seats DAEWOO NUBIRA 2004 Service Owner's Guide

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: NUBIRA, Model: DAEWOO NUBIRA 2004Pages: 2643, PDF Size: 80.54 MB

Page 2362 of 2643

9H – 6ISEATS

DAEWOO V–121 BL4

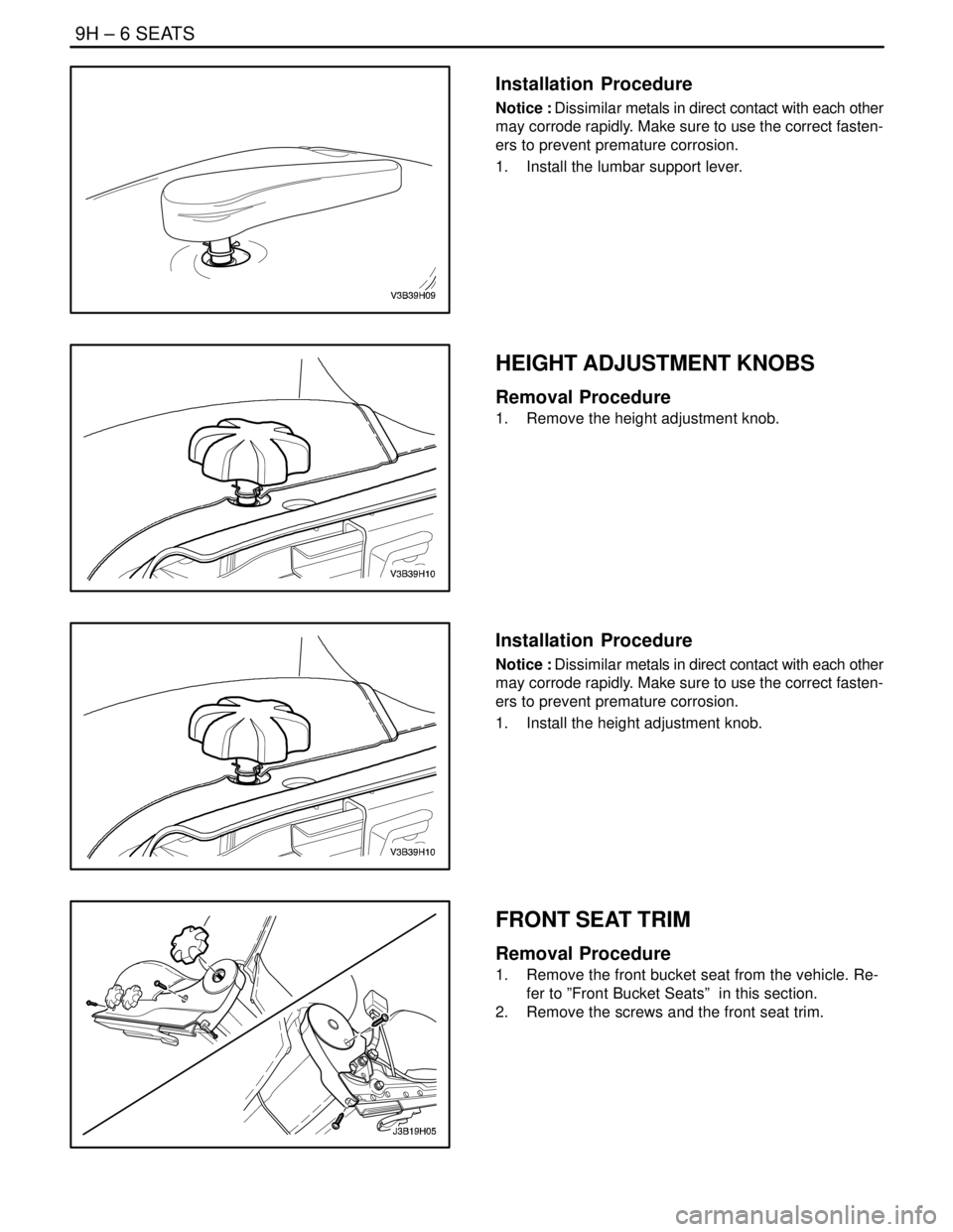

Installation Procedure

Notice : Dissimilar metals in direct contact with each other

may corrode rapidly. Make sure to use the correct fasten-

ers to prevent premature corrosion.

1. Install the lumbar support lever.

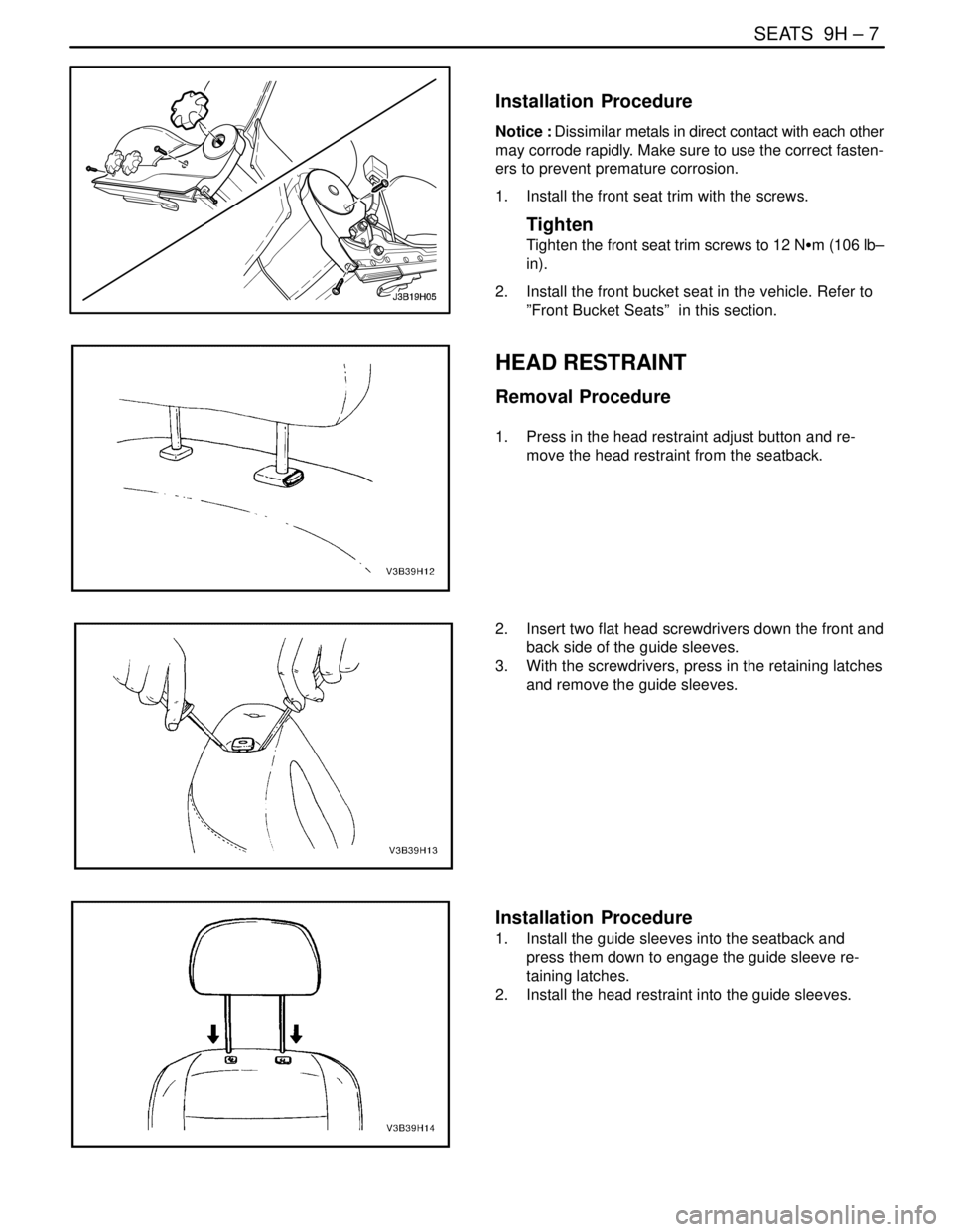

HEIGHT ADJUSTMENT KNOBS

Removal Procedure

1. Remove the height adjustment knob.

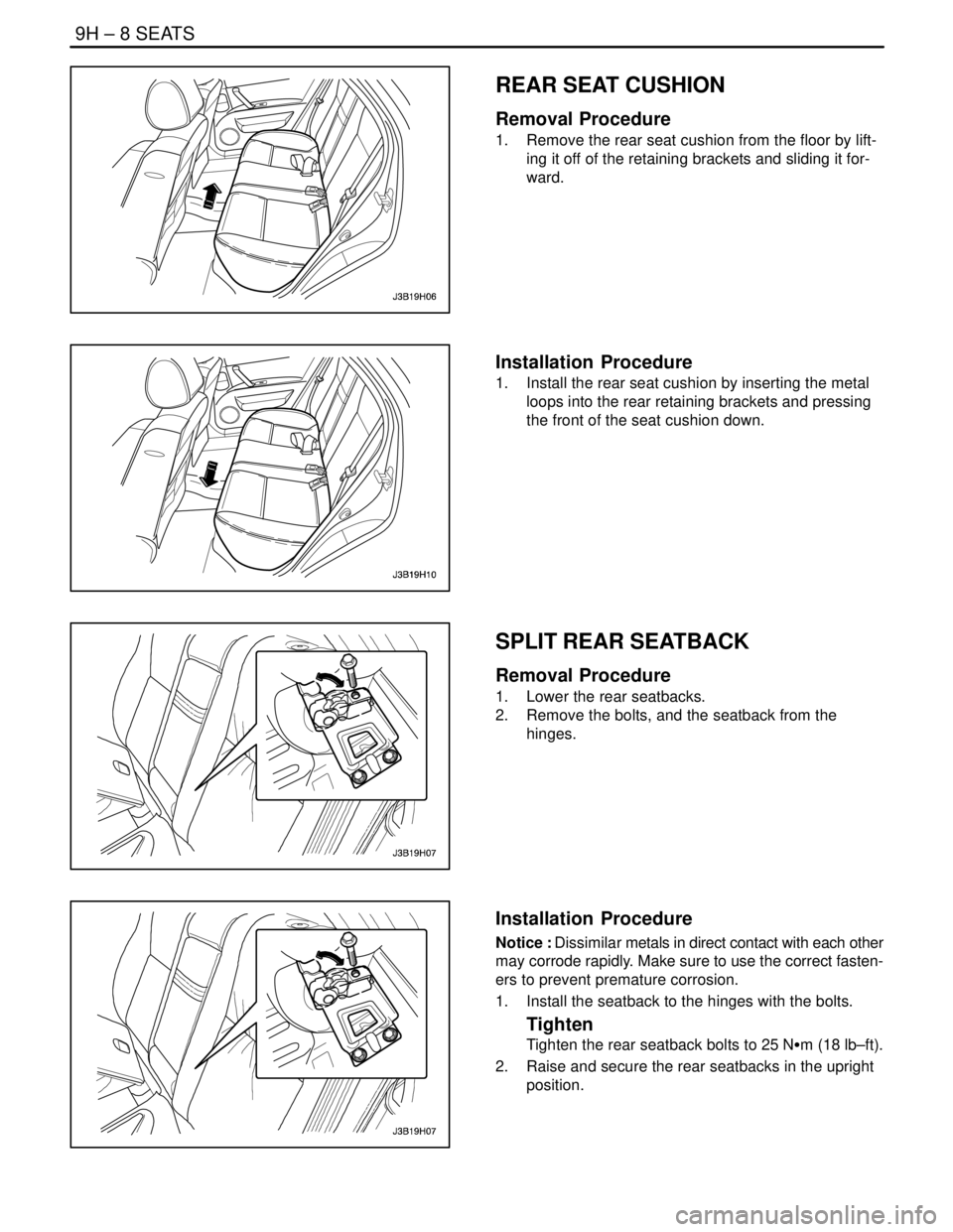

Installation Procedure

Notice : Dissimilar metals in direct contact with each other

may corrode rapidly. Make sure to use the correct fasten-

ers to prevent premature corrosion.

1. Install the height adjustment knob.

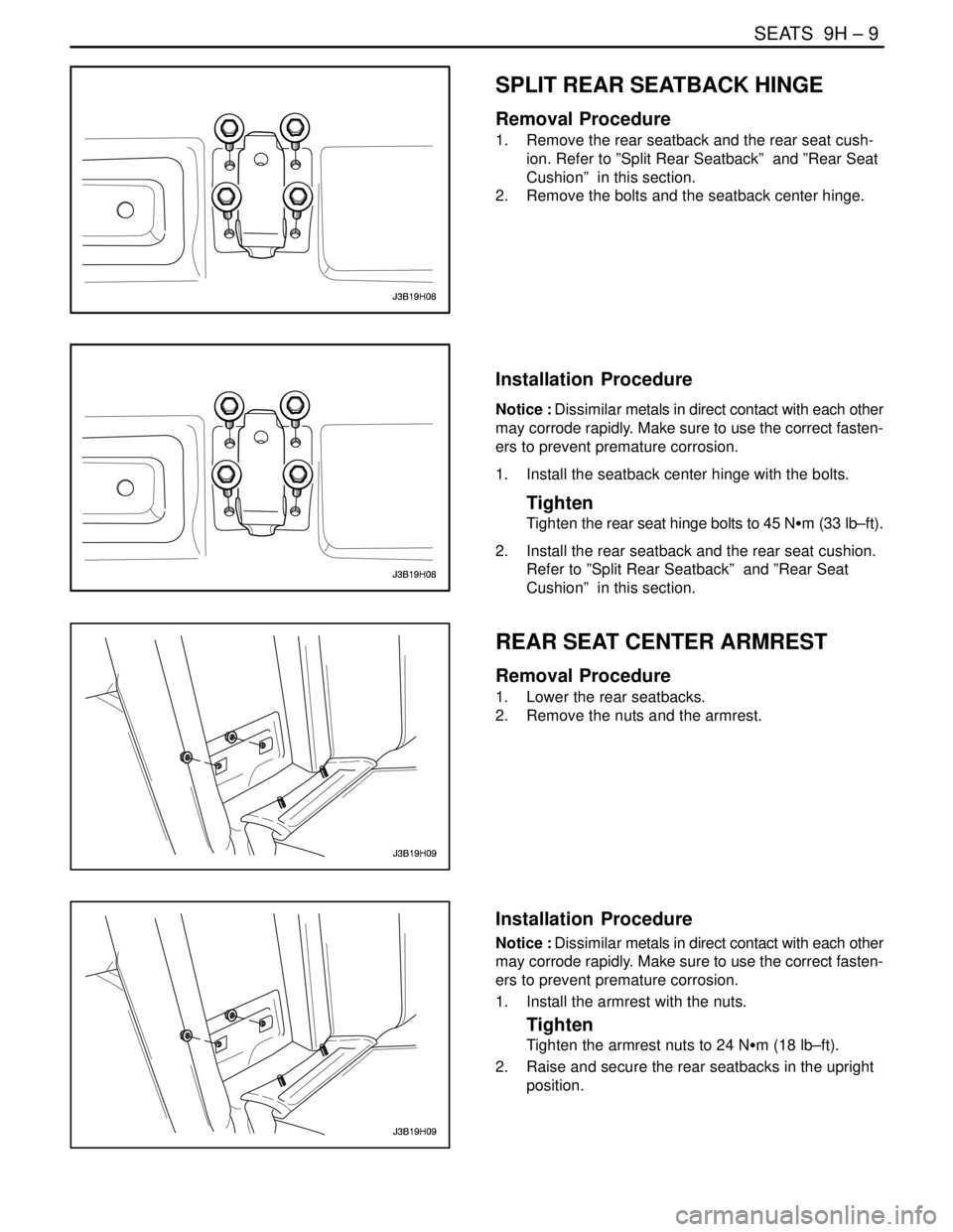

FRONT SEAT TRIM

Removal Procedure

1. Remove the front bucket seat from the vehicle. Re-

fer to ”Front Bucket Seats” in this section.

2. Remove the screws and the front seat trim.

Page 2363 of 2643

SEATS 9H – 7

DAEWOO V–121 BL4

Installation Procedure

Notice : Dissimilar metals in direct contact with each other

may corrode rapidly. Make sure to use the correct fasten-

ers to prevent premature corrosion.

1. Install the front seat trim with the screws.

Tighten

Tighten the front seat trim screws to 12 NSm (106 lb–

in).

2. Install the front bucket seat in the vehicle. Refer to

”Front Bucket Seats” in this section.

HEAD RESTRAINT

Removal Procedure

1. Press in the head restraint adjust button and re-

move the head restraint from the seatback.

2. Insert two flat head screwdrivers down the front and

back side of the guide sleeves.

3. With the screwdrivers, press in the retaining latches

and remove the guide sleeves.

Installation Procedure

1. Install the guide sleeves into the seatback and

press them down to engage the guide sleeve re-

taining latches.

2. Install the head restraint into the guide sleeves.

Page 2364 of 2643

9H – 8ISEATS

DAEWOO V–121 BL4

REAR SEAT CUSHION

Removal Procedure

1. Remove the rear seat cushion from the floor by lift-

ing it off of the retaining brackets and sliding it for-

ward.

Installation Procedure

1. Install the rear seat cushion by inserting the metal

loops into the rear retaining brackets and pressing

the front of the seat cushion down.

SPLIT REAR SEATBACK

Removal Procedure

1. Lower the rear seatbacks.

2. Remove the bolts, and the seatback from the

hinges.

Installation Procedure

Notice : Dissimilar metals in direct contact with each other

may corrode rapidly. Make sure to use the correct fasten-

ers to prevent premature corrosion.

1. Install the seatback to the hinges with the bolts.

Tighten

Tighten the rear seatback bolts to 25 NSm (18 lb–ft).

2. Raise and secure the rear seatbacks in the upright

position.

Page 2365 of 2643

SEATS 9H – 9

DAEWOO V–121 BL4

SPLIT REAR SEATBACK HINGE

Removal Procedure

1. Remove the rear seatback and the rear seat cush-

ion. Refer to ”Split Rear Seatback” and ”Rear Seat

Cushion” in this section.

2. Remove the bolts and the seatback center hinge.

Installation Procedure

Notice : Dissimilar metals in direct contact with each other

may corrode rapidly. Make sure to use the correct fasten-

ers to prevent premature corrosion.

1. Install the seatback center hinge with the bolts.

Tighten

Tighten the rear seat hinge bolts to 45 NSm (33 lb–ft).

2. Install the rear seatback and the rear seat cushion.

Refer to ”Split Rear Seatback” and ”Rear Seat

Cushion” in this section.

REAR SEAT CENTER ARMREST

Removal Procedure

1. Lower the rear seatbacks.

2. Remove the nuts and the armrest.

Installation Procedure

Notice : Dissimilar metals in direct contact with each other

may corrode rapidly. Make sure to use the correct fasten-

ers to prevent premature corrosion.

1. Install the armrest with the nuts.

Tighten

Tighten the armrest nuts to 24 NSm (18 lb–ft).

2. Raise and secure the rear seatbacks in the upright

position.

Page 2366 of 2643

9H – 10ISEATS

DAEWOO V–121 BL4

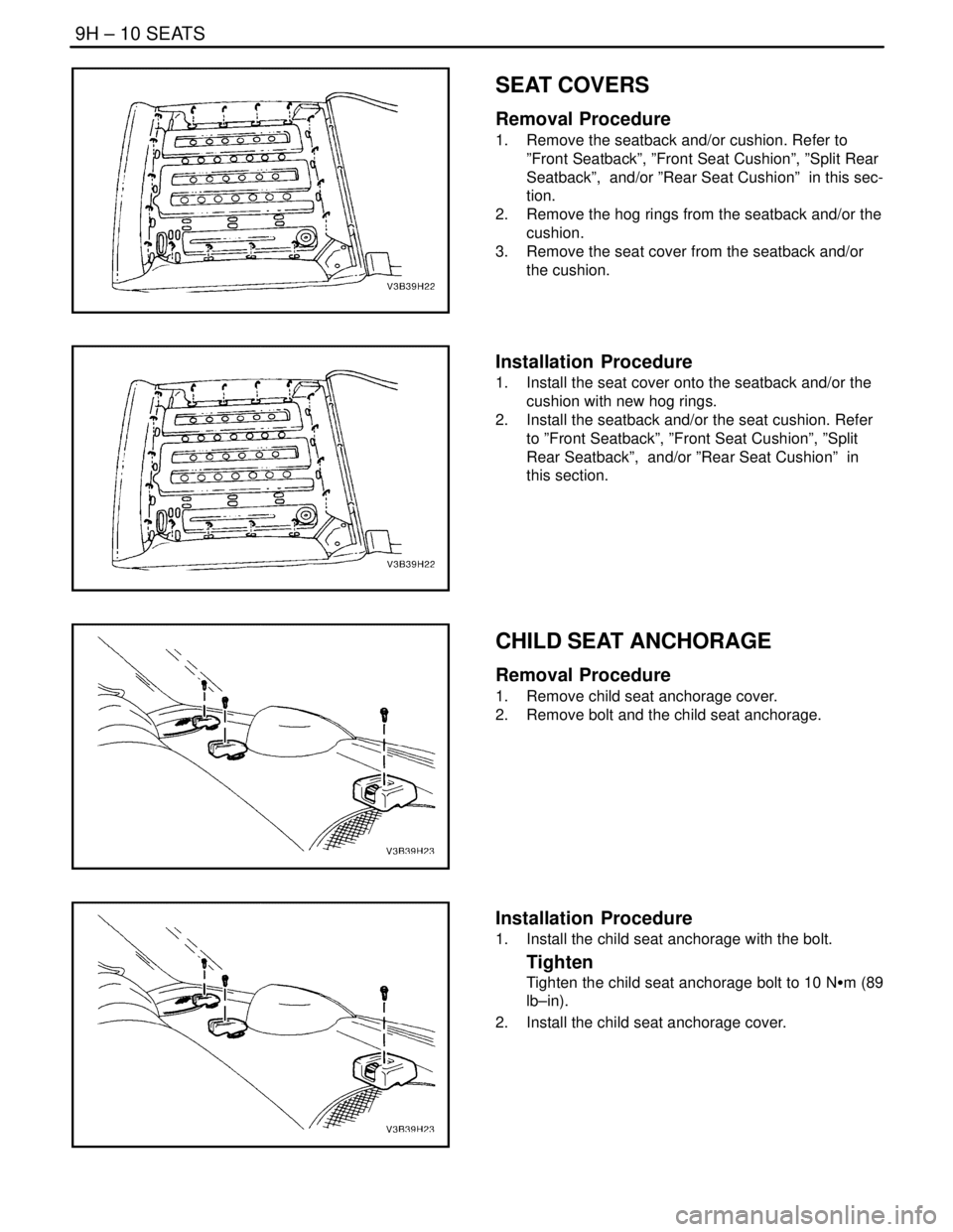

SEAT COVERS

Removal Procedure

1. Remove the seatback and/or cushion. Refer to

”Front Seatback”, ”Front Seat Cushion”, ”Split Rear

Seatback”, and/or ”Rear Seat Cushion” in this sec-

tion.

2. Remove the hog rings from the seatback and/or the

cushion.

3. Remove the seat cover from the seatback and/or

the cushion.

Installation Procedure

1. Install the seat cover onto the seatback and/or the

cushion with new hog rings.

2. Install the seatback and/or the seat cushion. Refer

to ”Front Seatback”, ”Front Seat Cushion”, ”Split

Rear Seatback”, and/or ”Rear Seat Cushion” in

this section.

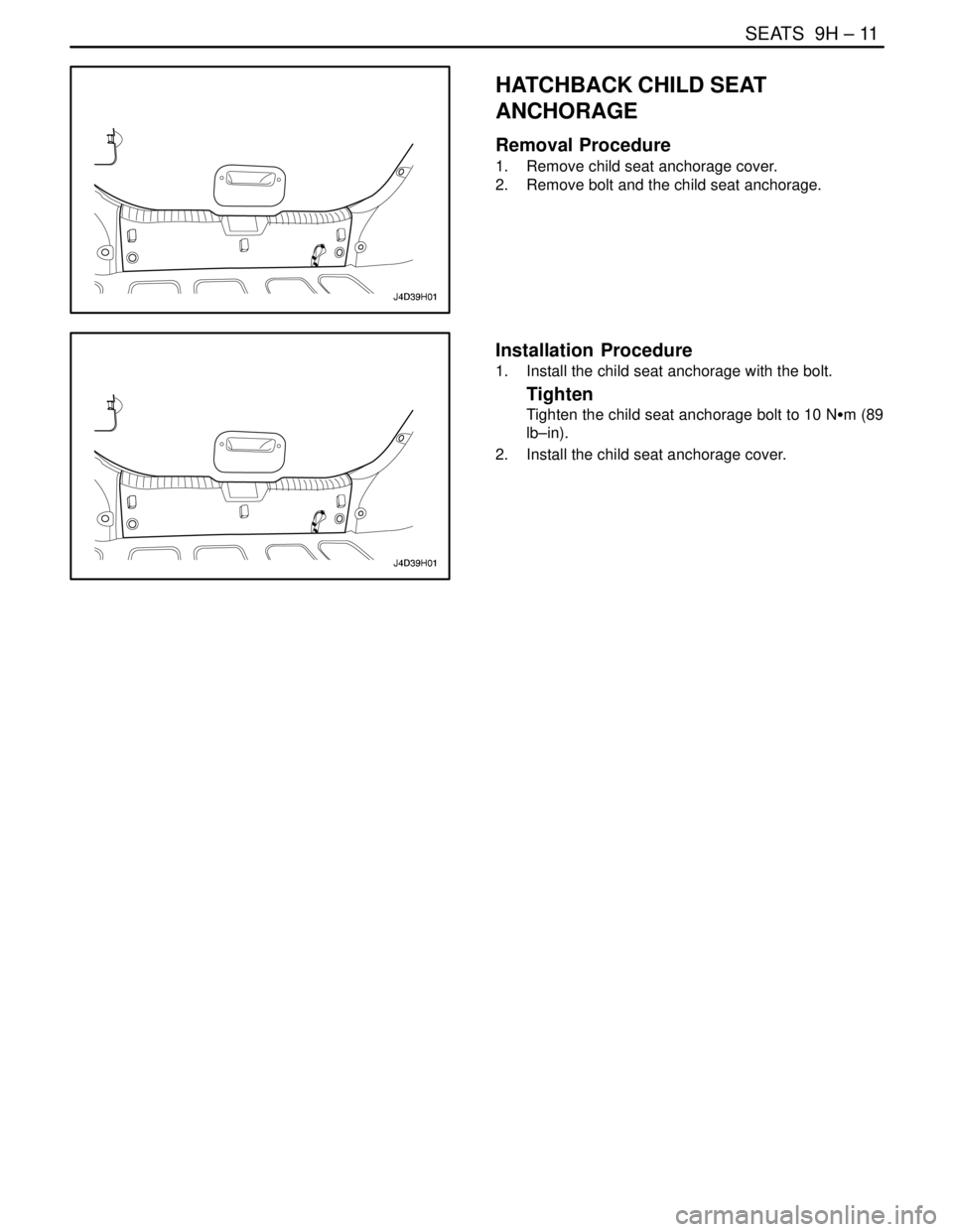

CHILD SEAT ANCHORAGE

Removal Procedure

1. Remove child seat anchorage cover.

2. Remove bolt and the child seat anchorage.

Installation Procedure

1. Install the child seat anchorage with the bolt.

Tighten

Tighten the child seat anchorage bolt to 10 NSm (89

lb–in).

2. Install the child seat anchorage cover.

Page 2367 of 2643

SEATS 9H – 11

DAEWOO V–121 BL4

HATCHBACK CHILD SEAT

ANCHORAGE

Removal Procedure

1. Remove child seat anchorage cover.

2. Remove bolt and the child seat anchorage.

Installation Procedure

1. Install the child seat anchorage with the bolt.

Tighten

Tighten the child seat anchorage bolt to 10 NSm (89

lb–in).

2. Install the child seat anchorage cover.

Page 2368 of 2643

9H – 12ISEATS

DAEWOO V–121 BL4

GENERAL DESCRIPTION

AND SYSTEM OPERATION

SEATS

Do not attempt to change the designed seat position by al-

tering the designed seat adjuster–to–floor pan anchor pro-

visions or the seat adjuster–to–seat frame anchor provi-

sions. Changing the seat position could affect the

performance of the seat system.This vehicle is equipped with front bucket seats with sepa-

rate, adjustable head restraints, and a three–passenger

rear bench seat with an optional split folding rear seat. The

front bucket seats also have a recline, a height, and a lum-

bar adjustment. A power driver seat is optional. Seat cush-

ions and seatbacks have formed foam pads, which fit the

contours of the full panel seatback frame assembly and

the designed contour of the seat cushion frame.

Page 2458 of 2643

ROOF 9Q – 9

DAEWOO V–121 BL4

6. Remove the power sunroof control switch, if

equipped. Refer to ”Power Sunroof Control Switch”

in this section.

7. Remove the A–, B–, and C–pillar trim panels. Refer

to Section 9G, Interior Trim.

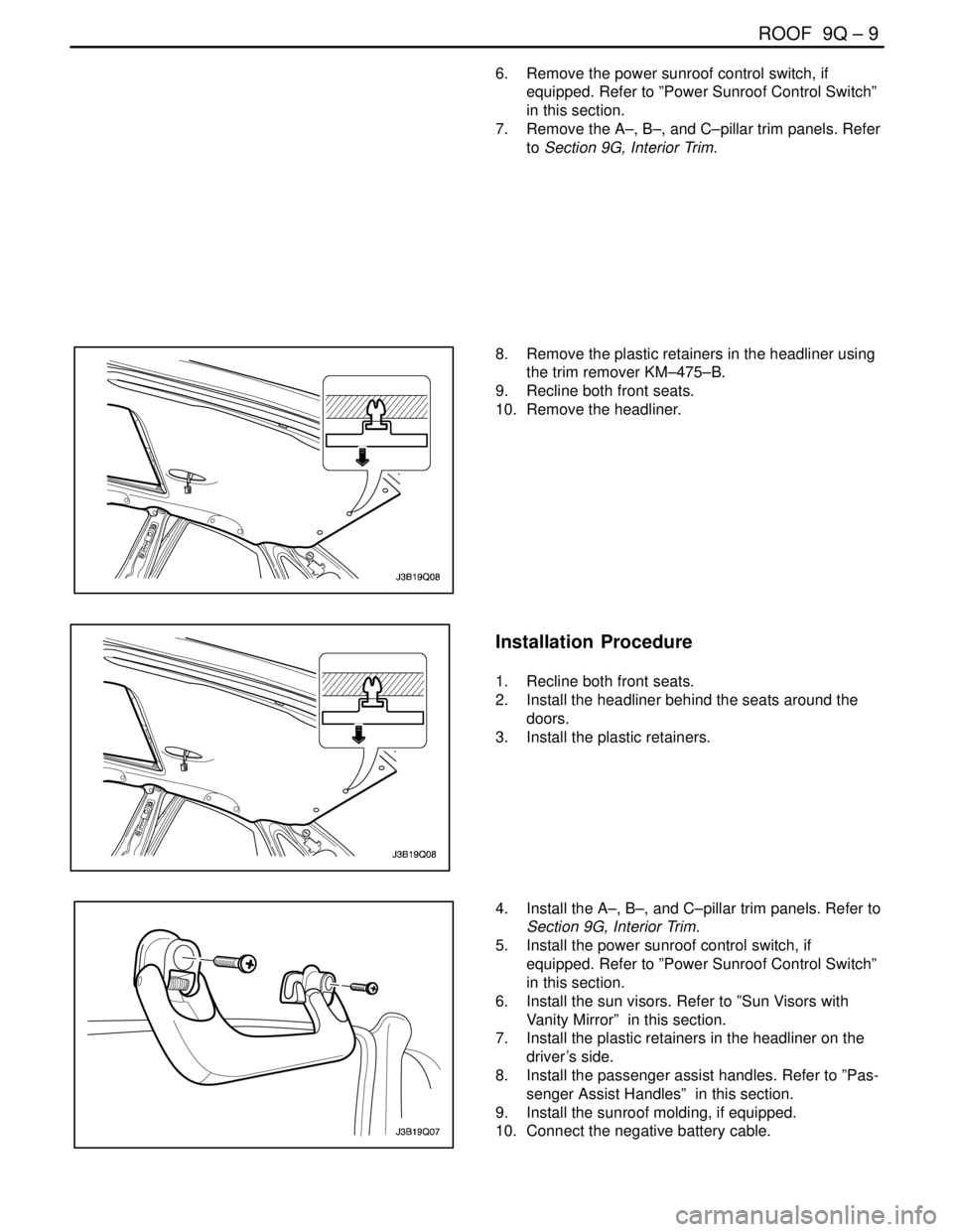

8. Remove the plastic retainers in the headliner using

the trim remover KM–475–B.

9. Recline both front seats.

10. Remove the headliner.

Installation Procedure

1. Recline both front seats.

2. Install the headliner behind the seats around the

doors.

3. Install the plastic retainers.

4. Install the A–, B–, and C–pillar trim panels. Refer to

Section 9G, Interior Trim.

5. Install the power sunroof control switch, if

equipped. Refer to ”Power Sunroof Control Switch”

in this section.

6. Install the sun visors. Refer to ”Sun Visors with

Vanity Mirror” in this section.

7. Install the plastic retainers in the headliner on the

driver’s side.

8. Install the passenger assist handles. Refer to ”Pas-

senger Assist Handles” in this section.

9. Install the sunroof molding, if equipped.

10. Connect the negative battery cable.

Page 2474 of 2643

BODY REAR END 9S – 3

DAEWOO V–121 BL4

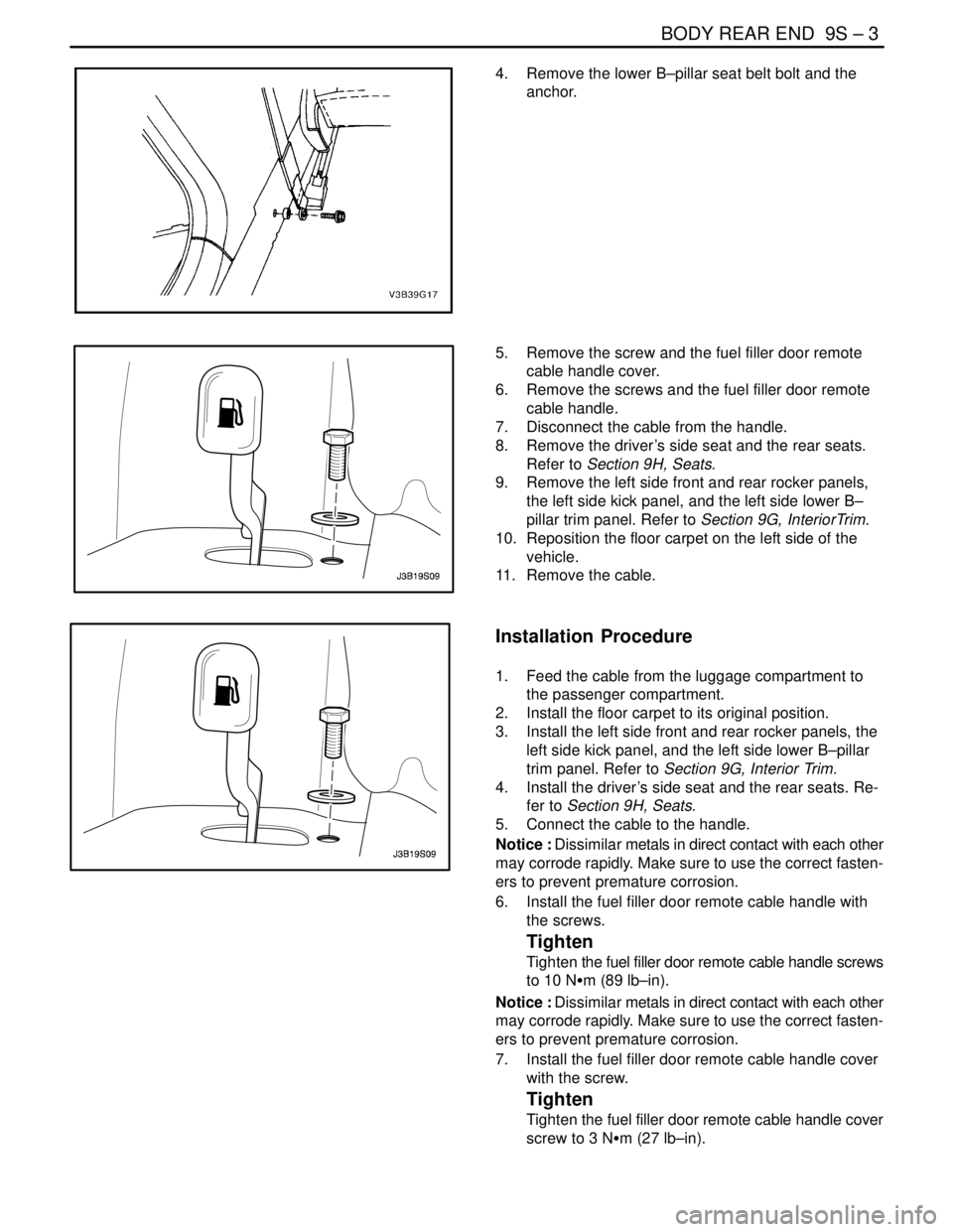

4. Remove the lower B–pillar seat belt bolt and the

anchor.

5. Remove the screw and the fuel filler door remote

cable handle cover.

6. Remove the screws and the fuel filler door remote

cable handle.

7. Disconnect the cable from the handle.

8. Remove the driver’s side seat and the rear seats.

Refer to Section 9H, Seats.

9. Remove the left side front and rear rocker panels,

the left side kick panel, and the left side lower B–

pillar trim panel. Refer to Section 9G, InteriorTrim.

10. Reposition the floor carpet on the left side of the

vehicle.

11. Remove the cable.

Installation Procedure

1. Feed the cable from the luggage compartment to

the passenger compartment.

2. Install the floor carpet to its original position.

3. Install the left side front and rear rocker panels, the

left side kick panel, and the left side lower B–pillar

trim panel. Refer to Section 9G, Interior Trim.

4. Install the driver’s side seat and the rear seats. Re-

fer to Section 9H, Seats.

5. Connect the cable to the handle.

Notice : Dissimilar metals in direct contact with each other

may corrode rapidly. Make sure to use the correct fasten-

ers to prevent premature corrosion.

6. Install the fuel filler door remote cable handle with

the screws.

Tighten

Tighten the fuel filler door remote cable handle screws

to 10 NSm (89 lb–in).

Notice : Dissimilar metals in direct contact with each other

may corrode rapidly. Make sure to use the correct fasten-

ers to prevent premature corrosion.

7. Install the fuel filler door remote cable handle cover

with the screw.

Tighten

Tighten the fuel filler door remote cable handle cover

screw to 3 NSm (27 lb–in).

Page 2510 of 2643

1–2 GENERAL INFORMATIONNUBIRA/LACETTI

1. GENERAL INSTRUCTION

This publication is designed to help you the body repair

technician with your specialized work. Vehicle bodywork

has changed a great deal over the years. As vehicles

have developed technically, vehicle bodywork has also

had to meet new requirements with design, changes to

reconcile apparently conflicting demands to name just a

few examples:

S strength and safety ; low weight

S spaciousness ; good aerodynamices

S high quality ; low price

.

The durability and ease of repair of the bodywork also

plays an important part.

.

Nowadays, the use of highly automated production

equipment makes it possible to maintain the tightest

tolerances and thus ensure a high level of quality.

.

When bodywork is damaged, the customer rightly ex-

pects it to be expertly repaired to the same quality stan-

dards.

.

At the same time, for his safety, the customer expects

you to have comprehensive knowledge of materials,

measuring and straightening methods, possible distor-

tion, optimum corrosion prevention and much more be-

sides.

.

This publication is designed to help you update your

knowledge and give you an idea of what you require to

rectify moderate or severe accident damage, for your

own safety and for the satisfaction of your customers.

2. IMPORTANT SAFETY NOTICE

2–1. BEFORE BEGINNING WORK

S Disconnect the battery to reduce the possibility of fire

caused by electrical shorts.

S Check for fuel leaks and repair as necessary.

S Remove the fuel tank and/or fuel lines if welding equip-

ment is to be used near the fuel system.

S Before welding, sanding or cutting, protect carpets and

seats with fire–proof covers.

S Follow standard safety practices when using toxic or

flammable liquids.

S Use standard safety equipment when spraying paint,

welding, cutting, sanding or grinding. Standard safety

equipment includes.

S Respirator and filter masks: Designed to filter out toxic

fumes, mist, dust or other airborn particles. Use a respi-

rator or filter mask designed to protect you from the haz-

ards of the particular job; some respirators, for example,

are designed to filter out only dust and airborn particles,

not toxic fumes.

S Safety goggles or glasses: Designed to protect your

eyes from projectiles, dust particles or splashing liquid.

S Gloves: Rubber gloves protect against corrosive chemi-

cals. Welding gloves protect against burns and abra-

sions caused by welding, sanding or grinding.

S Safety shoes: Non–slip soles protect against slipping.

Metal toe inserts protect against falling objects.

S Ear plugs: Protect eardrums from harmful noise levels.

.

2–2. DURING WORK

S Do not smoke while working near the fuel system.

S Deposit gas or solvent–soaked shop towels in an ap-

proved container.

S Brake lining contains asbestos, which can cause cancer.

Do not use an air hose to blow off brake assemblies: use

only an approved vacuum cleaner, and wear an ap-

proved filter mask or respirator.

S Always attach a safety cable when using a hydraulic ram

or a frame straightening table: do not stand in direct line

with the chains used on such equipment.