steering wheel DAEWOO NUBIRA 2004 Service Owner's Manual

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: NUBIRA, Model: DAEWOO NUBIRA 2004Pages: 2643, PDF Size: 80.54 MB

Page 151 of 2643

1.8L DOHC ENGINE MECHANICAL 1C2 – 31

DAEWOO V–121 BL4

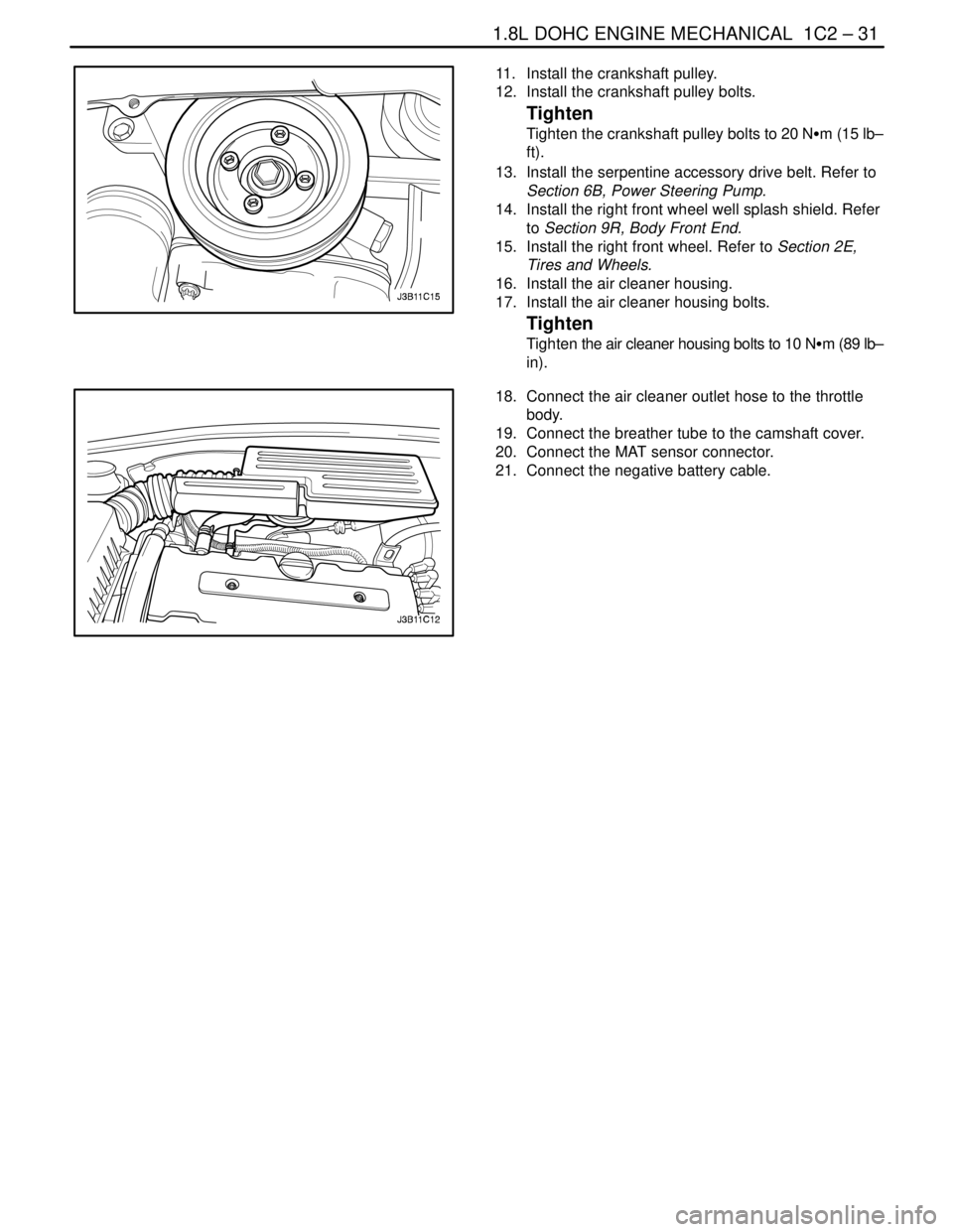

11. Install the crankshaft pulley.

12. Install the crankshaft pulley bolts.

Tighten

Tighten the crankshaft pulley bolts to 20 NSm (15 lb–

ft).

13. Install the serpentine accessory drive belt. Refer to

Section 6B, Power Steering Pump.

14. Install the right front wheel well splash shield. Refer

to Section 9R, Body Front End.

15. Install the right front wheel. Refer to Section 2E,

Tires and Wheels.

16. Install the air cleaner housing.

17. Install the air cleaner housing bolts.

Tighten

Tighten the air cleaner housing bolts to 10 NSm (89 lb–

in).

18. Connect the air cleaner outlet hose to the throttle

body.

19. Connect the breather tube to the camshaft cover.

20. Connect the MAT sensor connector.

21. Connect the negative battery cable.

Page 166 of 2643

1C2 – 46I1.8L DOHC ENGINE MECHANICAL

DAEWOO V–121 BL4

7. Install the timing belt automatic tensioner and bolt.

8. Install the camshaft gears. Refer to ”Camshaft

Gears” in this section.

9. Install the timing belt and timing belt cover. Refer to

”Timing Belt” in this section.

10. Connect the negative battery cable.

ENGINE

Removal Procedure

1. Remove the fuel pump fuse.

2. Start the engine. After it stalls, crank the engine for

10 seconds to rid the fuel system of fuel pressure.

3. Remove the hood. Refer to Section 9R, Body Front

End.

4. Drain the engine oil.

5. Disconnect the negative battery cable.

6. Discharge the air conditioning (A/C) system, if

equipped. Refer to Section 7B, Manual Control

Heating, Ventilation, and Air Conditioning Systems.

7. Disconnect the manifold air temperature (MAT)

sensor connector.

8. Remove the air cleaner outlet hose from the throttle

body and air cleaner housing.

9. Disconnect the breather tubes from the camshaft

cover.

10. Remove the right front wheel. Refer to Section 2E,

Tires and Wheels.

11. Remove the right front wheel well splash shield.

Refer to Section 9R, Body Font End.

12. Remove the serpentine accessory drive belt. Refer

to Section 6B, Power Steering Pump.

13. Drain the engine coolant. Refer to Section 1D, En-

gine Cooling.

14. Remove the cooling system radiator and the engine

cooling fans. Refer to Section 1D, Engine Cooling.

15. Disconnect the upper radiator hose from the ther-

mostat housing.

16. Disconnect the power steering return hose from the

power steering pump.

17. Disconnect the power steering pressure hose from

the power steering pump.

18. Disconnect the electrical connector at the direct

ignition system (DIS) coil and the electronic control

module (ECM) ground terminal and at the starter

motor.

Page 170 of 2643

1C2 – 50I1.8L DOHC ENGINE MECHANICAL

DAEWOO V–121 BL4

18. Install the exhaust flex pipe retaining nuts to the

catalytic converter or the connecting pipe.

Tighten

Tighten the exhaust flex pipe–to–catalytic converter

or connecting pipe retaining nuts to 35 NSm (26 lb–ft).

19. Connect the power steering pressure hose.

20. Connect the power steering return hose.

21. Install the A/C compressor, if equipped. Refer to

Section 7B, Manual Control Heating, Ventilation,

and Air Conditioning System.

22. Install the serpentine accessory drive belt. Refer to

Section 6B, Power Steering Pump.

23. Install the right front wheel well splash shield.

24. Install the right front wheel. Refer to Section 2E,

Tires and Wheels.

25. Connect the fuel feed line to the fuel rail.

26. Connect the fuel return line to fuel rail.

27. Install the fuel rail and injector channel cover as an

assembly. Refer to Section 1F, Engine Controls.

28. Connect all of the necessary vacuum lines including

the brake booster vacuum hose.

29. Connect the O2 sensor connector, if equipped.

30. Connect the starter solenoid ”S” terminal wire and

power lead.

31. Connect the generator voltage regulator connector.

32. Connect the CTS connector.

33. Connect the engine CTS connector.

34. Connect the TPS connector.

35. Connect the IAC valve connector.

36. Connect the MAP sensor connector.

37. Connect the knock sensor, if necessary

38. Connect the electrical connector at the DIS ignition

coil and the ECM ground terminal and at the starter

motor.

39. Install the air cleaner outlet hose between the

throttle body and the air cleaner housing.

40. Connect the breather tubes to the camshaft cover.

41. Connect the MAT sensor connector.

42. Install the cooling system radiator and the engine

cooling fans. Refer to Section 1D, Engine Cooling.

Page 902 of 2643

SECTION : 2A

SUSPENSION DIAGNOSIS

TABLE OF CONTENTS

DIAGNOSIS2A–1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Diagnosis 2A–1. . . . . . . . . . . . . . . . . . . . . . . . . Torque Steer 2A–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tapered Roller Bearing 2A–6. . . . . . . . . . . . . . . . . . . . .

DIAGNOSIS

GENERAL DIAGNOSIS

Problems in the steering, the suspension, the tires, and

the wheels involve several systems. Consider all systems

when diagnosing a complaint. Some problems, such as

abnormal or excessive tire wear and scuffed tires, may be

the result of hard driving. Always road test the vehicle first.If possible, do this road test with the customer.

Proceed with the following preliminary checks. Correct

any substandard conditions.

Preliminary Checks

ChecksAction

Inspect the tires for improper pressure and uneven wear.Inflate the tires to the proper pressure.

Inspect the joint from the steering column to the steering

gear for loose connections or wear.Tighten the intermediate shaft pinch bolts. Replace the in-

termediate shaft as needed.

Inspect the front and the rear suspension, the steering

gear, and the linkage for loose or damaged parts.Tighten the front and the rear suspension. Tighten the

steering gear mounting bracket bolts. Tighten the coupling

flange pinch bolts. Replace the front and the rear suspen-

sion as needed. Replace the steering gear as needed. Re-

place the intermediate shaft as needed.

Inspect for out–of–round tires.Perform a free runout test. Match–mount the tires.

Inspect for out–of–balance tires, bent wheels, and worn or

loose wheel bearings.Balance the wheels. Replace the wheels. Replace the

wheel bearings.

Check the power steering pump serpentine belt tension.Tighten the power steering pump serpentine belt.

Inspect the power steering system for leaks. Check the

power steering fluid level.Repair any leaks. Perform a power steering gear test. Add

power steering fluid.

Car Lead/Pull

ChecksAction

Inspect for mismatched or uneven tires.Replace the tires.

Inspect for a broken or a sagging spring.Replace the spring.

Inspect for a radial tire lateral force.Check the wheel alignment. Switch the wheels. Replace

the tires as needed.

Check the front–wheel alignment.Align the front wheels.

Inspect for an off–center steering gear.Reseat the pinion valve assembly. Replace the pinion

valve assembly as needed.

Inspect for front–brake dragging.Adjust the front brakes.

Page 903 of 2643

2A – 2ISUSPENSION DIAGNOSIS

DAEWOO V–121 BL4

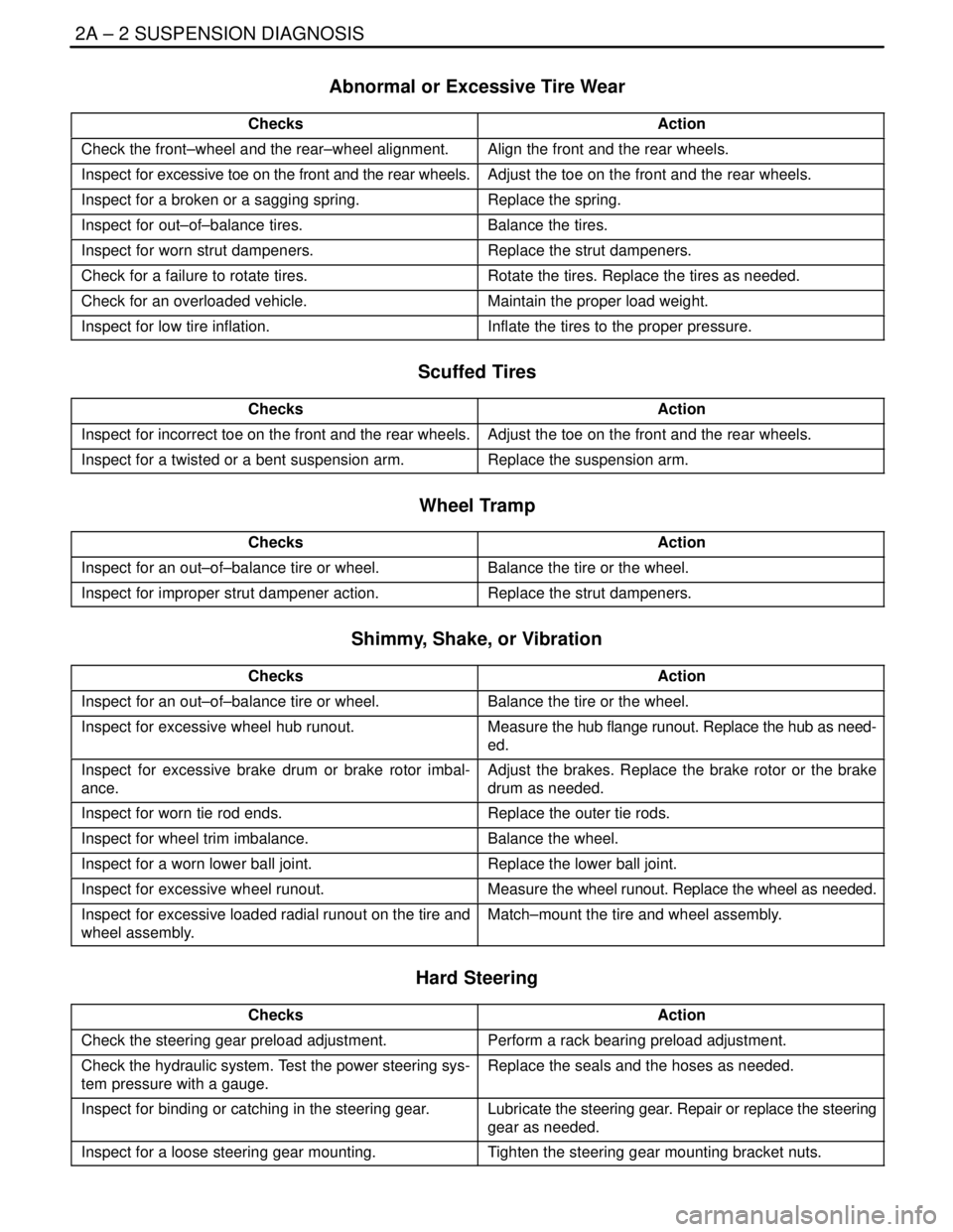

Abnormal or Excessive Tire Wear

ChecksAction

Check the front–wheel and the rear–wheel alignment.Align the front and the rear wheels.

Inspect for excessive toe on the front and the rear wheels.Adjust the toe on the front and the rear wheels.

Inspect for a broken or a sagging spring.Replace the spring.

Inspect for out–of–balance tires.Balance the tires.

Inspect for worn strut dampeners.Replace the strut dampeners.

Check for a failure to rotate tires.Rotate the tires. Replace the tires as needed.

Check for an overloaded vehicle.Maintain the proper load weight.

Inspect for low tire inflation.Inflate the tires to the proper pressure.

Scuffed Tires

ChecksAction

Inspect for incorrect toe on the front and the rear wheels.Adjust the toe on the front and the rear wheels.

Inspect for a twisted or a bent suspension arm.Replace the suspension arm.

Wheel Tramp

ChecksAction

Inspect for an out–of–balance tire or wheel.Balance the tire or the wheel.

Inspect for improper strut dampener action.Replace the strut dampeners.

Shimmy, Shake, or Vibration

ChecksAction

Inspect for an out–of–balance tire or wheel.Balance the tire or the wheel.

Inspect for excessive wheel hub runout.Measure the hub flange runout. Replace the hub as need-

ed.

Inspect for excessive brake drum or brake rotor imbal-

ance.Adjust the brakes. Replace the brake rotor or the brake

drum as needed.

Inspect for worn tie rod ends.Replace the outer tie rods.

Inspect for wheel trim imbalance.Balance the wheel.

Inspect for a worn lower ball joint.Replace the lower ball joint.

Inspect for excessive wheel runout.Measure the wheel runout. Replace the wheel as needed.

Inspect for excessive loaded radial runout on the tire and

wheel assembly.Match–mount the tire and wheel assembly.

Hard Steering

ChecksAction

Check the steering gear preload adjustment.Perform a rack bearing preload adjustment.

Check the hydraulic system. Test the power steering sys-

tem pressure with a gauge.Replace the seals and the hoses as needed.

Inspect for binding or catching in the steering gear.Lubricate the steering gear. Repair or replace the steering

gear as needed.

Inspect for a loose steering gear mounting.Tighten the steering gear mounting bracket nuts.

Page 904 of 2643

SUSPENSION DIAGNOSIS 2A – 3

DAEWOO V–121 BL4

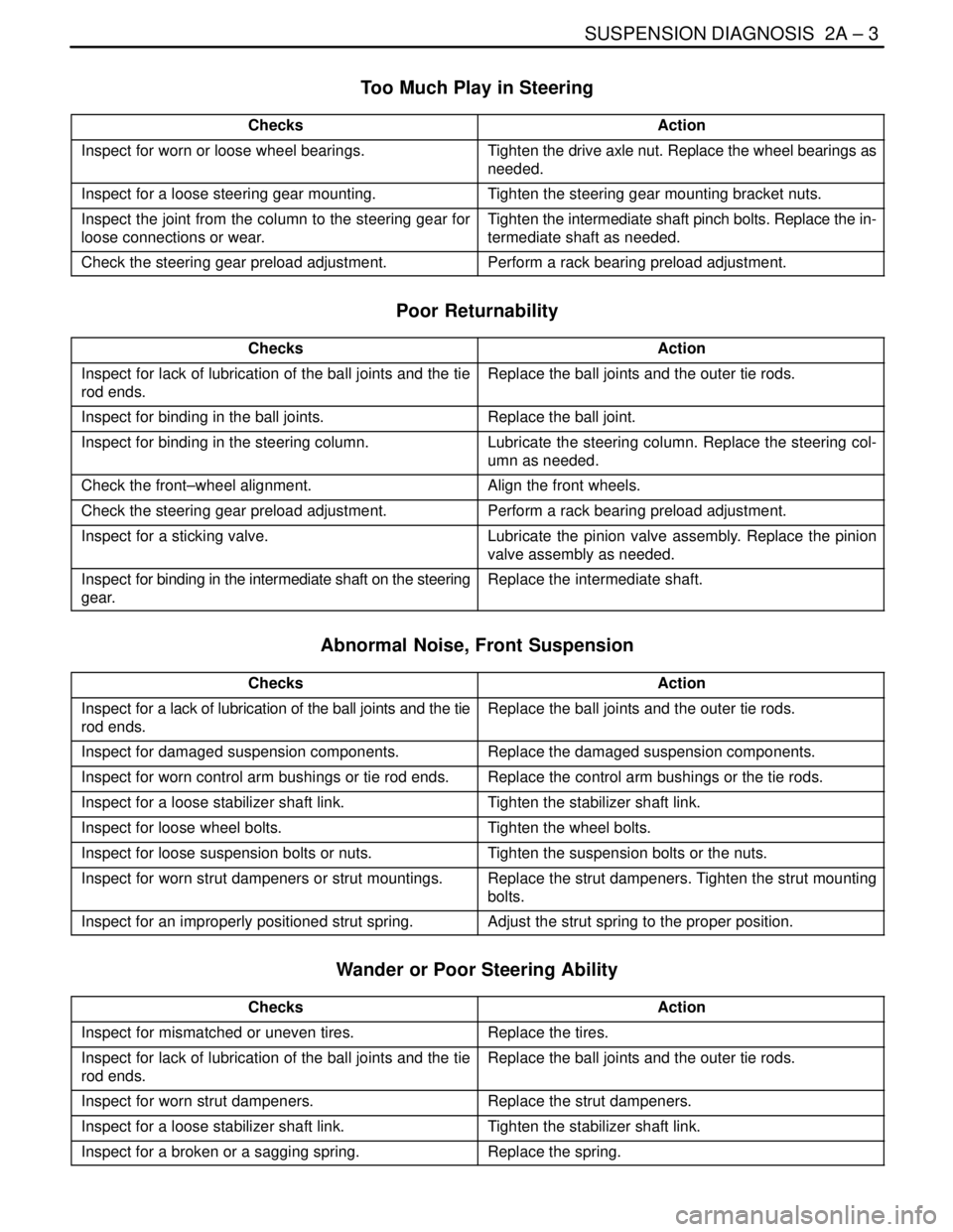

Too Much Play in Steering

ChecksAction

Inspect for worn or loose wheel bearings.Tighten the drive axle nut. Replace the wheel bearings as

needed.

Inspect for a loose steering gear mounting.Tighten the steering gear mounting bracket nuts.

Inspect the joint from the column to the steering gear for

loose connections or wear.Tighten the intermediate shaft pinch bolts. Replace the in-

termediate shaft as needed.

Check the steering gear preload adjustment.Perform a rack bearing preload adjustment.

Poor Returnability

ChecksAction

Inspect for lack of lubrication of the ball joints and the tie

rod ends.Replace the ball joints and the outer tie rods.

Inspect for binding in the ball joints.Replace the ball joint.

Inspect for binding in the steering column.Lubricate the steering column. Replace the steering col-

umn as needed.

Check the front–wheel alignment.Align the front wheels.

Check the steering gear preload adjustment.Perform a rack bearing preload adjustment.

Inspect for a sticking valve.Lubricate the pinion valve assembly. Replace the pinion

valve assembly as needed.

Inspect for binding in the intermediate shaft on the steering

gear.Replace the intermediate shaft.

Abnormal Noise, Front Suspension

ChecksAction

Inspect for a lack of lubrication of the ball joints and the tie

rod ends.Replace the ball joints and the outer tie rods.

Inspect for damaged suspension components.Replace the damaged suspension components.

Inspect for worn control arm bushings or tie rod ends.Replace the control arm bushings or the tie rods.

Inspect for a loose stabilizer shaft link.Tighten the stabilizer shaft link.

Inspect for loose wheel bolts.Tighten the wheel bolts.

Inspect for loose suspension bolts or nuts.Tighten the suspension bolts or the nuts.

Inspect for worn strut dampeners or strut mountings.Replace the strut dampeners. Tighten the strut mounting

bolts.

Inspect for an improperly positioned strut spring.Adjust the strut spring to the proper position.

Wander or Poor Steering Ability

ChecksAction

Inspect for mismatched or uneven tires.Replace the tires.

Inspect for lack of lubrication of the ball joints and the tie

rod ends.Replace the ball joints and the outer tie rods.

Inspect for worn strut dampeners.Replace the strut dampeners.

Inspect for a loose stabilizer shaft link.Tighten the stabilizer shaft link.

Inspect for a broken or a sagging spring.Replace the spring.

Page 905 of 2643

2A – 4ISUSPENSION DIAGNOSIS

DAEWOO V–121 BL4

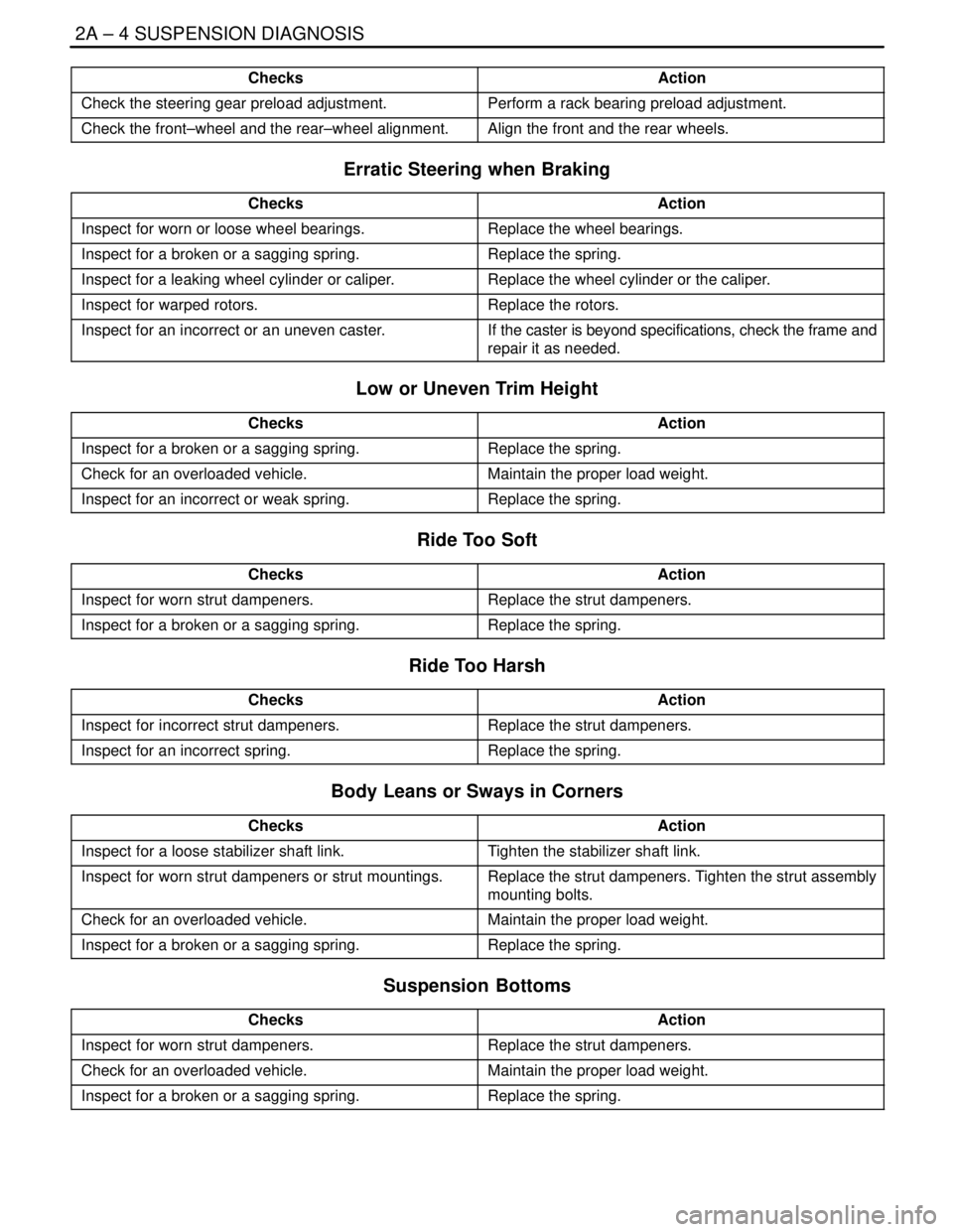

Checks Action

Check the steering gear preload adjustment.Perform a rack bearing preload adjustment.

Check the front–wheel and the rear–wheel alignment.Align the front and the rear wheels.

Erratic Steering when Braking

ChecksAction

Inspect for worn or loose wheel bearings.Replace the wheel bearings.

Inspect for a broken or a sagging spring.Replace the spring.

Inspect for a leaking wheel cylinder or caliper.Replace the wheel cylinder or the caliper.

Inspect for warped rotors.Replace the rotors.

Inspect for an incorrect or an uneven caster.If the caster is beyond specifications, check the frame and

repair it as needed.

Low or Uneven Trim Height

ChecksAction

Inspect for a broken or a sagging spring.Replace the spring.

Check for an overloaded vehicle.Maintain the proper load weight.

Inspect for an incorrect or weak spring.Replace the spring.

Ride Too Soft

ChecksAction

Inspect for worn strut dampeners.Replace the strut dampeners.

Inspect for a broken or a sagging spring.Replace the spring.

Ride Too Harsh

ChecksAction

Inspect for incorrect strut dampeners.Replace the strut dampeners.

Inspect for an incorrect spring.Replace the spring.

Body Leans or Sways in Corners

ChecksAction

Inspect for a loose stabilizer shaft link.Tighten the stabilizer shaft link.

Inspect for worn strut dampeners or strut mountings.Replace the strut dampeners. Tighten the strut assembly

mounting bolts.

Check for an overloaded vehicle.Maintain the proper load weight.

Inspect for a broken or a sagging spring.Replace the spring.

Suspension Bottoms

ChecksAction

Inspect for worn strut dampeners.Replace the strut dampeners.

Check for an overloaded vehicle.Maintain the proper load weight.

Inspect for a broken or a sagging spring.Replace the spring.

Page 906 of 2643

SUSPENSION DIAGNOSIS 2A – 5

DAEWOO V–121 BL4

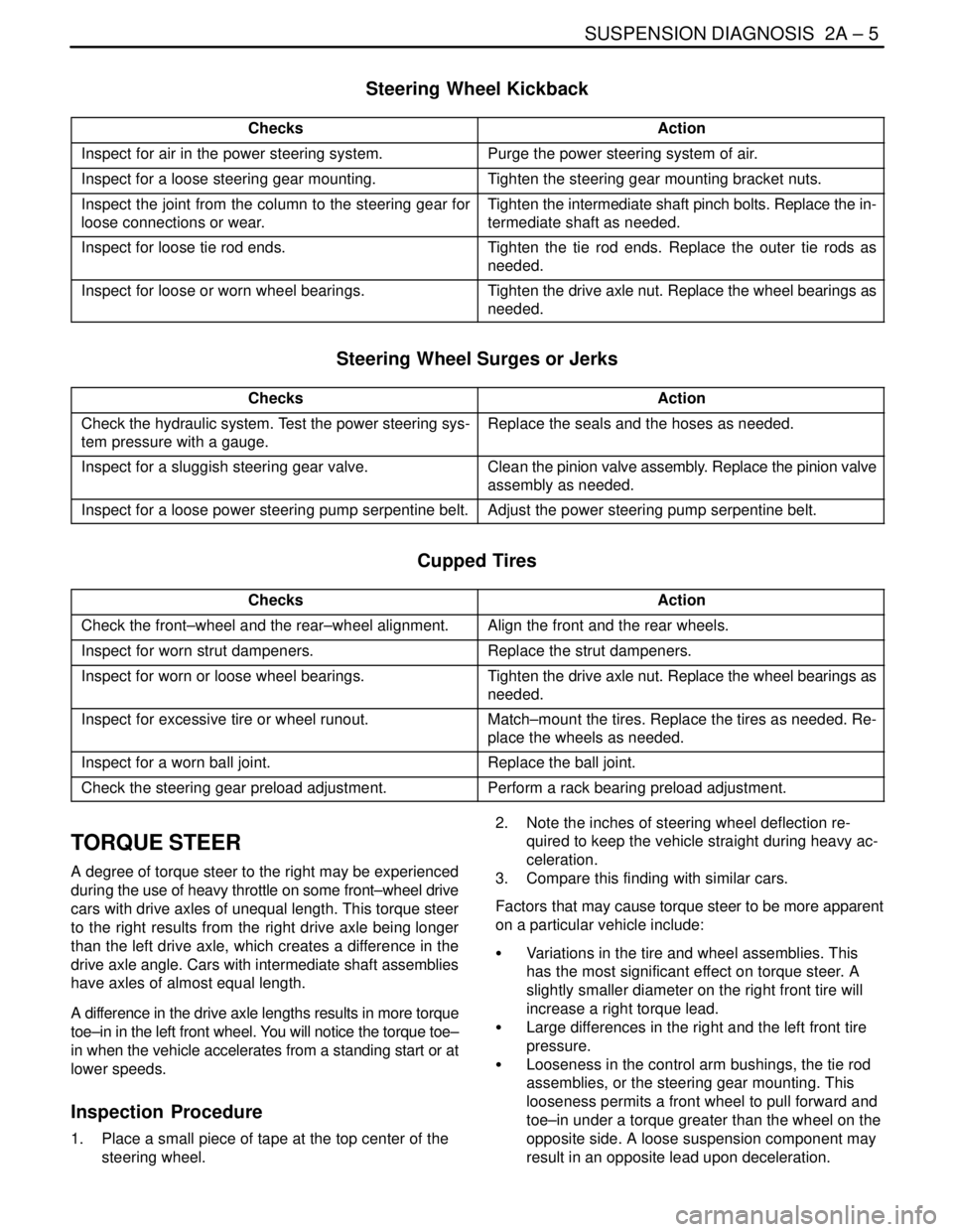

Steering Wheel Kickback

ChecksAction

Inspect for air in the power steering system.Purge the power steering system of air.

Inspect for a loose steering gear mounting.Tighten the steering gear mounting bracket nuts.

Inspect the joint from the column to the steering gear for

loose connections or wear.Tighten the intermediate shaft pinch bolts. Replace the in-

termediate shaft as needed.

Inspect for loose tie rod ends.Tighten the tie rod ends. Replace the outer tie rods as

needed.

Inspect for loose or worn wheel bearings.Tighten the drive axle nut. Replace the wheel bearings as

needed.

Steering Wheel Surges or Jerks

ChecksAction

Check the hydraulic system. Test the power steering sys-

tem pressure with a gauge.Replace the seals and the hoses as needed.

Inspect for a sluggish steering gear valve.Clean the pinion valve assembly. Replace the pinion valve

assembly as needed.

Inspect for a loose power steering pump serpentine belt.Adjust the power steering pump serpentine belt.

Cupped Tires

ChecksAction

Check the front–wheel and the rear–wheel alignment.Align the front and the rear wheels.

Inspect for worn strut dampeners.Replace the strut dampeners.

Inspect for worn or loose wheel bearings.Tighten the drive axle nut. Replace the wheel bearings as

needed.

Inspect for excessive tire or wheel runout.Match–mount the tires. Replace the tires as needed. Re-

place the wheels as needed.

Inspect for a worn ball joint.Replace the ball joint.

Check the steering gear preload adjustment.Perform a rack bearing preload adjustment.

TORQUE STEER

A degree of torque steer to the right may be experienced

during the use of heavy throttle on some front–wheel drive

cars with drive axles of unequal length. This torque steer

to the right results from the right drive axle being longer

than the left drive axle, which creates a difference in the

drive axle angle. Cars with intermediate shaft assemblies

have axles of almost equal length.

A difference in the drive axle lengths results in more torque

toe–in in the left front wheel. You will notice the torque toe–

in when the vehicle accelerates from a standing start or at

lower speeds.

Inspection Procedure

1. Place a small piece of tape at the top center of the

steering wheel.2. Note the inches of steering wheel deflection re-

quired to keep the vehicle straight during heavy ac-

celeration.

3. Compare this finding with similar cars.

Factors that may cause torque steer to be more apparent

on a particular vehicle include:

S Variations in the tire and wheel assemblies. This

has the most significant effect on torque steer. A

slightly smaller diameter on the right front tire will

increase a right torque lead.

S Large differences in the right and the left front tire

pressure.

S Looseness in the control arm bushings, the tie rod

assemblies, or the steering gear mounting. This

looseness permits a front wheel to pull forward and

toe–in under a torque greater than the wheel on the

opposite side. A loose suspension component may

result in an opposite lead upon deceleration.

Page 908 of 2643

SECTION : 2B

WHEEL ALIGNMENT

TABLE OF CONTENTS

SPECIFICATIONS2B–1 . . . . . . . . . . . . . . . . . . . . . . . . . .

Wheel Alignment Specifications 2B–1. . . . . . . . . . . . . .

Fastener Tightening Specifications 2B–1. . . . . . . . . . .

DIAGNOSIS2B–2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tire Diagnosis 2B–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Radial Tire Lead/Pull 2B–3. . . . . . . . . . . . . . . . . . . . . . .

Vibration Diagnosis 2B–5. . . . . . . . . . . . . . . . . . . . . . . .

Preliminary Inspection 2B–8. . . . . . . . . . . . . . . . . . . . . .

Front Toe Adjustment 2B–8. . . . . . . . . . . . . . . . . . . . . .

Front Camber and Caster Check 2B–8. . . . . . . . . . . . .

Rear Camber Check 2B–8. . . . . . . . . . . . . . . . . . . . . . . Rear Toe Adjustment 2B–9. . . . . . . . . . . . . . . . . . . . . . .

GENERAL DESCRIPTION AND SYSTEM

OPERATION2B–10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Four Wheel Alignment 2B–10. . . . . . . . . . . . . . . . . . . . .

Toe 2B–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Caster 2B–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Camber 2B–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Steering Axis Inclination 2B–10. . . . . . . . . . . . . . . . . . .

Included Angle 2B–10. . . . . . . . . . . . . . . . . . . . . . . . . . .

Scrub Radius 2B–10. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setback 2B–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Turning Angle 2B–10. . . . . . . . . . . . . . . . . . . . . . . . . . . .

SPECIFICATIONS

WHEEL ALIGNMENT SPECIFICATIONS

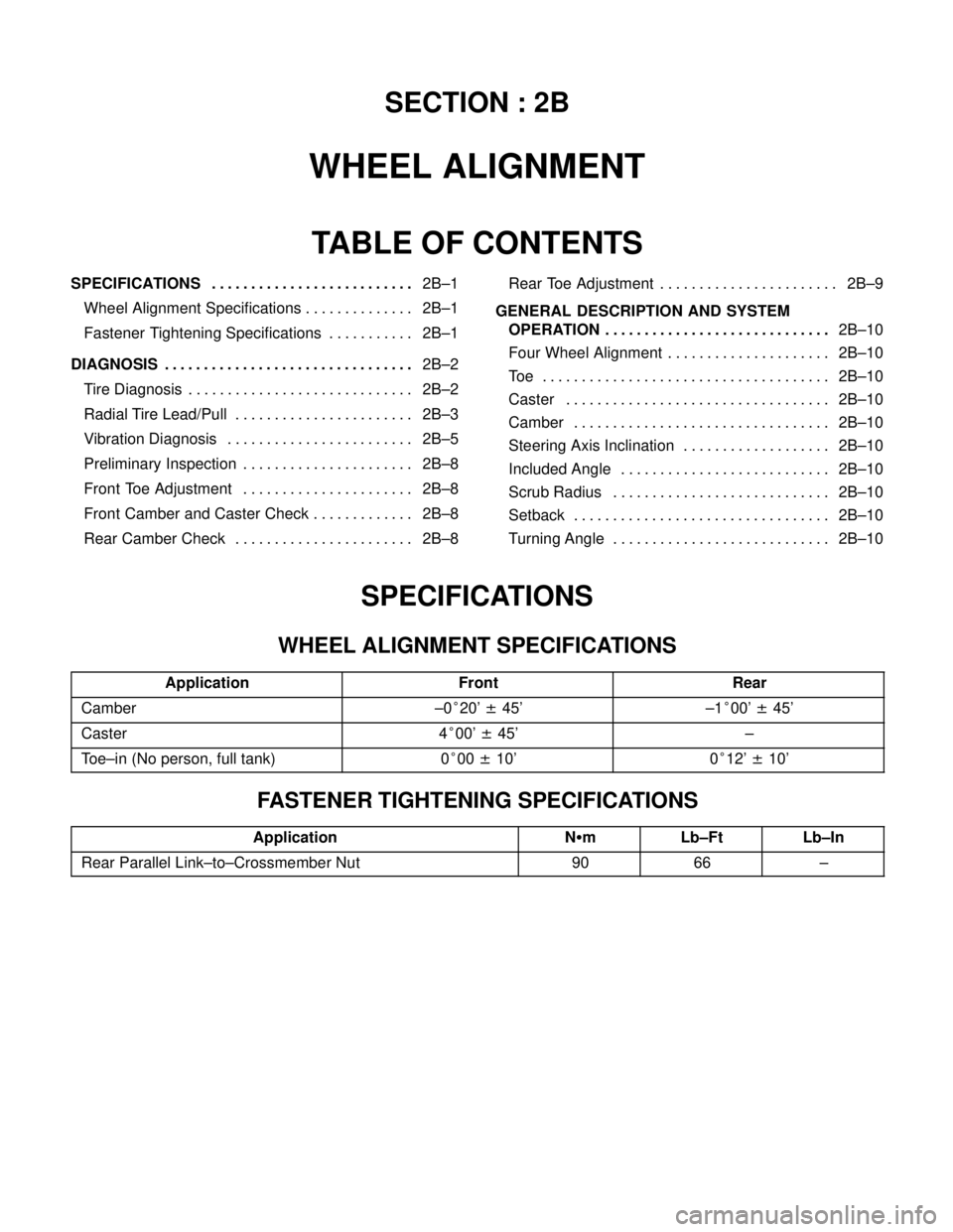

ApplicationFrontRear

Camber–0°20’ ± 45’–1°00’ ± 45’

Caster4°00’ ± 45’–

Toe–in (No person, full tank)0°00 ± 10’0°12’ ± 10’

FASTENER TIGHTENING SPECIFICATIONS

ApplicationNSmLb–FtLb–In

Rear Parallel Link–to–Crossmember Nut9066–

Page 910 of 2643

WHEEL ALIGNMENT 2B – 3

DAEWOO V–121 BL4

4. Install original tires one at a time to find the offend-

ing tire.

RADIAL TIRE LEAD/PULL

Lead/pull is the deviation of the vehicle from a straight pathon a level road with no pressure on the steering wheel.

Lead is usually caused by:

S Incorrect alignment.

S Uneven brake adjustment.

S Tire construction.

The way in which a tire is built can produce lead/pull in the

vehicle. Off–center belts on radial tires can cause the tire

to develop a side force while the vehicle rolls straight down

the road. If one side of the tire has even a little larger diam-

eter than the diameter of the other side, the tire will tend

to roll to one side. Unequal diameters will cause the tire to

develop a side force which can produce vehicle lead/pull.

The radial lead/pull diagnosis chart should be used to de-

termine whether the problem originates from an alignment

problem or from the tires. Part of the lead diagnosis proce-

dure calls for tire rotation that is different from the proper

tire rotation pattern. If a medium– to high–mileage tire is

moved to the other side of the vehicle, be sure to check for

ride roughness. Rear tires will not cause lead/pull.