DAEWOO NUBIRA 2004 Service Repair Manual

Manufacturer: DAEWOO, Model Year: 2004, Model line: NUBIRA, Model: DAEWOO NUBIRA 2004Pages: 2643, PDF Size: 80.54 MB

Page 351 of 2643

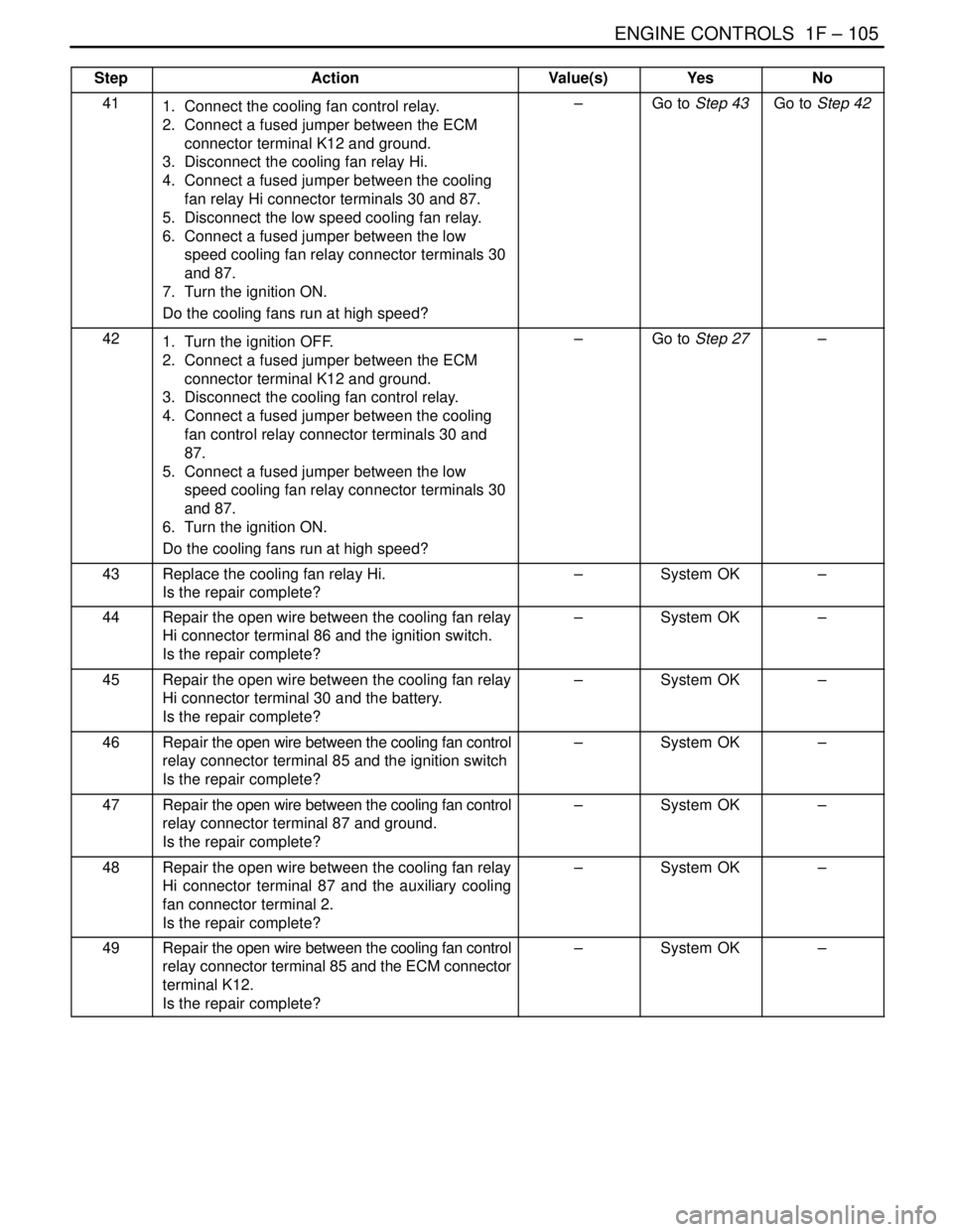

ENGINE CONTROLS 1F – 105

DAEWOO V–121 BL4

StepNo Yes Value(s) Action

411. Connect the cooling fan control relay.

2. Connect a fused jumper between the ECM

connector terminal K12 and ground.

3. Disconnect the cooling fan relay Hi.

4. Connect a fused jumper between the cooling

fan relay Hi connector terminals 30 and 87.

5. Disconnect the low speed cooling fan relay.

6. Connect a fused jumper between the low

speed cooling fan relay connector terminals 30

and 87.

7. Turn the ignition ON.

Do the cooling fans run at high speed?–Go to Step 43Go to Step 42

421. Turn the ignition OFF.

2. Connect a fused jumper between the ECM

connector terminal K12 and ground.

3. Disconnect the cooling fan control relay.

4. Connect a fused jumper between the cooling

fan control relay connector terminals 30 and

87.

5. Connect a fused jumper between the low

speed cooling fan relay connector terminals 30

and 87.

6. Turn the ignition ON.

Do the cooling fans run at high speed?–Go to Step 27–

43Replace the cooling fan relay Hi.

Is the repair complete?–System OK–

44Repair the open wire between the cooling fan relay

Hi connector terminal 86 and the ignition switch.

Is the repair complete?–System OK–

45Repair the open wire between the cooling fan relay

Hi connector terminal 30 and the battery.

Is the repair complete?–System OK–

46Repair the open wire between the cooling fan control

relay connector terminal 85 and the ignition switch

Is the repair complete?–System OK–

47Repair the open wire between the cooling fan control

relay connector terminal 87 and ground.

Is the repair complete?–System OK–

48Repair the open wire between the cooling fan relay

Hi connector terminal 87 and the auxiliary cooling

fan connector terminal 2.

Is the repair complete?–System OK–

49Repair the open wire between the cooling fan control

relay connector terminal 85 and the ECM connector

terminal K12.

Is the repair complete?–System OK–

Page 352 of 2643

1F – 106IENGINE CONTROLS

DAEWOO V–121 BL4

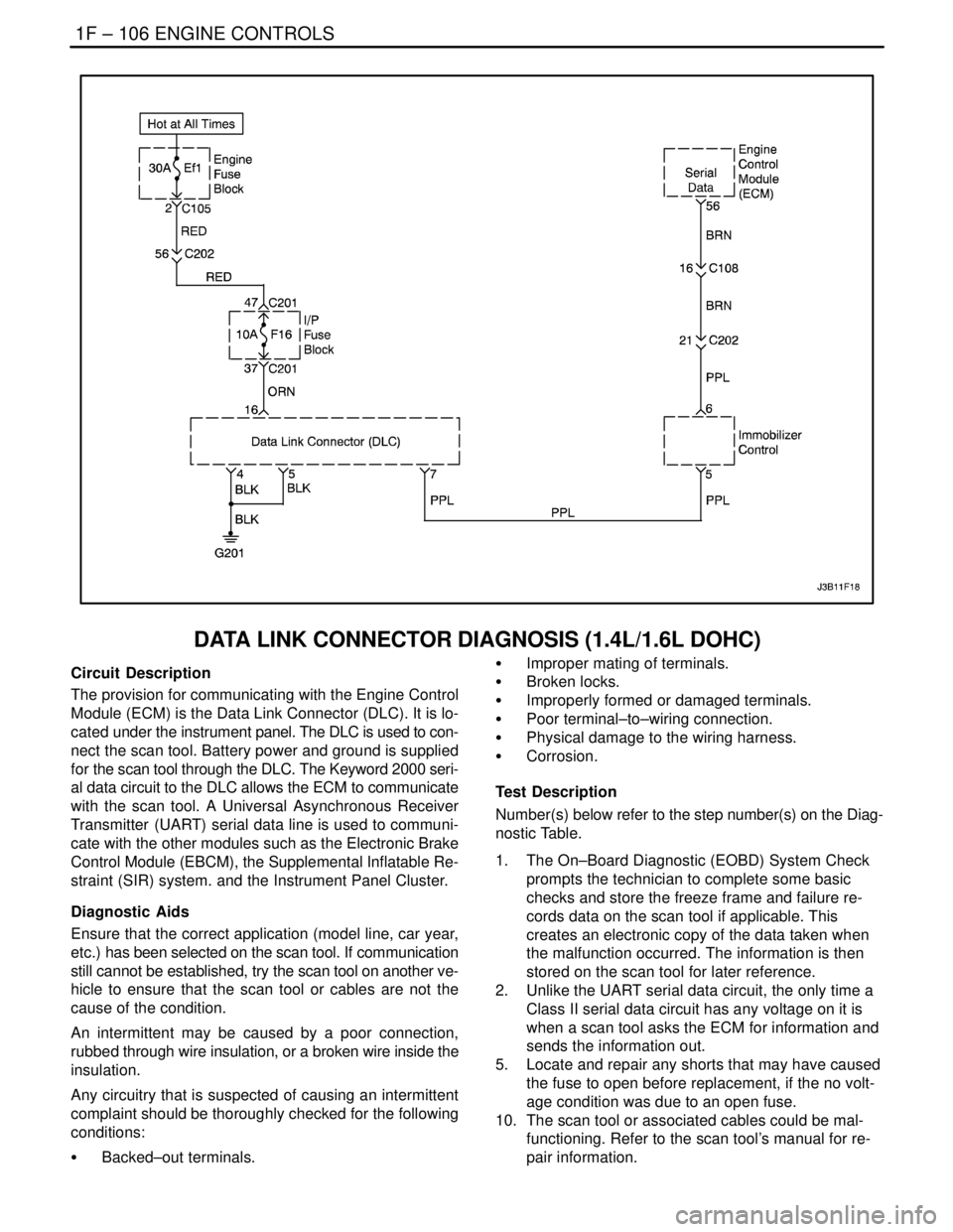

DATA LINK CONNECTOR DIAGNOSIS (1.4L/1.6L DOHC)

Circuit Description

The provision for communicating with the Engine Control

Module (ECM) is the Data Link Connector (DLC). It is lo-

cated under the instrument panel. The DLC is used to con-

nect the scan tool. Battery power and ground is supplied

for the scan tool through the DLC. The Keyword 2000 seri-

al data circuit to the DLC allows the ECM to communicate

with the scan tool. A Universal Asynchronous Receiver

Transmitter (UART) serial data line is used to communi-

cate with the other modules such as the Electronic Brake

Control Module (EBCM), the Supplemental Inflatable Re-

straint (SIR) system. and the Instrument Panel Cluster.

Diagnostic Aids

Ensure that the correct application (model line, car year,

etc.) has been selected on the scan tool. If communication

still cannot be established, try the scan tool on another ve-

hicle to ensure that the scan tool or cables are not the

cause of the condition.

An intermittent may be caused by a poor connection,

rubbed through wire insulation, or a broken wire inside the

insulation.

Any circuitry that is suspected of causing an intermittent

complaint should be thoroughly checked for the following

conditions:

S Backed–out terminals.S Improper mating of terminals.

S Broken locks.

S Improperly formed or damaged terminals.

S Poor terminal–to–wiring connection.

S Physical damage to the wiring harness.

S Corrosion.

Test Description

Number(s) below refer to the step number(s) on the Diag-

nostic Table.

1. The On–Board Diagnostic (EOBD) System Check

prompts the technician to complete some basic

checks and store the freeze frame and failure re-

cords data on the scan tool if applicable. This

creates an electronic copy of the data taken when

the malfunction occurred. The information is then

stored on the scan tool for later reference.

2. Unlike the UART serial data circuit, the only time a

Class II serial data circuit has any voltage on it is

when a scan tool asks the ECM for information and

sends the information out.

5. Locate and repair any shorts that may have caused

the fuse to open before replacement, if the no volt-

age condition was due to an open fuse.

10. The scan tool or associated cables could be mal-

functioning. Refer to the scan tool’s manual for re-

pair information.

Page 353 of 2643

ENGINE CONTROLS 1F – 107

DAEWOO V–121 BL4

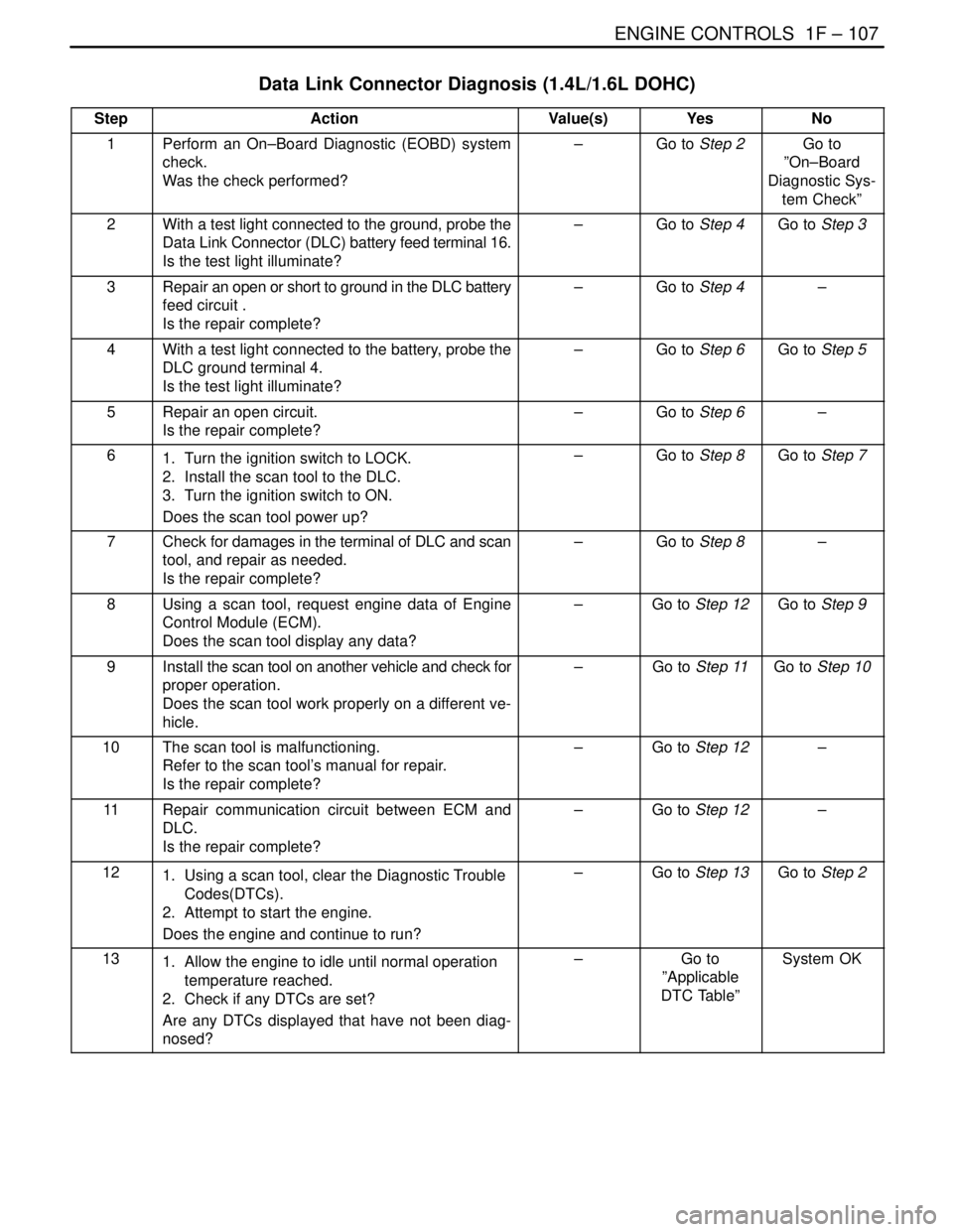

Data Link Connector Diagnosis (1.4L/1.6L DOHC)

StepActionValue(s)YesNo

1Perform an On–Board Diagnostic (EOBD) system

check.

Was the check performed?–Go to Step 2Go to

”On–Board

Diagnostic Sys-

tem Check”

2With a test light connected to the ground, probe the

Data Link Connector (DLC) battery feed terminal 16.

Is the test light illuminate?–Go to Step 4Go to Step 3

3Repair an open or short to ground in the DLC battery

feed circuit .

Is the repair complete?–Go to Step 4–

4With a test light connected to the battery, probe the

DLC ground terminal 4.

Is the test light illuminate?–Go to Step 6Go to Step 5

5Repair an open circuit.

Is the repair complete?–Go to Step 6–

61. Turn the ignition switch to LOCK.

2. Install the scan tool to the DLC.

3. Turn the ignition switch to ON.

Does the scan tool power up?–Go to Step 8Go to Step 7

7Check for damages in the terminal of DLC and scan

tool, and repair as needed.

Is the repair complete?–Go to Step 8–

8Using a scan tool, request engine data of Engine

Control Module (ECM).

Does the scan tool display any data?–Go to Step 12Go to Step 9

9Install the scan tool on another vehicle and check for

proper operation.

Does the scan tool work properly on a different ve-

hicle.–Go to Step 11Go to Step 10

10The scan tool is malfunctioning.

Refer to the scan tool’s manual for repair.

Is the repair complete?–Go to Step 12–

11Repair communication circuit between ECM and

DLC.

Is the repair complete?–Go to Step 12–

121. Using a scan tool, clear the Diagnostic Trouble

Codes(DTCs).

2. Attempt to start the engine.

Does the engine and continue to run?–Go to Step 13Go to Step 2

131. Allow the engine to idle until normal operation

temperature reached.

2. Check if any DTCs are set?

Are any DTCs displayed that have not been diag-

nosed?–Go to

”Applicable

DTC Table”System OK

Page 354 of 2643

1F – 108IENGINE CONTROLS

DAEWOO V–121 BL4

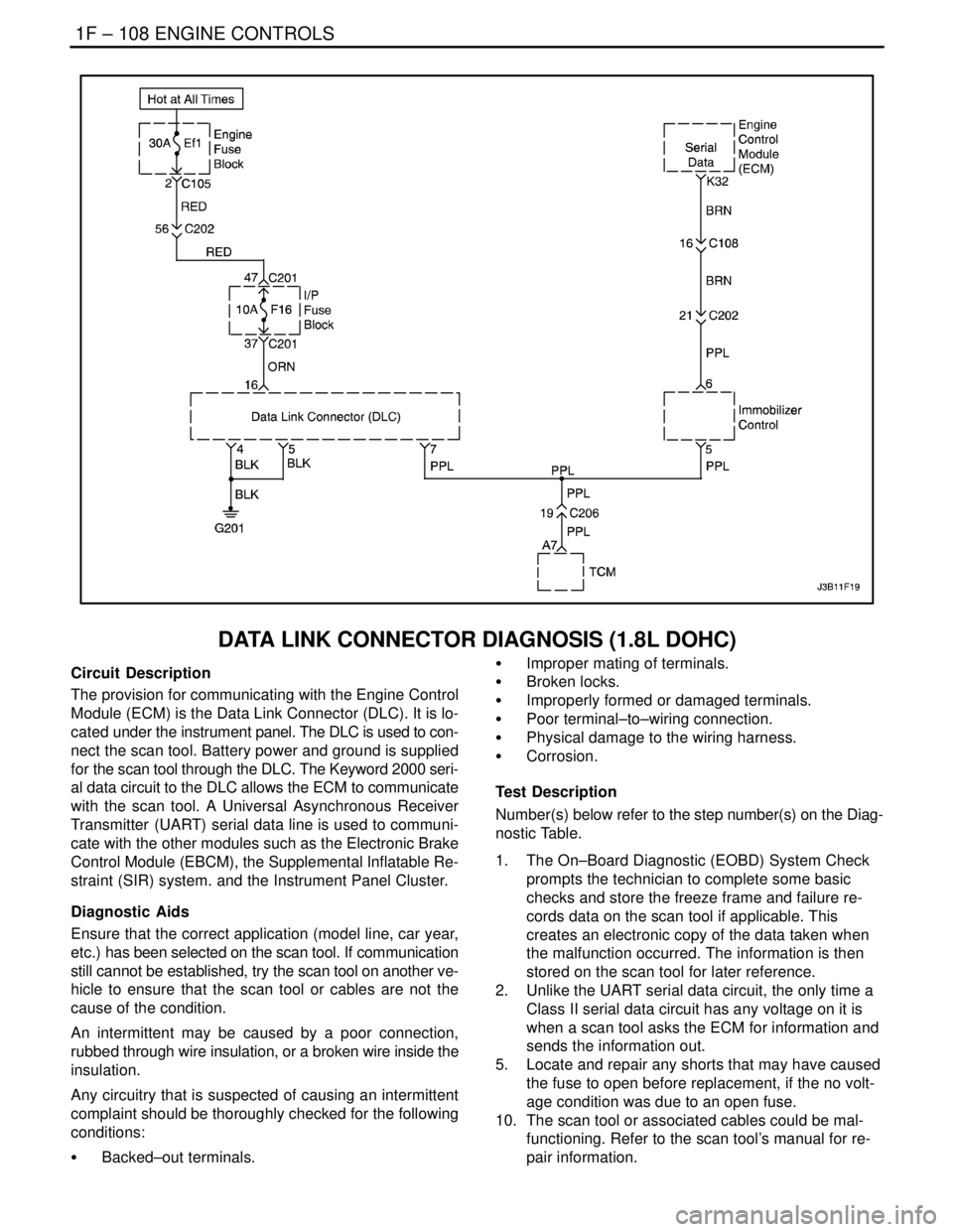

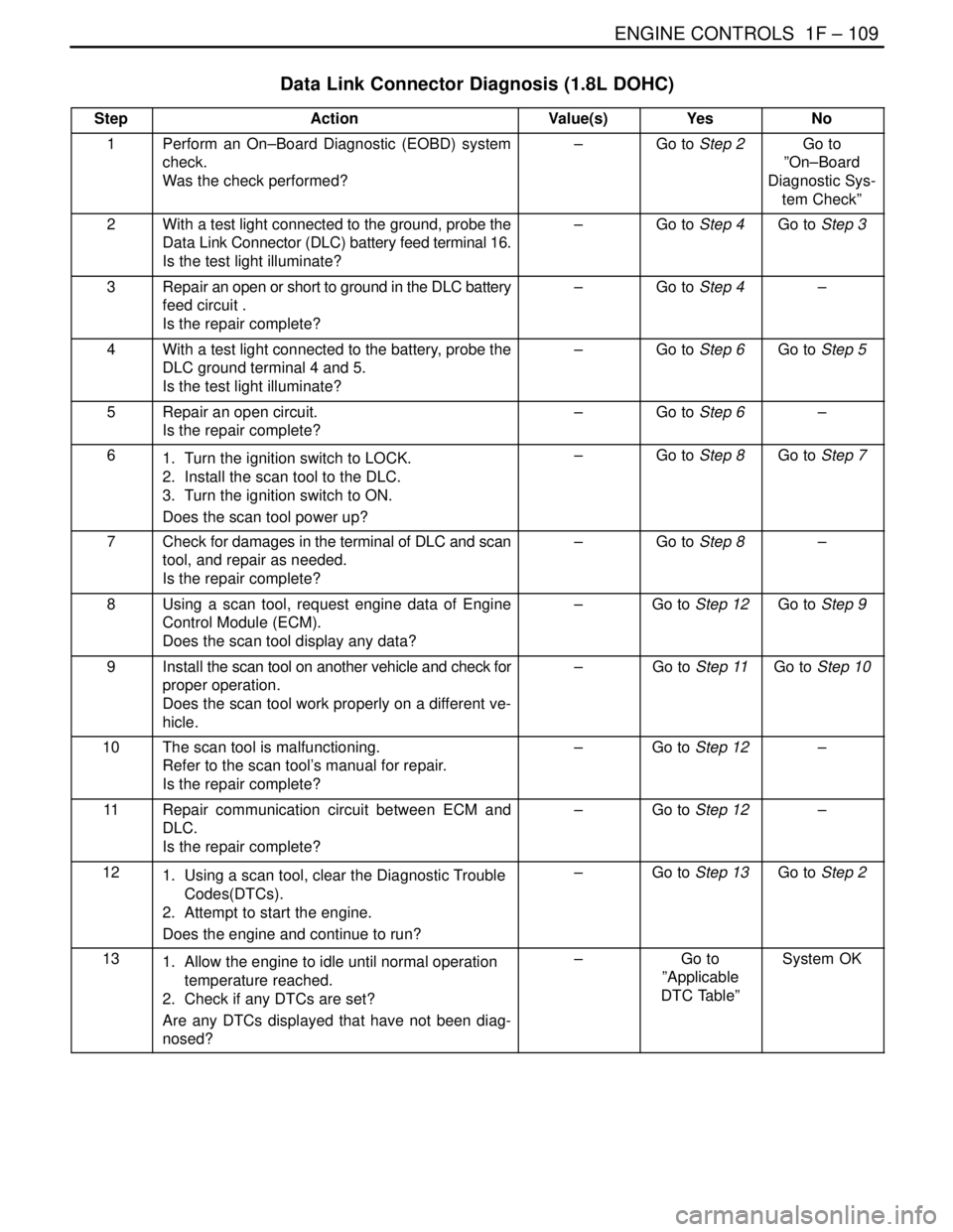

DATA LINK CONNECTOR DIAGNOSIS (1.8L DOHC)

Circuit Description

The provision for communicating with the Engine Control

Module (ECM) is the Data Link Connector (DLC). It is lo-

cated under the instrument panel. The DLC is used to con-

nect the scan tool. Battery power and ground is supplied

for the scan tool through the DLC. The Keyword 2000 seri-

al data circuit to the DLC allows the ECM to communicate

with the scan tool. A Universal Asynchronous Receiver

Transmitter (UART) serial data line is used to communi-

cate with the other modules such as the Electronic Brake

Control Module (EBCM), the Supplemental Inflatable Re-

straint (SIR) system. and the Instrument Panel Cluster.

Diagnostic Aids

Ensure that the correct application (model line, car year,

etc.) has been selected on the scan tool. If communication

still cannot be established, try the scan tool on another ve-

hicle to ensure that the scan tool or cables are not the

cause of the condition.

An intermittent may be caused by a poor connection,

rubbed through wire insulation, or a broken wire inside the

insulation.

Any circuitry that is suspected of causing an intermittent

complaint should be thoroughly checked for the following

conditions:

S Backed–out terminals.S Improper mating of terminals.

S Broken locks.

S Improperly formed or damaged terminals.

S Poor terminal–to–wiring connection.

S Physical damage to the wiring harness.

S Corrosion.

Test Description

Number(s) below refer to the step number(s) on the Diag-

nostic Table.

1. The On–Board Diagnostic (EOBD) System Check

prompts the technician to complete some basic

checks and store the freeze frame and failure re-

cords data on the scan tool if applicable. This

creates an electronic copy of the data taken when

the malfunction occurred. The information is then

stored on the scan tool for later reference.

2. Unlike the UART serial data circuit, the only time a

Class II serial data circuit has any voltage on it is

when a scan tool asks the ECM for information and

sends the information out.

5. Locate and repair any shorts that may have caused

the fuse to open before replacement, if the no volt-

age condition was due to an open fuse.

10. The scan tool or associated cables could be mal-

functioning. Refer to the scan tool’s manual for re-

pair information.

Page 355 of 2643

ENGINE CONTROLS 1F – 109

DAEWOO V–121 BL4

Data Link Connector Diagnosis (1.8L DOHC)

StepActionValue(s)YesNo

1Perform an On–Board Diagnostic (EOBD) system

check.

Was the check performed?–Go to Step 2Go to

”On–Board

Diagnostic Sys-

tem Check”

2With a test light connected to the ground, probe the

Data Link Connector (DLC) battery feed terminal 16.

Is the test light illuminate?–Go to Step 4Go to Step 3

3Repair an open or short to ground in the DLC battery

feed circuit .

Is the repair complete?–Go to Step 4–

4With a test light connected to the battery, probe the

DLC ground terminal 4 and 5.

Is the test light illuminate?–Go to Step 6Go to Step 5

5Repair an open circuit.

Is the repair complete?–Go to Step 6–

61. Turn the ignition switch to LOCK.

2. Install the scan tool to the DLC.

3. Turn the ignition switch to ON.

Does the scan tool power up?–Go to Step 8Go to Step 7

7Check for damages in the terminal of DLC and scan

tool, and repair as needed.

Is the repair complete?–Go to Step 8–

8Using a scan tool, request engine data of Engine

Control Module (ECM).

Does the scan tool display any data?–Go to Step 12Go to Step 9

9Install the scan tool on another vehicle and check for

proper operation.

Does the scan tool work properly on a different ve-

hicle.–Go to Step 11Go to Step 10

10The scan tool is malfunctioning.

Refer to the scan tool’s manual for repair.

Is the repair complete?–Go to Step 12–

11Repair communication circuit between ECM and

DLC.

Is the repair complete?–Go to Step 12–

121. Using a scan tool, clear the Diagnostic Trouble

Codes(DTCs).

2. Attempt to start the engine.

Does the engine and continue to run?–Go to Step 13Go to Step 2

131. Allow the engine to idle until normal operation

temperature reached.

2. Check if any DTCs are set?

Are any DTCs displayed that have not been diag-

nosed?–Go to

”Applicable

DTC Table”System OK

Page 356 of 2643

1F – 110IENGINE CONTROLS

DAEWOO V–121 BL4

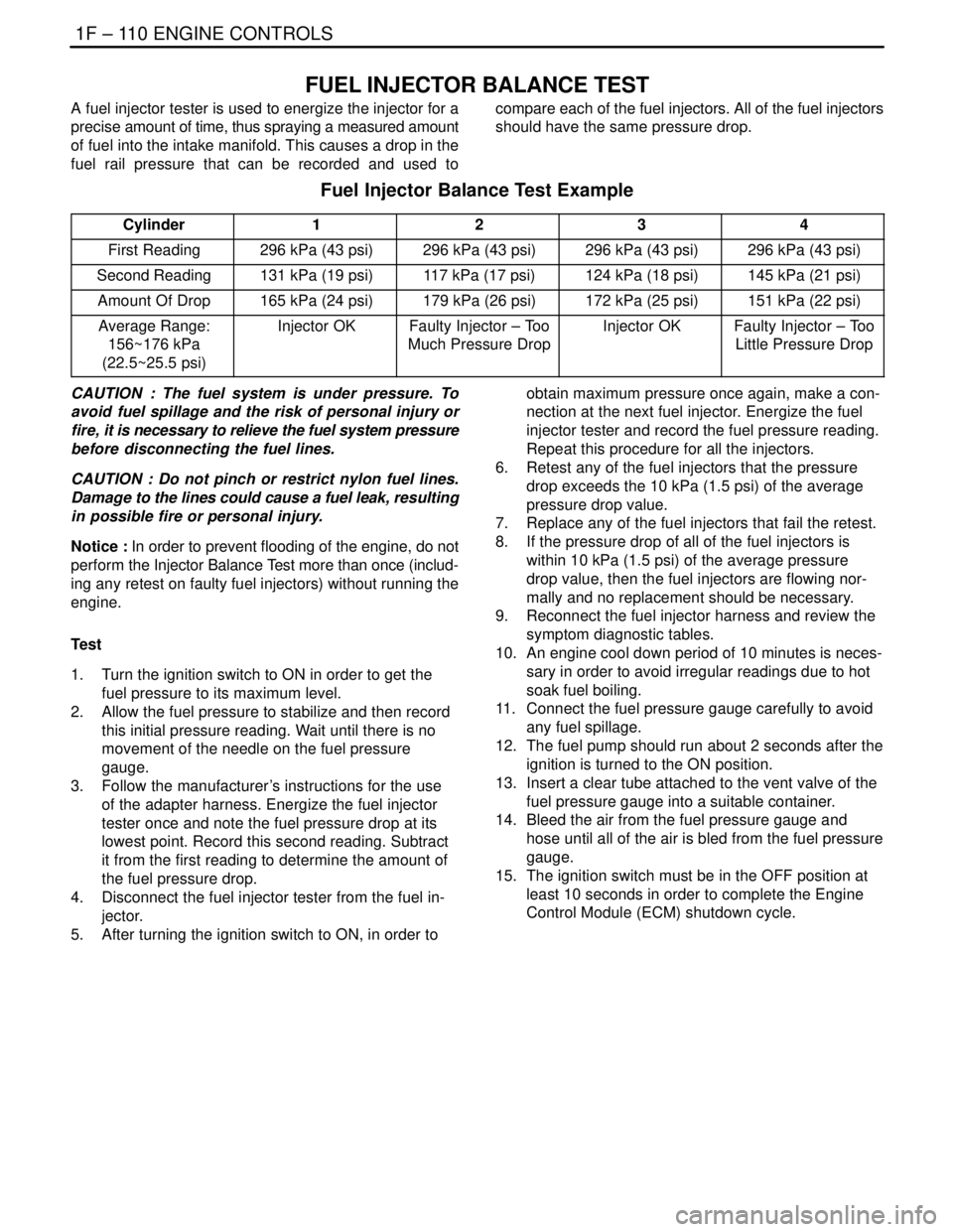

FUEL INJECTOR BALANCE TEST

A fuel injector tester is used to energize the injector for a

precise amount of time, thus spraying a measured amount

of fuel into the intake manifold. This causes a drop in the

fuel rail pressure that can be recorded and used tocompare each of the fuel injectors. All of the fuel injectors

should have the same pressure drop.

Fuel Injector Balance Test Example

Cylinder1234

First Reading296 kPa (43 psi)296 kPa (43 psi)296 kPa (43 psi)296 kPa (43 psi)

Second Reading131 kPa (19 psi)117 kPa (17 psi)124 kPa (18 psi)145 kPa (21 psi)

Amount Of Drop165 kPa (24 psi)179 kPa (26 psi)172 kPa (25 psi)151 kPa (22 psi)

Average Range:

156~176 kPa

(22.5~25.5 psi)Injector OKFaulty Injector – Too

Much Pressure DropInjector OKFaulty Injector – Too

Little Pressure Drop

CAUTION : The fuel system is under pressure. To

avoid fuel spillage and the risk of personal injury or

fire, it is necessary to relieve the fuel system pressure

before disconnecting the fuel lines.

CAUTION : Do not pinch or restrict nylon fuel lines.

Damage to the lines could cause a fuel leak, resulting

in possible fire or personal injury.

Notice : In order to prevent flooding of the engine, do not

perform the Injector Balance Test more than once (includ-

ing any retest on faulty fuel injectors) without running the

engine.

Test

1. Turn the ignition switch to ON in order to get the

fuel pressure to its maximum level.

2. Allow the fuel pressure to stabilize and then record

this initial pressure reading. Wait until there is no

movement of the needle on the fuel pressure

gauge.

3. Follow the manufacturer’s instructions for the use

of the adapter harness. Energize the fuel injector

tester once and note the fuel pressure drop at its

lowest point. Record this second reading. Subtract

it from the first reading to determine the amount of

the fuel pressure drop.

4. Disconnect the fuel injector tester from the fuel in-

jector.

5. After turning the ignition switch to ON, in order toobtain maximum pressure once again, make a con-

nection at the next fuel injector. Energize the fuel

injector tester and record the fuel pressure reading.

Repeat this procedure for all the injectors.

6. Retest any of the fuel injectors that the pressure

drop exceeds the 10 kPa (1.5 psi) of the average

pressure drop value.

7. Replace any of the fuel injectors that fail the retest.

8. If the pressure drop of all of the fuel injectors is

within 10 kPa (1.5 psi) of the average pressure

drop value, then the fuel injectors are flowing nor-

mally and no replacement should be necessary.

9. Reconnect the fuel injector harness and review the

symptom diagnostic tables.

10. An engine cool down period of 10 minutes is neces-

sary in order to avoid irregular readings due to hot

soak fuel boiling.

11. Connect the fuel pressure gauge carefully to avoid

any fuel spillage.

12. The fuel pump should run about 2 seconds after the

ignition is turned to the ON position.

13. Insert a clear tube attached to the vent valve of the

fuel pressure gauge into a suitable container.

14. Bleed the air from the fuel pressure gauge and

hose until all of the air is bled from the fuel pressure

gauge.

15. The ignition switch must be in the OFF position at

least 10 seconds in order to complete the Engine

Control Module (ECM) shutdown cycle.

Page 357 of 2643

ENGINE CONTROLS 1F – 111

DAEWOO V–121 BL4

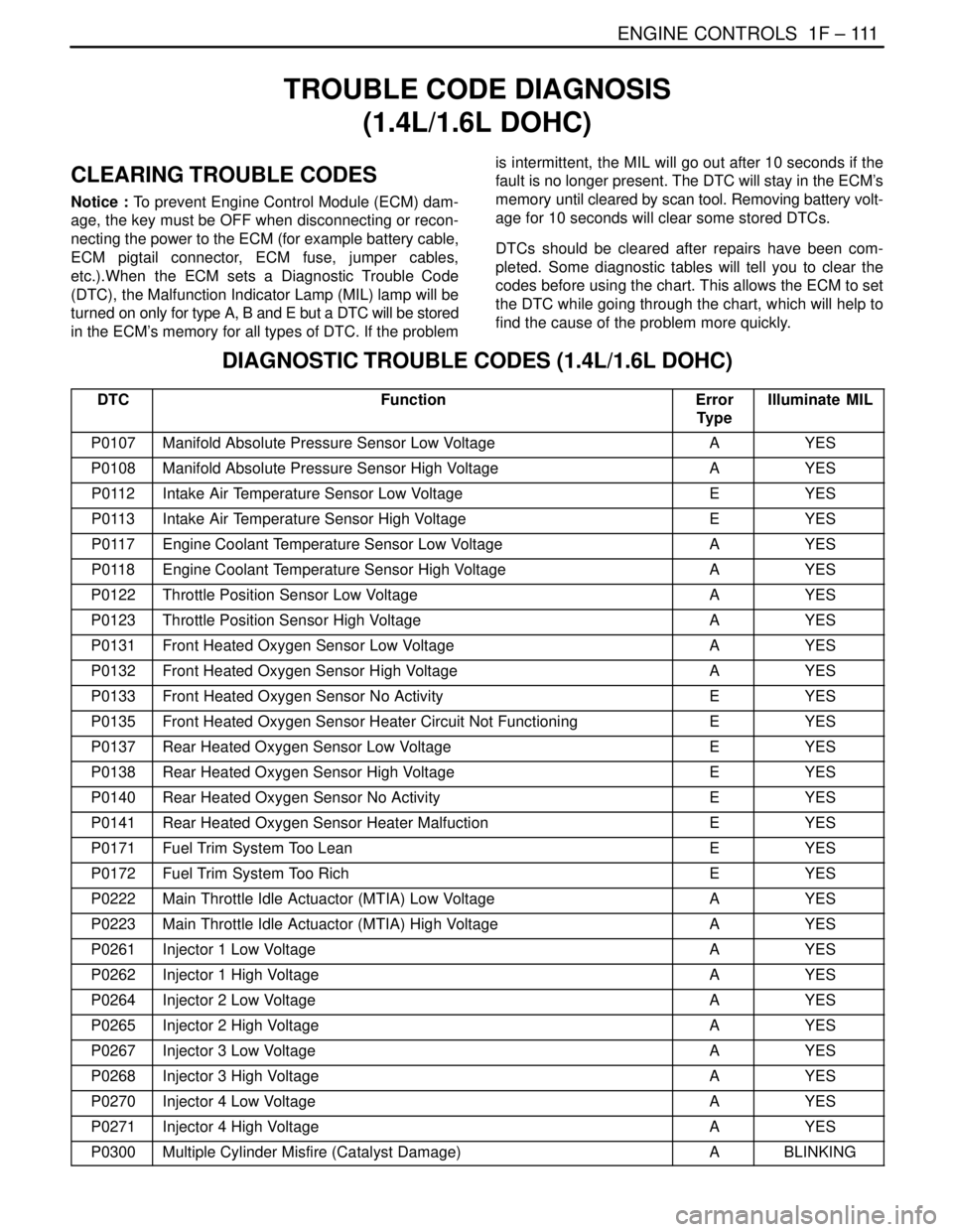

TROUBLE CODE DIAGNOSIS

(1.4L/1.6L DOHC)

CLEARING TROUBLE CODES

Notice : To prevent Engine Control Module (ECM) dam-

age, the key must be OFF when disconnecting or recon-

necting the power to the ECM (for example battery cable,

ECM pigtail connector, ECM fuse, jumper cables,

etc.).When the ECM sets a Diagnostic Trouble Code

(DTC), the Malfunction Indicator Lamp (MIL) lamp will be

turned on only for type A, B and E but a DTC will be stored

in the ECM’s memory for all types of DTC. If the problemis intermittent, the MIL will go out after 10 seconds if the

fault is no longer present. The DTC will stay in the ECM’s

memory until cleared by scan tool. Removing battery volt-

age for 10 seconds will clear some stored DTCs.

DTCs should be cleared after repairs have been com-

pleted. Some diagnostic tables will tell you to clear the

codes before using the chart. This allows the ECM to set

the DTC while going through the chart, which will help to

find the cause of the problem more quickly.

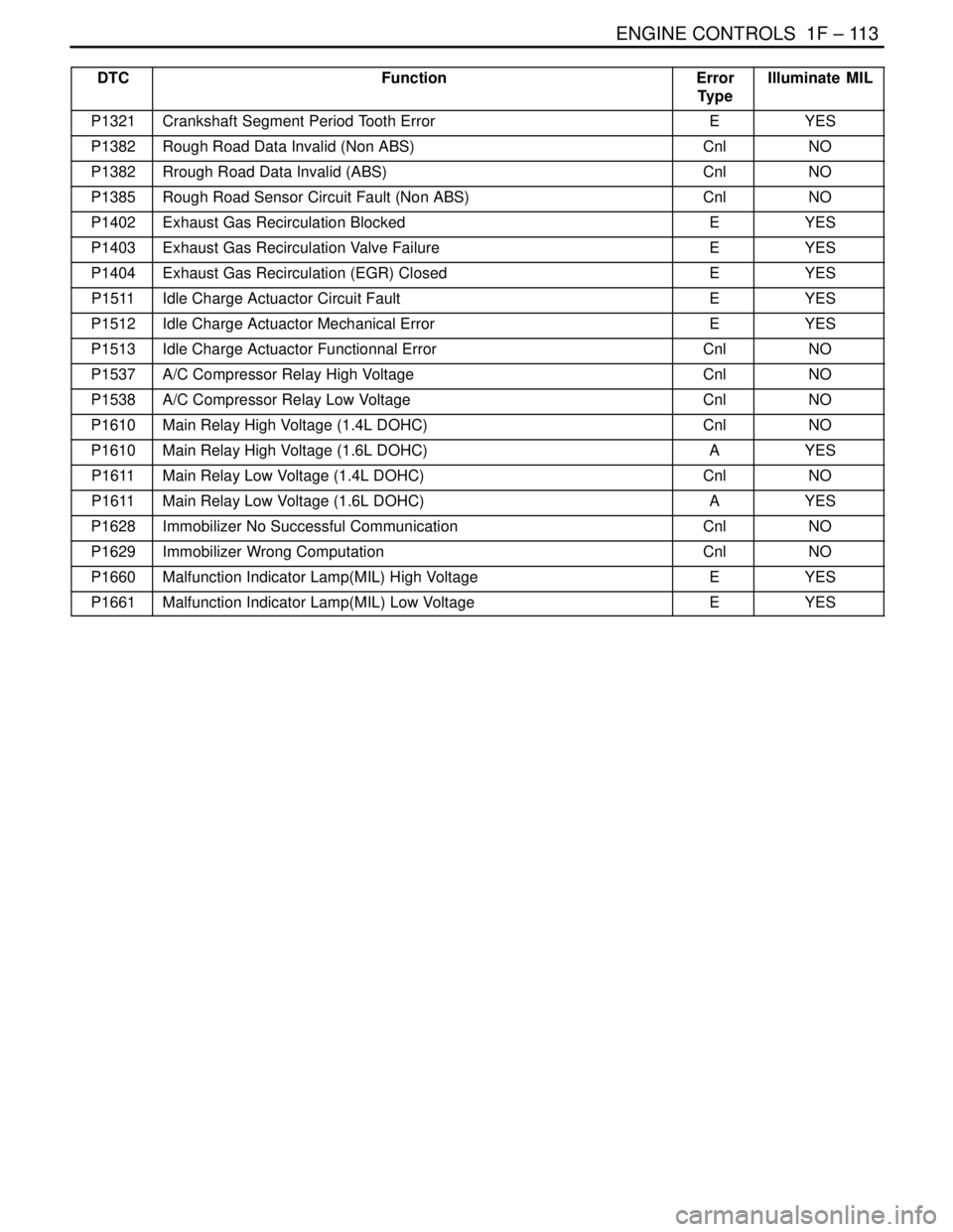

DIAGNOSTIC TROUBLE CODES (1.4L/1.6L DOHC)

DTCFunctionError

TypeIlluminate MIL

P0107Manifold Absolute Pressure Sensor Low VoltageAYES

P0108Manifold Absolute Pressure Sensor High VoltageAYES

P0112Intake Air Temperature Sensor Low VoltageEYES

P0113Intake Air Temperature Sensor High VoltageEYES

P0117Engine Coolant Temperature Sensor Low VoltageAYES

P0118Engine Coolant Temperature Sensor High VoltageAYES

P0122Throttle Position Sensor Low VoltageAYES

P0123Throttle Position Sensor High VoltageAYES

P0131Front Heated Oxygen Sensor Low VoltageAYES

P0132Front Heated Oxygen Sensor High VoltageAYES

P0133Front Heated Oxygen Sensor No ActivityEYES

P0135Front Heated Oxygen Sensor Heater Circuit Not FunctioningEYES

P0137Rear Heated Oxygen Sensor Low VoltageEYES

P0138Rear Heated Oxygen Sensor High VoltageEYES

P0140Rear Heated Oxygen Sensor No ActivityEYES

P0141Rear Heated Oxygen Sensor Heater MalfuctionEYES

P0171Fuel Trim System Too LeanEYES

P0172Fuel Trim System Too RichEYES

P0222Main Throttle Idle Actuactor (MTIA) Low VoltageAYES

P0223Main Throttle Idle Actuactor (MTIA) High VoltageAYES

P0261Injector 1 Low VoltageAYES

P0262Injector 1 High VoltageAYES

P0264Injector 2 Low VoltageAYES

P0265Injector 2 High VoltageAYES

P0267Injector 3 Low VoltageAYES

P0268Injector 3 High VoltageAYES

P0270Injector 4 Low VoltageAYES

P0271Injector 4 High VoltageAYES

P0300Multiple Cylinder Misfire (Catalyst Damage)ABLINKING

Page 358 of 2643

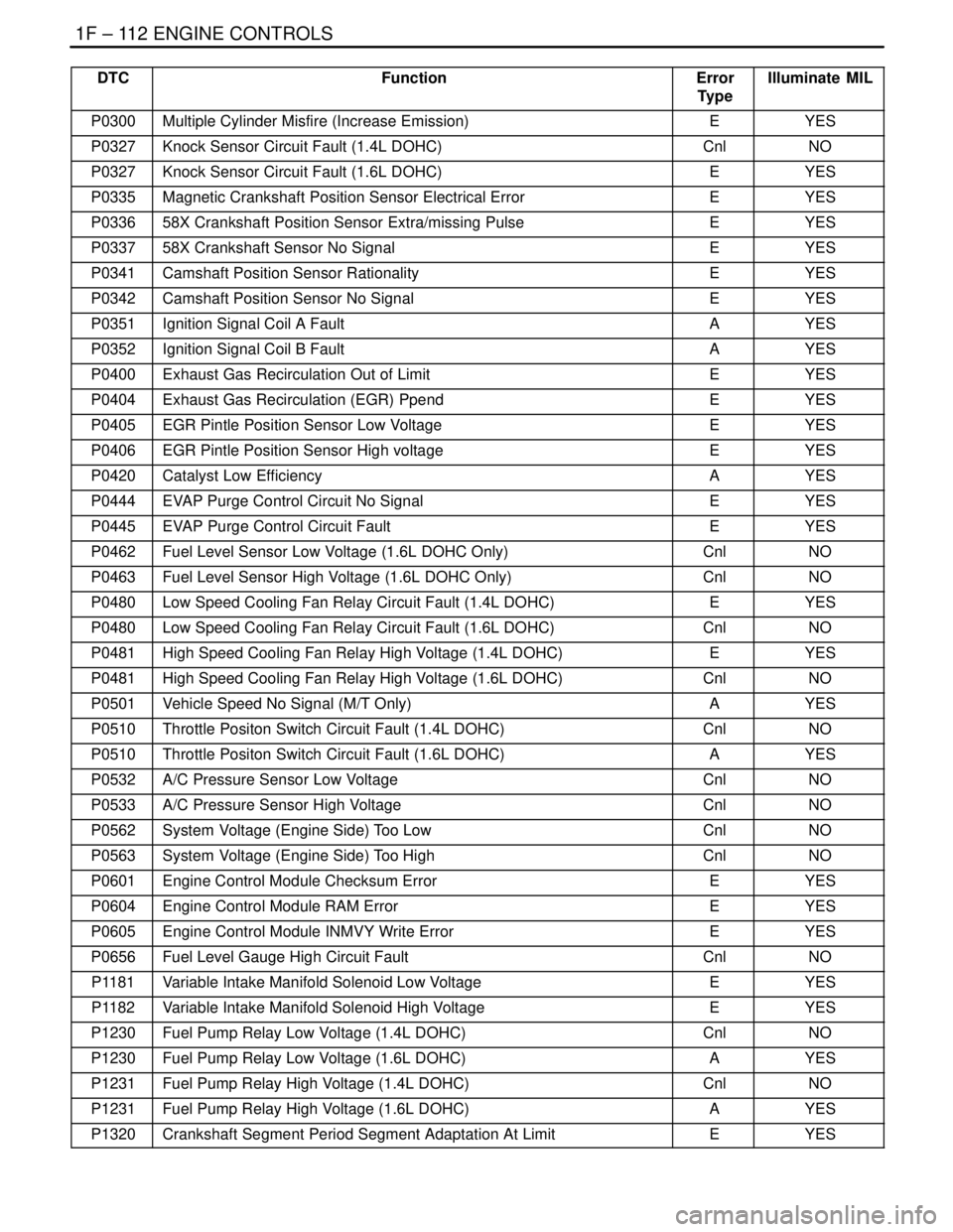

1F – 112IENGINE CONTROLS

DAEWOO V–121 BL4

DTCIlluminate MIL Error

Type Function

P0300Multiple Cylinder Misfire (Increase Emission)EYES

P0327Knock Sensor Circuit Fault (1.4L DOHC)CnlNO

P0327Knock Sensor Circuit Fault (1.6L DOHC)EYES

P0335Magnetic Crankshaft Position Sensor Electrical ErrorEYES

P033658X Crankshaft Position Sensor Extra/missing PulseEYES

P033758X Crankshaft Sensor No SignalEYES

P0341Camshaft Position Sensor RationalityEYES

P0342Camshaft Position Sensor No SignalEYES

P0351Ignition Signal Coil A FaultAYES

P0352Ignition Signal Coil B FaultAYES

P0400Exhaust Gas Recirculation Out of LimitEYES

P0404Exhaust Gas Recirculation (EGR) PpendEYES

P0405EGR Pintle Position Sensor Low VoltageEYES

P0406EGR Pintle Position Sensor High voltageEYES

P0420Catalyst Low EfficiencyAYES

P0444EVAP Purge Control Circuit No SignalEYES

P0445EVAP Purge Control Circuit FaultEYES

P0462Fuel Level Sensor Low Voltage (1.6L DOHC Only)CnlNO

P0463Fuel Level Sensor High Voltage (1.6L DOHC Only)CnlNO

P0480Low Speed Cooling Fan Relay Circuit Fault (1.4L DOHC)EYES

P0480Low Speed Cooling Fan Relay Circuit Fault (1.6L DOHC)CnlNO

P0481High Speed Cooling Fan Relay High Voltage (1.4L DOHC)EYES

P0481High Speed Cooling Fan Relay High Voltage (1.6L DOHC)CnlNO

P0501Vehicle Speed No Signal (M/T Only)AYES

P0510Throttle Positon Switch Circuit Fault (1.4L DOHC)CnlNO

P0510Throttle Positon Switch Circuit Fault (1.6L DOHC)AYES

P0532A/C Pressure Sensor Low VoltageCnlNO

P0533A/C Pressure Sensor High VoltageCnlNO

P0562System Voltage (Engine Side) Too LowCnlNO

P0563System Voltage (Engine Side) Too HighCnlNO

P0601Engine Control Module Checksum ErrorEYES

P0604Engine Control Module RAM ErrorEYES

P0605Engine Control Module INMVY Write ErrorEYES

P0656Fuel Level Gauge High Circuit FaultCnlNO

P1181Variable Intake Manifold Solenoid Low VoltageEYES

P1182Variable Intake Manifold Solenoid High VoltageEYES

P1230Fuel Pump Relay Low Voltage (1.4L DOHC)CnlNO

P1230Fuel Pump Relay Low Voltage (1.6L DOHC)AYES

P1231Fuel Pump Relay High Voltage (1.4L DOHC)CnlNO

P1231Fuel Pump Relay High Voltage (1.6L DOHC)AYES

P1320Crankshaft Segment Period Segment Adaptation At LimitEYES

Page 359 of 2643

ENGINE CONTROLS 1F – 113

DAEWOO V–121 BL4

DTCIlluminate MIL Error

Type Function

P1321Crankshaft Segment Period Tooth ErrorEYES

P1382Rough Road Data Invalid (Non ABS)CnlNO

P1382Rrough Road Data Invalid (ABS)CnlNO

P1385Rough Road Sensor Circuit Fault (Non ABS)CnlNO

P1402Exhaust Gas Recirculation BlockedEYES

P1403Exhaust Gas Recirculation Valve FailureEYES

P1404Exhaust Gas Recirculation (EGR) ClosedEYES

P1511Idle Charge Actuactor Circuit FaultEYES

P1512Idle Charge Actuactor Mechanical ErrorEYES

P1513Idle Charge Actuactor Functionnal ErrorCnlNO

P1537A/C Compressor Relay High VoltageCnlNO

P1538A/C Compressor Relay Low VoltageCnlNO

P1610Main Relay High Voltage (1.4L DOHC)CnlNO

P1610Main Relay High Voltage (1.6L DOHC)AYES

P1611Main Relay Low Voltage (1.4L DOHC)CnlNO

P1611Main Relay Low Voltage (1.6L DOHC)AYES

P1628Immobilizer No Successful CommunicationCnlNO

P1629Immobilizer Wrong ComputationCnlNO

P1660Malfunction Indicator Lamp(MIL) High VoltageEYES

P1661Malfunction Indicator Lamp(MIL) Low VoltageEYES

Page 360 of 2643

1F – 114IENGINE CONTROLS

DAEWOO V–121 BL4

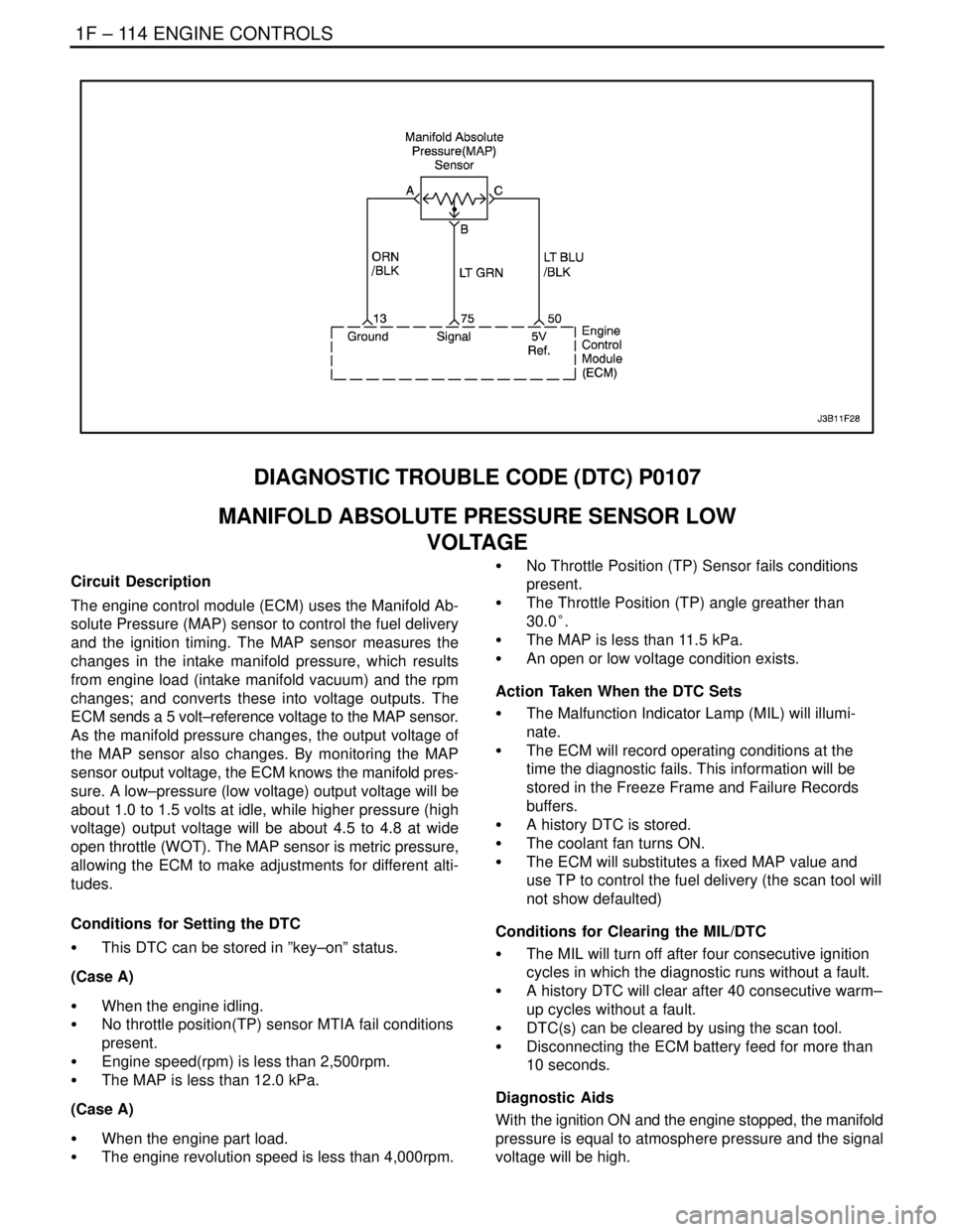

DIAGNOSTIC TROUBLE CODE (DTC) P0107

MANIFOLD ABSOLUTE PRESSURE SENSOR LOW

VOLTAGE

Circuit Description

The engine control module (ECM) uses the Manifold Ab-

solute Pressure (MAP) sensor to control the fuel delivery

and the ignition timing. The MAP sensor measures the

changes in the intake manifold pressure, which results

from engine load (intake manifold vacuum) and the rpm

changes; and converts these into voltage outputs. The

ECM sends a 5 volt–reference voltage to the MAP sensor.

As the manifold pressure changes, the output voltage of

the MAP sensor also changes. By monitoring the MAP

sensor output voltage, the ECM knows the manifold pres-

sure. A low–pressure (low voltage) output voltage will be

about 1.0 to 1.5 volts at idle, while higher pressure (high

voltage) output voltage will be about 4.5 to 4.8 at wide

open throttle (WOT). The MAP sensor is metric pressure,

allowing the ECM to make adjustments for different alti-

tudes.

Conditions for Setting the DTC

S This DTC can be stored in ”key–on” status.

(Case A)

S When the engine idling.

S No throttle position(TP) sensor MTIA fail conditions

present.

S Engine speed(rpm) is less than 2,500rpm.

S The MAP is less than 12.0 kPa.

(Case A)

S When the engine part load.

S The engine revolution speed is less than 4,000rpm.S No Throttle Position (TP) Sensor fails conditions

present.

S The Throttle Position (TP) angle greather than

30.0°.

S The MAP is less than 11.5 kPa.

S An open or low voltage condition exists.

Action Taken When the DTC Sets

S The Malfunction Indicator Lamp (MIL) will illumi-

nate.

S The ECM will record operating conditions at the

time the diagnostic fails. This information will be

stored in the Freeze Frame and Failure Records

buffers.

S A history DTC is stored.

S The coolant fan turns ON.

S The ECM will substitutes a fixed MAP value and

use TP to control the fuel delivery (the scan tool will

not show defaulted)

Conditions for Clearing the MIL/DTC

S The MIL will turn off after four consecutive ignition

cycles in which the diagnostic runs without a fault.

S A history DTC will clear after 40 consecutive warm–

up cycles without a fault.

S DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for more than

10 seconds.

Diagnostic Aids

With the ignition ON and the engine stopped, the manifold

pressure is equal to atmosphere pressure and the signal

voltage will be high.