wheel alignment DAEWOO NUBIRA 2004 Service Owner's Manual

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: NUBIRA, Model: DAEWOO NUBIRA 2004Pages: 2643, PDF Size: 80.54 MB

Page 917 of 2643

2B – 10IWHEEL ALIGNMENT

DAEWOO V–121 BL4

GENERAL DESCRIPTION

AND SYSTEM OPERATION

FOUR WHEEL ALIGNMENT

The first responsibility of engineering is to design safe

steering and suspension systems. Each component must

be strong enough to withstand and absorb extreme pun-

ishment. Both the steering system and the front and the

rear suspension must function geometrically with the body

mass.

The steering and the suspension systems require that the

front wheels self–return and that the tire rolling effort and

the road friction be held to a negligible force in order to al-

low the customer to direct the vehicle with the least effort

and the most comfort.

A complete wheel alignment check should include mea-

surements of the rear toe and camber.

Four–wheel alignment assures that all four wheels will be

running in precisely the same direction.

When the vehicle is geometrically aligned, fuel economy

and tire life are at their peak, and steering and perfor-

mance are maximized.

TOE

Toe–in is the turning in of the tires, while toe–out is the

turning out of the tires from the geometric centerline or

thrust line. The toe ensures parallel rolling of the wheels.

The toe serves to offset the small deflections of the wheel

support system which occur when the vehicle is rolling for-

ward. The specified toe angle is the setting which achieves

0 degrees of toe when the vehicle is moving.

Incorrect toe–in or toe–out will cause tire wear and re-

duced fuel economy. As the individual steering and sus-

pension components wear from vehicle mileage, addition-

al toe will be needed to compensate for the wear.

Always correct the toe dimension last.

CASTER

Caster is the tilting of the uppermost point of the steering

axis either forward or backward from the vertical when

viewed from the side of the vehicle. A backward tilt is posi-

tive, and a forward tilt is negative. Caster influences direc-

tional control of the steering but does not affect tire wear.

Weak springs or overloading a vehicle will affect caster.

One wheel with more positive caster will pull toward the

center of the car. This condition will cause the car to move

or lean toward the side with the least amount of positive

caster. Caster is measured in degrees and is not adjust-

able.

CAMBER

Camber is the tilting of the top of the tire from the vertical

when viewed from the front of the vehicle. When the tires

tilt outward, the camber is positive. When the tires tilt in-

ward, the camber is negative. The camber angle is mea-

sured in degrees from the vertical. Camber influences

both directional control and tire wear.

If the vehicle has too much positive camber, the outside

shoulder of the tire will wear. If the vehicle has too much

negative camber, the inside shoulder of the tire will wear.

Camber is not adjustable.

STEERING AXIS INCLINATION

Steering Axis Inclination (SAI) is the tilt at the top of the

steering knuckle from the vertical. Measure the SAI angle

from the true vertical to a line through the center of the strut

and the lower ball joint as viewed from the front of the ve-

hicle.

SAI helps the vehicle track straight down the road and as-

sists the wheel back into the straight ahead position. SAI

on front wheel drive vehicles should be negative.

INCLUDED ANGLE

The included angle is the angle measured from the cam-

ber angle to the line through the center of the strut and the

lower ball joint as viewed from the front of the vehicle.

The included angle is calculated in degrees. Most align-

ment racks will not measure the included angle directly. To

determine the included angle, subtract the negative or add

the positive camber readings to the Steering Axis Inclina-

tion (SAI).

SCRUB RADIUS

The scrub radius is the distance between true vertical and

the line through the center of the strut and lower ball joint

to the road surface. Scrub radius is built into the design of

the vehicle. Scrub radius is not adjustable.

SETBACK

The setback is the distance in which one front hub and

bearing assembly may be rearward of the other front hub

and bearing assembly. Setback is primarily caused by a

road hazard or vehicle collision.

TURNING ANGLE

The turning angle is the angle of each front wheel to the

vertical when the vehicle is making a turn.

Page 954 of 2643

2D – 12IREAR SUSPENSION

DAEWOO V–121 BL4

2. Install the trailing link bracket–to–body bolts.

Tighten

Tighten the trailing link bracket–to–body bolts to 70

NSm (52 lb–ft).

3. Connect the trailing link to the trailing link bracket

by installing the trailing link–to–trailing link bracket

nut and bolt.

Tighten

Tighten the trailing link–to–trailing link bracket nut to

100 NSm (74 lb–ft).

4. Lower the vehicle.

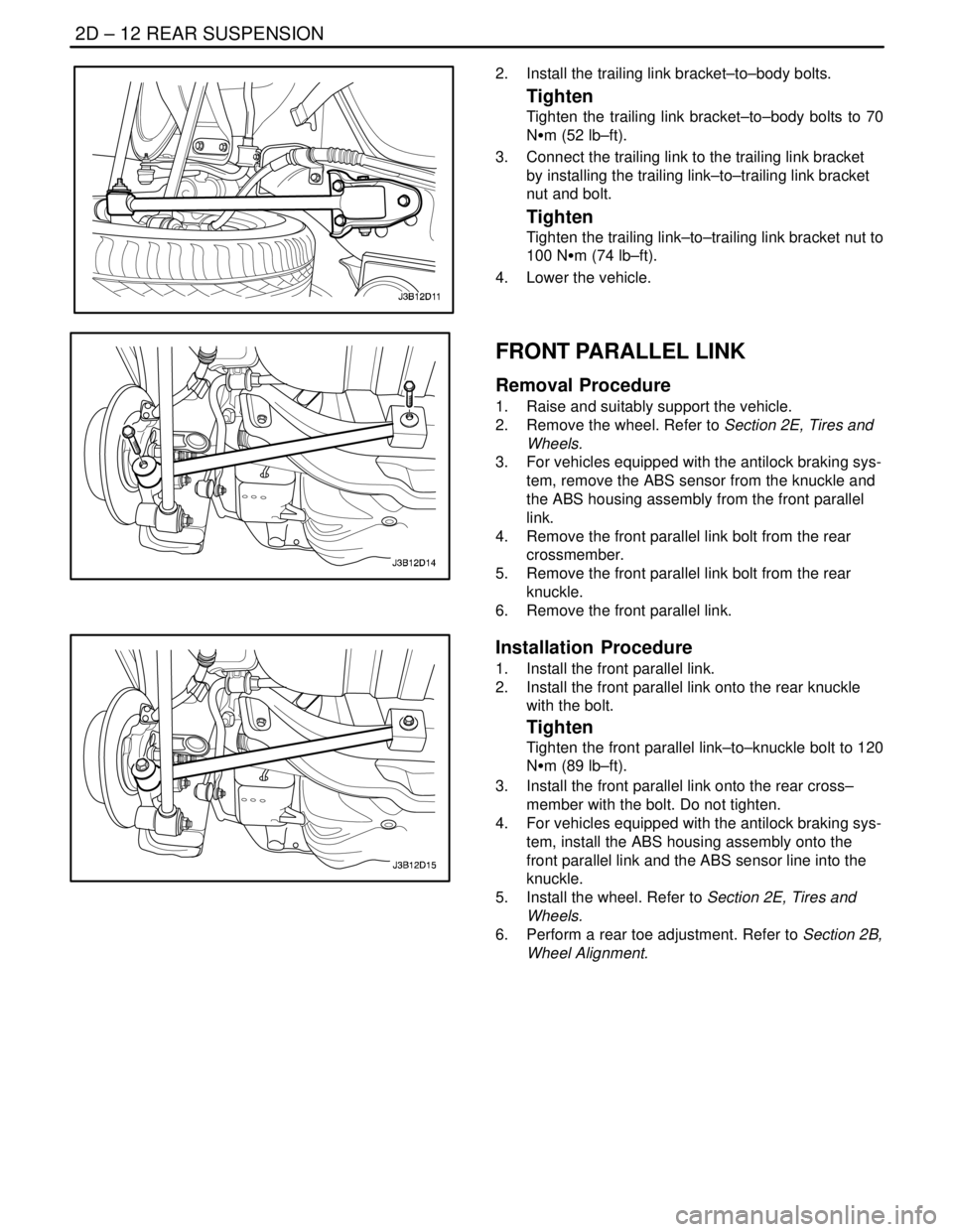

FRONT PARALLEL LINK

Removal Procedure

1. Raise and suitably support the vehicle.

2. Remove the wheel. Refer to Section 2E, Tires and

Wheels.

3. For vehicles equipped with the antilock braking sys-

tem, remove the ABS sensor from the knuckle and

the ABS housing assembly from the front parallel

link.

4. Remove the front parallel link bolt from the rear

crossmember.

5. Remove the front parallel link bolt from the rear

knuckle.

6. Remove the front parallel link.

Installation Procedure

1. Install the front parallel link.

2. Install the front parallel link onto the rear knuckle

with the bolt.

Tighten

Tighten the front parallel link–to–knuckle bolt to 120

NSm (89 lb–ft).

3. Install the front parallel link onto the rear cross–

member with the bolt. Do not tighten.

4. For vehicles equipped with the antilock braking sys-

tem, install the ABS housing assembly onto the

front parallel link and the ABS sensor line into the

knuckle.

5. Install the wheel. Refer to Section 2E, Tires and

Wheels.

6. Perform a rear toe adjustment. Refer to Section 2B,

Wheel Alignment.

Page 1021 of 2643

HYDRAULIC BRAKES 4A – 5

DAEWOO V–121 BL4

DIAGNOSIS

BRAKE SYSTEM TESTING

Brakes should be tested on a dry, clean, reasonably

smooth and level roadway. A true test of brake perfor-

mance cannot be made if the roadway is wet, greasy, or

covered with loose dirt whereby all tires do not grip the

road equally. Testing will also be adversely affected if the

roadway is crowned so as to throw the weight so roughly

that the wheels tend to bounce.

Test the brakes at different vehicle speeds with both light

and heavy pedal pressure; however, avoid locking the

brakes and sliding the tires. Locked brakes and sliding

tires do not indicate brake efficiency since heavily braked,

but turning, wheels will stop the vehicle in less distance

than locked brakes. More tire–to–road friction is present

with a heavily–braked, turning tire than with a sliding tire.

Because of the high deceleration capability, a firmer pedal

may be felt at higher deceleration levels.

There are three major external conditions that affect brake

performance:

S Tires having unequal contact and grip of the road

will cause unequal braking. Tires must be equally

inflated, and the tread pattern of the right and the

left tires must be approximately equal.

S Unequal loading of the vehicle can affect the brake

performance since the most heavily loaded wheels

require more braking power, and thus more braking

effort, than the others.

S Misalignment of the wheels, particularly conditions

of excessive camber and caster, will cause the

brakes to pull to one side.

To check for brake fluid leaks, hold constant foot pressure

on the pedal with the engine running at idle and the shift

lever in NEUTRAL. If the pedal gradually falls away with

the constant pressure, the hydraulic system may be leak-

ing. Perform a visual check to confirm any suspected

leaks.

Check the master cylinder fluid level. While a slight drop

in the reservoir level results from normal lining wear, an ab-

normally low level indicates a leak in the system. The hy-

draulic system may be leaking either internally or external-

ly. Refer to the procedure below to check the master

cylinder. Also, the system may appear to pass this test

while still having a slight leak. If the fluid level is normal,

check the vacuum booster pushrod length. If an incorrect

pushrod length is found, adjust or replace the rod.

Check the master cylinder using the following procedure:

S Check for a cracked master cylinder casting or

brake fluid leaking around the master cylinder.

Leaks are indicated only if there is at least one drop

of fluid. A damp condition is not abnormal.S Check for a binding pedal linkage and for an incor-

rect pushrod length. If both of these parts are in

satisfactory condition, disassemble the master cyl-

inder and check for an elongated or swollen primary

cylinder or piston seals. If swollen seals are found,

substandard or contaminated brake fluid should be

suspected. If contaminated brake fluid is found, all

the components should be disassembled and

cleaned, and all the rubber components should be

replaced. All of the pipes must also be flushed.

Improper brake fluid, or mineral oil or water in the fluid,

may cause the brake fluid to boil or cause deterioration of

the rubber components. If the primary piston cups in the

master cylinder are swollen, then the rubber parts have

deteriorated. This deterioration may also be evidenced by

swollen wheel cylinder piston seals on the drum brake

wheels.

If deterioration of rubber is evident, disassemble all the hy-

draulic parts and wash the parts with alcohol. Dry these

parts with compressed air before reassembly to keep alco-

hol out of the system. Replace all the rubber parts in the

system, including the hoses. Also, when working on the

brake mechanisms, check for fluid on the linings. If exces-

sive fluid is found, replace the linings.

If the master cylinder piston seals are in satisfactory condi-

tion, check for leaks or excessive heat conditions. If these

conditions are not found, drain the fluid, flush the master

cylinder with brake fluid, refill the master cylinder, and

bleed the system. Refer to ”Manual Bleeding the Brakes”

or”Pressure Bleeding the Brakes” in this section.

BRAKE HOSE INSPECTION

The hydraulic brake hoses should be inspected at least

twice a year. The brake hose assembly should be checked

for road hazard damage, cracks, chafing of the outer cov-

er, and for leaks or blisters. Inspect the hoses for proper

routing and mounting. A brake hose that rubs on a suspen-

sion component will wear and eventually fail. A light and

a mirror may be needed for an adequate inspection. If any

of the above conditions are observed on the brake hose,

adjust or replace the hose as necessary.

WARNING LAMP OPERATION

This brake system uses a BRAKE warning lamp located

in the instrument panel cluster. When the ignition switch

is in the START position, the BRAKE warning lamp should

glow and go OFF when the ignition switch returns to the

RUN position.

The following conditions will activate the BRAKE lamp:

S Parking brake applied. The light should be ON

whenever the parking brake is applied and the igni-

tion switch is ON.

S Low fluid level. A low fluid level in the master cylin-

der will turn the BRAKE lamp ON.

S EBD system is disabled. The light should be ON

when the EBD system is malfunctioning.

Page 1829 of 2643

FIVE–SPEED MANUAL TRANSAXLE 5B – 5

DAEWOO V–121 BL4

DIAGNOSIS

ISOLATE NOISE

Identify the cause of any noise before attempting to repair

the clutch, the transaxle, or their related link–ages.

Symptoms of trouble with the clutch or the manual trans-

axle include:

S A great effort required to shift gears.

S The sound of gears clashing and grinding.

S Gear blockout.

Any of these conditions requires a careful analysis. Make

the following checks before disassembling the clutch or

the transaxle for repairs.

Road Travel Noise

Many noises that appear to come from the transaxle may

actually originate with other sources such as the:

S Tires.

S Road surfaces.

S Wheel bearings.

S Engine.

S Exhaust system.

These noises may vary according to the:

S Size of the vehicle.

S Type of the vehicle.

S Amount of insulation used in the body of the ve-

hicle.

Transaxle Noise

Transaxle gears, like any mechanical device, are not ab-

solutely quiet and will make some noise during normal op-

eration.

To verify suspected transaxle noises:

1. Select a smooth, level asphalt road to reduce tire

and resonant body noise.

2. Drive the vehicle far enough to warm up all the lu-

bricants thoroughly.

3. Record the speed and the gear range of the trans-

axle when the noise occurs.

4. Check for noises with the vehicle stopped, but with

the engine running.

5. Determine if the noise occurs while the vehicle op-

erates in:

S Drive – under a light acceleration or a heavy

pull.

S Float – maintaining a constant speed with a light

throttle on a level road.

S Coast – with the transaxle in gear and the

throttle partly or fully closed.

S All of the above.

Bearing Noise

Differential Side Bearing Noise

Differential side bearing noise and wheel bearing noise

can be confused easily. Since side bearings are pre–

loaded, a differential side bearing noise should not dimin-

ish much when the differential/transaxle is run with the

wheels off the ground.

Wheel Bearing Noise

Wheel bearings produce a rough growl or grating sound

that will continue when the vehicle is coasting and the

transaxle is in NEUTRAL. Since wheel bearings are not

pre–loaded, a wheel bearing noise should diminish con-

siderably when the wheels are off the ground.

Other Noise

Brinelling

A brinelled bearing causes a ”knock” or ”click” approxi-

mately every second revolution of the wheel because the

bearing rollers do not travel at the same speed as the

wheel. In operation, the effect is characterized by a low–

pitched noise.

A brinelled bearing is caused by excessive thrust which

pushes the balls up on the pathway and creates a triangu-

lar–shaped spot in the bearing race. A brinelled bearing

can also be caused from pressing one race into position

by applying pressure on the other race.

A false indication of a brinelled bearing occurs as a result

of vibration near the area where the bearing is mounted.

Brinelling is identified by slight indentations, resulting in a

washboard effect in the bearing race.

Lapping

Lapped bearing noise occurs when fine particles of abra-

sive materials such as scale, sand, or emery circulate

through the oil in the vehicle, causing the surfaces of the

roller and the race to wear away. Bearings that wear loose

but remain smooth, without spalling or pitting, are the re-

sult of dirty oil.

Locking

Large particles of foreign material wedged between the

roller and the race usually causes one of the races to turn,

creating noise from a locked bearing. Pre–loading regular

taper roller bearings to a value higher than that specified

also can result in locked bearings

Pitting

Pitting on the rolling surface comes from normal wear and

the introduction of foreign materials.

Spalling

Spalled bearings have flaked or pitted rollers or races

caused by an overload or an incorrect assembly that re-

sults in a misalignment, a cocking of bearings, or adjust-

ments that are too tight.

After completing these checks, refer to the ”Diagnosis

Chart” in this section.

Page 1920 of 2643

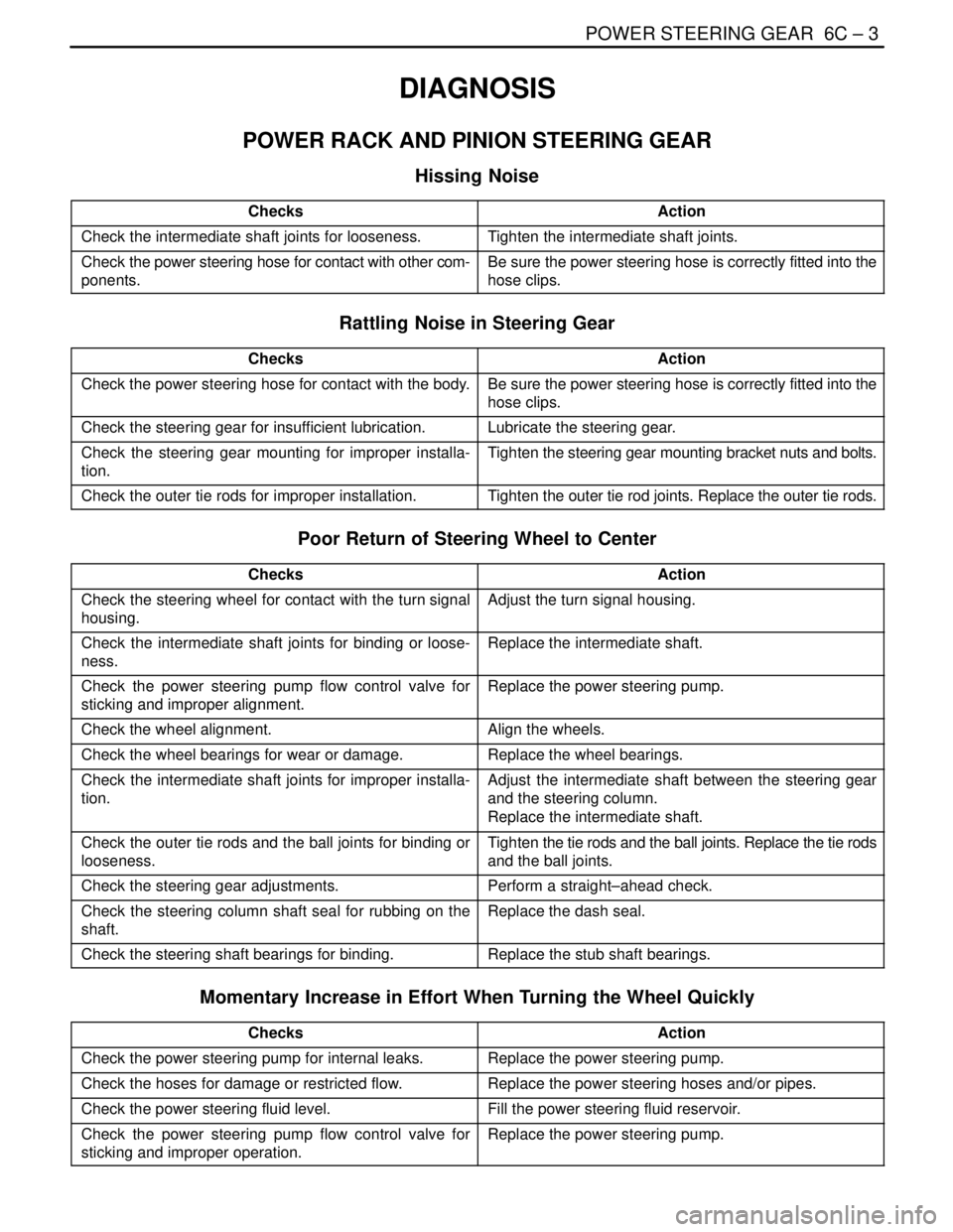

POWER STEERING GEAR 6C – 3

DAEWOO V–121 BL4

DIAGNOSIS

POWER RACK AND PINION STEERING GEAR

Hissing Noise

ChecksAction

Check the intermediate shaft joints for looseness.Tighten the intermediate shaft joints.

Check the power steering hose for contact with other com-

ponents.Be sure the power steering hose is correctly fitted into the

hose clips.

Rattling Noise in Steering Gear

ChecksAction

Check the power steering hose for contact with the body.Be sure the power steering hose is correctly fitted into the

hose clips.

Check the steering gear for insufficient lubrication.Lubricate the steering gear.

Check the steering gear mounting for improper installa-

tion.Tighten the steering gear mounting bracket nuts and bolts.

Check the outer tie rods for improper installation.Tighten the outer tie rod joints. Replace the outer tie rods.

Poor Return of Steering Wheel to Center

ChecksAction

Check the steering wheel for contact with the turn signal

housing.Adjust the turn signal housing.

Check the intermediate shaft joints for binding or loose-

ness.Replace the intermediate shaft.

Check the power steering pump flow control valve for

sticking and improper alignment.Replace the power steering pump.

Check the wheel alignment.Align the wheels.

Check the wheel bearings for wear or damage.Replace the wheel bearings.

Check the intermediate shaft joints for improper installa-

tion.Adjust the intermediate shaft between the steering gear

and the steering column.

Replace the intermediate shaft.

Check the outer tie rods and the ball joints for binding or

looseness.Tighten the tie rods and the ball joints. Replace the tie rods

and the ball joints.

Check the steering gear adjustments.Perform a straight–ahead check.

Check the steering column shaft seal for rubbing on the

shaft.Replace the dash seal.

Check the steering shaft bearings for binding.Replace the stub shaft bearings.

Momentary Increase in Effort When Turning the Wheel Quickly

ChecksAction

Check the power steering pump for internal leaks.Replace the power steering pump.

Check the hoses for damage or restricted flow.Replace the power steering hoses and/or pipes.

Check the power steering fluid level.Fill the power steering fluid reservoir.

Check the power steering pump flow control valve for

sticking and improper operation.Replace the power steering pump.

Page 1931 of 2643

6C – 14IPOWER STEERING GEAR

DAEWOO V–121 BL4

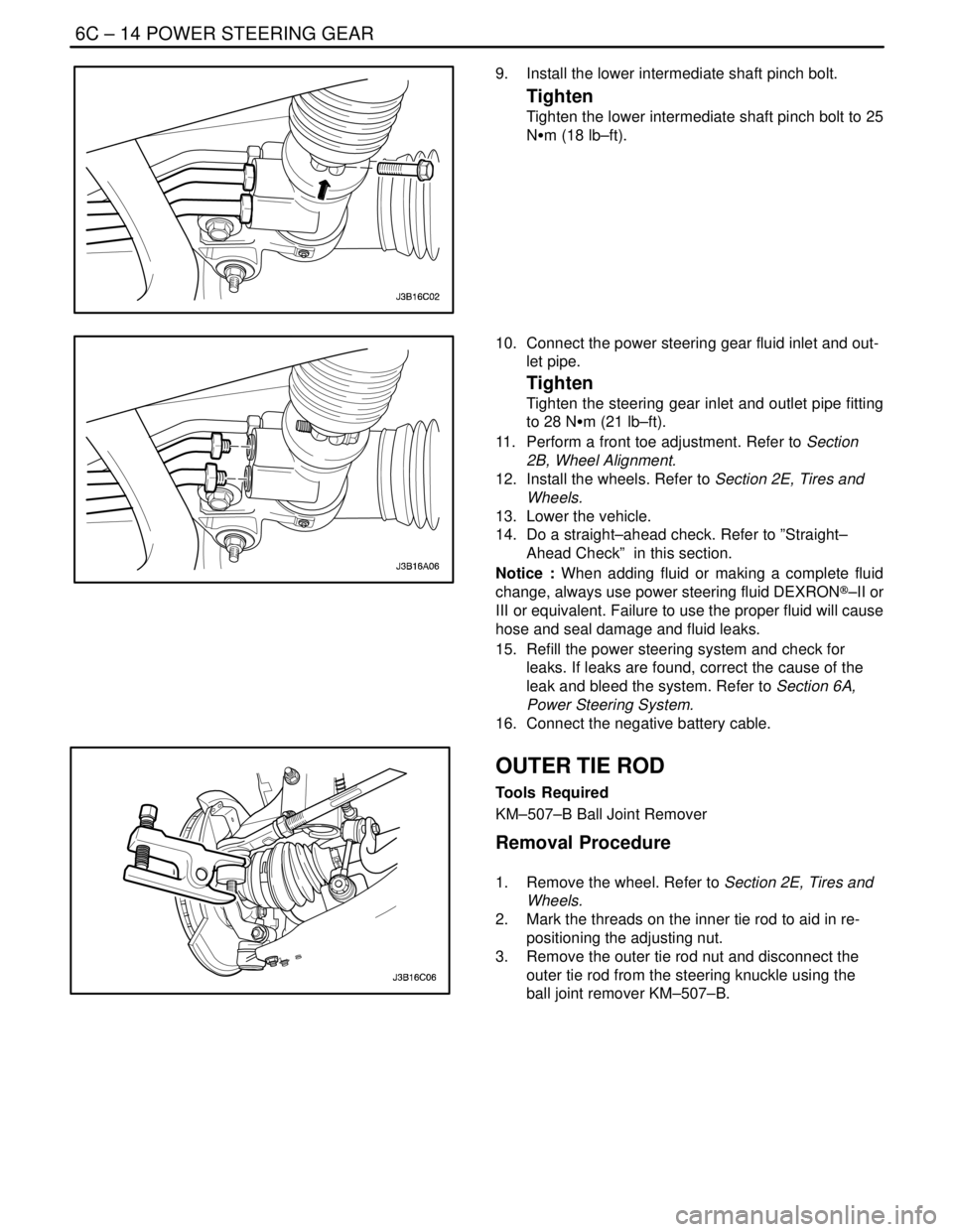

9. Install the lower intermediate shaft pinch bolt.

Tighten

Tighten the lower intermediate shaft pinch bolt to 25

NSm (18 lb–ft).

10. Connect the power steering gear fluid inlet and out-

let pipe.

Tighten

Tighten the steering gear inlet and outlet pipe fitting

to 28 NSm (21 lb–ft).

11. Perform a front toe adjustment. Refer to Section

2B, Wheel Alignment.

12. Install the wheels. Refer to Section 2E, Tires and

Wheels.

13. Lower the vehicle.

14. Do a straight–ahead check. Refer to ”Straight–

Ahead Check” in this section.

Notice : When adding fluid or making a complete fluid

change, always use power steering fluid DEXRON®–II or

III or equivalent. Failure to use the proper fluid will cause

hose and seal damage and fluid leaks.

15. Refill the power steering system and check for

leaks. If leaks are found, correct the cause of the

leak and bleed the system. Refer to Section 6A,

Power Steering System.

16. Connect the negative battery cable.

OUTER TIE ROD

Tools Required

KM–507–B Ball Joint Remover

Removal Procedure

1. Remove the wheel. Refer to Section 2E, Tires and

Wheels.

2. Mark the threads on the inner tie rod to aid in re-

positioning the adjusting nut.

3. Remove the outer tie rod nut and disconnect the

outer tie rod from the steering knuckle using the

ball joint remover KM–507–B.

Page 1932 of 2643

POWER STEERING GEAR 6C – 15

DAEWOO V–121 BL4

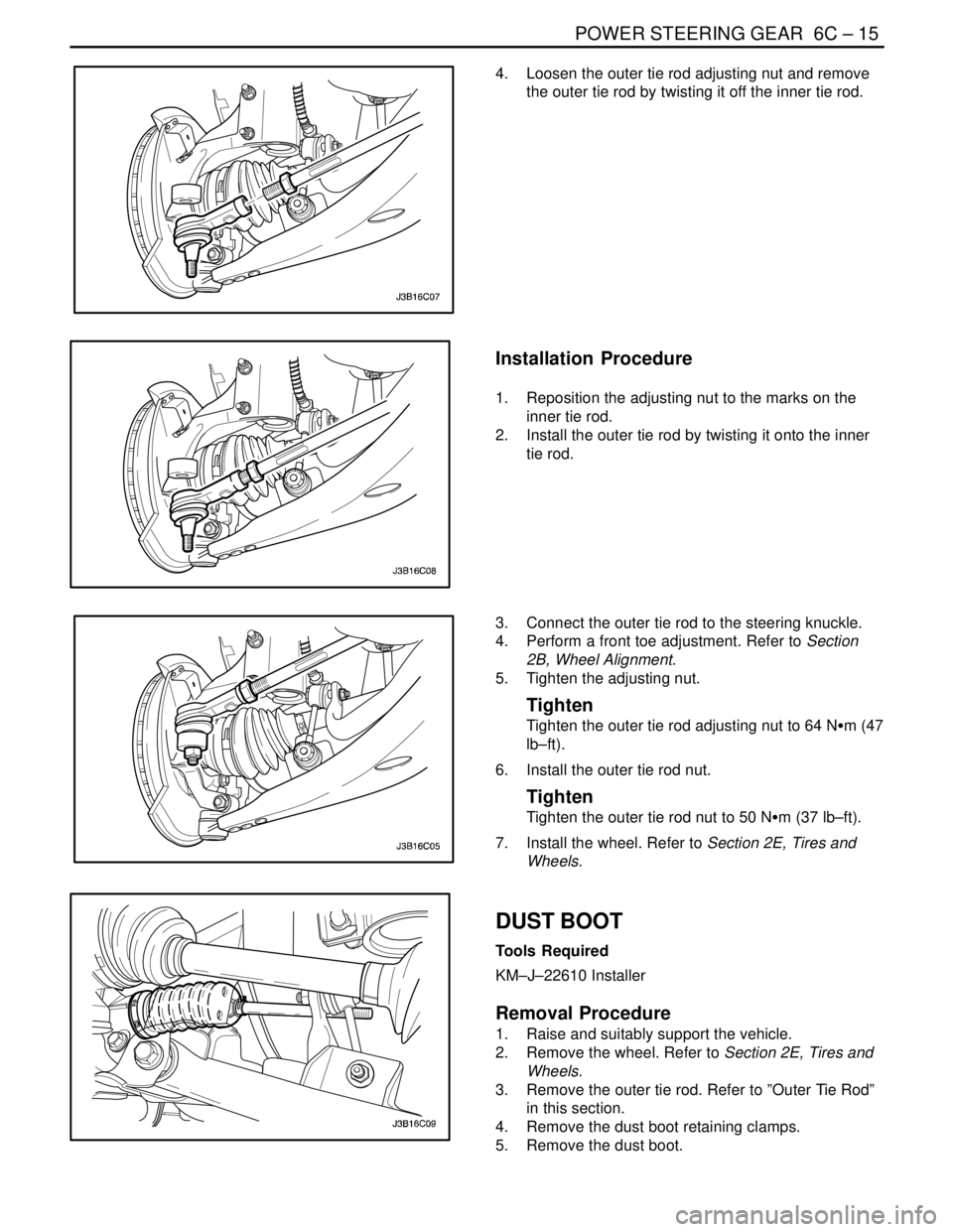

4. Loosen the outer tie rod adjusting nut and remove

the outer tie rod by twisting it off the inner tie rod.

Installation Procedure

1. Reposition the adjusting nut to the marks on the

inner tie rod.

2. Install the outer tie rod by twisting it onto the inner

tie rod.

3. Connect the outer tie rod to the steering knuckle.

4. Perform a front toe adjustment. Refer to Section

2B, Wheel Alignment.

5. Tighten the adjusting nut.

Tighten

Tighten the outer tie rod adjusting nut to 64 NSm (47

lb–ft).

6. Install the outer tie rod nut.

Tighten

Tighten the outer tie rod nut to 50 NSm (37 lb–ft).

7. Install the wheel. Refer to Section 2E, Tires and

Wheels.

DUST BOOT

Tools Required

KM–J–22610 Installer

Removal Procedure

1. Raise and suitably support the vehicle.

2. Remove the wheel. Refer to Section 2E, Tires and

Wheels.

3. Remove the outer tie rod. Refer to ”Outer Tie Rod”

in this section.

4. Remove the dust boot retaining clamps.

5. Remove the dust boot.

Page 1934 of 2643

POWER STEERING GEAR 6C – 17

DAEWOO V–121 BL4

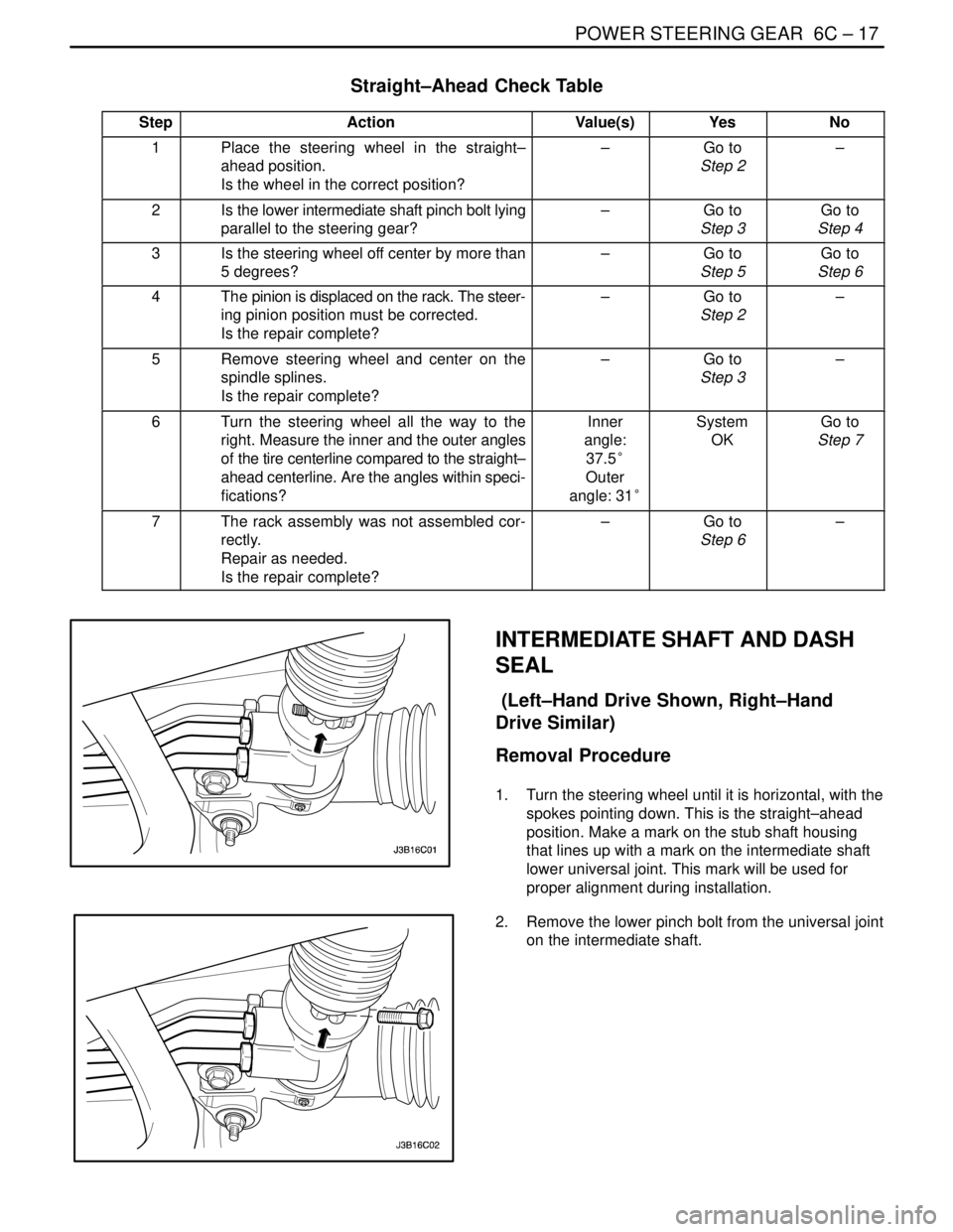

Straight–Ahead Check Table

StepActionValue(s)YesNo

1Place the steering wheel in the straight–

ahead position.

Is the wheel in the correct position?–Go to

Step 2–

2Is the lower intermediate shaft pinch bolt lying

parallel to the steering gear?–Go to

Step 3Go to

Step 4

3Is the steering wheel off center by more than

5 degrees?–Go to

Step 5Go to

Step 6

4The pinion is displaced on the rack. The steer-

ing pinion position must be corrected.

Is the repair complete?–Go to

Step 2–

5Remove steering wheel and center on the

spindle splines.

Is the repair complete?–Go to

Step 3–

6Turn the steering wheel all the way to the

right. Measure the inner and the outer angles

of the tire centerline compared to the straight–

ahead centerline. Are the angles within speci-

fications?Inner

angle:

37.5°

Outer

angle: 31°System

OKGo to

Step 7

7The rack assembly was not assembled cor-

rectly.

Repair as needed.

Is the repair complete?–Go to

Step 6–

INTERMEDIATE SHAFT AND DASH

SEAL

(Left–Hand Drive Shown, Right–Hand

Drive Similar)

Removal Procedure

1. Turn the steering wheel until it is horizontal, with the

spokes pointing down. This is the straight–ahead

position. Make a mark on the stub shaft housing

that lines up with a mark on the intermediate shaft

lower universal joint. This mark will be used for

proper alignment during installation.

2. Remove the lower pinch bolt from the universal joint

on the intermediate shaft.

Page 1942 of 2643

POWER STEERING GEAR 6C – 25

DAEWOO V–121 BL4

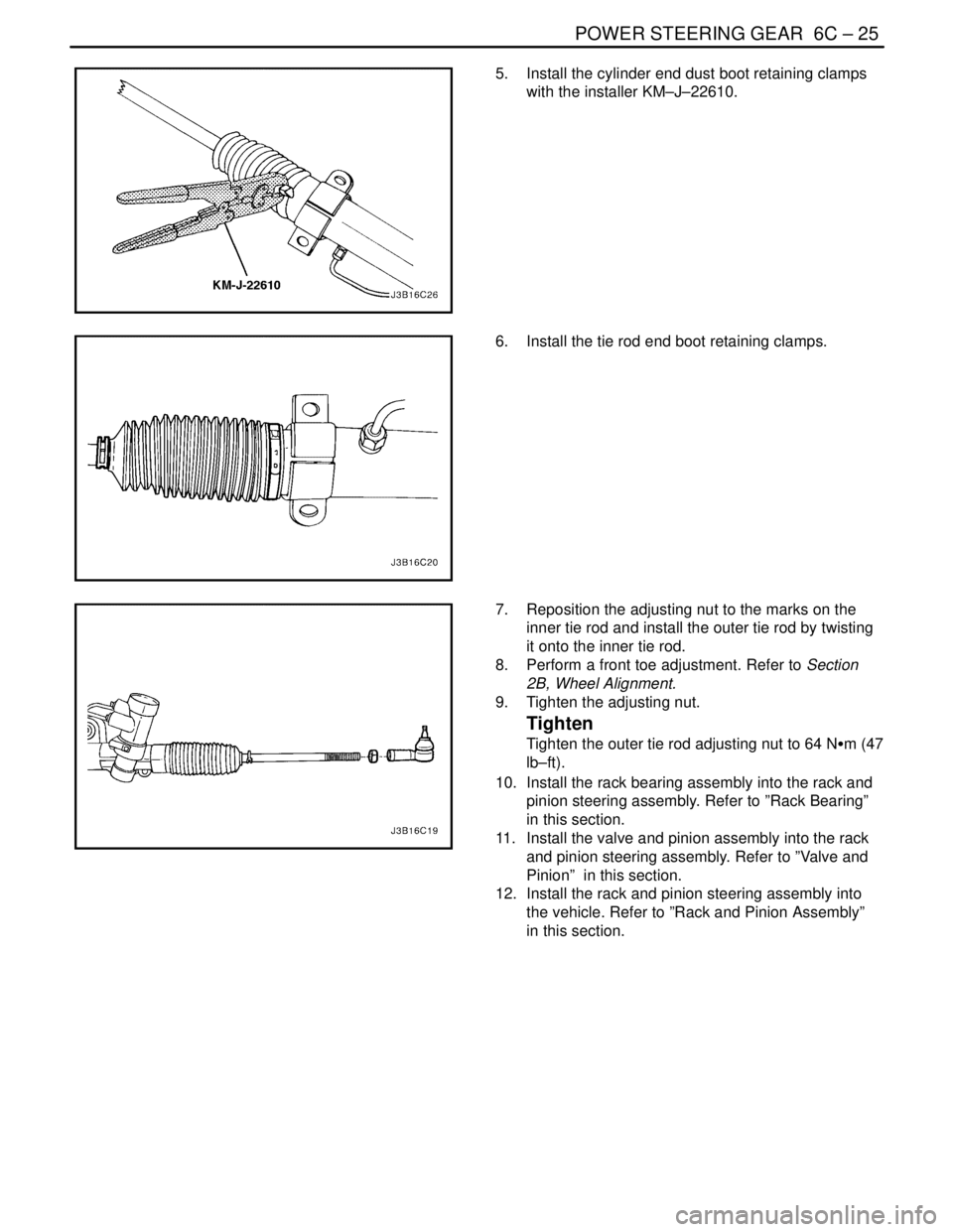

5. Install the cylinder end dust boot retaining clamps

with the installer KM–J–22610.

6. Install the tie rod end boot retaining clamps.

7. Reposition the adjusting nut to the marks on the

inner tie rod and install the outer tie rod by twisting

it onto the inner tie rod.

8. Perform a front toe adjustment. Refer to Section

2B, Wheel Alignment.

9. Tighten the adjusting nut.

Tighten

Tighten the outer tie rod adjusting nut to 64 NSm (47

lb–ft).

10. Install the rack bearing assembly into the rack and

pinion steering assembly. Refer to ”Rack Bearing”

in this section.

11. Install the valve and pinion assembly into the rack

and pinion steering assembly. Refer to ”Valve and

Pinion” in this section.

12. Install the rack and pinion steering assembly into

the vehicle. Refer to ”Rack and Pinion Assembly”

in this section.

Page 1957 of 2643

STEERING WHEEL AND COLUMN 6E – 3

DAEWOO V–121 BL4

High Lock Effort

ChecksAction

Check the lock cylinder for damage.Replace the lock cylinder.

Check the ignition switch for lack of free movement.Lubricate the ignition switch.

Check for extreme misalignment of the housing to the cov-

er.Realign the cover on the housing. Replace the cover as

needed.

Check for a bent ignition switch mounting bracket.Replace the ignition switch mounting bracket.

Key Cannot Be Removed in the LOCK Position

ChecksAction

Check to see that the ignition switch is set correctly.Reset the ignition switch.

Check the lock cylinder for damage.Replace the lock cylinder.

Check the fuse F17 from the I/P fuse block.Replace the fuse F17

Check for an open or short in the circuit between terminal

2 of key interlock solenoid and the I/P fuse block.Replace the fuse F17

Select the gear shift lever to ”P” position.

Check the resistance between the terminal 2 and 1 of the

”P” position switch.Replace the ”P” position switch.

Check for an open or short in the circuit between the

ground G202 and terminal 1 of the key interlock unit.Replace the open or short from the circuit.

Turn the ignition ON.

Select the gear shift lever to ”P” position.

Check the resistance between the terminal 1 and 2 of the

key interlock solenoid.Replace the key interlock solenoid.