remote control DAEWOO NUBIRA 2004 Service Repair Manual

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: NUBIRA, Model: DAEWOO NUBIRA 2004Pages: 2643, PDF Size: 80.54 MB

Page 5 of 2643

v

TABLE OF CONTENTS

Section 0B General Information

Section 1 Engine

Section 1A General Engine Information

Section 1C1 1.4L/1.6L DOHC Engine Mechanical

Section 1C2 1.8L DOHC Engine Mechanical

Section 1D Engine Cooling

Section 1E Engine Electrical

Section 1F Engine Controls

Section 1G Engine Exhaust

Section 2 Suspension

Section 2A Suspension Diagnosis

Section 2B Wheel Alignment

Section 2C Front Suspension

Section 2D Rear Suspension

Section 2E Tires and Wheels

Section 3 Driveline/Axle

Section 3A Automatic Transaxle Drive Axle

Section 3B Manual Transaxle Drive Axle

Section 4 Brakes

Section 4A Hydraulic Brakes

Section 4B Master Cylinder

Section 4C Power Booster

Section 4D Front Disc Brakes

Section 4E1 Rear Disc Brakes

Section 4E2 Rear Drum Brakes

Section 4F Antilock Brake System

Section 4G Parking Brake

Section 5 Transmission/Transaxle

Section 5A1 ZF 4HP16 Automatic Transaxle

Section 5A2 AISIN Automatic Transaxle

Section 5B Five-Speed Manual Transaxle

Section 5C Clutch

Section 6 Steering

Section 6A Power Steering System

Section 6B Power Steering PumpSection 6C Power Steering Gear

Section 6E Steering Wheel and Column

Section 7 Heating, Ventilation, and Air

Conditioning (HVAC)

Section 7A Heating and Ventilation System

Section 7B Manual Control Heating, Ventilation,

and Air Conditioning System

Section 7D Automatic Temperature Control HVAC

Section 8 Restraints

Section 8A Seat Belts

Section 8B Supplemental Inflatable Restraints

(SIR)

Section 9 Body and Accessories

Section 9A Body Wiring System

Section 9B Lighting Systems

Section 9C Horns

Section 9D Wipers/Washer Systems

Section 9E Instrumentation/Driver Information

Section 9F Audio Systems

Section 9G Interior Trim

Section 9H Seats

Section 9I Waterleaks

Section 9J Windnoise

Section 9K Squeaks and Rattles

Section 9L Glass and Mirrors

Section 9M Exterior Trim

Section 9N Frame and Underbody

Section 9O Bumpers and Fascias

Section 9P Doors

Section 9Q Roof

Section 9R Body Front End

Section 9S Body Rear End

Section 9T1 Remote Keyless Entry and Anti–Theft

System

Section 9T2 Immobilizer Anti–Theft System

Page 2206 of 2643

8B – 102ISUPPLEMENTAL INFLATABLE RESTRAINTS (SIR)

DAEWOO V–121 BL4

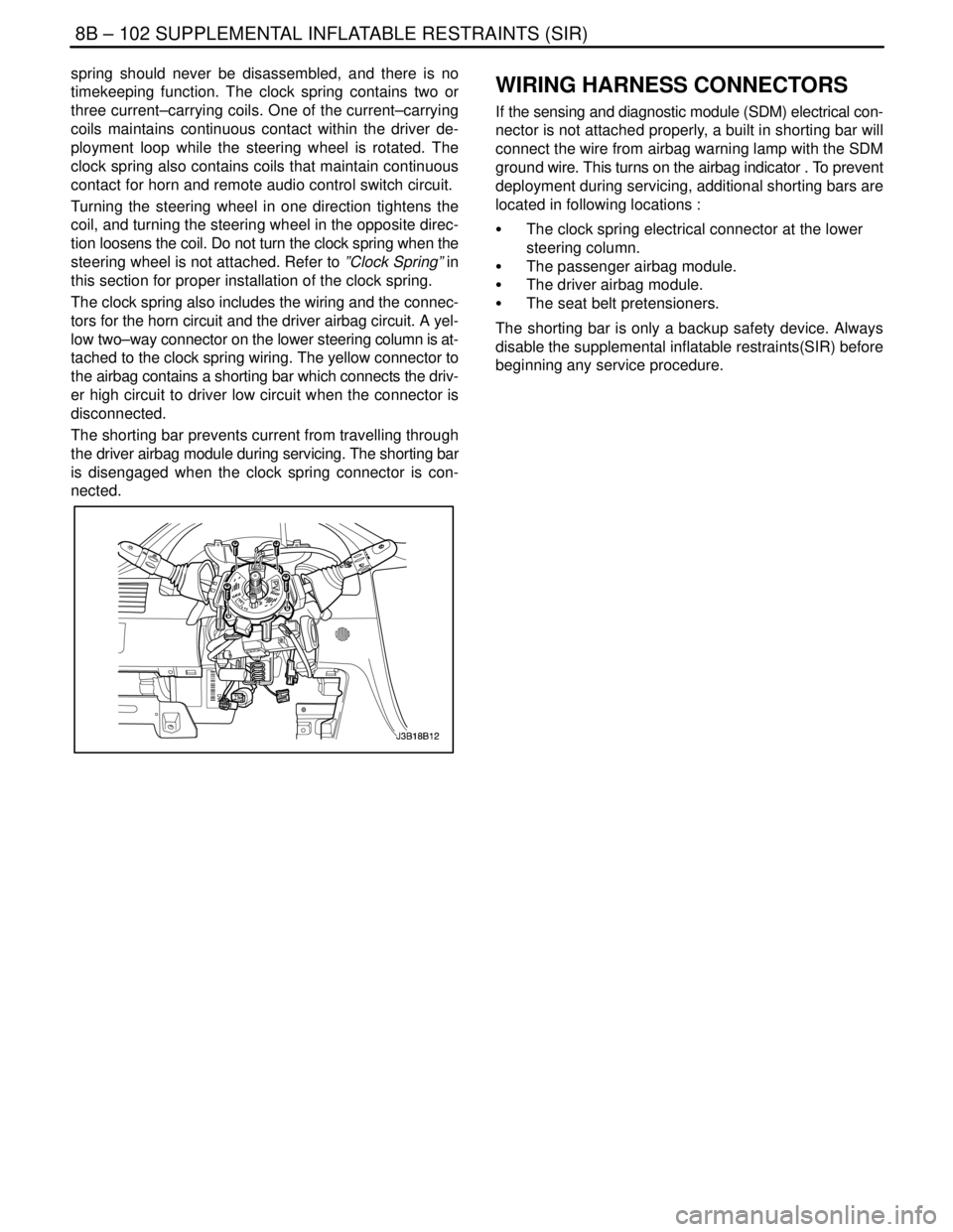

spring should never be disassembled, and there is no

timekeeping function. The clock spring contains two or

three current–carrying coils. One of the current–carrying

coils maintains continuous contact within the driver de-

ployment loop while the steering wheel is rotated. The

clock spring also contains coils that maintain continuous

contact for horn and remote audio control switch circuit.

Turning the steering wheel in one direction tightens the

coil, and turning the steering wheel in the opposite direc-

tion loosens the coil. Do not turn the clock spring when the

steering wheel is not attached. Refer to ”Clock Spring” in

this section for proper installation of the clock spring.

The clock spring also includes the wiring and the connec-

tors for the horn circuit and the driver airbag circuit. A yel-

low two–way connector on the lower steering column is at-

tached to the clock spring wiring. The yellow connector to

the airbag contains a shorting bar which connects the driv-

er high circuit to driver low circuit when the connector is

disconnected.

The shorting bar prevents current from travelling through

the driver airbag module during servicing. The shorting bar

is disengaged when the clock spring connector is con-

nected.WIRING HARNESS CONNECTORS

If the sensing and diagnostic module (SDM) electrical con-

nector is not attached properly, a built in shorting bar will

connect the wire from airbag warning lamp with the SDM

ground wire. This turns on the airbag indicator . To prevent

deployment during servicing, additional shorting bars are

located in following locations :

S The clock spring electrical connector at the lower

steering column.

S The passenger airbag module.

S The driver airbag module.

S The seat belt pretensioners.

The shorting bar is only a backup safety device. Always

disable the supplemental inflatable restraints(SIR) before

beginning any service procedure.

Page 2330 of 2643

SECTION : 9F

AUDIO SYSTEMS

CAUTION : Disconnect the negative battery cable before removing or installing any electrical unit or when a tool

or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable will help

prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwise noted.

TABLE OF CONTENTS

SPECIFICATIONS9F–1 . . . . . . . . . . . . . . . . . . . . . . . . . .

Fastener Tightening Specifications 9F–1. . . . . . . . . . .

SCHEMATIC AND ROUTING DIAGRAMS9F–2 . . . . .

Audio System Circuit 9F–2. . . . . . . . . . . . . . . . . . . . . . .

DIAGNOSIS9F–3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Stereo Cassette AM/FM Radio 9F–3. . . . . . . . . . . . . .

Speakers 9F–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MAINTENANCE AND REPAIR9F–7 . . . . . . . . . . . . . . .

ON–VEHICLE SERVICE 9F–7. . . . . . . . . . . . . . . . . . . . .

Stereo Cassette AM/FM Radio 9F–7. . . . . . . . . . . . . .

Audio Remote Controller 9F–7. . . . . . . . . . . . . . . . . . . . Notchback CD Changer 9F–8. . . . . . . . . . . . . . . . . . . .

Door Speakers 9F–8. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tweeter Speakers 9F–9. . . . . . . . . . . . . . . . . . . . . . . . .

Glass Antenna Module 9F–9. . . . . . . . . . . . . . . . . . . . .

Hatchback Windshield Antenna Module 9F–10. . . . . .

GENERAL DESCRIPTION AND SYSTEM

OPERATION9F–11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Stereo Cassette AM/FM Radio 9F–11. . . . . . . . . . . . . .

Audio Scurity System 9F–11. . . . . . . . . . . . . . . . . . . . . .

Speakers 9F–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tape Player and Cassette Care 9F–11. . . . . . . . . . . . . .

Compact Disc Care 9F–11. . . . . . . . . . . . . . . . . . . . . . . .

SPECIFICATIONS

FASTENER TIGHTENING SPECIFICATIONS

ApplicationNSmLb–FtLb–In

Door Speaker Screws2–18

Rear Speaker Screws2–18

Glass Antenna Screws2–18

Page 2336 of 2643

AUDIO SYSTEMS 9F – 7

DAEWOO V–121 BL4

MAINTENANCE AND REPAIR

ON–VEHICLE SERVICE

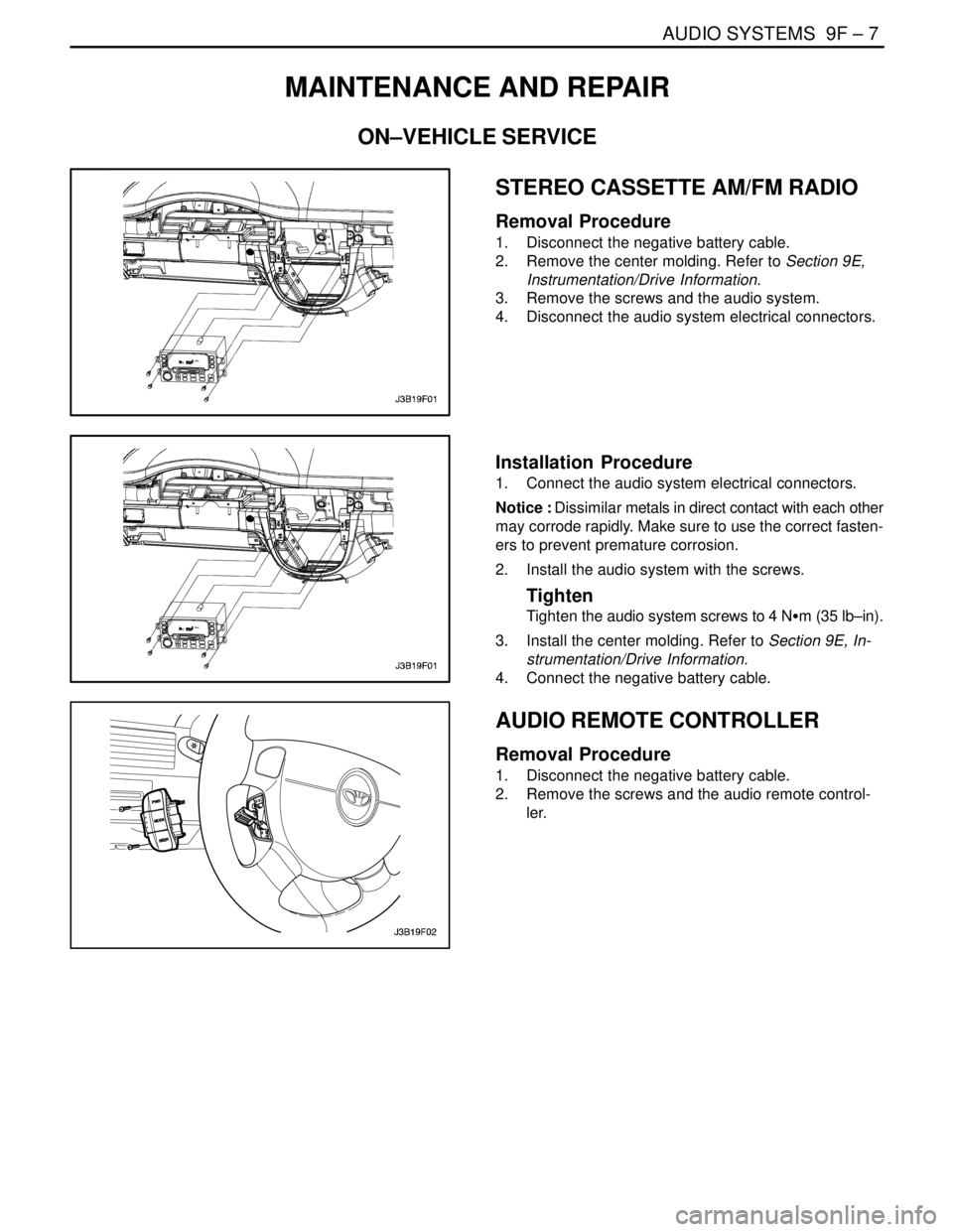

STEREO CASSETTE AM/FM RADIO

Removal Procedure

1. Disconnect the negative battery cable.

2. Remove the center molding. Refer to Section 9E,

Instrumentation/Drive Information.

3. Remove the screws and the audio system.

4. Disconnect the audio system electrical connectors.

Installation Procedure

1. Connect the audio system electrical connectors.

Notice : Dissimilar metals in direct contact with each other

may corrode rapidly. Make sure to use the correct fasten-

ers to prevent premature corrosion.

2. Install the audio system with the screws.

Tighten

Tighten the audio system screws to 4 NSm (35 lb–in).

3. Install the center molding. Refer to Section 9E, In-

strumentation/Drive Information.

4. Connect the negative battery cable.

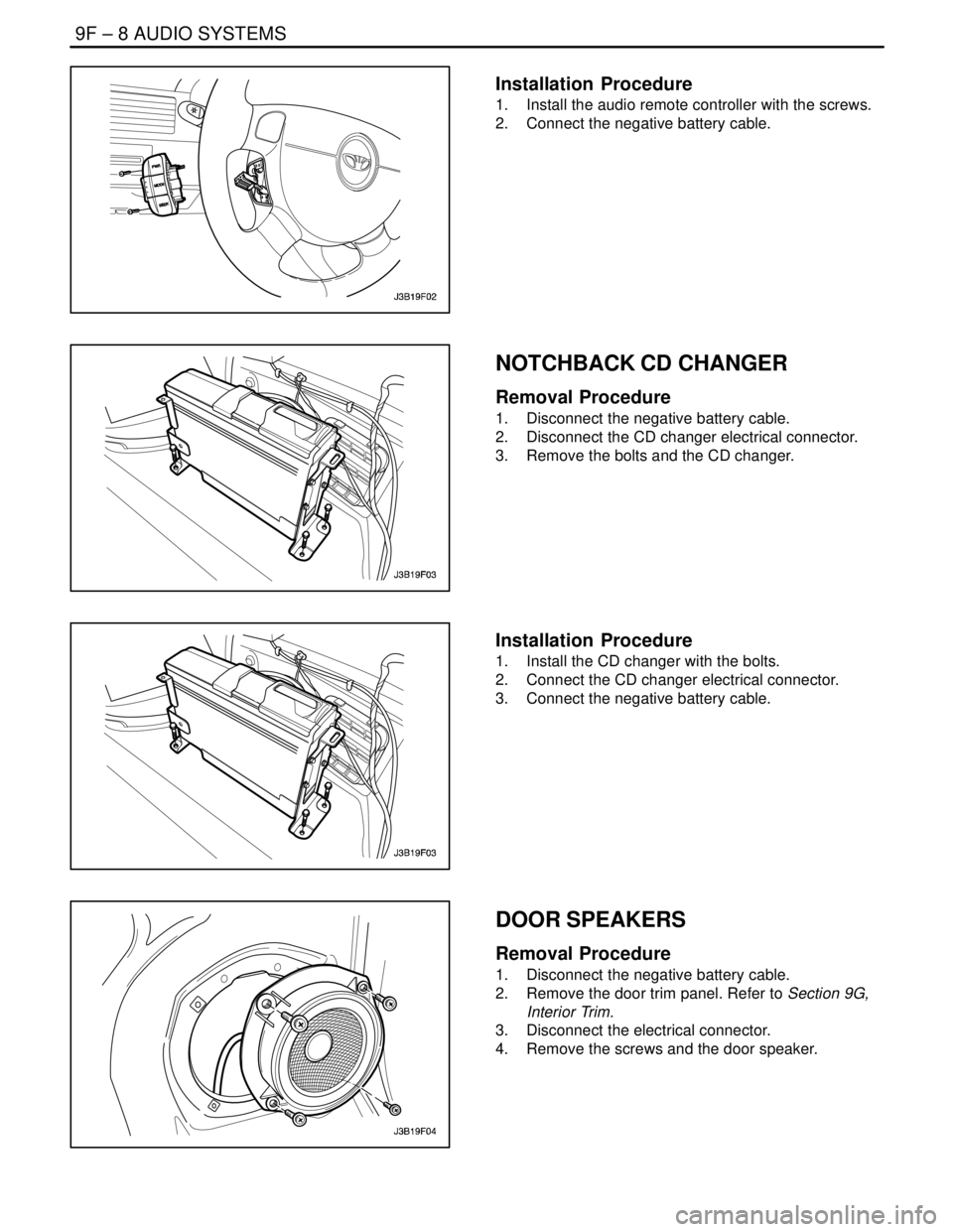

AUDIO REMOTE CONTROLLER

Removal Procedure

1. Disconnect the negative battery cable.

2. Remove the screws and the audio remote control-

ler.

Page 2337 of 2643

9F – 8IAUDIO SYSTEMS

DAEWOO V–121 BL4

Installation Procedure

1. Install the audio remote controller with the screws.

2. Connect the negative battery cable.

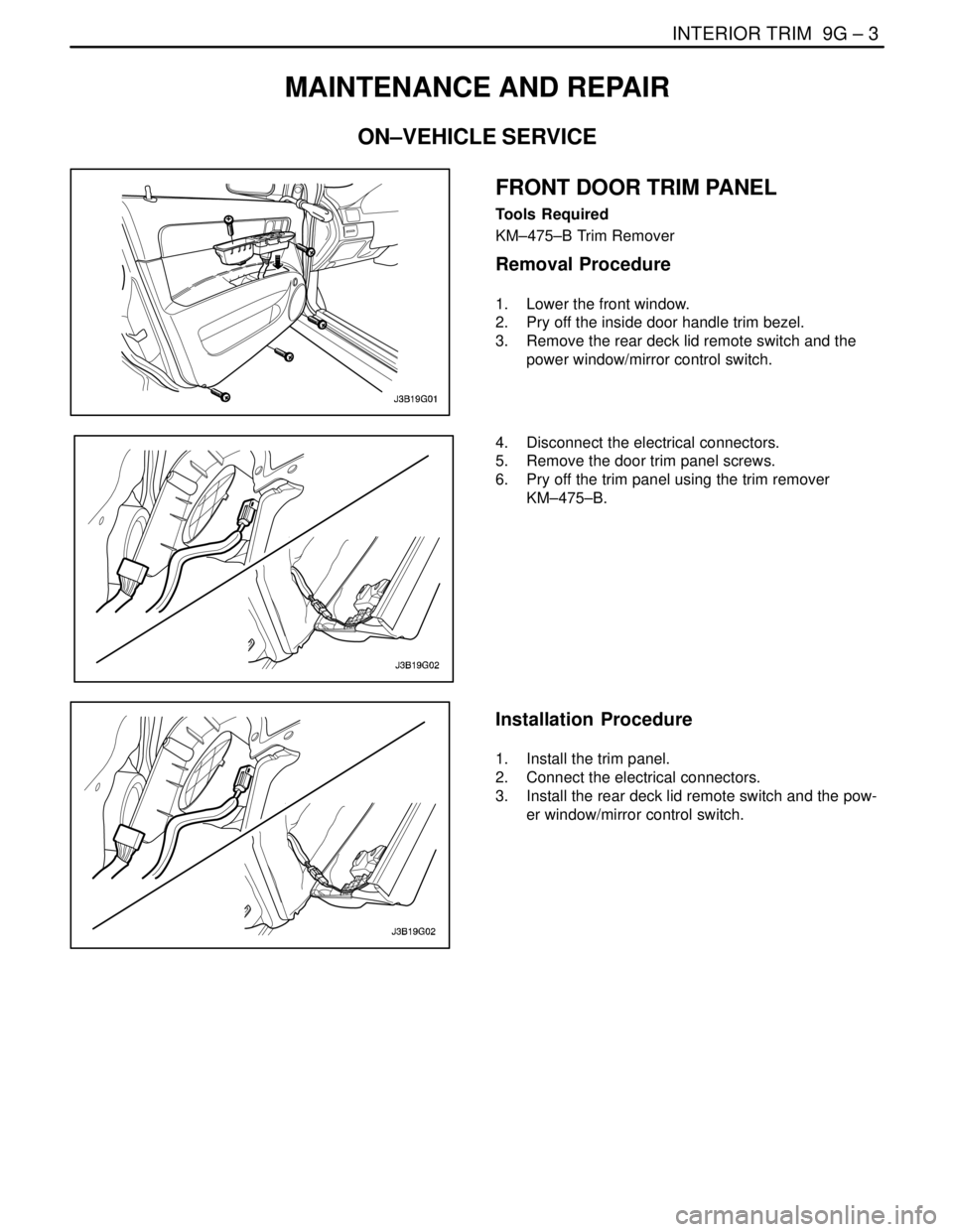

NOTCHBACK CD CHANGER

Removal Procedure

1. Disconnect the negative battery cable.

2. Disconnect the CD changer electrical connector.

3. Remove the bolts and the CD changer.

Installation Procedure

1. Install the CD changer with the bolts.

2. Connect the CD changer electrical connector.

3. Connect the negative battery cable.

DOOR SPEAKERS

Removal Procedure

1. Disconnect the negative battery cable.

2. Remove the door trim panel. Refer to Section 9G,

Interior Trim.

3. Disconnect the electrical connector.

4. Remove the screws and the door speaker.

Page 2343 of 2643

INTERIOR TRIM 9G – 3

DAEWOO V–121 BL4

MAINTENANCE AND REPAIR

ON–VEHICLE SERVICE

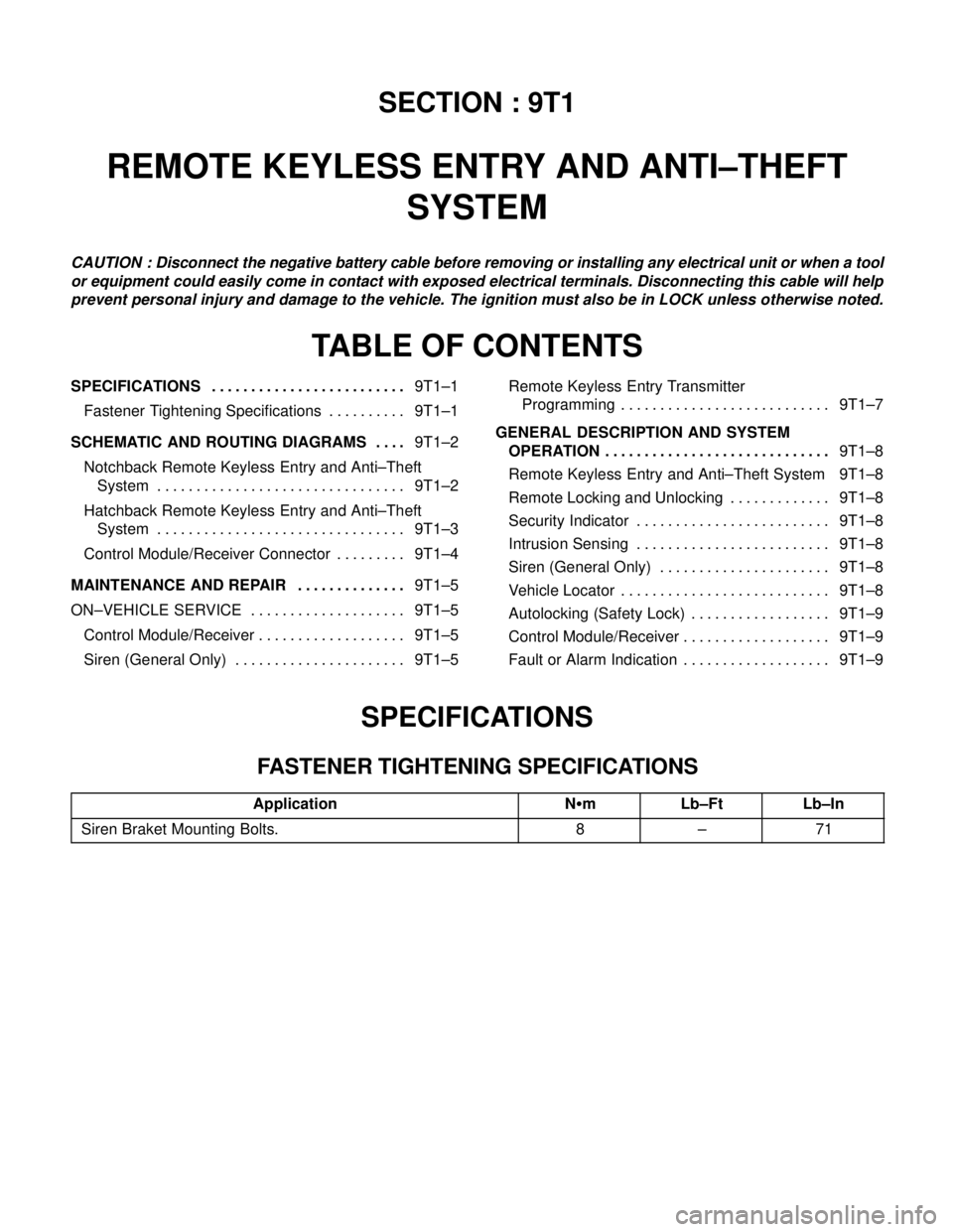

FRONT DOOR TRIM PANEL

Tools Required

KM–475–B Trim Remover

Removal Procedure

1. Lower the front window.

2. Pry off the inside door handle trim bezel.

3. Remove the rear deck lid remote switch and the

power window/mirror control switch.

4. Disconnect the electrical connectors.

5. Remove the door trim panel screws.

6. Pry off the trim panel using the trim remover

KM–475–B.

Installation Procedure

1. Install the trim panel.

2. Connect the electrical connectors.

3. Install the rear deck lid remote switch and the pow-

er window/mirror control switch.

Page 2482 of 2643

SECTION : 9T1

REMOTE KEYLESS ENTRY AND ANTI–THEFT

SYSTEM

CAUTION : Disconnect the negative battery cable before removing or installing any electrical unit or when a tool

or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable will help

prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwise noted.

TABLE OF CONTENTS

SPECIFICATIONS 9T1–1 . . . . . . . . . . . . . . . . . . . . . . . . .

Fastener Tightening Specifications 9T1–1. . . . . . . . . .

SCHEMATIC AND ROUTING DIAGRAMS9T1–2 . . . .

Notchback Remote Keyless Entry and Anti–Theft

System 9T1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hatchback Remote Keyless Entry and Anti–Theft

System 9T1–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Control Module/Receiver Connector 9T1–4. . . . . . . . .

MAINTENANCE AND REPAIR9T1–5 . . . . . . . . . . . . . .

ON–VEHICLE SERVICE 9T1–5. . . . . . . . . . . . . . . . . . . .

Control Module/Receiver 9T1–5. . . . . . . . . . . . . . . . . . .

Siren (General Only) 9T1–5. . . . . . . . . . . . . . . . . . . . . . Remote Keyless Entry Transmitter

Programming 9T1–7. . . . . . . . . . . . . . . . . . . . . . . . . . .

GENERAL DESCRIPTION AND SYSTEM

OPERATION9T1–8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Remote Keyless Entry and Anti–Theft System 9T1–8

Remote Locking and Unlocking 9T1–8. . . . . . . . . . . . .

Security Indicator 9T1–8. . . . . . . . . . . . . . . . . . . . . . . . .

Intrusion Sensing 9T1–8. . . . . . . . . . . . . . . . . . . . . . . . .

Siren (General Only) 9T1–8. . . . . . . . . . . . . . . . . . . . . .

Vehicle Locator 9T1–8. . . . . . . . . . . . . . . . . . . . . . . . . . .

Autolocking (Safety Lock) 9T1–9. . . . . . . . . . . . . . . . . .

Control Module/Receiver 9T1–9. . . . . . . . . . . . . . . . . . .

Fault or Alarm Indication 9T1–9. . . . . . . . . . . . . . . . . . .

SPECIFICATIONS

FASTENER TIGHTENING SPECIFICATIONS

ApplicationNSmLb–FtLb–In

Siren Braket Mounting Bolts.8–71

Page 2485 of 2643

9T1 – 4IREMOTE KEYLESS ENTRY AND ANTI–THEFT SYSTEM

DAEWOO V–121 BL4

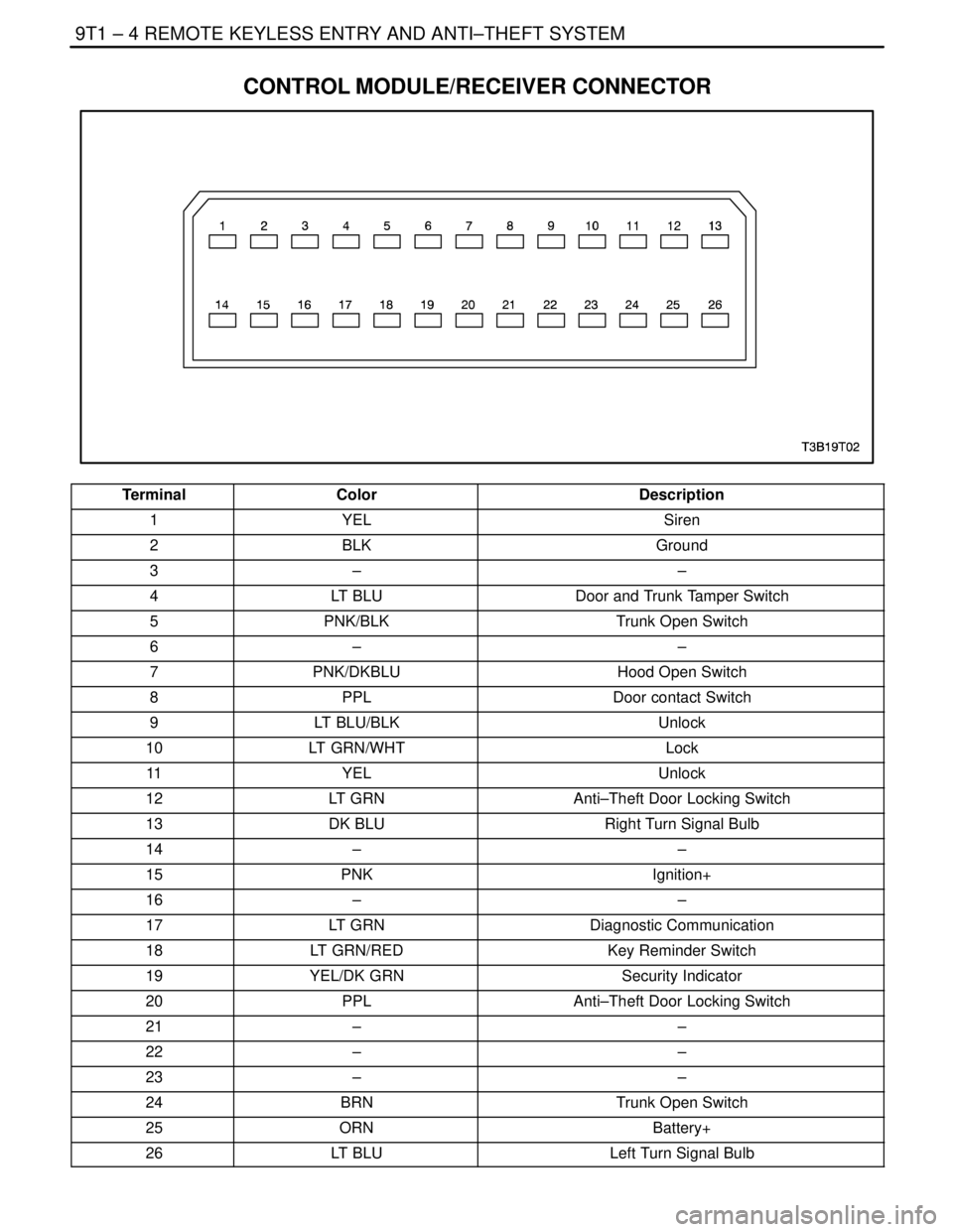

CONTROL MODULE/RECEIVER CONNECTOR

TerminalColorDescription

1YELSiren

2BLKGround

3––

4LT BLUDoor and Trunk Tamper Switch

5PNK/BLKTrunk Open Switch

6––

7PNK/DKBLUHood Open Switch

8PPLDoor contact Switch

9LT BLU/BLKUnlock

10LT GRN/WHTLock

11YELUnlock

12LT GRNAnti–Theft Door Locking Switch

13DK BLURight Turn Signal Bulb

14––

15PNKIgnition+

16––

17LT GRNDiagnostic Communication

18LT GRN/REDKey Reminder Switch

19YEL/DK GRNSecurity Indicator

20PPLAnti–Theft Door Locking Switch

21––

22––

23––

24BRNTrunk Open Switch

25ORNBattery+

26LT BLULeft Turn Signal Bulb

Page 2486 of 2643

REMOTE KEYLESS ENTRY AND ANTI–THEFT SYSTEM 9T1 – 5

DAEWOO V–121 BL4

MAINTENANCE AND REPAIR

ON–VEHICLE SERVICE

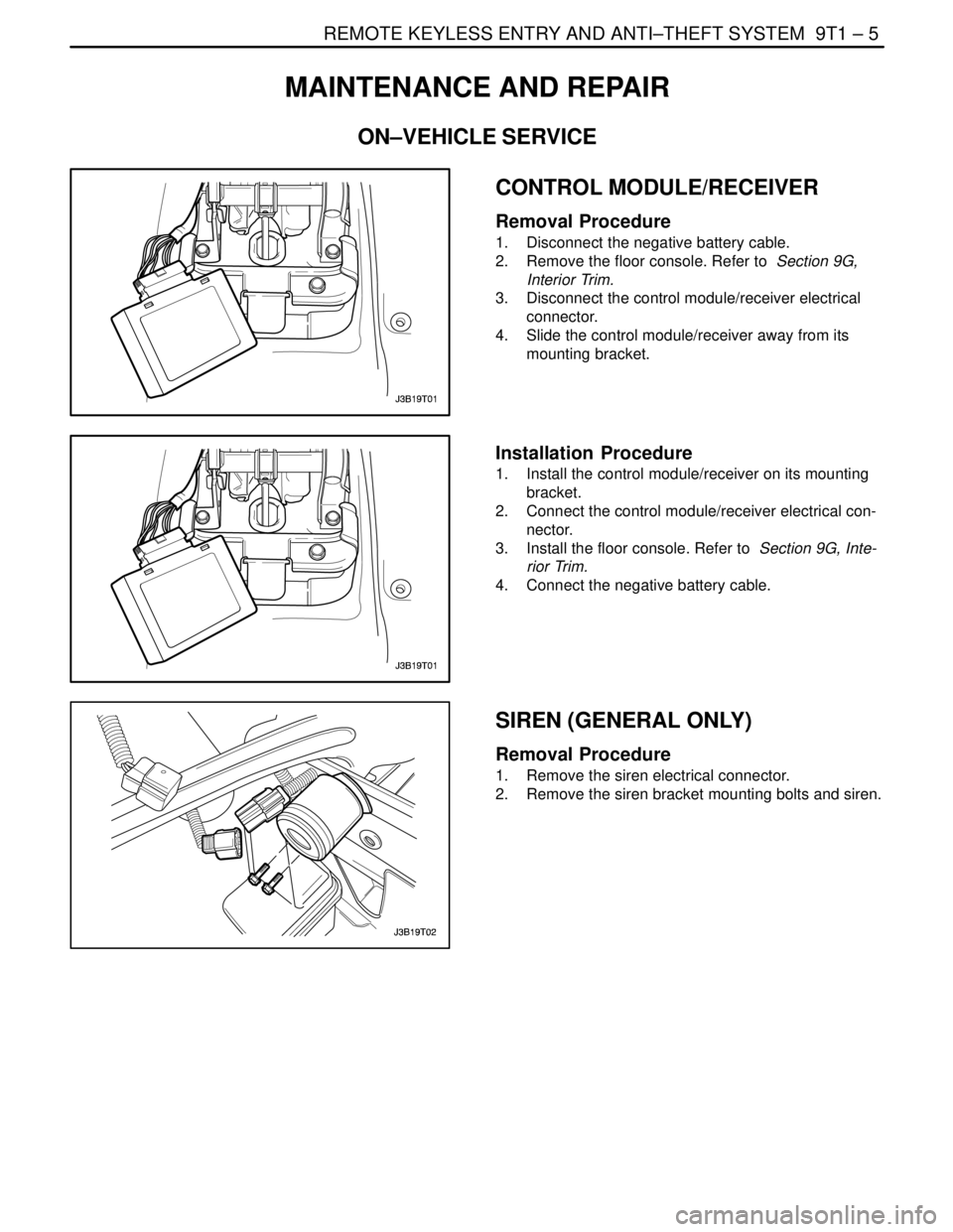

CONTROL MODULE/RECEIVER

Removal Procedure

1. Disconnect the negative battery cable.

2. Remove the floor console. Refer to Section 9G,

Interior Trim.

3. Disconnect the control module/receiver electrical

connector.

4. Slide the control module/receiver away from its

mounting bracket.

Installation Procedure

1. Install the control module/receiver on its mounting

bracket.

2. Connect the control module/receiver electrical con-

nector.

3. Install the floor console. Refer to Section 9G, Inte-

rior Trim.

4. Connect the negative battery cable.

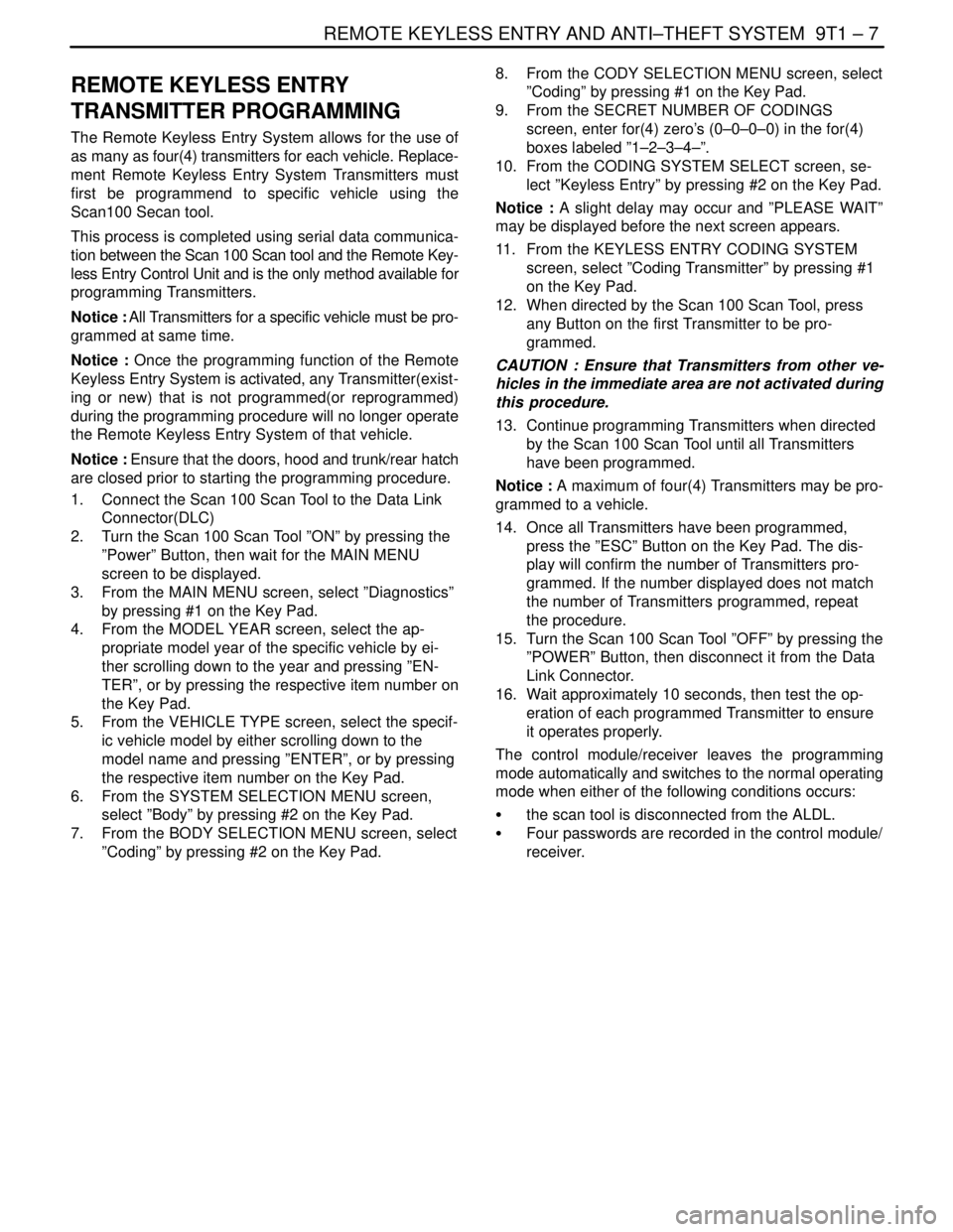

SIREN (GENERAL ONLY)

Removal Procedure

1. Remove the siren electrical connector.

2. Remove the siren bracket mounting bolts and siren.

Page 2488 of 2643

REMOTE KEYLESS ENTRY AND ANTI–THEFT SYSTEM 9T1 – 7

DAEWOO V–121 BL4

REMOTE KEYLESS ENTRY

TRANSMITTER PROGRAMMING

The Remote Keyless Entry System allows for the use of

as many as four(4) transmitters for each vehicle. Replace-

ment Remote Keyless Entry System Transmitters must

first be programmend to specific vehicle using the

Scan100 Secan tool.

This process is completed using serial data communica-

tion between the Scan 100 Scan tool and the Remote Key-

less Entry Control Unit and is the only method available for

programming Transmitters.

Notice : All Transmitters for a specific vehicle must be pro-

grammed at same time.

Notice : Once the programming function of the Remote

Keyless Entry System is activated, any Transmitter(exist-

ing or new) that is not programmed(or reprogrammed)

during the programming procedure will no longer operate

the Remote Keyless Entry System of that vehicle.

Notice : Ensure that the doors, hood and trunk/rear hatch

are closed prior to starting the programming procedure.

1. Connect the Scan 100 Scan Tool to the Data Link

Connector(DLC)

2. Turn the Scan 100 Scan Tool ”ON” by pressing the

”Power” Button, then wait for the MAIN MENU

screen to be displayed.

3. From the MAIN MENU screen, select ”Diagnostics”

by pressing #1 on the Key Pad.

4. From the MODEL YEAR screen, select the ap-

propriate model year of the specific vehicle by ei-

ther scrolling down to the year and pressing ”EN-

TER”, or by pressing the respective item number on

the Key Pad.

5. From the VEHICLE TYPE screen, select the specif-

ic vehicle model by either scrolling down to the

model name and pressing ”ENTER”, or by pressing

the respective item number on the Key Pad.

6. From the SYSTEM SELECTION MENU screen,

select ”Body” by pressing #2 on the Key Pad.

7. From the BODY SELECTION MENU screen, select

”Coding” by pressing #2 on the Key Pad.8. From the CODY SELECTION MENU screen, select

”Coding” by pressing #1 on the Key Pad.

9. From the SECRET NUMBER OF CODINGS

screen, enter for(4) zero’s (0–0–0–0) in the for(4)

boxes labeled ”1–2–3–4–”.

10. From the CODING SYSTEM SELECT screen, se-

lect ”Keyless Entry” by pressing #2 on the Key Pad.

Notice : A slight delay may occur and ”PLEASE WAIT”

may be displayed before the next screen appears.

11. From the KEYLESS ENTRY CODING SYSTEM

screen, select ”Coding Transmitter” by pressing #1

on the Key Pad.

12. When directed by the Scan 100 Scan Tool, press

any Button on the first Transmitter to be pro-

grammed.

CAUTION : Ensure that Transmitters from other ve-

hicles in the immediate area are not activated during

this procedure.

13. Continue programming Transmitters when directed

by the Scan 100 Scan Tool until all Transmitters

have been programmed.

Notice : A maximum of four(4) Transmitters may be pro-

grammed to a vehicle.

14. Once all Transmitters have been programmed,

press the ”ESC” Button on the Key Pad. The dis-

play will confirm the number of Transmitters pro-

grammed. If the number displayed does not match

the number of Transmitters programmed, repeat

the procedure.

15. Turn the Scan 100 Scan Tool ”OFF” by pressing the

”POWER” Button, then disconnect it from the Data

Link Connector.

16. Wait approximately 10 seconds, then test the op-

eration of each programmed Transmitter to ensure

it operates properly.

The control module/receiver leaves the programming

mode automatically and switches to the normal operating

mode when either of the following conditions occurs:

S the scan tool is disconnected from the ALDL.

S Four passwords are recorded in the control module/

receiver.