Operating cylinder DATSUN 210 1979 User Guide

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1979, Model line: 210, Model: DATSUN 210 1979Pages: 548, PDF Size: 28.66 MB

Page 213 of 548

Clutch

Clutch

cover

Diaphragm

spring

height

mm

in

Unevenness

of

diaphragm

spnng

toe

height

mm

in

29

0

to

31

0

1

142

to

1

220

Less

than

O

5

0

020

TIGHTENING

TORQUE

Pedal

stopper

lock

nut

Master

cylinder

push

rod

lock

nut

Operating

cylinder

push

rod

lock

nut

Operating

cylinder

bleeder

screw

Master

cylinder

to

dash

panel

securing

nut

kg

m

ft

lb

Clutch

tube

flare

nut

kg

m

ft

Ib

kg

m

ft

b

kg

m

ft

Ib

kg

m

ft

b

kg

m

ft

b

0

8

to

1

2

5

8

to

8

7

0

8

to

1

2

5

8

to

8

7

0

8

to

1

2

5

8

to

8

7

0

7

to

0

9

5

1

to

6

5

0

8

to

1

2

5

8

to

8

7

1

5

to

1

8

11

to

13

Operating

cylinder

to

clutch

housing

securing

bolt

Qutch

hose

to

operating

cylinder

Qutch

cover

bolt

kg

m

ft

lb

kg

m

ft

Ib

kg

m

ft

Ib

3

1

to

4

1

22

to

30

17

to

2

0

12

to

14

1

6

to

2

1

12

to

15

CL

11

Page 219 of 548

I

ht

2nd

fork

r

2

3rd

top

fork

rod

3

Reverse

fork

rod

4

Retaining

pin

5

I

t

2nd

shift

fork

6

3rd

top

shift

fork

7

Checking

ball

plug

8

Check

ban

spring

9

Check

ball

10

Interlock

plunger

11

S

topper

ring

12

Shift

rod

A

bracket

13

Reverse

shift

fork

14

Lock

pin

15

Striking

lever

Manual

Transmission

16

Striking

rod

17

Return

spring

plug

18

Reverse

check

spring

19

Return

pring

20

Plunger

21

D

ring

22

Stopper

pin

bolt

23

Striking

guide

assembly

24

Striking

guide

oil

seal

REMOVAL

To

dismount

transmission

from

the

car

proceed

as

follows

Disconnect

battery

ground

cable

2

Remove

console

box

and

detach

rubber

boots

if

so

equipped

3

Place

transmission

control

lever

in

neutral

position

and

remove

it

m

TM781

Fig

MT

4

Removing

Control

Lever

@

@

25

Control

lever

bushing

26

Expansion

plug

27

Control

pin

bushing

28

Control

arm

pin

29

Control

lever

o

Tightening

torque

kg

m

ft

lb

@

0

5

to

0

8

3

6

tn

5

8

@

1

3

to

1

7

9

to

12

Fig

MT

3

F4W60L

Tra11lmiBSion

Shift

Control

Components

TM094A

4

Jack

up

the

car

and

support

its

weight

on

safety

stands

Use

a

hy

draulic

hoist

or

open

pit

if

available

Make

sure

that

safety

is

insured

5

Disconnect

front

exhaust

tube

and

remove

bolt

securing

exhaust

mounting

bracket

from

exhaust

front

tube

side

6

Disconnect

wires

from

reverse

back

up

lamp

switch

7

Disconnect

speedometer

cable

from

rear

extension

At

the

same

time

removey

top

detecting

switch

if

so

equipped

8

Remove

propeller

shaft

Refer

to

Removal

Section

PO

Note

Plug

up

the

opening

in

the

rear

extension

to

prevent

oil

from

flow

ing

out

MT

3

9

Remove

clutch

operating

cylinder

from

transmission

case

10

Support

engine

by

placing

a

jack

under

oil

pan

with

a

wooden

block

used

between

oil

pan

and

jack

CAUTION

00

not

place

the

jack

under

the

oil

pan

drain

plug

11

Support

transmission

with

a

transmission

jack

12

Loosen

rear

engine

mount

se

curing

bolts

CD

temporarily

and

re

move

crossmember

mounting

bolts

V

Page 233 of 548

Manual

Transmission

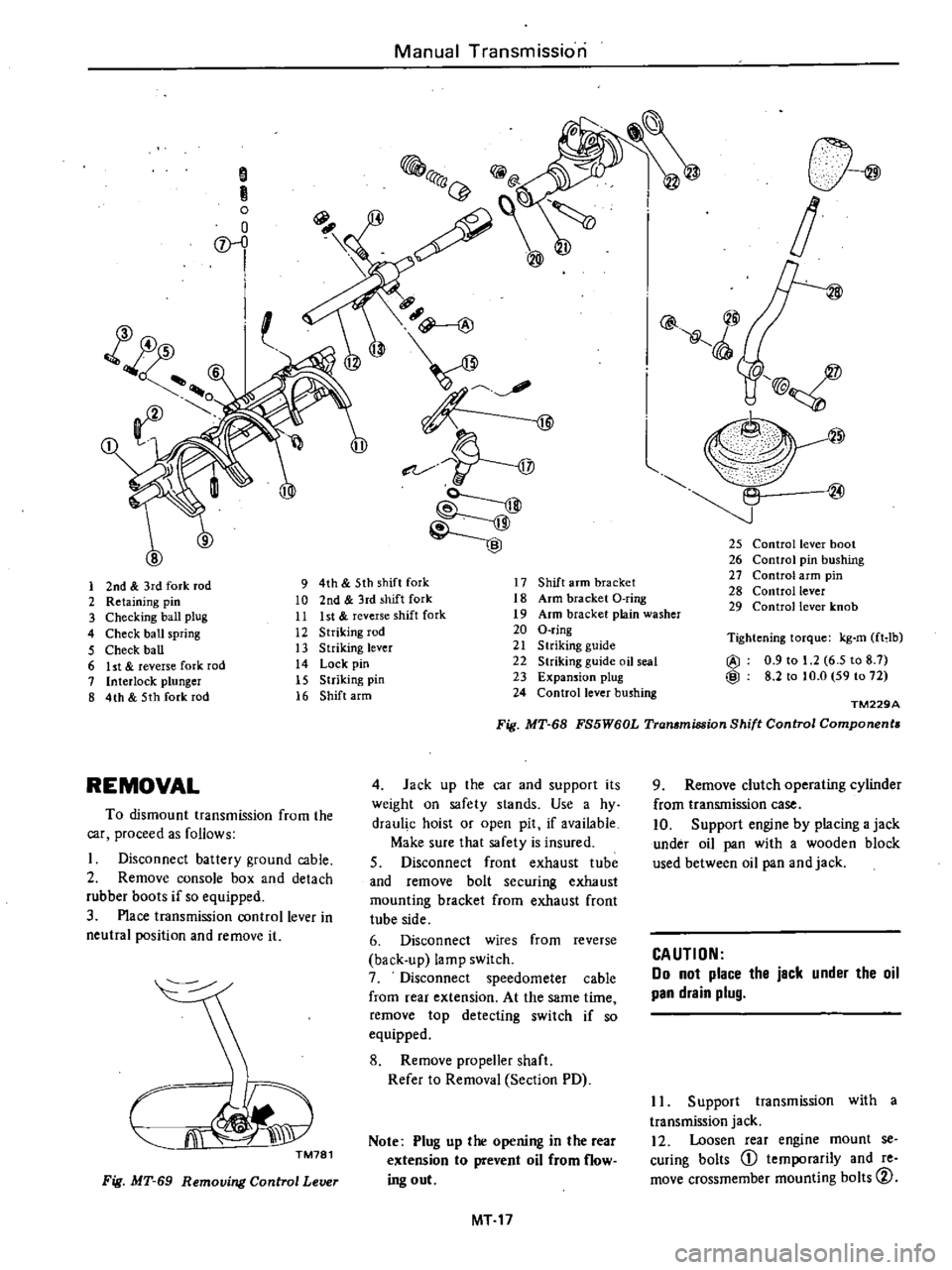

S

R

o

o

D

l

@

@

l

@

l

25

Control

lever

boot

26

Control

pin

bushing

27

Control

arm

pin

28

Control

lever

29

Control

lever

knob

1

2nd

3rd

fork

rod

9

4th

5th

shift

fork

17

Shift

arm

bracket

2

Retaining

pin

10

2nd

3rd

shift

fork

18

Arm

bracket

O

ring

3

Checking

ball

plug

11

Ist

reverse

shift

fork

19

Arm

bracket

plain

washer

4

Check

ball

spring

12

Striking

rod

20

O

ring

5

Check

ball

13

Striking

lever

21

S

lriking

guide

6

ht

reverse

fork

rod

14

Lock

pin

22

Striking

guide

oil

seal

7

Interlock

plunger

15

Striking

pin

23

Expansion

plug

8

4th

5th

fork

rod

16

Shift

arm

24

Control

lever

bushing

Tightening

torque

kg

m

fHb

@

0

9

to

1

2

6

5

to

8

7

@

8

2

to

to

O

59

to

72

TM229A

Fig

MT

68

FS5W60L

Transmission

Shift

Control

Components

REMOVAL

4

Jack

up

the

car

and

supporl

its

weight

on

safety

slands

Use

a

hy

draul

c

hoist

or

open

pit

if

available

Make

sure

that

safety

is

insured

S

Disconnect

front

exhaust

tube

and

remove

bolt

securing

exhaust

mounting

bracket

from

exhaust

front

tube

side

6

Disconnect

wires

from

reverse

back

up

lamp

switch

7

Disconnect

speedometer

cable

from

rear

extension

At

the

same

time

remove

top

detecting

switch

if

so

equipped

8

Remove

propeller

shaft

Refer

to

Removal

Section

PD

To

dismount

transmission

from

the

car

proceed

as

follows

Disconnect

battery

ground

cable

2

Remove

console

box

and

detach

rubber

boots

if

so

equipped

3

Place

transmission

control

lever

in

neutral

position

and

remove

it

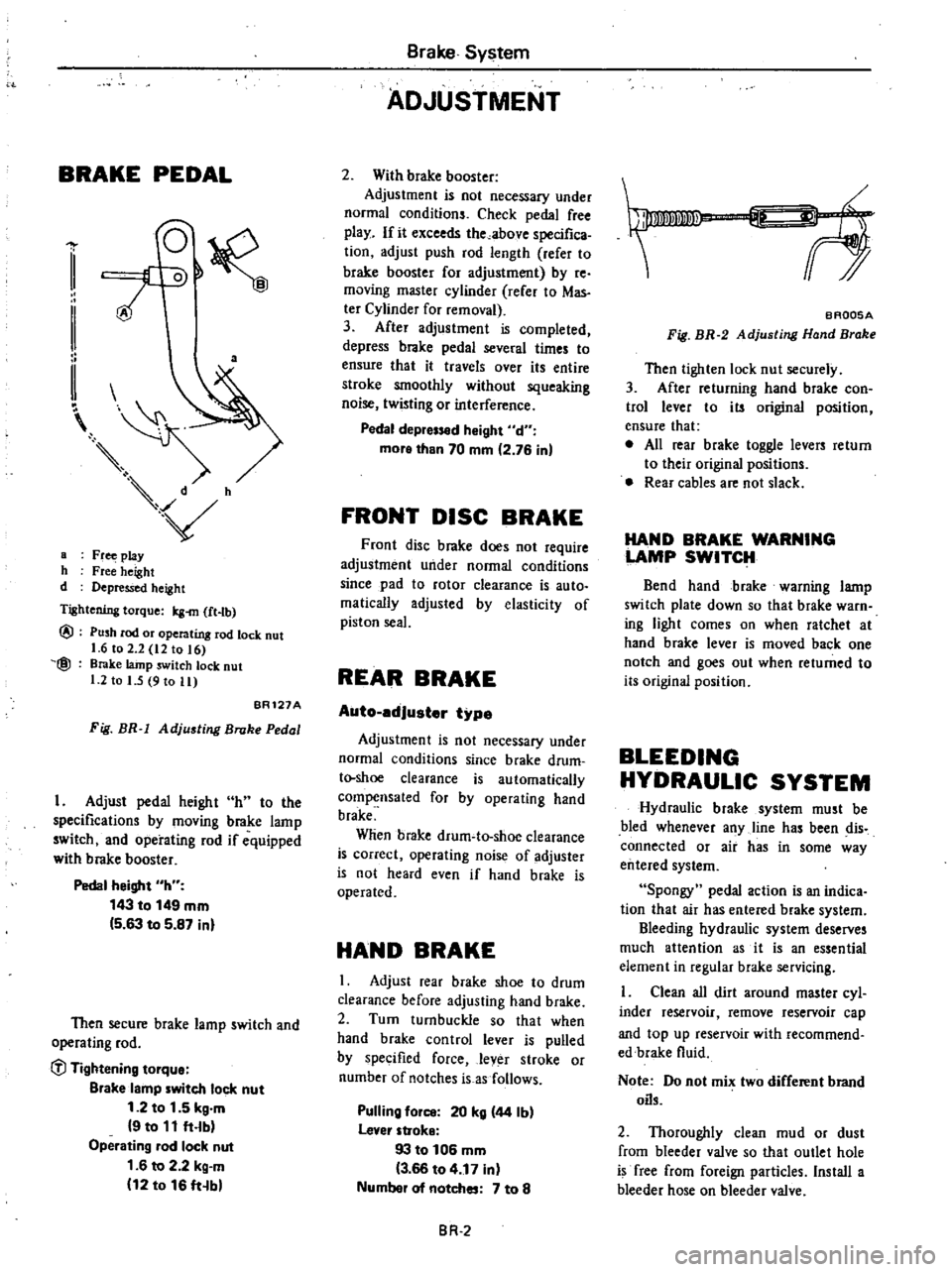

CJi

J

TM781

Note

Plug

up

the

opening

in

the

rear

extension

to

prevent

oil

from

flow

ing

out

Fig

MT

69

Removing

Control

Lever

MT

17

9

Remove

clutch

operating

cylinder

from

transmission

case

10

Support

engine

by

placing

a

jack

under

oil

pan

with

a

wooden

block

used

between

oil

pan

and

jack

CAUTION

Do

not

place

the

jack

under

the

oil

pan

drain

plug

II

Support

transmission

with

a

transmission

jack

12

Loosen

rear

engine

mount

se

curing

bolts

CD

temporarily

and

re

move

crossmember

mounting

bolts

CV

Page 249 of 548

TIGHTENING

TORQUE

Ball

pin

Striking

lever

lock

nut

S

llft

arm

bracket

Mainshaft

bearing

retainer

screw

Mainshaft

lock

nut

Rear

extension

installation

bolt

Stopper

pin

bolt

Front

cover

installation

bolt

Speedometer

sleeve

lock

ing

plate

bolt

Top

detecting

switch

Reverse

lamp

switch

Neutral

switch

Return

spring

plug

Gear

oil

filler

plug

Gear

oil

drain

plug

Transmission

to

engine

installation

bolt

Tr

msmissiori

to

engihe

rear

plate

installation

bolt

Transmission

to

gusset

installation

bolt

Starting

motor

to

trans

inissi

n

installation

bolt

Rear

mounting

insulator

to

transmission

installation

bolt

Crossmember

mounting

bolt

Rear

engine

mount

installation

bolt

Clutch

operating

cylinder

installation

bolt

Propeller

shaft

to

differential

carrier

Control

lever

pin

installation

nut

Exhaust

mounting

bracket

to

exhaust

front

tube

FU

model

only

Manual

Transmission

F4W60L

2

0

to

3

0

14

to

22

0

9

to

1

2

6

5

to

8

7

0

7

to

1

0

5

1

to

7

2

1

6

to

2

2

12

to

16

0

5

to

0

8

3

6

to

5

8

1

0

to

1

6

7

to

12

0

3

to

0

5

2

2

to

3

6

2

0

to

3

5

14

to

25

2

0

to

3

5

14

to

25

0

5

to

1

0

3

6

to

7

2

2

5

to

4

0

18

to

29

2

5

to

4

0

18

to

29

1

6

to

2

2

12Jo

16

1

6

to

2

2

12

t

16

4

6

to

6

1

33

to

44

3

0

to

4

0

22

to

29

0

9

to

1

2

6

5

to

8

7

3

2

to

4

3

23

to

31

0

9

to

1

2

6

5

to

8

7

3

1

to

4

1

22

to

30

2

4

to

3

3

17

to

24

1

3

to

1

7

9

to

12

3

2

to

4

3

23

to

31

MT33

Unit

kg

m

ft

lb

FS5W60L

2

0

to

3

0

14

to

22

0

9

to

1

2

6

5

to

8

7

8

2

to

10

0

59

to

72

0

8

to

1

3

5

8

to

9

4

10

0

to

11

0

72

to

80

1

6

to

2

2

12

to

16

1

0

to

1

6

7

to

12

0

3

to

0

5

2

2

to

3

6

2

0

to

3

5

14

to

25

2

0

to

3

5

14

to

25

2

0

to

3

5

14

to

25

0

5

to

1

0

3

6

to

7

2

2

5

to

4

0

18

to

29

i

5

to

4

0

18

to

29

1

6

to

2

2

12

to

16

1

6

to

2

2

12

to

16

4

6

to

6

1

33

to

44

3

0

to

4

0

22

to

29

0

9

to

1

2

6

5

to

8

7

3

2

to

4

3

23

to

31

0

9

to

1

2

6

5

to

8

7

3

1

to

4

1

22

to

30

2

4

to

3

3

17

to

24

1

3

to

1

7

9

to

12

3

2

to

4

3

23

to

31

Page 354 of 548

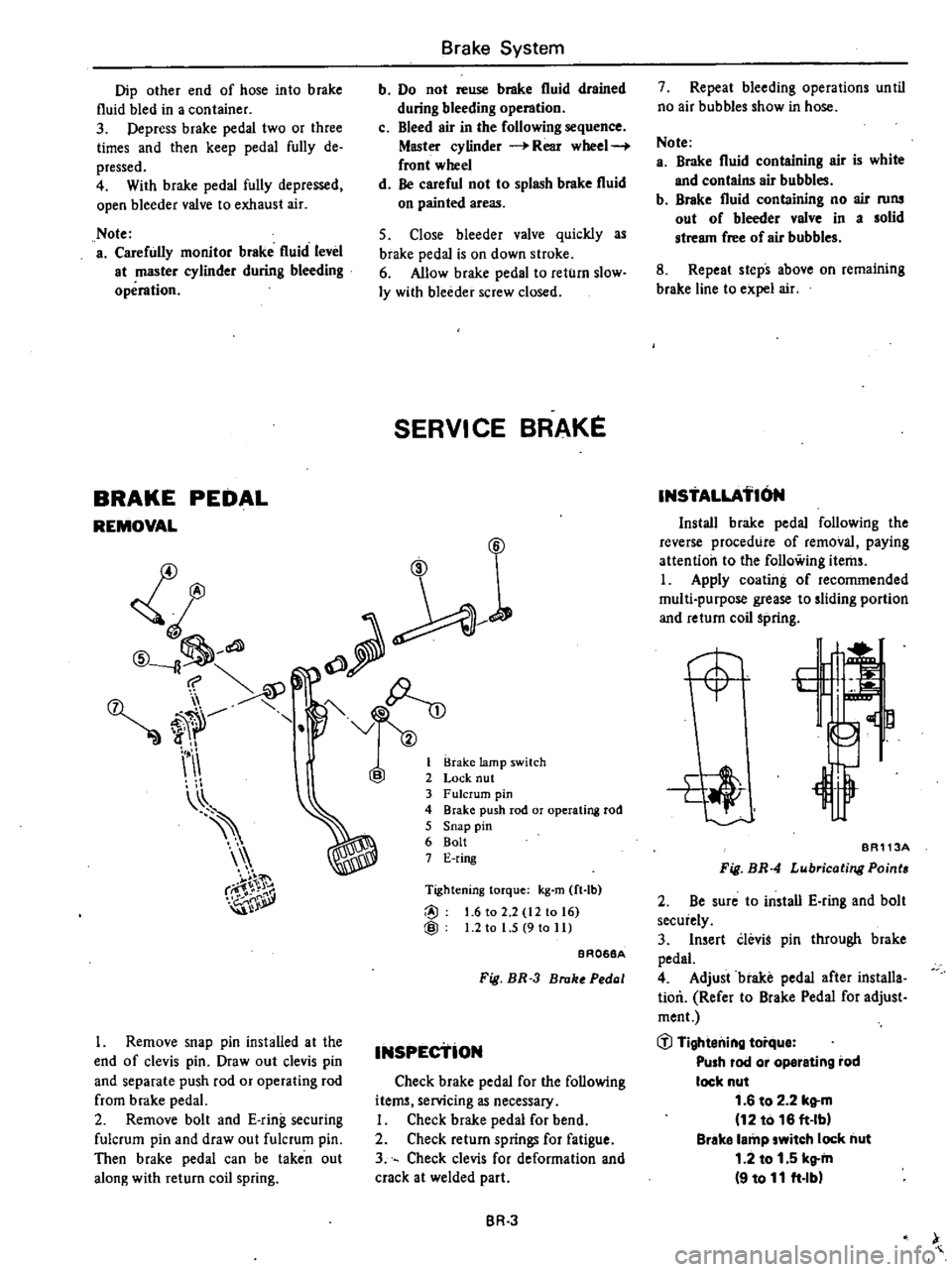

BRAKE

PEDAL

a

a

Fr

play

h

Free

height

d

Depressed

height

Tightening

torque

Icg

m

ft

tb

@

@

Push

rod

or

operating

rod

lock

nut

1

6

to

2

2

12

to

16

Brake

lainp

switch

lock

nut

1

2

to

I

5

9

to

11

BR121A

Fig

BR

1

Adjusting

Broke

Pedal

I

Adjust

pedal

height

h

to

the

specifications

by

moving

brake

lamp

switch

and

operating

rod

if

equipped

with

brake

booster

Pedal

height

h

143

to

149

mm

5

63

to

5

87

inl

Then

secure

brake

lamp

switch

and

operating

rod

C

l

Tightening

tOlque

Blake

lamp

witch

lock

nut

1

2

to

1

5

kg

m

9

to

11

ft

lb

Operating

lad

lock

nut

1

6

to

2

2

kg

m

12

to

16

ft

b

Brake

System

ADJUSTMENT

2

With

brake

booster

Adjustment

is

not

necessary

under

normal

conditions

Check

pedal

free

play

If

it

exceeds

the

above

specifica

tion

adjust

push

rod

length

refer

to

brake

booster

for

adjustment

by

re

moving

master

cylinder

rerer

to

Mas

ter

Cylinder

for

removal

3

After

adjustment

is

completed

depress

brake

pedal

several

times

to

ensure

that

it

travels

over

its

entire

stroke

smoothly

without

squeaking

noise

twisting

or

interference

Pedal

depr

d

Might

d

more

than

70

mm

2

76

in

FRONT

DISC

BRAKE

Front

disc

brake

does

not

require

adjustment

under

normal

conditions

since

pad

to

rotor

clearance

is

auto

malically

adjusted

by

elasticity

of

piston

seal

REAR

BRAKE

Auto

edJuster

type

Adjustment

is

not

necessary

under

normal

conditions

since

brake

drum

t

shoe

clearance

is

automatically

compensated

for

by

operating

hand

brake

Wlien

brake

drum

to

shoe

clearance

is

correct

operating

noise

of

adjuster

is

not

heard

even

if

hand

brake

is

operated

HAND

BRAKE

I

Adjust

rear

brake

shoe

to

drum

clearance

before

adjusting

hand

brake

2

Turn

turnbuckle

so

that

when

hand

brake

control

lever

is

pulled

by

specified

force

lever

stroke

or

number

of

notches

is

as

follows

Pulling

fOil

20

kg

44

Ib

lever

stroke

93

to

106

mm

3

66

to

4

17

in

Numbel

of

notches

7

to

8

BR

2

f

BAQ05A

Fig

BR

2

Adjusting

Hand

Brake

Then

tighten

lock

nut

securely

3

After

returning

hand

brake

con

trol

lever

to

its

original

position

ensure

that

e

All

rear

brake

toggle

levers

return

to

their

original

positions

Rear

cables

are

not

slack

HAND

BRAKE

WARNING

LAMP

SWITCH

Bend

hand

brake

warning

lamp

switch

plate

down

so

that

brake

warn

ing

light

comes

on

when

ratchet

at

hand

brake

lever

is

moved

back

one

notch

and

goes

out

when

returned

to

its

original

position

BLEEDING

HYDRAULIC

SYSTEM

Hydraulic

brake

system

must

be

bled

whenever

any

line

has

been

dis

connected

or

air

has

in

some

way

entered

system

Spongy

pedal

action

is

an

indica

tion

that

air

has

entered

brake

system

Bleeding

hydraulic

system

deserves

much

attention

as

it

is

an

essential

element

in

regular

brake

servicing

Clean

all

dirt

around

master

cyl

inder

reservoir

remove

reservoir

cap

and

top

up

reservoir

with

recommend

edbrake

fluid

Note

Do

not

mix

two

different

brand

oils

2

Thoroughly

clean

mud

or

dust

from

bleeder

valve

so

that

outlet

hole

is

free

from

foreign

particles

Install

a

bleeder

hose

on

bleeder

valve

Page 355 of 548

L

@

fl

JJ

l

f

m

ff

v

1

II

2

I

I

II

B

s1

r

Dip

other

end

of

hose

into

brake

fluid

bled

in

a

container

3

Pepress

brake

pedal

two

or

three

times

and

then

keep

pedal

fully

de

pressed

4

With

brake

pedal

fully

depressed

open

bleeder

valve

to

exhaust

air

Note

a

Carefully

monitor

brake

fluid

level

at

master

cylinder

during

bleeding

operation

BRAKE

PEDAL

REMOVAL

I

Remove

snap

pin

installed

at

the

end

of

clevis

pin

Draw

out

clevis

pin

and

separate

push

rod

or

operating

rod

from

brake

pedal

2

Remove

bolt

and

E

ring

securing

fulcrum

pin

and

draw

out

fulcrum

pin

Then

brake

pedal

can

be

taken

out

along

with

return

coil

spring

Brake

System

b

Do

not

reuse

brake

fluid

drained

during

bleeding

operation

c

Bleed

air

in

the

following

sequence

Master

cylinder

Rear

wheel

front

wheel

d

Be

careful

not

to

splash

brake

fluid

on

painted

areas

5

Close

bleeder

valve

quickly

as

brake

pedal

is

on

down

stroke

6

Allow

brake

pedal

to

return

slow

ly

with

bleeder

screw

closed

SERVI

CE

BRAKE

fJ

Brake

lamp

switch

Lock

nut

Fulcrum

pin

Brake

push

rod

or

operating

rod

Snap

pin

Bolt

E

ring

Tightening

torque

kg

m

ft

Ib

@

1

6

to

2

2

12

10

16

@

1

2

to

l

S

9

to

II

BROS8A

Fig

BR

3

Broke

Pedal

INSPEctioN

Check

brake

pedal

for

the

following

items

servicing

as

necessary

I

Check

brake

pedal

for

bend

2

Check

return

springs

for

fatigue

3

Check

clevis

for

deformation

and

crack

at

welded

part

BR

3

7

Repeat

bleeding

operations

until

no

air

bubbles

show

in

hose

Note

a

Brake

fluid

containing

air

is

white

and

contalns

air

bubbles

b

Brake

fluid

containing

no

air

rons

out

of

bleeder

valve

in

a

solid

stream

free

of

air

bubbles

8

Repeat

steps

above

on

remaining

brake

line

to

expel

air

INSTALLATION

Install

brake

pedal

following

the

reverse

procedure

of

removal

paying

attention

to

the

following

items

I

Apply

coating

of

recommended

multi

purpose

grease

to

sliding

portion

and

return

coil

spring

BA113A

Fit

BR

4

Lubricating

Point

2

Be

sure

to

install

E

ring

and

bolt

securely

3

Insert

CleviS

pin

through

brake

pedal

4

Adjust

brake

pedal

after

installa

tion

Refer

to

Blake

Pedal

for

adjust

ment

j

Tightening

torque

Push

rod

or

op8leting

rod

lock

nut

1

6

to

2

2

kltm

12

to

16

ft

Ibl

Brake

lamp

switch

lock

nut

1

2

to

1

5

kltin

9

to

11

ft

lb

Page 365 of 548

INSPECTION

Brake

drum

I

Check

inner

diameter

of

brake

drum

to

make

sure

it

is

properly

round

and

tapered

If

it

is

not

repair

or

replace

brake

drum

Inner

diameter

Standard

diametel

203

2

mm

8

in

Maximum

diameter

204

5

mm

8

05

in

Out

of

loundness

ellipticity

less

than

0

02

mm

0

0008

in

Radial

runout

less

than

0

1

mm

0

004

in

Total

indicator

reading

Taper

less

than

0

02

mm

0

0008

in

Measured

at

a

point

40

mm

1

57

in

flam

inlet

2

Contact

surface

with

which

lin

ings

come

into

contact

should

be

fine

finished

with

No

120

to

150

sandpaper

3

Using

a

drum

racer

finish

brake

drum

by

machining

if

it

shows

any

sign

of

score

marks

partial

wear

or

stepped

wear

on

its

contact

surface

Note

After

brake

drum

has

been

completely

re

conditioned

or

re

placed

check

drum

and

shoes

for

proper

contact

pattern

Brake

e

embly

1

Replace

any

linings

which

are

cracked

worn

or

oil

stained

2

If

lining

is

worn

to

less

than

the

specified

value

replace

Lining

wear

limit

Minimum

thickness

1

5

mm

0

059

in

3

Replace

any

shoe

return

springs

which

are

broken

or

fatigued

4

Replace

fatigued

anti

rattle

spring

damaged

pin

and

or

retainer

Wheel

cylinder

I

Replace

any

cylinder

or

piston

which

is

scratched

scored

or

worn

on

its

sliding

contact

surface

Brake

System

2

Replace

worn

parts

if

piston

to

cylinder

clearance

is

beyond

limit

Piston

ta

cylinder

clearance

less

than

0

15

mm

0

0059

in

3

Replace

any

piston

cup

which

is

worn

or

otherwise

damaged

4

Replace

if

contacting

face

of

cyl

inder

and

shoe

is

worn

locally

or

in

step

5

Replace

any

damaged

dust

cover

fatigued

piston

spring

or

faulty

thread

ed

parts

6

Replace

any

tube

connector

which

is

worn

on

its

threaded

portion

INSTALLATION

Install

rear

brake

in

reverse

order

of

removal

closely

observing

the

follow

ing

1

Tighten

following

parts

to

speci

fied

torque

CAUTION

When

installing

brake

tube

use

Flare

Nut

Torque

Wrench

6694310000

ifl

Tightening

torque

Flared

nut

1

5

to

1

8

kg

m

11

to

13

fHb

Ail

bleedel

0

7

to

0

9

kg

m

15

1

to

6

5

ft

Ib

Wheel

cylinder

mounting

bolt

0

6

to

0

8

kg

m

4

3

to

5

8

ft

b

2

There

are

two

types

of

adjusters

which

have

right

thread

or

left

thread

R

H

brake

Right

thread

adjuster

L

H

brake

Left

thread

adjuster

3

Sparingly

apply

a

coat

of

brake

grease

to

the

following

points

Lubricating

points

e

Adjuster

nut

and

rod

threads

Mating

surfaces

between

adjuster

and

toggle

lever

and

pin

and

roller

BR

ll

0

J

o

BR

117

A

Fig

BR

24

Lubricating

Points

of

Adju

ter

4

Referring

to

Fig

BR

25

for

locations

of

lubricating

points

apply

a

coat

of

brake

grease

to

these

points

Exercise

care

not

to

allow

grease

to

come

into

contact

with

lining

or

ad

juster

screws

Lubricating

points

e

Contact

areas

between

wheel

cyl

inder

anchor

block

and

brake

shoe

e

Mating

surfaces

between

brake

shoe

and

brake

disc

Contact

areas

between

hand

brake

adjuster

and

brake

shoe

Contact

areas

between

brake

disc

brake

shoe

and

toggle

lever

Contact

areas

between

anti

rattle

pin

spring

retainer

and

brake

shoe

Fig

BR

25

Lubricating

Points

5

To

prevent

water

from

entering

brake

drum

apply

dry

sealant

to

brake

disc

mounting

surfaces

of

the

follow

ing

parts

Wheel

cylinder

Anti

rattle

spring

6

Make

sure

that

entire

brake

shoe

fits

in

place

7

Make

sure

that

adjuster

operates

properly

8

After

installation

is

completed

check

and

adjust

shoe

to

drum

clear

ance

by

operating

hand

brake

several

times

9

Bleed

brake

system

Page 366 of 548

BRAKE

BOOSTE

R

INSPECTION

OF

OPERATION

Checking

vecuum

pressure

I

Connect

a

vacuum

gauge

in

the

tine

between

check

velve

and

brake

booster

1

Check

valVe

2

Vacuum

gauge

BA942

Fig

BR

26

Air

Tighte

Te

Set

Up

Probable

cause

Air

leakage

at

check

valve

2

Air

leakage

at

push

rod

seal

3

Air

leakage

between

valve

body

and

seal

4

Air

leakage

at

valve

plunger

seat

5

Damaged

piping

or

joints

Air

tight

test

Under

loed

Fifteen

seconds

after

engine

is

stopped

and

brake

fully

applied

ob

serve

the

rate

of

drop

in

air

pressure

registered

by

vacuum

gauge

If

vacuum

Probable

cause

Air

leakage

at

check

valve

2

Damaged

diaphragm

3

Reaction

disc

dropped

off

4

Air

leakage

at

poppet

assembly

seat

and

valve

body

Inspec

tinK

chec

k

valve

Remove

clip

and

disconnect

hoses

Brake

System

2

Start

engine

end

merease

engine

speed

Stop

engine

when

vacuum

gauge

indicates

500

mmHg

l9

69

inHg

Air

tiKht

test

No

load

Fifteen

seconds

after

engine

is

stopped

observe

the

rate

of

drop

in

air

pressure

registered

by

vacuum

gauge

If

vacuum

pressure

drop

below

the

specified

value

refer

to

the

following

chart

to

determine

the

cause

of

failure

Maximum

vacuum

leakage

25

mmHg

0

98

inHgl

Corrective

action

Replace

check

valve

Replace

brake

booster

as

an

assembly

Repair

or

replace

pressure

drops

below

the

specified

value

refer

to

the

following

chart

to

determine

the

cause

of

failure

Maximum

vacuum

leakage

25

mmHg

0

98

inHgl

Corrective

action

Replace

check

valve

Replace

brake

booster

as

an

assembly

at

connections

The

check

valve

can

now

be

removed

BR

12

JQeL

i

l

f

BR119A

Fis

BR

27

Location

of

Check

Valllt

2

Using

a

brake

booster

testel

apply

a

vacuum

pressure

of

500

mmHg

19

69

inHg

to

the

port

of

check

valve

on

the

brake

booster

side

If

vacuum

pressure

drops

below

the

specified

value

in

15

seconds

replace

check

valve

with

a

new

one

Maximum

vacuum

leakage

01

eheck

valn

10

mmHg

0

39

inHgl

3

When

pressure

is

applied

to

the

b

rake

booster

side

of

check

valve

and

valve

does

not

open

replace

check

valve

with

a

new

one

I

0

tLLiJ

Manifold

side

Brake

booster

side

1

Spring

2

Valve

BR963

Fig

BR

28

Check

Value

4

When

installing

check

valve

be

careful

to

avoid

incorrect

connectiolU

See

Fig

DR

28

Operetlns

test

1

Connect

an

oil

pressure

gauge

to

brake

ine

at

connection

on

master

cylinder

2

Install

a

pedal

force

gauge

on

brake

pedal

3

Start

engine

end

increase

engine

speed

until

a

vacuum

pressure

of

500

mmHg

19

69

inHg

is

registered

on

vacuum

pressure

gauge

With

a

steady

vacuum

pressure

of

500

mmHg

19

69

inHg

measure

oil

pressure

with

res

pect

to

each

pedal

operating

force

Page 367 of 548

Relationship

between

oil

pressure

and

pedal

operating

force

is

illustrated

in

Fig

BR

29

If

test

results

are

not

as

specified

in

Fig

BR

29

check

brake

booster

for

condition

in

manner

des

cribed

under

Inspection

before

re

moval

of

this

unit

REMOVAL

M60

120

1

710

AA

I

1

1

110

1

560

1

v

e

100

1

420

I

90

1

280

I

1

1

80

1

140

I

Z

I

t

70

1

000

i

60

850

I

o

50

710

d

40

570

g

i

gl

j

ll

10

140

J

0

1

0

2

0

221

441

Rod

operating

force

kg

lb

Brake

System

Also

check

brake

line

for

evidence

of

fluid

leakage

Note

Detennine

whether

source

of

problem

is

in

brake

booster

or

check

valve

Before

you

reach

a

fmal

conclusion

always

inspect

check

valve

first

o

10

20

30

40

50

22

44

66

88

110

Pedal

operating

force

kg

lb

BA121A

Fig

BR

29

Performance

Diagram

of

Brake

Booster

Remo

parts

in

numerical

order

enumerated

BR593

ti

J

Fig

BR

30

Procedures

for

Removing

Brake

Booster

ADJUSTMENT

I

Adjust

the

length

of

push

rod

to

the

value

indicated

below

Length

ad

justment

of

push

rod

is

made

at

the

tip

of

push

rod

Length

A

9

75

to

10

00

mm

0

3839

to

0

3937

in

j

f

Irl

I

l

if

L

J

BA290

Fig

BR

31

Length

A

BR

13

BR288

Fig

BR

32

Adjusting

Push

Rod

Length

2

Install

clevis

Adjust

length

of

operating

rod

to

specified

value

length

B

135

mm

5

31

in

c

f

lIJ

t

t

B

BR947

Fig

BR

33

Length

B

INSTALLATION

Install

in

the

reverse

sequence

of

removaJ

IiJ

Tightening

torque

Master

cylinder

to

brake

booster

0

8

to

1

1

kg

m

5

8

to

8

0

ft

Ib

Brake

booster

to

body

0

8

to

1

1

kg

m

5

8

to

8

0

ft

lbl

Note

After

brake

boOster

is

properly

installed

in

car

conduct

an

air

tight

and

op

rational

tests

as

previously

described

Page 371 of 548

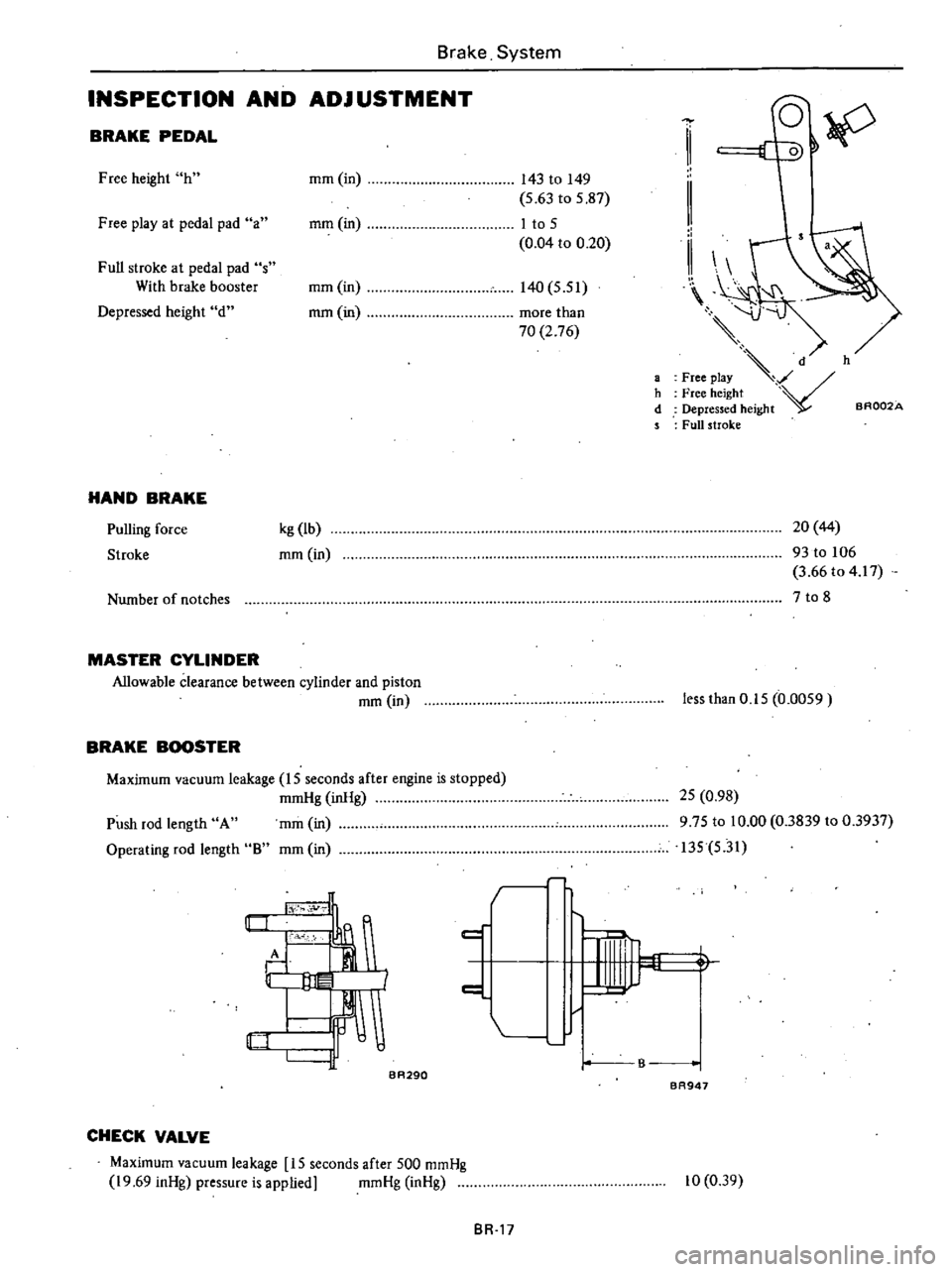

Brake

System

INSPECTION

AND

ADJ

USTMENT

BRAKE

PEDAL

Free

height

h

mm

in

143

to

149

5

63

to

5

87

Free

play

at

pedal

pad

a

mm

in

I

to

5

0

04

to

0

20

Full

stroke

at

pedal

pad

s

With

brake

booster

mm

in

140

5

51

Depressed

height

d

mm

in

more

than

70

2

76

HAND

BRAKE

Pulling

force

Stroke

kg

lb

mm

in

Number

of

notches

MASTER

CYLINDER

Allowable

clearance

between

cylinder

and

piston

mm

in

BRAKE

BOOSTER

Maximum

vacuum

leakage

15

seconds

after

engine

is

stopped

mmHg

inHg

mm

in

mm

in

Push

rod

length

A

Operating

rod

length

8

I

c

tY

1I1

fF

I

BA290

d

IF

CHECK

VALVE

Maximum

vacuum

leakage

15

seconds

after

500

mmHg

19

69

inHg

pressure

is

applied

mmHg

inHg

BR

17

h

d

1

II

II

d

h

Free

play

V

Free

height

Depressed

height

aR002A

Full

stroke

20

44

93

to

106

3

66

to

4

17

7

to

8

less

than

0

15

0

0059

25

0

98

975

to

10

00

0

3839

to

0

3937

135

5

31

1

B

BR947

10

0

39