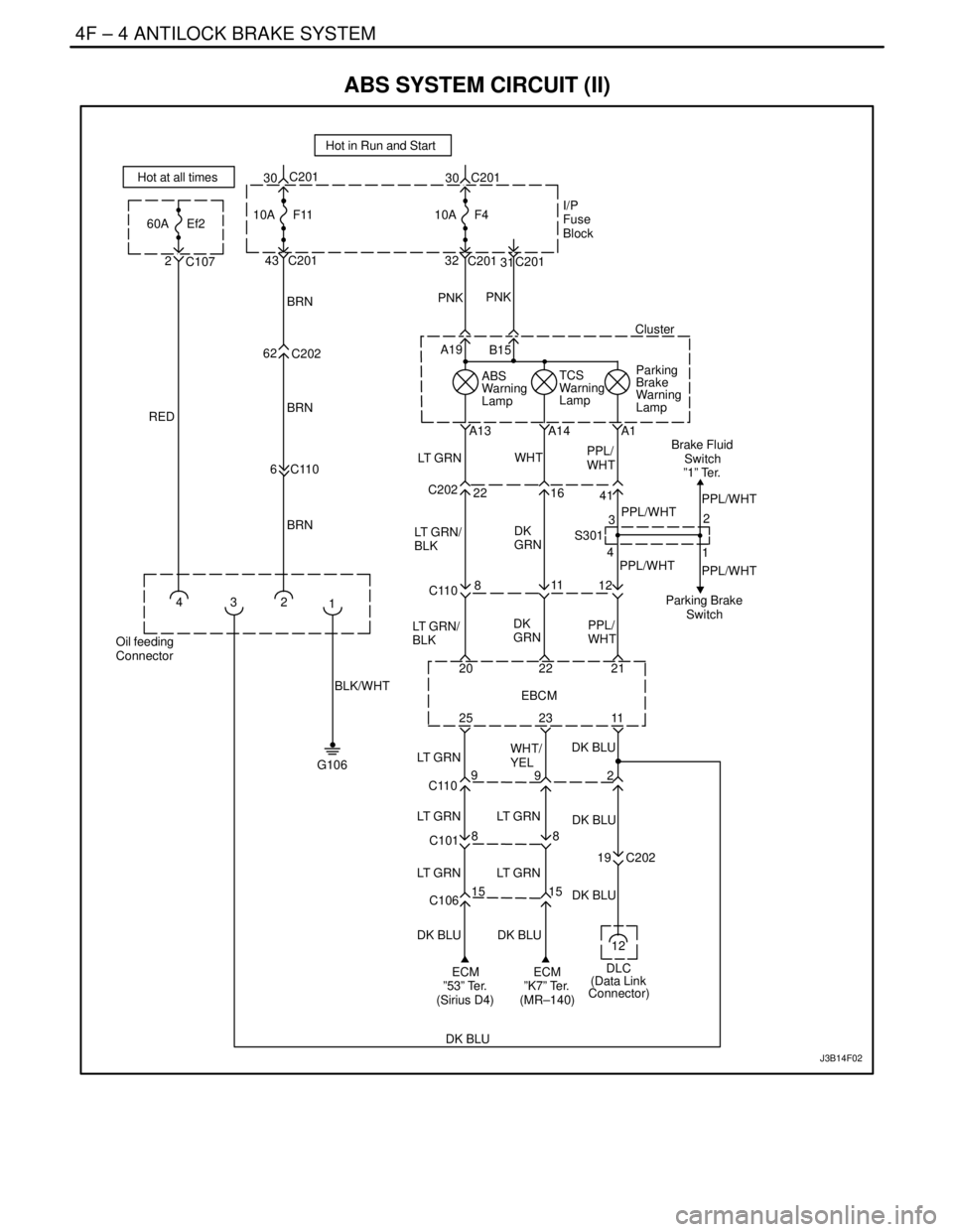

4F – 4IANTILOCK BRAKE SYSTEM

DAEWOO V–121 BL4

ABS SYSTEM CIRCUIT (II)

60A

REDEf2

2

C107

J3B14F02

Oil feeding

Connector

BLK/WHT

G106

10A30

F4

32 43

A19

A13 A14

S301A1 C201 C201

31C201 C201 C201

C202

C110

C110

C101

C106C202 WHT

BRN BRN BRN

DLC

(Data Link

Connector) LT GRN

DK

GRN

DK

GRN LT GRN/

BLK

LT GRN/

BLK

LT GRN

LT GRN LT GRN

LT GRN LT GRN

DK BLU

DK BLUDK BLUDK BLU

DK BLU

DK BLU

ECM

”53” Ter.

(Sirius D4)ECM

”K7” Ter.

(MR–140)PPL/

WHT

PPL/

WHT

WHT/

YELPPL/WHTPPL/WHT

PPL/WHT PPL/WHT ABS

Warning

LampTCS

Warning

LampParking

Brake

Warning

Lamp

Hot in Run and Start

Hot at all times

PNK

Cluster I/P

Fuse

Block

PNK

EBCMBrake Fluid

Switch

”1” Ter.

Parking Brake

Switch 8

88 9

92 20 2222 16

41

3

42

1

11

12

19

12 432

1

21

25 23 11

6C110

C202

10A30

F11

62B15

15 15

Page 1090 of 2643

ANTILOCK BRAKE SYSTEM 4F – 9

DAEWOO V–121 BL4

J3B14F04

60A Ef230A Ef5

2

42

C107 C105

2

C110

G106

A19

A13 A1 A14

C110 C202

C202WHT LT GRN

DK

GRN LT GRN/

BLK

BLK

DK BLUDK BLU

PPL/WHT

PPL/WHT ABS

TCS Parking

Brake

Hot at all times

RED REDRED/WHT

Ignition

Switch

RED

RED

I/P Cluster

EBCM8

20

22 2216 41

1211

18 1621

1

C107

10A F410AF11

32 31

43

6 62 C201

C201 C201C201

C110 C202

Hot in Run and Start

30

4

1711

C202

15

B15

DLC

(Data Link

Connector)12

G106

BLK/WHTOil Feeding

Connector

”2” Ter.

BRNBRN BRN

BRN PNK PNK PNK

19J1

59B1

ONStart Lock

Acc

IG1

19

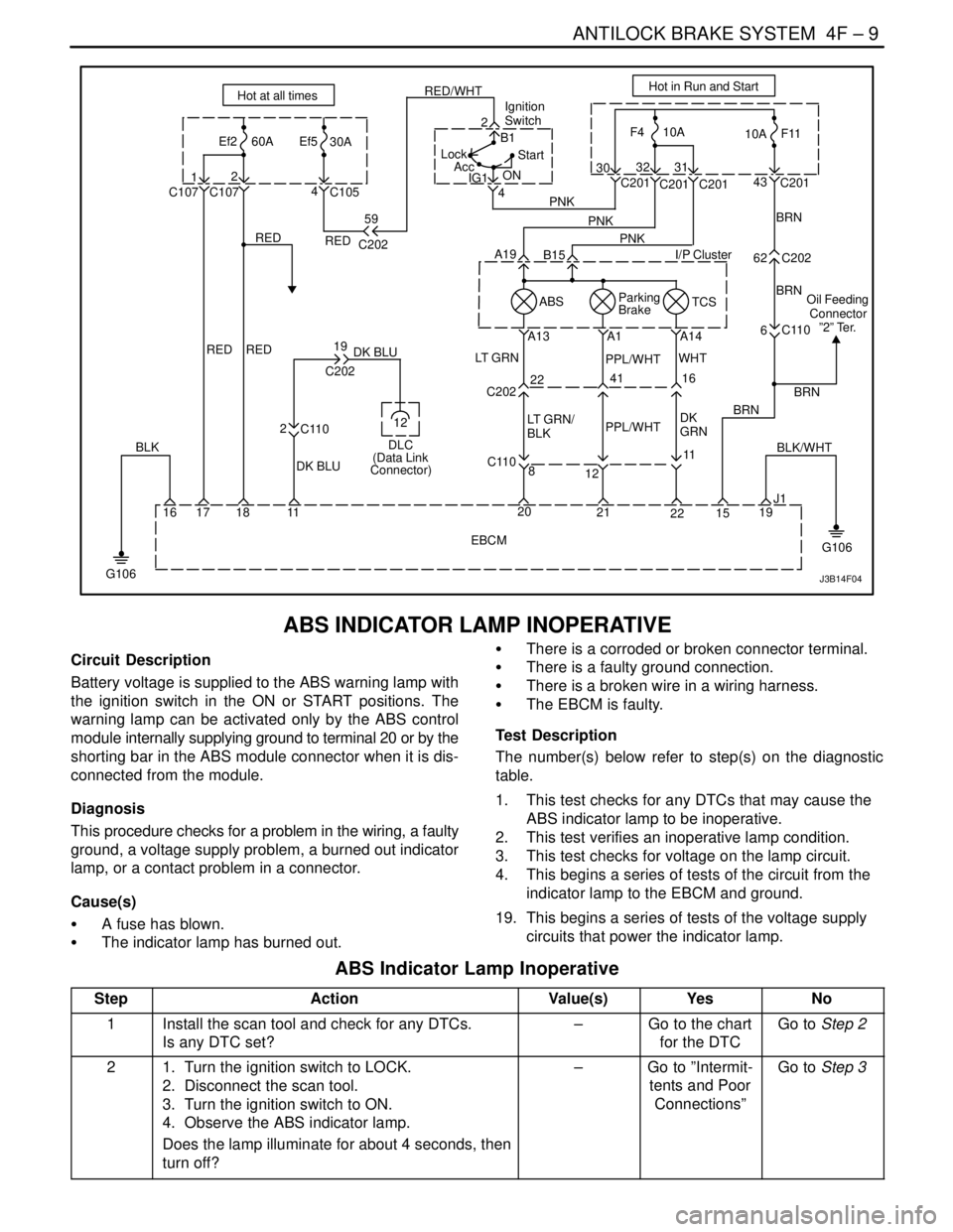

ABS INDICATOR LAMP INOPERATIVE

Circuit Description

Battery voltage is supplied to the ABS warning lamp with

the ignition switch in the ON or START positions. The

warning lamp can be activated only by the ABS control

module internally supplying ground to terminal 20 or by the

shorting bar in the ABS module connector when it is dis-

connected from the module.

Diagnosis

This procedure checks for a problem in the wiring, a faulty

ground, a voltage supply problem, a burned out indicator

lamp, or a contact problem in a connector.

Cause(s)

S A fuse has blown.

S The indicator lamp has burned out.S There is a corroded or broken connector terminal.

S There is a faulty ground connection.

S There is a broken wire in a wiring harness.

S The EBCM is faulty.

Test Description

The number(s) below refer to step(s) on the diagnostic

table.

1. This test checks for any DTCs that may cause the

ABS indicator lamp to be inoperative.

2. This test verifies an inoperative lamp condition.

3. This test checks for voltage on the lamp circuit.

4. This begins a series of tests of the circuit from the

indicator lamp to the EBCM and ground.

19. This begins a series of tests of the voltage supply

circuits that power the indicator lamp.

ABS Indicator Lamp Inoperative

StepActionValue(s)YesNo

1Install the scan tool and check for any DTCs.

Is any DTC set?–Go to the chart

for the DTCGo to Step 2

21. Turn the ignition switch to LOCK.

2. Disconnect the scan tool.

3. Turn the ignition switch to ON.

4. Observe the ABS indicator lamp.

Does the lamp illuminate for about 4 seconds, then

turn off?–Go to ”Intermit-

tents and Poor

Connections”Go to Step 3

Page 1099 of 2643

4F – 18IANTILOCK BRAKE SYSTEM

DAEWOO V–121 BL4

J3B14F04

60A Ef230A Ef5

2

42

C107 C105

2

C110

G106

A19

A13 A1 A14

C110 C202

C202WHT LT GRN

DK

GRN LT GRN/

BLK

BLK

DK BLUDK BLU

PPL/WHT

PPL/WHT ABS

TCS Parking

Brake

Hot at all times

RED REDRED/WHT

Ignition

Switch

RED

RED

I/P Cluster

EBCM8

20

22 2216 41

1211

18 1621

1

C107

10A F410AF11

32 31

43

6 62 C201

C201 C201C201

C110 C202

Hot in Run and Start

30

4

1711

C202

15

B15

DLC

(Data Link

Connector)12

G106

BLK/WHTOil Feeding

Connector

”2” Ter.

BRNBRN BRN

BRN PNK PNK PNK

19J1

59B1

ONStart Lock

Acc

IG1

19

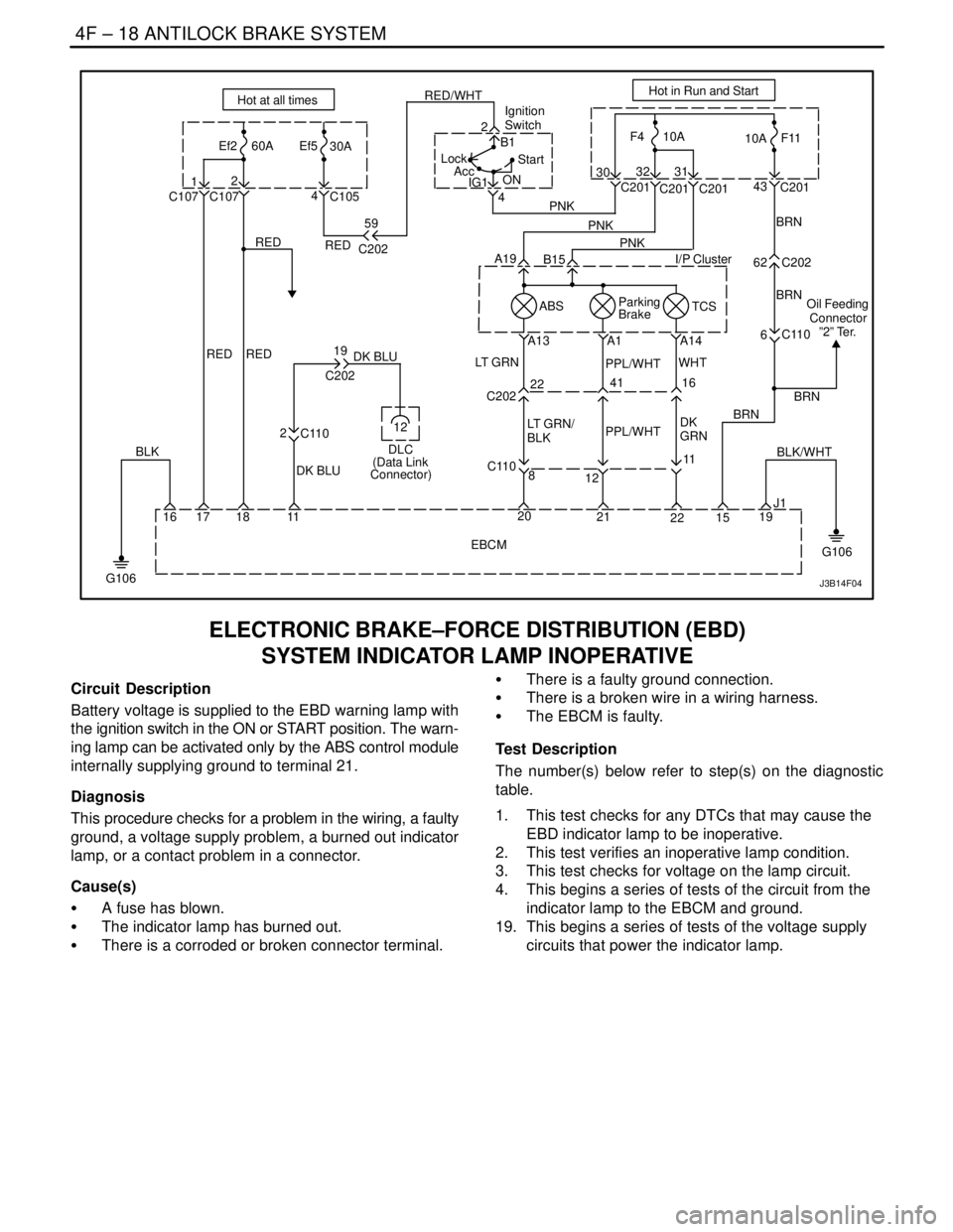

ELECTRONIC BRAKE–FORCE DISTRIBUTION (EBD)

SYSTEM INDICATOR LAMP INOPERATIVE

Circuit Description

Battery voltage is supplied to the EBD warning lamp with

the ignition switch in the ON or START position. The warn-

ing lamp can be activated only by the ABS control module

internally supplying ground to terminal 21.

Diagnosis

This procedure checks for a problem in the wiring, a faulty

ground, a voltage supply problem, a burned out indicator

lamp, or a contact problem in a connector.

Cause(s)

S A fuse has blown.

S The indicator lamp has burned out.

S There is a corroded or broken connector terminal.S There is a faulty ground connection.

S There is a broken wire in a wiring harness.

S The EBCM is faulty.

Test Description

The number(s) below refer to step(s) on the diagnostic

table.

1. This test checks for any DTCs that may cause the

EBD indicator lamp to be inoperative.

2. This test verifies an inoperative lamp condition.

3. This test checks for voltage on the lamp circuit.

4. This begins a series of tests of the circuit from the

indicator lamp to the EBCM and ground.

19. This begins a series of tests of the voltage supply

circuits that power the indicator lamp.

Page 1128 of 2643

ANTILOCK BRAKE SYSTEM 4F – 47

DAEWOO V–121 BL4

J3B14F10

EBCM

ORN/

BLK

LT BLULT B L U

BLK/ WHT

C201 C202

141

40

19

61

G1062

4

15A Ef13

6

C10211

S30114

C201C110

76

C202 11

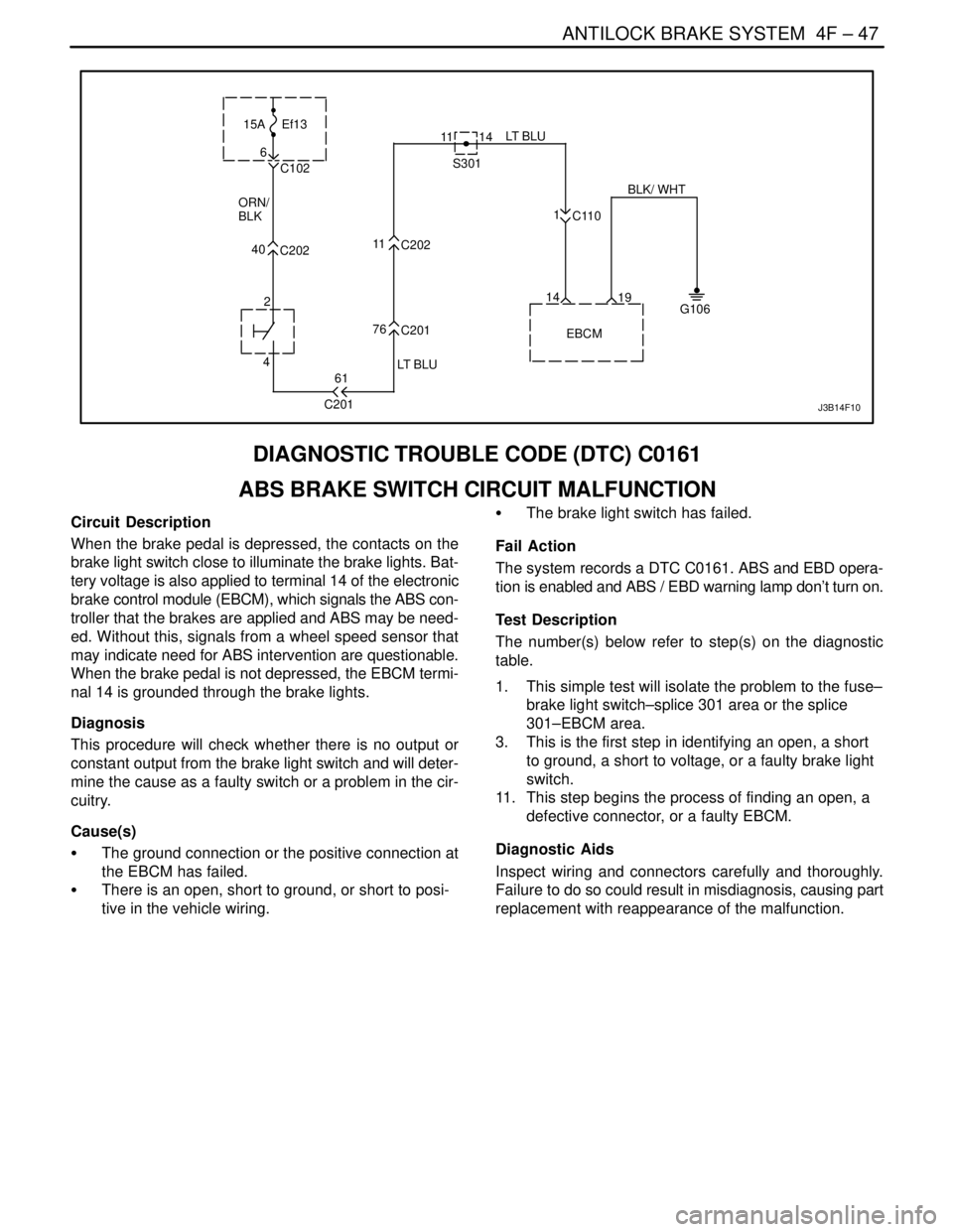

DIAGNOSTIC TROUBLE CODE (DTC) C0161

ABS BRAKE SWITCH CIRCUIT MALFUNCTION

Circuit Description

When the brake pedal is depressed, the contacts on the

brake light switch close to illuminate the brake lights. Bat-

tery voltage is also applied to terminal 14 of the electronic

brake control module (EBCM), which signals the ABS con-

troller that the brakes are applied and ABS may be need-

ed. Without this, signals from a wheel speed sensor that

may indicate need for ABS intervention are questionable.

When the brake pedal is not depressed, the EBCM termi-

nal 14 is grounded through the brake lights.

Diagnosis

This procedure will check whether there is no output or

constant output from the brake light switch and will deter-

mine the cause as a faulty switch or a problem in the cir-

cuitry.

Cause(s)

S The ground connection or the positive connection at

the EBCM has failed.

S There is an open, short to ground, or short to posi-

tive in the vehicle wiring.S The brake light switch has failed.

Fail Action

The system records a DTC C0161. ABS and EBD opera-

tion is enabled and ABS / EBD warning lamp don’t turn on.

Test Description

The number(s) below refer to step(s) on the diagnostic

table.

1. This simple test will isolate the problem to the fuse–

brake light switch–splice 301 area or the splice

301–EBCM area.

3. This is the first step in identifying an open, a short

to ground, a short to voltage, or a faulty brake light

switch.

11. This step begins the process of finding an open, a

defective connector, or a faulty EBCM.

Diagnostic Aids

Inspect wiring and connectors carefully and thoroughly.

Failure to do so could result in misdiagnosis, causing part

replacement with reappearance of the malfunction.

Page 1129 of 2643

4F – 48IANTILOCK BRAKE SYSTEM

DAEWOO V–121 BL4

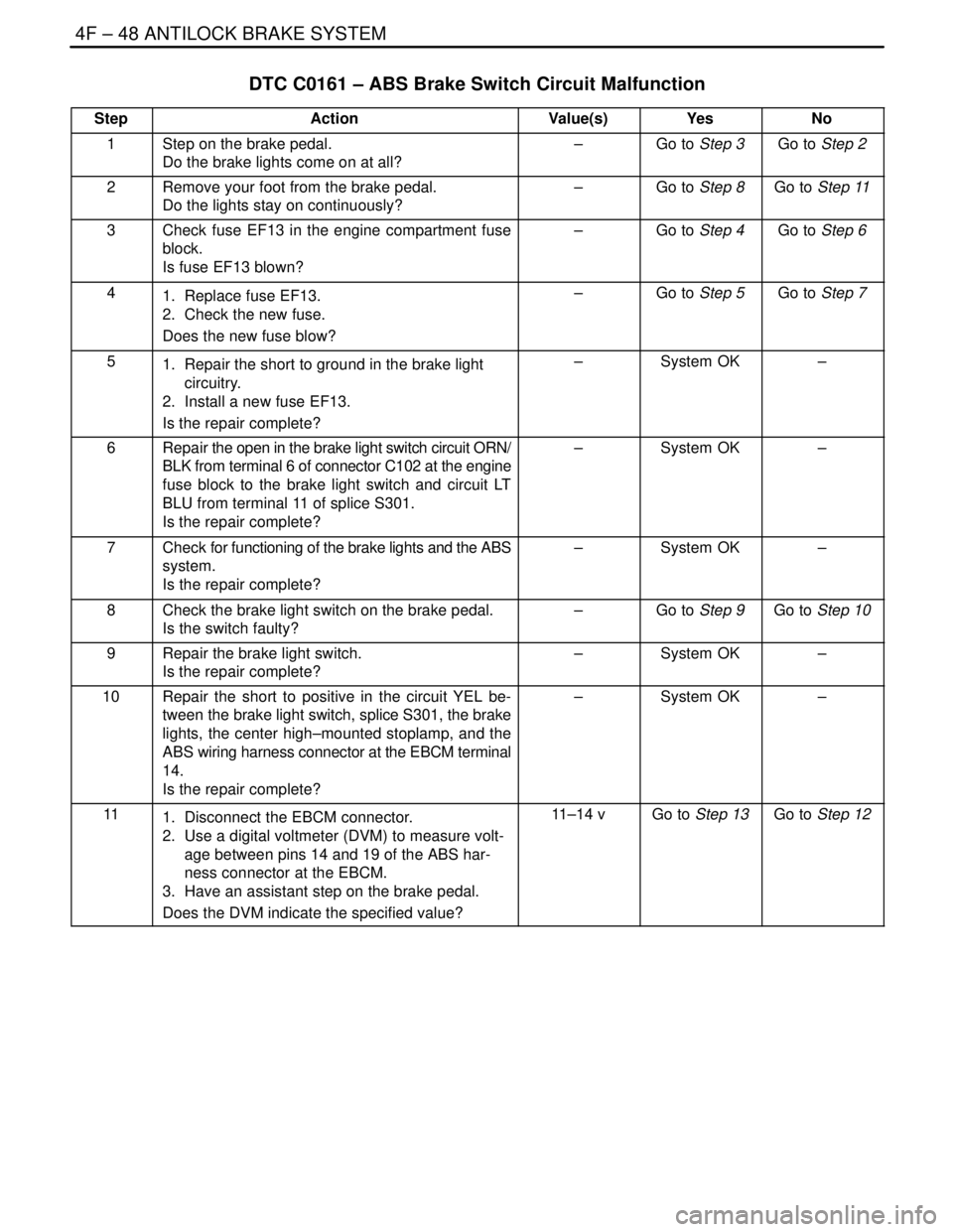

DTC C0161 – ABS Brake Switch Circuit Malfunction

StepActionValue(s)YesNo

1Step on the brake pedal.

Do the brake lights come on at all?–Go to Step 3Go to Step 2

2Remove your foot from the brake pedal.

Do the lights stay on continuously?–Go to Step 8Go to Step 11

3Check fuse EF13 in the engine compartment fuse

block.

Is fuse EF13 blown?–Go to Step 4Go to Step 6

41. Replace fuse EF13.

2. Check the new fuse.

Does the new fuse blow?–Go to Step 5Go to Step 7

51. Repair the short to ground in the brake light

circuitry.

2. Install a new fuse EF13.

Is the repair complete?–System OK–

6Repair the open in the brake light switch circuit ORN/

BLK from terminal 6 of connector C102 at the engine

fuse block to the brake light switch and circuit LT

BLU from terminal 11 of splice S301.

Is the repair complete?–System OK–

7Check for functioning of the brake lights and the ABS

system.

Is the repair complete?–System OK–

8Check the brake light switch on the brake pedal.

Is the switch faulty?–Go to Step 9Go to Step 10

9Repair the brake light switch.

Is the repair complete?–System OK–

10Repair the short to positive in the circuit YEL be-

tween the brake light switch, splice S301, the brake

lights, the center high–mounted stoplamp, and the

ABS wiring harness connector at the EBCM terminal

14.

Is the repair complete?–System OK–

111. Disconnect the EBCM connector.

2. Use a digital voltmeter (DVM) to measure volt-

age between pins 14 and 19 of the ABS har-

ness connector at the EBCM.

3. Have an assistant step on the brake pedal.

Does the DVM indicate the specified value?11–14 vGo to Step 13Go to Step 12

Page 1137 of 2643

4F – 56IANTILOCK BRAKE SYSTEM

DAEWOO V–121 BL4

J3B14F04

60A Ef230A Ef5

2

42

C107 C105

2

C110

G106

A19

A13 A1 A14

C110 C202

C202WHT LT GRN

DK

GRN LT GRN/

BLK

BLK

DK BLUDK BLU

PPL/WHT

PPL/WHT ABS

TCS Parking

Brake

Hot at all times

RED REDRED/WHT

Ignition

Switch

RED

RED

I/P Cluster

EBCM8

20

22 2216 41

1211

18 1621

1

C107

10A F410AF11

32 31

43

6 62 C201

C201 C201C201

C110 C202

Hot in Run and Start

30

4

1711

C202

15

B15

DLC

(Data Link

Connector)12

G106

BLK/WHTOil Feeding

Connector

”2” Ter.

BRNBRN BRN

BRN PNK PNK PNK

19J1

59B1

ONStart Lock

Acc

IG1

19

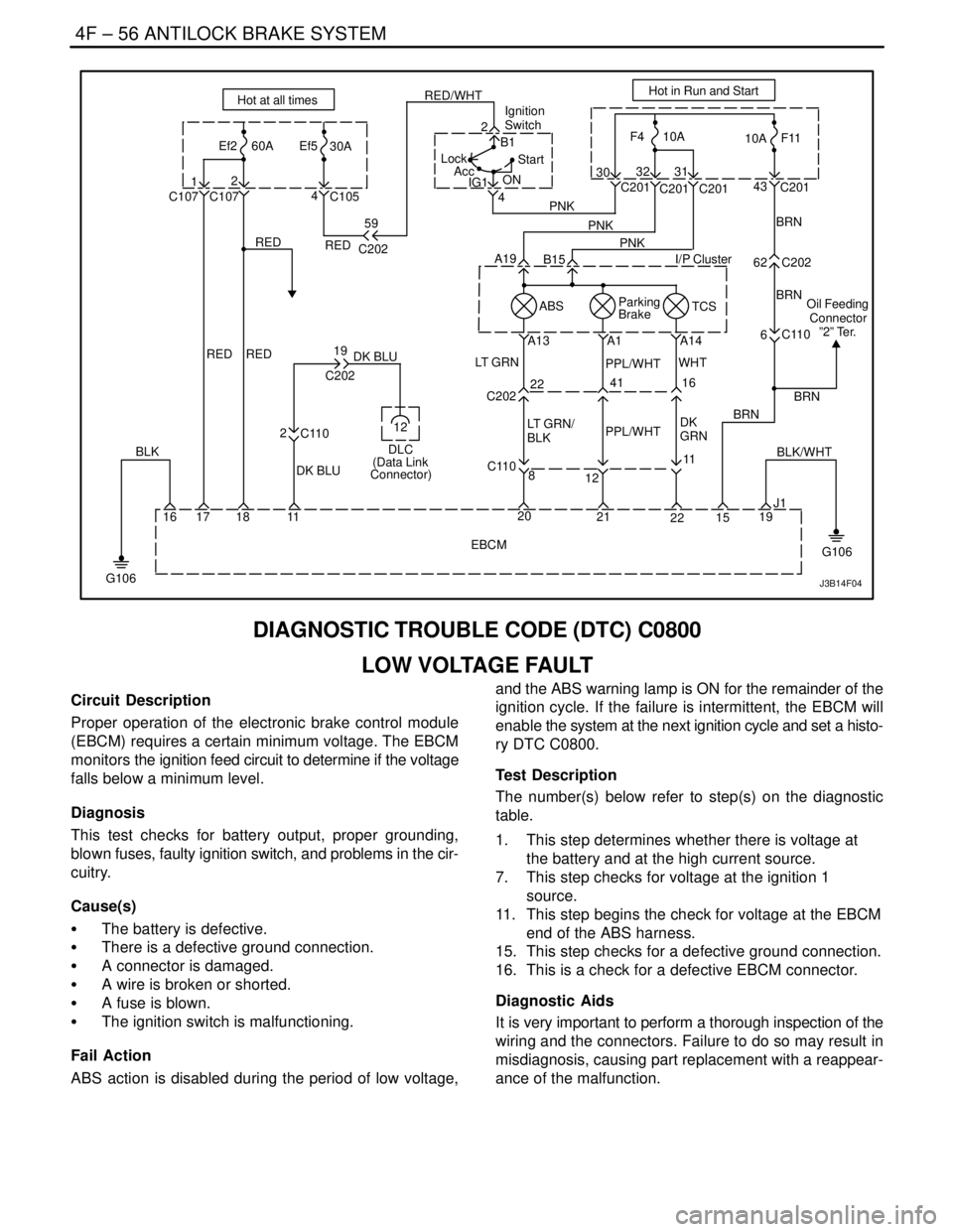

DIAGNOSTIC TROUBLE CODE (DTC) C0800

LOW VOLTAGE FAULT

Circuit Description

Proper operation of the electronic brake control module

(EBCM) requires a certain minimum voltage. The EBCM

monitors the ignition feed circuit to determine if the voltage

falls below a minimum level.

Diagnosis

This test checks for battery output, proper grounding,

blown fuses, faulty ignition switch, and problems in the cir-

cuitry.

Cause(s)

S The battery is defective.

S There is a defective ground connection.

S A connector is damaged.

S A wire is broken or shorted.

S A fuse is blown.

S The ignition switch is malfunctioning.

Fail Action

ABS action is disabled during the period of low voltage,and the ABS warning lamp is ON for the remainder of the

ignition cycle. If the failure is intermittent, the EBCM will

enable the system at the next ignition cycle and set a histo-

ry DTC C0800.

Test Description

The number(s) below refer to step(s) on the diagnostic

table.

1. This step determines whether there is voltage at

the battery and at the high current source.

7. This step checks for voltage at the ignition 1

source.

11. This step begins the check for voltage at the EBCM

end of the ABS harness.

15. This step checks for a defective ground connection.

16. This is a check for a defective EBCM connector.

Diagnostic Aids

It is very important to perform a thorough inspection of the

wiring and the connectors. Failure to do so may result in

misdiagnosis, causing part replacement with a reappear-

ance of the malfunction.

Page 1146 of 2643

ANTILOCK BRAKE SYSTEM 4F – 65

DAEWOO V–121 BL4

GENERAL DESCRIPTION AND SYSTEM

OPERATION

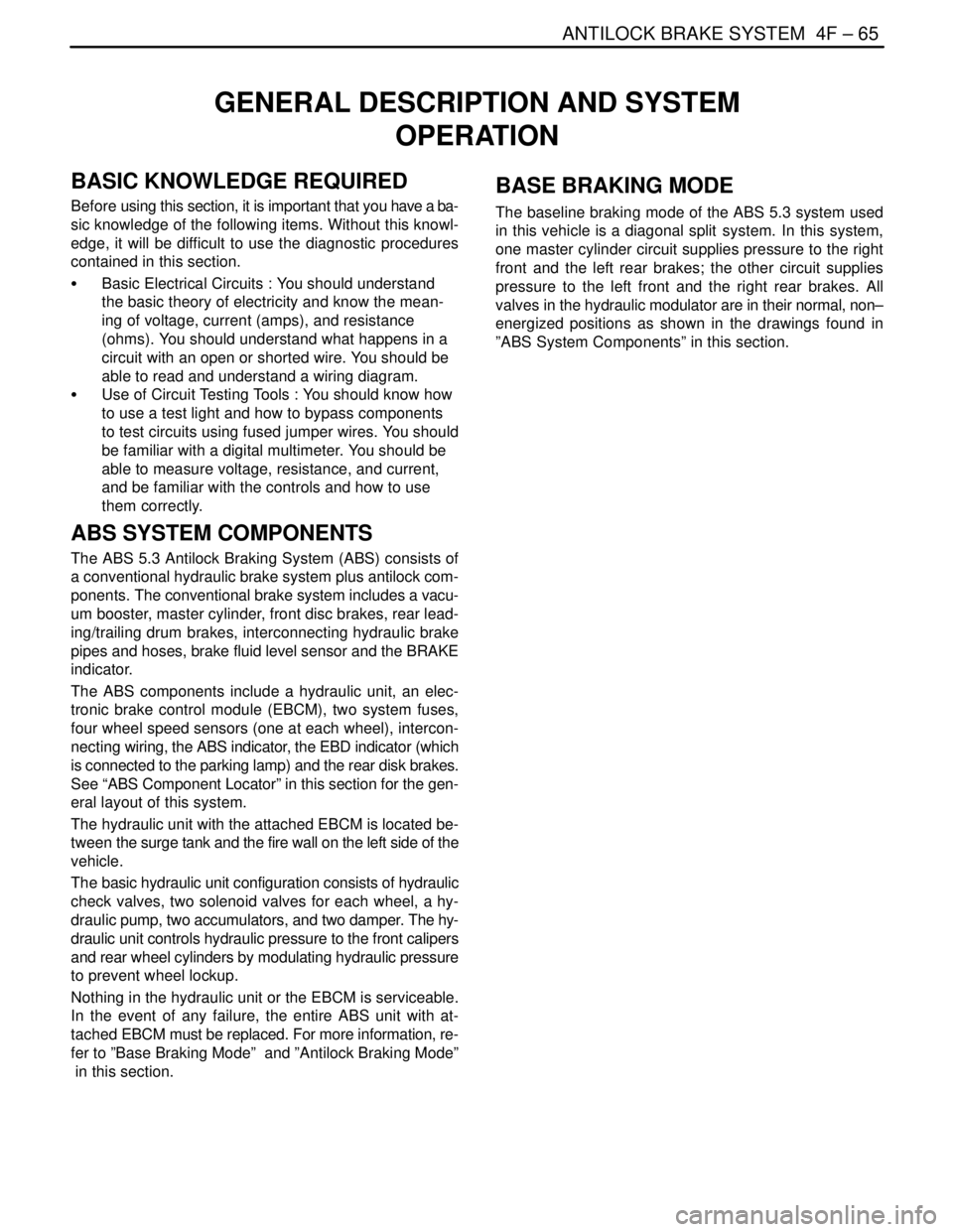

BASIC KNOWLEDGE REQUIRED

Before using this section, it is important that you have a ba-

sic knowledge of the following items. Without this knowl-

edge, it will be difficult to use the diagnostic procedures

contained in this section.

S Basic Electrical Circuits : You should understand

the basic theory of electricity and know the mean-

ing of voltage, current (amps), and resistance

(ohms). You should understand what happens in a

circuit with an open or shorted wire. You should be

able to read and understand a wiring diagram.

S Use of Circuit Testing Tools : You should know how

to use a test light and how to bypass components

to test circuits using fused jumper wires. You should

be familiar with a digital multimeter. You should be

able to measure voltage, resistance, and current,

and be familiar with the controls and how to use

them correctly.

ABS SYSTEM COMPONENTS

The ABS 5.3 Antilock Braking System (ABS) consists of

a conventional hydraulic brake system plus antilock com-

ponents. The conventional brake system includes a vacu-

um booster, master cylinder, front disc brakes, rear lead-

ing/trailing drum brakes, interconnecting hydraulic brake

pipes and hoses, brake fluid level sensor and the BRAKE

indicator.

The ABS components include a hydraulic unit, an elec-

tronic brake control module (EBCM), two system fuses,

four wheel speed sensors (one at each wheel), intercon-

necting wiring, the ABS indicator, the EBD indicator (which

is connected to the parking lamp) and the rear disk brakes.

See “ABS Component Locator” in this section for the gen-

eral layout of this system.

The hydraulic unit with the attached EBCM is located be-

tween the surge tank and the fire wall on the left side of the

vehicle.

The basic hydraulic unit configuration consists of hydraulic

check valves, two solenoid valves for each wheel, a hy-

draulic pump, two accumulators, and two damper. The hy-

draulic unit controls hydraulic pressure to the front calipers

and rear wheel cylinders by modulating hydraulic pressure

to prevent wheel lockup.

Nothing in the hydraulic unit or the EBCM is serviceable.

In the event of any failure, the entire ABS unit with at-

tached EBCM must be replaced. For more information, re-

fer to ”Base Braking Mode” and ”Antilock Braking Mode”

in this section.

BASE BRAKING MODE

The baseline braking mode of the ABS 5.3 system used

in this vehicle is a diagonal split system. In this system,

one master cylinder circuit supplies pressure to the right

front and the left rear brakes; the other circuit supplies

pressure to the left front and the right rear brakes. All

valves in the hydraulic modulator are in their normal, non–

energized positions as shown in the drawings found in

”ABS System Components” in this section.