oil DAEWOO NUBIRA 2004 Service Service Manual

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: NUBIRA, Model: DAEWOO NUBIRA 2004Pages: 2643, PDF Size: 80.54 MB

Page 93 of 2643

1C1 – 50I1.4L/1.6L DOHC ENGINE MECHANICAL

DAEWOO V–121 BL4

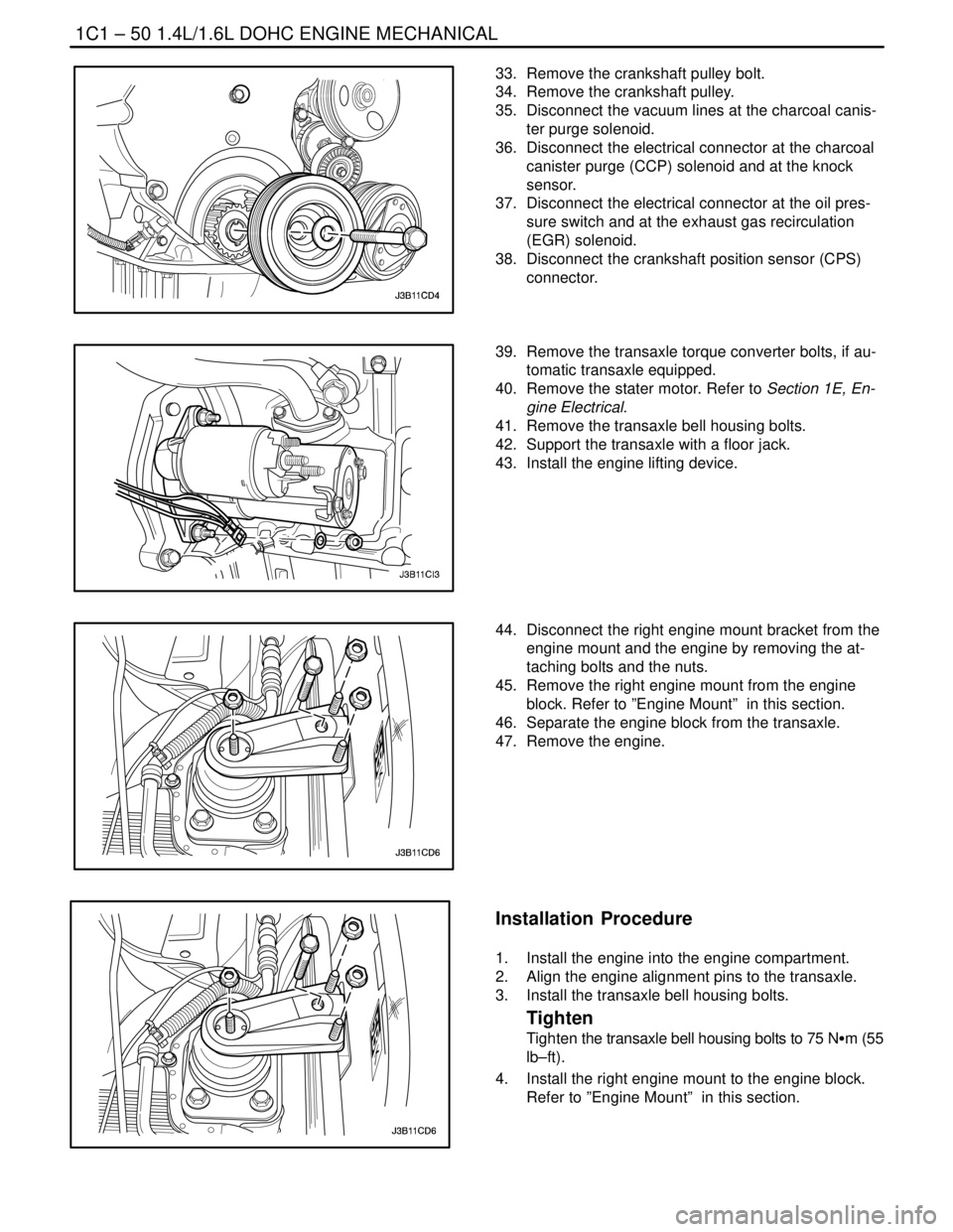

33. Remove the crankshaft pulley bolt.

34. Remove the crankshaft pulley.

35. Disconnect the vacuum lines at the charcoal canis-

ter purge solenoid.

36. Disconnect the electrical connector at the charcoal

canister purge (CCP) solenoid and at the knock

sensor.

37. Disconnect the electrical connector at the oil pres-

sure switch and at the exhaust gas recirculation

(EGR) solenoid.

38. Disconnect the crankshaft position sensor (CPS)

connector.

39. Remove the transaxle torque converter bolts, if au-

tomatic transaxle equipped.

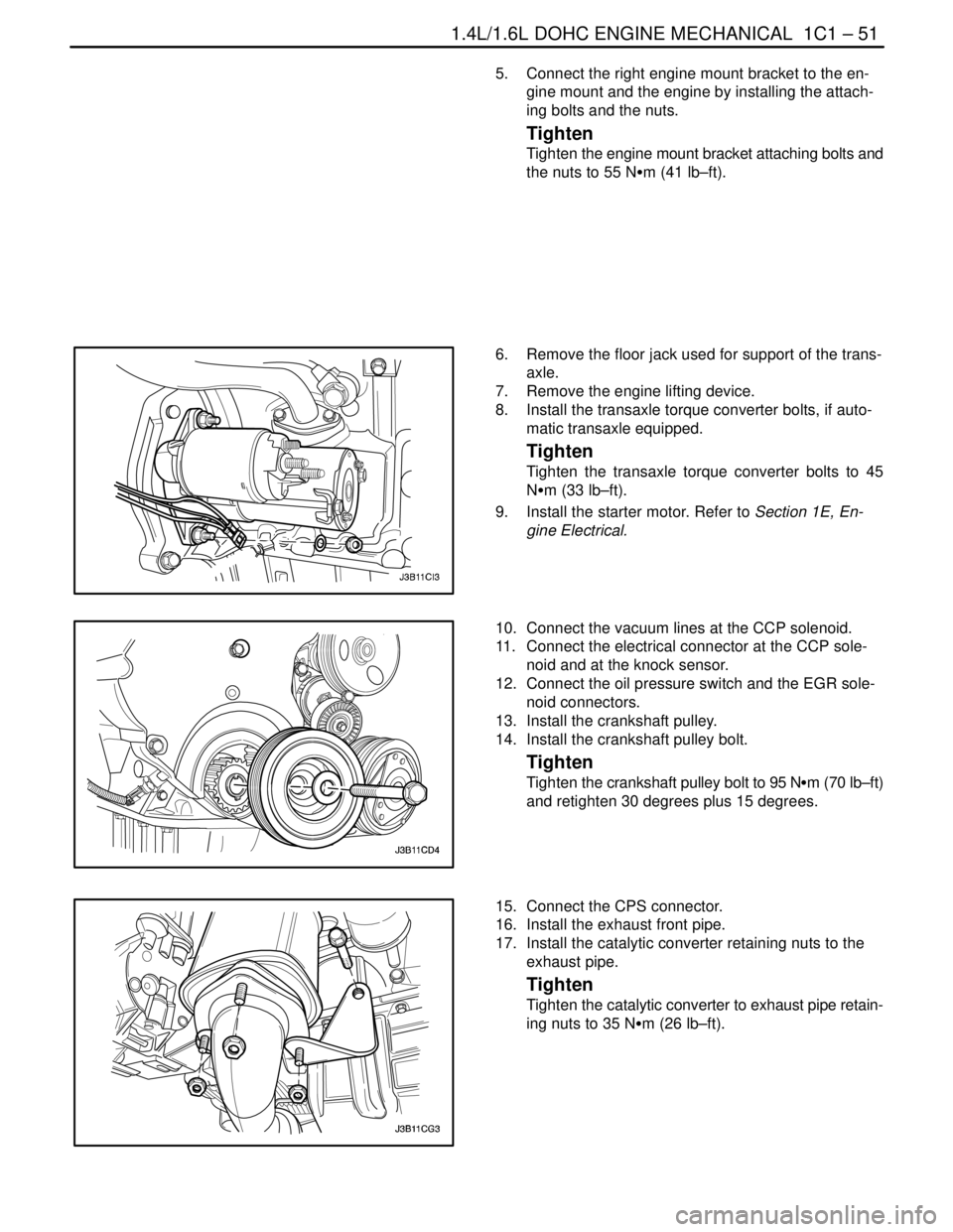

40. Remove the stater motor. Refer to Section 1E, En-

gine Electrical.

41. Remove the transaxle bell housing bolts.

42. Support the transaxle with a floor jack.

43. Install the engine lifting device.

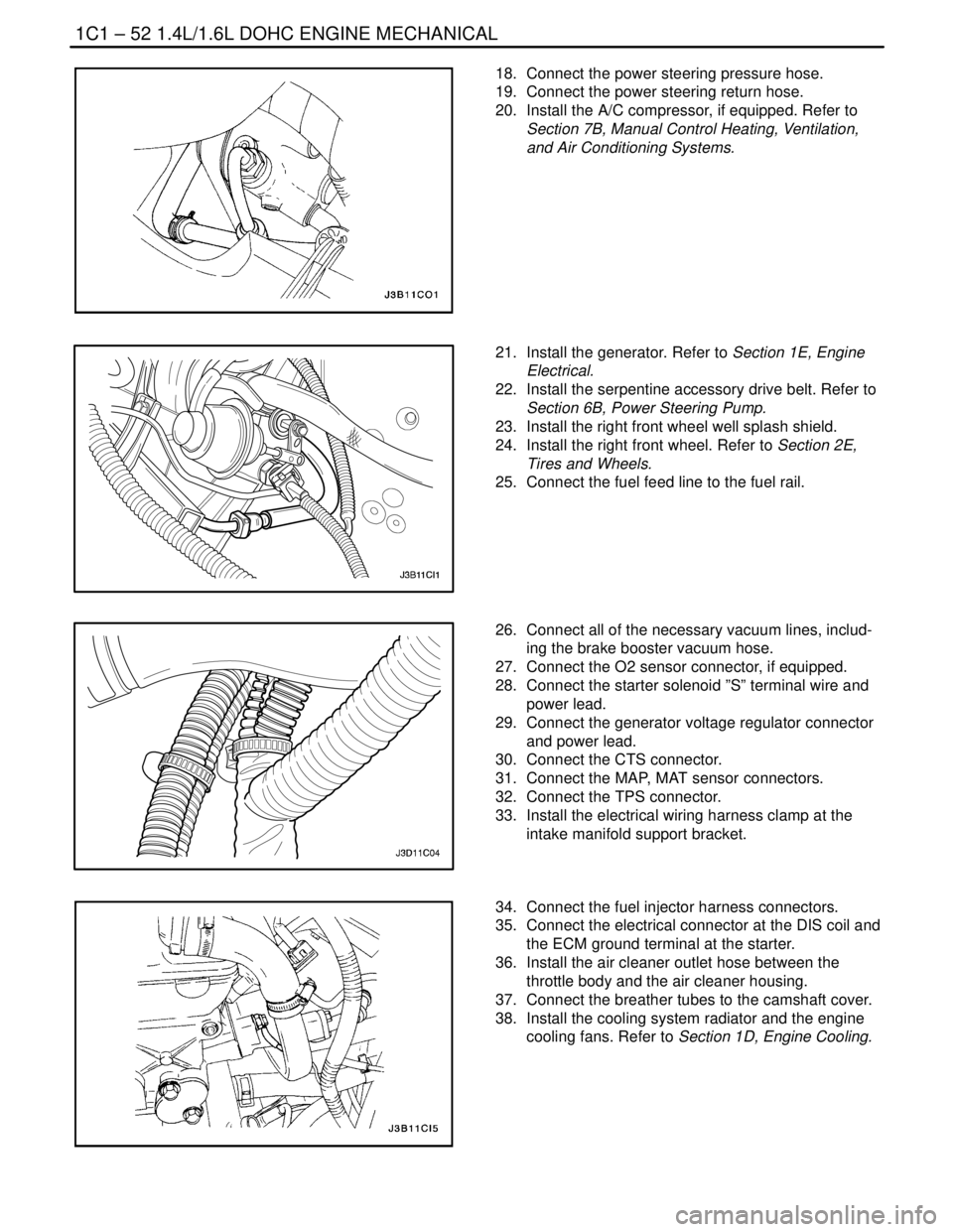

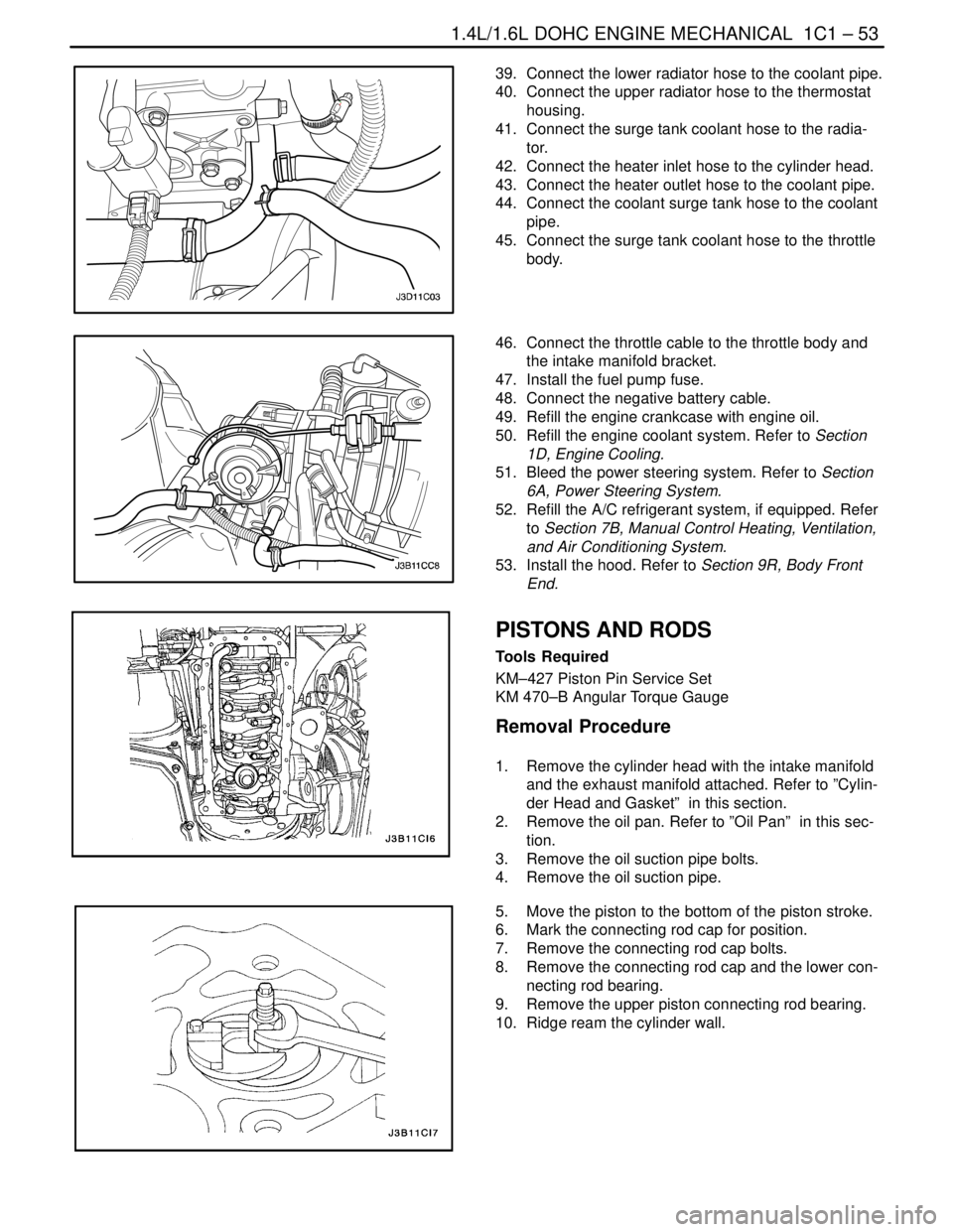

44. Disconnect the right engine mount bracket from the

engine mount and the engine by removing the at-

taching bolts and the nuts.

45. Remove the right engine mount from the engine

block. Refer to ”Engine Mount” in this section.

46. Separate the engine block from the transaxle.

47. Remove the engine.

Installation Procedure

1. Install the engine into the engine compartment.

2. Align the engine alignment pins to the transaxle.

3. Install the transaxle bell housing bolts.

Tighten

Tighten the transaxle bell housing bolts to 75 NSm (55

lb–ft).

4. Install the right engine mount to the engine block.

Refer to ”Engine Mount” in this section.

Page 94 of 2643

1.4L/1.6L DOHC ENGINE MECHANICAL 1C1 – 51

DAEWOO V–121 BL4

5. Connect the right engine mount bracket to the en-

gine mount and the engine by installing the attach-

ing bolts and the nuts.

Tighten

Tighten the engine mount bracket attaching bolts and

the nuts to 55 NSm (41 lb–ft).

6. Remove the floor jack used for support of the trans-

axle.

7. Remove the engine lifting device.

8. Install the transaxle torque converter bolts, if auto-

matic transaxle equipped.

Tighten

Tighten the transaxle torque converter bolts to 45

NSm (33 lb–ft).

9. Install the starter motor. Refer to Section 1E, En-

gine Electrical.

10. Connect the vacuum lines at the CCP solenoid.

11. Connect the electrical connector at the CCP sole-

noid and at the knock sensor.

12. Connect the oil pressure switch and the EGR sole-

noid connectors.

13. Install the crankshaft pulley.

14. Install the crankshaft pulley bolt.

Tighten

Tighten the crankshaft pulley bolt to 95 NSm (70 lb–ft)

and retighten 30 degrees plus 15 degrees.

15. Connect the CPS connector.

16. Install the exhaust front pipe.

17. Install the catalytic converter retaining nuts to the

exhaust pipe.

Tighten

Tighten the catalytic converter to exhaust pipe retain-

ing nuts to 35 NSm (26 lb–ft).

Page 95 of 2643

1C1 – 52I1.4L/1.6L DOHC ENGINE MECHANICAL

DAEWOO V–121 BL4

18. Connect the power steering pressure hose.

19. Connect the power steering return hose.

20. Install the A/C compressor, if equipped. Refer to

Section 7B, Manual Control Heating, Ventilation,

and Air Conditioning Systems.

21. Install the generator. Refer to Section 1E, Engine

Electrical.

22. Install the serpentine accessory drive belt. Refer to

Section 6B, Power Steering Pump.

23. Install the right front wheel well splash shield.

24. Install the right front wheel. Refer to Section 2E,

Tires and Wheels.

25. Connect the fuel feed line to the fuel rail.

26. Connect all of the necessary vacuum lines, includ-

ing the brake booster vacuum hose.

27. Connect the O2 sensor connector, if equipped.

28. Connect the starter solenoid ”S” terminal wire and

power lead.

29. Connect the generator voltage regulator connector

and power lead.

30. Connect the CTS connector.

31. Connect the MAP, MAT sensor connectors.

32. Connect the TPS connector.

33. Install the electrical wiring harness clamp at the

intake manifold support bracket.

34. Connect the fuel injector harness connectors.

35. Connect the electrical connector at the DIS coil and

the ECM ground terminal at the starter.

36. Install the air cleaner outlet hose between the

throttle body and the air cleaner housing.

37. Connect the breather tubes to the camshaft cover.

38. Install the cooling system radiator and the engine

cooling fans. Refer to Section 1D, Engine Cooling.

Page 96 of 2643

1.4L/1.6L DOHC ENGINE MECHANICAL 1C1 – 53

DAEWOO V–121 BL4

39. Connect the lower radiator hose to the coolant pipe.

40. Connect the upper radiator hose to the thermostat

housing.

41. Connect the surge tank coolant hose to the radia-

tor.

42. Connect the heater inlet hose to the cylinder head.

43. Connect the heater outlet hose to the coolant pipe.

44. Connect the coolant surge tank hose to the coolant

pipe.

45. Connect the surge tank coolant hose to the throttle

body.

46. Connect the throttle cable to the throttle body and

the intake manifold bracket.

47. Install the fuel pump fuse.

48. Connect the negative battery cable.

49. Refill the engine crankcase with engine oil.

50. Refill the engine coolant system. Refer to Section

1D, Engine Cooling.

51. Bleed the power steering system. Refer to Section

6A, Power Steering System.

52. Refill the A/C refrigerant system, if equipped. Refer

to Section 7B, Manual Control Heating, Ventilation,

and Air Conditioning System.

53. Install the hood. Refer to Section 9R, Body Front

End.

PISTONS AND RODS

Tools Required

KM–427 Piston Pin Service Set

KM 470–B Angular Torque Gauge

Removal Procedure

1. Remove the cylinder head with the intake manifold

and the exhaust manifold attached. Refer to ”Cylin-

der Head and Gasket” in this section.

2. Remove the oil pan. Refer to ”Oil Pan” in this sec-

tion.

3. Remove the oil suction pipe bolts.

4. Remove the oil suction pipe.

5. Move the piston to the bottom of the piston stroke.

6. Mark the connecting rod cap for position.

7. Remove the connecting rod cap bolts.

8. Remove the connecting rod cap and the lower con-

necting rod bearing.

9. Remove the upper piston connecting rod bearing.

10. Ridge ream the cylinder wall.

Page 98 of 2643

1.4L/1.6L DOHC ENGINE MECHANICAL 1C1 – 55

DAEWOO V–121 BL4

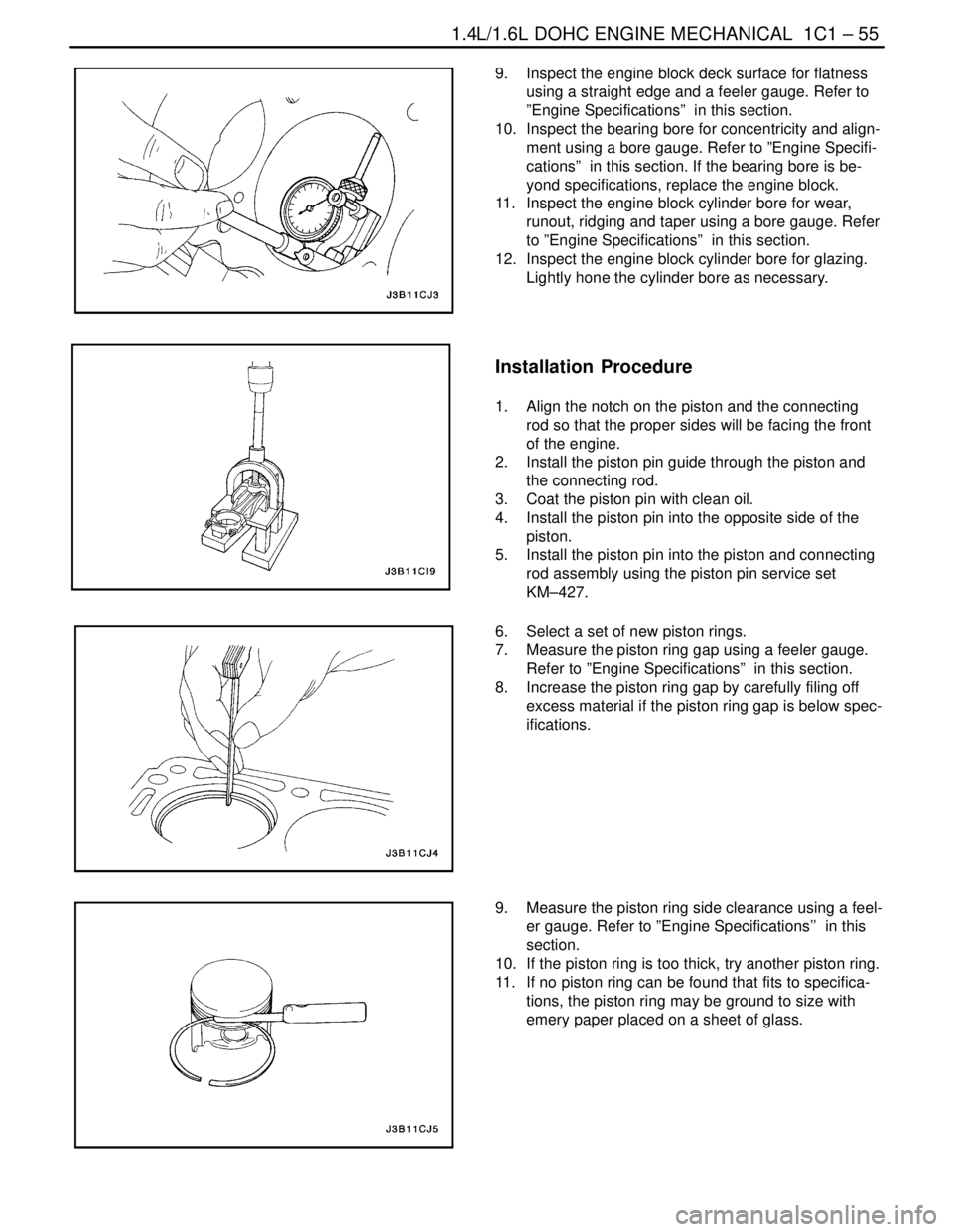

9. Inspect the engine block deck surface for flatness

using a straight edge and a feeler gauge. Refer to

”Engine Specifications” in this section.

10. Inspect the bearing bore for concentricity and align-

ment using a bore gauge. Refer to ”Engine Specifi-

cations” in this section. If the bearing bore is be-

yond specifications, replace the engine block.

11. Inspect the engine block cylinder bore for wear,

runout, ridging and taper using a bore gauge. Refer

to ”Engine Specifications” in this section.

12. Inspect the engine block cylinder bore for glazing.

Lightly hone the cylinder bore as necessary.

Installation Procedure

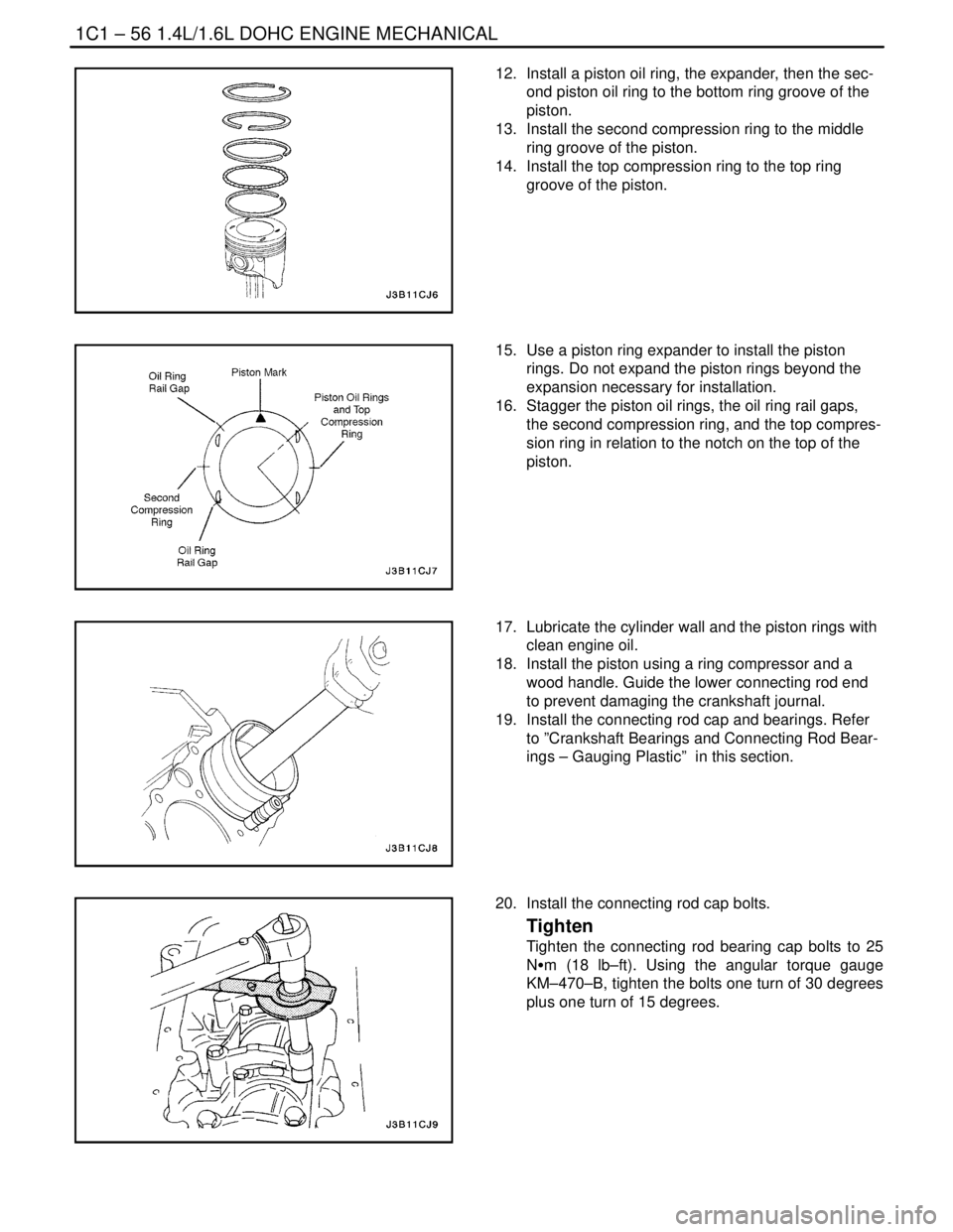

1. Align the notch on the piston and the connecting

rod so that the proper sides will be facing the front

of the engine.

2. Install the piston pin guide through the piston and

the connecting rod.

3. Coat the piston pin with clean oil.

4. Install the piston pin into the opposite side of the

piston.

5. Install the piston pin into the piston and connecting

rod assembly using the piston pin service set

KM–427.

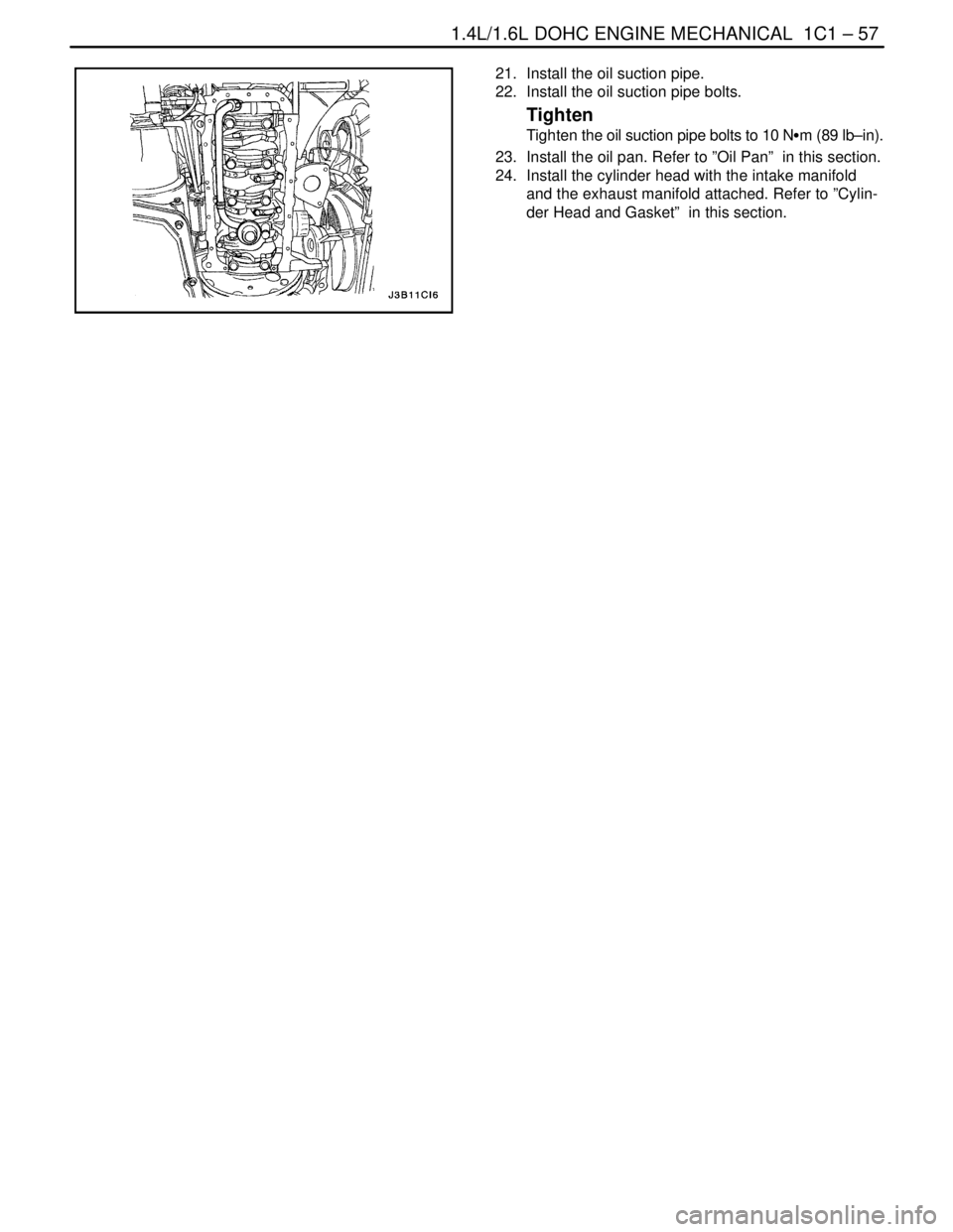

6. Select a set of new piston rings.

7. Measure the piston ring gap using a feeler gauge.

Refer to ”Engine Specifications” in this section.

8. Increase the piston ring gap by carefully filing off

excess material if the piston ring gap is below spec-

ifications.

9. Measure the piston ring side clearance using a feel-

er gauge. Refer to ”Engine Specifications’’ in this

section.

10. If the piston ring is too thick, try another piston ring.

11. If no piston ring can be found that fits to specifica-

tions, the piston ring may be ground to size with

emery paper placed on a sheet of glass.

Page 99 of 2643

1C1 – 56I1.4L/1.6L DOHC ENGINE MECHANICAL

DAEWOO V–121 BL4

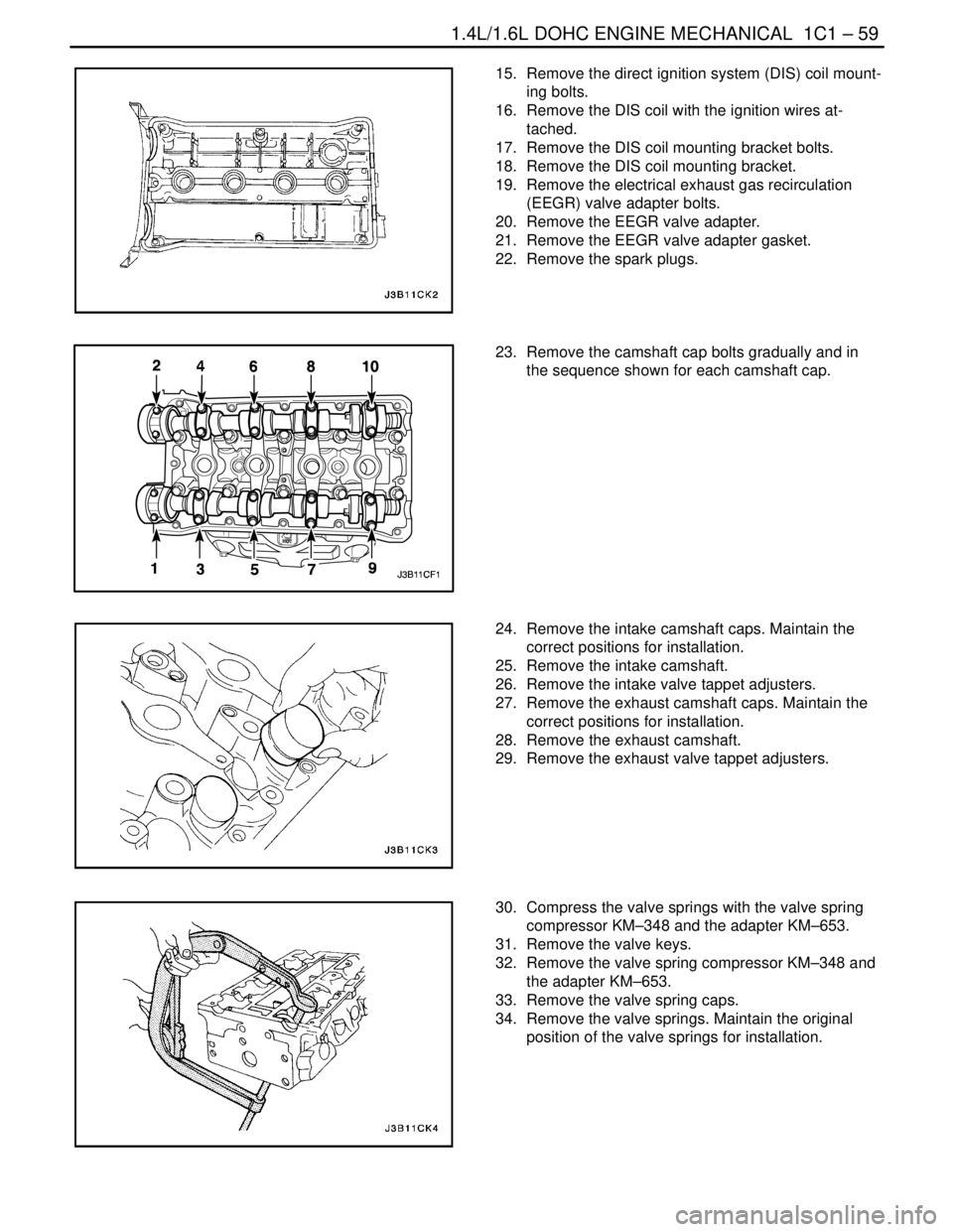

12. Install a piston oil ring, the expander, then the sec-

ond piston oil ring to the bottom ring groove of the

piston.

13. Install the second compression ring to the middle

ring groove of the piston.

14. Install the top compression ring to the top ring

groove of the piston.

15. Use a piston ring expander to install the piston

rings. Do not expand the piston rings beyond the

expansion necessary for installation.

16. Stagger the piston oil rings, the oil ring rail gaps,

the second compression ring, and the top compres-

sion ring in relation to the notch on the top of the

piston.

17. Lubricate the cylinder wall and the piston rings with

clean engine oil.

18. Install the piston using a ring compressor and a

wood handle. Guide the lower connecting rod end

to prevent damaging the crankshaft journal.

19. Install the connecting rod cap and bearings. Refer

to ”Crankshaft Bearings and Connecting Rod Bear-

ings – Gauging Plastic” in this section.

20. Install the connecting rod cap bolts.

Tighten

Tighten the connecting rod bearing cap bolts to 25

NSm (18 lb–ft). Using the angular torque gauge

KM–470–B, tighten the bolts one turn of 30 degrees

plus one turn of 15 degrees.

Page 100 of 2643

1.4L/1.6L DOHC ENGINE MECHANICAL 1C1 – 57

DAEWOO V–121 BL4

21. Install the oil suction pipe.

22. Install the oil suction pipe bolts.

Tighten

Tighten the oil suction pipe bolts to 10 NSm (89 lb–in).

23. Install the oil pan. Refer to ”Oil Pan” in this section.

24. Install the cylinder head with the intake manifold

and the exhaust manifold attached. Refer to ”Cylin-

der Head and Gasket” in this section.

Page 102 of 2643

1.4L/1.6L DOHC ENGINE MECHANICAL 1C1 – 59

DAEWOO V–121 BL4

15. Remove the direct ignition system (DIS) coil mount-

ing bolts.

16. Remove the DIS coil with the ignition wires at-

tached.

17. Remove the DIS coil mounting bracket bolts.

18. Remove the DIS coil mounting bracket.

19. Remove the electrical exhaust gas recirculation

(EEGR) valve adapter bolts.

20. Remove the EEGR valve adapter.

21. Remove the EEGR valve adapter gasket.

22. Remove the spark plugs.

23. Remove the camshaft cap bolts gradually and in

the sequence shown for each camshaft cap.

24. Remove the intake camshaft caps. Maintain the

correct positions for installation.

25. Remove the intake camshaft.

26. Remove the intake valve tappet adjusters.

27. Remove the exhaust camshaft caps. Maintain the

correct positions for installation.

28. Remove the exhaust camshaft.

29. Remove the exhaust valve tappet adjusters.

30. Compress the valve springs with the valve spring

compressor KM–348 and the adapter KM–653.

31. Remove the valve keys.

32. Remove the valve spring compressor KM–348 and

the adapter KM–653.

33. Remove the valve spring caps.

34. Remove the valve springs. Maintain the original

position of the valve springs for installation.

Page 103 of 2643

1C1 – 60I1.4L/1.6L DOHC ENGINE MECHANICAL

DAEWOO V–121 BL4

35. Remove the valves. Maintain the original position of

the valves for installation.

36. Remove the valve stem seals.

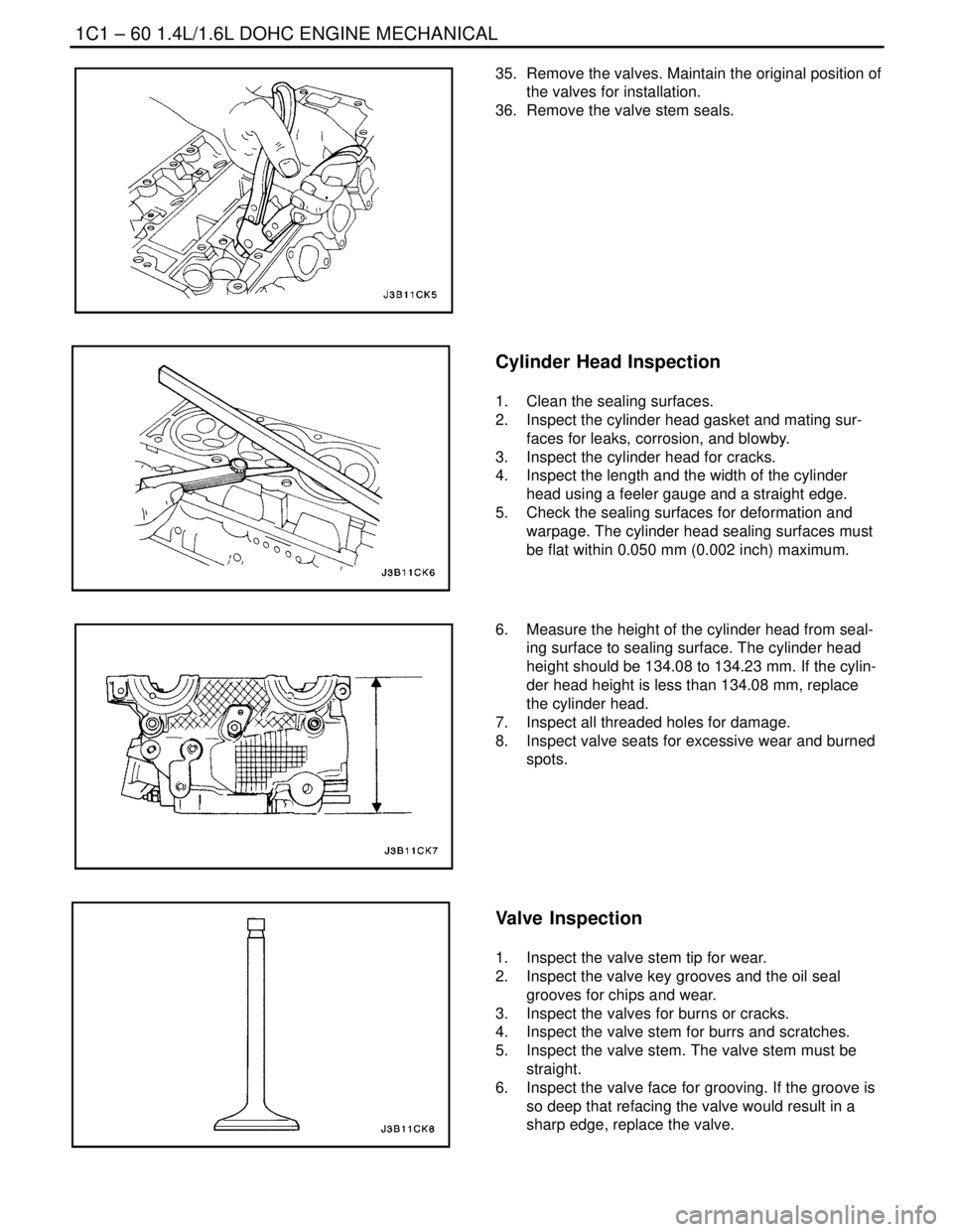

Cylinder Head Inspection

1. Clean the sealing surfaces.

2. Inspect the cylinder head gasket and mating sur-

faces for leaks, corrosion, and blowby.

3. Inspect the cylinder head for cracks.

4. Inspect the length and the width of the cylinder

head using a feeler gauge and a straight edge.

5. Check the sealing surfaces for deformation and

warpage. The cylinder head sealing surfaces must

be flat within 0.050 mm (0.002 inch) maximum.

6. Measure the height of the cylinder head from seal-

ing surface to sealing surface. The cylinder head

height should be 134.08 to 134.23 mm. If the cylin-

der head height is less than 134.08 mm, replace

the cylinder head.

7. Inspect all threaded holes for damage.

8. Inspect valve seats for excessive wear and burned

spots.

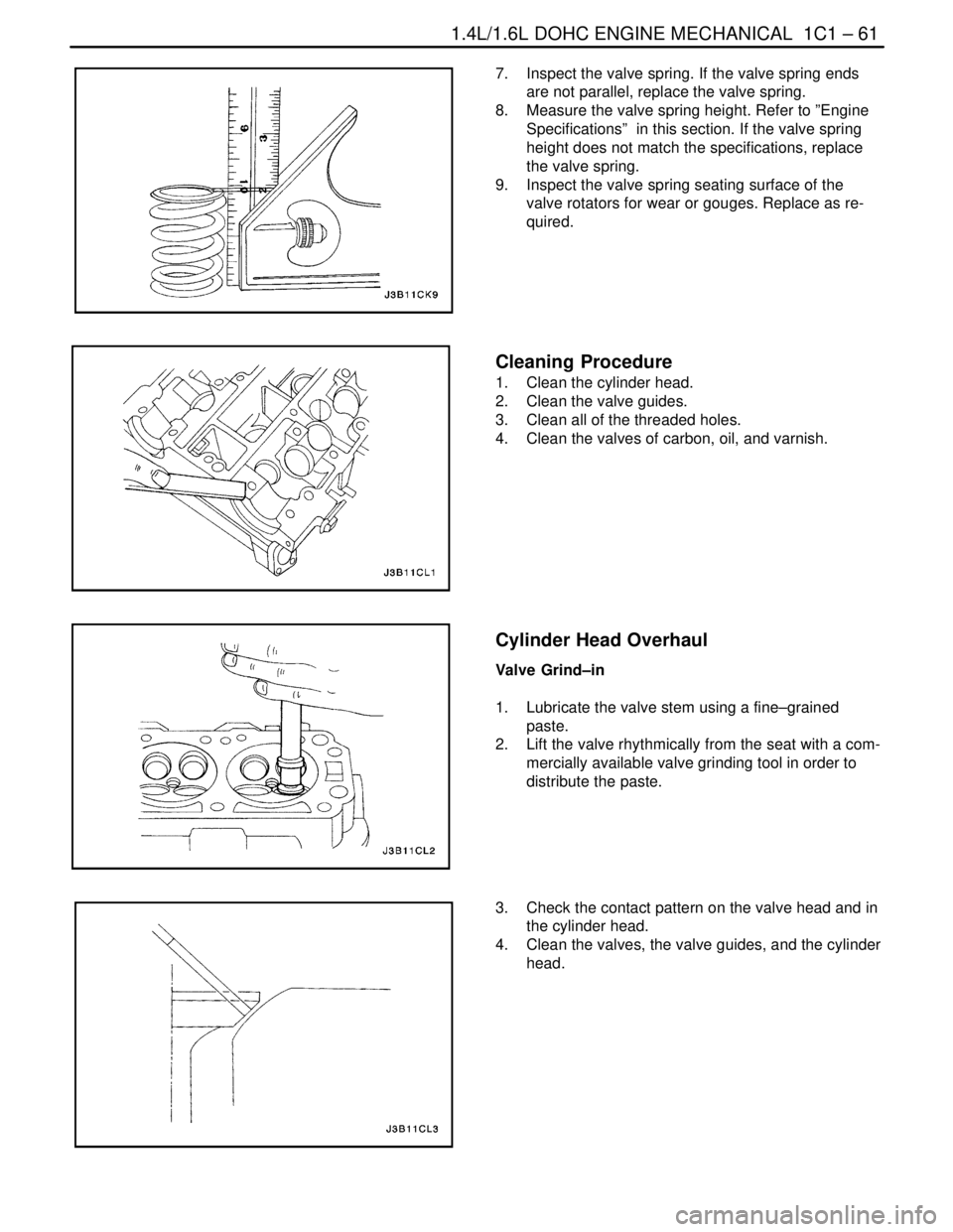

Valve Inspection

1. Inspect the valve stem tip for wear.

2. Inspect the valve key grooves and the oil seal

grooves for chips and wear.

3. Inspect the valves for burns or cracks.

4. Inspect the valve stem for burrs and scratches.

5. Inspect the valve stem. The valve stem must be

straight.

6. Inspect the valve face for grooving. If the groove is

so deep that refacing the valve would result in a

sharp edge, replace the valve.

Page 104 of 2643

1.4L/1.6L DOHC ENGINE MECHANICAL 1C1 – 61

DAEWOO V–121 BL4

7. Inspect the valve spring. If the valve spring ends

are not parallel, replace the valve spring.

8. Measure the valve spring height. Refer to ”Engine

Specifications” in this section. If the valve spring

height does not match the specifications, replace

the valve spring.

9. Inspect the valve spring seating surface of the

valve rotators for wear or gouges. Replace as re-

quired.

Cleaning Procedure

1. Clean the cylinder head.

2. Clean the valve guides.

3. Clean all of the threaded holes.

4. Clean the valves of carbon, oil, and varnish.

Cylinder Head Overhaul

Valve Grind–in

1. Lubricate the valve stem using a fine–grained

paste.

2. Lift the valve rhythmically from the seat with a com-

mercially available valve grinding tool in order to

distribute the paste.

3. Check the contact pattern on the valve head and in

the cylinder head.

4. Clean the valves, the valve guides, and the cylinder

head.