check engine DAEWOO NUBIRA 2004 Service Repair Manual

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: NUBIRA, Model: DAEWOO NUBIRA 2004Pages: 2643, PDF Size: 80.54 MB

Page 620 of 2643

1F – 374IENGINE CONTROLS

DAEWOO V–121 BL4

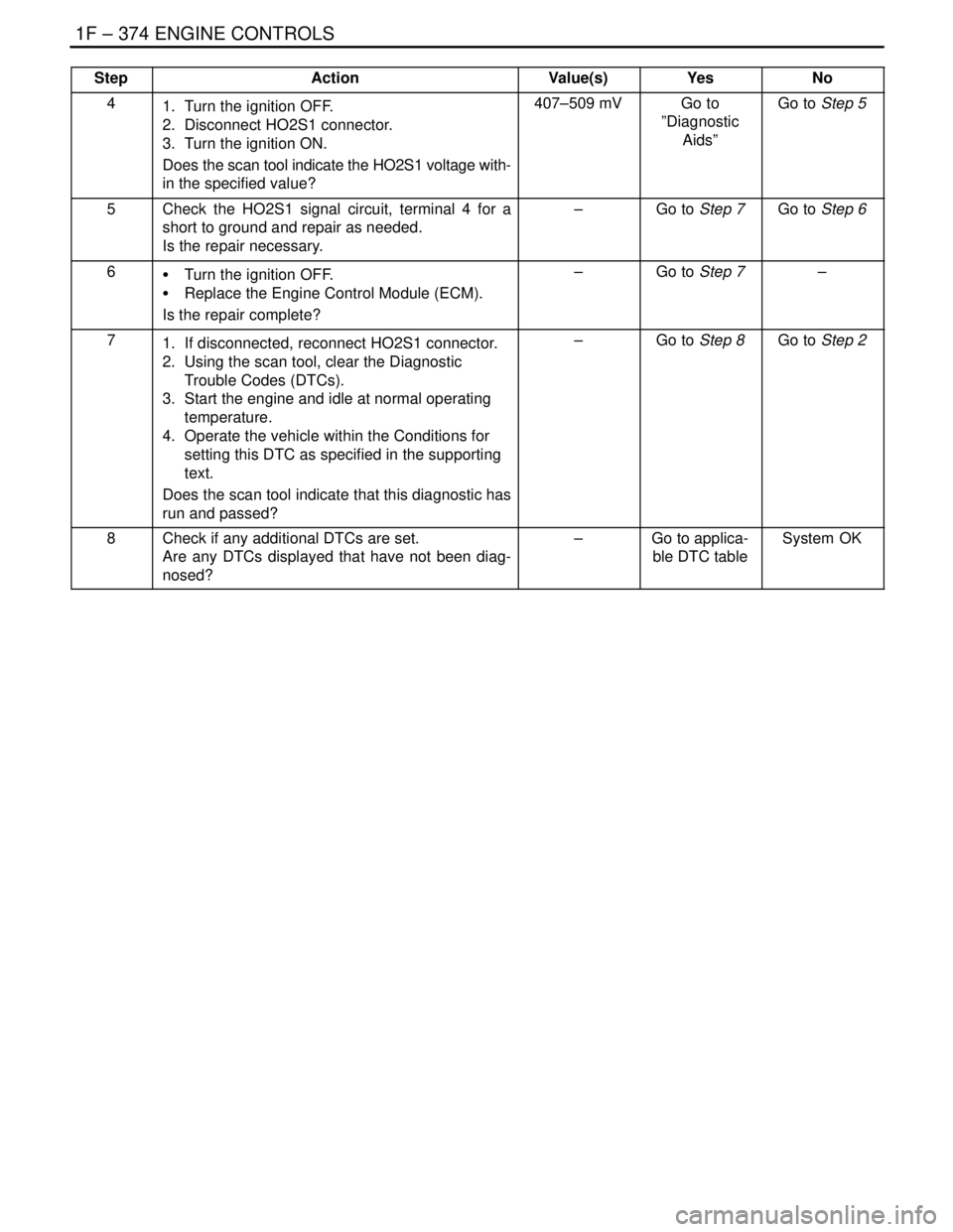

StepNo Yes Value(s) Action

41. Turn the ignition OFF.

2. Disconnect HO2S1 connector.

3. Turn the ignition ON.

Does the scan tool indicate the HO2S1 voltage with-

in the specified value?407–509 mVGo to

”Diagnostic

Aids”Go to Step 5

5Check the HO2S1 signal circuit, terminal 4 for a

short to ground and repair as needed.

Is the repair necessary.–Go to Step 7Go to Step 6

6S Turn the ignition OFF.

S Replace the Engine Control Module (ECM).

Is the repair complete?–Go to Step 7–

71. If disconnected, reconnect HO2S1 connector.

2. Using the scan tool, clear the Diagnostic

Trouble Codes (DTCs).

3. Start the engine and idle at normal operating

temperature.

4. Operate the vehicle within the Conditions for

setting this DTC as specified in the supporting

text.

Does the scan tool indicate that this diagnostic has

run and passed?–Go to Step 8Go to Step 2

8Check if any additional DTCs are set.

Are any DTCs displayed that have not been diag-

nosed?–Go to applica-

ble DTC tableSystem OK

Page 622 of 2643

1F – 376IENGINE CONTROLS

DAEWOO V–121 BL4

S A history DTC will clear after 40 consecutive warm–

up cycles without a fault.

S The DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for more than

10 seconds.

Diagnostic Aids

The DTC P0132 or rich exhaust is most likely caused by

one of the following items:

S Fuel pressure – The system will go rich if the fuel

pressure is too high. The ECM can compensate for

some increase, but if it gets too high, a DTC P0132

will be set

S Leaking injector – A leaking or malfunctioning injec-

tor can cause the system to go rich causing a DTC

P0132.

S Manifold Absolute Pressure (MAP) sensor – An

output that causes the ECM to sense a higher than

normal manifold pressure (low vacuum) can cause

the system to go rich. Disconnecting the MAP sen-

sor will allow the ECM to substitute a fixed value for

the MAP sensor. Substitute a different a MAP sen-

sor, if the rich condition is gone while the sensor is

disconnected.

S Pressure regulator – Check for a leaking fuel pres-

sure regulator diaphragm by checking for the pres-

ence of liquid fuel in the vacuum line to the regula-

tor.

S TP sensor – An intermittent TP sensor output will

cause the system to go rich due to a false indica-

tion of the engine accelerating.

S HO2S1 contamination – Inspect the HO2S1 for sili-

cone contamination from fuel or the use of improper

Room Temperature Vulcanizing sealant. The sensormay have a white powdery coating which may re-

sult in a high but false voltage signal (rich exhaust

indication). The ECM will then reduce the amount

of fuel delivered to the engine, causing a severe

surge or driveability problem.

Test Description

Number(s) below refer to the step number(s) on the Diag-

nostic Table.

1. The On–Board Diagnostic (EOBD) System Check

prompts the technician to complete some basic

checks and store the freeze frame and failure re-

cords data on the scan tool if applicable. This

creates an electronic copy of the data taken when

the malfunction occurred. The information is then

stored on the scan tool for later reference.

2. This step determines if DTC P0132 is the result of

a hard failure or an intermittent condition. It may be

necessary to operate the vehicle within the Freeze

Frame conditions and Conditions for Setting the

DTC in order to duplicate the malfunction detected

by the ECM.

4. This step simulates a DTC P0131. If the ECM

senses the change, the ECM and the wiring are

OK.

6. The replacement ECM must be reprogrammed.

Refer to the latest Techline procedure for ECM re-

programming.

8. If no malfunctions have been found at this point and

no additional DTCs were set, refer to ”Diagnostic

Aids” in this section for additional checks and infor-

mation.

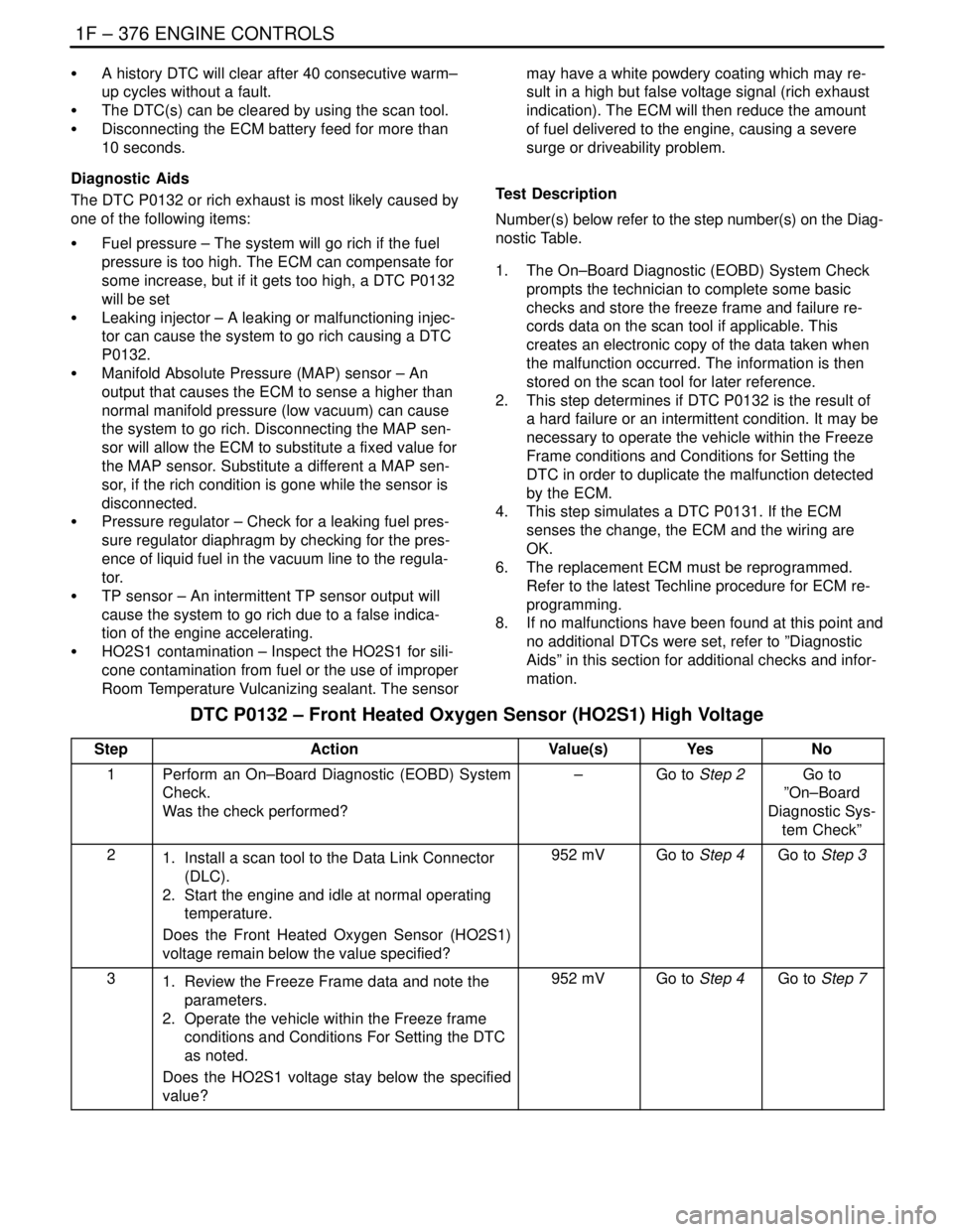

DTC P0132 – Front Heated Oxygen Sensor (HO2S1) High Voltage

StepActionValue(s)YesNo

1Perform an On–Board Diagnostic (EOBD) System

Check.

Was the check performed?–Go to Step 2Go to

”On–Board

Diagnostic Sys-

tem Check”

21. Install a scan tool to the Data Link Connector

(DLC).

2. Start the engine and idle at normal operating

temperature.

Does the Front Heated Oxygen Sensor (HO2S1)

voltage remain below the value specified?952 mVGo to Step 4Go to Step 3

31. Review the Freeze Frame data and note the

parameters.

2. Operate the vehicle within the Freeze frame

conditions and Conditions For Setting the DTC

as noted.

Does the HO2S1 voltage stay below the specified

value?952 mVGo to Step 4Go to Step 7

Page 623 of 2643

ENGINE CONTROLS 1F – 377

DAEWOO V–121 BL4

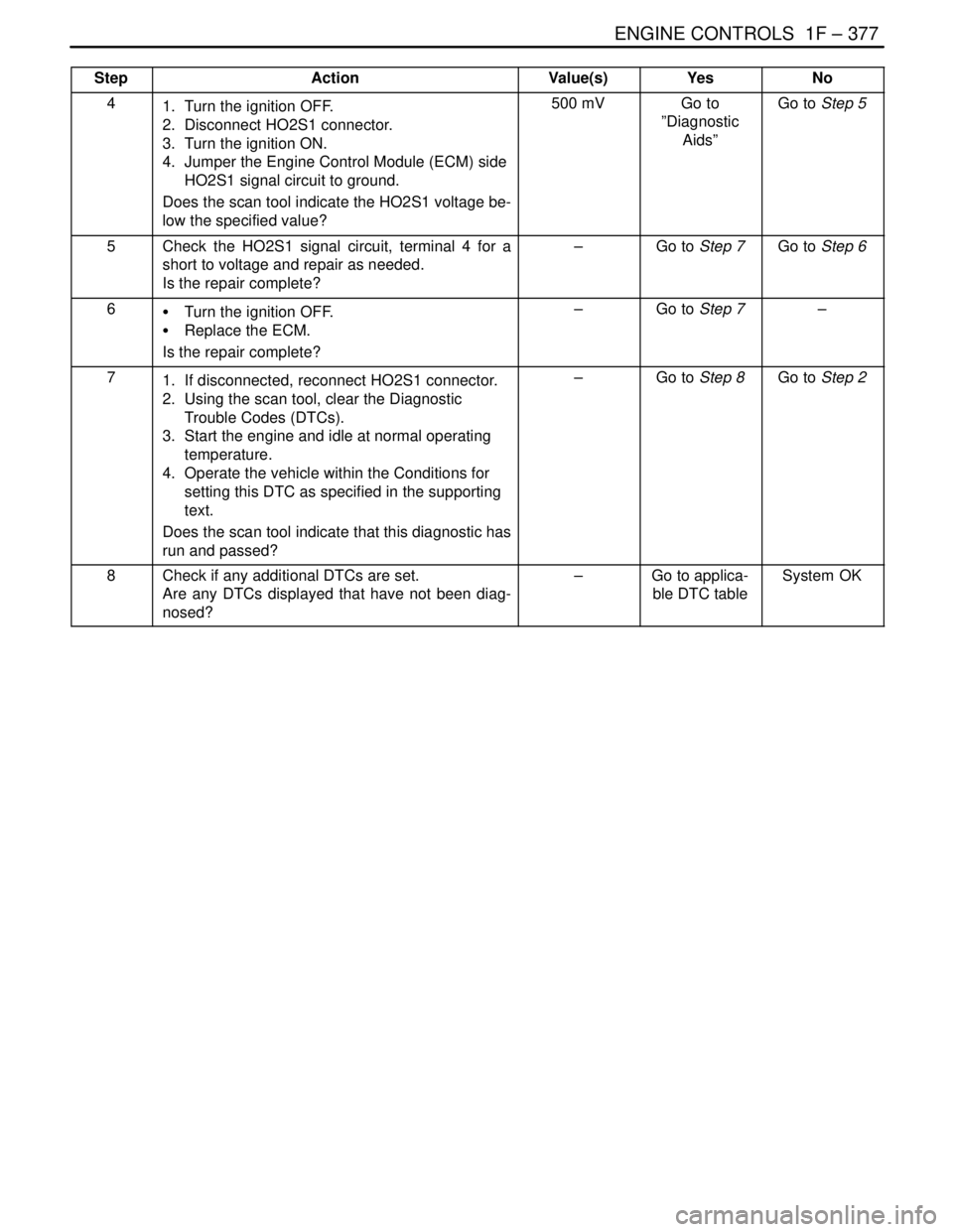

StepNo Yes Value(s) Action

41. Turn the ignition OFF.

2. Disconnect HO2S1 connector.

3. Turn the ignition ON.

4. Jumper the Engine Control Module (ECM) side

HO2S1 signal circuit to ground.

Does the scan tool indicate the HO2S1 voltage be-

low the specified value?500 mVGo to

”Diagnostic

Aids”Go to Step 5

5Check the HO2S1 signal circuit, terminal 4 for a

short to voltage and repair as needed.

Is the repair complete?–Go to Step 7Go to Step 6

6S Turn the ignition OFF.

S Replace the ECM.

Is the repair complete?–Go to Step 7–

71. If disconnected, reconnect HO2S1 connector.

2. Using the scan tool, clear the Diagnostic

Trouble Codes (DTCs).

3. Start the engine and idle at normal operating

temperature.

4. Operate the vehicle within the Conditions for

setting this DTC as specified in the supporting

text.

Does the scan tool indicate that this diagnostic has

run and passed?–Go to Step 8Go to Step 2

8Check if any additional DTCs are set.

Are any DTCs displayed that have not been diag-

nosed?–Go to applica-

ble DTC tableSystem OK

Page 625 of 2643

ENGINE CONTROLS 1F – 379

DAEWOO V–121 BL4

S The ECM will record operating conditions at the

time the diagnostic fails. This information will be

stored in the Freeze Frame and Failure Records

buffers.

S A history DTC is stored.

Conditions for Clearing the MIL/DTC

S The MIL will turn off after four consecutive ignition

cycles in which the diagnostic runs without a fault.

S A history DTC will clear after 40 consecutive warm–

up cycles without a fault.

S The DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for more than

10 seconds.

Diagnostic Aids

DTC P0133 or slow response is most likely caused by one

of the following items:

S Fuel pressure – The system will go rich if fuel pres-

sure is too high. The ECM can compensate for

some increase, but if it gets too high, a DTC P0133

may set. Refer to”Fuel System Diagnosis” in this

section.

S Leaking injector – A leaking or malfunctioning injec-

tor can cause the system to go rich.

S Manifold Absolute Pressure (MAP) sensor – An

output that causes the ECM to sense a higher than

normal manifold pressure (low vacuum) can cause

the system to go rich. Disconnecting the MAP sen-

sor will allow the ECM to set a fixed value for the

MAP sensor. Substitute a different MAP sensor if

the rich condition is gone while the sensor is dis-

connected.S Pressure regulator – Check for a leaking fuel pres-

sure regulator diaphragm by checking for the pres-

ence of liquid fuel in the vacuum line to the pres-

sure regulator.

S Throttle Position (TP) sensor – An intermittent TP

sensor output can cause the system to go rich due

to a false indication of the engine accelerating.

S HO2S1 contamination – Inspect HO2S1 for silicone

contamination from fuel or use of improper room

temperature vulcanizing (RTV) sealant. The sensor

may have a white powdery coating, resulting in a

high but false voltage signal (rich exhaust indica-

tion). The ECM will then reduce the amount of fuel

delivered to the engine causing a severe surge or

driveability problem.

Test Description

Number(s) below refer to the step number(s) on the Diag-

nostic Table.

1. The On–Board Diagnostic (EOBD) System Check

prompts the technician to complete some basic

checks and store the freeze frame and failure re-

cords data on the scan tool if applicable. This

creates an electronic copy of the data taken when

the malfunction occurred. The information is then

stored on the scan tool for later reference.

14. The replacement ECM must be reprogrammed.

Refer to the latest Techline procedure for ECM re-

programming.

17. If no malfunctions have been found at this point and

no additional DTCs were set, refer to ”Diagnostic

Aids” for additional checks and information.

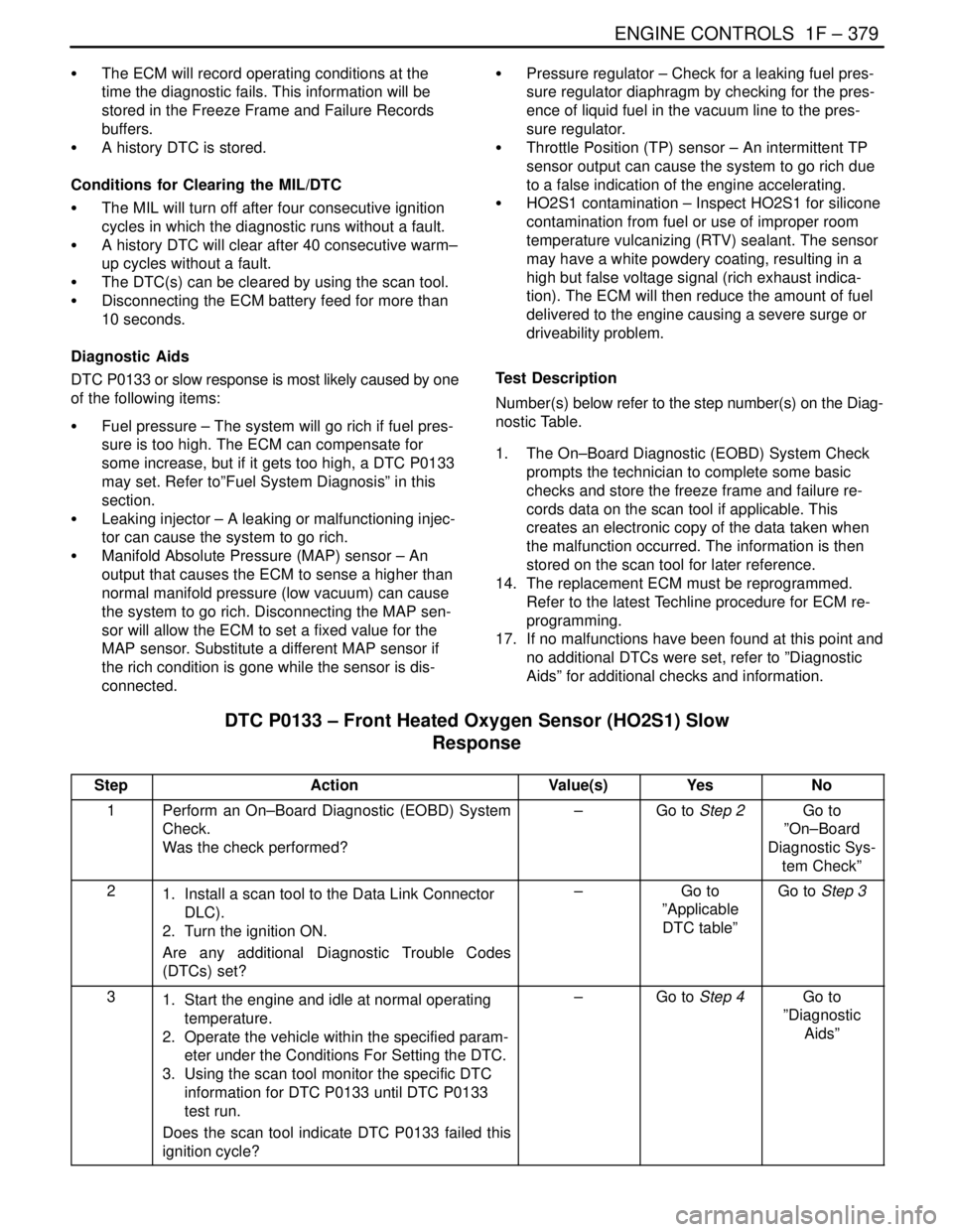

DTC P0133 – Front Heated Oxygen Sensor (HO2S1) Slow

Response

StepActionValue(s)YesNo

1Perform an On–Board Diagnostic (EOBD) System

Check.

Was the check performed?–Go to Step 2Go to

”On–Board

Diagnostic Sys-

tem Check”

21. Install a scan tool to the Data Link Connector

DLC).

2. Turn the ignition ON.

Are any additional Diagnostic Trouble Codes

(DTCs) set?–Go to

”Applicable

DTC table”Go to Step 3

31. Start the engine and idle at normal operating

temperature.

2. Operate the vehicle within the specified param-

eter under the Conditions For Setting the DTC.

3. Using the scan tool monitor the specific DTC

information for DTC P0133 until DTC P0133

test run.

Does the scan tool indicate DTC P0133 failed this

ignition cycle?–Go to Step 4Go to

”Diagnostic

Aids”

Page 626 of 2643

1F – 380IENGINE CONTROLS

DAEWOO V–121 BL4

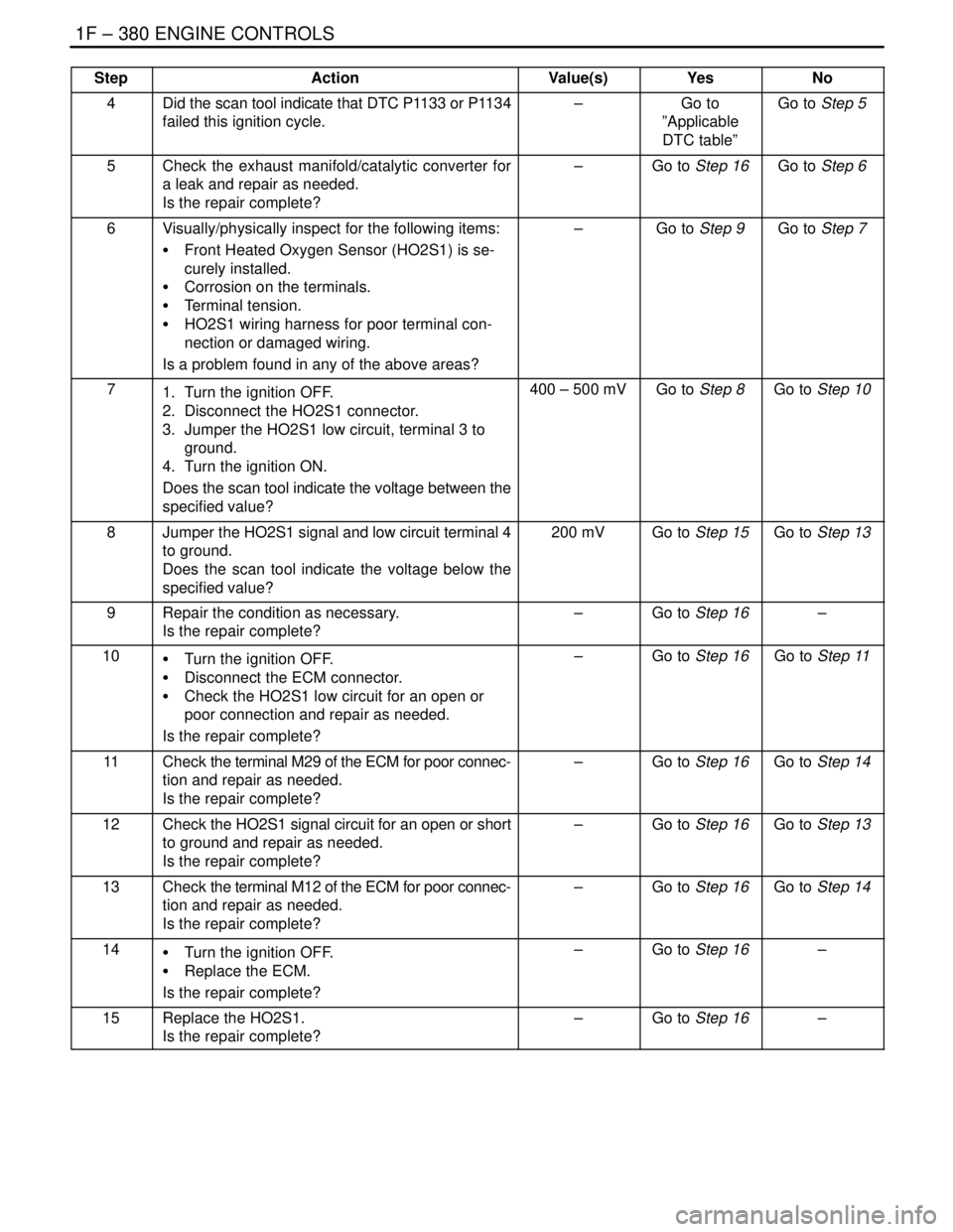

StepNo Yes Value(s) Action

4Did the scan tool indicate that DTC P1133 or P1134

failed this ignition cycle.–Go to

”Applicable

DTC table”Go to Step 5

5Check the exhaust manifold/catalytic converter for

a leak and repair as needed.

Is the repair complete?–Go to Step 16Go to Step 6

6Visually/physically inspect for the following items:

S Front Heated Oxygen Sensor (HO2S1) is se-

curely installed.

S Corrosion on the terminals.

S Terminal tension.

S HO2S1 wiring harness for poor terminal con-

nection or damaged wiring.

Is a problem found in any of the above areas?–Go to Step 9Go to Step 7

71. Turn the ignition OFF.

2. Disconnect the HO2S1 connector.

3. Jumper the HO2S1 low circuit, terminal 3 to

ground.

4. Turn the ignition ON.

Does the scan tool indicate the voltage between the

specified value?400 – 500 mVGo to Step 8Go to Step 10

8Jumper the HO2S1 signal and low circuit terminal 4

to ground.

Does the scan tool indicate the voltage below the

specified value?200 mVGo to Step 15Go to Step 13

9Repair the condition as necessary.

Is the repair complete?–Go to Step 16–

10S Turn the ignition OFF.

S Disconnect the ECM connector.

S Check the HO2S1 low circuit for an open or

poor connection and repair as needed.

Is the repair complete?–Go to Step 16Go to Step 11

11Check the terminal M29 of the ECM for poor connec-

tion and repair as needed.

Is the repair complete?–Go to Step 16Go to Step 14

12Check the HO2S1 signal circuit for an open or short

to ground and repair as needed.

Is the repair complete?–Go to Step 16Go to Step 13

13Check the terminal M12 of the ECM for poor connec-

tion and repair as needed.

Is the repair complete?–Go to Step 16Go to Step 14

14S Turn the ignition OFF.

S Replace the ECM.

Is the repair complete?–Go to Step 16–

15Replace the HO2S1.

Is the repair complete?–Go to Step 16–

Page 627 of 2643

ENGINE CONTROLS 1F – 381

DAEWOO V–121 BL4

StepNo Yes Value(s) Action

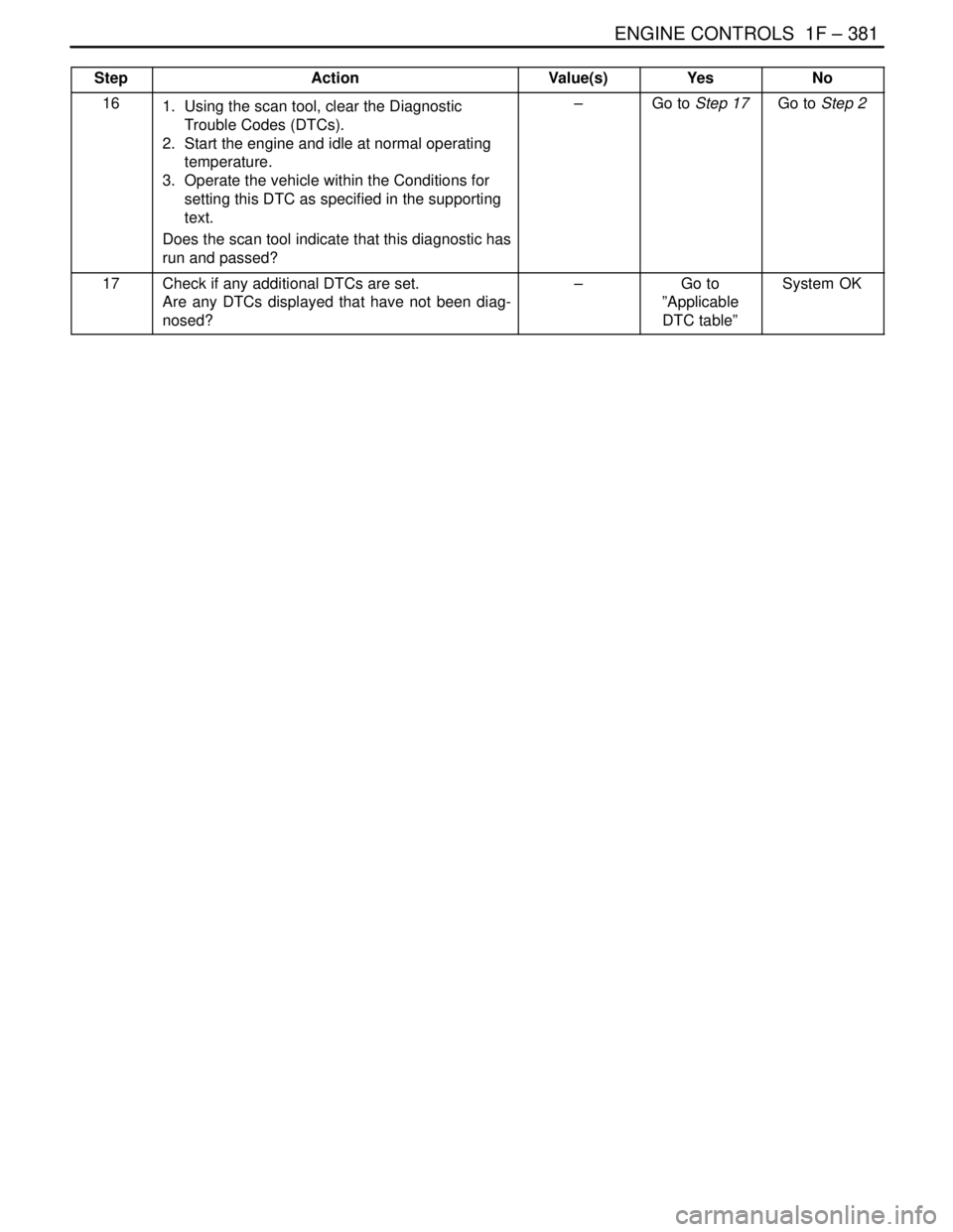

161. Using the scan tool, clear the Diagnostic

Trouble Codes (DTCs).

2. Start the engine and idle at normal operating

temperature.

3. Operate the vehicle within the Conditions for

setting this DTC as specified in the supporting

text.

Does the scan tool indicate that this diagnostic has

run and passed?–Go to Step 17Go to Step 2

17Check if any additional DTCs are set.

Are any DTCs displayed that have not been diag-

nosed?–Go to

”Applicable

DTC table”System OK

Page 629 of 2643

ENGINE CONTROLS 1F – 383

DAEWOO V–121 BL4

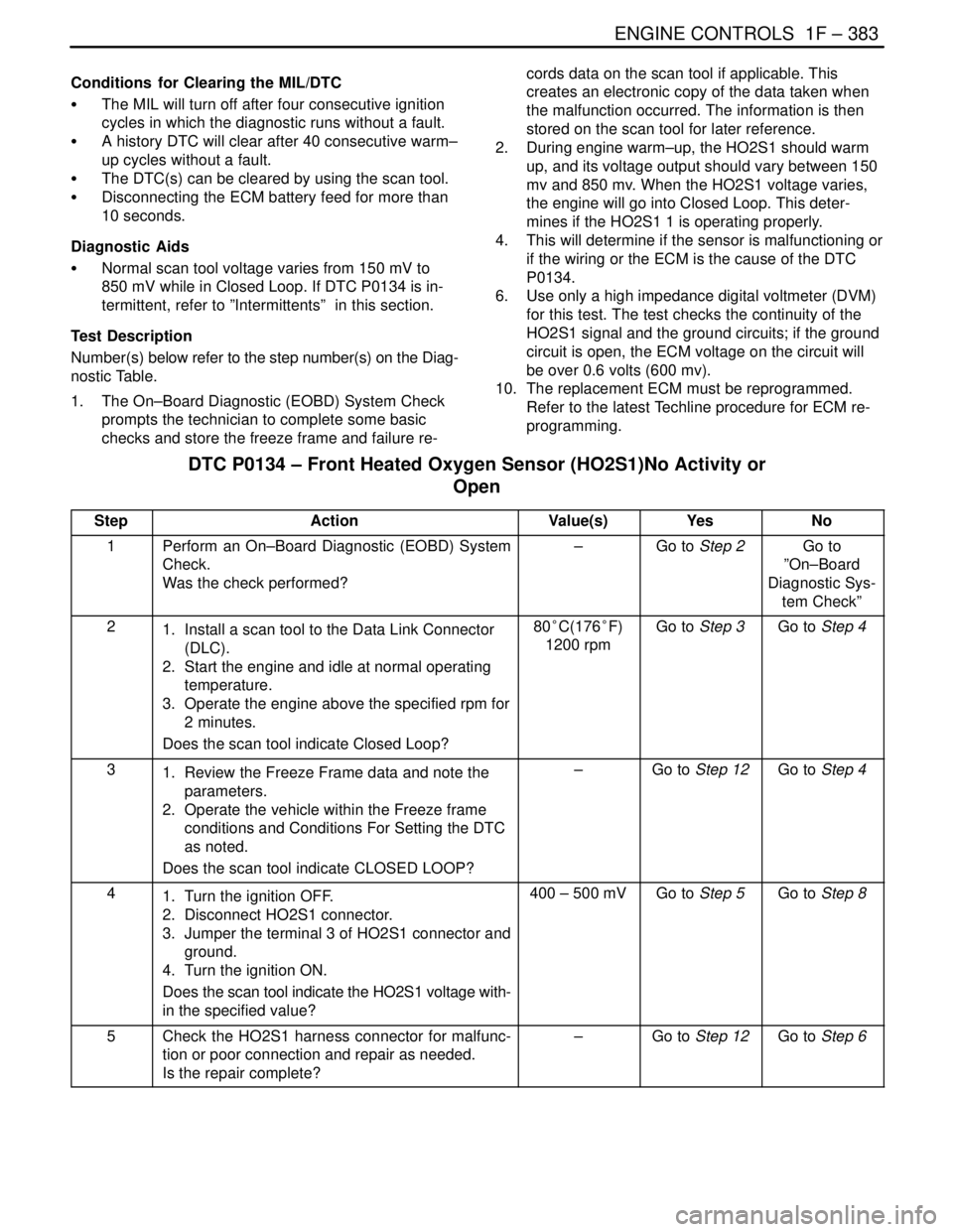

Conditions for Clearing the MIL/DTC

S The MIL will turn off after four consecutive ignition

cycles in which the diagnostic runs without a fault.

S A history DTC will clear after 40 consecutive warm–

up cycles without a fault.

S The DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for more than

10 seconds.

Diagnostic Aids

S Normal scan tool voltage varies from 150 mV to

850 mV while in Closed Loop. If DTC P0134 is in-

termittent, refer to ”Intermittents” in this section.

Test Description

Number(s) below refer to the step number(s) on the Diag-

nostic Table.

1. The On–Board Diagnostic (EOBD) System Check

prompts the technician to complete some basic

checks and store the freeze frame and failure re-cords data on the scan tool if applicable. This

creates an electronic copy of the data taken when

the malfunction occurred. The information is then

stored on the scan tool for later reference.

2. During engine warm–up, the HO2S1 should warm

up, and its voltage output should vary between 150

mv and 850 mv. When the HO2S1 voltage varies,

the engine will go into Closed Loop. This deter-

mines if the HO2S1 1 is operating properly.

4. This will determine if the sensor is malfunctioning or

if the wiring or the ECM is the cause of the DTC

P0134.

6. Use only a high impedance digital voltmeter (DVM)

for this test. The test checks the continuity of the

HO2S1 signal and the ground circuits; if the ground

circuit is open, the ECM voltage on the circuit will

be over 0.6 volts (600 mv).

10. The replacement ECM must be reprogrammed.

Refer to the latest Techline procedure for ECM re-

programming.

DTC P0134 – Front Heated Oxygen Sensor (HO2S1)No Activity or

Open

StepActionValue(s)YesNo

1Perform an On–Board Diagnostic (EOBD) System

Check.

Was the check performed?–Go to Step 2Go to

”On–Board

Diagnostic Sys-

tem Check”

21. Install a scan tool to the Data Link Connector

(DLC).

2. Start the engine and idle at normal operating

temperature.

3. Operate the engine above the specified rpm for

2 minutes.

Does the scan tool indicate Closed Loop?80°C(176°F)

1200 rpmGo to Step 3Go to Step 4

31. Review the Freeze Frame data and note the

parameters.

2. Operate the vehicle within the Freeze frame

conditions and Conditions For Setting the DTC

as noted.

Does the scan tool indicate CLOSED LOOP?–Go to Step 12Go to Step 4

41. Turn the ignition OFF.

2. Disconnect HO2S1 connector.

3. Jumper the terminal 3 of HO2S1 connector and

ground.

4. Turn the ignition ON.

Does the scan tool indicate the HO2S1 voltage with-

in the specified value?400 – 500 mVGo to Step 5Go to Step 8

5Check the HO2S1 harness connector for malfunc-

tion or poor connection and repair as needed.

Is the repair complete?–Go to Step 12Go to Step 6

Page 630 of 2643

1F – 384IENGINE CONTROLS

DAEWOO V–121 BL4

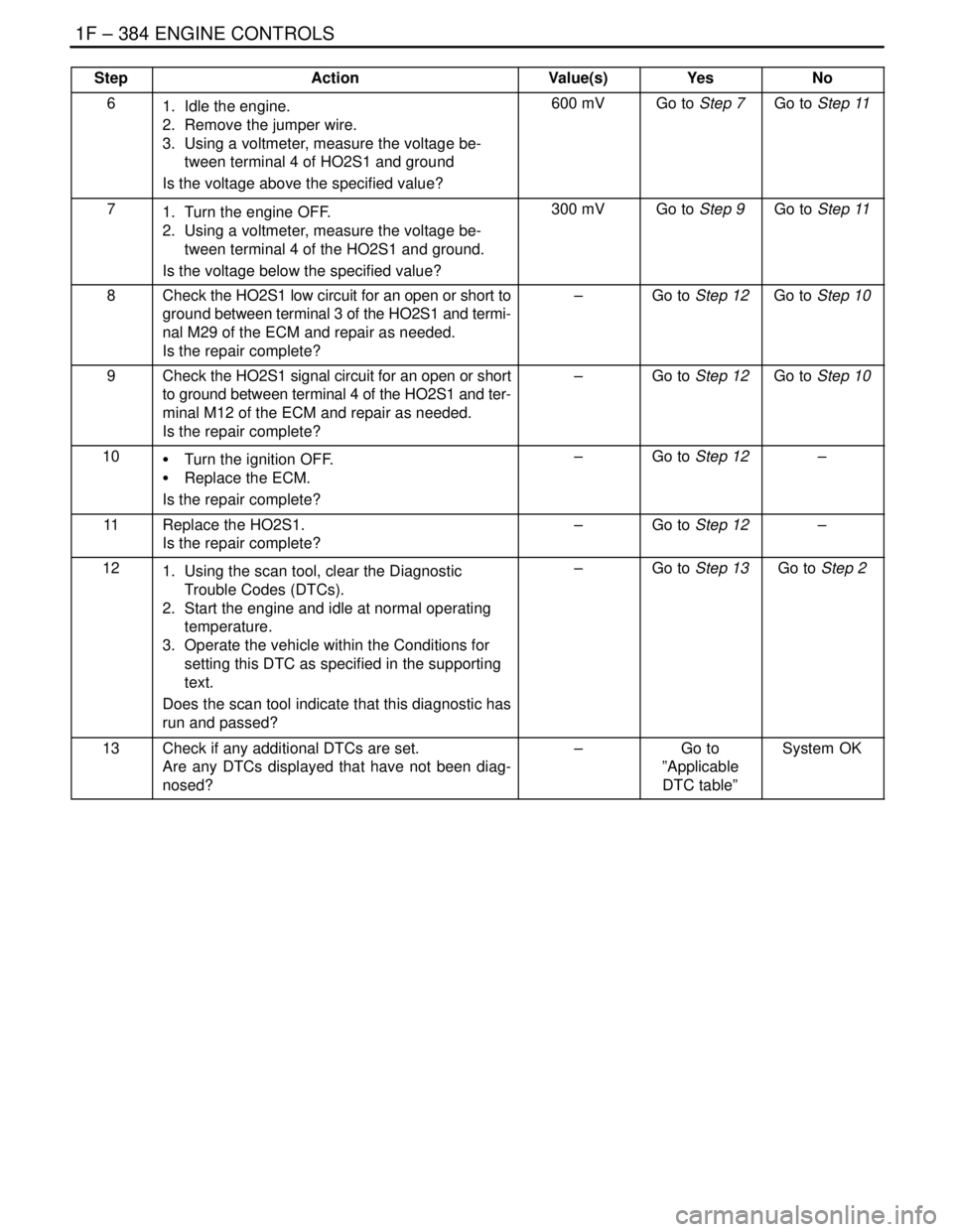

StepNo Yes Value(s) Action

61. Idle the engine.

2. Remove the jumper wire.

3. Using a voltmeter, measure the voltage be-

tween terminal 4 of HO2S1 and ground

Is the voltage above the specified value?600 mVGo to Step 7Go to Step 11

71. Turn the engine OFF.

2. Using a voltmeter, measure the voltage be-

tween terminal 4 of the HO2S1 and ground.

Is the voltage below the specified value?300 mVGo to Step 9Go to Step 11

8Check the HO2S1 low circuit for an open or short to

ground between terminal 3 of the HO2S1 and termi-

nal M29 of the ECM and repair as needed.

Is the repair complete?–Go to Step 12Go to Step 10

9Check the HO2S1 signal circuit for an open or short

to ground between terminal 4 of the HO2S1 and ter-

minal M12 of the ECM and repair as needed.

Is the repair complete?–Go to Step 12Go to Step 10

10S Turn the ignition OFF.

S Replace the ECM.

Is the repair complete?–Go to Step 12–

11Replace the HO2S1.

Is the repair complete?–Go to Step 12–

121. Using the scan tool, clear the Diagnostic

Trouble Codes (DTCs).

2. Start the engine and idle at normal operating

temperature.

3. Operate the vehicle within the Conditions for

setting this DTC as specified in the supporting

text.

Does the scan tool indicate that this diagnostic has

run and passed?–Go to Step 13Go to Step 2

13Check if any additional DTCs are set.

Are any DTCs displayed that have not been diag-

nosed?–Go to

”Applicable

DTC table”System OK

Page 631 of 2643

ENGINE CONTROLS 1F – 385

DAEWOO V–121 BL4

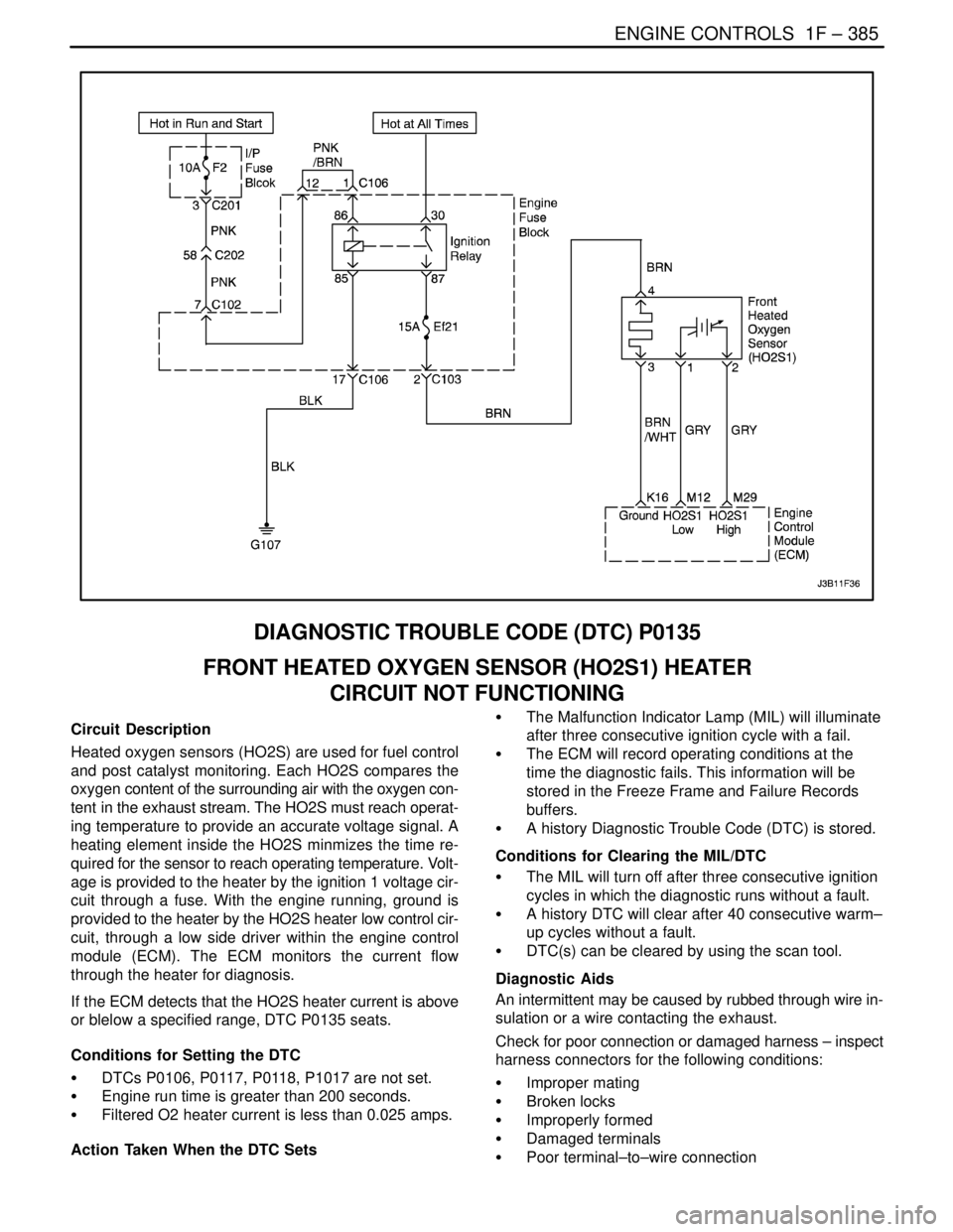

DIAGNOSTIC TROUBLE CODE (DTC) P0135

FRONT HEATED OXYGEN SENSOR (HO2S1) HEATER

CIRCUIT NOT FUNCTIONING

Circuit Description

Heated oxygen sensors (HO2S) are used for fuel control

and post catalyst monitoring. Each HO2S compares the

oxygen content of the surrounding air with the oxygen con-

tent in the exhaust stream. The HO2S must reach operat-

ing temperature to provide an accurate voltage signal. A

heating element inside the HO2S minmizes the time re-

quired for the sensor to reach operating temperature. Volt-

age is provided to the heater by the ignition 1 voltage cir-

cuit through a fuse. With the engine running, ground is

provided to the heater by the HO2S heater low control cir-

cuit, through a low side driver within the engine control

module (ECM). The ECM monitors the current flow

through the heater for diagnosis.

If the ECM detects that the HO2S heater current is above

or blelow a specified range, DTC P0135 seats.

Conditions for Setting the DTC

S DTCs P0106, P0117, P0118, P1017 are not set.

S Engine run time is greater than 200 seconds.

S Filtered O2 heater current is less than 0.025 amps.

Action Taken When the DTC SetsS The Malfunction Indicator Lamp (MIL) will illuminate

after three consecutive ignition cycle with a fail.

S The ECM will record operating conditions at the

time the diagnostic fails. This information will be

stored in the Freeze Frame and Failure Records

buffers.

S A history Diagnostic Trouble Code (DTC) is stored.

Conditions for Clearing the MIL/DTC

S The MIL will turn off after three consecutive ignition

cycles in which the diagnostic runs without a fault.

S A history DTC will clear after 40 consecutive warm–

up cycles without a fault.

S DTC(s) can be cleared by using the scan tool.

Diagnostic Aids

An intermittent may be caused by rubbed through wire in-

sulation or a wire contacting the exhaust.

Check for poor connection or damaged harness – inspect

harness connectors for the following conditions:

S Improper mating

S Broken locks

S Improperly formed

S Damaged terminals

S Poor terminal–to–wire connection

Page 632 of 2643

1F – 386IENGINE CONTROLS

DAEWOO V–121 BL4

S Damaged harness

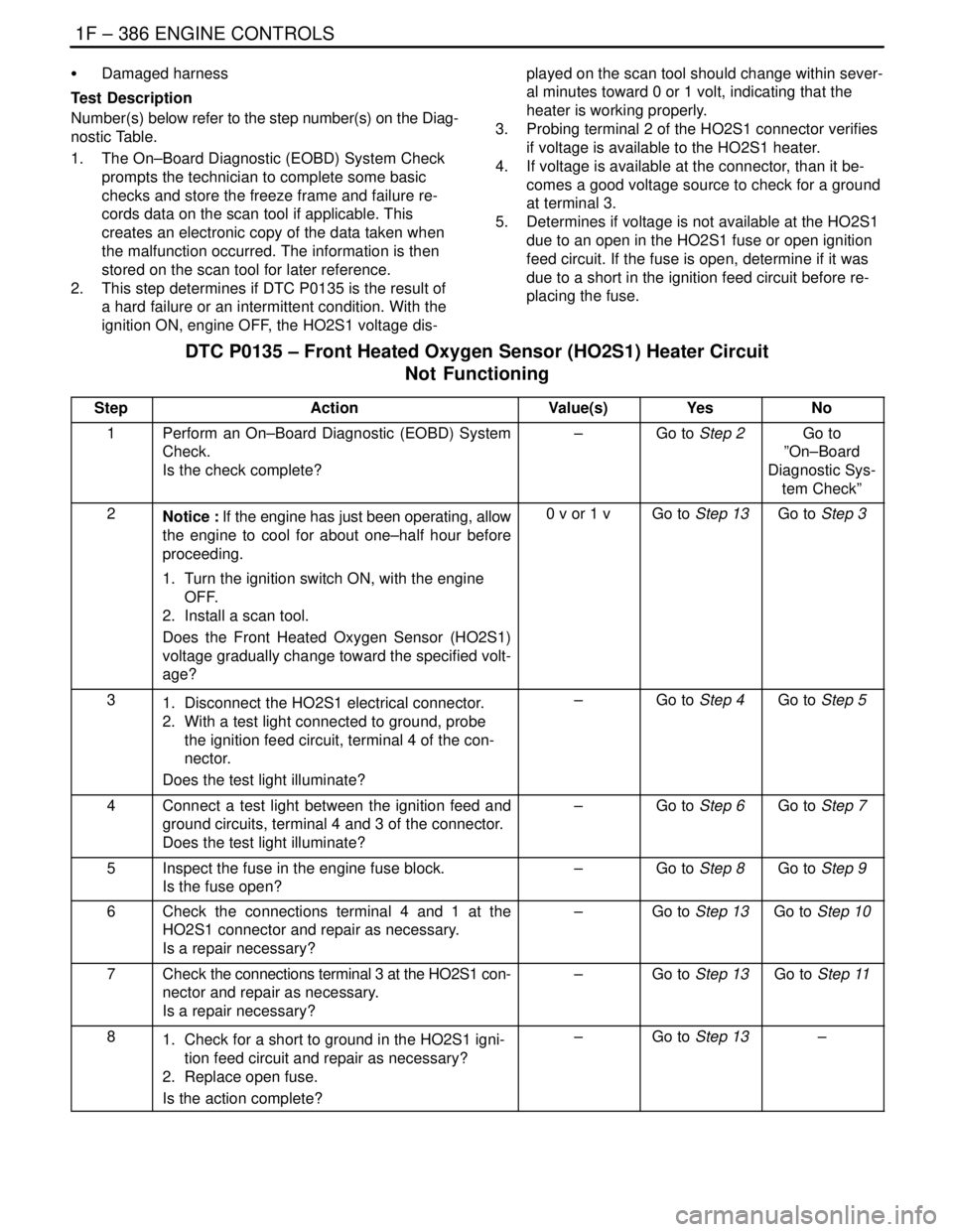

Test Description

Number(s) below refer to the step number(s) on the Diag-

nostic Table.

1. The On–Board Diagnostic (EOBD) System Check

prompts the technician to complete some basic

checks and store the freeze frame and failure re-

cords data on the scan tool if applicable. This

creates an electronic copy of the data taken when

the malfunction occurred. The information is then

stored on the scan tool for later reference.

2. This step determines if DTC P0135 is the result of

a hard failure or an intermittent condition. With the

ignition ON, engine OFF, the HO2S1 voltage dis-played on the scan tool should change within sever-

al minutes toward 0 or 1 volt, indicating that the

heater is working properly.

3. Probing terminal 2 of the HO2S1 connector verifies

if voltage is available to the HO2S1 heater.

4. If voltage is available at the connector, than it be-

comes a good voltage source to check for a ground

at terminal 3.

5. Determines if voltage is not available at the HO2S1

due to an open in the HO2S1 fuse or open ignition

feed circuit. If the fuse is open, determine if it was

due to a short in the ignition feed circuit before re-

placing the fuse.

DTC P0135 – Front Heated Oxygen Sensor (HO2S1) Heater Circuit

Not Functioning

StepActionValue(s)YesNo

1Perform an On–Board Diagnostic (EOBD) System

Check.

Is the check complete?–Go to Step 2Go to

”On–Board

Diagnostic Sys-

tem Check”

2Notice : If the engine has just been operating, allow

the engine to cool for about one–half hour before

proceeding.

1. Turn the ignition switch ON, with the engine

OFF.

2. Install a scan tool.

Does the Front Heated Oxygen Sensor (HO2S1)

voltage gradually change toward the specified volt-

age?0 v or 1 vGo to Step 13Go to Step 3

31. Disconnect the HO2S1 electrical connector.

2. With a test light connected to ground, probe

the ignition feed circuit, terminal 4 of the con-

nector.

Does the test light illuminate?–Go to Step 4Go to Step 5

4Connect a test light between the ignition feed and

ground circuits, terminal 4 and 3 of the connector.

Does the test light illuminate?–Go to Step 6Go to Step 7

5Inspect the fuse in the engine fuse block.

Is the fuse open?–Go to Step 8Go to Step 9

6Check the connections terminal 4 and 1 at the

HO2S1 connector and repair as necessary.

Is a repair necessary?–Go to Step 13Go to Step 10

7Check the connections terminal 3 at the HO2S1 con-

nector and repair as necessary.

Is a repair necessary?–Go to Step 13Go to Step 11

81. Check for a short to ground in the HO2S1 igni-

tion feed circuit and repair as necessary?

2. Replace open fuse.

Is the action complete?–Go to Step 13–