Break DAEWOO NUBIRA 2004 Service Repair Manual

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: NUBIRA, Model: DAEWOO NUBIRA 2004Pages: 2643, PDF Size: 80.54 MB

Page 231 of 2643

ENGINE ELECTRICAL 1E – 17

DAEWOO V–121 BL4

UNIT REPAIR

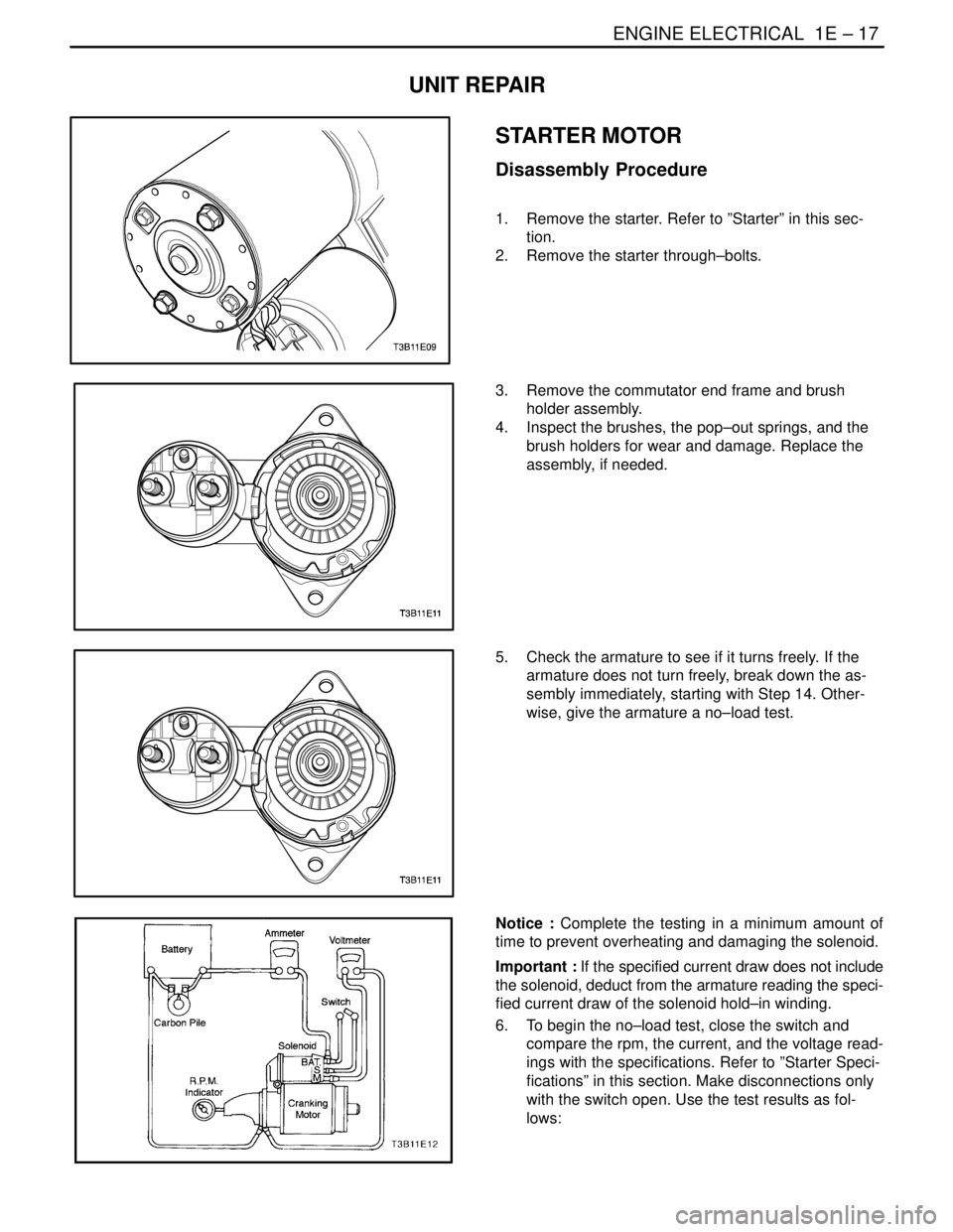

STARTER MOTOR

Disassembly Procedure

1. Remove the starter. Refer to ”Starter” in this sec-

tion.

2. Remove the starter through–bolts.

3. Remove the commutator end frame and brush

holder assembly.

4. Inspect the brushes, the pop–out springs, and the

brush holders for wear and damage. Replace the

assembly, if needed.

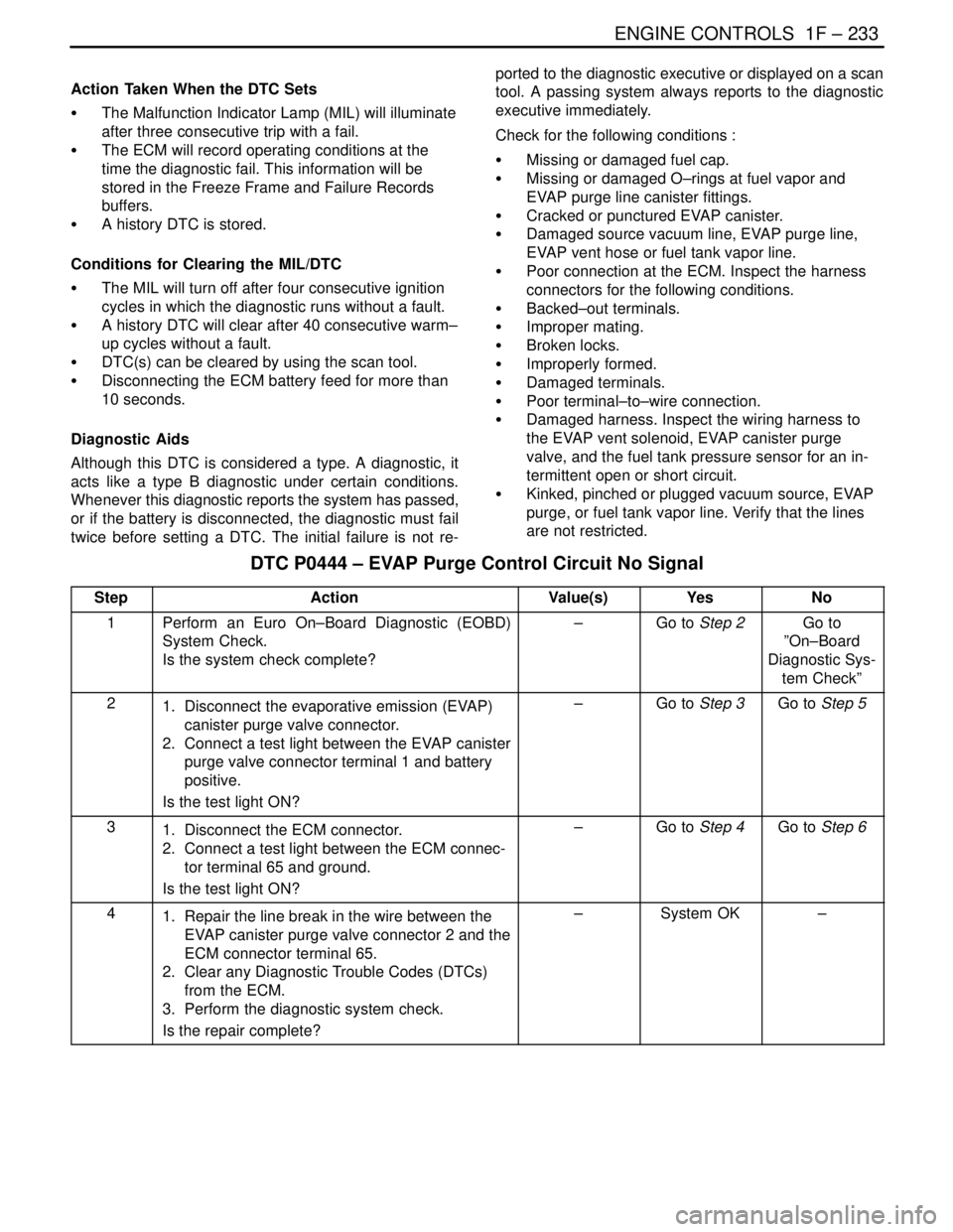

5. Check the armature to see if it turns freely. If the

armature does not turn freely, break down the as-

sembly immediately, starting with Step 14. Other-

wise, give the armature a no–load test.

Notice : Complete the testing in a minimum amount of

time to prevent overheating and damaging the solenoid.

Important : If the specified current draw does not include

the solenoid, deduct from the armature reading the speci-

fied current draw of the solenoid hold–in winding.

6. To begin the no–load test, close the switch and

compare the rpm, the current, and the voltage read-

ings with the specifications. Refer to ”Starter Speci-

fications” in this section. Make disconnections only

with the switch open. Use the test results as fol-

lows:

Page 479 of 2643

ENGINE CONTROLS 1F – 233

DAEWOO V–121 BL4

Action Taken When the DTC Sets

S The Malfunction Indicator Lamp (MIL) will illuminate

after three consecutive trip with a fail.

S The ECM will record operating conditions at the

time the diagnostic fail. This information will be

stored in the Freeze Frame and Failure Records

buffers.

S A history DTC is stored.

Conditions for Clearing the MIL/DTC

S The MIL will turn off after four consecutive ignition

cycles in which the diagnostic runs without a fault.

S A history DTC will clear after 40 consecutive warm–

up cycles without a fault.

S DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for more than

10 seconds.

Diagnostic Aids

Although this DTC is considered a type. A diagnostic, it

acts like a type B diagnostic under certain conditions.

Whenever this diagnostic reports the system has passed,

or if the battery is disconnected, the diagnostic must fail

twice before setting a DTC. The initial failure is not re-ported to the diagnostic executive or displayed on a scan

tool. A passing system always reports to the diagnostic

executive immediately.

Check for the following conditions :

S Missing or damaged fuel cap.

S Missing or damaged O–rings at fuel vapor and

EVAP purge line canister fittings.

S Cracked or punctured EVAP canister.

S Damaged source vacuum line, EVAP purge line,

EVAP vent hose or fuel tank vapor line.

S Poor connection at the ECM. Inspect the harness

connectors for the following conditions.

S Backed–out terminals.

S Improper mating.

S Broken locks.

S Improperly formed.

S Damaged terminals.

S Poor terminal–to–wire connection.

S Damaged harness. Inspect the wiring harness to

the EVAP vent solenoid, EVAP canister purge

valve, and the fuel tank pressure sensor for an in-

termittent open or short circuit.

S Kinked, pinched or plugged vacuum source, EVAP

purge, or fuel tank vapor line. Verify that the lines

are not restricted.

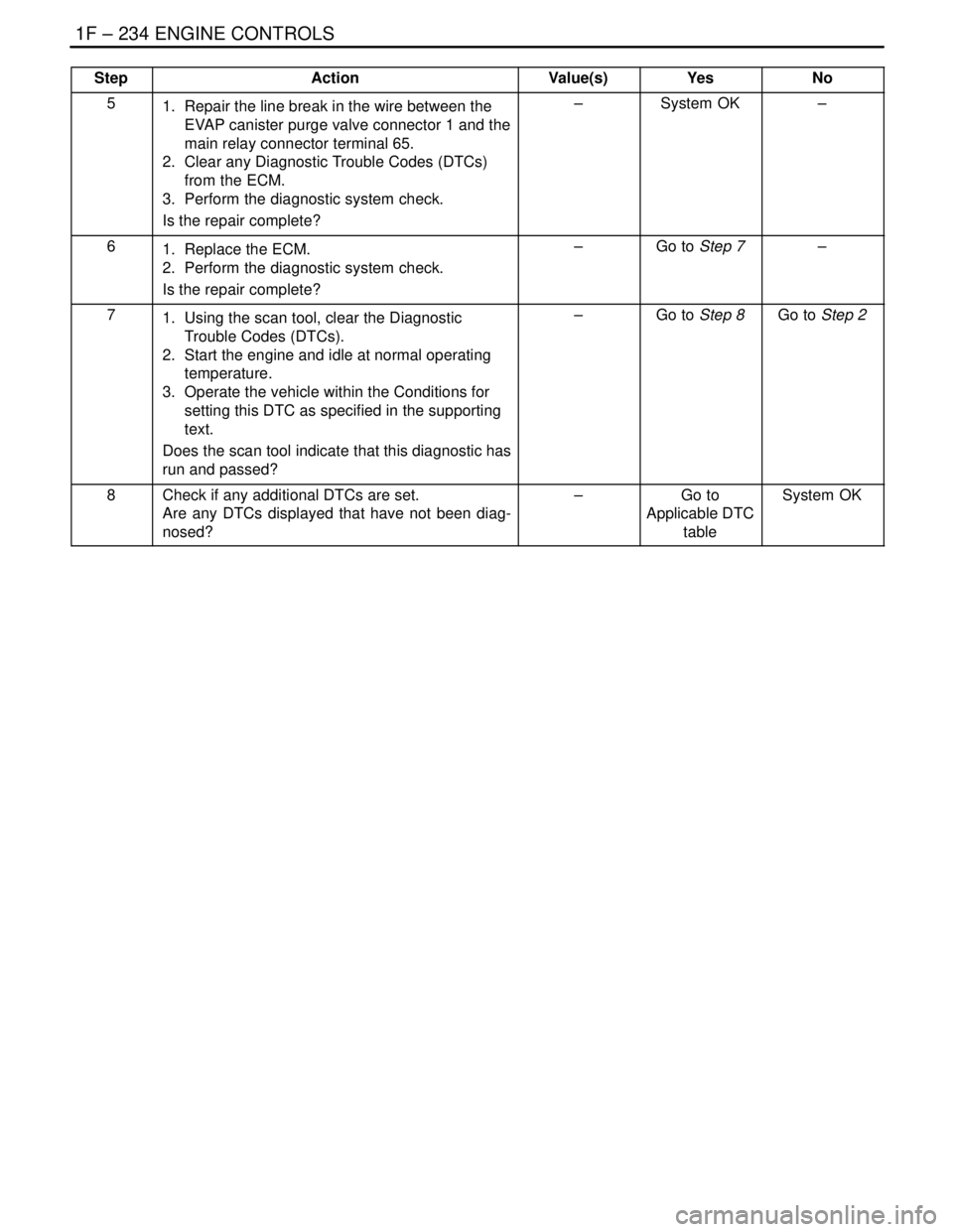

DTC P0444 – EVAP Purge Control Circuit No Signal

StepActionValue(s)YesNo

1Perform an Euro On–Board Diagnostic (EOBD)

System Check.

Is the system check complete?–Go to Step 2Go to

”On–Board

Diagnostic Sys-

tem Check”

21. Disconnect the evaporative emission (EVAP)

canister purge valve connector.

2. Connect a test light between the EVAP canister

purge valve connector terminal 1 and battery

positive.

Is the test light ON?–Go to Step 3Go to Step 5

31. Disconnect the ECM connector.

2. Connect a test light between the ECM connec-

tor terminal 65 and ground.

Is the test light ON?–Go to Step 4Go to Step 6

41. Repair the line break in the wire between the

EVAP canister purge valve connector 2 and the

ECM connector terminal 65.

2. Clear any Diagnostic Trouble Codes (DTCs)

from the ECM.

3. Perform the diagnostic system check.

Is the repair complete?–System OK–

Page 480 of 2643

1F – 234IENGINE CONTROLS

DAEWOO V–121 BL4

StepNo Yes Value(s) Action

51. Repair the line break in the wire between the

EVAP canister purge valve connector 1 and the

main relay connector terminal 65.

2. Clear any Diagnostic Trouble Codes (DTCs)

from the ECM.

3. Perform the diagnostic system check.

Is the repair complete?–System OK–

61. Replace the ECM.

2. Perform the diagnostic system check.

Is the repair complete?–Go to Step 7–

71. Using the scan tool, clear the Diagnostic

Trouble Codes (DTCs).

2. Start the engine and idle at normal operating

temperature.

3. Operate the vehicle within the Conditions for

setting this DTC as specified in the supporting

text.

Does the scan tool indicate that this diagnostic has

run and passed?–Go to Step 8Go to Step 2

8Check if any additional DTCs are set.

Are any DTCs displayed that have not been diag-

nosed?–Go to

Applicable DTC

tableSystem OK

Page 967 of 2643

TIRES AND WHEELS 2E – 5

DAEWOO V–121 BL4

UNIT REPAIR

ALLOY WHEEL POROSITY

Wheel repairs that use welding, heating or peening are not

approved.

1. Raise and suitably support the vehicle.

2. Remove the wheel. Refer to ”Wheel” in this sec-

tion.

CAUTION : To avoid serious injury, do not stand over

the tire when inflating, because the bead may break

when it snaps over the safety hump. Do not exceed

275 kPa (40 psi) of air pressure in any tire if the beads

are not seated. If 275 kPa (40 psi) of air pressure will

not seat the beads, deflate the tire. Relubricate the

beads. Reinflate the tire. Overinflation may cause the

bead to break and cause serious injury.

3. Locate leaking areas by inflating the tire to 345 kPa

(50 psi) and dipping the tire and wheel assembly

into a water bath.

4. Mark the leak areas and remove the tire from the

wheel.

5. Scuff the inside wheel surface at the leak area with

80–grit sandpaper. Clean the leak area with a gen-

eral–purpose cleaner.

6. Apply a 3.3 mm (0.13 inch) thick layer of adhesive/

sealant to the leak area. Allow it to dry for 12 hours.

7. Install the tire on the wheel. Inflate the tire to 345

kPa (50 psi) and check for leaks as in step 3.

8. Adjust the tire pressure to meet specifications. Re-

fer to ”Tire Size and Pressure Specifications” in

this section.

9. Balance the wheel. Refer to ”Tire and Wheel Bal-

ancing” in this section.

10. Install the wheel. Refer to ”Wheel” in this section.

11. Lower the vehicle.

ALLOY WHEEL REFINISHING

A protective clear or color coating is applied to the surface

of the original equipment cast alloy wheels. Surface deg-

radation can develop if this clear coating is damaged or re-

moved. This can happen at some automatic car wash fa-

cilities that use silicon carbide–tipped tire brushes to clean

white walls and tires. Once the protective coating is dam-

aged, exposure to caustic cleaners or road salt causes fur-

ther surface degradation. The following procedure details

how to strip, clean and recoat alloy wheels.

CAUTION : To avoid serious personal injury, follow

the manufacturer’s recommendations and cautions

when using these materials.

Required materials:

S Amchem Alumi Prep No. 33. Stock No. DX533 or

equivalent cleaning and conditioning chemical for

alloys.

Page 970 of 2643

2E – 8ITIRES AND WHEELS

DAEWOO V–121 BL4

TIRE AND WHEEL

MATCH–MOUNTING

The tires and wheels are match–mounted at the assembly

plant. Match–mounting aligns the radially stiffest part of

the tire, or high spot, to the smallest radius, or low spot, of

the wheel.

The high spot of the tire is originally marked by a red paint

mark or an adhesive label on the outboard sidewall.

The low spot of the wheel will be at the location of the valve

stem.

Before dismounting a tire from its wheel, scribe a line on

the tire at the valve stem to assure that it is remounted in

the same position.

Replacement tires that are of original equipment quality

will have their high and low spot marked in the same man-

ner.

TIRE MOUNTING AND DISMOUNTING

Notice : Use a tire–changing machine to mount or dis-

mount the tires. Follow the equipment manufacturer’s in-

structions. Do not use hand tools or tire irons to change

tires. These tools may damage the beads or the wheel rim.

1. Clean the rim bead seats with a wire brush or

coarse steel wool to remove lubricants, old rubber,

and light rust. Before mounting or dismounting a

tire, lubricate the bead area well with an approved

tire lubricant.

CAUTION : To avoid serious injury, do not stand over

the tire when inflating it, because the bead may break

when it snaps over the safety hump. Do not exceed

275 kPa (40 psi) of air pressure in any tire if the beads

are not seated. If 275 kPa (40 psi) of air pressure will

not seat the beads, deflate the tire. Relubricate the

bead and reinflate the tire. Overinflation may cause

the bead to break and cause serious injury.

2. fter mounting the tire, inflate it until the beads are

seated. Never exceed 275 kPa (40 psi) to seat the

beads.

3. Install the valve core and inflate the tire to the prop-

er pressure. Make sure the locating ring outside of

the bead of the tire shows around the rim flanges of

the wheel on both sides. This positioning of the tire

will insure that the bead of the tire is seated.

Page 973 of 2643

TIRES AND WHEELS 2E – 11

DAEWOO V–121 BL4

pacity, diameter, rim width, offset, and mounting configu-

ration. A wheel of improper size or type may affect wheel

and bearing life, brake cooling, speedometer/odometer

calibration, vehicle ground clearance, and tire clearance

to the body and the chassis. The wheel offset is 49 ± 1 mm

(1.93 ± 0.04 inches). Steel wheels may be identified by a

two– or three–letter code stamped into the rim near the

valve stem. Alloy wheels should have the code, the part

number, and the manufacturer ID cast into the back side.

INFLATION O TIRES

The pressure recommended for any vehicle line is careful-

ly calculated to give a satisfactory ride, handling, tread life,

and load–carrying capacity.

Tire pressure should be checked monthly or before any

extended trip. Check the tires when they are cold, after the

vehicle has sat for 3 hours or more, or has been driven less

than 1 mile. Set the tire pressure to the specifications on

the tire label located on the rear face of the driver’s door.

Tire inflation pressure is also given under ”Tire Size and

Pressure Specifications” in this section.

Valve caps or extensions should be on the valves to keep

dust and water out.

For sustained driving at speeds up to 140 km/h (85 mph),

inflate the tires to the pressure recommended on the tire.

Sustained driving at speeds faster than 140 km/h (85mph), even if permitted by law, is not advised unless the

vehicle has special high–speed tires available from many

tire dealers. Tire pressures may increase as much as 41

kPa (6 psi) when the tires are hot.

Higher than recommended tire pressure can cause

S Hard ride.

S Tire bruising or damage.

S Rapid tread wear at the center of the tire.

Lower than recommended pressure can cause

S Tire squeal on turns.

S Hard steering.

S Rapid and uneven wear on the edges of the tread.

S Tire rim bruises and rupture.

S Tire cord breakage.

S High tire temperatures.

Unequal tire pressures on same axle can cause

S Uneven braking.

S Steering lead.

S Reduced handling.

S Swerve on acceleration.

S Torque steer.

Page 1144 of 2643

ANTILOCK BRAKE SYSTEM 4F – 63

DAEWOO V–121 BL4

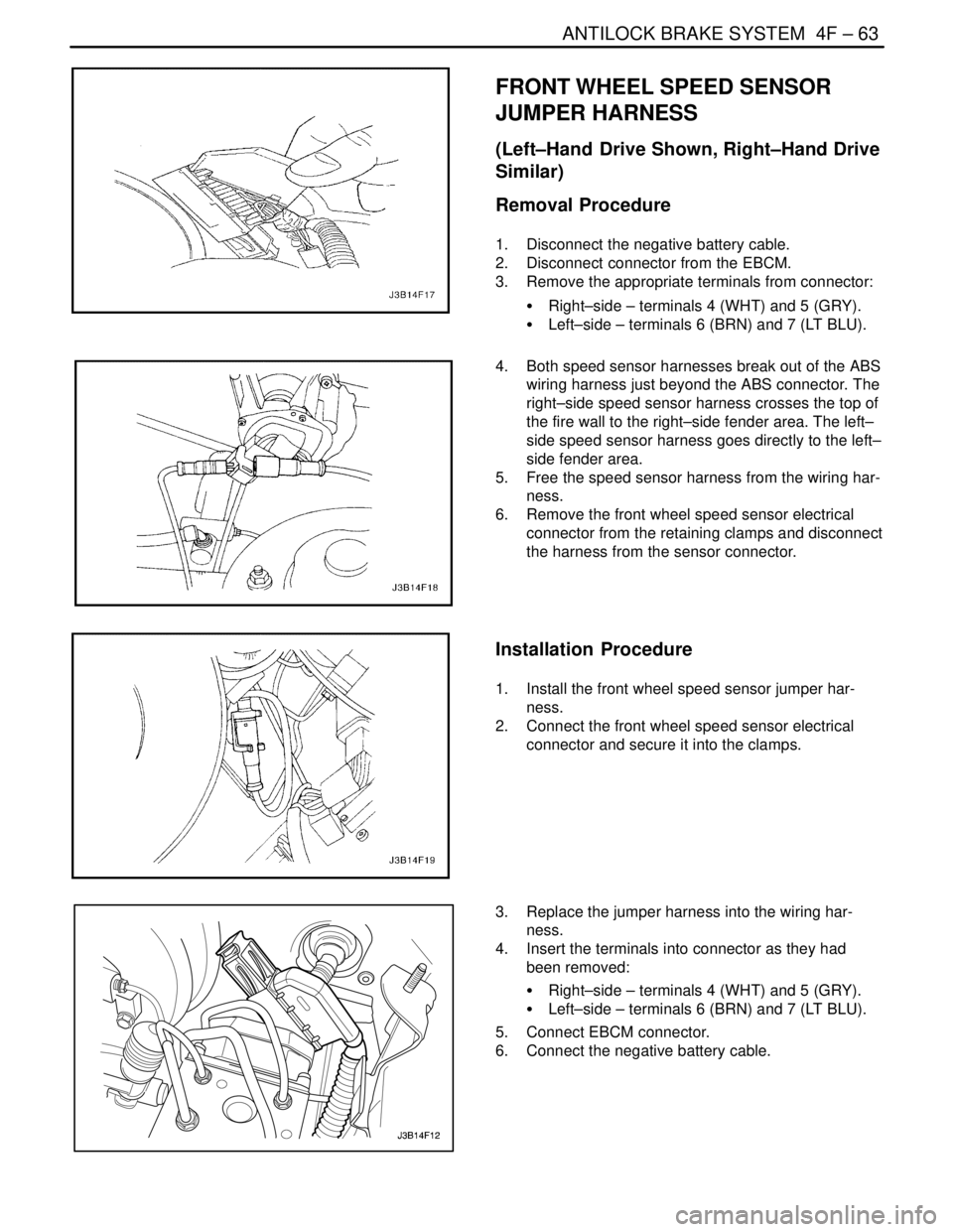

FRONT WHEEL SPEED SENSOR

JUMPER HARNESS

(Left–Hand Drive Shown, Right–Hand Drive

Similar)

Removal Procedure

1. Disconnect the negative battery cable.

2. Disconnect connector from the EBCM.

3. Remove the appropriate terminals from connector:

S Right–side – terminals 4 (WHT) and 5 (GRY).

S Left–side – terminals 6 (BRN) and 7 (LT BLU).

4. Both speed sensor harnesses break out of the ABS

wiring harness just beyond the ABS connector. The

right–side speed sensor harness crosses the top of

the fire wall to the right–side fender area. The left–

side speed sensor harness goes directly to the left–

side fender area.

5. Free the speed sensor harness from the wiring har-

ness.

6. Remove the front wheel speed sensor electrical

connector from the retaining clamps and disconnect

the harness from the sensor connector.

Installation Procedure

1. Install the front wheel speed sensor jumper har-

ness.

2. Connect the front wheel speed sensor electrical

connector and secure it into the clamps.

3. Replace the jumper harness into the wiring har-

ness.

4. Insert the terminals into connector as they had

been removed:

S Right–side – terminals 4 (WHT) and 5 (GRY).

S Left–side – terminals 6 (BRN) and 7 (LT BLU).

5. Connect EBCM connector.

6. Connect the negative battery cable.

Page 1150 of 2643

ANTILOCK BRAKE SYSTEM 4F – 69

DAEWOO V–121 BL4

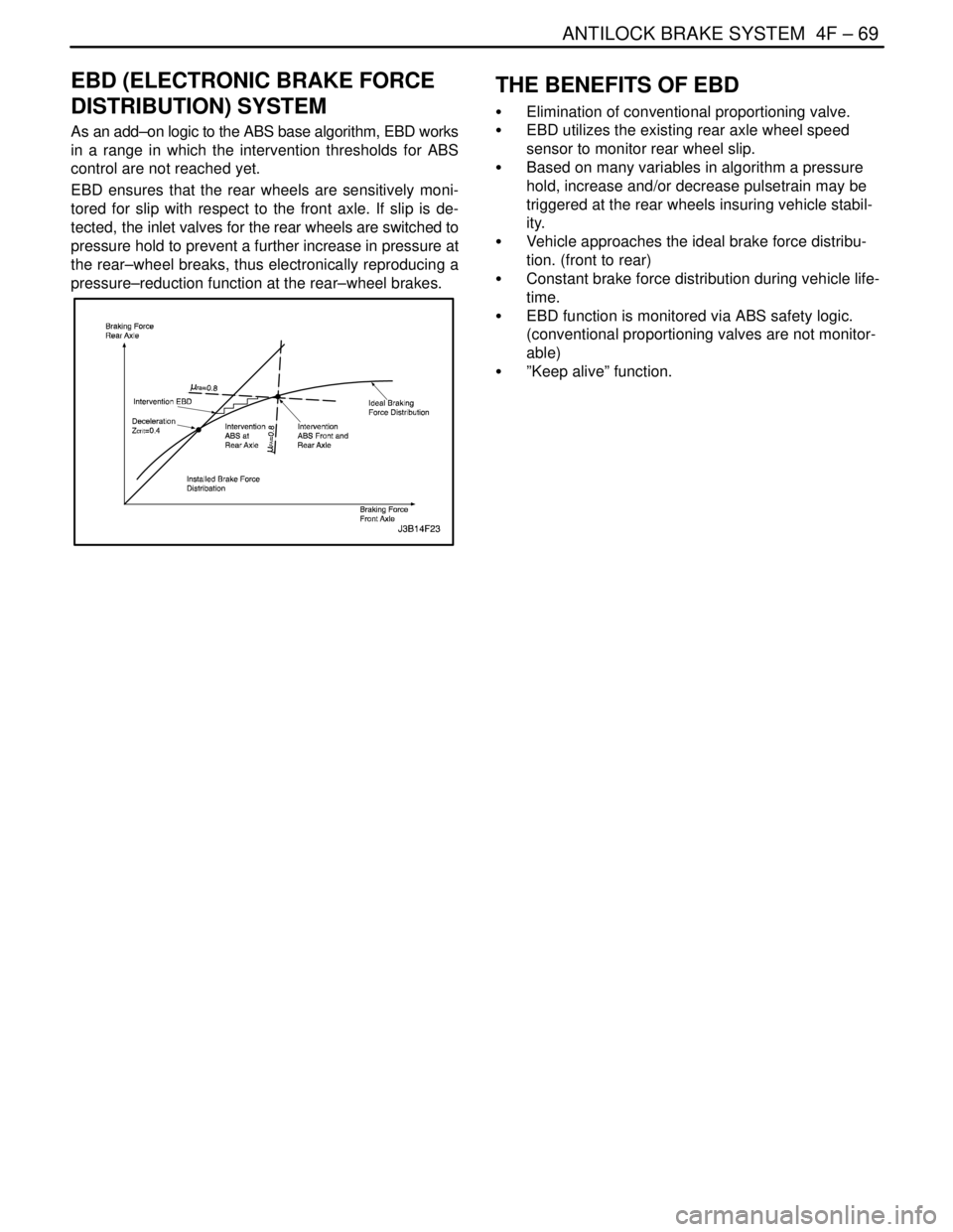

EBD (ELECTRONIC BRAKE FORCE

DISTRIBUTION) SYSTEM

As an add–on logic to the ABS base algorithm, EBD works

in a range in which the intervention thresholds for ABS

control are not reached yet.

EBD ensures that the rear wheels are sensitively moni-

tored for slip with respect to the front axle. If slip is de-

tected, the inlet valves for the rear wheels are switched to

pressure hold to prevent a further increase in pressure at

the rear–wheel breaks, thus electronically reproducing a

pressure–reduction function at the rear–wheel brakes.

THE BENEFITS OF EBD

S Elimination of conventional proportioning valve.

S EBD utilizes the existing rear axle wheel speed

sensor to monitor rear wheel slip.

S Based on many variables in algorithm a pressure

hold, increase and/or decrease pulsetrain may be

triggered at the rear wheels insuring vehicle stabil-

ity.

S Vehicle approaches the ideal brake force distribu-

tion. (front to rear)

S Constant brake force distribution during vehicle life-

time.

S EBD function is monitored via ABS safety logic.

(conventional proportioning valves are not monitor-

able)

S ”Keep alive” function.

Page 2041 of 2643

MANUAL CONTROL HEATING, VENTILATION AND AIR CONDITIONING SYSTEM 7B – 39

DAEWOO V–121 BL4

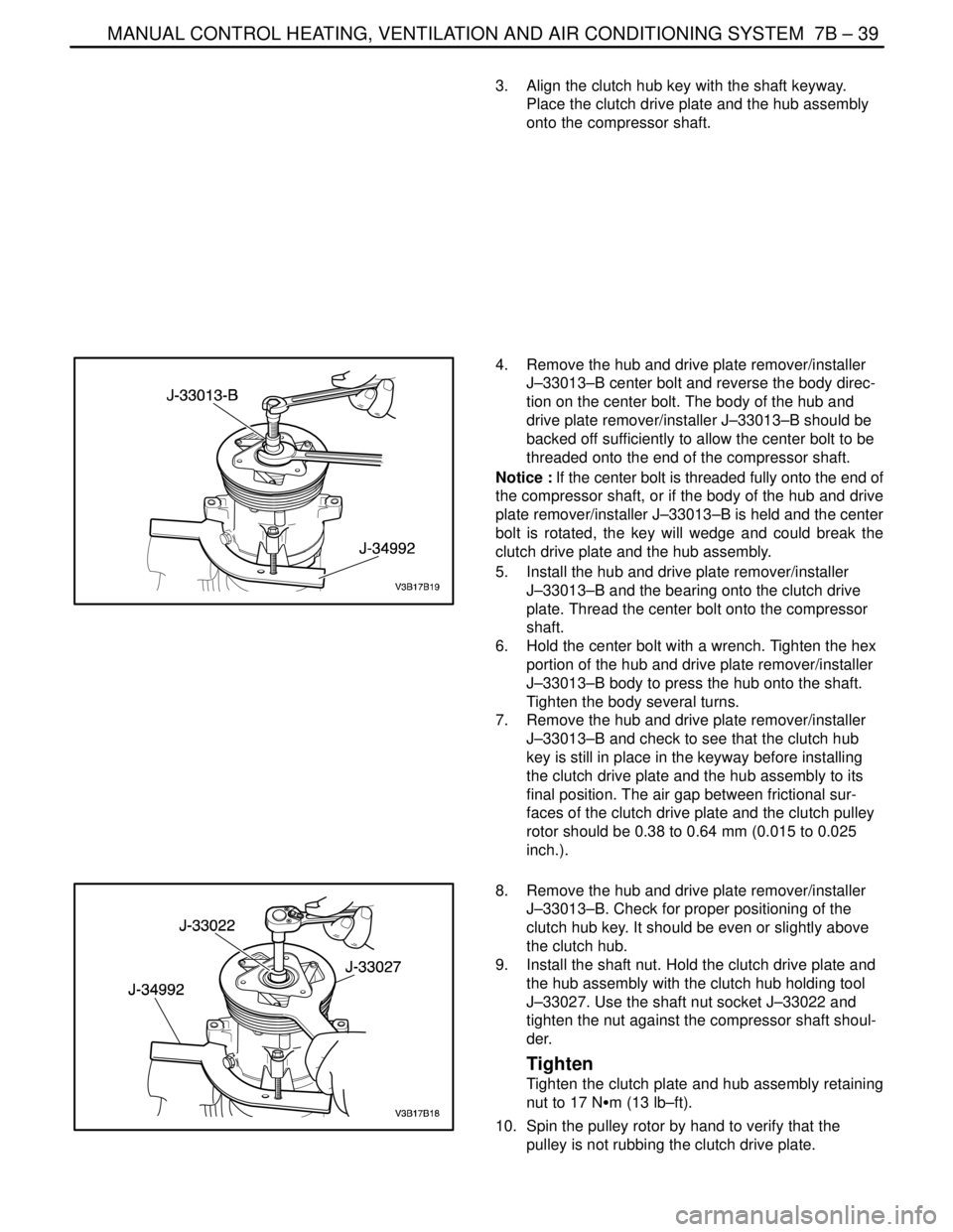

3. Align the clutch hub key with the shaft keyway.

Place the clutch drive plate and the hub assembly

onto the compressor shaft.

4. Remove the hub and drive plate remover/installer

J–33013–B center bolt and reverse the body direc-

tion on the center bolt. The body of the hub and

drive plate remover/installer J–33013–B should be

backed off sufficiently to allow the center bolt to be

threaded onto the end of the compressor shaft.

Notice : If the center bolt is threaded fully onto the end of

the compressor shaft, or if the body of the hub and drive

plate remover/installer J–33013–B is held and the center

bolt is rotated, the key will wedge and could break the

clutch drive plate and the hub assembly.

5. Install the hub and drive plate remover/installer

J–33013–B and the bearing onto the clutch drive

plate. Thread the center bolt onto the compressor

shaft.

6. Hold the center bolt with a wrench. Tighten the hex

portion of the hub and drive plate remover/installer

J–33013–B body to press the hub onto the shaft.

Tighten the body several turns.

7. Remove the hub and drive plate remover/installer

J–33013–B and check to see that the clutch hub

key is still in place in the keyway before installing

the clutch drive plate and the hub assembly to its

final position. The air gap between frictional sur-

faces of the clutch drive plate and the clutch pulley

rotor should be 0.38 to 0.64 mm (0.015 to 0.025

inch.).

8. Remove the hub and drive plate remover/installer

J–33013–B. Check for proper positioning of the

clutch hub key. It should be even or slightly above

the clutch hub.

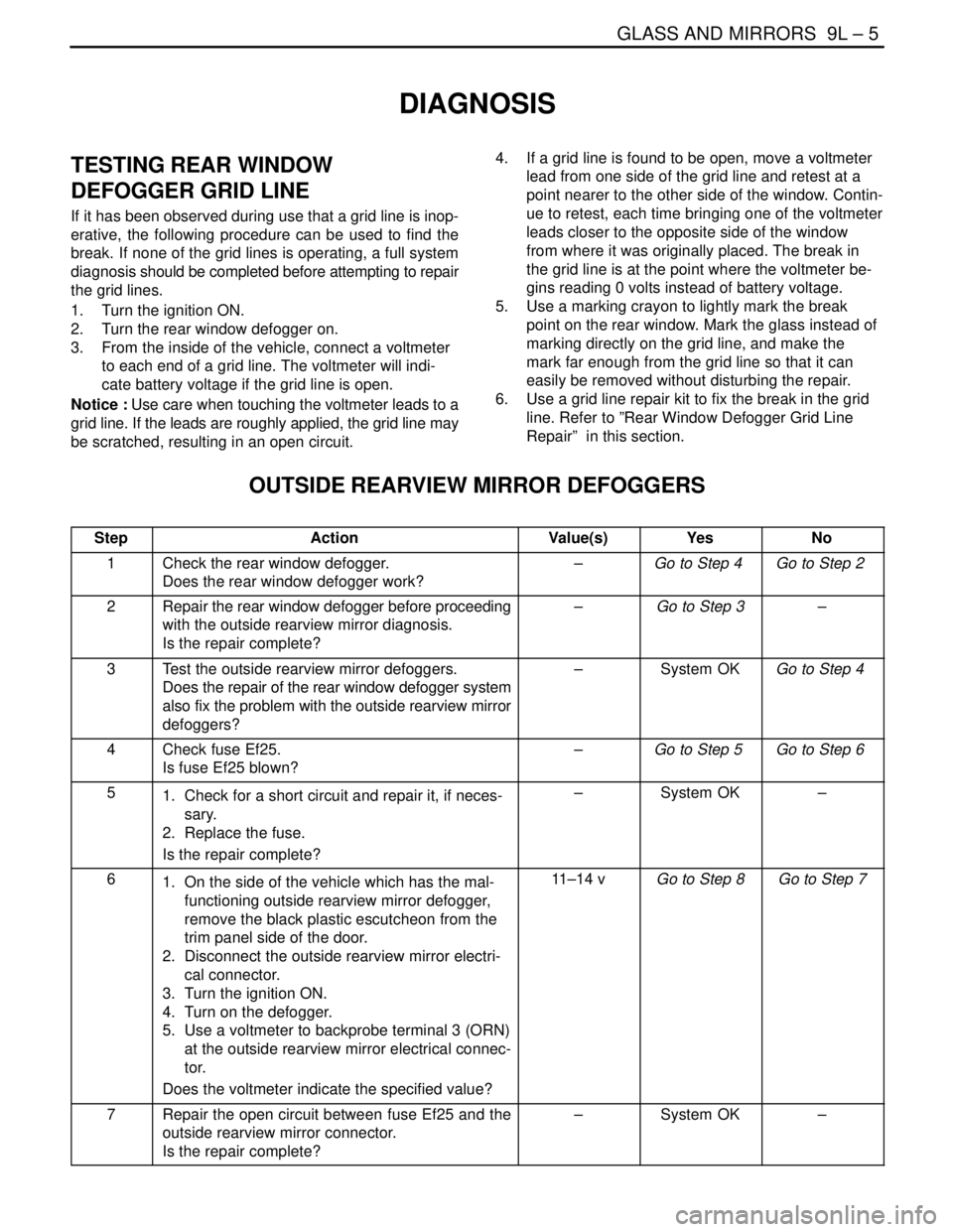

9. Install the shaft nut. Hold the clutch drive plate and

the hub assembly with the clutch hub holding tool

J–33027. Use the shaft nut socket J–33022 and

tighten the nut against the compressor shaft shoul-

der.

Tighten

Tighten the clutch plate and hub assembly retaining

nut to 17 NSm (13 lb–ft).

10. Spin the pulley rotor by hand to verify that the

pulley is not rubbing the clutch drive plate.

Page 2384 of 2643

GLASS AND MIRRORS 9L – 5

DAEWOO V–121 BL4

DIAGNOSIS

TESTING REAR WINDOW

DEFOGGER GRID LINE

If it has been observed during use that a grid line is inop-

erative, the following procedure can be used to find the

break. If none of the grid lines is operating, a full system

diagnosis should be completed before attempting to repair

the grid lines.

1. Turn the ignition ON.

2. Turn the rear window defogger on.

3. From the inside of the vehicle, connect a voltmeter

to each end of a grid line. The voltmeter will indi-

cate battery voltage if the grid line is open.

Notice : Use care when touching the voltmeter leads to a

grid line. If the leads are roughly applied, the grid line may

be scratched, resulting in an open circuit.4. If a grid line is found to be open, move a voltmeter

lead from one side of the grid line and retest at a

point nearer to the other side of the window. Contin-

ue to retest, each time bringing one of the voltmeter

leads closer to the opposite side of the window

from where it was originally placed. The break in

the grid line is at the point where the voltmeter be-

gins reading 0 volts instead of battery voltage.

5. Use a marking crayon to lightly mark the break

point on the rear window. Mark the glass instead of

marking directly on the grid line, and make the

mark far enough from the grid line so that it can

easily be removed without disturbing the repair.

6. Use a grid line repair kit to fix the break in the grid

line. Refer to ”Rear Window Defogger Grid Line

Repair” in this section.

OUTSIDE REARVIEW MIRROR DEFOGGERS

StepActionValue(s)YesNo

1Check the rear window defogger.

Does the rear window defogger work?–Go to Step 4 Go to Step 2

2Repair the rear window defogger before proceeding

with the outside rearview mirror diagnosis.

Is the repair complete?–Go to Step 3–

3Test the outside rearview mirror defoggers.

Does the repair of the rear window defogger system

also fix the problem with the outside rearview mirror

defoggers?–System OKGo to Step 4

4Check fuse Ef25.

Is fuse Ef25 blown?–Go to Step 5 Go to Step 6

51. Check for a short circuit and repair it, if neces-

sary.

2. Replace the fuse.

Is the repair complete?–System OK–

61. On the side of the vehicle which has the mal-

functioning outside rearview mirror defogger,

remove the black plastic escutcheon from the

trim panel side of the door.

2. Disconnect the outside rearview mirror electri-

cal connector.

3. Turn the ignition ON.

4. Turn on the defogger.

5. Use a voltmeter to backprobe terminal 3 (ORN)

at the outside rearview mirror electrical connec-

tor.

Does the voltmeter indicate the specified value?11–14 v Go to Step 8 Go to Step 7

7Repair the open circuit between fuse Ef25 and the

outside rearview mirror connector.

Is the repair complete?–System OK–