fold seats DAEWOO NUBIRA 2004 Service Repair Manual

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: NUBIRA, Model: DAEWOO NUBIRA 2004Pages: 2643, PDF Size: 80.54 MB

Page 2021 of 2643

MANUAL CONTROL HEATING, VENTILATION AND AIR CONDITIONING SYSTEM 7B – 19

DAEWOO V–121 BL4

MAINTENANCE AND REPAIR

ON–VEHICLE SERVICE

GENERAL A/C SYSTEM SERVICE PROCEDURES

O–RING REPLACEMENT

Important : Even though O–rings may look identical, it is

extremely important that only recommended service re-

placement air conditioning O–rings be used or excessive

leakage of refrigerant may occur.

Important : Always slip the O–ring onto the flange tube to

ensure proper locating and sealing.

Install new Daewoo–approved service replacement air

conditioning (A/C) O–rings whenever a joint or a fitting is

disassembled, except when the O–rings are provided on

new components.

When replacing O–rings on an A/C component or a joint

connection, the fitting design should be identified to en-

sure installation of the correct air conditioning service re-

placement O–ring. Some joint connections and compo-

nents will implement a ”captured” O–ring design fitting that

uses a groove to retain the O–ring. Others do not have a

groove and use a ”non–captured” or ”standard” O–ring.

Assembly and tightening procedures are the same for

both designs, but the O–rings are different.

Notice : Before installation, verify that both O–rings and

fittings have not been nicked or deformed. Deformed or

nicked parts must be replaced. Failure to use the proper

service replacement parts and procedures may result in

excessive refrigerant leakage.

HANDLING REFRIGERANT

CAUTION : Always work in a well–ventilated area and

avoid breathing any refrigerant fumes. If you have dif-

ficulty with breathing, seek medical attention immedi-

ately. If refrigerant comes in contact with any part of

your body, flush the exposed area with water. If a rash

or pain develops, seek medical attention.

Air conditioning systems contain refrigerant. This is a

chemical mixture which requires special handling proce-

dures to avoid personal injury.

Always wear goggles and wrap a clean cloth around the

fittings, the valves and the connections when performing

work that involves opening the refrigerant system. Do not

weld or steam clean on or near any vehicle–installed air

conditioning lines or components.

All refrigerant drums are shipped with a heavy metal screw

cap. The purpose of the cap is to protect the valve and the

safety plug from damage. It is good practice to replace the

cap after each use of the drum.If it is necessary to transport or carry any container of re-

frigerant in a vehicle, do not carry it in the passenger

compartment.

HANDLING OF REFRIGERANT LINES

AND FITTINGS

Notice : Using too low or too high torque when tightening

a fitting can result in loose joints or deformed joint parts.

Both conditions can result in refrigerant leakage.

S Keep all metal tubing lines free of dents or kinks.

Any line restrictions will cause the loss of system

capacity.

S Never bend a flexible hose line to a radius of less

than four times the diameter of the hose.

S Never allow a flexible hose line to come within 65

mm (2–1/2 inches) of the exhaust manifold.

S Inspect flexible hose lines regularly for leaks or

brittleness.

S Replace flexible hose lines with new lines if you find

signs of deterioration or leaking.

S Discharge all refrigerant of the refrigeration system

before disconnecting any fitting in the refrigeration

system.

S Proceed very cautiously regardless of the gauge

readings.

CAUTION : Keep your face and your hands away from

the fitting so that you will not be injured if there hap-

pens to be liquid refrigerant in the line.

S Open the fittings very slowly.

S If you notice pressure when you loosen a fitting,

allow the pressure to bleed off as described under

”Discharging, Adding Oil, Evacuating, and Charging

Procedures for A/C System” in this section.

S Cap or tape any refrigerant line immediately after it

is opened. This will prevent the entrance of mois-

ture and dirt, which can cause internal compressor

wear or plugged lines in the condenser, the evapo-

rator core, the expansion valve, or the compressor

inlet screens.

Important : Use two proper wrenches to connect the O–

ring fittings.

S Back up the opposing fitting to prevent distortion of

the connecting lines or the components.

S Back up both the swagged fitting on the flexible

hose connections and the coupling to which it is

attached with two wrenches to prevent turning the

fitting and damaging the ground seat.

S Keep the O–rings and the seats in perfect condi-

tion. A burr or a piece of dirt may cause a refriger-

ant leak.

Page 2204 of 2643

8B – 100ISUPPLEMENTAL INFLATABLE RESTRAINTS (SIR)

DAEWOO V–121 BL4

GENERAL DESCRIPTION

AND SYSTEM OPERATION

SUPPLEMENTAL INFLATABLE

RESTRAINTS(SIR)

The supplemental inflatable restraints(SIR) is a safety de-

vice used in conjunction with the seat belt. The air bag

does not replace the fuction of the seatbelt. The driver and

the passengers must always fasten their seat belts and

adjust them for a proper fit.

The SIR is designed to protect the driver and the front seat

passenger in the event of a significant frontal impact to the

vehicle. The airbags deploy if the force is applied from a

direction within 30 degrees of the vehicle’s center line.

The SIR system consists of a

S Driver airbag module

S Driver side airbag module

S Passenger airbag module

S Passenger side airbag module

S Driver’s and front passenger’s seat belt pretension-

ers(and load limiter for some model).

S Sensing and diagnostic module(SDM)

S Clock spring.

S Wire harness and connectors.

S AIRBAG indicator on the instrument cluster.

S Side airbag sensor

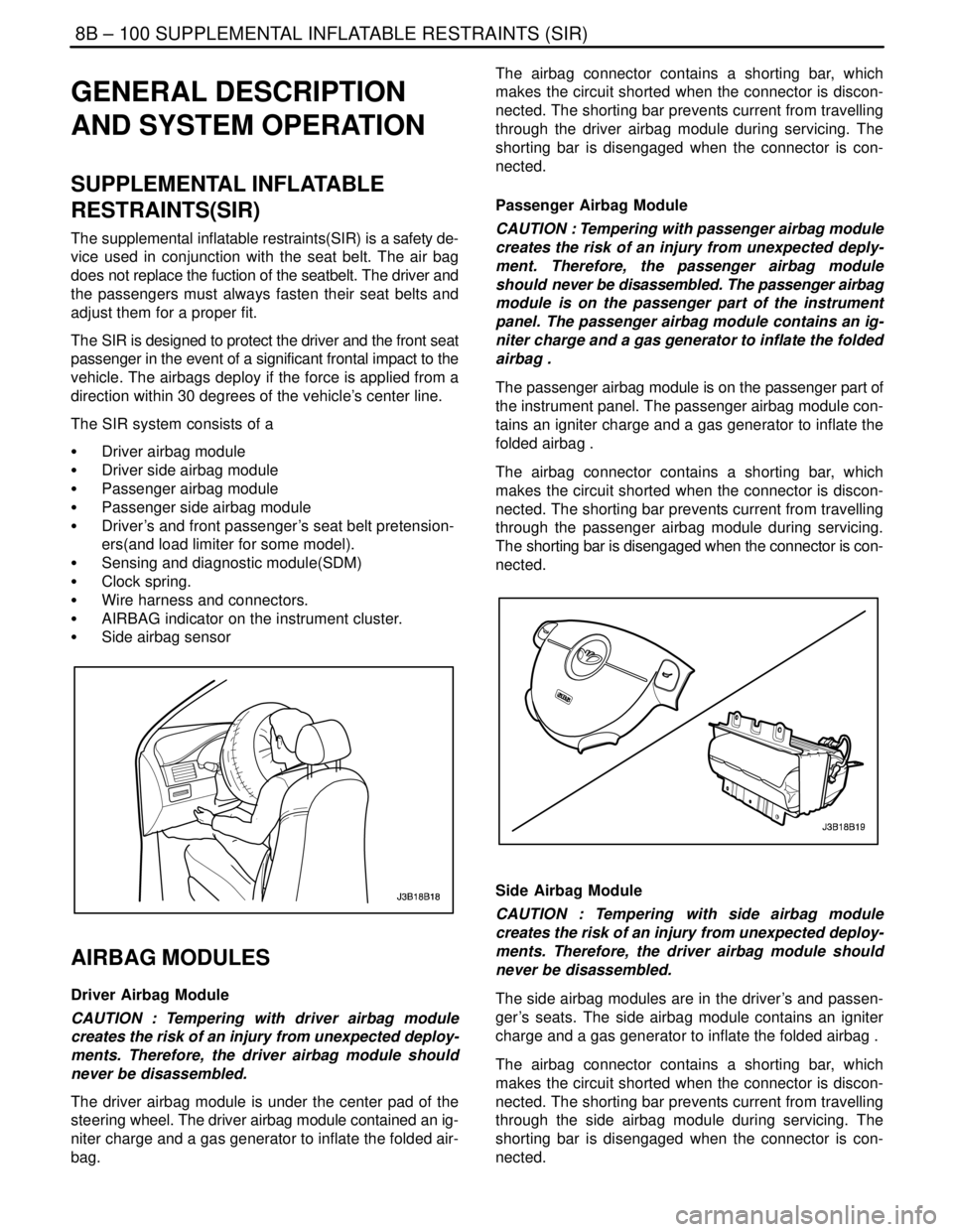

AIRBAG MODULES

Driver Airbag Module

CAUTION : Tempering with driver airbag module

creates the risk of an injury from unexpected deploy-

ments. Therefore, the driver airbag module should

never be disassembled.

The driver airbag module is under the center pad of the

steering wheel. The driver airbag module contained an ig-

niter charge and a gas generator to inflate the folded air-

bag.The airbag connector contains a shorting bar, which

makes the circuit shorted when the connector is discon-

nected. The shorting bar prevents current from travelling

through the driver airbag module during servicing. The

shorting bar is disengaged when the connector is con-

nected.

Passenger Airbag Module

CAUTION : Tempering with passenger airbag module

creates the risk of an injury from unexpected deply-

ment. Therefore, the passenger airbag module

should never be disassembled. The passenger airbag

module is on the passenger part of the instrument

panel. The passenger airbag module contains an ig-

niter charge and a gas generator to inflate the folded

airbag .

The passenger airbag module is on the passenger part of

the instrument panel. The passenger airbag module con-

tains an igniter charge and a gas generator to inflate the

folded airbag .

The airbag connector contains a shorting bar, which

makes the circuit shorted when the connector is discon-

nected. The shorting bar prevents current from travelling

through the passenger airbag module during servicing.

The shorting bar is disengaged when the connector is con-

nected.

Side Airbag Module

CAUTION : Tempering with side airbag module

creates the risk of an injury from unexpected deploy-

ments. Therefore, the driver airbag module should

never be disassembled.

The side airbag modules are in the driver’s and passen-

ger’s seats. The side airbag module contains an igniter

charge and a gas generator to inflate the folded airbag .

The airbag connector contains a shorting bar, which

makes the circuit shorted when the connector is discon-

nected. The shorting bar prevents current from travelling

through the side airbag module during servicing. The

shorting bar is disengaged when the connector is con-

nected.

Page 2368 of 2643

9H – 12ISEATS

DAEWOO V–121 BL4

GENERAL DESCRIPTION

AND SYSTEM OPERATION

SEATS

Do not attempt to change the designed seat position by al-

tering the designed seat adjuster–to–floor pan anchor pro-

visions or the seat adjuster–to–seat frame anchor provi-

sions. Changing the seat position could affect the

performance of the seat system.This vehicle is equipped with front bucket seats with sepa-

rate, adjustable head restraints, and a three–passenger

rear bench seat with an optional split folding rear seat. The

front bucket seats also have a recline, a height, and a lum-

bar adjustment. A power driver seat is optional. Seat cush-

ions and seatbacks have formed foam pads, which fit the

contours of the full panel seatback frame assembly and

the designed contour of the seat cushion frame.