Spark DAEWOO NUBIRA 2004 Service Manual PDF

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: NUBIRA, Model: DAEWOO NUBIRA 2004Pages: 2643, PDF Size: 80.54 MB

Page 710 of 2643

1F – 464IENGINE CONTROLS

DAEWOO V–121 BL4

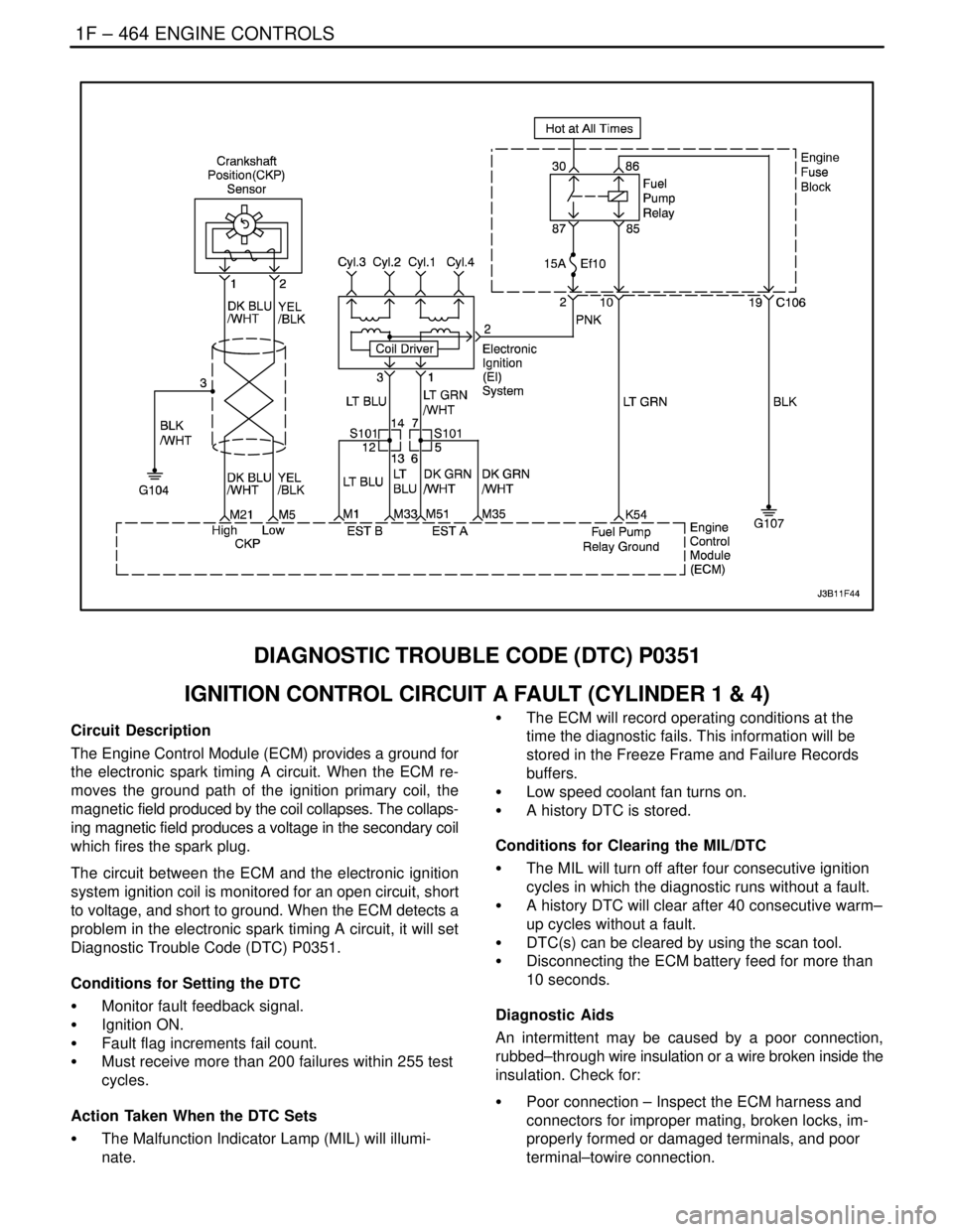

DIAGNOSTIC TROUBLE CODE (DTC) P0351

IGNITION CONTROL CIRCUIT A FAULT (CYLINDER 1 & 4)

Circuit Description

The Engine Control Module (ECM) provides a ground for

the electronic spark timing A circuit. When the ECM re-

moves the ground path of the ignition primary coil, the

magnetic field produced by the coil collapses. The collaps-

ing magnetic field produces a voltage in the secondary coil

which fires the spark plug.

The circuit between the ECM and the electronic ignition

system ignition coil is monitored for an open circuit, short

to voltage, and short to ground. When the ECM detects a

problem in the electronic spark timing A circuit, it will set

Diagnostic Trouble Code (DTC) P0351.

Conditions for Setting the DTC

S Monitor fault feedback signal.

S Ignition ON.

S Fault flag increments fail count.

S Must receive more than 200 failures within 255 test

cycles.

Action Taken When the DTC Sets

S The Malfunction Indicator Lamp (MIL) will illumi-

nate.S The ECM will record operating conditions at the

time the diagnostic fails. This information will be

stored in the Freeze Frame and Failure Records

buffers.

S Low speed coolant fan turns on.

S A history DTC is stored.

Conditions for Clearing the MIL/DTC

S The MIL will turn off after four consecutive ignition

cycles in which the diagnostic runs without a fault.

S A history DTC will clear after 40 consecutive warm–

up cycles without a fault.

S DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for more than

10 seconds.

Diagnostic Aids

An intermittent may be caused by a poor connection,

rubbed–through wire insulation or a wire broken inside the

insulation. Check for:

S Poor connection – Inspect the ECM harness and

connectors for improper mating, broken locks, im-

properly formed or damaged terminals, and poor

terminal–towire connection.

Page 712 of 2643

1F – 466IENGINE CONTROLS

DAEWOO V–121 BL4

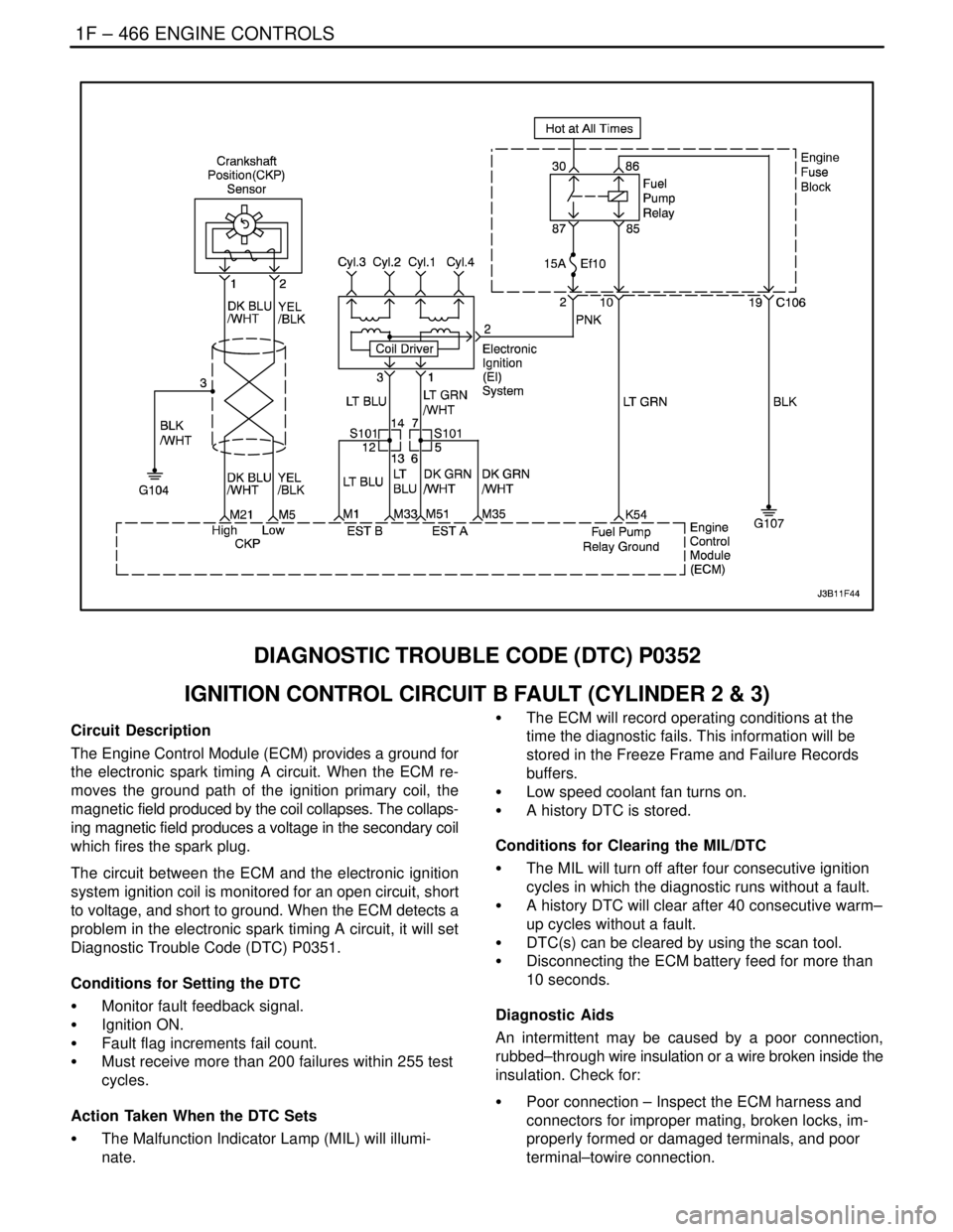

DIAGNOSTIC TROUBLE CODE (DTC) P0352

IGNITION CONTROL CIRCUIT B FAULT (CYLINDER 2 & 3)

Circuit Description

The Engine Control Module (ECM) provides a ground for

the electronic spark timing A circuit. When the ECM re-

moves the ground path of the ignition primary coil, the

magnetic field produced by the coil collapses. The collaps-

ing magnetic field produces a voltage in the secondary coil

which fires the spark plug.

The circuit between the ECM and the electronic ignition

system ignition coil is monitored for an open circuit, short

to voltage, and short to ground. When the ECM detects a

problem in the electronic spark timing A circuit, it will set

Diagnostic Trouble Code (DTC) P0351.

Conditions for Setting the DTC

S Monitor fault feedback signal.

S Ignition ON.

S Fault flag increments fail count.

S Must receive more than 200 failures within 255 test

cycles.

Action Taken When the DTC Sets

S The Malfunction Indicator Lamp (MIL) will illumi-

nate.S The ECM will record operating conditions at the

time the diagnostic fails. This information will be

stored in the Freeze Frame and Failure Records

buffers.

S Low speed coolant fan turns on.

S A history DTC is stored.

Conditions for Clearing the MIL/DTC

S The MIL will turn off after four consecutive ignition

cycles in which the diagnostic runs without a fault.

S A history DTC will clear after 40 consecutive warm–

up cycles without a fault.

S DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for more than

10 seconds.

Diagnostic Aids

An intermittent may be caused by a poor connection,

rubbed–through wire insulation or a wire broken inside the

insulation. Check for:

S Poor connection – Inspect the ECM harness and

connectors for improper mating, broken locks, im-

properly formed or damaged terminals, and poor

terminal–towire connection.

Page 731 of 2643

ENGINE CONTROLS 1F – 485

DAEWOO V–121 BL4

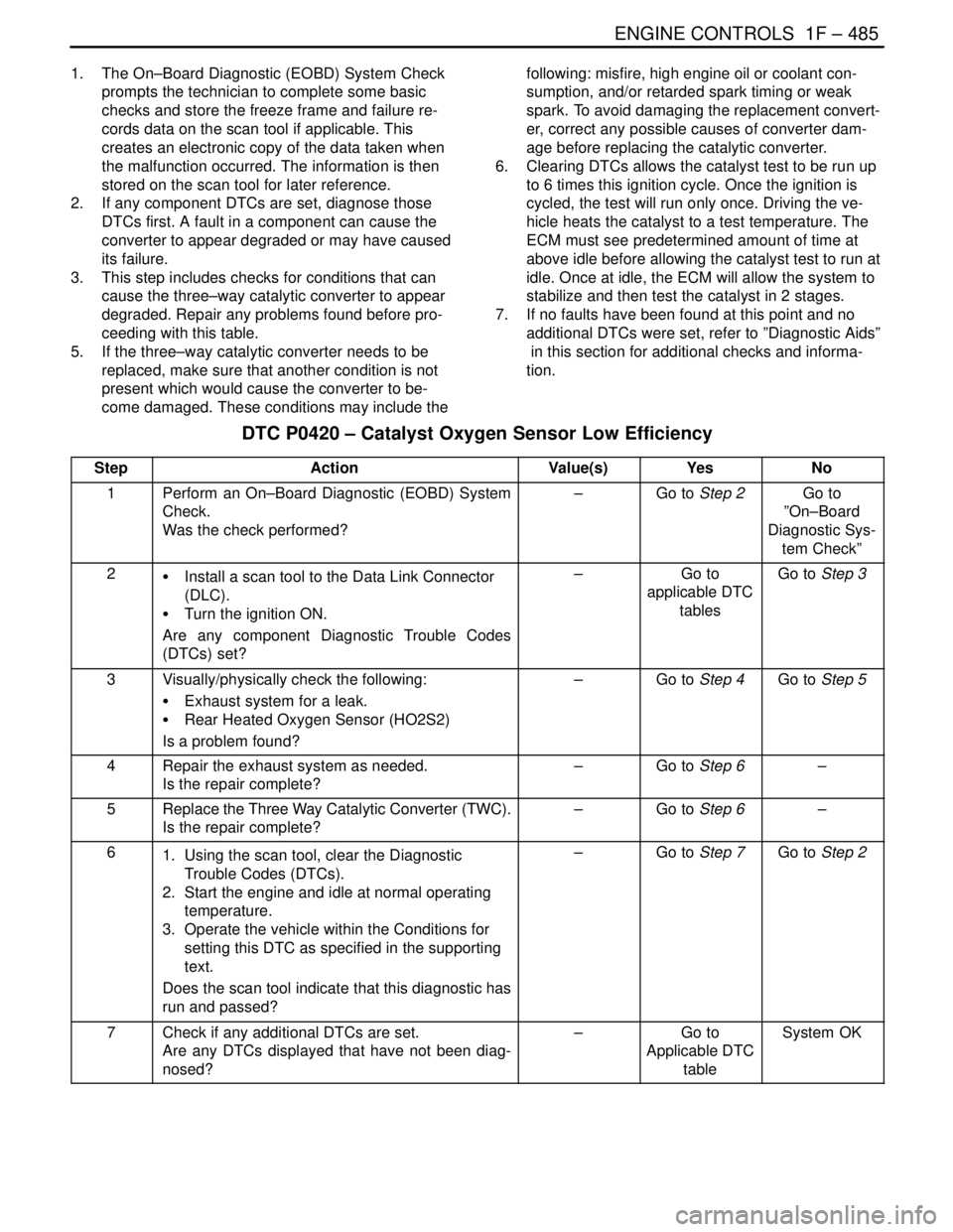

1. The On–Board Diagnostic (EOBD) System Check

prompts the technician to complete some basic

checks and store the freeze frame and failure re-

cords data on the scan tool if applicable. This

creates an electronic copy of the data taken when

the malfunction occurred. The information is then

stored on the scan tool for later reference.

2. If any component DTCs are set, diagnose those

DTCs first. A fault in a component can cause the

converter to appear degraded or may have caused

its failure.

3. This step includes checks for conditions that can

cause the three–way catalytic converter to appear

degraded. Repair any problems found before pro-

ceeding with this table.

5. If the three–way catalytic converter needs to be

replaced, make sure that another condition is not

present which would cause the converter to be-

come damaged. These conditions may include thefollowing: misfire, high engine oil or coolant con-

sumption, and/or retarded spark timing or weak

spark. To avoid damaging the replacement convert-

er, correct any possible causes of converter dam-

age before replacing the catalytic converter.

6. Clearing DTCs allows the catalyst test to be run up

to 6 times this ignition cycle. Once the ignition is

cycled, the test will run only once. Driving the ve-

hicle heats the catalyst to a test temperature. The

ECM must see predetermined amount of time at

above idle before allowing the catalyst test to run at

idle. Once at idle, the ECM will allow the system to

stabilize and then test the catalyst in 2 stages.

7. If no faults have been found at this point and no

additional DTCs were set, refer to ”Diagnostic Aids”

in this section for additional checks and informa-

tion.

DTC P0420 – Catalyst Oxygen Sensor Low Efficiency

StepActionValue(s)YesNo

1Perform an On–Board Diagnostic (EOBD) System

Check.

Was the check performed?–Go to Step 2Go to

”On–Board

Diagnostic Sys-

tem Check”

2S Install a scan tool to the Data Link Connector

(DLC).

S Turn the ignition ON.

Are any component Diagnostic Trouble Codes

(DTCs) set?–Go to

applicable DTC

tablesGo to Step 3

3Visually/physically check the following:

S Exhaust system for a leak.

S Rear Heated Oxygen Sensor (HO2S2)

Is a problem found?–Go to Step 4Go to Step 5

4Repair the exhaust system as needed.

Is the repair complete?–Go to Step 6–

5Replace the Three Way Catalytic Converter (TWC).

Is the repair complete?–Go to Step 6–

61. Using the scan tool, clear the Diagnostic

Trouble Codes (DTCs).

2. Start the engine and idle at normal operating

temperature.

3. Operate the vehicle within the Conditions for

setting this DTC as specified in the supporting

text.

Does the scan tool indicate that this diagnostic has

run and passed?–Go to Step 7Go to Step 2

7Check if any additional DTCs are set.

Are any DTCs displayed that have not been diag-

nosed?–Go to

Applicable DTC

tableSystem OK

Page 823 of 2643

ENGINE CONTROLS 1F – 577

DAEWOO V–121 BL4

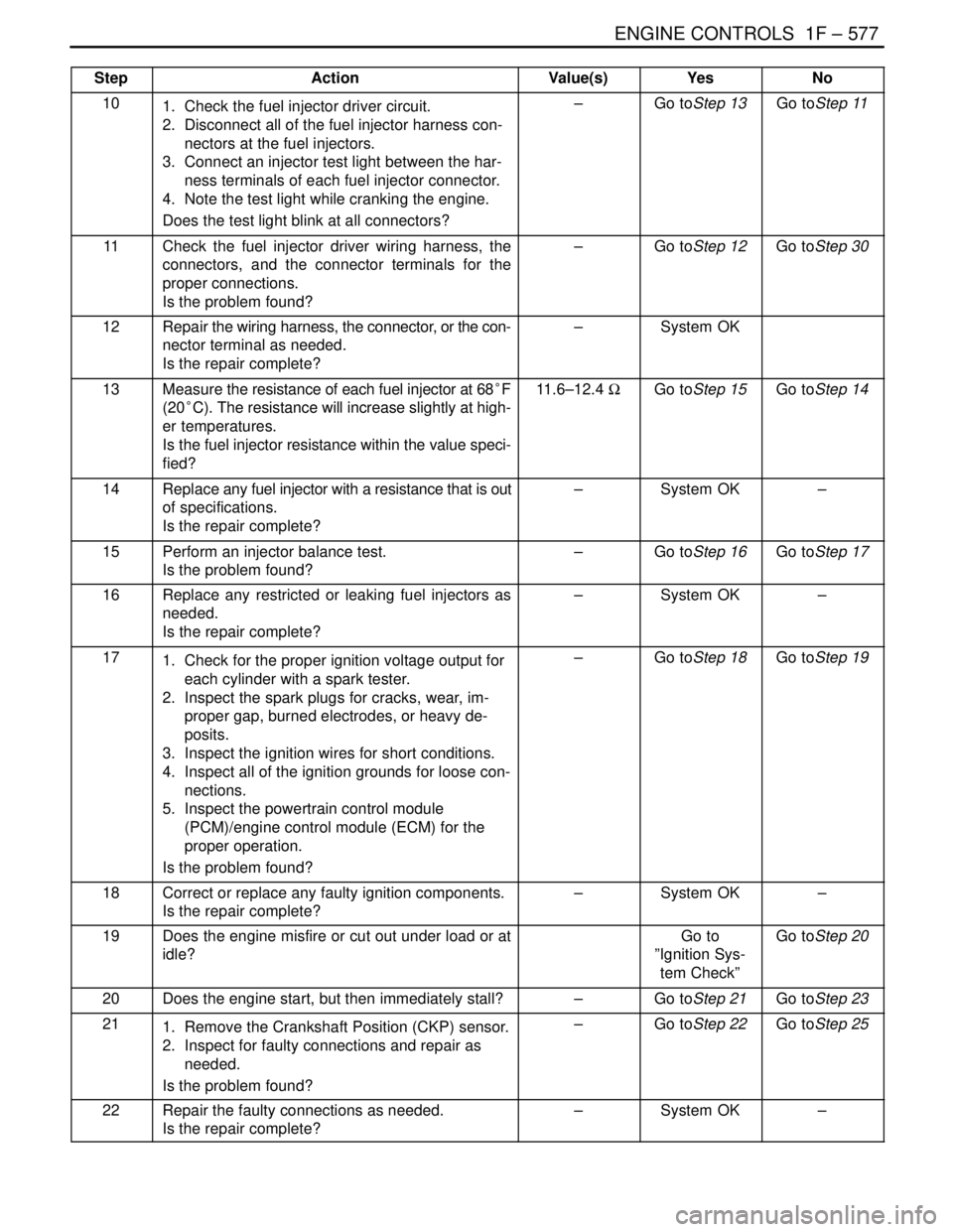

StepNo Yes Value(s) Action

101. Check the fuel injector driver circuit.

2. Disconnect all of the fuel injector harness con-

nectors at the fuel injectors.

3. Connect an injector test light between the har-

ness terminals of each fuel injector connector.

4. Note the test light while cranking the engine.

Does the test light blink at all connectors?–Go toStep 13Go toStep 11

11Check the fuel injector driver wiring harness, the

connectors, and the connector terminals for the

proper connections.

Is the problem found?–Go toStep 12Go toStep 30

12Repair the wiring harness, the connector, or the con-

nector terminal as needed.

Is the repair complete?–System OK

13Measure the resistance of each fuel injector at 68°F

(20°C). The resistance will increase slightly at high-

er temperatures.

Is the fuel injector resistance within the value speci-

fied?11.6–12.4 ΩGo toStep 15Go toStep 14

14Replace any fuel injector with a resistance that is out

of specifications.

Is the repair complete?–System OK–

15Perform an injector balance test.

Is the problem found?–Go toStep 16Go toStep 17

16Replace any restricted or leaking fuel injectors as

needed.

Is the repair complete?–System OK–

171. Check for the proper ignition voltage output for

each cylinder with a spark tester.

2. Inspect the spark plugs for cracks, wear, im-

proper gap, burned electrodes, or heavy de-

posits.

3. Inspect the ignition wires for short conditions.

4. Inspect all of the ignition grounds for loose con-

nections.

5. Inspect the powertrain control module

(PCM)/engine control module (ECM) for the

proper operation.

Is the problem found?–Go toStep 18Go toStep 19

18Correct or replace any faulty ignition components.

Is the repair complete?–System OK–

19Does the engine misfire or cut out under load or at

idle?Go to

”Ignition Sys-

tem Check”Go toStep 20

20Does the engine start, but then immediately stall?–Go toStep 21Go toStep 23

211. Remove the Crankshaft Position (CKP) sensor.

2. Inspect for faulty connections and repair as

needed.

Is the problem found?–Go toStep 22Go toStep 25

22Repair the faulty connections as needed.

Is the repair complete?–System OK–

Page 825 of 2643

ENGINE CONTROLS 1F – 579

DAEWOO V–121 BL4

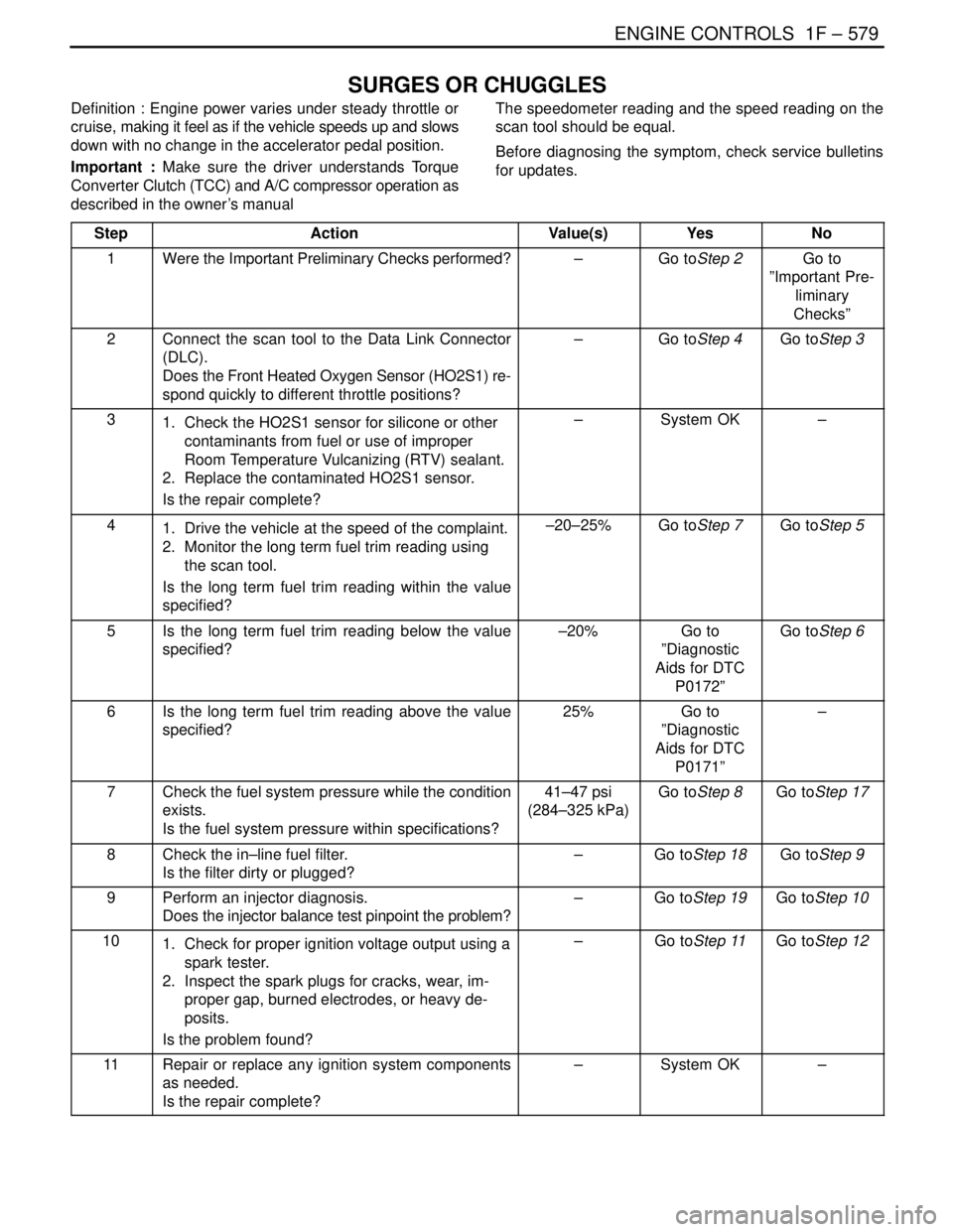

SURGES OR CHUGGLES

Definition : Engine power varies under steady throttle or

cruise, making it feel as if the vehicle speeds up and slows

down with no change in the accelerator pedal position.

Important : Make sure the driver understands Torque

Converter Clutch (TCC) and A/C compressor operation as

described in the owner’s manualThe speedometer reading and the speed reading on the

scan tool should be equal.

Before diagnosing the symptom, check service bulletins

for updates.

Step

ActionValue(s)YesNo

1Were the Important Preliminary Checks performed?–Go toStep 2Go to

”Important Pre-

liminary

Checks”

2Connect the scan tool to the Data Link Connector

(DLC).

Does the Front Heated Oxygen Sensor (HO2S1) re-

spond quickly to different throttle positions?–Go toStep 4Go toStep 3

31. Check the HO2S1 sensor for silicone or other

contaminants from fuel or use of improper

Room Temperature Vulcanizing (RTV) sealant.

2. Replace the contaminated HO2S1 sensor.

Is the repair complete?–System OK–

41. Drive the vehicle at the speed of the complaint.

2. Monitor the long term fuel trim reading using

the scan tool.

Is the long term fuel trim reading within the value

specified?–20–25%Go toStep 7Go toStep 5

5Is the long term fuel trim reading below the value

specified?–20%Go to

”Diagnostic

Aids for DTC

P0172”Go toStep 6

6Is the long term fuel trim reading above the value

specified?25%Go to

”Diagnostic

Aids for DTC

P0171”–

7Check the fuel system pressure while the condition

exists.

Is the fuel system pressure within specifications?41–47 psi

(284–325 kPa)Go toStep 8Go toStep 17

8Check the in–line fuel filter.

Is the filter dirty or plugged?–Go toStep 18Go toStep 9

9Perform an injector diagnosis.

Does the injector balance test pinpoint the problem?–Go toStep 19Go toStep 10

101. Check for proper ignition voltage output using a

spark tester.

2. Inspect the spark plugs for cracks, wear, im-

proper gap, burned electrodes, or heavy de-

posits.

Is the problem found?–Go toStep 11Go toStep 12

11Repair or replace any ignition system components

as needed.

Is the repair complete?–System OK–

Page 827 of 2643

ENGINE CONTROLS 1F – 581

DAEWOO V–121 BL4

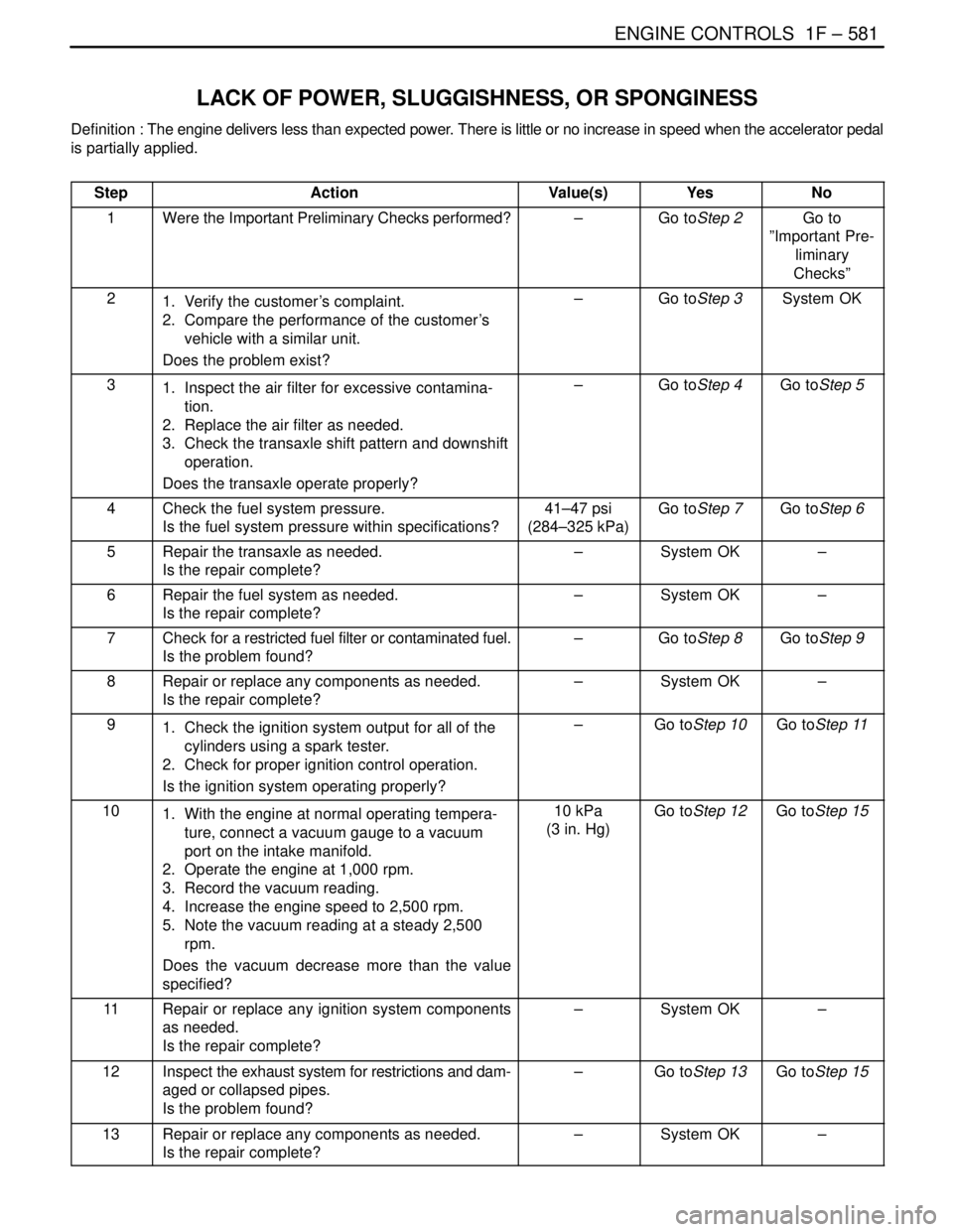

LACK OF POWER, SLUGGISHNESS, OR SPONGINESS

Definition : The engine delivers less than expected power. There is little or no increase in speed when the accelerator pedal

is partially applied.

Step

ActionValue(s)YesNo

1Were the Important Preliminary Checks performed?–Go toStep 2Go to

”Important Pre-

liminary

Checks”

21. Verify the customer’s complaint.

2. Compare the performance of the customer’s

vehicle with a similar unit.

Does the problem exist?–Go toStep 3System OK

31. Inspect the air filter for excessive contamina-

tion.

2. Replace the air filter as needed.

3. Check the transaxle shift pattern and downshift

operation.

Does the transaxle operate properly?–Go toStep 4Go toStep 5

4Check the fuel system pressure.

Is the fuel system pressure within specifications?41–47 psi

(284–325 kPa)Go toStep 7Go toStep 6

5Repair the transaxle as needed.

Is the repair complete?–System OK–

6Repair the fuel system as needed.

Is the repair complete?–System OK–

7Check for a restricted fuel filter or contaminated fuel.

Is the problem found?–Go toStep 8Go toStep 9

8Repair or replace any components as needed.

Is the repair complete?–System OK–

91. Check the ignition system output for all of the

cylinders using a spark tester.

2. Check for proper ignition control operation.

Is the ignition system operating properly?–Go toStep 10Go toStep 11

101. With the engine at normal operating tempera-

ture, connect a vacuum gauge to a vacuum

port on the intake manifold.

2. Operate the engine at 1,000 rpm.

3. Record the vacuum reading.

4. Increase the engine speed to 2,500 rpm.

5. Note the vacuum reading at a steady 2,500

rpm.

Does the vacuum decrease more than the value

specified?10 kPa

(3 in. Hg)Go toStep 12Go toStep 15

11Repair or replace any ignition system components

as needed.

Is the repair complete?–System OK–

12Inspect the exhaust system for restrictions and dam-

aged or collapsed pipes.

Is the problem found?–Go toStep 13Go toStep 15

13Repair or replace any components as needed.

Is the repair complete?–System OK–

Page 830 of 2643

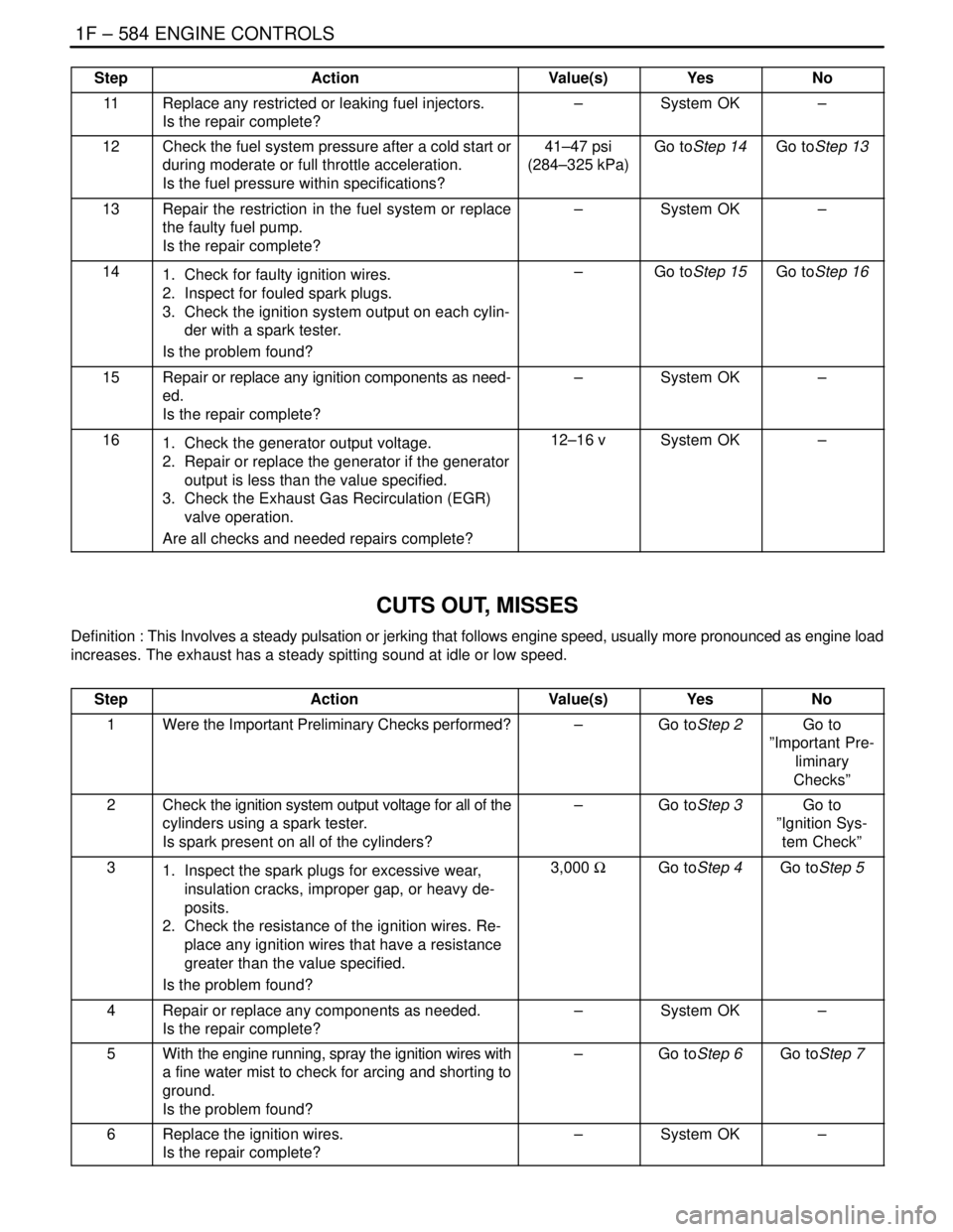

1F – 584IENGINE CONTROLS

DAEWOO V–121 BL4

StepNo Yes Value(s) Action

11Replace any restricted or leaking fuel injectors.

Is the repair complete?–System OK–

12Check the fuel system pressure after a cold start or

during moderate or full throttle acceleration.

Is the fuel pressure within specifications?41–47 psi

(284–325 kPa)Go toStep 14Go toStep 13

13Repair the restriction in the fuel system or replace

the faulty fuel pump.

Is the repair complete?–System OK–

141. Check for faulty ignition wires.

2. Inspect for fouled spark plugs.

3. Check the ignition system output on each cylin-

der with a spark tester.

Is the problem found?–Go toStep 15Go toStep 16

15Repair or replace any ignition components as need-

ed.

Is the repair complete?–System OK–

161. Check the generator output voltage.

2. Repair or replace the generator if the generator

output is less than the value specified.

3. Check the Exhaust Gas Recirculation (EGR)

valve operation.

Are all checks and needed repairs complete?12–16 vSystem OK–

CUTS OUT, MISSES

Definition : This Involves a steady pulsation or jerking that follows engine speed, usually more pronounced as engine load

increases. The exhaust has a steady spitting sound at idle or low speed.

Step

ActionValue(s)YesNo

1Were the Important Preliminary Checks performed?–Go toStep 2Go to

”Important Pre-

liminary

Checks”

2Check the ignition system output voltage for all of the

cylinders using a spark tester.

Is spark present on all of the cylinders?–Go toStep 3Go to

”Ignition Sys-

tem Check”

31. Inspect the spark plugs for excessive wear,

insulation cracks, improper gap, or heavy de-

posits.

2. Check the resistance of the ignition wires. Re-

place any ignition wires that have a resistance

greater than the value specified.

Is the problem found?3,000 ΩGo toStep 4Go toStep 5

4Repair or replace any components as needed.

Is the repair complete?–System OK–

5With the engine running, spray the ignition wires with

a fine water mist to check for arcing and shorting to

ground.

Is the problem found?–Go toStep 6Go toStep 7

6Replace the ignition wires.

Is the repair complete?–System OK–

Page 833 of 2643

ENGINE CONTROLS 1F – 587

DAEWOO V–121 BL4

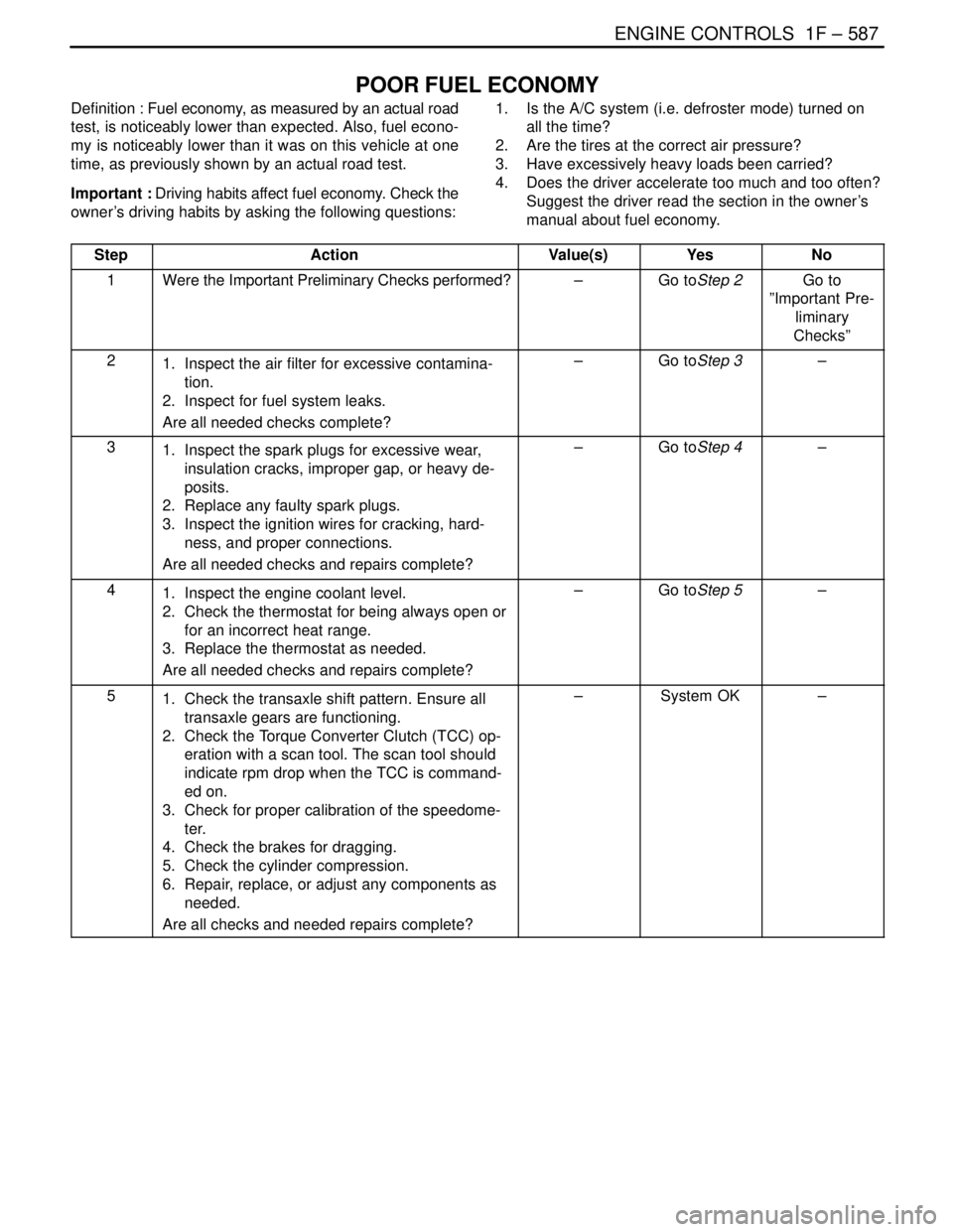

POOR FUEL ECONOMY

Definition : Fuel economy, as measured by an actual road

test, is noticeably lower than expected. Also, fuel econo-

my is noticeably lower than it was on this vehicle at one

time, as previously shown by an actual road test.

Important : Driving habits affect fuel economy. Check the

owner’s driving habits by asking the following questions:1. Is the A/C system (i.e. defroster mode) turned on

all the time?

2. Are the tires at the correct air pressure?

3. Have excessively heavy loads been carried?

4. Does the driver accelerate too much and too often?

Suggest the driver read the section in the owner’s

manual about fuel economy.

Step

ActionValue(s)YesNo

1Were the Important Preliminary Checks performed?–Go toStep 2Go to

”Important Pre-

liminary

Checks”

21. Inspect the air filter for excessive contamina-

tion.

2. Inspect for fuel system leaks.

Are all needed checks complete?–Go toStep 3–

31. Inspect the spark plugs for excessive wear,

insulation cracks, improper gap, or heavy de-

posits.

2. Replace any faulty spark plugs.

3. Inspect the ignition wires for cracking, hard-

ness, and proper connections.

Are all needed checks and repairs complete?–Go toStep 4–

41. Inspect the engine coolant level.

2. Check the thermostat for being always open or

for an incorrect heat range.

3. Replace the thermostat as needed.

Are all needed checks and repairs complete?–Go toStep 5–

51. Check the transaxle shift pattern. Ensure all

transaxle gears are functioning.

2. Check the Torque Converter Clutch (TCC) op-

eration with a scan tool. The scan tool should

indicate rpm drop when the TCC is command-

ed on.

3. Check for proper calibration of the speedome-

ter.

4. Check the brakes for dragging.

5. Check the cylinder compression.

6. Repair, replace, or adjust any components as

needed.

Are all checks and needed repairs complete?–System OK–

Page 836 of 2643

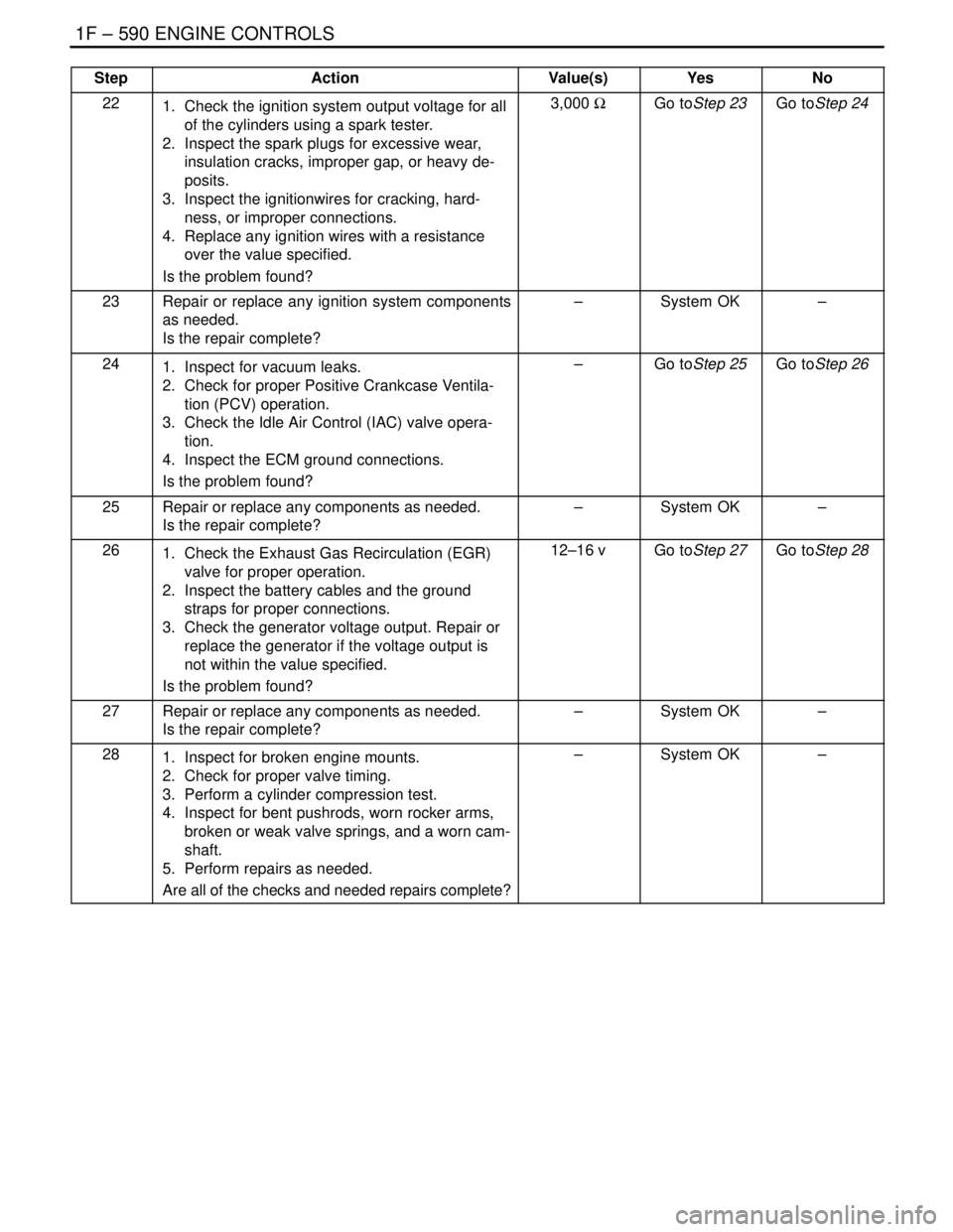

1F – 590IENGINE CONTROLS

DAEWOO V–121 BL4

StepNo Yes Value(s) Action

221. Check the ignition system output voltage for all

of the cylinders using a spark tester.

2. Inspect the spark plugs for excessive wear,

insulation cracks, improper gap, or heavy de-

posits.

3. Inspect the ignitionwires for cracking, hard-

ness, or improper connections.

4. Replace any ignition wires with a resistance

over the value specified.

Is the problem found?3,000 ΩGo toStep 23Go toStep 24

23Repair or replace any ignition system components

as needed.

Is the repair complete?–System OK–

241. Inspect for vacuum leaks.

2. Check for proper Positive Crankcase Ventila-

tion (PCV) operation.

3. Check the Idle Air Control (IAC) valve opera-

tion.

4. Inspect the ECM ground connections.

Is the problem found?–Go toStep 25Go toStep 26

25Repair or replace any components as needed.

Is the repair complete?–System OK–

261. Check the Exhaust Gas Recirculation (EGR)

valve for proper operation.

2. Inspect the battery cables and the ground

straps for proper connections.

3. Check the generator voltage output. Repair or

replace the generator if the voltage output is

not within the value specified.

Is the problem found?12–16 vGo toStep 27Go toStep 28

27Repair or replace any components as needed.

Is the repair complete?–System OK–

281. Inspect for broken engine mounts.

2. Check for proper valve timing.

3. Perform a cylinder compression test.

4. Inspect for bent pushrods, worn rocker arms,

broken or weak valve springs, and a worn cam-

shaft.

5. Perform repairs as needed.

Are all of the checks and needed repairs complete?–System OK–

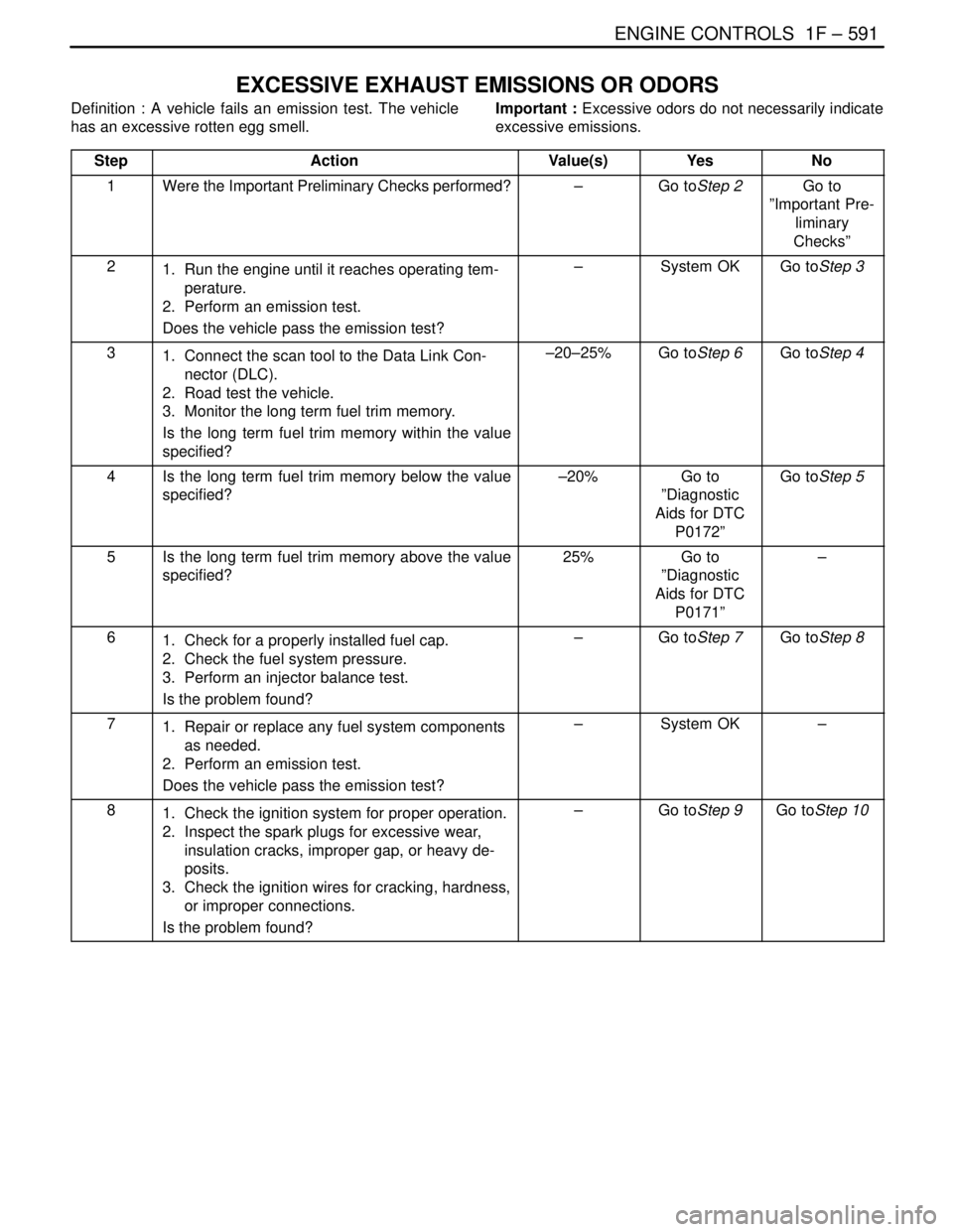

Page 837 of 2643

ENGINE CONTROLS 1F – 591

DAEWOO V–121 BL4

EXCESSIVE EXHAUST EMISSIONS OR ODORS

Definition : A vehicle fails an emission test. The vehicle

has an excessive rotten egg smell.Important : Excessive odors do not necessarily indicate

excessive emissions.

Step

ActionValue(s)YesNo

1Were the Important Preliminary Checks performed?–Go toStep 2Go to

”Important Pre-

liminary

Checks”

21. Run the engine until it reaches operating tem-

perature.

2. Perform an emission test.

Does the vehicle pass the emission test?–System OKGo toStep 3

31. Connect the scan tool to the Data Link Con-

nector (DLC).

2. Road test the vehicle.

3. Monitor the long term fuel trim memory.

Is the long term fuel trim memory within the value

specified?–20–25%Go toStep 6Go toStep 4

4Is the long term fuel trim memory below the value

specified?–20%Go to

”Diagnostic

Aids for DTC

P0172”Go toStep 5

5Is the long term fuel trim memory above the value

specified?25%Go to

”Diagnostic

Aids for DTC

P0171”–

61. Check for a properly installed fuel cap.

2. Check the fuel system pressure.

3. Perform an injector balance test.

Is the problem found?–Go toStep 7Go toStep 8

71. Repair or replace any fuel system components

as needed.

2. Perform an emission test.

Does the vehicle pass the emission test?–System OK–

81. Check the ignition system for proper operation.

2. Inspect the spark plugs for excessive wear,

insulation cracks, improper gap, or heavy de-

posits.

3. Check the ignition wires for cracking, hardness,

or improper connections.

Is the problem found?–Go toStep 9Go toStep 10