DAEWOO NUBIRA 2004 Service Repair Manual

Manufacturer: DAEWOO, Model Year: 2004, Model line: NUBIRA, Model: DAEWOO NUBIRA 2004Pages: 2643, PDF Size: 80.54 MB

Page 331 of 2643

ENGINE CONTROLS 1F – 85

DAEWOO V–121 BL4

IGNITION SYSTEM CHECK (1.4L/1.6L DOHC)

Circuit Description

The Electronic Ignition (EI) system uses a waste spark

method of spark distribution. In this type of EI system, the

Crankshaft Position (CKP) sensor is mounted to the oil

pump near a slotted wheel that is a part of the crankshaft

pulley. The CKP sensor sends reference pulses to the en-

gine control module (ECM). The ECM then triggers the EI

system ignition coil. Once the ECM triggers the EI system

ignition coil, both of the connected spark plugs fire at the

same time. One cylinder is on its compression stroke at

the same time that the other is on the exhaust stroke, re-

sulting in lower energy needed to fire the spark plug in the

cylinder on its exhaust stroke.

This leaves the remainder of the high voltage to be used

to fire the spark plug in the cylinder on its compression

stroke. Since the CKP sensor is in a fixed position, timing

adjustments are not possible or needed.

Test Description

The number(s) below refer to step(s) on the diagnostictable.

2. It is important to check for the presence of spark to

all of the cylinders to isolate the problem to either

EI system ignition coil inputs or outputs.

5. In checking the ECM outputs for the electronic

spark timing signal, it recommended to use an os-

cilloscope to view the varying voltage signals. In

measuring these outputs with a voltmeter, intermit-

tent errors may occur that cannot be seen by a volt-

meter.

6. After confirming ECM inputs for the electronic spark

timing to the EI system ignition coil are OK, it can

be determined that a faulty EI system ignition coil is

at fault.

11. After confirming proper CKP sensor inputs to the

ECM and no wiring problems present, it can be de-

termined that the ECM is at fault.

24. This step, along with step 25, checks for battery

voltage and a ground to the EI system ignition coil.

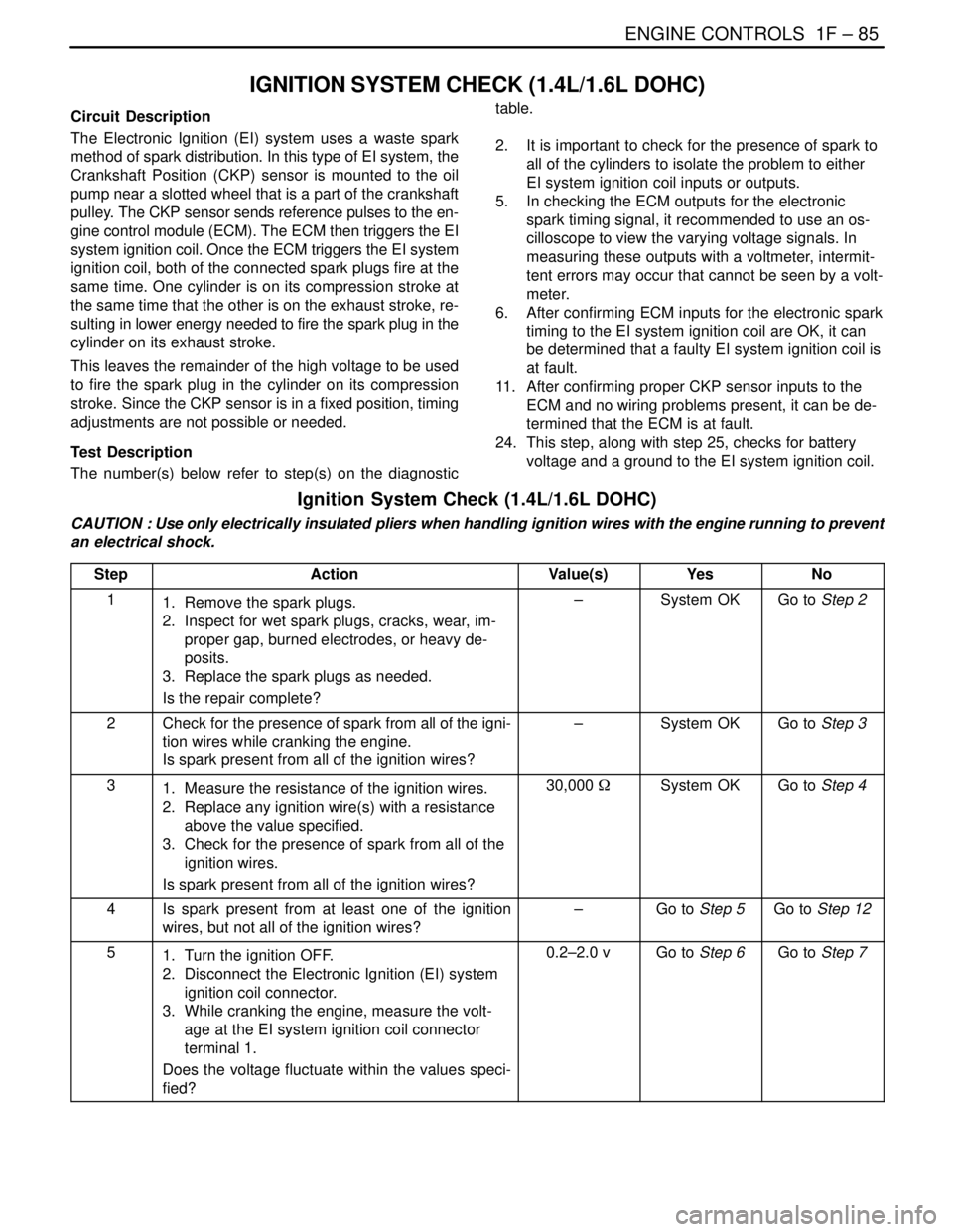

Ignition System Check (1.4L/1.6L DOHC)

CAUTION : Use only electrically insulated pliers when handling ignition wires with the engine running to prevent

an electrical shock.

Step

ActionValue(s)YesNo

11. Remove the spark plugs.

2. Inspect for wet spark plugs, cracks, wear, im-

proper gap, burned electrodes, or heavy de-

posits.

3. Replace the spark plugs as needed.

Is the repair complete?–System OKGo to Step 2

2Check for the presence of spark from all of the igni-

tion wires while cranking the engine.

Is spark present from all of the ignition wires?–System OKGo to Step 3

31. Measure the resistance of the ignition wires.

2. Replace any ignition wire(s) with a resistance

above the value specified.

3. Check for the presence of spark from all of the

ignition wires.

Is spark present from all of the ignition wires?30,000 WSystem OKGo to Step 4

4Is spark present from at least one of the ignition

wires, but not all of the ignition wires?–Go to Step 5Go to Step 12

51. Turn the ignition OFF.

2. Disconnect the Electronic Ignition (EI) system

ignition coil connector.

3. While cranking the engine, measure the volt-

age at the EI system ignition coil connector

terminal 1.

Does the voltage fluctuate within the values speci-

fied?0.2–2.0 vGo to Step 6Go to Step 7

Page 332 of 2643

1F – 86IENGINE CONTROLS

DAEWOO V–121 BL4

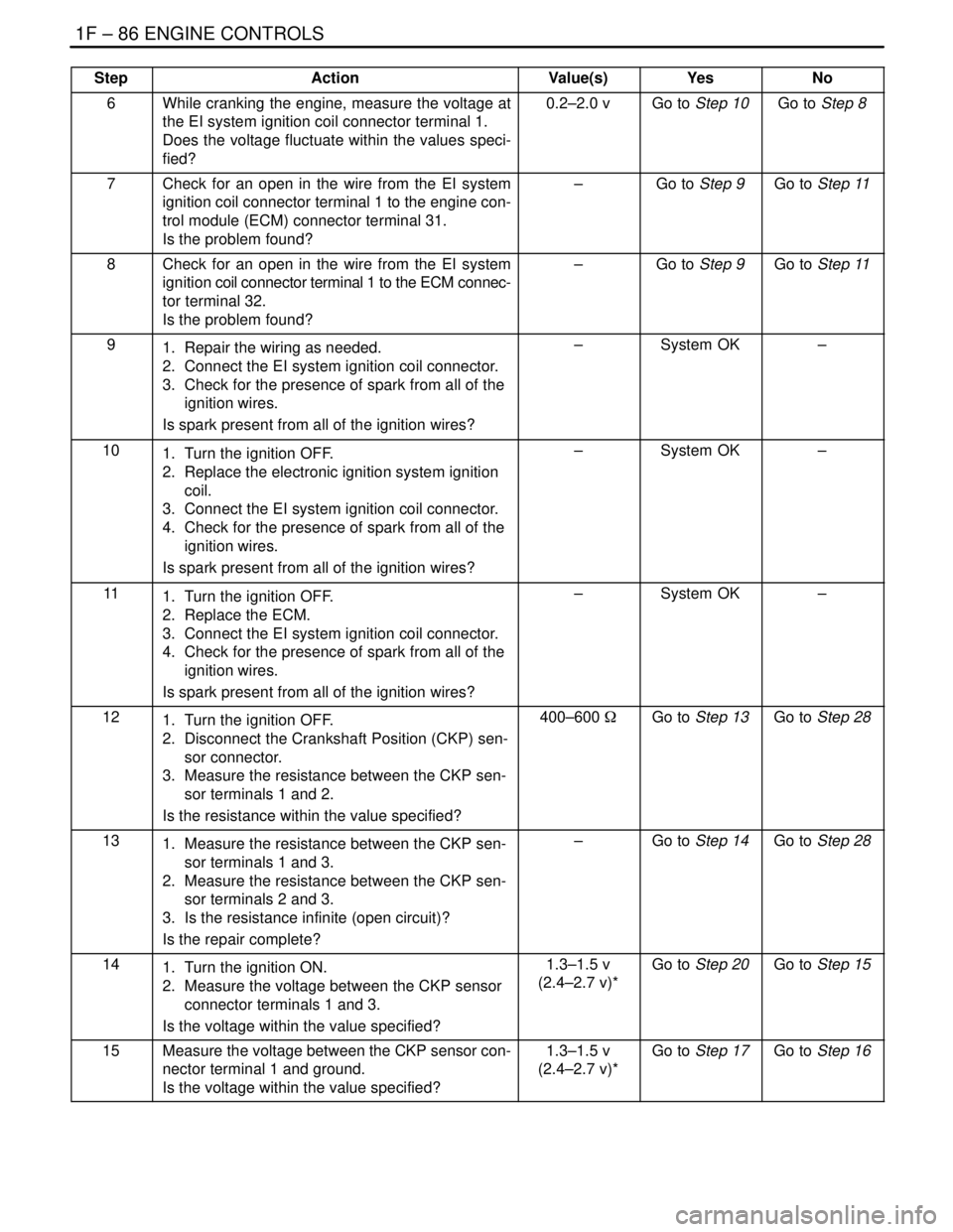

StepNo Yes Value(s) Action

6While cranking the engine, measure the voltage at

the EI system ignition coil connector terminal 1.

Does the voltage fluctuate within the values speci-

fied?0.2–2.0 vGo to Step 10Go to Step 8

7Check for an open in the wire from the EI system

ignition coil connector terminal 1 to the engine con-

trol module (ECM) connector terminal 31.

Is the problem found?–Go to Step 9Go to Step 11

8Check for an open in the wire from the EI system

ignition coil connector terminal 1 to the ECM connec-

tor terminal 32.

Is the problem found?–Go to Step 9Go to Step 11

91. Repair the wiring as needed.

2. Connect the EI system ignition coil connector.

3. Check for the presence of spark from all of the

ignition wires.

Is spark present from all of the ignition wires?–System OK–

101. Turn the ignition OFF.

2. Replace the electronic ignition system ignition

coil.

3. Connect the EI system ignition coil connector.

4. Check for the presence of spark from all of the

ignition wires.

Is spark present from all of the ignition wires?–System OK–

111. Turn the ignition OFF.

2. Replace the ECM.

3. Connect the EI system ignition coil connector.

4. Check for the presence of spark from all of the

ignition wires.

Is spark present from all of the ignition wires?–System OK–

121. Turn the ignition OFF.

2. Disconnect the Crankshaft Position (CKP) sen-

sor connector.

3. Measure the resistance between the CKP sen-

sor terminals 1 and 2.

Is the resistance within the value specified?400–600 WGo to Step 13Go to Step 28

131. Measure the resistance between the CKP sen-

sor terminals 1 and 3.

2. Measure the resistance between the CKP sen-

sor terminals 2 and 3.

3. Is the resistance infinite (open circuit)?

Is the repair complete?–Go to Step 14Go to Step 28

141. Turn the ignition ON.

2. Measure the voltage between the CKP sensor

connector terminals 1 and 3.

Is the voltage within the value specified?1.3–1.5 v

(2.4–2.7 v)*Go to Step 20Go to Step 15

15Measure the voltage between the CKP sensor con-

nector terminal 1 and ground.

Is the voltage within the value specified?1.3–1.5 v

(2.4–2.7 v)*Go to Step 17Go to Step 16

Page 333 of 2643

ENGINE CONTROLS 1F – 87

DAEWOO V–121 BL4

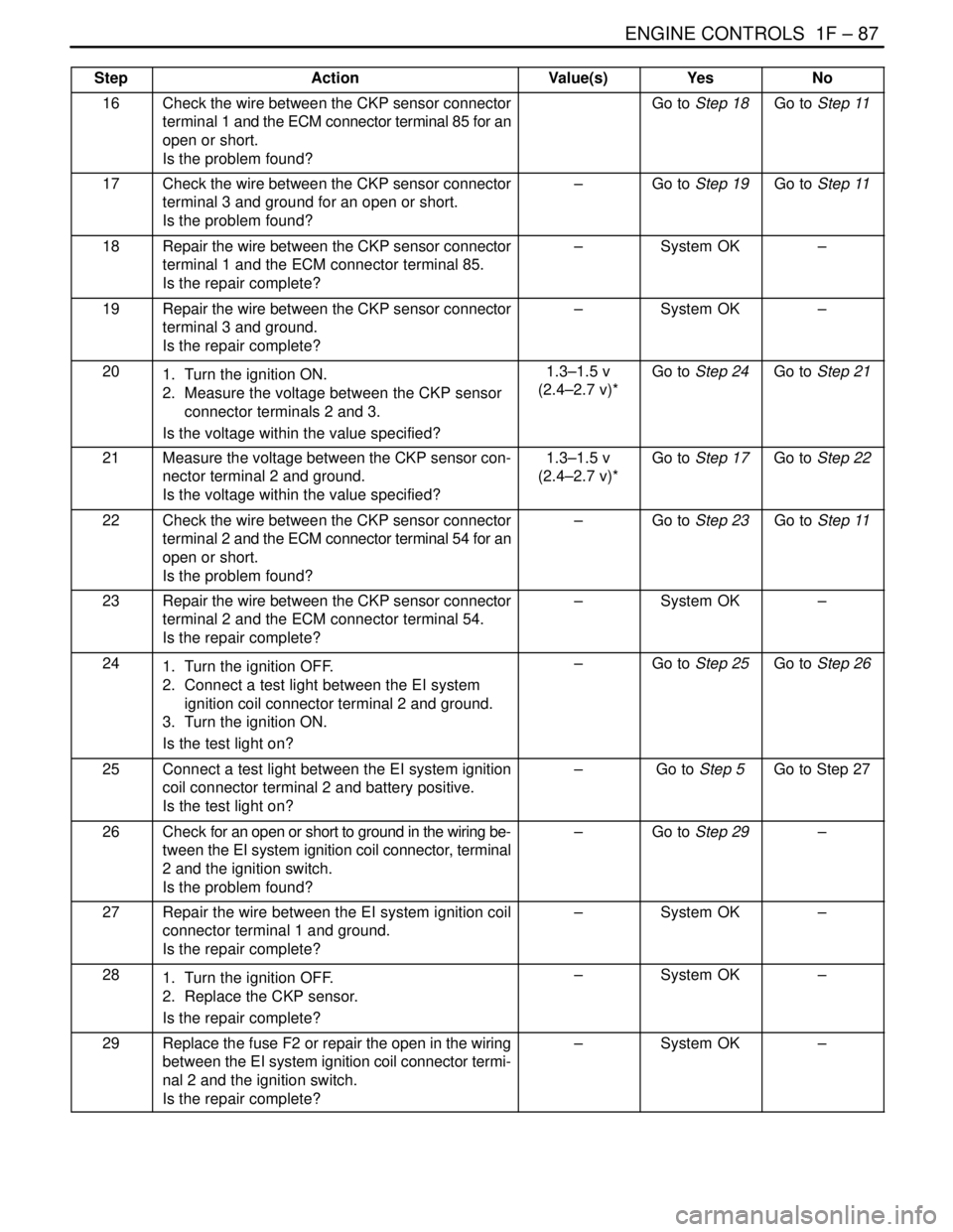

StepNo Yes Value(s) Action

16Check the wire between the CKP sensor connector

terminal 1 and the ECM connector terminal 85 for an

open or short.

Is the problem found?Go to Step 18Go to Step 11

17Check the wire between the CKP sensor connector

terminal 3 and ground for an open or short.

Is the problem found?–Go to Step 19Go to Step 11

18Repair the wire between the CKP sensor connector

terminal 1 and the ECM connector terminal 85.

Is the repair complete?–System OK–

19Repair the wire between the CKP sensor connector

terminal 3 and ground.

Is the repair complete?–System OK–

201. Turn the ignition ON.

2. Measure the voltage between the CKP sensor

connector terminals 2 and 3.

Is the voltage within the value specified?1.3–1.5 v

(2.4–2.7 v)*Go to Step 24Go to Step 21

21Measure the voltage between the CKP sensor con-

nector terminal 2 and ground.

Is the voltage within the value specified?1.3–1.5 v

(2.4–2.7 v)*Go to Step 17Go to Step 22

22Check the wire between the CKP sensor connector

terminal 2 and the ECM connector terminal 54 for an

open or short.

Is the problem found?–Go to Step 23Go to Step 11

23Repair the wire between the CKP sensor connector

terminal 2 and the ECM connector terminal 54.

Is the repair complete?–System OK–

241. Turn the ignition OFF.

2. Connect a test light between the EI system

ignition coil connector terminal 2 and ground.

3. Turn the ignition ON.

Is the test light on?–Go to Step 25Go to Step 26

25Connect a test light between the EI system ignition

coil connector terminal 2 and battery positive.

Is the test light on?–Go to Step 5Go to Step 27

26Check for an open or short to ground in the wiring be-

tween the EI system ignition coil connector, terminal

2 and the ignition switch.

Is the problem found?–Go to Step 29–

27Repair the wire between the EI system ignition coil

connector terminal 1 and ground.

Is the repair complete?–System OK–

281. Turn the ignition OFF.

2. Replace the CKP sensor.

Is the repair complete?–System OK–

29Replace the fuse F2 or repair the open in the wiring

between the EI system ignition coil connector termi-

nal 2 and the ignition switch.

Is the repair complete?–System OK–

Page 334 of 2643

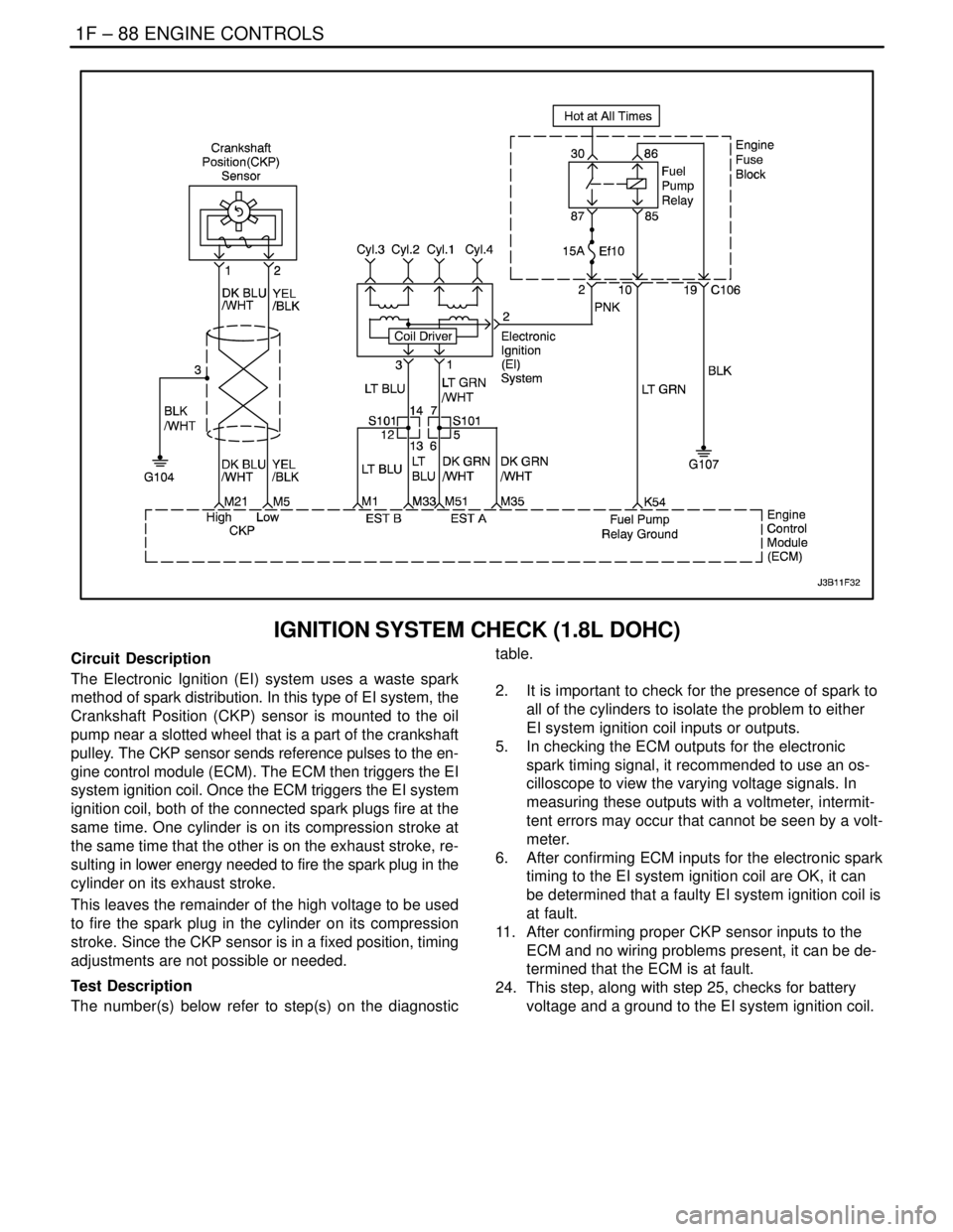

1F – 88IENGINE CONTROLS

DAEWOO V–121 BL4

IGNITION SYSTEM CHECK (1.8L DOHC)

Circuit Description

The Electronic Ignition (EI) system uses a waste spark

method of spark distribution. In this type of EI system, the

Crankshaft Position (CKP) sensor is mounted to the oil

pump near a slotted wheel that is a part of the crankshaft

pulley. The CKP sensor sends reference pulses to the en-

gine control module (ECM). The ECM then triggers the EI

system ignition coil. Once the ECM triggers the EI system

ignition coil, both of the connected spark plugs fire at the

same time. One cylinder is on its compression stroke at

the same time that the other is on the exhaust stroke, re-

sulting in lower energy needed to fire the spark plug in the

cylinder on its exhaust stroke.

This leaves the remainder of the high voltage to be used

to fire the spark plug in the cylinder on its compression

stroke. Since the CKP sensor is in a fixed position, timing

adjustments are not possible or needed.

Test Description

The number(s) below refer to step(s) on the diagnostictable.

2. It is important to check for the presence of spark to

all of the cylinders to isolate the problem to either

EI system ignition coil inputs or outputs.

5. In checking the ECM outputs for the electronic

spark timing signal, it recommended to use an os-

cilloscope to view the varying voltage signals. In

measuring these outputs with a voltmeter, intermit-

tent errors may occur that cannot be seen by a volt-

meter.

6. After confirming ECM inputs for the electronic spark

timing to the EI system ignition coil are OK, it can

be determined that a faulty EI system ignition coil is

at fault.

11. After confirming proper CKP sensor inputs to the

ECM and no wiring problems present, it can be de-

termined that the ECM is at fault.

24. This step, along with step 25, checks for battery

voltage and a ground to the EI system ignition coil.

Page 335 of 2643

ENGINE CONTROLS 1F – 89

DAEWOO V–121 BL4

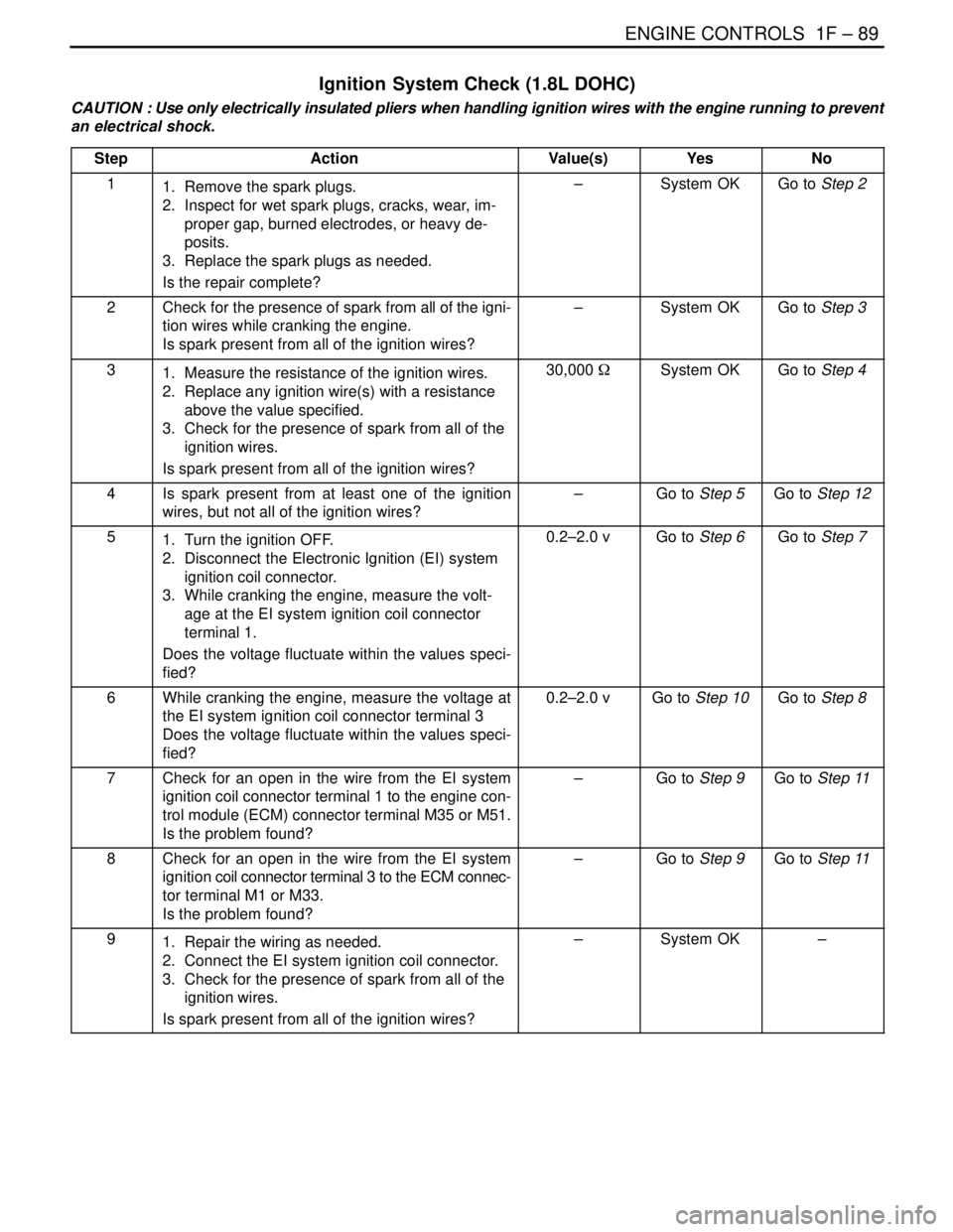

Ignition System Check (1.8L DOHC)

CAUTION : Use only electrically insulated pliers when handling ignition wires with the engine running to prevent

an electrical shock.

Step

ActionValue(s)YesNo

11. Remove the spark plugs.

2. Inspect for wet spark plugs, cracks, wear, im-

proper gap, burned electrodes, or heavy de-

posits.

3. Replace the spark plugs as needed.

Is the repair complete?–System OKGo to Step 2

2Check for the presence of spark from all of the igni-

tion wires while cranking the engine.

Is spark present from all of the ignition wires?–System OKGo to Step 3

31. Measure the resistance of the ignition wires.

2. Replace any ignition wire(s) with a resistance

above the value specified.

3. Check for the presence of spark from all of the

ignition wires.

Is spark present from all of the ignition wires?30,000 WSystem OKGo to Step 4

4Is spark present from at least one of the ignition

wires, but not all of the ignition wires?–Go to Step 5Go to Step 12

51. Turn the ignition OFF.

2. Disconnect the Electronic Ignition (EI) system

ignition coil connector.

3. While cranking the engine, measure the volt-

age at the EI system ignition coil connector

terminal 1.

Does the voltage fluctuate within the values speci-

fied?0.2–2.0 vGo to Step 6Go to Step 7

6While cranking the engine, measure the voltage at

the EI system ignition coil connector terminal 3

Does the voltage fluctuate within the values speci-

fied?0.2–2.0 vGo to Step 10Go to Step 8

7Check for an open in the wire from the EI system

ignition coil connector terminal 1 to the engine con-

trol module (ECM) connector terminal M35 or M51.

Is the problem found?–Go to Step 9Go to Step 11

8Check for an open in the wire from the EI system

ignition coil connector terminal 3 to the ECM connec-

tor terminal M1 or M33.

Is the problem found?–Go to Step 9Go to Step 11

91. Repair the wiring as needed.

2. Connect the EI system ignition coil connector.

3. Check for the presence of spark from all of the

ignition wires.

Is spark present from all of the ignition wires?–System OK–

Page 336 of 2643

1F – 90IENGINE CONTROLS

DAEWOO V–121 BL4

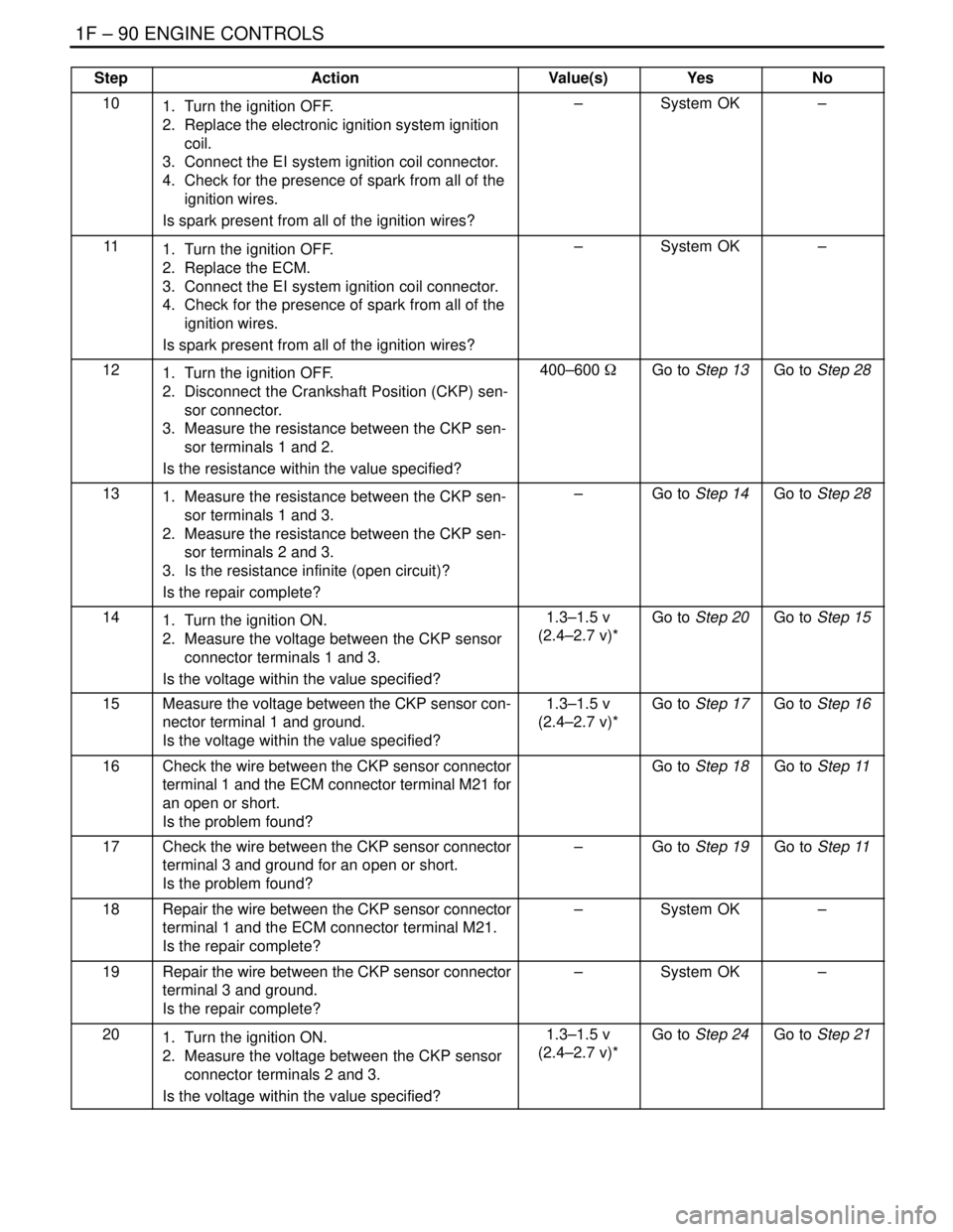

StepNo Yes Value(s) Action

101. Turn the ignition OFF.

2. Replace the electronic ignition system ignition

coil.

3. Connect the EI system ignition coil connector.

4. Check for the presence of spark from all of the

ignition wires.

Is spark present from all of the ignition wires?–System OK–

111. Turn the ignition OFF.

2. Replace the ECM.

3. Connect the EI system ignition coil connector.

4. Check for the presence of spark from all of the

ignition wires.

Is spark present from all of the ignition wires?–System OK–

121. Turn the ignition OFF.

2. Disconnect the Crankshaft Position (CKP) sen-

sor connector.

3. Measure the resistance between the CKP sen-

sor terminals 1 and 2.

Is the resistance within the value specified?400–600 WGo to Step 13Go to Step 28

131. Measure the resistance between the CKP sen-

sor terminals 1 and 3.

2. Measure the resistance between the CKP sen-

sor terminals 2 and 3.

3. Is the resistance infinite (open circuit)?

Is the repair complete?–Go to Step 14Go to Step 28

141. Turn the ignition ON.

2. Measure the voltage between the CKP sensor

connector terminals 1 and 3.

Is the voltage within the value specified?1.3–1.5 v

(2.4–2.7 v)*Go to Step 20Go to Step 15

15Measure the voltage between the CKP sensor con-

nector terminal 1 and ground.

Is the voltage within the value specified?1.3–1.5 v

(2.4–2.7 v)*Go to Step 17Go to Step 16

16Check the wire between the CKP sensor connector

terminal 1 and the ECM connector terminal M21 for

an open or short.

Is the problem found?Go to Step 18Go to Step 11

17Check the wire between the CKP sensor connector

terminal 3 and ground for an open or short.

Is the problem found?–Go to Step 19Go to Step 11

18Repair the wire between the CKP sensor connector

terminal 1 and the ECM connector terminal M21.

Is the repair complete?–System OK–

19Repair the wire between the CKP sensor connector

terminal 3 and ground.

Is the repair complete?–System OK–

201. Turn the ignition ON.

2. Measure the voltage between the CKP sensor

connector terminals 2 and 3.

Is the voltage within the value specified?1.3–1.5 v

(2.4–2.7 v)*Go to Step 24Go to Step 21

Page 337 of 2643

ENGINE CONTROLS 1F – 91

DAEWOO V–121 BL4

StepNo Yes Value(s) Action

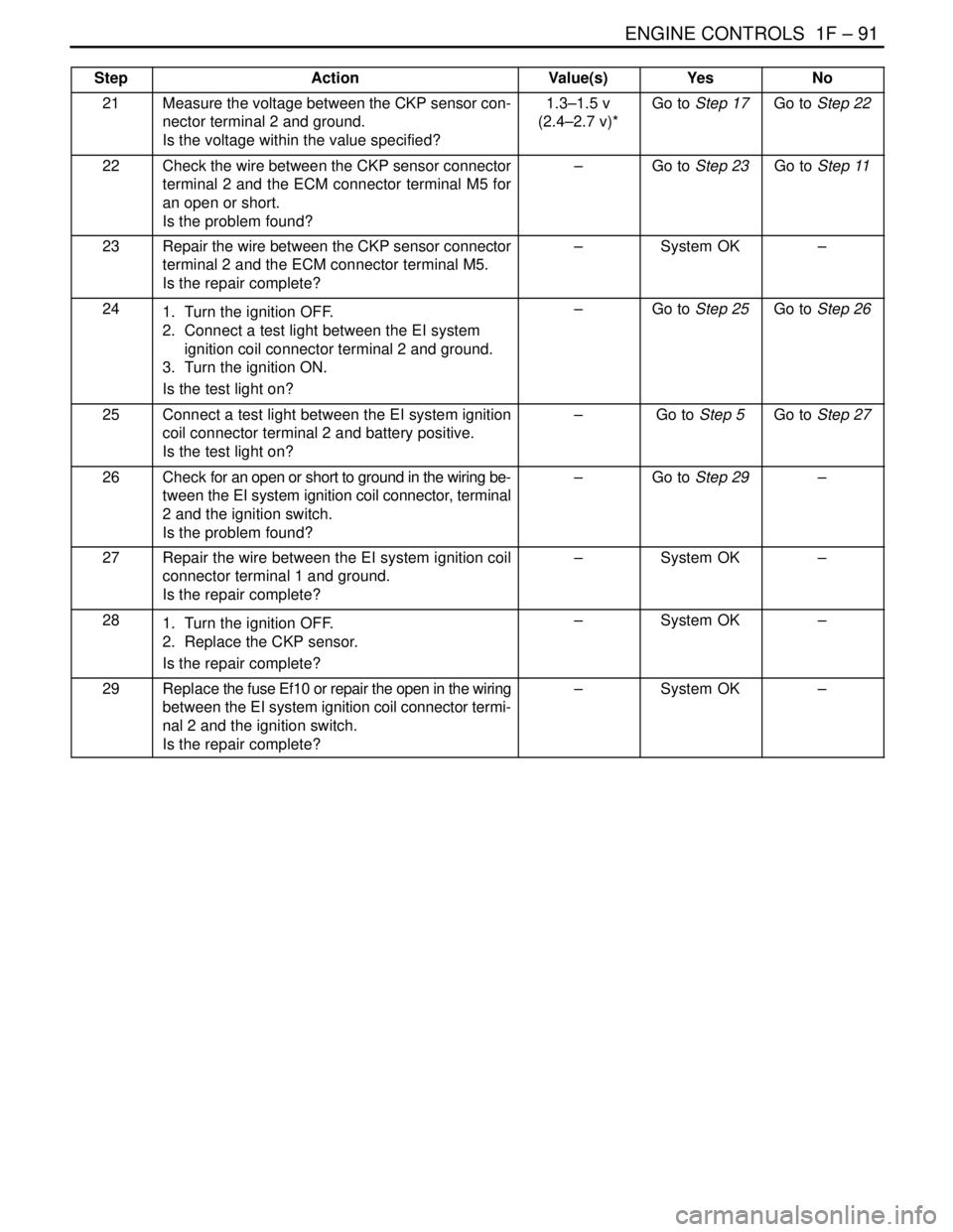

21Measure the voltage between the CKP sensor con-

nector terminal 2 and ground.

Is the voltage within the value specified?1.3–1.5 v

(2.4–2.7 v)*Go to Step 17Go to Step 22

22Check the wire between the CKP sensor connector

terminal 2 and the ECM connector terminal M5 for

an open or short.

Is the problem found?–Go to Step 23Go to Step 11

23Repair the wire between the CKP sensor connector

terminal 2 and the ECM connector terminal M5.

Is the repair complete?–System OK–

241. Turn the ignition OFF.

2. Connect a test light between the EI system

ignition coil connector terminal 2 and ground.

3. Turn the ignition ON.

Is the test light on?–Go to Step 25Go to Step 26

25Connect a test light between the EI system ignition

coil connector terminal 2 and battery positive.

Is the test light on?–Go to Step 5Go to Step 27

26Check for an open or short to ground in the wiring be-

tween the EI system ignition coil connector, terminal

2 and the ignition switch.

Is the problem found?–Go to Step 29–

27Repair the wire between the EI system ignition coil

connector terminal 1 and ground.

Is the repair complete?–System OK–

281. Turn the ignition OFF.

2. Replace the CKP sensor.

Is the repair complete?–System OK–

29Replace the fuse Ef10 or repair the open in the wiring

between the EI system ignition coil connector termi-

nal 2 and the ignition switch.

Is the repair complete?–System OK–

Page 338 of 2643

1F – 92IENGINE CONTROLS

DAEWOO V–121 BL4

Page 339 of 2643

ENGINE CONTROLS 1F – 93

DAEWOO V–121 BL4

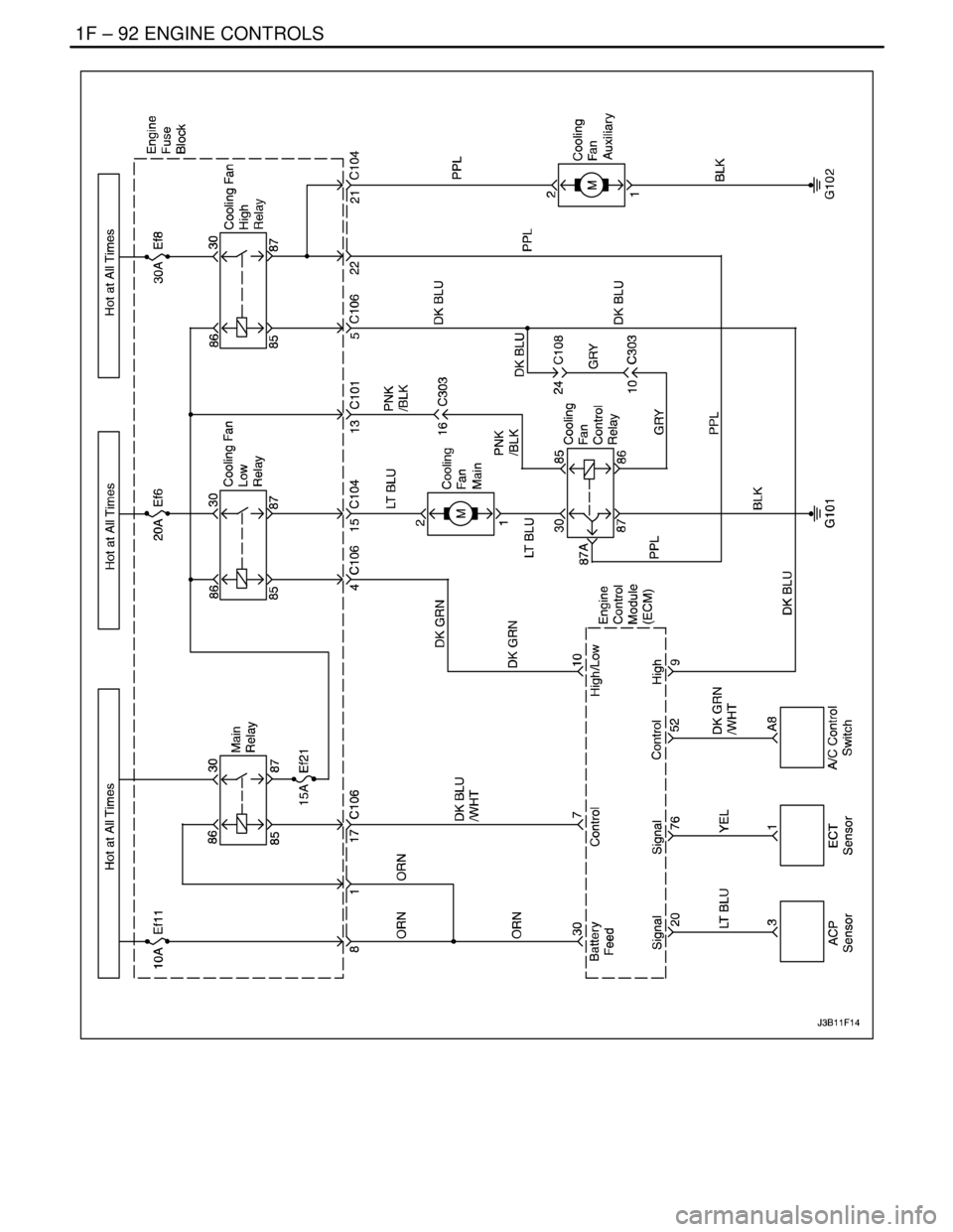

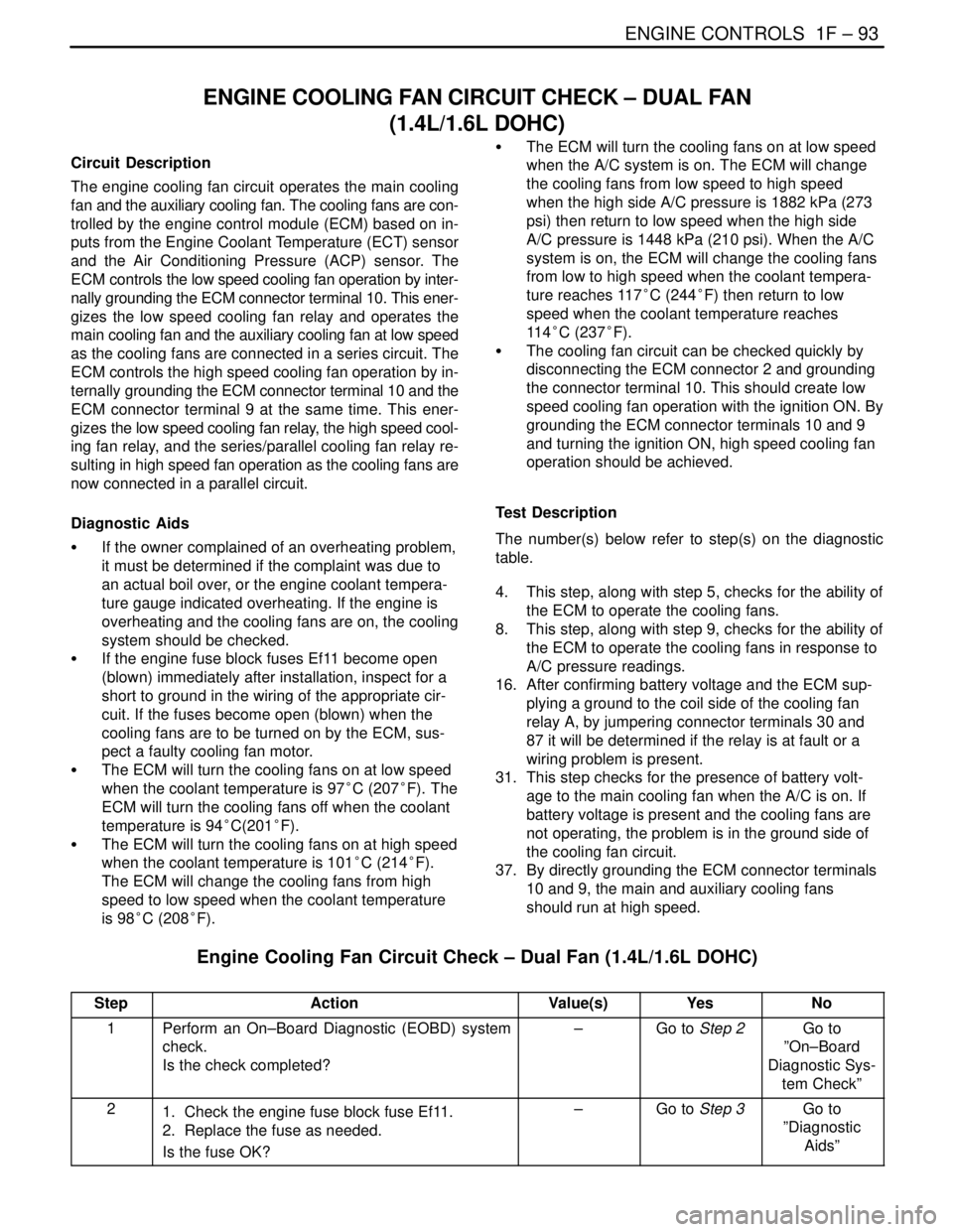

ENGINE COOLING FAN CIRCUIT CHECK – DUAL FAN

(1.4L/1.6L DOHC)

Circuit Description

The engine cooling fan circuit operates the main cooling

fan and the auxiliary cooling fan. The cooling fans are con-

trolled by the engine control module (ECM) based on in-

puts from the Engine Coolant Temperature (ECT) sensor

and the Air Conditioning Pressure (ACP) sensor. The

ECM controls the low speed cooling fan operation by inter-

nally grounding the ECM connector terminal 10. This ener-

gizes the low speed cooling fan relay and operates the

main cooling fan and the auxiliary cooling fan at low speed

as the cooling fans are connected in a series circuit. The

ECM controls the high speed cooling fan operation by in-

ternally grounding the ECM connector terminal 10 and the

ECM connector terminal 9 at the same time. This ener-

gizes the low speed cooling fan relay, the high speed cool-

ing fan relay, and the series/parallel cooling fan relay re-

sulting in high speed fan operation as the cooling fans are

now connected in a parallel circuit.

Diagnostic Aids

S If the owner complained of an overheating problem,

it must be determined if the complaint was due to

an actual boil over, or the engine coolant tempera-

ture gauge indicated overheating. If the engine is

overheating and the cooling fans are on, the cooling

system should be checked.

S If the engine fuse block fuses Ef11 become open

(blown) immediately after installation, inspect for a

short to ground in the wiring of the appropriate cir-

cuit. If the fuses become open (blown) when the

cooling fans are to be turned on by the ECM, sus-

pect a faulty cooling fan motor.

S The ECM will turn the cooling fans on at low speed

when the coolant temperature is 97°C (207°F). The

ECM will turn the cooling fans off when the coolant

temperature is 94°C(201°F).

S The ECM will turn the cooling fans on at high speed

when the coolant temperature is 101°C (214°F).

The ECM will change the cooling fans from high

speed to low speed when the coolant temperature

is 98°C (208°F).S The ECM will turn the cooling fans on at low speed

when the A/C system is on. The ECM will change

the cooling fans from low speed to high speed

when the high side A/C pressure is 1882 kPa (273

psi) then return to low speed when the high side

A/C pressure is 1448 kPa (210 psi). When the A/C

system is on, the ECM will change the cooling fans

from low to high speed when the coolant tempera-

ture reaches 117°C (244°F) then return to low

speed when the coolant temperature reaches

11 4°C (237°F).

S The cooling fan circuit can be checked quickly by

disconnecting the ECM connector 2 and grounding

the connector terminal 10. This should create low

speed cooling fan operation with the ignition ON. By

grounding the ECM connector terminals 10 and 9

and turning the ignition ON, high speed cooling fan

operation should be achieved.

Test Description

The number(s) below refer to step(s) on the diagnostic

table.

4. This step, along with step 5, checks for the ability of

the ECM to operate the cooling fans.

8. This step, along with step 9, checks for the ability of

the ECM to operate the cooling fans in response to

A/C pressure readings.

16. After confirming battery voltage and the ECM sup-

plying a ground to the coil side of the cooling fan

relay A, by jumpering connector terminals 30 and

87 it will be determined if the relay is at fault or a

wiring problem is present.

31. This step checks for the presence of battery volt-

age to the main cooling fan when the A/C is on. If

battery voltage is present and the cooling fans are

not operating, the problem is in the ground side of

the cooling fan circuit.

37. By directly grounding the ECM connector terminals

10 and 9, the main and auxiliary cooling fans

should run at high speed.

Engine Cooling Fan Circuit Check – Dual Fan (1.4L/1.6L DOHC)

StepActionValue(s)YesNo

1Perform an On–Board Diagnostic (EOBD) system

check.

Is the check completed?–Go to Step 2Go to

”On–Board

Diagnostic Sys-

tem Check”

21. Check the engine fuse block fuse Ef11.

2. Replace the fuse as needed.

Is the fuse OK?–Go to Step 3Go to

”Diagnostic

Aids”

Page 340 of 2643

1F – 94IENGINE CONTROLS

DAEWOO V–121 BL4

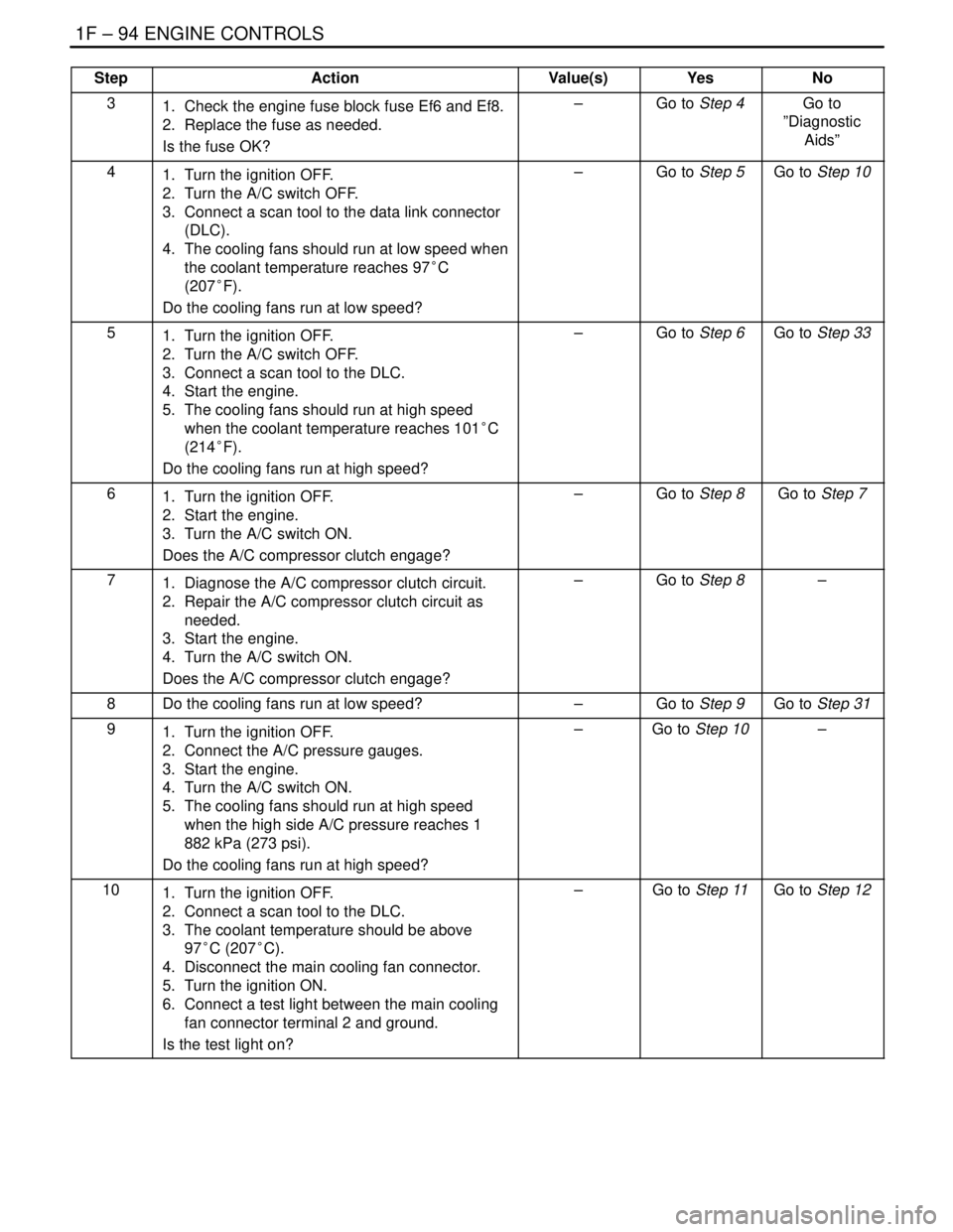

StepNo Yes Value(s) Action

31. Check the engine fuse block fuse Ef6 and Ef8.

2. Replace the fuse as needed.

Is the fuse OK?–Go to Step 4Go to

”Diagnostic

Aids”

41. Turn the ignition OFF.

2. Turn the A/C switch OFF.

3. Connect a scan tool to the data link connector

(DLC).

4. The cooling fans should run at low speed when

the coolant temperature reaches 97°C

(207°F).

Do the cooling fans run at low speed?–Go to Step 5Go to Step 10

51. Turn the ignition OFF.

2. Turn the A/C switch OFF.

3. Connect a scan tool to the DLC.

4. Start the engine.

5. The cooling fans should run at high speed

when the coolant temperature reaches 101°C

(214°F).

Do the cooling fans run at high speed?–Go to Step 6Go to Step 33

61. Turn the ignition OFF.

2. Start the engine.

3. Turn the A/C switch ON.

Does the A/C compressor clutch engage?–Go to Step 8Go to Step 7

71. Diagnose the A/C compressor clutch circuit.

2. Repair the A/C compressor clutch circuit as

needed.

3. Start the engine.

4. Turn the A/C switch ON.

Does the A/C compressor clutch engage?–Go to Step 8–

8Do the cooling fans run at low speed?–Go to Step 9Go to Step 31

91. Turn the ignition OFF.

2. Connect the A/C pressure gauges.

3. Start the engine.

4. Turn the A/C switch ON.

5. The cooling fans should run at high speed

when the high side A/C pressure reaches 1

882 kPa (273 psi).

Do the cooling fans run at high speed?–Go to Step 10–

101. Turn the ignition OFF.

2. Connect a scan tool to the DLC.

3. The coolant temperature should be above

97°C (207°C).

4. Disconnect the main cooling fan connector.

5. Turn the ignition ON.

6. Connect a test light between the main cooling

fan connector terminal 2 and ground.

Is the test light on?–Go to Step 11Go to Step 12