run flat DAEWOO NUBIRA 2004 Service Repair Manual

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: NUBIRA, Model: DAEWOO NUBIRA 2004Pages: 2643, PDF Size: 80.54 MB

Page 98 of 2643

1.4L/1.6L DOHC ENGINE MECHANICAL 1C1 – 55

DAEWOO V–121 BL4

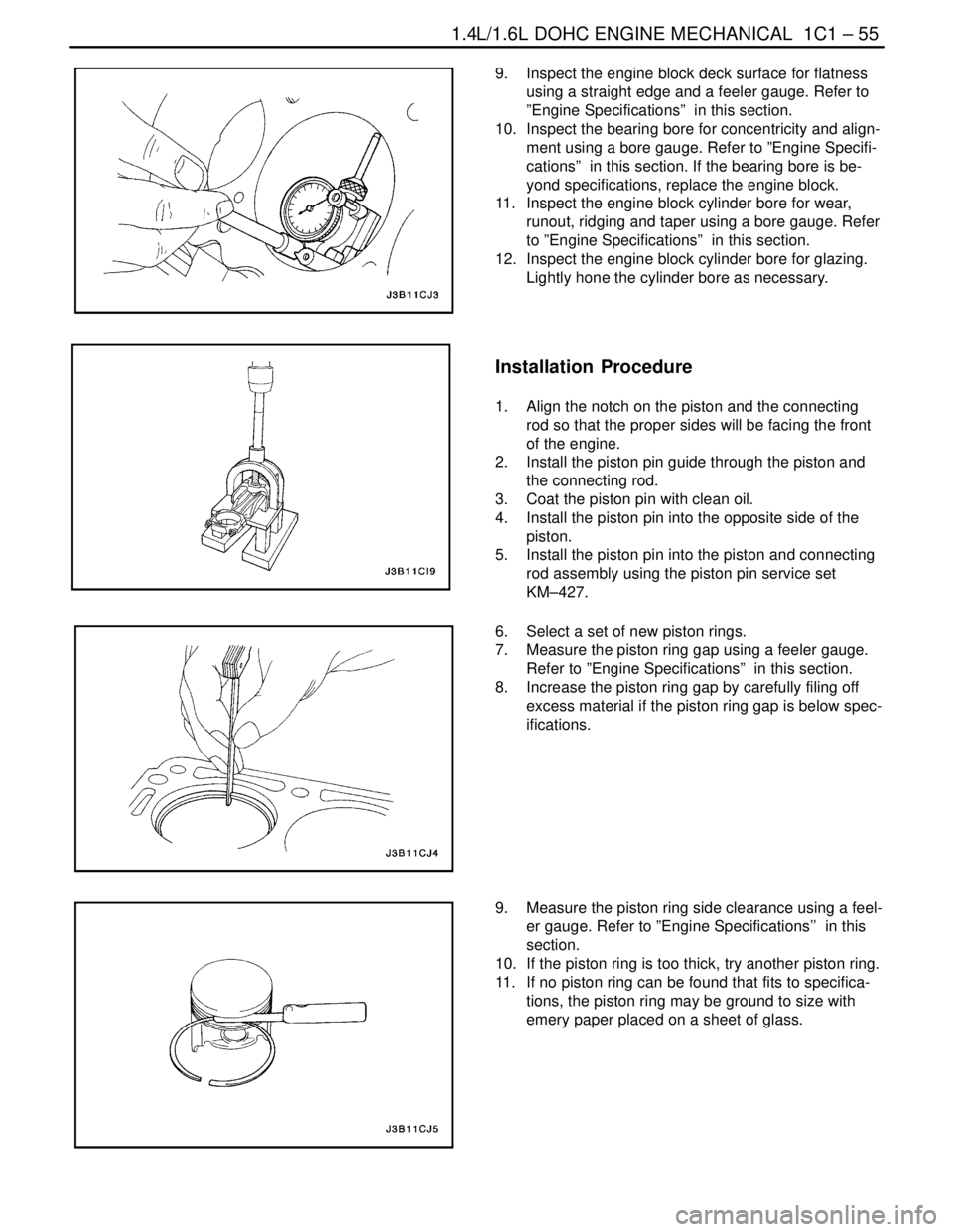

9. Inspect the engine block deck surface for flatness

using a straight edge and a feeler gauge. Refer to

”Engine Specifications” in this section.

10. Inspect the bearing bore for concentricity and align-

ment using a bore gauge. Refer to ”Engine Specifi-

cations” in this section. If the bearing bore is be-

yond specifications, replace the engine block.

11. Inspect the engine block cylinder bore for wear,

runout, ridging and taper using a bore gauge. Refer

to ”Engine Specifications” in this section.

12. Inspect the engine block cylinder bore for glazing.

Lightly hone the cylinder bore as necessary.

Installation Procedure

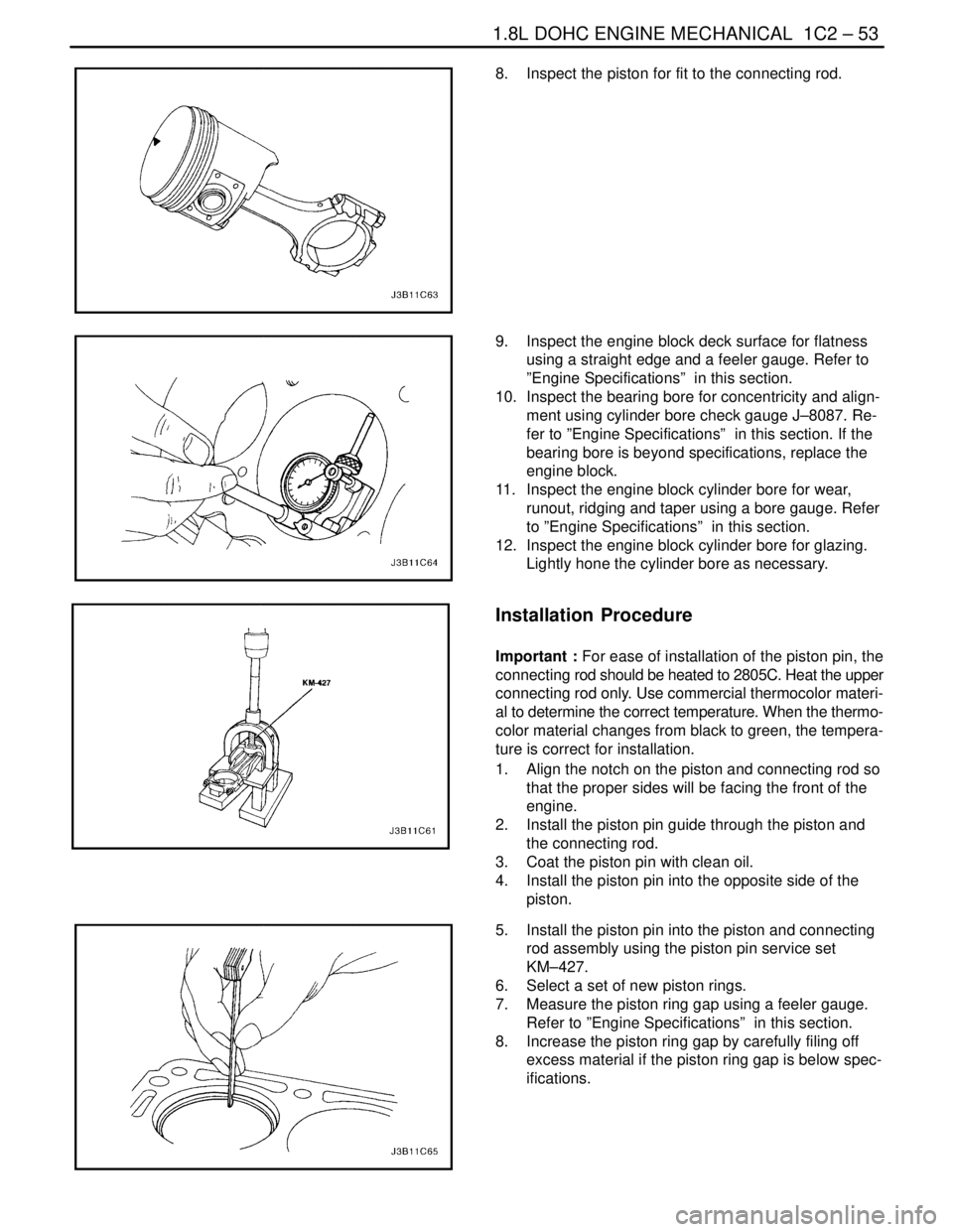

1. Align the notch on the piston and the connecting

rod so that the proper sides will be facing the front

of the engine.

2. Install the piston pin guide through the piston and

the connecting rod.

3. Coat the piston pin with clean oil.

4. Install the piston pin into the opposite side of the

piston.

5. Install the piston pin into the piston and connecting

rod assembly using the piston pin service set

KM–427.

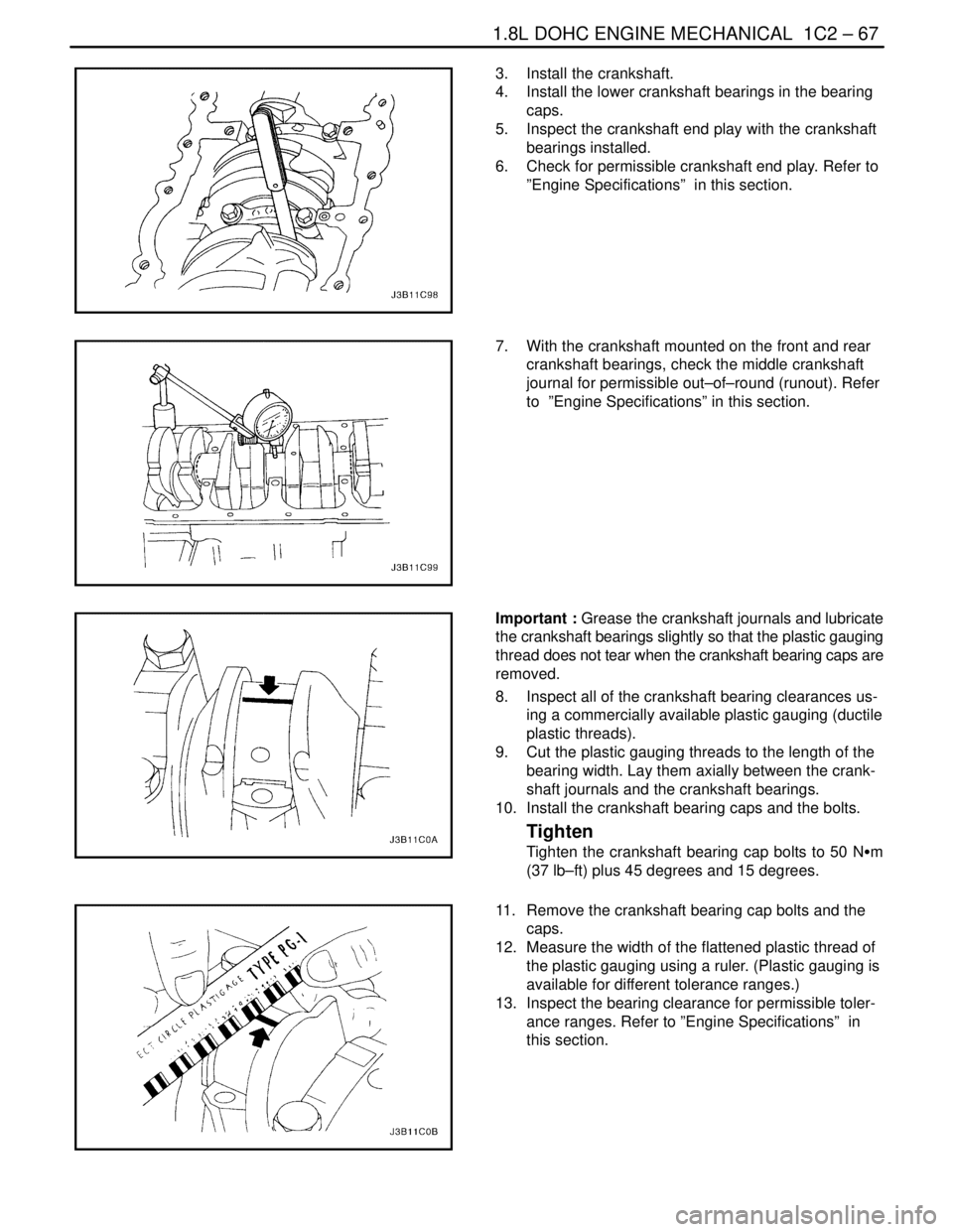

6. Select a set of new piston rings.

7. Measure the piston ring gap using a feeler gauge.

Refer to ”Engine Specifications” in this section.

8. Increase the piston ring gap by carefully filing off

excess material if the piston ring gap is below spec-

ifications.

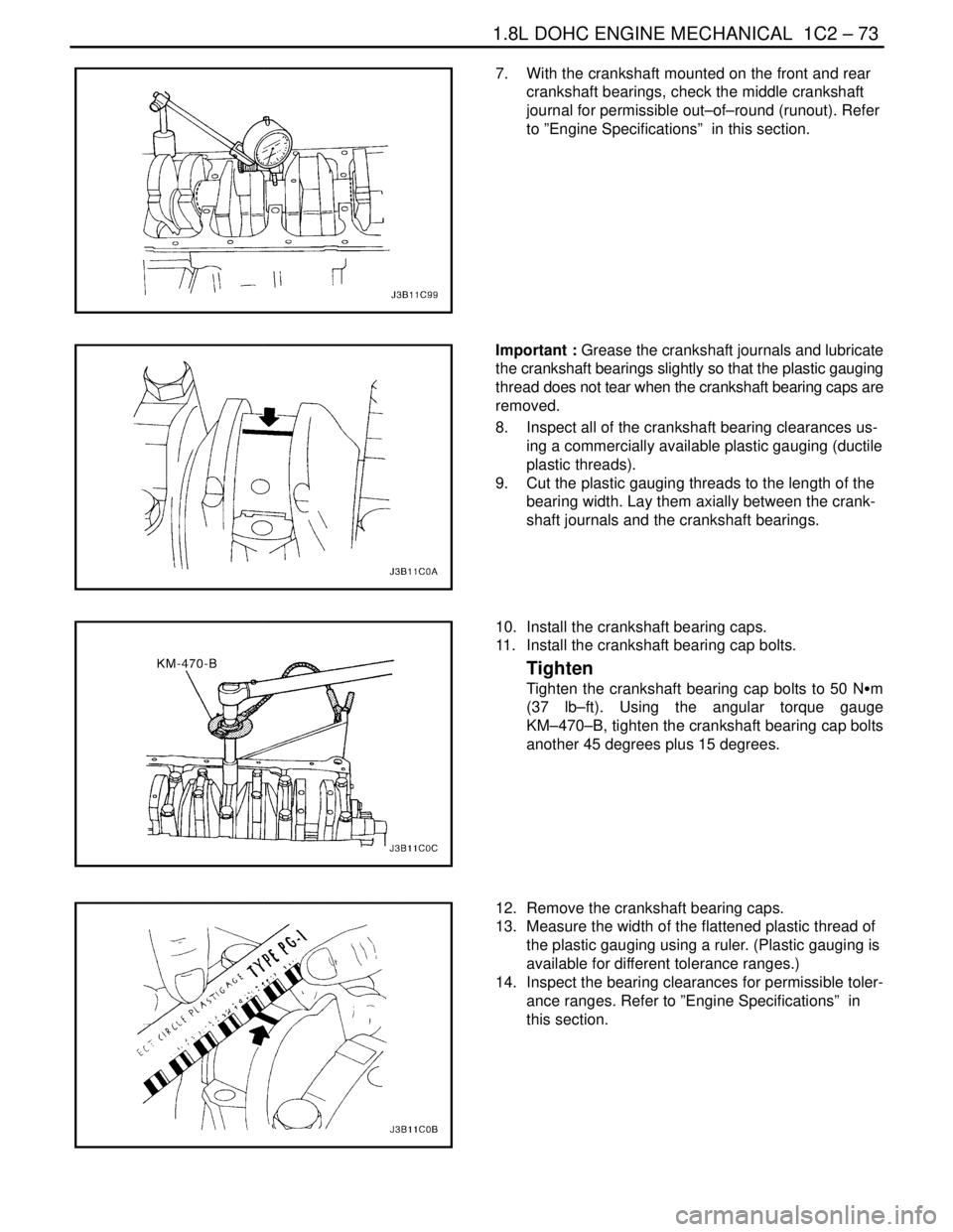

9. Measure the piston ring side clearance using a feel-

er gauge. Refer to ”Engine Specifications’’ in this

section.

10. If the piston ring is too thick, try another piston ring.

11. If no piston ring can be found that fits to specifica-

tions, the piston ring may be ground to size with

emery paper placed on a sheet of glass.

Page 173 of 2643

1.8L DOHC ENGINE MECHANICAL 1C2 – 53

DAEWOO V–121 BL4

8. Inspect the piston for fit to the connecting rod.

9. Inspect the engine block deck surface for flatness

using a straight edge and a feeler gauge. Refer to

”Engine Specifications” in this section.

10. Inspect the bearing bore for concentricity and align-

ment using cylinder bore check gauge J–8087. Re-

fer to ”Engine Specifications” in this section. If the

bearing bore is beyond specifications, replace the

engine block.

11. Inspect the engine block cylinder bore for wear,

runout, ridging and taper using a bore gauge. Refer

to ”Engine Specifications” in this section.

12. Inspect the engine block cylinder bore for glazing.

Lightly hone the cylinder bore as necessary.

Installation Procedure

Important : For ease of installation of the piston pin, the

connecting rod should be heated to 2805C. Heat the upper

connecting rod only. Use commercial thermocolor materi-

al to determine the correct temperature. When the thermo-

color material changes from black to green, the tempera-

ture is correct for installation.

1. Align the notch on the piston and connecting rod so

that the proper sides will be facing the front of the

engine.

2. Install the piston pin guide through the piston and

the connecting rod.

3. Coat the piston pin with clean oil.

4. Install the piston pin into the opposite side of the

piston.

5. Install the piston pin into the piston and connecting

rod assembly using the piston pin service set

KM–427.

6. Select a set of new piston rings.

7. Measure the piston ring gap using a feeler gauge.

Refer to ”Engine Specifications” in this section.

8. Increase the piston ring gap by carefully filing off

excess material if the piston ring gap is below spec-

ifications.

Page 187 of 2643

1.8L DOHC ENGINE MECHANICAL 1C2 – 67

DAEWOO V–121 BL4

3. Install the crankshaft.

4. Install the lower crankshaft bearings in the bearing

caps.

5. Inspect the crankshaft end play with the crankshaft

bearings installed.

6. Check for permissible crankshaft end play. Refer to

”Engine Specifications” in this section.

7. With the crankshaft mounted on the front and rear

crankshaft bearings, check the middle crankshaft

journal for permissible out–of–round (runout). Refer

to ”Engine Specifications” in this section.

Important : Grease the crankshaft journals and lubricate

the crankshaft bearings slightly so that the plastic gauging

thread does not tear when the crankshaft bearing caps are

removed.

8. Inspect all of the crankshaft bearing clearances us-

ing a commercially available plastic gauging (ductile

plastic threads).

9. Cut the plastic gauging threads to the length of the

bearing width. Lay them axially between the crank-

shaft journals and the crankshaft bearings.

10. Install the crankshaft bearing caps and the bolts.

Tighten

Tighten the crankshaft bearing cap bolts to 50 NSm

(37 lb–ft) plus 45 degrees and 15 degrees.

11. Remove the crankshaft bearing cap bolts and the

caps.

12. Measure the width of the flattened plastic thread of

the plastic gauging using a ruler. (Plastic gauging is

available for different tolerance ranges.)

13. Inspect the bearing clearance for permissible toler-

ance ranges. Refer to ”Engine Specifications” in

this section.

Page 193 of 2643

1.8L DOHC ENGINE MECHANICAL 1C2 – 73

DAEWOO V–121 BL4

7. With the crankshaft mounted on the front and rear

crankshaft bearings, check the middle crankshaft

journal for permissible out–of–round (runout). Refer

to ”Engine Specifications” in this section.

Important : Grease the crankshaft journals and lubricate

the crankshaft bearings slightly so that the plastic gauging

thread does not tear when the crankshaft bearing caps are

removed.

8. Inspect all of the crankshaft bearing clearances us-

ing a commercially available plastic gauging (ductile

plastic threads).

9. Cut the plastic gauging threads to the length of the

bearing width. Lay them axially between the crank-

shaft journals and the crankshaft bearings.

10. Install the crankshaft bearing caps.

11. Install the crankshaft bearing cap bolts.

Tighten

Tighten the crankshaft bearing cap bolts to 50 NSm

(37 lb–ft). Using the angular torque gauge

KM–470–B, tighten the crankshaft bearing cap bolts

another 45 degrees plus 15 degrees.

12. Remove the crankshaft bearing caps.

13. Measure the width of the flattened plastic thread of

the plastic gauging using a ruler. (Plastic gauging is

available for different tolerance ranges.)

14. Inspect the bearing clearances for permissible toler-

ance ranges. Refer to ”Engine Specifications” in

this section.

Page 902 of 2643

SECTION : 2A

SUSPENSION DIAGNOSIS

TABLE OF CONTENTS

DIAGNOSIS2A–1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Diagnosis 2A–1. . . . . . . . . . . . . . . . . . . . . . . . . Torque Steer 2A–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tapered Roller Bearing 2A–6. . . . . . . . . . . . . . . . . . . . .

DIAGNOSIS

GENERAL DIAGNOSIS

Problems in the steering, the suspension, the tires, and

the wheels involve several systems. Consider all systems

when diagnosing a complaint. Some problems, such as

abnormal or excessive tire wear and scuffed tires, may be

the result of hard driving. Always road test the vehicle first.If possible, do this road test with the customer.

Proceed with the following preliminary checks. Correct

any substandard conditions.

Preliminary Checks

ChecksAction

Inspect the tires for improper pressure and uneven wear.Inflate the tires to the proper pressure.

Inspect the joint from the steering column to the steering

gear for loose connections or wear.Tighten the intermediate shaft pinch bolts. Replace the in-

termediate shaft as needed.

Inspect the front and the rear suspension, the steering

gear, and the linkage for loose or damaged parts.Tighten the front and the rear suspension. Tighten the

steering gear mounting bracket bolts. Tighten the coupling

flange pinch bolts. Replace the front and the rear suspen-

sion as needed. Replace the steering gear as needed. Re-

place the intermediate shaft as needed.

Inspect for out–of–round tires.Perform a free runout test. Match–mount the tires.

Inspect for out–of–balance tires, bent wheels, and worn or

loose wheel bearings.Balance the wheels. Replace the wheels. Replace the

wheel bearings.

Check the power steering pump serpentine belt tension.Tighten the power steering pump serpentine belt.

Inspect the power steering system for leaks. Check the

power steering fluid level.Repair any leaks. Perform a power steering gear test. Add

power steering fluid.

Car Lead/Pull

ChecksAction

Inspect for mismatched or uneven tires.Replace the tires.

Inspect for a broken or a sagging spring.Replace the spring.

Inspect for a radial tire lateral force.Check the wheel alignment. Switch the wheels. Replace

the tires as needed.

Check the front–wheel alignment.Align the front wheels.

Inspect for an off–center steering gear.Reseat the pinion valve assembly. Replace the pinion

valve assembly as needed.

Inspect for front–brake dragging.Adjust the front brakes.

Page 903 of 2643

2A – 2ISUSPENSION DIAGNOSIS

DAEWOO V–121 BL4

Abnormal or Excessive Tire Wear

ChecksAction

Check the front–wheel and the rear–wheel alignment.Align the front and the rear wheels.

Inspect for excessive toe on the front and the rear wheels.Adjust the toe on the front and the rear wheels.

Inspect for a broken or a sagging spring.Replace the spring.

Inspect for out–of–balance tires.Balance the tires.

Inspect for worn strut dampeners.Replace the strut dampeners.

Check for a failure to rotate tires.Rotate the tires. Replace the tires as needed.

Check for an overloaded vehicle.Maintain the proper load weight.

Inspect for low tire inflation.Inflate the tires to the proper pressure.

Scuffed Tires

ChecksAction

Inspect for incorrect toe on the front and the rear wheels.Adjust the toe on the front and the rear wheels.

Inspect for a twisted or a bent suspension arm.Replace the suspension arm.

Wheel Tramp

ChecksAction

Inspect for an out–of–balance tire or wheel.Balance the tire or the wheel.

Inspect for improper strut dampener action.Replace the strut dampeners.

Shimmy, Shake, or Vibration

ChecksAction

Inspect for an out–of–balance tire or wheel.Balance the tire or the wheel.

Inspect for excessive wheel hub runout.Measure the hub flange runout. Replace the hub as need-

ed.

Inspect for excessive brake drum or brake rotor imbal-

ance.Adjust the brakes. Replace the brake rotor or the brake

drum as needed.

Inspect for worn tie rod ends.Replace the outer tie rods.

Inspect for wheel trim imbalance.Balance the wheel.

Inspect for a worn lower ball joint.Replace the lower ball joint.

Inspect for excessive wheel runout.Measure the wheel runout. Replace the wheel as needed.

Inspect for excessive loaded radial runout on the tire and

wheel assembly.Match–mount the tire and wheel assembly.

Hard Steering

ChecksAction

Check the steering gear preload adjustment.Perform a rack bearing preload adjustment.

Check the hydraulic system. Test the power steering sys-

tem pressure with a gauge.Replace the seals and the hoses as needed.

Inspect for binding or catching in the steering gear.Lubricate the steering gear. Repair or replace the steering

gear as needed.

Inspect for a loose steering gear mounting.Tighten the steering gear mounting bracket nuts.

Page 909 of 2643

2B – 2IWHEEL ALIGNMENT

DAEWOO V–121 BL4

DIAGNOSIS

TIRE DIAGNOSIS

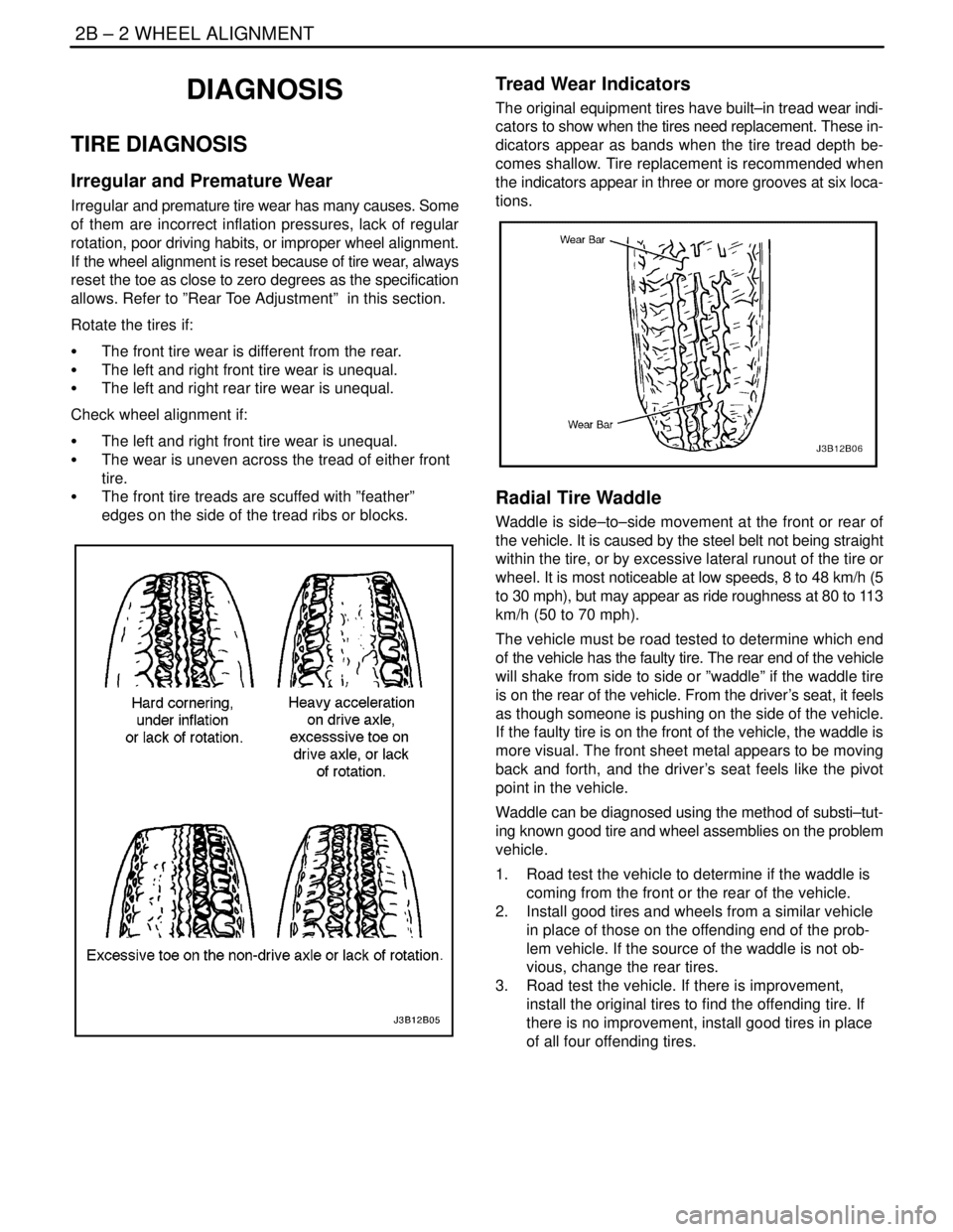

Irregular and Premature Wear

Irregular and premature tire wear has many causes. Some

of them are incorrect inflation pressures, lack of regular

rotation, poor driving habits, or improper wheel alignment.

If the wheel alignment is reset because of tire wear, always

reset the toe as close to zero degrees as the specification

allows. Refer to ”Rear Toe Adjustment” in this section.

Rotate the tires if:

S The front tire wear is different from the rear.

S The left and right front tire wear is unequal.

S The left and right rear tire wear is unequal.

Check wheel alignment if:

S The left and right front tire wear is unequal.

S The wear is uneven across the tread of either front

tire.

S The front tire treads are scuffed with ”feather”

edges on the side of the tread ribs or blocks.

Tread Wear Indicators

The original equipment tires have built–in tread wear indi-

cators to show when the tires need replacement. These in-

dicators appear as bands when the tire tread depth be-

comes shallow. Tire replacement is recommended when

the indicators appear in three or more grooves at six loca-

tions.

Radial Tire Waddle

Waddle is side–to–side movement at the front or rear of

the vehicle. It is caused by the steel belt not being straight

within the tire, or by excessive lateral runout of the tire or

wheel. It is most noticeable at low speeds, 8 to 48 km/h (5

to 30 mph), but may appear as ride roughness at 80 to 113

km/h (50 to 70 mph).

The vehicle must be road tested to determine which end

of the vehicle has the faulty tire. The rear end of the vehicle

will shake from side to side or ”waddle” if the waddle tire

is on the rear of the vehicle. From the driver’s seat, it feels

as though someone is pushing on the side of the vehicle.

If the faulty tire is on the front of the vehicle, the waddle is

more visual. The front sheet metal appears to be moving

back and forth, and the driver’s seat feels like the pivot

point in the vehicle.

Waddle can be diagnosed using the method of substi–tut-

ing known good tire and wheel assemblies on the problem

vehicle.

1. Road test the vehicle to determine if the waddle is

coming from the front or the rear of the vehicle.

2. Install good tires and wheels from a similar vehicle

in place of those on the offending end of the prob-

lem vehicle. If the source of the waddle is not ob-

vious, change the rear tires.

3. Road test the vehicle. If there is improvement,

install the original tires to find the offending tire. If

there is no improvement, install good tires in place

of all four offending tires.

Page 912 of 2643

WHEEL ALIGNMENT 2B – 5

DAEWOO V–121 BL4

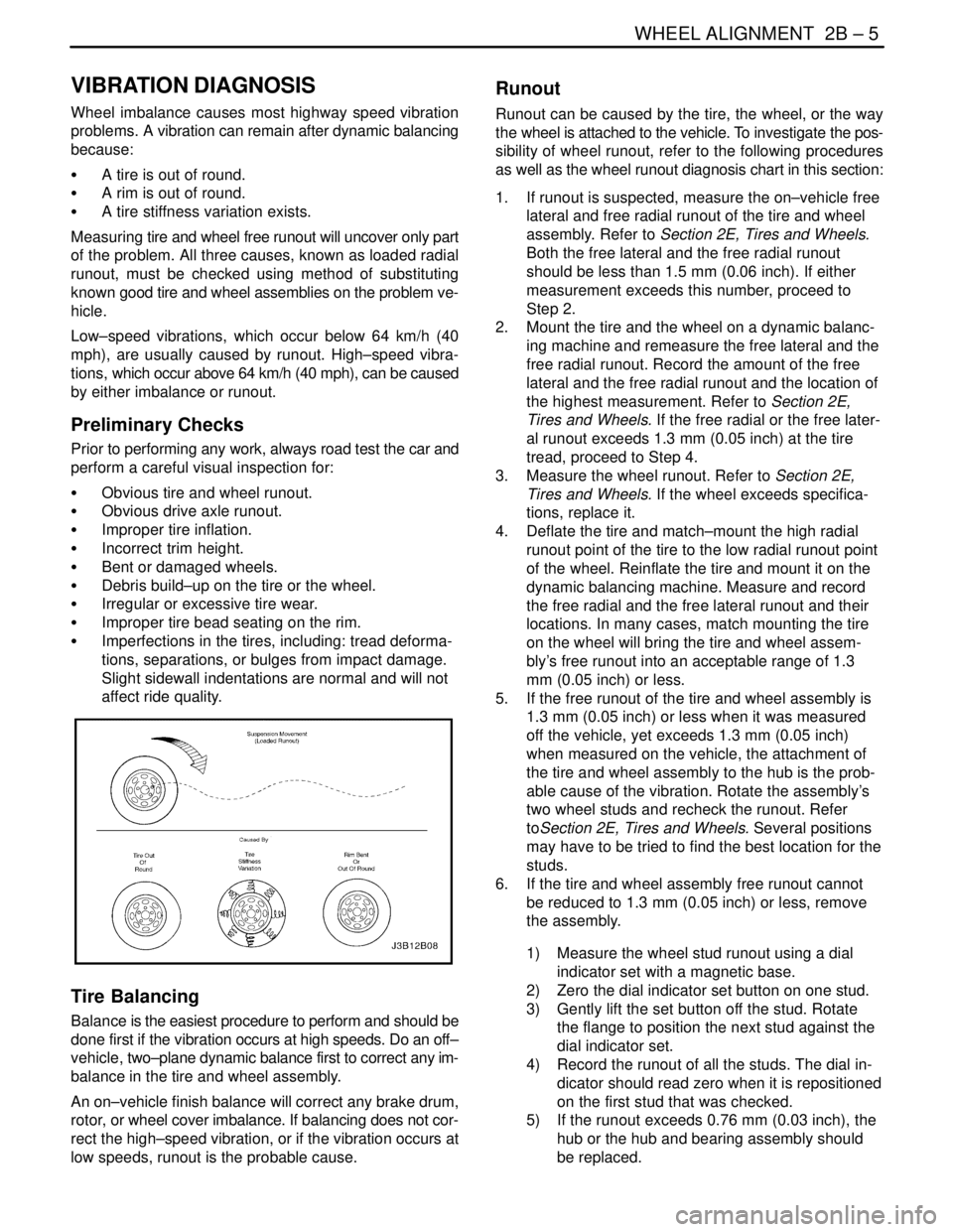

VIBRATION DIAGNOSIS

Wheel imbalance causes most highway speed vibration

problems. A vibration can remain after dynamic balancing

because:

S A tire is out of round.

S A rim is out of round.

S A tire stiffness variation exists.

Measuring tire and wheel free runout will uncover only part

of the problem. All three causes, known as loaded radial

runout, must be checked using method of substituting

known good tire and wheel assemblies on the problem ve-

hicle.

Low–speed vibrations, which occur below 64 km/h (40

mph), are usually caused by runout. High–speed vibra-

tions, which occur above 64 km/h (40 mph), can be caused

by either imbalance or runout.

Preliminary Checks

Prior to performing any work, always road test the car and

perform a careful visual inspection for:

S Obvious tire and wheel runout.

S Obvious drive axle runout.

S Improper tire inflation.

S Incorrect trim height.

S Bent or damaged wheels.

S Debris build–up on the tire or the wheel.

S Irregular or excessive tire wear.

S Improper tire bead seating on the rim.

S Imperfections in the tires, including: tread deforma-

tions, separations, or bulges from impact damage.

Slight sidewall indentations are normal and will not

affect ride quality.

Tire Balancing

Balance is the easiest procedure to perform and should be

done first if the vibration occurs at high speeds. Do an off–

vehicle, two–plane dynamic balance first to correct any im-

balance in the tire and wheel assembly.

An on–vehicle finish balance will correct any brake drum,

rotor, or wheel cover imbalance. If balancing does not cor-

rect the high–speed vibration, or if the vibration occurs at

low speeds, runout is the probable cause.

Runout

Runout can be caused by the tire, the wheel, or the way

the wheel is attached to the vehicle. To investigate the pos-

sibility of wheel runout, refer to the following procedures

as well as the wheel runout diagnosis chart in this section:

1. If runout is suspected, measure the on–vehicle free

lateral and free radial runout of the tire and wheel

assembly. Refer to Section 2E, Tires and Wheels.

Both the free lateral and the free radial runout

should be less than 1.5 mm (0.06 inch). If either

measurement exceeds this number, proceed to

Step 2.

2. Mount the tire and the wheel on a dynamic balanc-

ing machine and remeasure the free lateral and the

free radial runout. Record the amount of the free

lateral and the free radial runout and the location of

the highest measurement. Refer to Section 2E,

Tires and Wheels. If the free radial or the free later-

al runout exceeds 1.3 mm (0.05 inch) at the tire

tread, proceed to Step 4.

3. Measure the wheel runout. Refer to Section 2E,

Tires and Wheels. If the wheel exceeds specifica-

tions, replace it.

4. Deflate the tire and match–mount the high radial

runout point of the tire to the low radial runout point

of the wheel. Reinflate the tire and mount it on the

dynamic balancing machine. Measure and record

the free radial and the free lateral runout and their

locations. In many cases, match mounting the tire

on the wheel will bring the tire and wheel assem-

bly’s free runout into an acceptable range of 1.3

mm (0.05 inch) or less.

5. If the free runout of the tire and wheel assembly is

1.3 mm (0.05 inch) or less when it was measured

off the vehicle, yet exceeds 1.3 mm (0.05 inch)

when measured on the vehicle, the attachment of

the tire and wheel assembly to the hub is the prob-

able cause of the vibration. Rotate the assembly’s

two wheel studs and recheck the runout. Refer

toSection 2E, Tires and Wheels. Several positions

may have to be tried to find the best location for the

studs.

6. If the tire and wheel assembly free runout cannot

be reduced to 1.3 mm (0.05 inch) or less, remove

the assembly.

1) Measure the wheel stud runout using a dial

indicator set with a magnetic base.

2) Zero the dial indicator set button on one stud.

3) Gently lift the set button off the stud. Rotate

the flange to position the next stud against the

dial indicator set.

4) Record the runout of all the studs. The dial in-

dicator should read zero when it is repositioned

on the first stud that was checked.

5) If the runout exceeds 0.76 mm (0.03 inch), the

hub or the hub and bearing assembly should

be replaced.

Page 915 of 2643

2B – 8IWHEEL ALIGNMENT

DAEWOO V–121 BL4

PRELIMINARY INSPECTION

ChecksAction

Check the tires for proper inflation pressures and normal

tread wear.Inflate the tires to the proper tire pressure. Replace the

tires as needed.

Check the wheel bearings for looseness.Tighten the axle nut to the proper specification. Replace

the strut wheel bearing as needed.

Check for loose ball joints and tie rod ends.Tighten the ball joints and the tie rods.

Check the runout of the wheels and the tires.Measure and correct the tire runout.

Check the vehicle trim heights.Correct the trim heights. Make the correction before ad-

justing the toe.

Check for loose rack and pinion mounting.Tighten the mounting brackets for the rack and pinion as-

sembly.

Check for improperly operating struts.Replace the strut assembly.

Check for loose control arms.Tighten the control arm attachment bolts. Replace the con-

trol arm bushings as needed.

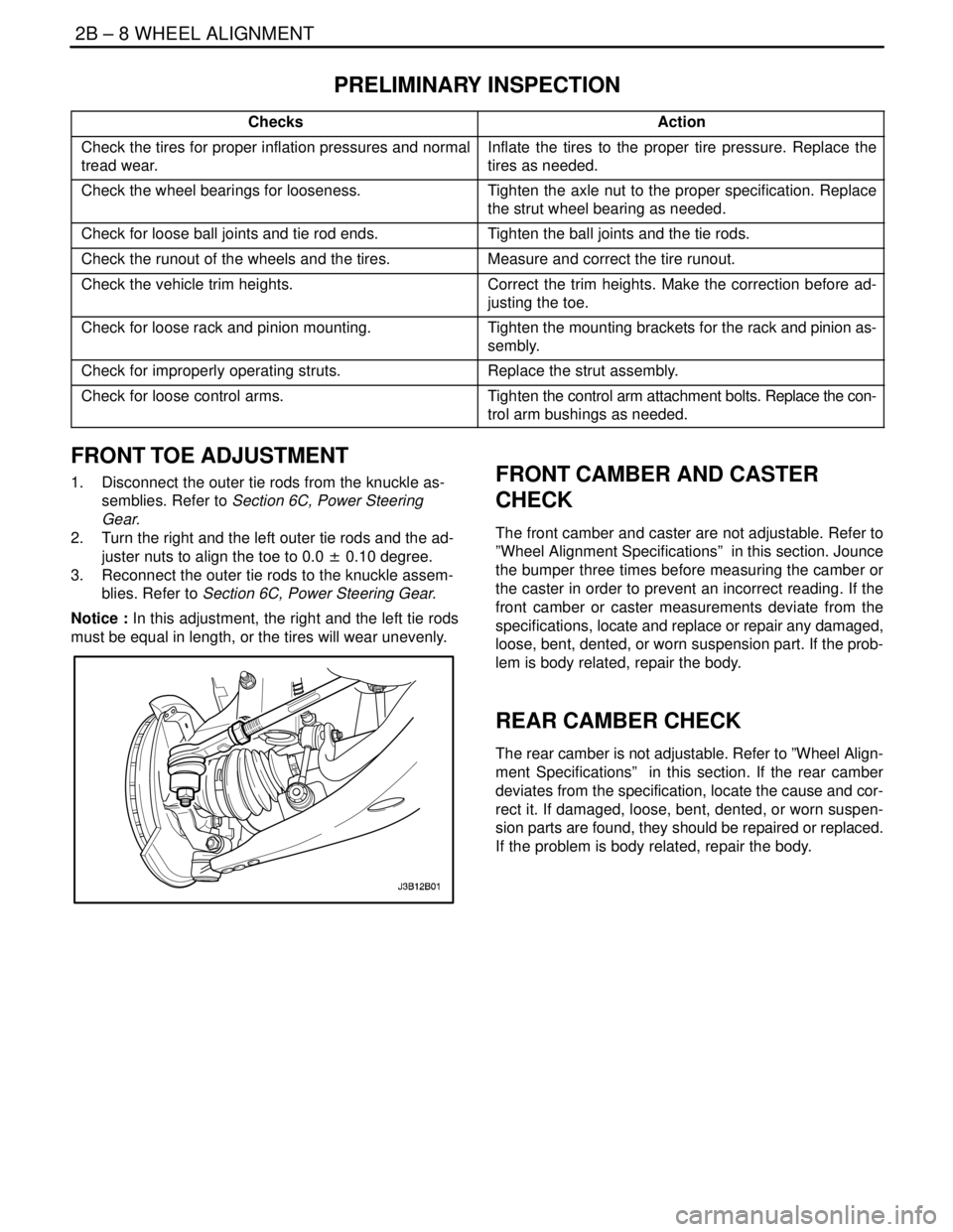

FRONT TOE ADJUSTMENT

1. Disconnect the outer tie rods from the knuckle as-

semblies. Refer to Section 6C, Power Steering

Gear.

2. Turn the right and the left outer tie rods and the ad-

juster nuts to align the toe to 0.0 ± 0.10 degree.

3. Reconnect the outer tie rods to the knuckle assem-

blies. Refer to Section 6C, Power Steering Gear.

Notice : In this adjustment, the right and the left tie rods

must be equal in length, or the tires will wear unevenly.FRONT CAMBER AND CASTER

CHECK

The front camber and caster are not adjustable. Refer to

”Wheel Alignment Specifications” in this section. Jounce

the bumper three times before measuring the camber or

the caster in order to prevent an incorrect reading. If the

front camber or caster measurements deviate from the

specifications, locate and replace or repair any damaged,

loose, bent, dented, or worn suspension part. If the prob-

lem is body related, repair the body.

REAR CAMBER CHECK

The rear camber is not adjustable. Refer to ”Wheel Align-

ment Specifications” in this section. If the rear camber

deviates from the specification, locate the cause and cor-

rect it. If damaged, loose, bent, dented, or worn suspen-

sion parts are found, they should be repaired or replaced.

If the problem is body related, repair the body.

Page 963 of 2643

SECTION : 2E

TIRES AND WHEELS

TABLE OF CONTENTS

SPECIFICATIONS2E–1 . . . . . . . . . . . . . . . . . . . . . . . . . .

Tire Size and Pressure Specifications 2E–1. . . . . . . .

Inflation Pressure Conversion Specifications 2E–2. .

Fastener Tightening Specifications 2E–2. . . . . . . . . . .

DIAGNOSIS2E–2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Wheel Runout 2E–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MAINTENANCE AND REPAIR2E–3 . . . . . . . . . . . . . . .

ON–VEHICLE SERVICE 2E–3. . . . . . . . . . . . . . . . . . . . .

Wheel 2E–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

On–Vehicle Balancing 2E–4. . . . . . . . . . . . . . . . . . . . . .

UNIT REPAIR 2E–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Alloy Wheel Porosity 2E–5. . . . . . . . . . . . . . . . . . . . . . .

Alloy Wheel Refinishing 2E–5. . . . . . . . . . . . . . . . . . . . .

Off–Vehicle Balancing 2E–7. . . . . . . . . . . . . . . . . . . . . . Correcting Non–Uniform Tires 2E–7. . . . . . . . . . . . . . .

Tire and Wheel Match–Mounting 2E–8. . . . . . . . . . . . .

Tire Mounting and Dismounting 2E–8. . . . . . . . . . . . . .

GENERAL DESCRIPTION AND SYSTEM

OPERATION 2E–9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tire and Wheel Balancing 2E–9. . . . . . . . . . . . . . . . . . .

Tire Chain Usage 2E–9. . . . . . . . . . . . . . . . . . . . . . . . . .

Replacement Tires 2E–10. . . . . . . . . . . . . . . . . . . . . . . .

All Season Tires 2E–10. . . . . . . . . . . . . . . . . . . . . . . . . .

Passenger Metric Sized Tires 2E–10. . . . . . . . . . . . . .

Tire Label 2E–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Spare Tire 2E–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Wheels 2E–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inflation o Tires 2E–11. . . . . . . . . . . . . . . . . . . . . . . . . . .

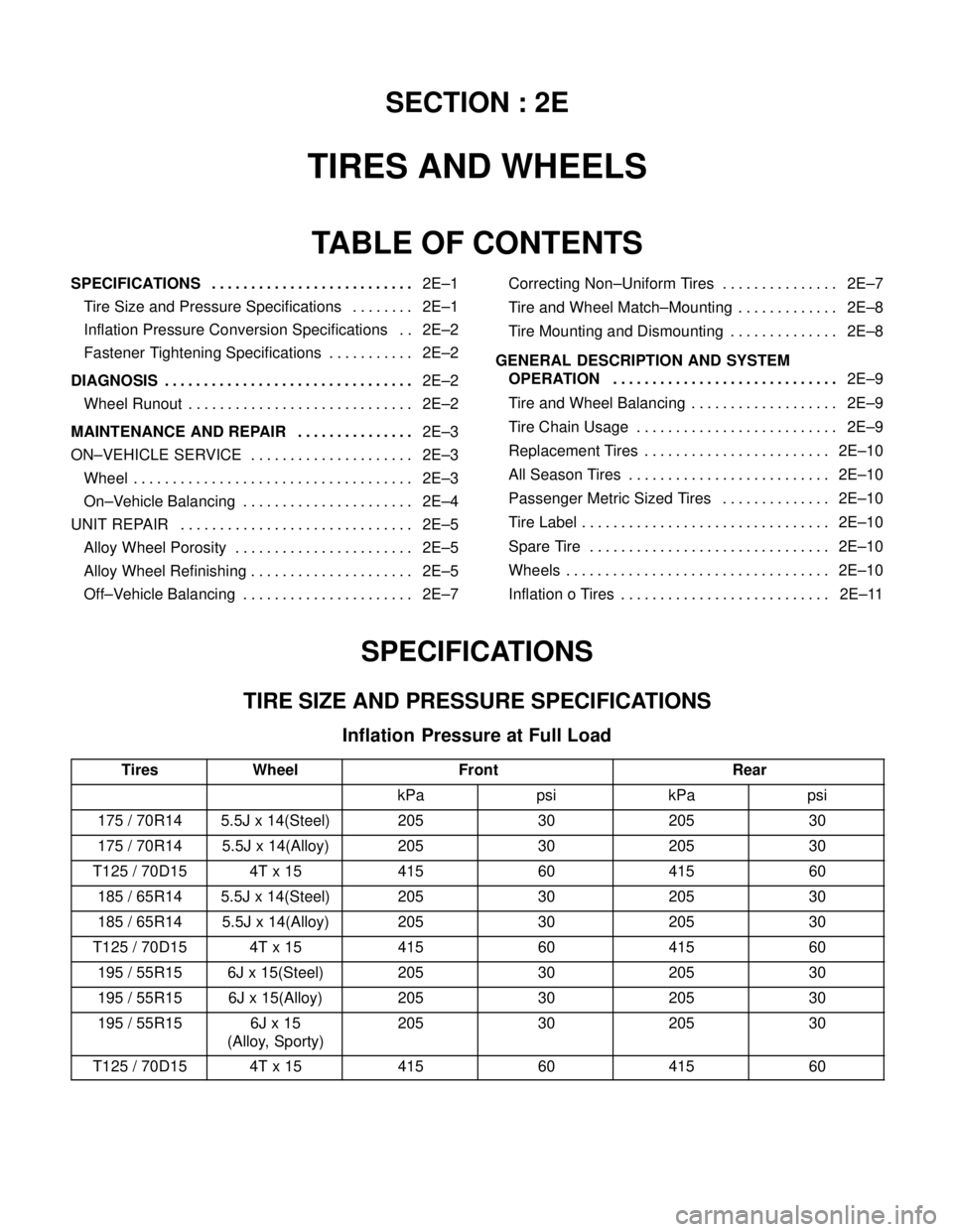

SPECIFICATIONS

TIRE SIZE AND PRESSURE SPECIFICATIONS

Inflation Pressure at Full Load

TiresWheelFrontRear

kPapsikPapsi

175 / 70R145.5J x 14(Steel)2053020530

175 / 70R145.5J x 14(Alloy)2053020530

T125 / 70D154T x 154156041560

185 / 65R145.5J x 14(Steel)2053020530

185 / 65R145.5J x 14(Alloy)2053020530

T125 / 70D154T x 154156041560

195 / 55R156J x 15(Steel)2053020530

195 / 55R156J x 15(Alloy)2053020530

195 / 55R156J x 15

(Alloy, Sporty)2053020530

T125 / 70D154T x 154156041560