light DAEWOO NUBIRA 2004 Service Workshop Manual

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: NUBIRA, Model: DAEWOO NUBIRA 2004Pages: 2643, PDF Size: 80.54 MB

Page 342 of 2643

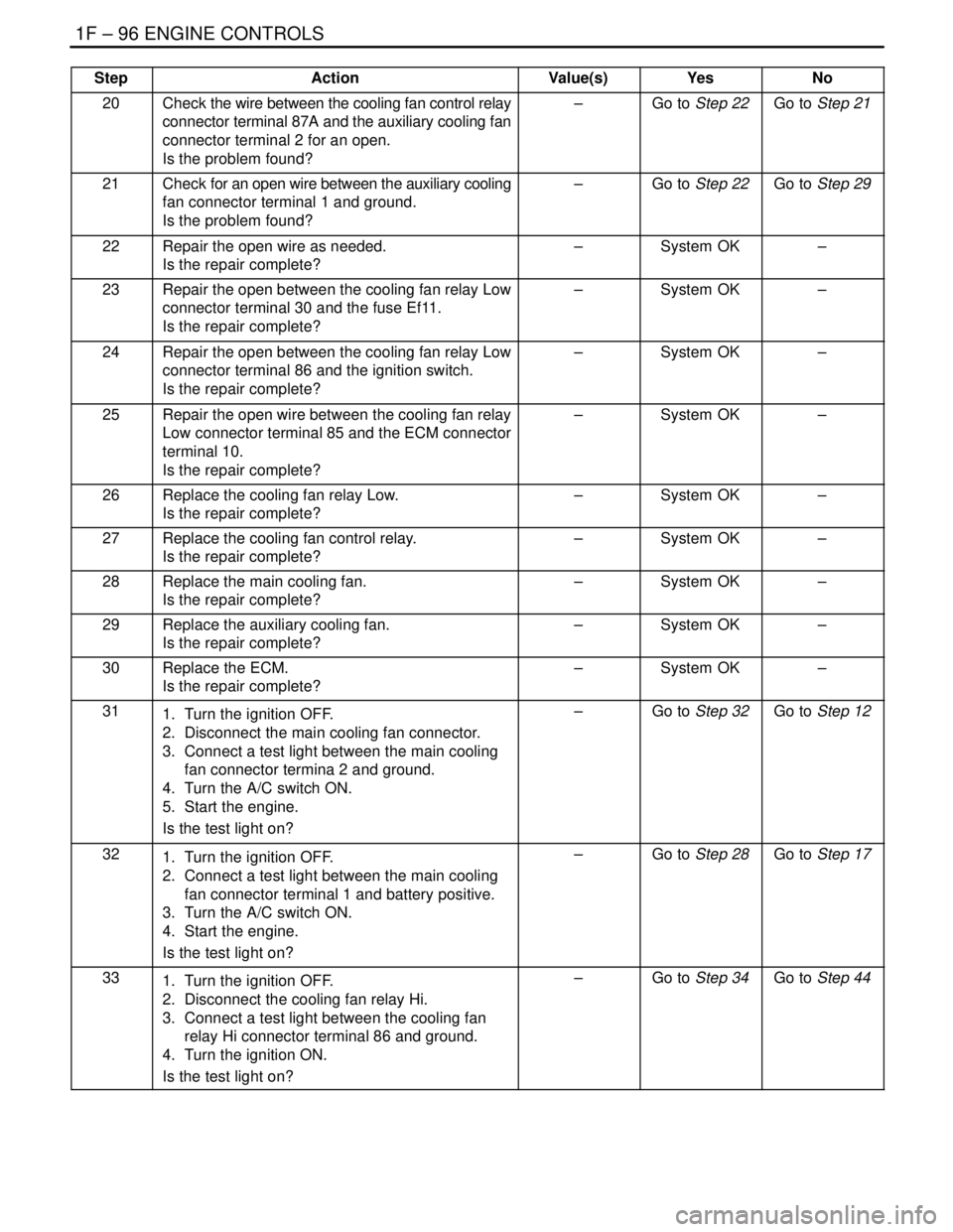

1F – 96IENGINE CONTROLS

DAEWOO V–121 BL4

StepNo Yes Value(s) Action

20Check the wire between the cooling fan control relay

connector terminal 87A and the auxiliary cooling fan

connector terminal 2 for an open.

Is the problem found?–Go to Step 22Go to Step 21

21Check for an open wire between the auxiliary cooling

fan connector terminal 1 and ground.

Is the problem found?–Go to Step 22Go to Step 29

22Repair the open wire as needed.

Is the repair complete?–System OK–

23Repair the open between the cooling fan relay Low

connector terminal 30 and the fuse Ef11.

Is the repair complete?–System OK–

24Repair the open between the cooling fan relay Low

connector terminal 86 and the ignition switch.

Is the repair complete?–System OK–

25Repair the open wire between the cooling fan relay

Low connector terminal 85 and the ECM connector

terminal 10.

Is the repair complete?–System OK–

26Replace the cooling fan relay Low.

Is the repair complete?–System OK–

27Replace the cooling fan control relay.

Is the repair complete?–System OK–

28Replace the main cooling fan.

Is the repair complete?–System OK–

29Replace the auxiliary cooling fan.

Is the repair complete?–System OK–

30Replace the ECM.

Is the repair complete?–System OK–

311. Turn the ignition OFF.

2. Disconnect the main cooling fan connector.

3. Connect a test light between the main cooling

fan connector termina 2 and ground.

4. Turn the A/C switch ON.

5. Start the engine.

Is the test light on?–Go to Step 32Go to Step 12

321. Turn the ignition OFF.

2. Connect a test light between the main cooling

fan connector terminal 1 and battery positive.

3. Turn the A/C switch ON.

4. Start the engine.

Is the test light on?–Go to Step 28Go to Step 17

331. Turn the ignition OFF.

2. Disconnect the cooling fan relay Hi.

3. Connect a test light between the cooling fan

relay Hi connector terminal 86 and ground.

4. Turn the ignition ON.

Is the test light on?–Go to Step 34Go to Step 44

Page 343 of 2643

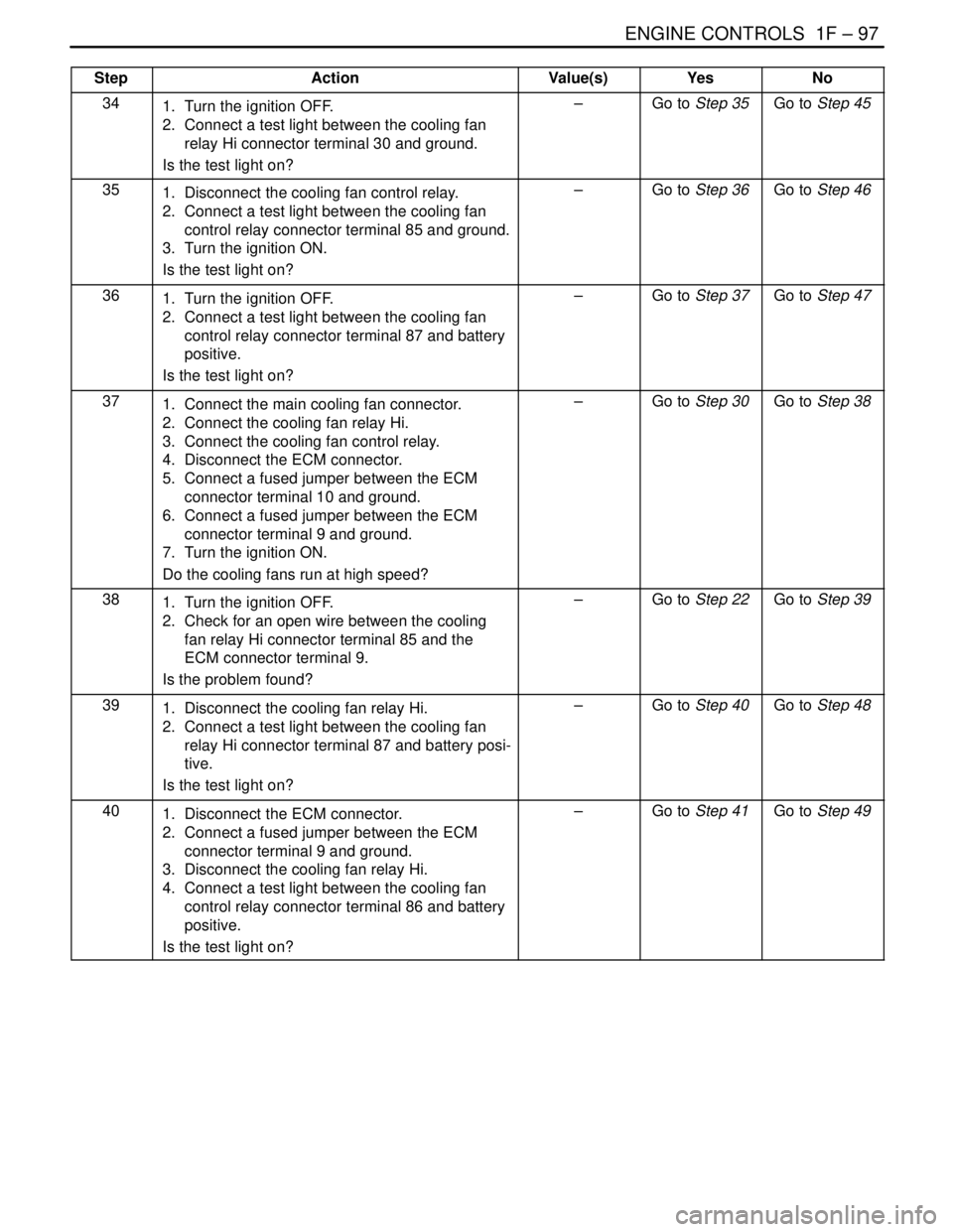

ENGINE CONTROLS 1F – 97

DAEWOO V–121 BL4

StepNo Yes Value(s) Action

341. Turn the ignition OFF.

2. Connect a test light between the cooling fan

relay Hi connector terminal 30 and ground.

Is the test light on?–Go to Step 35Go to Step 45

351. Disconnect the cooling fan control relay.

2. Connect a test light between the cooling fan

control relay connector terminal 85 and ground.

3. Turn the ignition ON.

Is the test light on?–Go to Step 36Go to Step 46

361. Turn the ignition OFF.

2. Connect a test light between the cooling fan

control relay connector terminal 87 and battery

positive.

Is the test light on?–Go to Step 37Go to Step 47

371. Connect the main cooling fan connector.

2. Connect the cooling fan relay Hi.

3. Connect the cooling fan control relay.

4. Disconnect the ECM connector.

5. Connect a fused jumper between the ECM

connector terminal 10 and ground.

6. Connect a fused jumper between the ECM

connector terminal 9 and ground.

7. Turn the ignition ON.

Do the cooling fans run at high speed?–Go to Step 30Go to Step 38

381. Turn the ignition OFF.

2. Check for an open wire between the cooling

fan relay Hi connector terminal 85 and the

ECM connector terminal 9.

Is the problem found?–Go to Step 22Go to Step 39

391. Disconnect the cooling fan relay Hi.

2. Connect a test light between the cooling fan

relay Hi connector terminal 87 and battery posi-

tive.

Is the test light on?–Go to Step 40Go to Step 48

401. Disconnect the ECM connector.

2. Connect a fused jumper between the ECM

connector terminal 9 and ground.

3. Disconnect the cooling fan relay Hi.

4. Connect a test light between the cooling fan

control relay connector terminal 86 and battery

positive.

Is the test light on?–Go to Step 41Go to Step 49

Page 347 of 2643

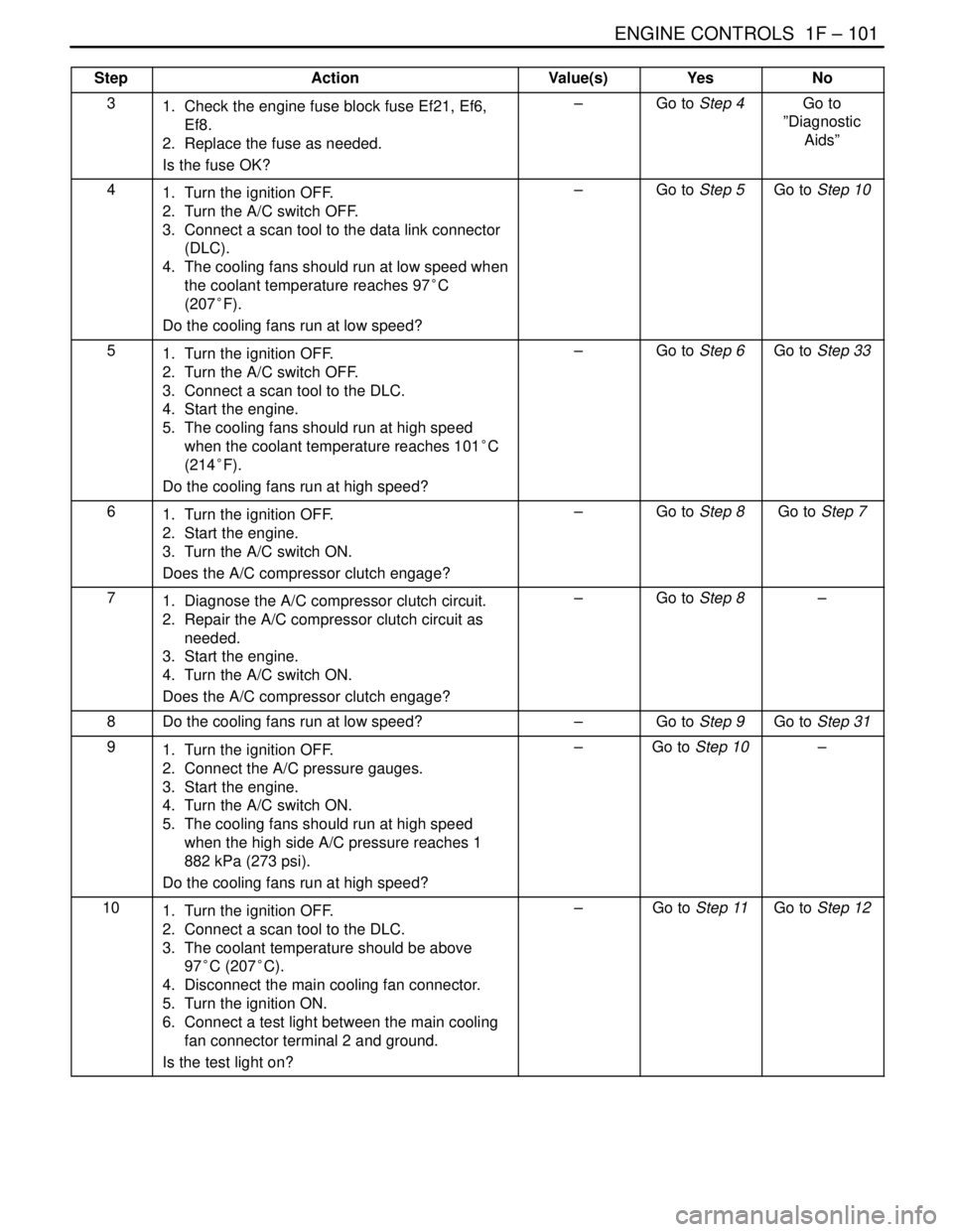

ENGINE CONTROLS 1F – 101

DAEWOO V–121 BL4

StepNo Yes Value(s) Action

31. Check the engine fuse block fuse Ef21, Ef6,

Ef8.

2. Replace the fuse as needed.

Is the fuse OK?–Go to Step 4Go to

”Diagnostic

Aids”

41. Turn the ignition OFF.

2. Turn the A/C switch OFF.

3. Connect a scan tool to the data link connector

(DLC).

4. The cooling fans should run at low speed when

the coolant temperature reaches 97°C

(207°F).

Do the cooling fans run at low speed?–Go to Step 5Go to Step 10

51. Turn the ignition OFF.

2. Turn the A/C switch OFF.

3. Connect a scan tool to the DLC.

4. Start the engine.

5. The cooling fans should run at high speed

when the coolant temperature reaches 101°C

(214°F).

Do the cooling fans run at high speed?–Go to Step 6Go to Step 33

61. Turn the ignition OFF.

2. Start the engine.

3. Turn the A/C switch ON.

Does the A/C compressor clutch engage?–Go to Step 8Go to Step 7

71. Diagnose the A/C compressor clutch circuit.

2. Repair the A/C compressor clutch circuit as

needed.

3. Start the engine.

4. Turn the A/C switch ON.

Does the A/C compressor clutch engage?–Go to Step 8–

8Do the cooling fans run at low speed?–Go to Step 9Go to Step 31

91. Turn the ignition OFF.

2. Connect the A/C pressure gauges.

3. Start the engine.

4. Turn the A/C switch ON.

5. The cooling fans should run at high speed

when the high side A/C pressure reaches 1

882 kPa (273 psi).

Do the cooling fans run at high speed?–Go to Step 10–

101. Turn the ignition OFF.

2. Connect a scan tool to the DLC.

3. The coolant temperature should be above

97°C (207°C).

4. Disconnect the main cooling fan connector.

5. Turn the ignition ON.

6. Connect a test light between the main cooling

fan connector terminal 2 and ground.

Is the test light on?–Go to Step 11Go to Step 12

Page 348 of 2643

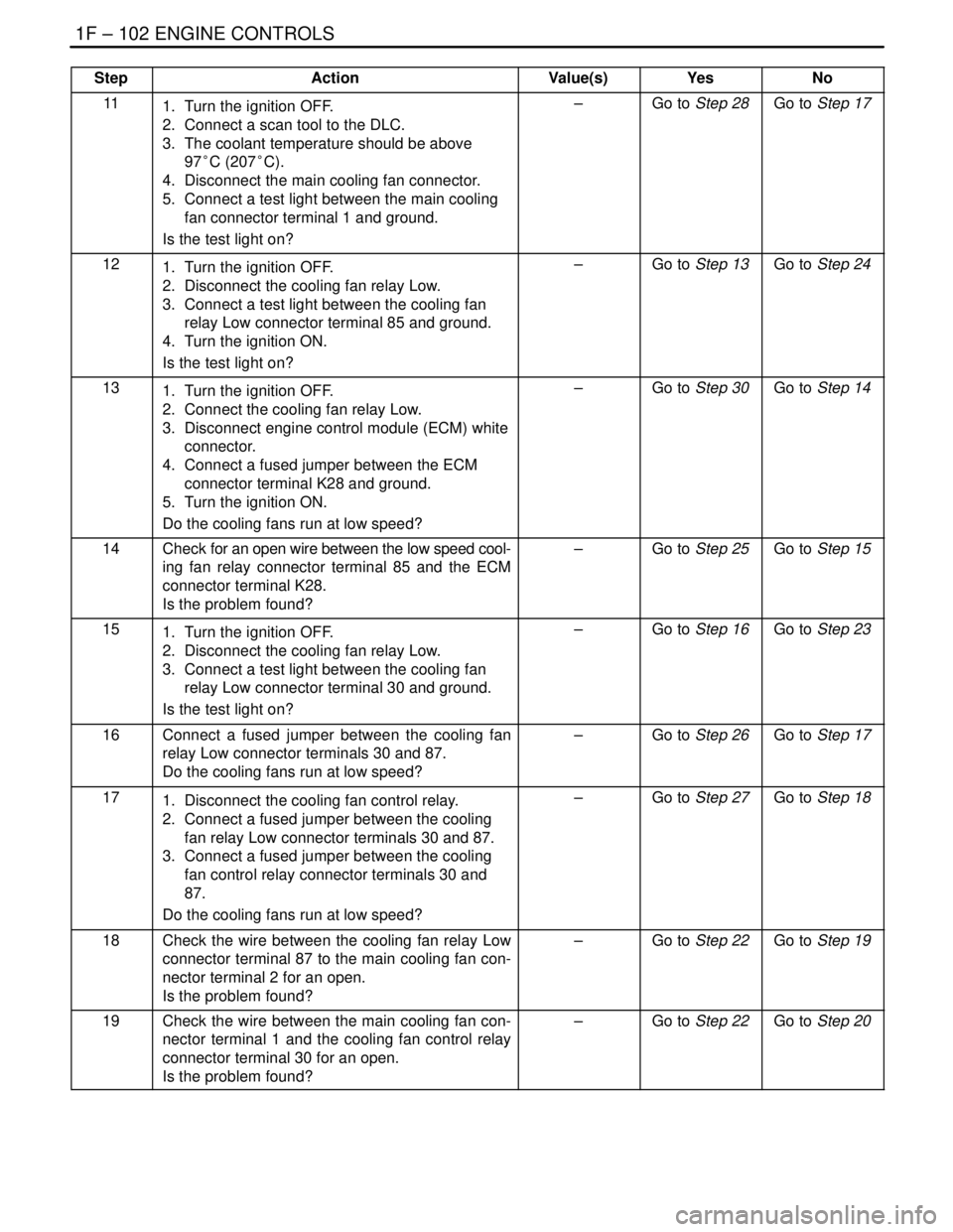

1F – 102IENGINE CONTROLS

DAEWOO V–121 BL4

StepNo Yes Value(s) Action

111. Turn the ignition OFF.

2. Connect a scan tool to the DLC.

3. The coolant temperature should be above

97°C (207°C).

4. Disconnect the main cooling fan connector.

5. Connect a test light between the main cooling

fan connector terminal 1 and ground.

Is the test light on?–Go to Step 28Go to Step 17

121. Turn the ignition OFF.

2. Disconnect the cooling fan relay Low.

3. Connect a test light between the cooling fan

relay Low connector terminal 85 and ground.

4. Turn the ignition ON.

Is the test light on?–Go to Step 13Go to Step 24

131. Turn the ignition OFF.

2. Connect the cooling fan relay Low.

3. Disconnect engine control module (ECM) white

connector.

4. Connect a fused jumper between the ECM

connector terminal K28 and ground.

5. Turn the ignition ON.

Do the cooling fans run at low speed?–Go to Step 30Go to Step 14

14Check for an open wire between the low speed cool-

ing fan relay connector terminal 85 and the ECM

connector terminal K28.

Is the problem found?–Go to Step 25Go to Step 15

151. Turn the ignition OFF.

2. Disconnect the cooling fan relay Low.

3. Connect a test light between the cooling fan

relay Low connector terminal 30 and ground.

Is the test light on?–Go to Step 16Go to Step 23

16Connect a fused jumper between the cooling fan

relay Low connector terminals 30 and 87.

Do the cooling fans run at low speed?–Go to Step 26Go to Step 17

171. Disconnect the cooling fan control relay.

2. Connect a fused jumper between the cooling

fan relay Low connector terminals 30 and 87.

3. Connect a fused jumper between the cooling

fan control relay connector terminals 30 and

87.

Do the cooling fans run at low speed?–Go to Step 27Go to Step 18

18Check the wire between the cooling fan relay Low

connector terminal 87 to the main cooling fan con-

nector terminal 2 for an open.

Is the problem found?–Go to Step 22Go to Step 19

19Check the wire between the main cooling fan con-

nector terminal 1 and the cooling fan control relay

connector terminal 30 for an open.

Is the problem found?–Go to Step 22Go to Step 20

Page 349 of 2643

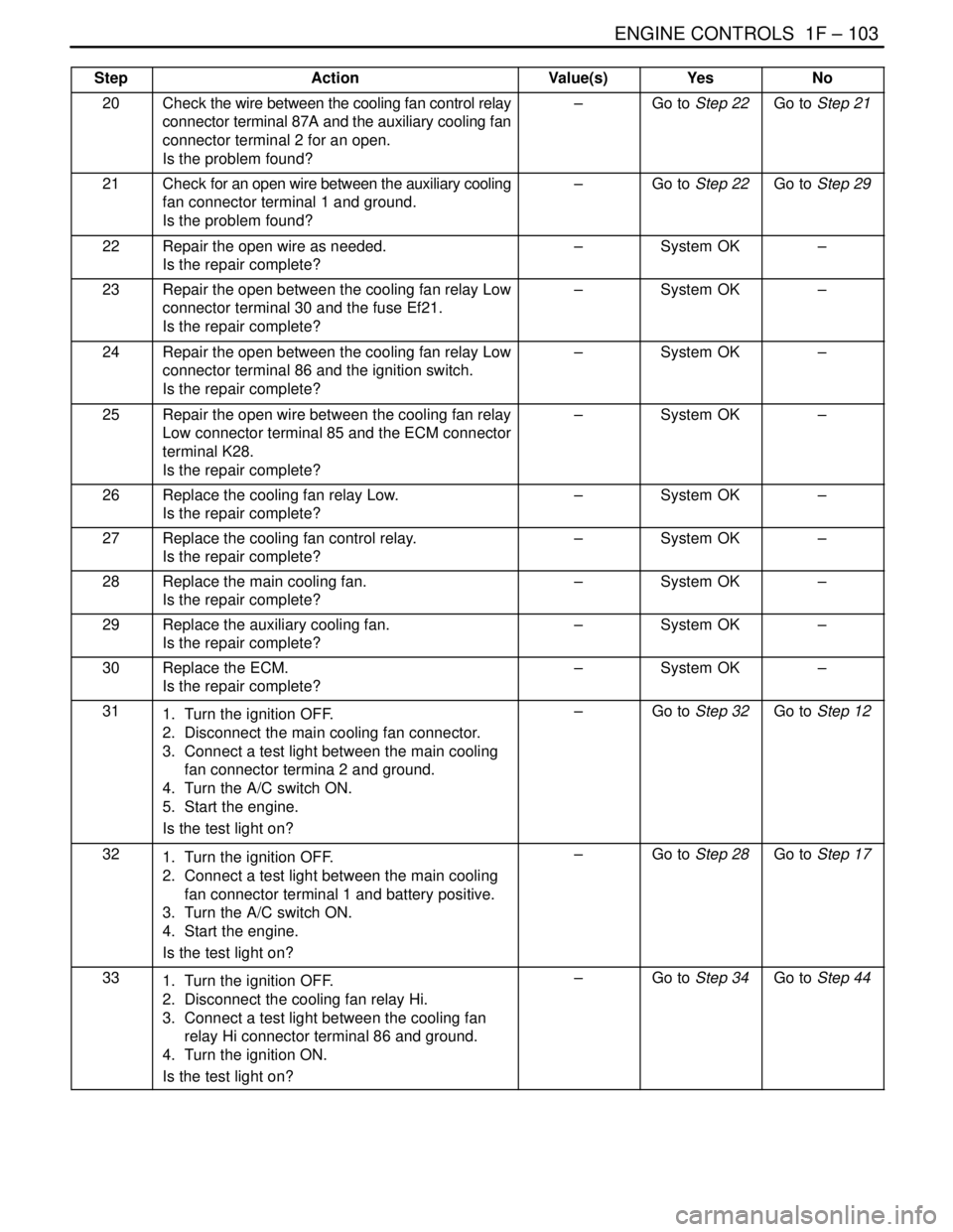

ENGINE CONTROLS 1F – 103

DAEWOO V–121 BL4

StepNo Yes Value(s) Action

20Check the wire between the cooling fan control relay

connector terminal 87A and the auxiliary cooling fan

connector terminal 2 for an open.

Is the problem found?–Go to Step 22Go to Step 21

21Check for an open wire between the auxiliary cooling

fan connector terminal 1 and ground.

Is the problem found?–Go to Step 22Go to Step 29

22Repair the open wire as needed.

Is the repair complete?–System OK–

23Repair the open between the cooling fan relay Low

connector terminal 30 and the fuse Ef21.

Is the repair complete?–System OK–

24Repair the open between the cooling fan relay Low

connector terminal 86 and the ignition switch.

Is the repair complete?–System OK–

25Repair the open wire between the cooling fan relay

Low connector terminal 85 and the ECM connector

terminal K28.

Is the repair complete?–System OK–

26Replace the cooling fan relay Low.

Is the repair complete?–System OK–

27Replace the cooling fan control relay.

Is the repair complete?–System OK–

28Replace the main cooling fan.

Is the repair complete?–System OK–

29Replace the auxiliary cooling fan.

Is the repair complete?–System OK–

30Replace the ECM.

Is the repair complete?–System OK–

311. Turn the ignition OFF.

2. Disconnect the main cooling fan connector.

3. Connect a test light between the main cooling

fan connector termina 2 and ground.

4. Turn the A/C switch ON.

5. Start the engine.

Is the test light on?–Go to Step 32Go to Step 12

321. Turn the ignition OFF.

2. Connect a test light between the main cooling

fan connector terminal 1 and battery positive.

3. Turn the A/C switch ON.

4. Start the engine.

Is the test light on?–Go to Step 28Go to Step 17

331. Turn the ignition OFF.

2. Disconnect the cooling fan relay Hi.

3. Connect a test light between the cooling fan

relay Hi connector terminal 86 and ground.

4. Turn the ignition ON.

Is the test light on?–Go to Step 34Go to Step 44

Page 350 of 2643

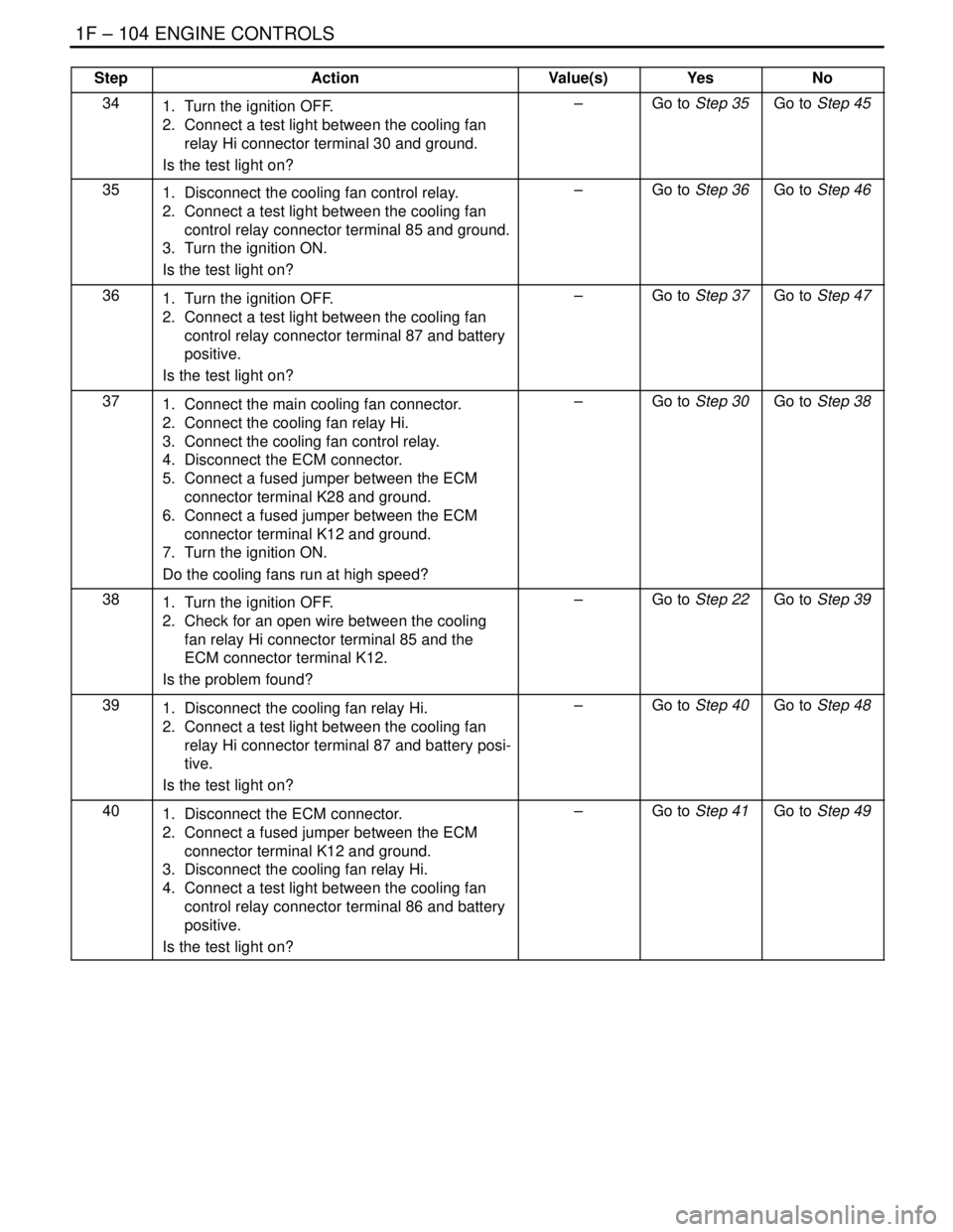

1F – 104IENGINE CONTROLS

DAEWOO V–121 BL4

StepNo Yes Value(s) Action

341. Turn the ignition OFF.

2. Connect a test light between the cooling fan

relay Hi connector terminal 30 and ground.

Is the test light on?–Go to Step 35Go to Step 45

351. Disconnect the cooling fan control relay.

2. Connect a test light between the cooling fan

control relay connector terminal 85 and ground.

3. Turn the ignition ON.

Is the test light on?–Go to Step 36Go to Step 46

361. Turn the ignition OFF.

2. Connect a test light between the cooling fan

control relay connector terminal 87 and battery

positive.

Is the test light on?–Go to Step 37Go to Step 47

371. Connect the main cooling fan connector.

2. Connect the cooling fan relay Hi.

3. Connect the cooling fan control relay.

4. Disconnect the ECM connector.

5. Connect a fused jumper between the ECM

connector terminal K28 and ground.

6. Connect a fused jumper between the ECM

connector terminal K12 and ground.

7. Turn the ignition ON.

Do the cooling fans run at high speed?–Go to Step 30Go to Step 38

381. Turn the ignition OFF.

2. Check for an open wire between the cooling

fan relay Hi connector terminal 85 and the

ECM connector terminal K12.

Is the problem found?–Go to Step 22Go to Step 39

391. Disconnect the cooling fan relay Hi.

2. Connect a test light between the cooling fan

relay Hi connector terminal 87 and battery posi-

tive.

Is the test light on?–Go to Step 40Go to Step 48

401. Disconnect the ECM connector.

2. Connect a fused jumper between the ECM

connector terminal K12 and ground.

3. Disconnect the cooling fan relay Hi.

4. Connect a test light between the cooling fan

control relay connector terminal 86 and battery

positive.

Is the test light on?–Go to Step 41Go to Step 49

Page 353 of 2643

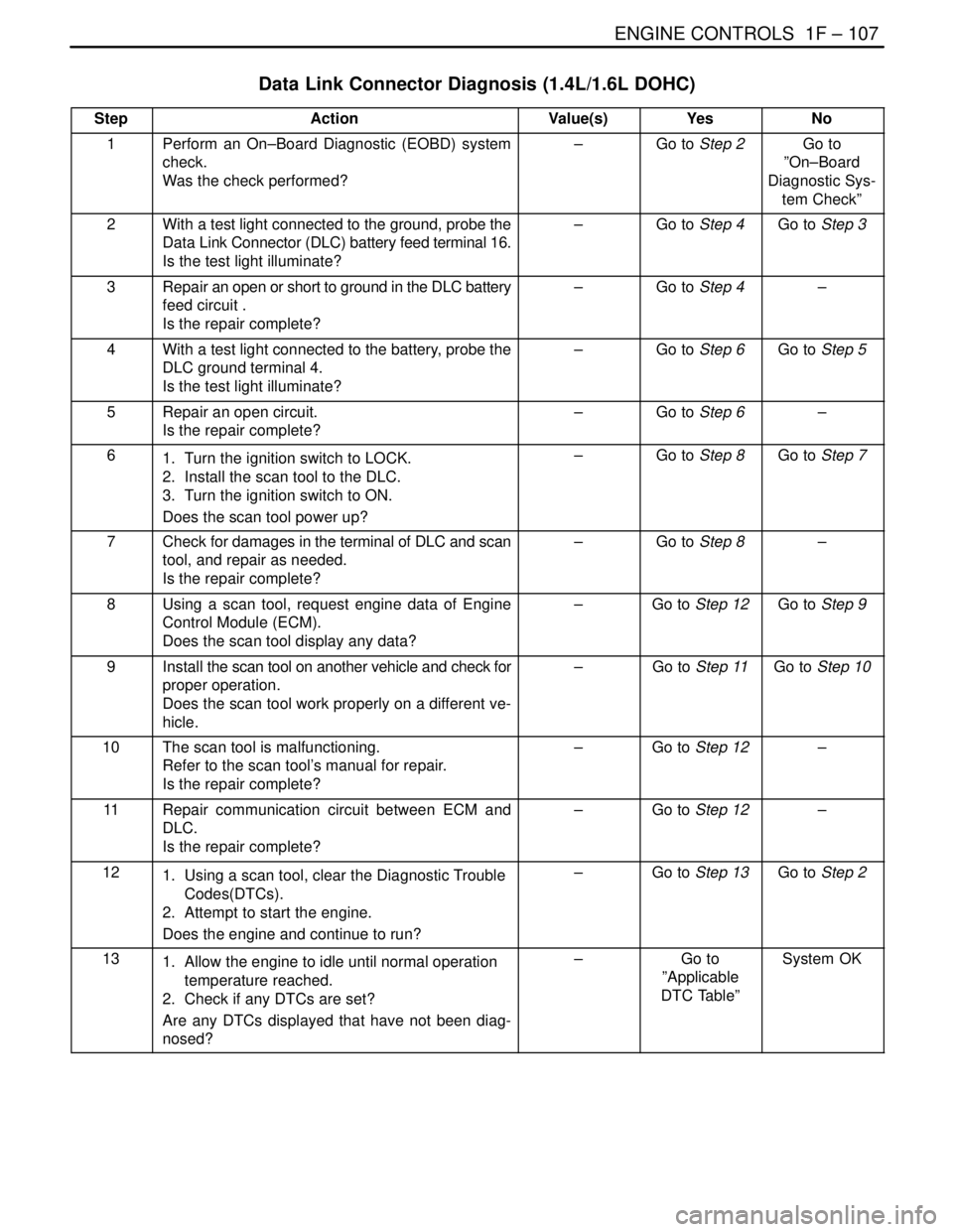

ENGINE CONTROLS 1F – 107

DAEWOO V–121 BL4

Data Link Connector Diagnosis (1.4L/1.6L DOHC)

StepActionValue(s)YesNo

1Perform an On–Board Diagnostic (EOBD) system

check.

Was the check performed?–Go to Step 2Go to

”On–Board

Diagnostic Sys-

tem Check”

2With a test light connected to the ground, probe the

Data Link Connector (DLC) battery feed terminal 16.

Is the test light illuminate?–Go to Step 4Go to Step 3

3Repair an open or short to ground in the DLC battery

feed circuit .

Is the repair complete?–Go to Step 4–

4With a test light connected to the battery, probe the

DLC ground terminal 4.

Is the test light illuminate?–Go to Step 6Go to Step 5

5Repair an open circuit.

Is the repair complete?–Go to Step 6–

61. Turn the ignition switch to LOCK.

2. Install the scan tool to the DLC.

3. Turn the ignition switch to ON.

Does the scan tool power up?–Go to Step 8Go to Step 7

7Check for damages in the terminal of DLC and scan

tool, and repair as needed.

Is the repair complete?–Go to Step 8–

8Using a scan tool, request engine data of Engine

Control Module (ECM).

Does the scan tool display any data?–Go to Step 12Go to Step 9

9Install the scan tool on another vehicle and check for

proper operation.

Does the scan tool work properly on a different ve-

hicle.–Go to Step 11Go to Step 10

10The scan tool is malfunctioning.

Refer to the scan tool’s manual for repair.

Is the repair complete?–Go to Step 12–

11Repair communication circuit between ECM and

DLC.

Is the repair complete?–Go to Step 12–

121. Using a scan tool, clear the Diagnostic Trouble

Codes(DTCs).

2. Attempt to start the engine.

Does the engine and continue to run?–Go to Step 13Go to Step 2

131. Allow the engine to idle until normal operation

temperature reached.

2. Check if any DTCs are set?

Are any DTCs displayed that have not been diag-

nosed?–Go to

”Applicable

DTC Table”System OK

Page 355 of 2643

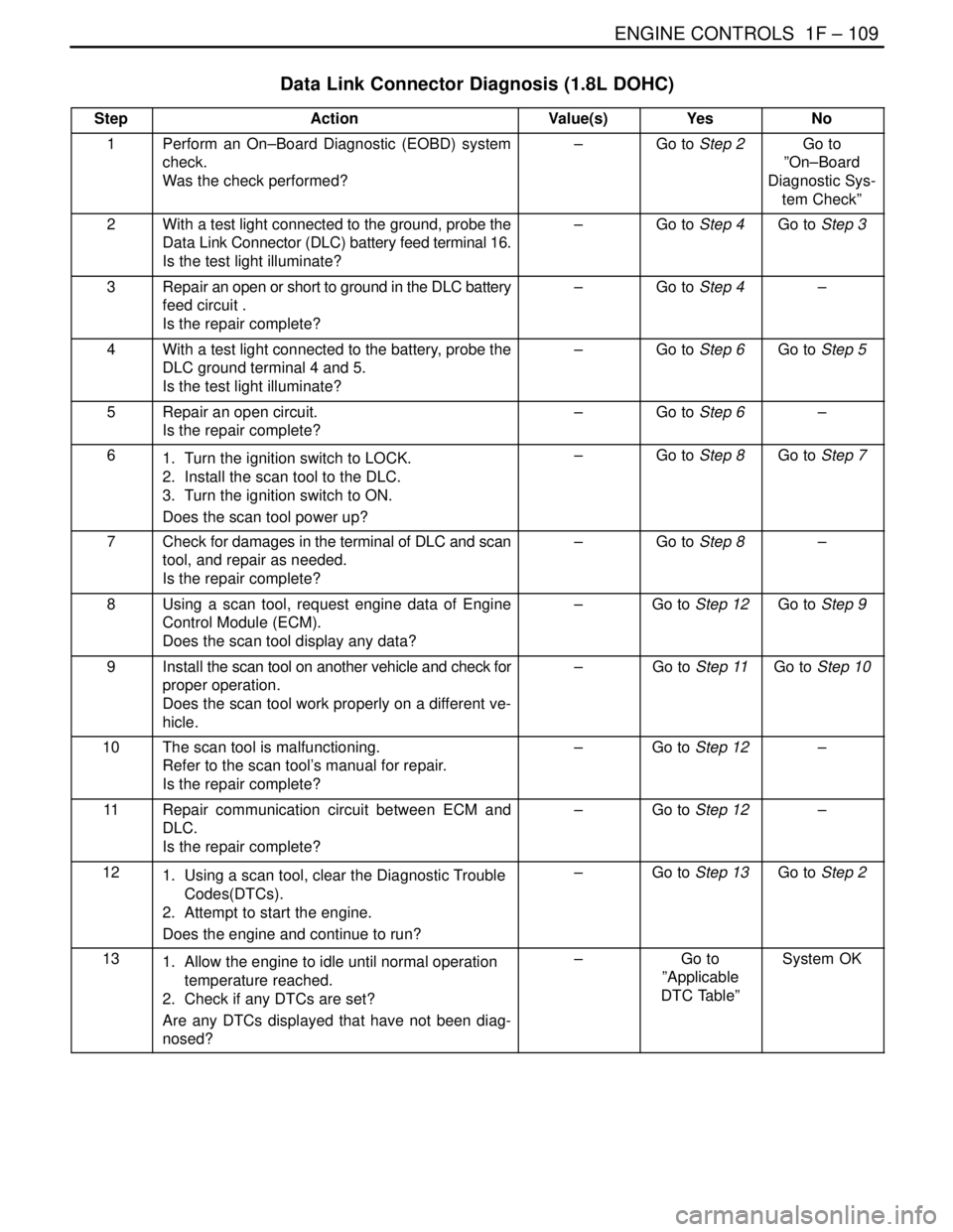

ENGINE CONTROLS 1F – 109

DAEWOO V–121 BL4

Data Link Connector Diagnosis (1.8L DOHC)

StepActionValue(s)YesNo

1Perform an On–Board Diagnostic (EOBD) system

check.

Was the check performed?–Go to Step 2Go to

”On–Board

Diagnostic Sys-

tem Check”

2With a test light connected to the ground, probe the

Data Link Connector (DLC) battery feed terminal 16.

Is the test light illuminate?–Go to Step 4Go to Step 3

3Repair an open or short to ground in the DLC battery

feed circuit .

Is the repair complete?–Go to Step 4–

4With a test light connected to the battery, probe the

DLC ground terminal 4 and 5.

Is the test light illuminate?–Go to Step 6Go to Step 5

5Repair an open circuit.

Is the repair complete?–Go to Step 6–

61. Turn the ignition switch to LOCK.

2. Install the scan tool to the DLC.

3. Turn the ignition switch to ON.

Does the scan tool power up?–Go to Step 8Go to Step 7

7Check for damages in the terminal of DLC and scan

tool, and repair as needed.

Is the repair complete?–Go to Step 8–

8Using a scan tool, request engine data of Engine

Control Module (ECM).

Does the scan tool display any data?–Go to Step 12Go to Step 9

9Install the scan tool on another vehicle and check for

proper operation.

Does the scan tool work properly on a different ve-

hicle.–Go to Step 11Go to Step 10

10The scan tool is malfunctioning.

Refer to the scan tool’s manual for repair.

Is the repair complete?–Go to Step 12–

11Repair communication circuit between ECM and

DLC.

Is the repair complete?–Go to Step 12–

121. Using a scan tool, clear the Diagnostic Trouble

Codes(DTCs).

2. Attempt to start the engine.

Does the engine and continue to run?–Go to Step 13Go to Step 2

131. Allow the engine to idle until normal operation

temperature reached.

2. Check if any DTCs are set?

Are any DTCs displayed that have not been diag-

nosed?–Go to

”Applicable

DTC Table”System OK

Page 392 of 2643

1F – 146IENGINE CONTROLS

DAEWOO V–121 BL4

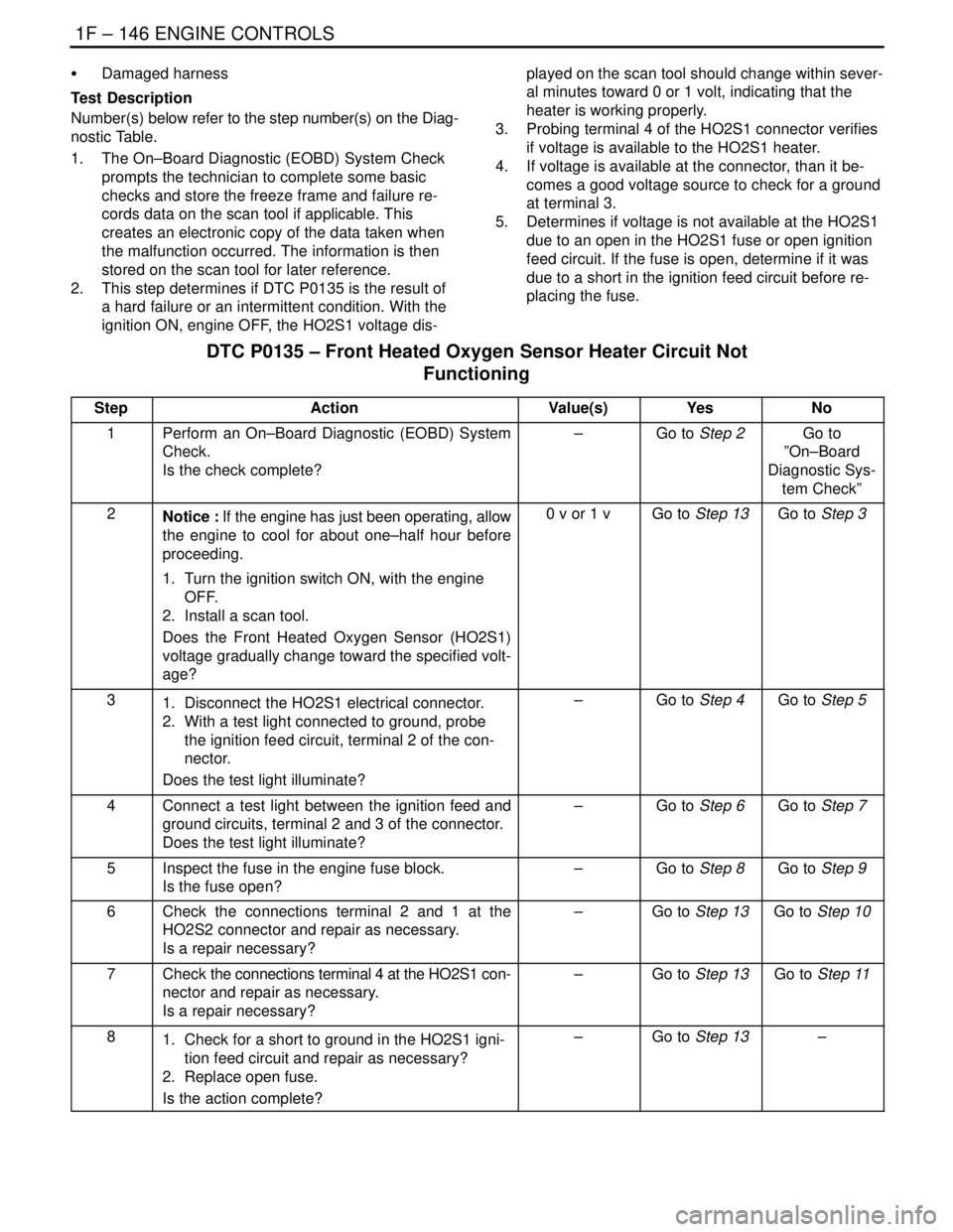

S Damaged harness

Test Description

Number(s) below refer to the step number(s) on the Diag-

nostic Table.

1. The On–Board Diagnostic (EOBD) System Check

prompts the technician to complete some basic

checks and store the freeze frame and failure re-

cords data on the scan tool if applicable. This

creates an electronic copy of the data taken when

the malfunction occurred. The information is then

stored on the scan tool for later reference.

2. This step determines if DTC P0135 is the result of

a hard failure or an intermittent condition. With the

ignition ON, engine OFF, the HO2S1 voltage dis-played on the scan tool should change within sever-

al minutes toward 0 or 1 volt, indicating that the

heater is working properly.

3. Probing terminal 4 of the HO2S1 connector verifies

if voltage is available to the HO2S1 heater.

4. If voltage is available at the connector, than it be-

comes a good voltage source to check for a ground

at terminal 3.

5. Determines if voltage is not available at the HO2S1

due to an open in the HO2S1 fuse or open ignition

feed circuit. If the fuse is open, determine if it was

due to a short in the ignition feed circuit before re-

placing the fuse.

DTC P0135 – Front Heated Oxygen Sensor Heater Circuit Not

Functioning

StepActionValue(s)YesNo

1Perform an On–Board Diagnostic (EOBD) System

Check.

Is the check complete?–Go to Step 2Go to

”On–Board

Diagnostic Sys-

tem Check”

2Notice : If the engine has just been operating, allow

the engine to cool for about one–half hour before

proceeding.

1. Turn the ignition switch ON, with the engine

OFF.

2. Install a scan tool.

Does the Front Heated Oxygen Sensor (HO2S1)

voltage gradually change toward the specified volt-

age?0 v or 1 vGo to Step 13Go to Step 3

31. Disconnect the HO2S1 electrical connector.

2. With a test light connected to ground, probe

the ignition feed circuit, terminal 2 of the con-

nector.

Does the test light illuminate?–Go to Step 4Go to Step 5

4Connect a test light between the ignition feed and

ground circuits, terminal 2 and 3 of the connector.

Does the test light illuminate?–Go to Step 6Go to Step 7

5Inspect the fuse in the engine fuse block.

Is the fuse open?–Go to Step 8Go to Step 9

6Check the connections terminal 2 and 1 at the

HO2S2 connector and repair as necessary.

Is a repair necessary?–Go to Step 13Go to Step 10

7Check the connections terminal 4 at the HO2S1 con-

nector and repair as necessary.

Is a repair necessary?–Go to Step 13Go to Step 11

81. Check for a short to ground in the HO2S1 igni-

tion feed circuit and repair as necessary?

2. Replace open fuse.

Is the action complete?–Go to Step 13–

Page 406 of 2643

1F – 160IENGINE CONTROLS

DAEWOO V–121 BL4

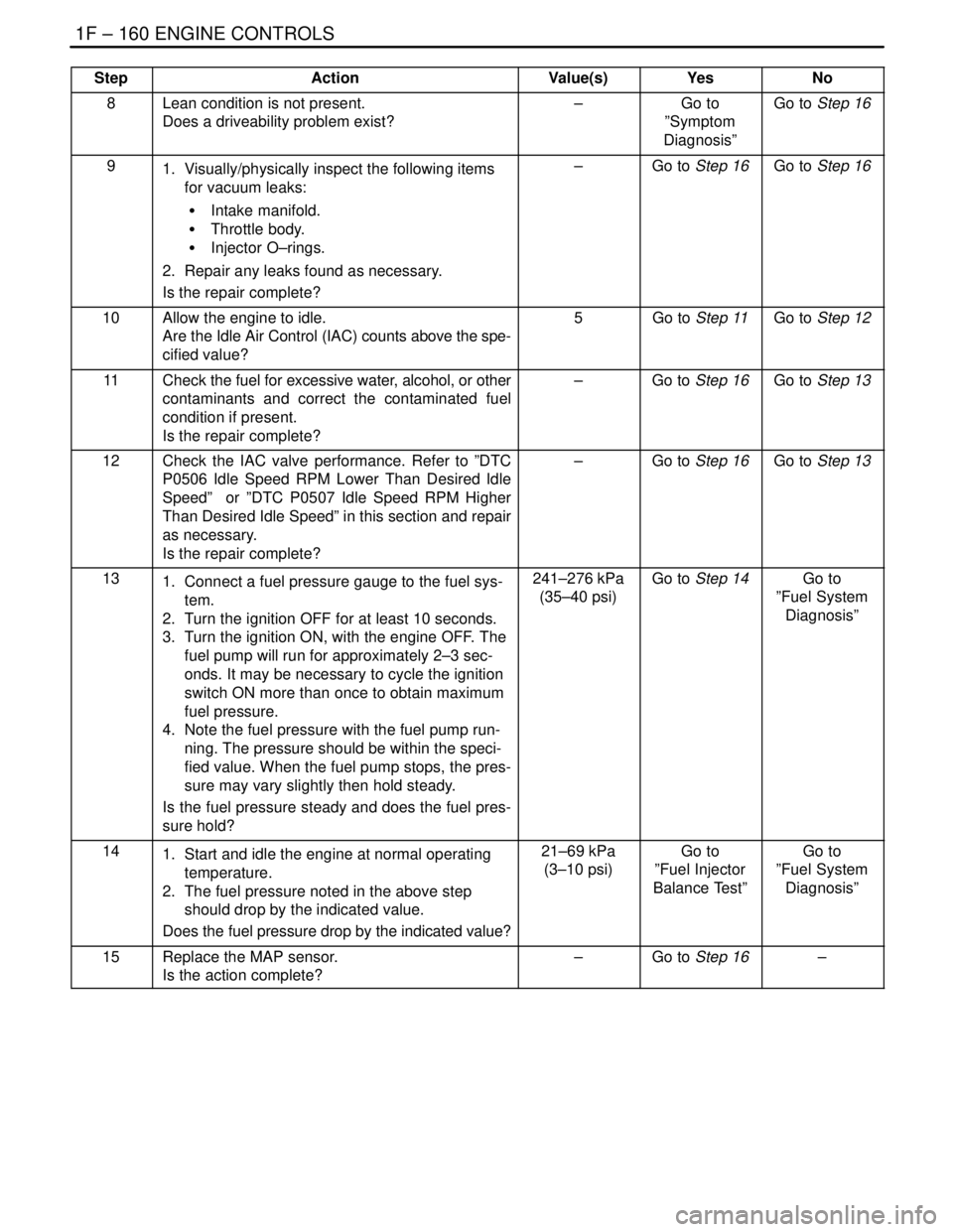

StepNo Yes Value(s) Action

8Lean condition is not present.

Does a driveability problem exist?–Go to

”Symptom

Diagnosis”Go to Step 16

91. Visually/physically inspect the following items

for vacuum leaks:

S Intake manifold.

S Throttle body.

S Injector O–rings.

2. Repair any leaks found as necessary.

Is the repair complete?–Go to Step 16Go to Step 16

10Allow the engine to idle.

Are the Idle Air Control (IAC) counts above the spe-

cified value?5Go to Step 11Go to Step 12

11Check the fuel for excessive water, alcohol, or other

contaminants and correct the contaminated fuel

condition if present.

Is the repair complete?–Go to Step 16Go to Step 13

12Check the IAC valve performance. Refer to ”DTC

P0506 Idle Speed RPM Lower Than Desired Idle

Speed” or ”DTC P0507 Idle Speed RPM Higher

Than Desired Idle Speed” in this section and repair

as necessary.

Is the repair complete?–Go to Step 16Go to Step 13

131. Connect a fuel pressure gauge to the fuel sys-

tem.

2. Turn the ignition OFF for at least 10 seconds.

3. Turn the ignition ON, with the engine OFF. The

fuel pump will run for approximately 2–3 sec-

onds. It may be necessary to cycle the ignition

switch ON more than once to obtain maximum

fuel pressure.

4. Note the fuel pressure with the fuel pump run-

ning. The pressure should be within the speci-

fied value. When the fuel pump stops, the pres-

sure may vary slightly then hold steady.

Is the fuel pressure steady and does the fuel pres-

sure hold?241–276 kPa

(35–40 psi)Go to Step 14Go to

”Fuel System

Diagnosis”

141. Start and idle the engine at normal operating

temperature.

2. The fuel pressure noted in the above step

should drop by the indicated value.

Does the fuel pressure drop by the indicated value?21–69 kPa

(3–10 psi)Go to

”Fuel Injector

Balance Test”Go to

”Fuel System

Diagnosis”

15Replace the MAP sensor.

Is the action complete?–Go to Step 16–