TPS DAEWOO NUBIRA 2004 Service Owner's Guide

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: NUBIRA, Model: DAEWOO NUBIRA 2004Pages: 2643, PDF Size: 80.54 MB

Page 1534 of 2643

ZF 4 HP 16 AUTOMATIC TRANSAXLE 5A1 – 185

DAEWOO V–121 BL4

S No input speed error DTCs P0715, P0716, or

P0717.

S Output speed is greater than 256 rpm.

S Input speed is greater than 400 rpm.

S 4–3 gear shift is active.

S Immediately after the above condition occurs.

Action Taken When The DTC Sets

S The Malfunction Indicator Lamp(MIL) will illuminate.

S The TCM will record operating conditions at the

time the diagnostic fails. This information will be

stored in the Failure Records buffer.

S Adopt Emergency/ Substitute mode and constant

4th gear.S Open lock–up clutch.

Conditions for Clearing the MIL/DTC

S The MIL will turn OFF when the malfunction has

not occurred after three–ignition cycle.

S A history DTC will clear after 40 consecutive warm

up cycles without a fault.

S Using a scan tool can clear history DTCs.

Diagnostic Aids

S When DTC P1884 sets, the possible cause of fault

could be TCM.

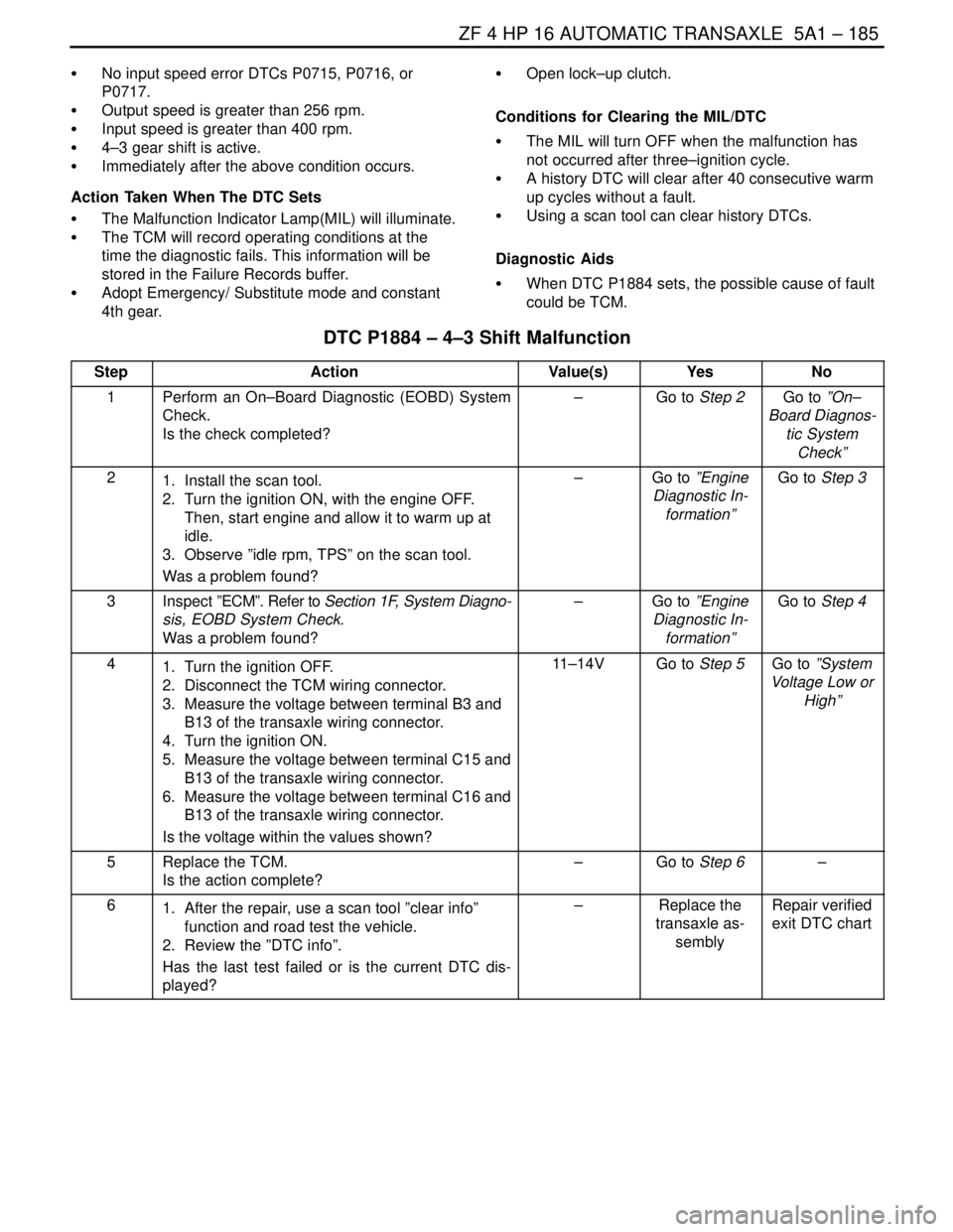

DTC P1884 – 4–3 Shift Malfunction

StepActionValue(s)YesNo

1Perform an On–Board Diagnostic (EOBD) System

Check.

Is the check completed?–Go to Step 2Go to ”On–

Board Diagnos-

tic System

Check”

21. Install the scan tool.

2. Turn the ignition ON, with the engine OFF.

Then, start engine and allow it to warm up at

idle.

3. Observe ”idle rpm, TPS” on the scan tool.

Was a problem found?–Go to ”Engine

Diagnostic In-

formation”Go to Step 3

3Inspect ”ECM”. Refer to Section 1F, System Diagno-

sis, EOBD System Check.

Was a problem found?–Go to ”Engine

Diagnostic In-

formation”Go to Step 4

41. Turn the ignition OFF.

2. Disconnect the TCM wiring connector.

3. Measure the voltage between terminal B3 and

B13 of the transaxle wiring connector.

4. Turn the ignition ON.

5. Measure the voltage between terminal C15 and

B13 of the transaxle wiring connector.

6. Measure the voltage between terminal C16 and

B13 of the transaxle wiring connector.

Is the voltage within the values shown?11–14VGo to Step 5Go to ”System

Voltage Low or

High”

5Replace the TCM.

Is the action complete?–Go to Step 6–

61. After the repair, use a scan tool ”clear info”

function and road test the vehicle.

2. Review the ”DTC info”.

Has the last test failed or is the current DTC dis-

played?–Replace the

transaxle as-

semblyRepair verified

exit DTC chart

Page 1536 of 2643

ZF 4 HP 16 AUTOMATIC TRANSAXLE 5A1 – 187

DAEWOO V–121 BL4

S No input speed error DTCs P0715, P0716, or

P0717.

S Output speed is greater than 256 rpm.

S Input speed is greater than 400 rpm.

S 3–1 gear shift is active.

S Immediately after the above condition occurs.

Action Taken When The DTC Sets

S The Malfunction Indicator Lamp(MIL) will illuminate.

S The TCM will record operating conditions at the

time the diagnostic fails. This information will be

stored in the Failure Records buffer.

S Adopt Emergency/ Substitute mode and constant

3rd gear.S Open lock–up clutch.

Conditions for Clearing the MIL/DTC

S The MIL will turn OFF when the malfunction has

not occurred after three–ignition cycle.

S A history DTC will clear after 40 consecutive warm

up cycles without a fault.

S Using a scan tool can clear history DTCs.

Diagnostic Aids

S When DTC P1885 sets, the possible cause of fault

could be TCM.

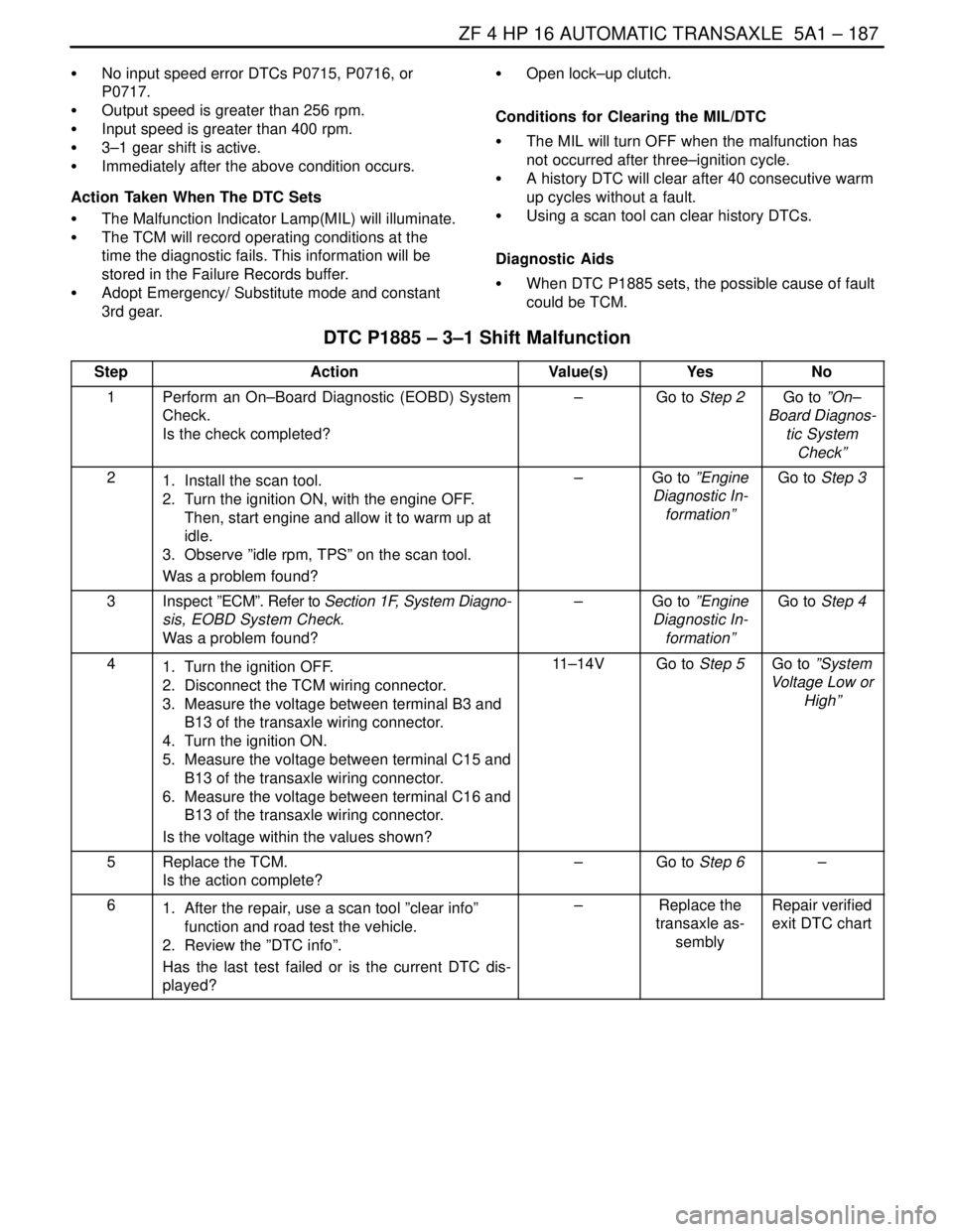

DTC P1885 – 3–1 Shift Malfunction

StepActionValue(s)YesNo

1Perform an On–Board Diagnostic (EOBD) System

Check.

Is the check completed?–Go to Step 2Go to ”On–

Board Diagnos-

tic System

Check”

21. Install the scan tool.

2. Turn the ignition ON, with the engine OFF.

Then, start engine and allow it to warm up at

idle.

3. Observe ”idle rpm, TPS” on the scan tool.

Was a problem found?–Go to ”Engine

Diagnostic In-

formation”Go to Step 3

3Inspect ”ECM”. Refer to Section 1F, System Diagno-

sis, EOBD System Check.

Was a problem found?–Go to ”Engine

Diagnostic In-

formation”Go to Step 4

41. Turn the ignition OFF.

2. Disconnect the TCM wiring connector.

3. Measure the voltage between terminal B3 and

B13 of the transaxle wiring connector.

4. Turn the ignition ON.

5. Measure the voltage between terminal C15 and

B13 of the transaxle wiring connector.

6. Measure the voltage between terminal C16 and

B13 of the transaxle wiring connector.

Is the voltage within the values shown?11–14VGo to Step 5Go to ”System

Voltage Low or

High”

5Replace the TCM.

Is the action complete?–Go to Step 6–

61. After the repair, use a scan tool ”clear info”

function and road test the vehicle.

2. Review the ”DTC info”.

Has the last test failed or is the current DTC dis-

played?–Replace the

transaxle as-

semblyRepair verified

exit DTC chart

Page 1538 of 2643

ZF 4 HP 16 AUTOMATIC TRANSAXLE 5A1 – 189

DAEWOO V–121 BL4

S No input speed error DTCs P0715, P0716, or

P0717.

S Output speed is greater than 256 rpm.

S Input speed is greater than 400 rpm.

S 4–2 gear shift is active.

S Immediately after the above condition occurs.

Action Taken When The DTC Sets

S The Malfunction Indicator Lamp(MIL) will illuminate.

S The TCM will record operating conditions at the

time the diagnostic fails. This information will be

stored in the Failure Records buffer.

S Adopt Emergency/ Substitute mode and constant

4th gear.S Open lock–up clutch.

Conditions for Clearing the MIL/DTC

S The MIL will turn OFF when the malfunction has

not occurred after three–ignition cycle.

S A history DTC will clear after 40 consecutive warm

up cycles without a fault.

S Using a scan tool can clear history DTCs.

Diagnostic Aids

S When DTC P1886 sets, the possible cause of fault

could be TCM.

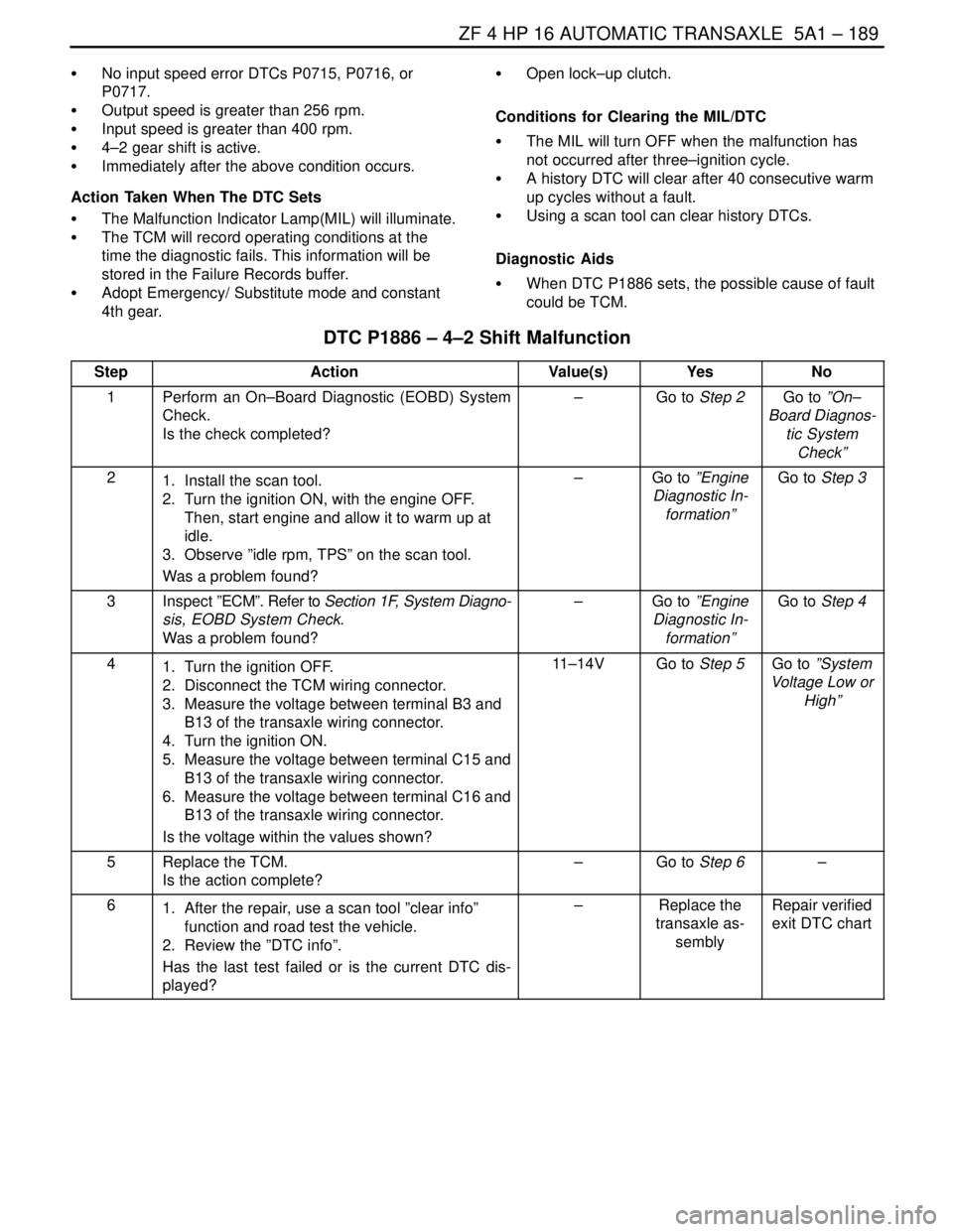

DTC P1886 – 4–2 Shift Malfunction

StepActionValue(s)YesNo

1Perform an On–Board Diagnostic (EOBD) System

Check.

Is the check completed?–Go to Step 2Go to ”On–

Board Diagnos-

tic System

Check”

21. Install the scan tool.

2. Turn the ignition ON, with the engine OFF.

Then, start engine and allow it to warm up at

idle.

3. Observe ”idle rpm, TPS” on the scan tool.

Was a problem found?–Go to ”Engine

Diagnostic In-

formation”Go to Step 3

3Inspect ”ECM”. Refer to Section 1F, System Diagno-

sis, EOBD System Check.

Was a problem found?–Go to ”Engine

Diagnostic In-

formation”Go to Step 4

41. Turn the ignition OFF.

2. Disconnect the TCM wiring connector.

3. Measure the voltage between terminal B3 and

B13 of the transaxle wiring connector.

4. Turn the ignition ON.

5. Measure the voltage between terminal C15 and

B13 of the transaxle wiring connector.

6. Measure the voltage between terminal C16 and

B13 of the transaxle wiring connector.

Is the voltage within the values shown?11–14VGo to Step 5Go to ”System

Voltage Low or

High”

5Replace the TCM.

Is the action complete?–Go to Step 6–

61. After the repair, use a scan tool ”clear info”

function and road test the vehicle.

2. Review the ”DTC info”.

Has the last test failed or is the current DTC dis-

played?–Replace the

transaxle as-

semblyRepair verified

exit DTC chart

Page 2054 of 2643

7B – 52IMANUAL CONTROL HEATING, VENTILATION AND AIR CONDITIONING SYSTEM

DAEWOO V–121 BL4

SYSTEM COMPONENTS–CONTROL

Controller

The operation of the A/C system is controlled by the

switches and the lever on the control head. The compres-

sor clutch and the blower are connected electrically to the

control head by a wiring harness. The blower circuit is

open in the OFF mode. Airflow is provided by the four

blower speeds available in the remaining modes. Cooled

and dehumidified air is available in the MAX, NORMAL,

BI–LEVEL, and DEFROST modes.

The temperature is controlled by the position of the tem-

perature knob on the control head. A cable connects this

knob to the temperature door, which controls the airflow

through the heater core. As the temperature knob is

moved through its range of travel, a sliding clip on the

cable at the temperature valve connection should assume

a position ensuring that the temperature door will seat in

both extreme positions. The temperature door position is

independent of the mode control switch. The temperature

door on some models is controlled electrically, eliminating

the need for the temperature cable.

The electric engine cooling fan on some vehicles is not

part of the A/C control system; however, the fan is opera-

tional any time the A/C control is in the MAX, NORMAL,

or BI–LEVEL modes. Some models provide for engine

cooling fan operation when the controller is in the DE-

FROST mode. This added feature is part of the A/C con-

troller function and is aimed at preventing excessive com-

pressor head temperatures. It also allows the A/C system

to function more efficiently. On some models, the engine

cooling fan will be turned off during road speed conditions

above 56 km/h (35 mph), when the airflow though the con-

denser coil is adequate for efficient cooling. The operation

of the cooling fan is controlled by the powertrain control

module (PCM), or the engine control module (ECM),

through the cooling fan relay.

Pressure Transducer

The pressure transducer incorporates the functions of the

high–pressure and the low–pressure cutout switches

along with the fan cycling switch. The pressure transducer

is located in the high–side liquid refrigerant line near the

right front strut tower and the air filter assembly.

Wide–Open Throttle (WOT) Compressor

Cutoff

During full throttle acceleration on vehicles equipped with

multi–port injection (MPI), the throttle position sensor

(TPS) sends a signal to the PCM or the ECM, which then

controls the compressor clutch.

A/C Time Delay Relay

This relay on some vehicles controls the current to the en-

tire A/C system and provides a short delay of A/C opera-

tion upon start–up.

V5 COMPRESSOR–GENERAL

DESCRIPTION

Different vehicles with V5 compressors may exhibit differ-

ences in mounting and installation, but overhaul proce-

dures are similar.

Before removing the compressor or performing on–ve-

hicle repairs, clean the compressor connections and the

outside of the compressor.

Important : After removing a compressor from the vehicle

for servicing, drain the oil by removing the oil drain plug.

Also drain the oil from the suction and the discharge ports

to insure complete draining. Measure the amount of oil

drained, and record that amount. Discard the used oil and

add the same amount of new polyalkaline glycol (PAG) re-

frigerant oil to the compressor.

The compressor has been removed from the vehicle un-

less otherwise indicated.

Clean tools and a clean work area are important for proper

servicing. Keep dirt and foreign material from getting on or

into the compressor parts. Parts that are to be reassem-

bled should be cleaned with trichloroethane, naphtha,

stoddard solvent, kerosene, or equivalent solvents. Dry

the cleaned parts with clean dry air. Use only lint–free

cloths to wipe the parts.

V5 COMPRESSOR–DESCRIPTION OF

OPERATION

The V5 is a variable displacement compressor that can

match the automotive air conditioning (A/C) demand un-

der all conditions without cycling. The basic compressor

mechanism is a variable angle wobble–plate with five ax-

ially oriented cylinders. The center of control of the com-

pressor displacement is a bellows–actuated control valve

located in the rear head of the compressor. The control

valve senses compressor suction pressure.

The wobble–plate angle and the compressor displace-

ment are controlled by the crankcase suction pressure dif-

ferential. When the A/C capacity demand is high, the suc-

tion pressure will be above the control point. The valve will

maintain a bleed from crankcase to suction. With no

crankcase suction pressure differential, the compressor

will have maximum displacement.

When the A/C capacity demand is lower and the suction

pressure reaches the control point, the valve will bleed dis-

charge gas into the crankcase and close off a passage

from the crankcase to the suction plenum. The angle of the

wobble–plate is controlled by a force balance on the five

pistons. A slight elevation of the crankcase suction pres-

sure differential creates total force on the pistons resulting

in a movement about the wobbleplate pivot pin that re-

duces the plate angle.

The compressor has a unique lubrication system. The

crankcase suction bleed is routed through the rotating

wobble–plate for lubrication of the wobble–plate bearing.

The rotation acts as an oil separator which removes some

Page 2095 of 2643

7D – 40IAUTOMATIC TEMPERATURE CONTROL HEATING, VENTILATION, AND AIR CONDITIONING SYSTEM

DAEWOO V–121 BL4

GENERAL DESCRIPTION

AND SYSTEM OPERATION

GENERAL INFORMATION

THE V5 SYSTEM

Refer to Section 7B, Manual Control Heating, Ventilation,

and Air Conditioning System,for general information de-

tails for the following:

S System Components – Functional.

S The V5 A/C System.

S V5 Compressor – Description of Operation.

S V5 Compressor – General Description.

SYSTEM COMPONENTS–CONTROL

Controller

The operation of the A/C system is controlled by the

switches on the control head. This console–mounted

heating and ventilation system contains the following

knobs and display:

Temperature Control Push Knobs

1. Raise the temperature of the air entering the ve-

hicle by pressing the top switch, with the red arrow

pointing upward.

2. Lower the temperature by pressing the bottom

switch, with the blue arrow pointing downward.

3. Actuate the air mix door by an electric motor.

4. Vary the mix of the air passing through the heater

core with the air bypassing the core.

Each press of a switch changes the set temperature by in-

crements of 0.5°C (1°F). This is shown in the temperature

window on the function display.

The Function Display

This is an LCD display indicating the status of the control

settings selected. Starting from the left end of the display,

the sections are as follows:

1. Temperature setting – Indicates the temperature set

with the temperature control knob.

2. Auto status – Indicates whether the system is oper-

ating in the full auto mode or the manual mode.

3. Defroster icon – Indicates manual selection of full

defrost mode.

4. Mode – Indicated by icon, the mode chosen by the

system in auto (or by the operator in manual) is

shown by an illumination arrow indicating the air

path.

5. A/C – A snowflake icon indicating whether the A/C

is ON or OFF.

6. Fan speed – Indicates the fan speed by illuminating

a bar based on the segment at the front, for low

speed, and adding additional segments in order up

to the fifth, for high speed.Eight Additional Push Knobs

1. Full defrost – Causes the mode motors to direct all

air to the windshield and aide window outlets for

maximum defrosting.

2. Air intake – Switches between fresh air intake, the

default, and recirculating air. Airflow arrows on the

display indicate the mode in effect.

3. Full Auto Switch – Maintains the set temperature

automatically. In this mode, the fully automatic tem-

perature control (FATC) system controls the follow-

ing:

S The air mix door motor.

S The mode door motor.

S The blower motor speed.

S The inlet air door motor.

S A/C ON/OFF.

4. OFF Switch – Turns the automatic air conditioning

and fan control off.

5. Mode Switch – Allows manual selection of the air-

flow direction.

S Selection is shown on the function display.

S Each time the mode switch is pressed, the next

function is displayed.

6. A/C Switch – Allows manual selection and control

of the air conditioning function.

7. Fan Control Switch – Allows manual selection

among five fan speeds.

8. Defogger Switch – Turns on the electric defogging

heater in the rear window and the outside rearview

mirrors, if the vehicle is equipped with heated mir-

rors.

Pressure Transducer

Pressure transducer switching incorporates the functions

of the high–pressure and the low–pressure cutout

switches along with the fan cycling switch. The pressure

transducer is located in the high–side liquid refrigerant line

behind the right strut tower, between the right strut tower

and the fire wall. The output from this pressure transducer

goes to the electronic control module (ECM), which con-

trols the compressor function based on the pressure sig-

nal.

Wide–Open Throttle (WOT) Compressor

Cutoff

During full–throttle acceleration, the throttle position sen-

sor (TPS) sends a signal to the ECM, which then controls

the compressor clutch.

High RPM Cutoff

As engine rpm approaches the maximum limit, the ECM

will disengage the compressor clutch until the engine

slows to a lower rpm.