camshaft sensor DAEWOO NUBIRA 2004 Service Repair Manual

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: NUBIRA, Model: DAEWOO NUBIRA 2004Pages: 2643, PDF Size: 80.54 MB

Page 48 of 2643

1.4L/1.6L DOHC ENGINE MECHANICAL 1C1 – 5

DAEWOO V–121 BL4

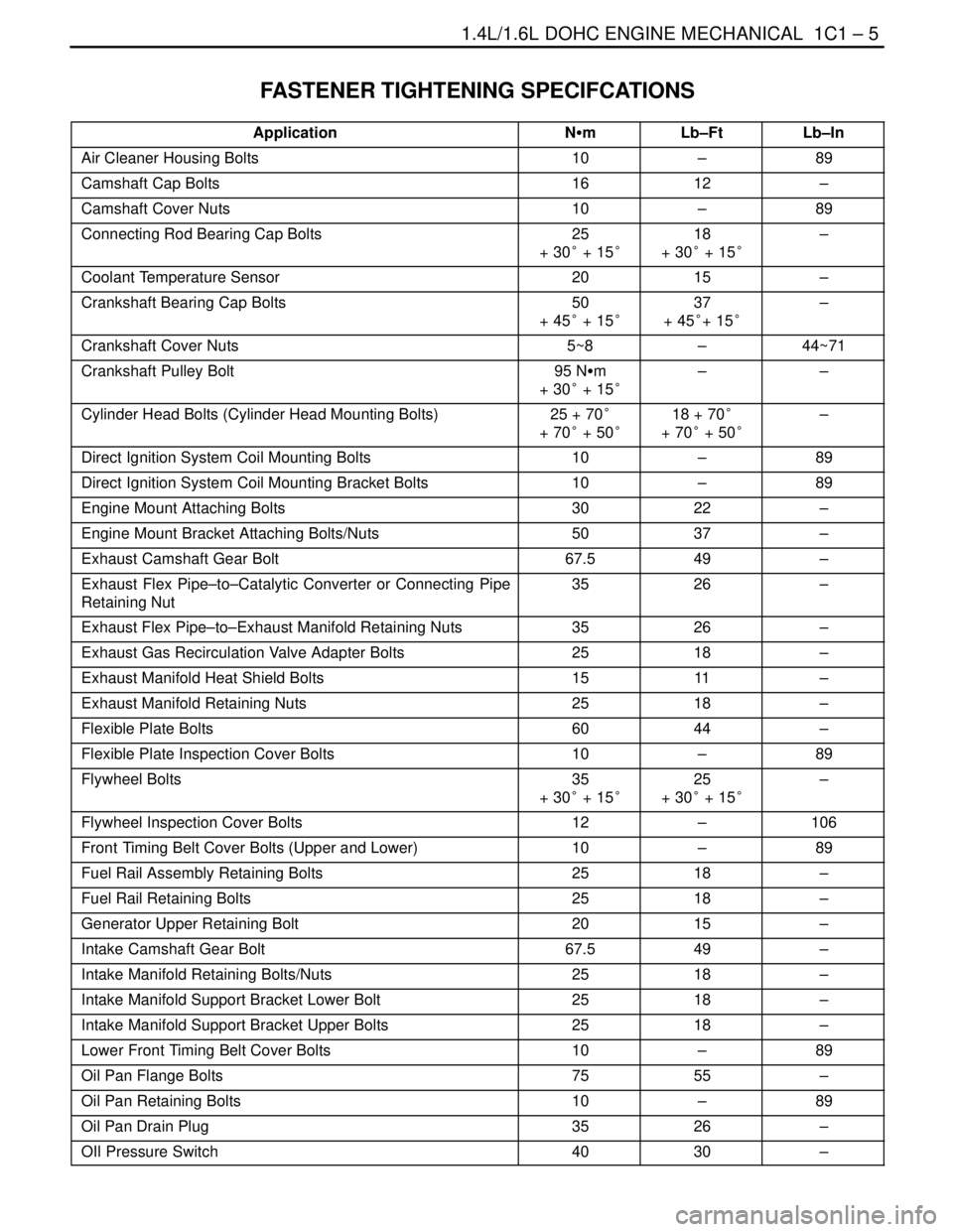

FASTENER TIGHTENING SPECIFCATIONS

ApplicationNSmLb–FtLb–In

Air Cleaner Housing Bolts10–89

Camshaft Cap Bolts1612–

Camshaft Cover Nuts10–89

Connecting Rod Bearing Cap Bolts25

+ 30° + 15°18

+ 30° + 15°–

Coolant Temperature Sensor2015–

Crankshaft Bearing Cap Bolts50

+ 45° + 15°37

+ 45°+ 15°–

Crankshaft Cover Nuts5~8–44~71

Crankshaft Pulley Bolt95 NSm

+ 30° + 15°––

Cylinder Head Bolts (Cylinder Head Mounting Bolts)25 + 70°

+ 70° + 50°18 + 70°

+ 70° + 50°–

Direct Ignition System Coil Mounting Bolts10–89

Direct Ignition System Coil Mounting Bracket Bolts10–89

Engine Mount Attaching Bolts3022–

Engine Mount Bracket Attaching Bolts/Nuts5037–

Exhaust Camshaft Gear Bolt67.549–

Exhaust Flex Pipe–to–Catalytic Converter or Connecting Pipe

Retaining Nut3526–

Exhaust Flex Pipe–to–Exhaust Manifold Retaining Nuts3526–

Exhaust Gas Recirculation Valve Adapter Bolts2518–

Exhaust Manifold Heat Shield Bolts1511–

Exhaust Manifold Retaining Nuts2518–

Flexible Plate Bolts6044–

Flexible Plate Inspection Cover Bolts10–89

Flywheel Bolts35

+ 30° + 15°25

+ 30° + 15°–

Flywheel Inspection Cover Bolts12–106

Front Timing Belt Cover Bolts (Upper and Lower)10–89

Fuel Rail Assembly Retaining Bolts2518–

Fuel Rail Retaining Bolts2518–

Generator Upper Retaining Bolt2015–

Intake Camshaft Gear Bolt67.549–

Intake Manifold Retaining Bolts/Nuts2518–

Intake Manifold Support Bracket Lower Bolt2518–

Intake Manifold Support Bracket Upper Bolts2518–

Lower Front Timing Belt Cover Bolts10–89

Oil Pan Flange Bolts7555–

Oil Pan Retaining Bolts10–89

Oil Pan Drain Plug3526–

OIl Pressure Switch4030–

Page 52 of 2643

1.4L/1.6L DOHC ENGINE MECHANICAL 1C1 – 9

DAEWOO V–121 BL4

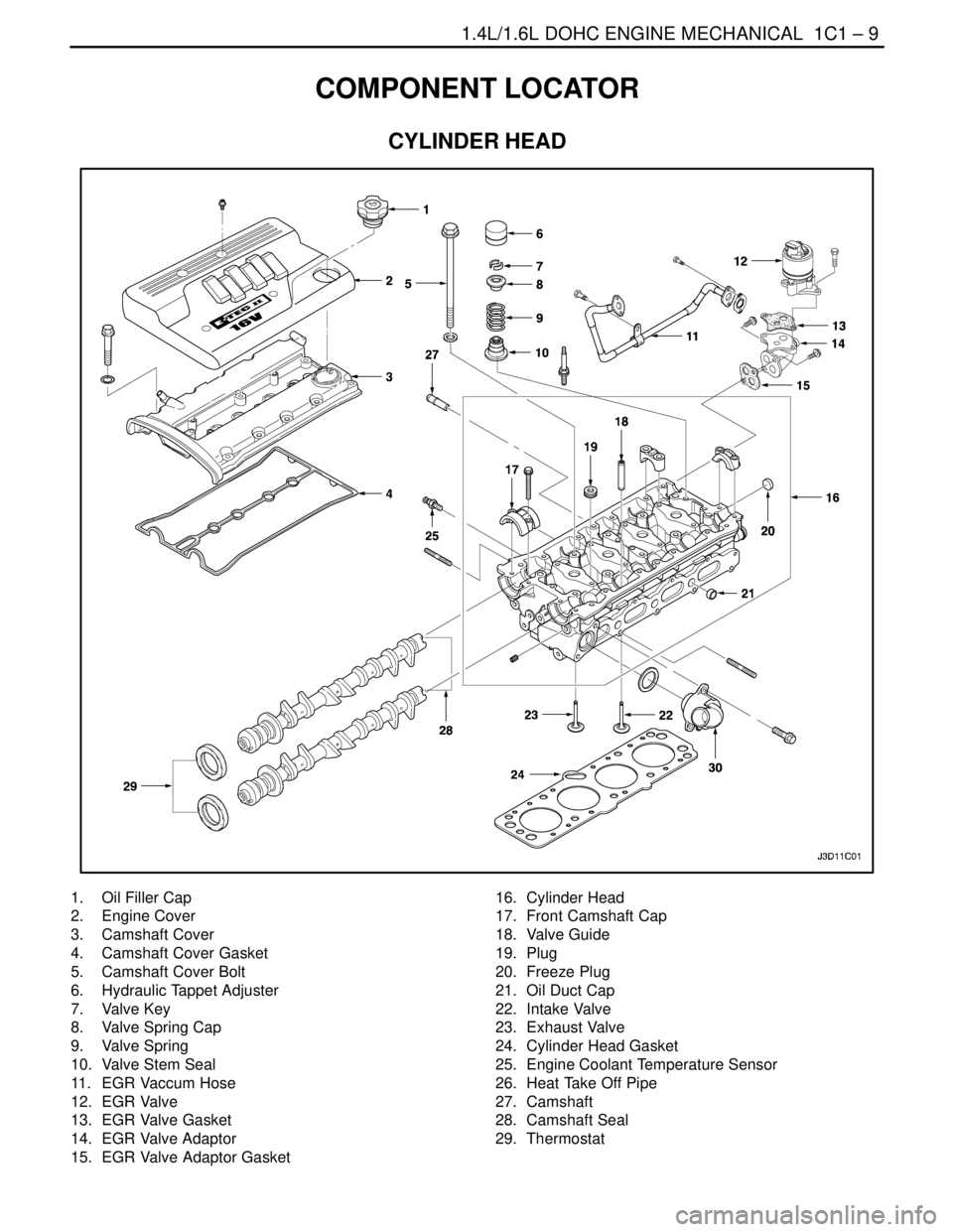

COMPONENT LOCATOR

CYLINDER HEAD

1. Oil Filler Cap

2. Engine Cover

3. Camshaft Cover

4. Camshaft Cover Gasket

5. Camshaft Cover Bolt

6. Hydraulic Tappet Adjuster

7. Valve Key

8. Valve Spring Cap

9. Valve Spring

10. Valve Stem Seal

11. EGR Vaccum Hose

12. EGR Valve

13. EGR Valve Gasket

14. EGR Valve Adaptor

15. EGR Valve Adaptor Gasket16. Cylinder Head

17. Front Camshaft Cap

18. Valve Guide

19. Plug

20. Freeze Plug

21. Oil Duct Cap

22. Intake Valve

23. Exhaust Valve

24. Cylinder Head Gasket

25. Engine Coolant Temperature Sensor

26. Heat Take Off Pipe

27. Camshaft

28. Camshaft Seal

29. Thermostat

Page 56 of 2643

1.4L/1.6L DOHC ENGINE MECHANICAL 1C1 – 13

DAEWOO V–121 BL4

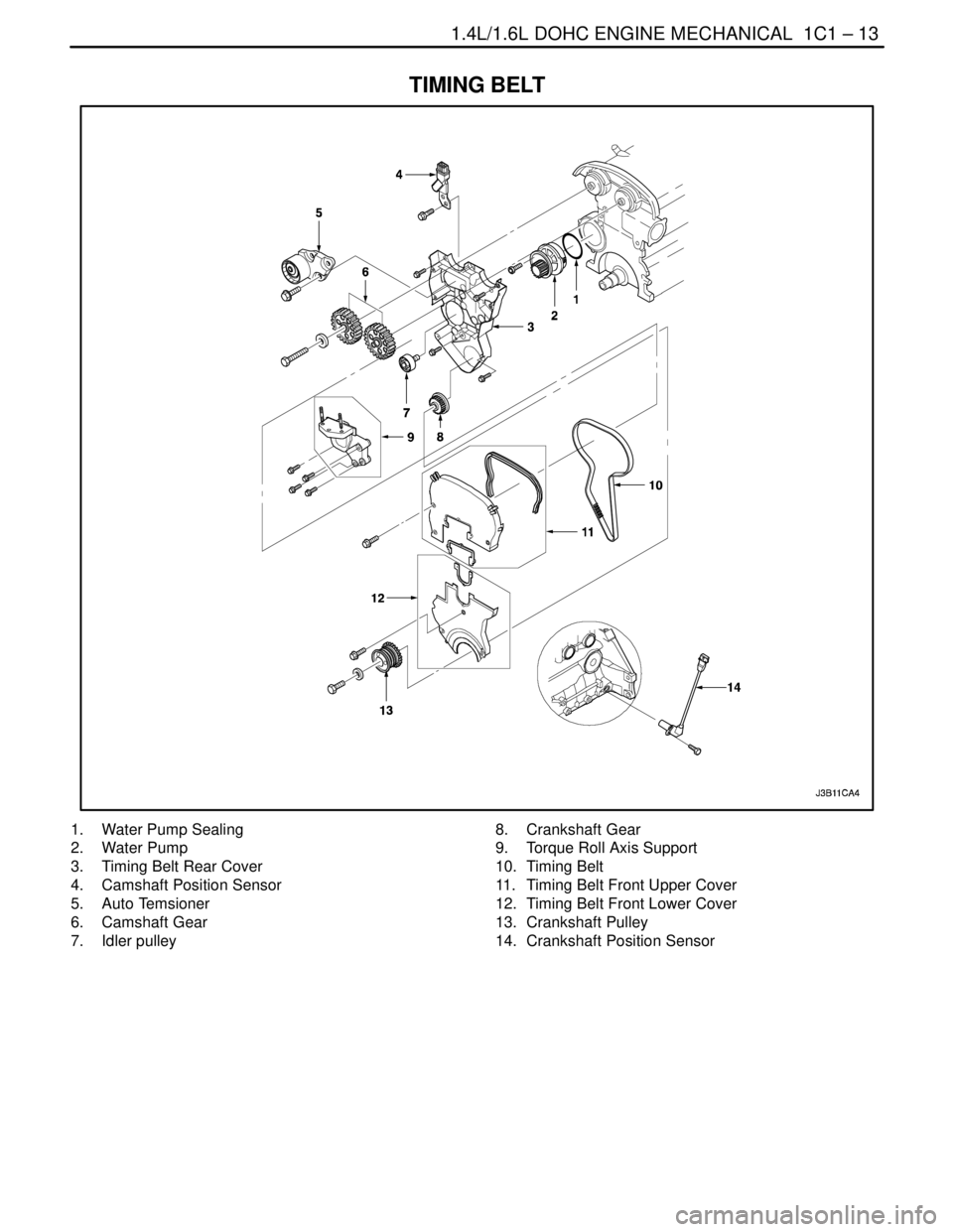

TIMING BELT

1. Water Pump Sealing

2. Water Pump

3. Timing Belt Rear Cover

4. Camshaft Position Sensor

5. Auto Temsioner

6. Camshaft Gear

7. Idler pulley8. Crankshaft Gear

9. Torque Roll Axis Support

10. Timing Belt

11. Timing Belt Front Upper Cover

12. Timing Belt Front Lower Cover

13. Crankshaft Pulley

14. Crankshaft Position Sensor

Page 58 of 2643

1.4L/1.6L DOHC ENGINE MECHANICAL 1C1 – 15

DAEWOO V–121 BL4

MAINTENANCE AND REPAIR

ON–VEHICLE SERVICE

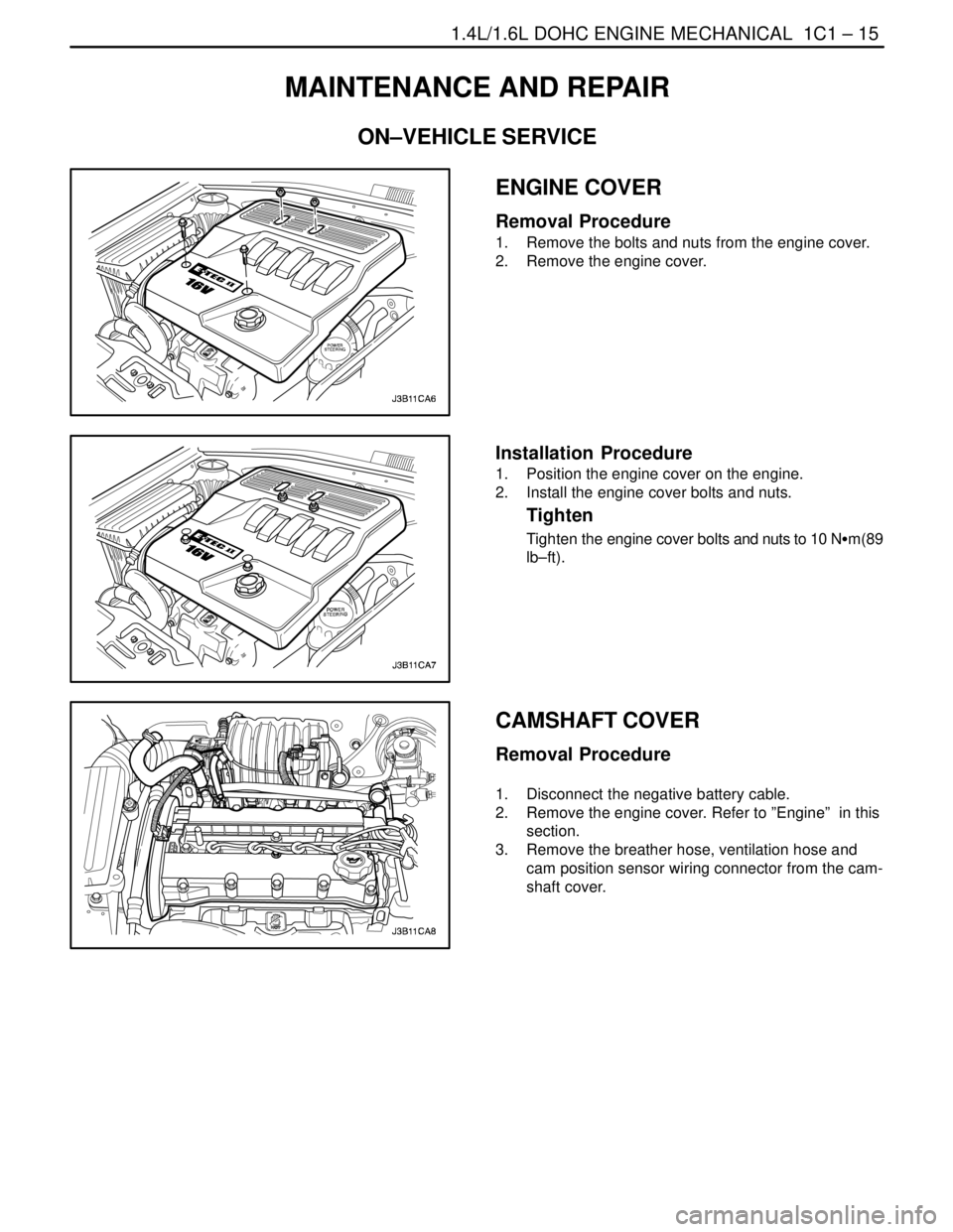

ENGINE COVER

Removal Procedure

1. Remove the bolts and nuts from the engine cover.

2. Remove the engine cover.

Installation Procedure

1. Position the engine cover on the engine.

2. Install the engine cover bolts and nuts.

Tighten

Tighten the engine cover bolts and nuts to 10 NSm(89

lb–ft).

CAMSHAFT COVER

Removal Procedure

1. Disconnect the negative battery cable.

2. Remove the engine cover. Refer to ”Engine” in this

section.

3. Remove the breather hose, ventilation hose and

cam position sensor wiring connector from the cam-

shaft cover.

Page 59 of 2643

1C1 – 16I1.4L/1.6L DOHC ENGINE MECHANICAL

DAEWOO V–121 BL4

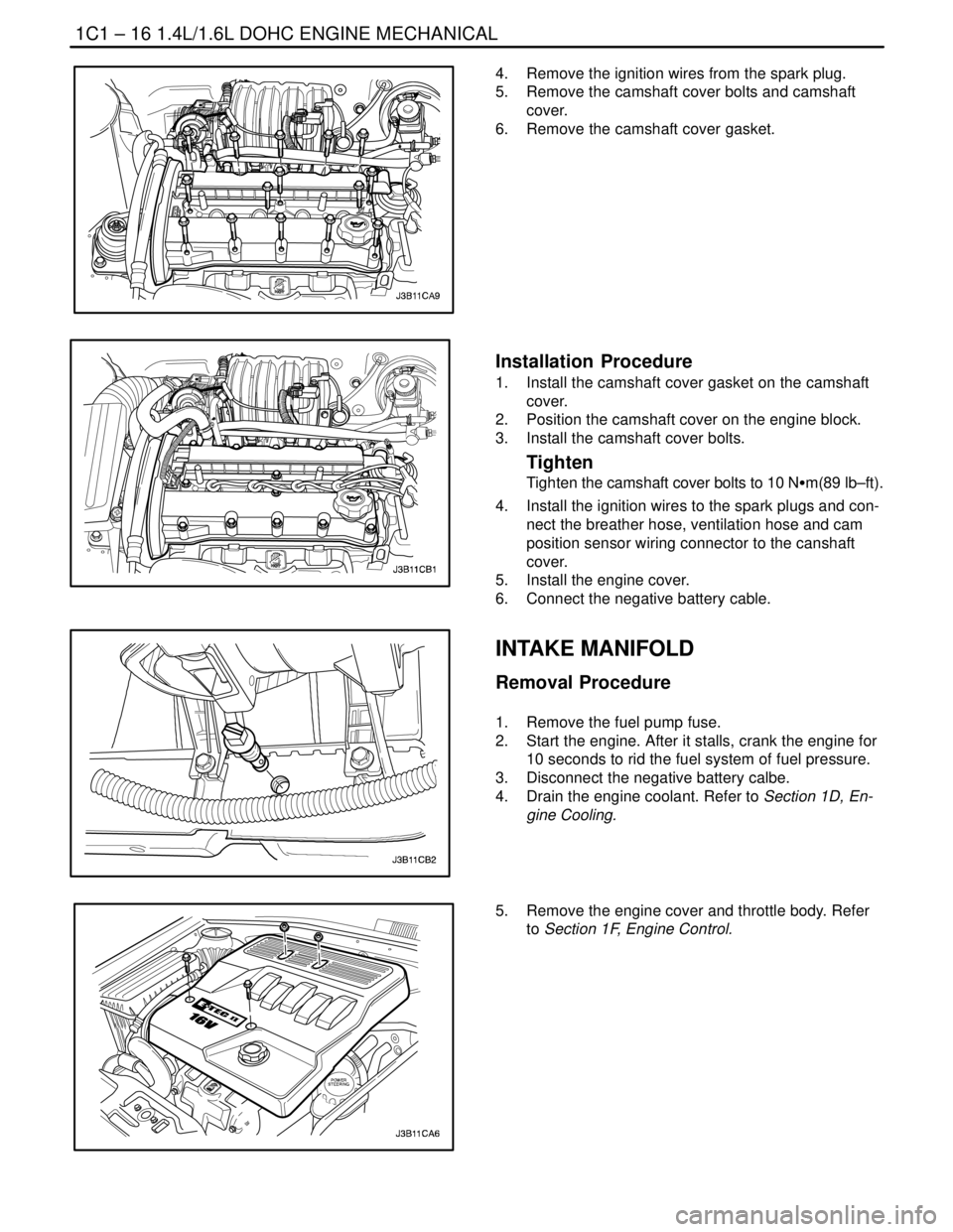

4. Remove the ignition wires from the spark plug.

5. Remove the camshaft cover bolts and camshaft

cover.

6. Remove the camshaft cover gasket.

Installation Procedure

1. Install the camshaft cover gasket on the camshaft

cover.

2. Position the camshaft cover on the engine block.

3. Install the camshaft cover bolts.

Tighten

Tighten the camshaft cover bolts to 10 NSm(89 lb–ft).

4. Install the ignition wires to the spark plugs and con-

nect the breather hose, ventilation hose and cam

position sensor wiring connector to the canshaft

cover.

5. Install the engine cover.

6. Connect the negative battery cable.

INTAKE MANIFOLD

Removal Procedure

1. Remove the fuel pump fuse.

2. Start the engine. After it stalls, crank the engine for

10 seconds to rid the fuel system of fuel pressure.

3. Disconnect the negative battery calbe.

4. Drain the engine coolant. Refer to Section 1D, En-

gine Cooling.

5. Remove the engine cover and throttle body. Refer

to Section 1F, Engine Control.

Page 65 of 2643

1C1 – 22I1.4L/1.6L DOHC ENGINE MECHANICAL

DAEWOO V–121 BL4

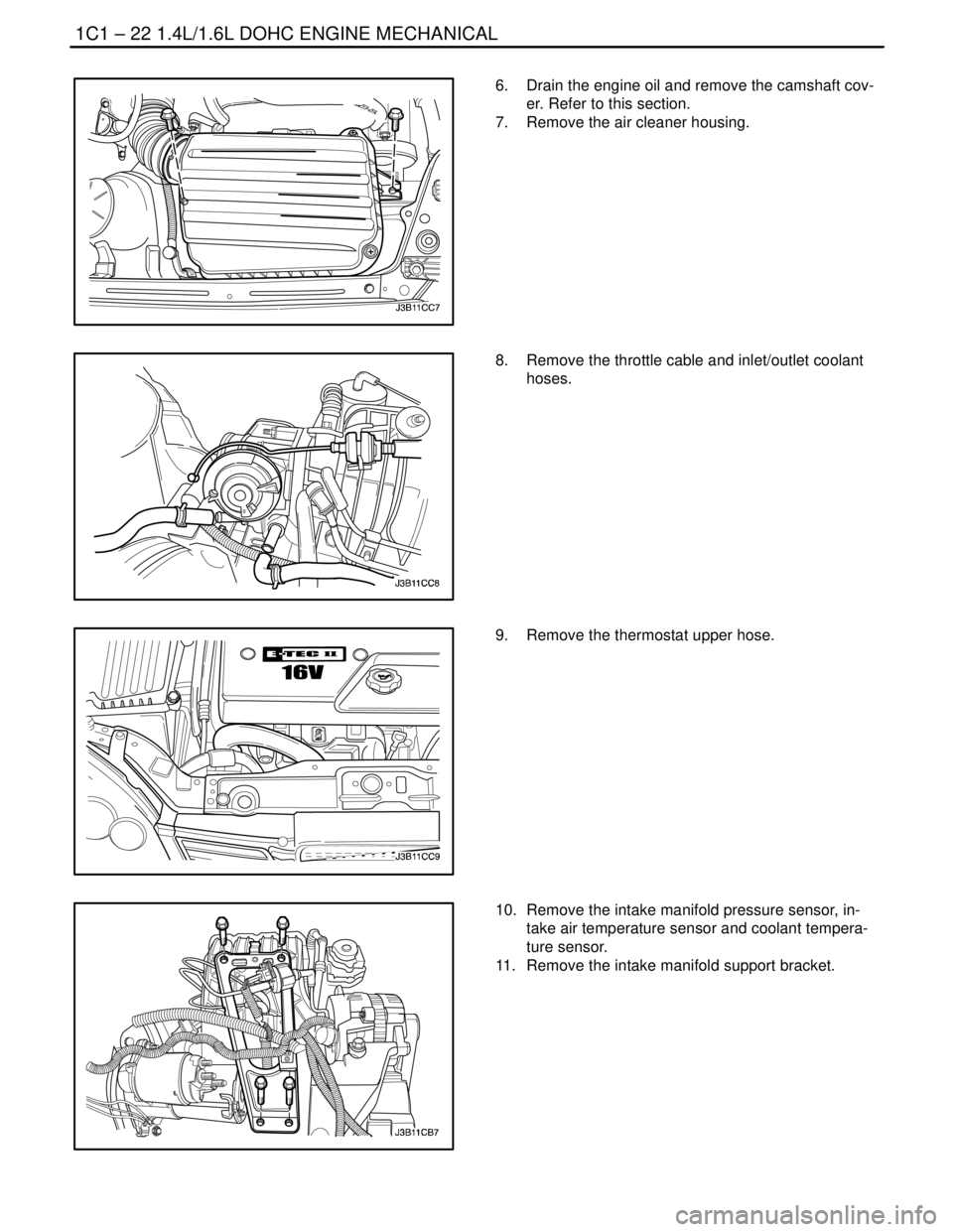

6. Drain the engine oil and remove the camshaft cov-

er. Refer to this section.

7. Remove the air cleaner housing.

8. Remove the throttle cable and inlet/outlet coolant

hoses.

9. Remove the thermostat upper hose.

10. Remove the intake manifold pressure sensor, in-

take air temperature sensor and coolant tempera-

ture sensor.

11. Remove the intake manifold support bracket.

Page 72 of 2643

1.4L/1.6L DOHC ENGINE MECHANICAL 1C1 – 29

DAEWOO V–121 BL4

38. Connect the DIS coil connector.

39. Connect the fuel injector harness connectors.

40. Connect the oxygen sensor connector and the

ECM ground terminal at the intake manifold.

41. Install the fuel pump fuse.

42. Connect the negative battery ground cable.

43. Refill the engine cooling system. Refer to Sec-

tion1D, Engine Cooling.

CAMSHAFTS

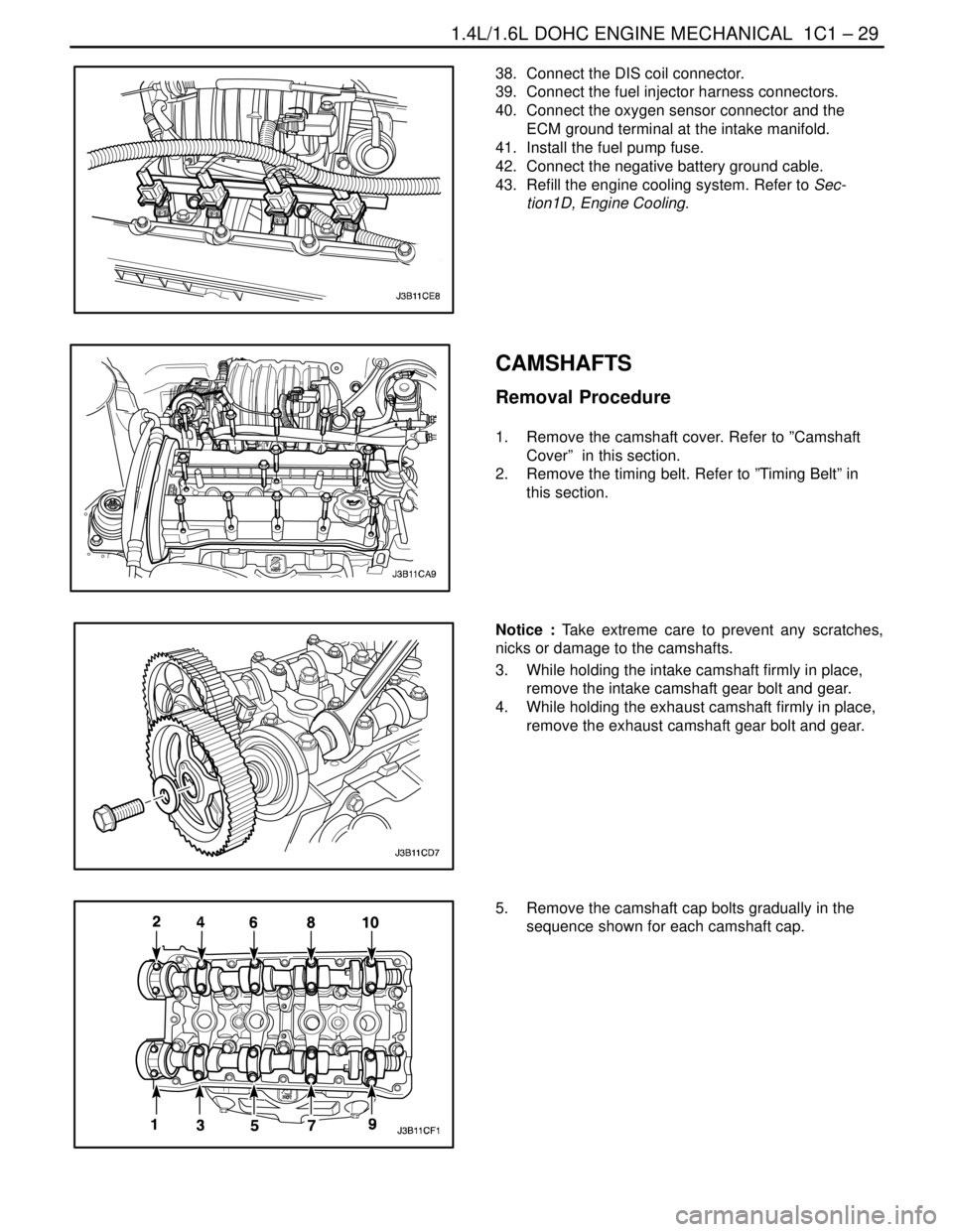

Removal Procedure

1. Remove the camshaft cover. Refer to ”Camshaft

Cover” in this section.

2. Remove the timing belt. Refer to ”Timing Belt” in

this section.

Notice : Take extreme care to prevent any scratches,

nicks or damage to the camshafts.

3. While holding the intake camshaft firmly in place,

remove the intake camshaft gear bolt and gear.

4. While holding the exhaust camshaft firmly in place,

remove the exhaust camshaft gear bolt and gear.

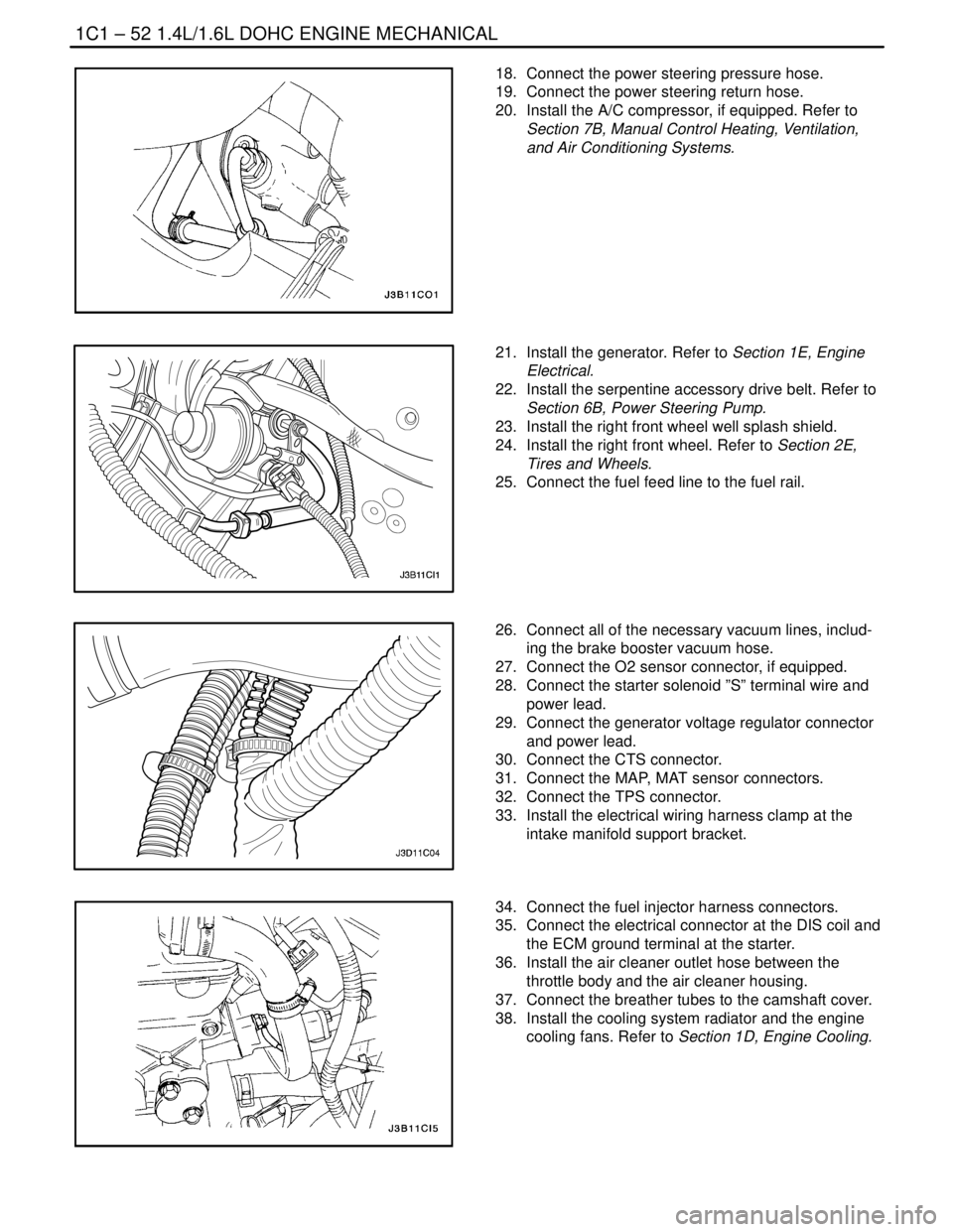

5. Remove the camshaft cap bolts gradually in the

sequence shown for each camshaft cap.

Page 95 of 2643

1C1 – 52I1.4L/1.6L DOHC ENGINE MECHANICAL

DAEWOO V–121 BL4

18. Connect the power steering pressure hose.

19. Connect the power steering return hose.

20. Install the A/C compressor, if equipped. Refer to

Section 7B, Manual Control Heating, Ventilation,

and Air Conditioning Systems.

21. Install the generator. Refer to Section 1E, Engine

Electrical.

22. Install the serpentine accessory drive belt. Refer to

Section 6B, Power Steering Pump.

23. Install the right front wheel well splash shield.

24. Install the right front wheel. Refer to Section 2E,

Tires and Wheels.

25. Connect the fuel feed line to the fuel rail.

26. Connect all of the necessary vacuum lines, includ-

ing the brake booster vacuum hose.

27. Connect the O2 sensor connector, if equipped.

28. Connect the starter solenoid ”S” terminal wire and

power lead.

29. Connect the generator voltage regulator connector

and power lead.

30. Connect the CTS connector.

31. Connect the MAP, MAT sensor connectors.

32. Connect the TPS connector.

33. Install the electrical wiring harness clamp at the

intake manifold support bracket.

34. Connect the fuel injector harness connectors.

35. Connect the electrical connector at the DIS coil and

the ECM ground terminal at the starter.

36. Install the air cleaner outlet hose between the

throttle body and the air cleaner housing.

37. Connect the breather tubes to the camshaft cover.

38. Install the cooling system radiator and the engine

cooling fans. Refer to Section 1D, Engine Cooling.

Page 108 of 2643

1.4L/1.6L DOHC ENGINE MECHANICAL 1C1 – 65

DAEWOO V–121 BL4

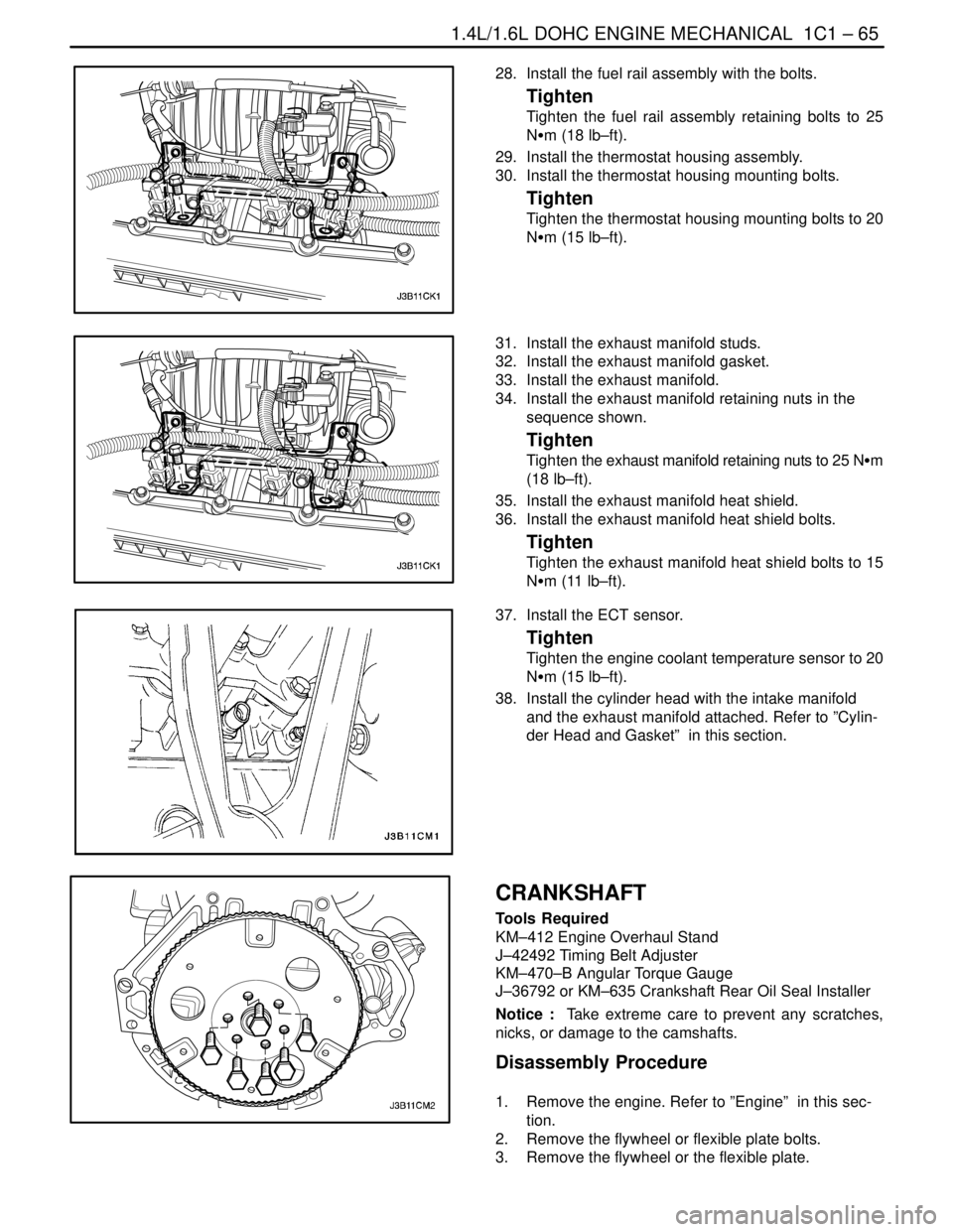

28. Install the fuel rail assembly with the bolts.

Tighten

Tighten the fuel rail assembly retaining bolts to 25

NSm (18 lb–ft).

29. Install the thermostat housing assembly.

30. Install the thermostat housing mounting bolts.

Tighten

Tighten the thermostat housing mounting bolts to 20

NSm (15 lb–ft).

31. Install the exhaust manifold studs.

32. Install the exhaust manifold gasket.

33. Install the exhaust manifold.

34. Install the exhaust manifold retaining nuts in the

sequence shown.

Tighten

Tighten the exhaust manifold retaining nuts to 25 NSm

(18 lb–ft).

35. Install the exhaust manifold heat shield.

36. Install the exhaust manifold heat shield bolts.

Tighten

Tighten the exhaust manifold heat shield bolts to 15

NSm (11 lb–ft).

37. Install the ECT sensor.

Tighten

Tighten the engine coolant temperature sensor to 20

NSm (15 lb–ft).

38. Install the cylinder head with the intake manifold

and the exhaust manifold attached. Refer to ”Cylin-

der Head and Gasket” in this section.

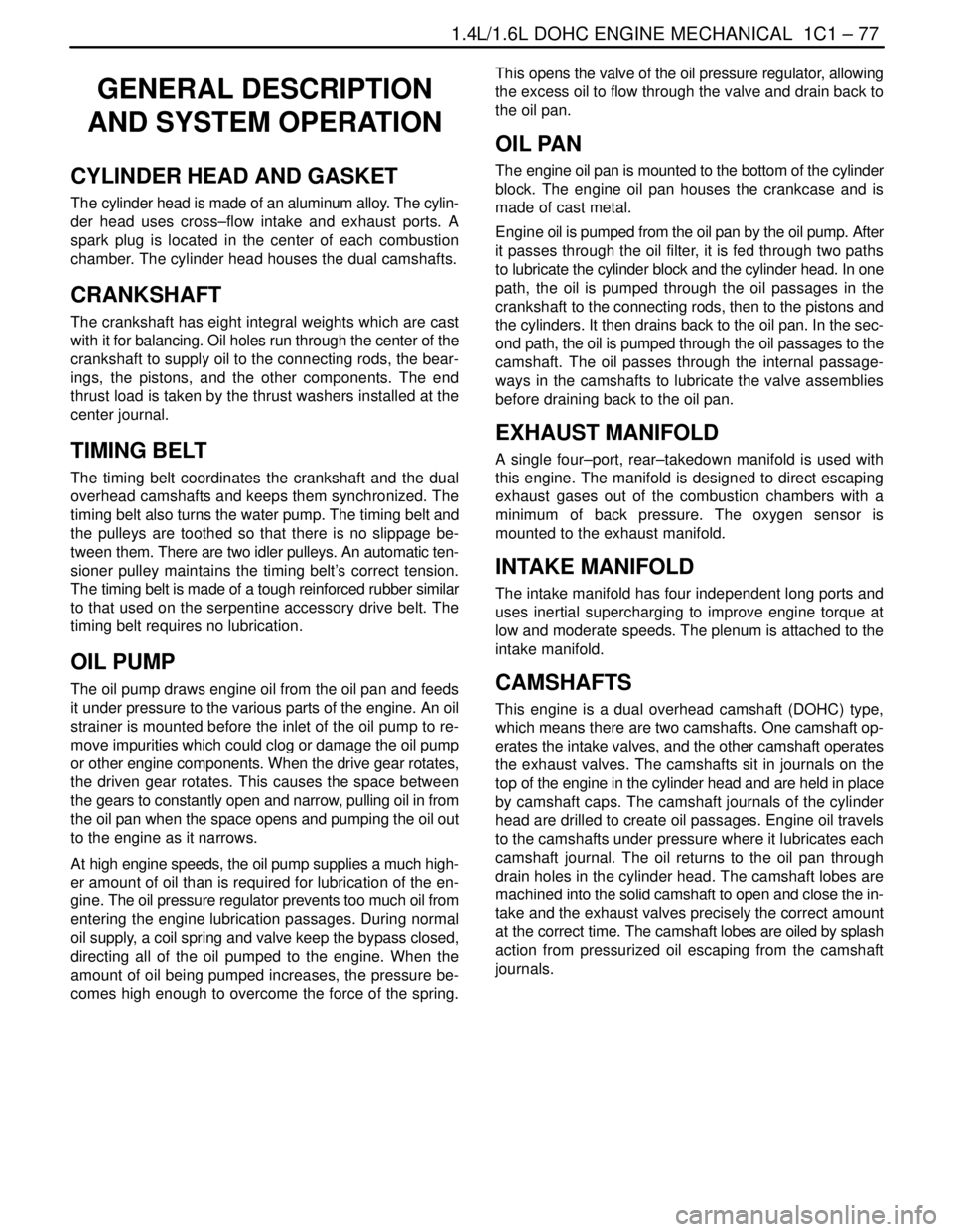

CRANKSHAFT

Tools Required

KM–412 Engine Overhaul Stand

J–42492 Timing Belt Adjuster

KM–470–B Angular Torque Gauge

J–36792 or KM–635 Crankshaft Rear Oil Seal Installer

Notice : Take extreme care to prevent any scratches,

nicks, or damage to the camshafts.

Disassembly Procedure

1. Remove the engine. Refer to ”Engine” in this sec-

tion.

2. Remove the flywheel or flexible plate bolts.

3. Remove the flywheel or the flexible plate.

Page 120 of 2643

1.4L/1.6L DOHC ENGINE MECHANICAL 1C1 – 77

DAEWOO V–121 BL4

GENERAL DESCRIPTION

AND SYSTEM OPERATION

CYLINDER HEAD AND GASKET

The cylinder head is made of an aluminum alloy. The cylin-

der head uses cross–flow intake and exhaust ports. A

spark plug is located in the center of each combustion

chamber. The cylinder head houses the dual camshafts.

CRANKSHAFT

The crankshaft has eight integral weights which are cast

with it for balancing. Oil holes run through the center of the

crankshaft to supply oil to the connecting rods, the bear-

ings, the pistons, and the other components. The end

thrust load is taken by the thrust washers installed at the

center journal.

TIMING BELT

The timing belt coordinates the crankshaft and the dual

overhead camshafts and keeps them synchronized. The

timing belt also turns the water pump. The timing belt and

the pulleys are toothed so that there is no slippage be-

tween them. There are two idler pulleys. An automatic ten-

sioner pulley maintains the timing belt’s correct tension.

The timing belt is made of a tough reinforced rubber similar

to that used on the serpentine accessory drive belt. The

timing belt requires no lubrication.

OIL PUMP

The oil pump draws engine oil from the oil pan and feeds

it under pressure to the various parts of the engine. An oil

strainer is mounted before the inlet of the oil pump to re-

move impurities which could clog or damage the oil pump

or other engine components. When the drive gear rotates,

the driven gear rotates. This causes the space between

the gears to constantly open and narrow, pulling oil in from

the oil pan when the space opens and pumping the oil out

to the engine as it narrows.

At high engine speeds, the oil pump supplies a much high-

er amount of oil than is required for lubrication of the en-

gine. The oil pressure regulator prevents too much oil from

entering the engine lubrication passages. During normal

oil supply, a coil spring and valve keep the bypass closed,

directing all of the oil pumped to the engine. When the

amount of oil being pumped increases, the pressure be-

comes high enough to overcome the force of the spring.This opens the valve of the oil pressure regulator, allowing

the excess oil to flow through the valve and drain back to

the oil pan.

OIL PAN

The engine oil pan is mounted to the bottom of the cylinder

block. The engine oil pan houses the crankcase and is

made of cast metal.

Engine oil is pumped from the oil pan by the oil pump. After

it passes through the oil filter, it is fed through two paths

to lubricate the cylinder block and the cylinder head. In one

path, the oil is pumped through the oil passages in the

crankshaft to the connecting rods, then to the pistons and

the cylinders. It then drains back to the oil pan. In the sec-

ond path, the oil is pumped through the oil passages to the

camshaft. The oil passes through the internal passage-

ways in the camshafts to lubricate the valve assemblies

before draining back to the oil pan.

EXHAUST MANIFOLD

A single four–port, rear–takedown manifold is used with

this engine. The manifold is designed to direct escaping

exhaust gases out of the combustion chambers with a

minimum of back pressure. The oxygen sensor is

mounted to the exhaust manifold.

INTAKE MANIFOLD

The intake manifold has four independent long ports and

uses inertial supercharging to improve engine torque at

low and moderate speeds. The plenum is attached to the

intake manifold.

CAMSHAFTS

This engine is a dual overhead camshaft (DOHC) type,

which means there are two camshafts. One camshaft op-

erates the intake valves, and the other camshaft operates

the exhaust valves. The camshafts sit in journals on the

top of the engine in the cylinder head and are held in place

by camshaft caps. The camshaft journals of the cylinder

head are drilled to create oil passages. Engine oil travels

to the camshafts under pressure where it lubricates each

camshaft journal. The oil returns to the oil pan through

drain holes in the cylinder head. The camshaft lobes are

machined into the solid camshaft to open and close the in-

take and the exhaust valves precisely the correct amount

at the correct time. The camshaft lobes are oiled by splash

action from pressurized oil escaping from the camshaft

journals.