seats DAEWOO NUBIRA 2004 Service Service Manual

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: NUBIRA, Model: DAEWOO NUBIRA 2004Pages: 2643, PDF Size: 80.54 MB

Page 2555 of 2643

NUBIRA/LACETTI ROOF, BACK PANEL AND REAR FLOOR PANEL 5–3

1–2. REPAIR PROCEDURE

1. Remove the related parts.

S Room lamp, door weatherstrip and pillar trims.

S Headlining and wiring harness.

S Wiper, cowl and windshield.

S Rear glass and others.

2. Pull out and straighten the damaged area to approxi-

mately the original shape.

Note : Use heat–resistant protective cover for protect

painting areas, seats, carpets and other parts.

S Attach the car to the frame straightener by tightening the

underbody clamps at the horizontal pinch welds.

S Before cutting off the roof panel, pull them out so that

they are restored to the original shape.

S Do not pull out more than necessary.

S Pull out and straighten the related damaged parts to

approximately their original shape.

Note : Make sure that the right and left pillars are parallel

with the windshield surface. Check the door for proper

opening and closing.

3. Keep the body, level.

S Jack up the body, and place safety stands at the four

designated places of the frame door opening.

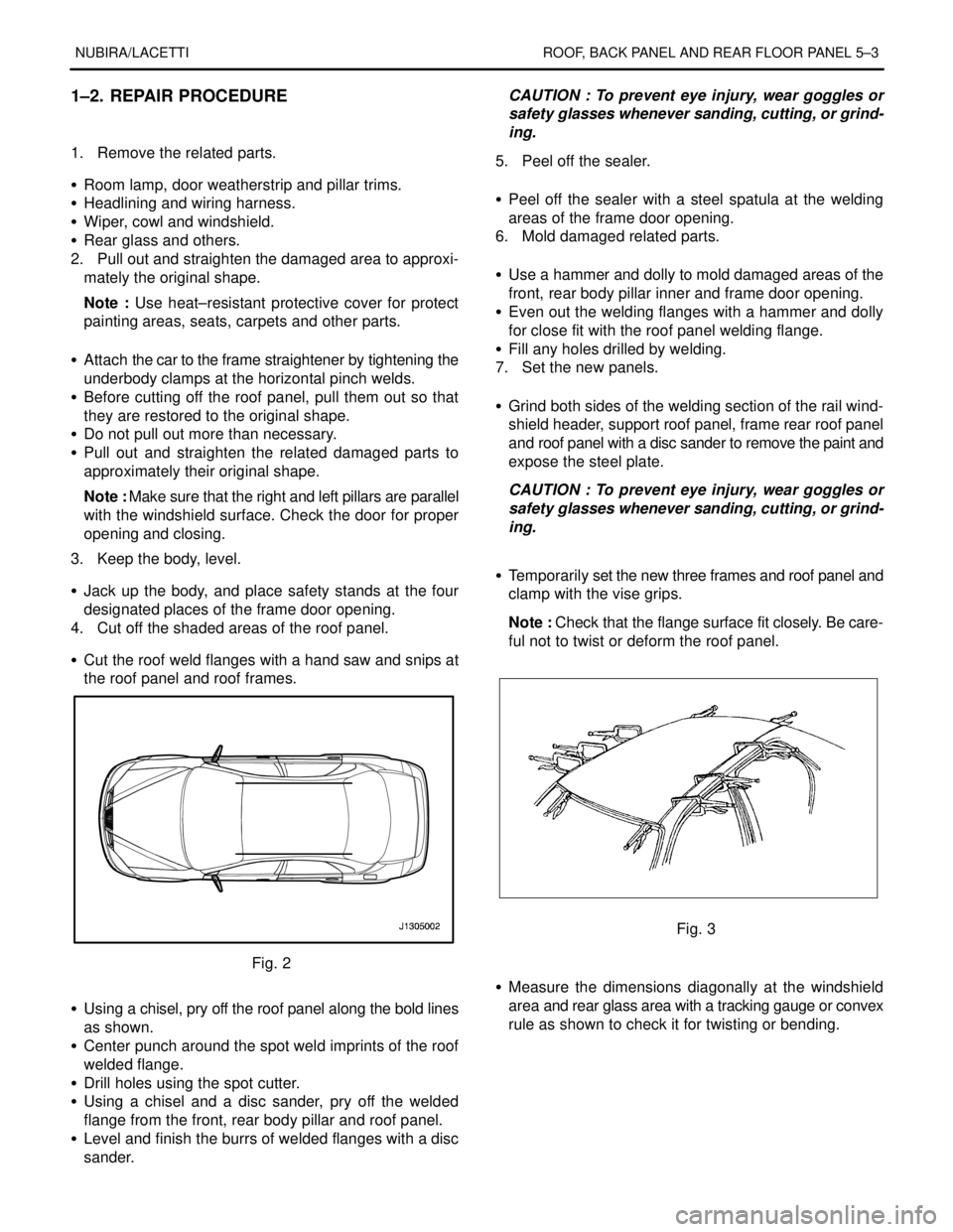

4. Cut off the shaded areas of the roof panel.

S Cut the roof weld flanges with a hand saw and snips at

the roof panel and roof frames.

Fig. 2

S Using a chisel, pry off the roof panel along the bold lines

as shown.

S Center punch around the spot weld imprints of the roof

welded flange.

S Drill holes using the spot cutter.

S Using a chisel and a disc sander, pry off the welded

flange from the front, rear body pillar and roof panel.

S Level and finish the burrs of welded flanges with a disc

sander.CAUTION : To prevent eye injury, wear goggles or

safety glasses whenever sanding, cutting, or grind-

ing.

5. Peel off the sealer.

S Peel off the sealer with a steel spatula at the welding

areas of the frame door opening.

6. Mold damaged related parts.

S Use a hammer and dolly to mold damaged areas of the

front, rear body pillar inner and frame door opening.

S Even out the welding flanges with a hammer and dolly

for close fit with the roof panel welding flange.

S Fill any holes drilled by welding.

7. Set the new panels.

S Grind both sides of the welding section of the rail wind-

shield header, support roof panel, frame rear roof panel

and roof panel with a disc sander to remove the paint and

expose the steel plate.

CAUTION : To prevent eye injury, wear goggles or

safety glasses whenever sanding, cutting, or grind-

ing.

S Temporarily set the new three frames and roof panel and

clamp with the vise grips.

Note : Check that the flange surface fit closely. Be care-

ful not to twist or deform the roof panel.

Fig. 3

S Measure the dimensions diagonally at the windshield

area and rear glass area with a tracking gauge or convex

rule as shown to check it for twisting or bending.

Page 2568 of 2643

NUBIRA/LACETTI FRAME DOOR OPENING, DOOR AND SIDE PANEL OUTER 6–3

1–2. REPAIR PROCEDURE

1. Remove the related parts.

S Doors.

S Weather strips, pillar trims and related parts.

S Carpet.

S Seat belt assembly

S Door switch and wiring harness.

S Fuel pipe and brake oil pipe.

S Other related parts.

Note : Pull out and straighten the damaged area to

approximately the original shape.

2. Remove the related parts.

S Damage may extend to the inner roof frame, the inner

frame door opening and the floor. Determine the extent

of the damage first, so the frame can be pulled out prop-

erly.

Note : Use heat–resistant protective cover for protect

painting areas, seats, carpets and other parts.

S Pull out and straighten the damaged areas.

S Do not pull out more than necessary.

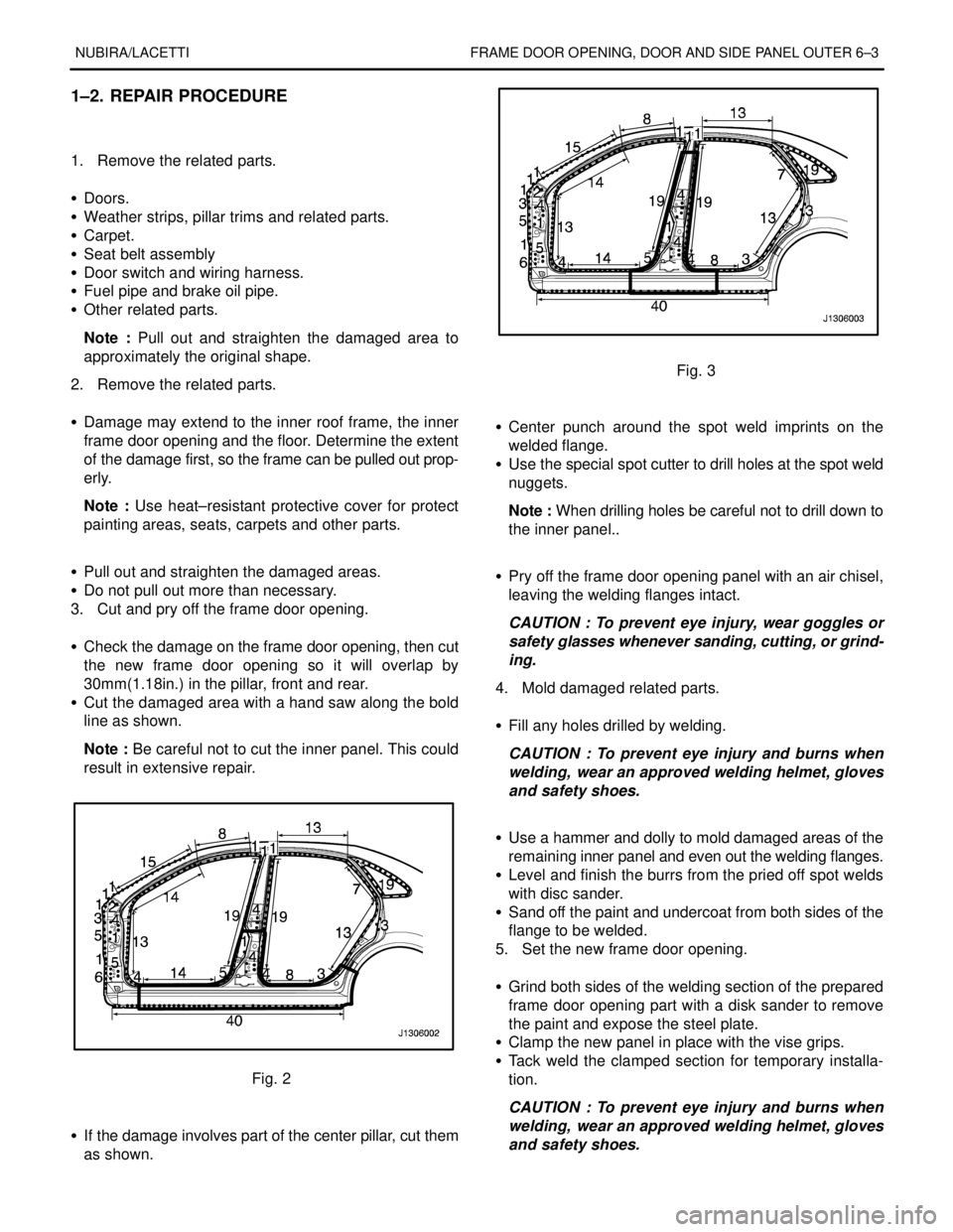

3. Cut and pry off the frame door opening.

S Check the damage on the frame door opening, then cut

the new frame door opening so it will overlap by

30mm(1.18in.) in the pillar, front and rear.

S Cut the damaged area with a hand saw along the bold

line as shown.

Note : Be careful not to cut the inner panel. This could

result in extensive repair.

Fig. 2

S If the damage involves part of the center pillar, cut them

as shown.

Fig. 3

S Center punch around the spot weld imprints on the

welded flange.

S Use the special spot cutter to drill holes at the spot weld

nuggets.

Note : When drilling holes be careful not to drill down to

the inner panel..

S Pry off the frame door opening panel with an air chisel,

leaving the welding flanges intact.

CAUTION : To prevent eye injury, wear goggles or

safety glasses whenever sanding, cutting, or grind-

ing.

4. Mold damaged related parts.

S Fill any holes drilled by welding.

CAUTION : To prevent eye injury and burns when

welding, wear an approved welding helmet, gloves

and safety shoes.

S Use a hammer and dolly to mold damaged areas of the

remaining inner panel and even out the welding flanges.

S Level and finish the burrs from the pried off spot welds

with disc sander.

S Sand off the paint and undercoat from both sides of the

flange to be welded.

5. Set the new frame door opening.

S Grind both sides of the welding section of the prepared

frame door opening part with a disk sander to remove

the paint and expose the steel plate.

S Clamp the new panel in place with the vise grips.

S Tack weld the clamped section for temporary installa-

tion.

CAUTION : To prevent eye injury and burns when

welding, wear an approved welding helmet, gloves

and safety shoes.

Page 2617 of 2643

9–14 SEALING, CAULKING AND DEADNER NUBIRA/LACETTI

2. DEADNER

2–1. GENERAL DESCRIPTION

.

Deadner is properly designed and applied for reduce the

vibration and noise. Also, it plays in maintaining the

structural rigidity of the panel.

.

2–2. REPAIR PROCEDURE

.

1. Remove the related parts.

S Seats, carpet.

S Trims, others.

.

2. Removal of the damaged deadner.

S Peel off the damaged deadner with a steel spatula, care-

fully.

.

3. Clean and dry.

S Before applying the deadner, thoroughly clean and dry

the areas to be applied.

.

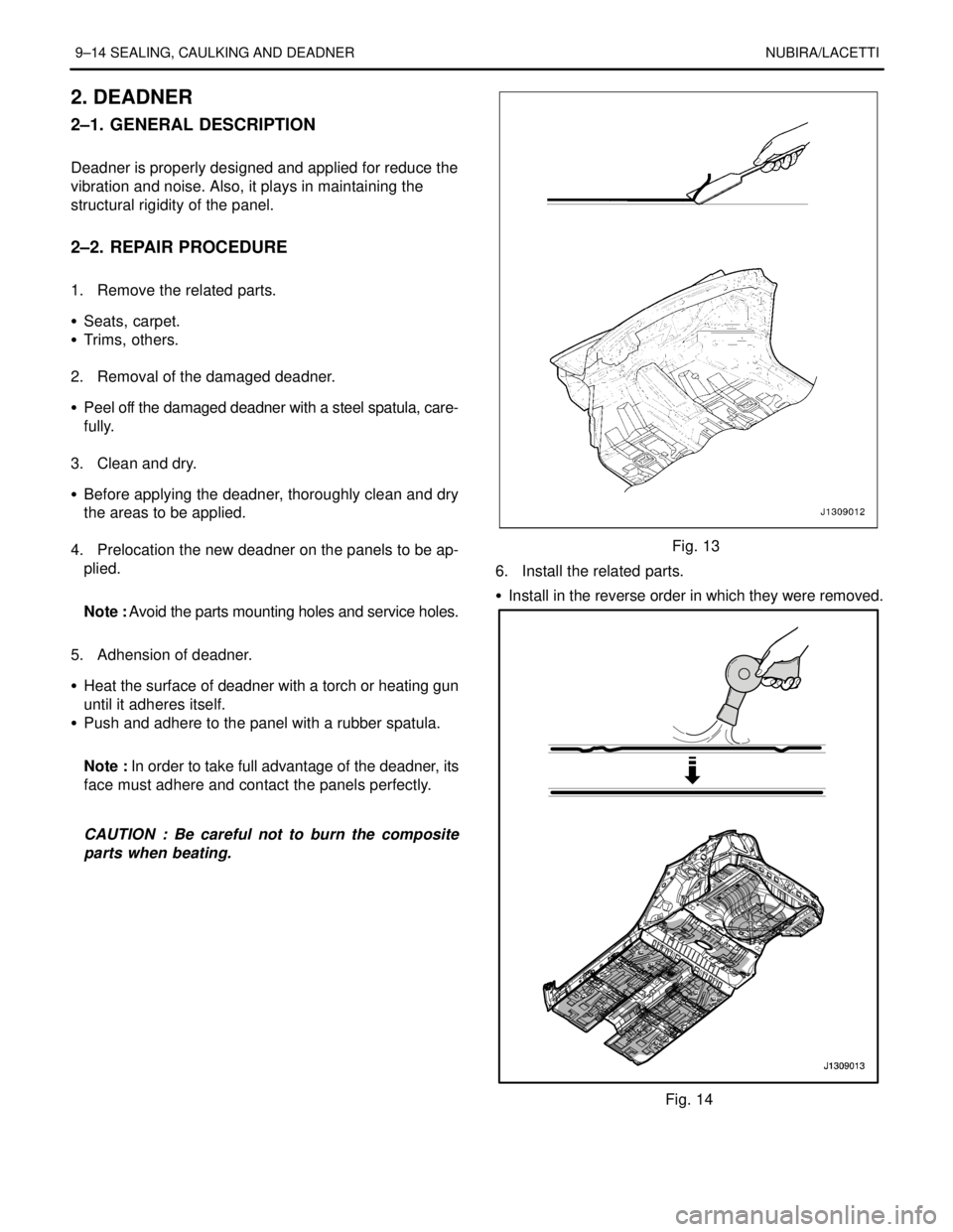

4. Prelocation the new deadner on the panels to be ap-

plied.

.

Note : Avoid the parts mounting holes and service holes.

.

5. Adhension of deadner.

S Heat the surface of deadner with a torch or heating gun

until it adheres itself.

S Push and adhere to the panel with a rubber spatula.

.

Note : In order to take full advantage of the deadner, its

face must adhere and contact the panels perfectly.

.

CAUTION : Be careful not to burn the composite

parts when beating.

Fig. 13

6. Install the related parts.

S Install in the reverse order in which they were removed.

Fig. 14