Operating cylinder DATSUN 210 1979 Owner's Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1979, Model line: 210, Model: DATSUN 210 1979Pages: 548, PDF Size: 28.66 MB

Page 372 of 548

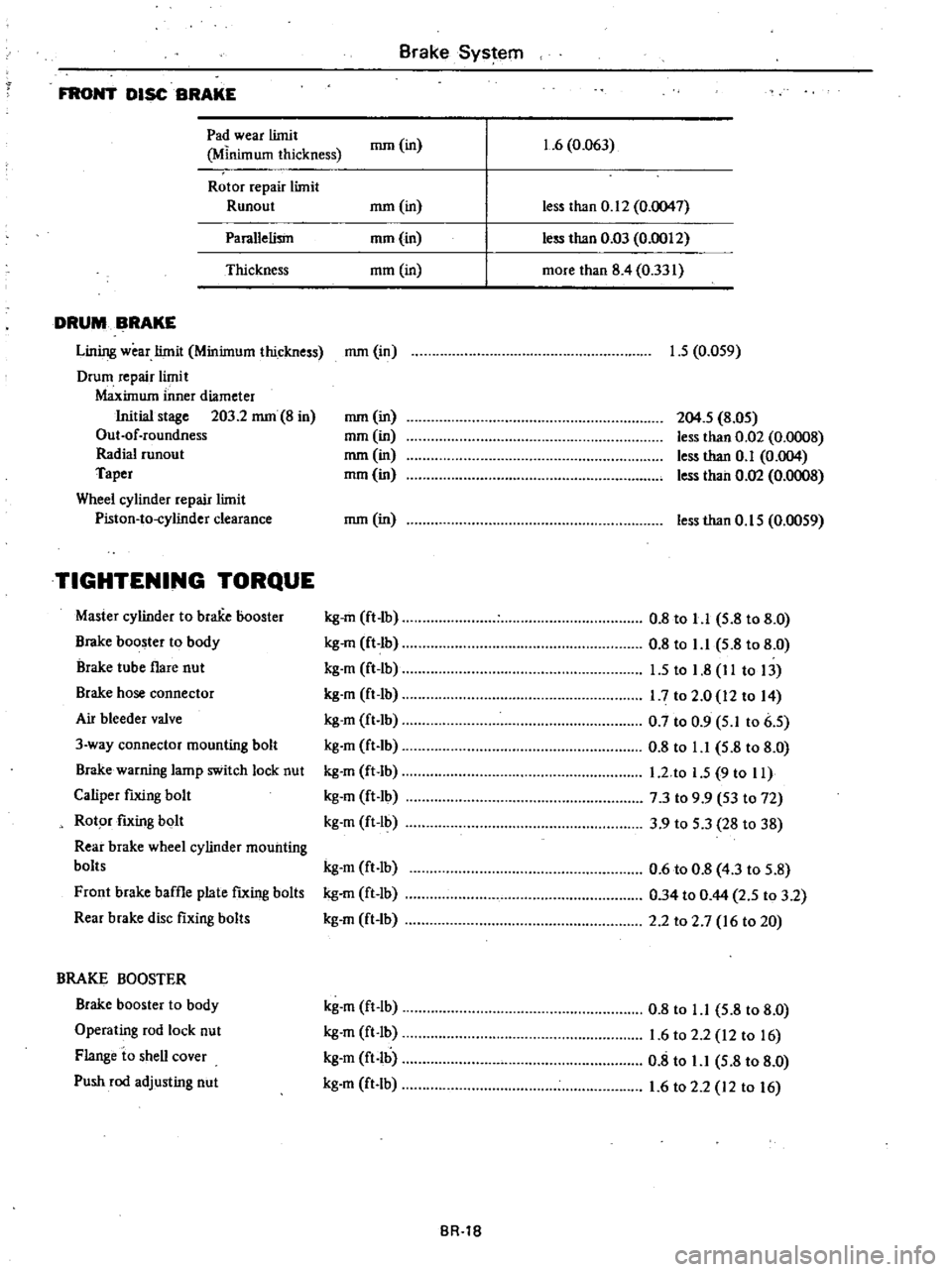

FRONT

DISC

BRAKE

Pad

wear

limit

Minim

urn

thickness

Rotor

repair

limit

Runout

Parallelism

Thickness

DRUM

BRAKE

Lining

wear

limit

Minimum

thickness

Drum

repair

limit

Maximum

inner

diameter

Initial

stage

203

2

nun

8

in

Out

of

roundness

Radial

cunout

Taper

Wheel

cylinder

repair

limit

Piston

to

cylinder

clearance

TIGHTENING

TORQUE

Master

cylinder

to

brake

booster

Brake

booster

to

body

Brake

tube

flare

nut

Brake

hose

connector

Air

bleeder

valve

3

way

connector

mounting

bolt

Brake

warning

lamp

switch

lock

nut

Caliper

fixing

bolt

Rotor

fixing

bolt

Rear

brake

wheel

cylinder

mounting

bolts

Front

brake

baffle

plate

fixing

bolts

Rear

brake

disc

fixing

bolts

BRAKE

BOOSTER

Brake

booster

to

body

Operating

rod

lock

nut

Flange

io

shell

cover

Push

rod

adjusting

nut

nun

in

nun

in

nun

in

mm

in

nun

in

nun

in

mm

in

nun

in

mm

in

nun

in

kg

m

ft

lb

kg

m

ft

lb

kg

m

ft

Ib

kg

m

ft

lb

kg

m

ft

Ib

kg

m

ft

lb

kg

m

ft

Ib

kg

m

ft

lb

kg

m

ft

Ib

kg

m

ft

lb

kg

m

ft

Ib

kg

m

ft

Ib

kg

m

ft

lb

kg

m

ft

lb

kg

m

ft

lb

kg

m

ft

lb

Brake

System

BR

1B

1

6

0

063

less

than

0

12

0

0047

less

than

0

03

0

0012

more

than

8

4

0

331

1

5

0

059

204

5

8

05

less

than

0

02

0

0008

less

than

0

1

0

004

less

than

0

02

0

0008

less

than

0

15

0

0059

0

8

to

1

1

5

8

to

8

0

0

8

to

1

1

5

8

to

8

0

1

5

to

1

8

II

to

13

1

7

to

2

0

12

to

14

0

7

to

0

9

5

1

to

6

5

0

8

to

1

1

5

8

to

8

0

l

2

to

1

5

9

to

II

7

3

to

9

9

53

to

72

3

9

to

5

3

28

to

38

0

6

to

0

8

4

3

to

5

8

0

34

to

0

44

2

5

to

3

2

2

2

to

2

7

16

to

20

0

8

to

1

1

5

8

to

8

0

1

6

to

2

2

12

to

16

0

8

to

1

1

5

8

to

8

0

1

6

to

2

2

12

to

16

Page 388 of 548

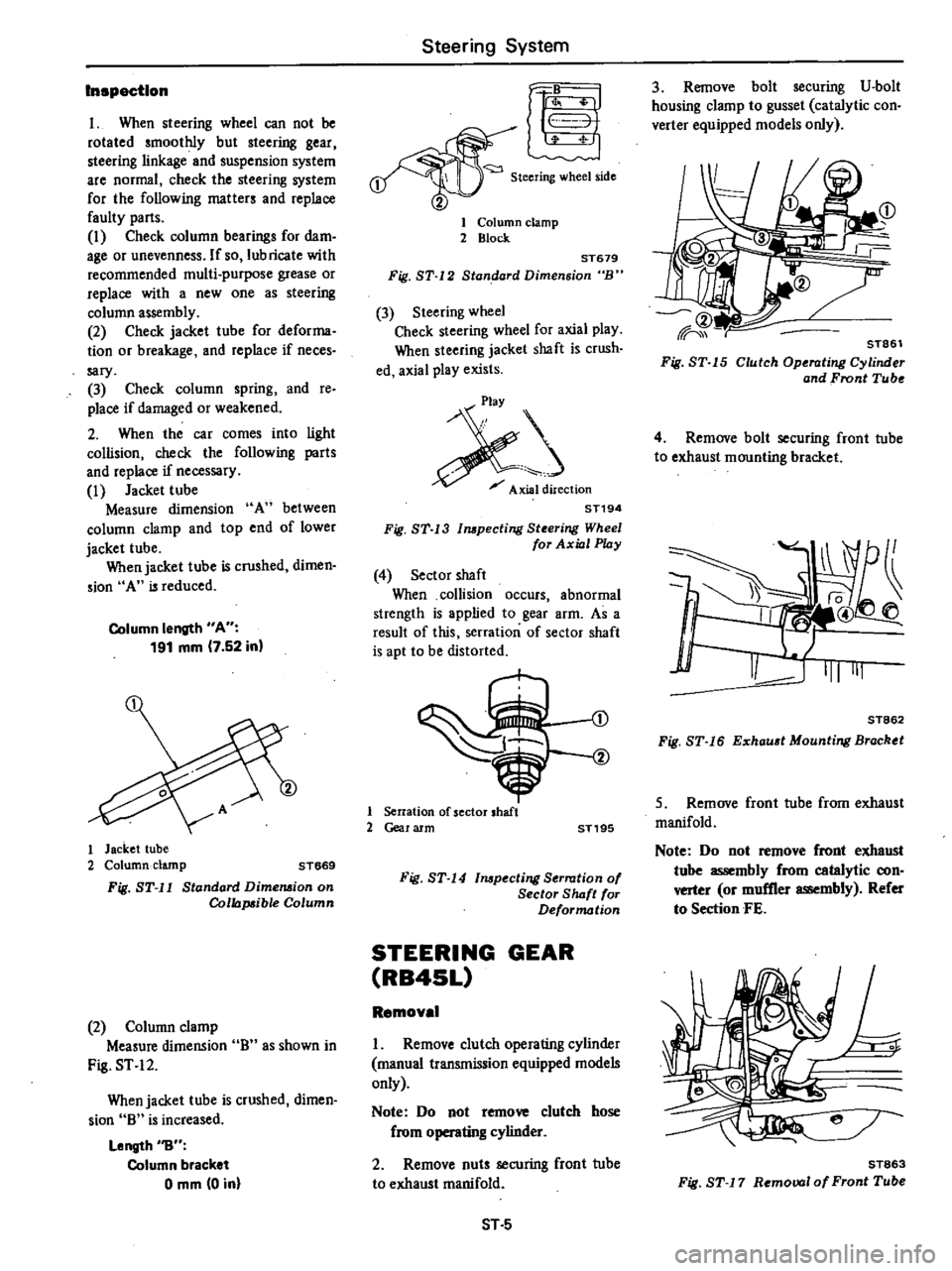

Inspection

I

When

steering

wheel

can

not

be

rotated

smoothly

but

steering

gear

steering

linkage

and

suspension

system

are

normal

check

the

steering

system

for

the

following

matters

and

replace

faulty

parts

I

Check

column

bearings

for

dam

age

or

unevenness

If

so

lubricate

with

recommended

multi

purpose

grease

or

replace

with

a

new

one

as

steering

column

assembly

2

Check

jacket

tube

for

deforma

tion

or

breakage

and

replace

if

neces

sary

3

Check

column

spring

and

re

place

if

damaged

or

weakened

2

When

the

car

comes

into

light

collision

check

the

following

parts

and

replace

if

necessary

I

Jacket

tube

Measure

dimension

A

between

column

clamp

and

top

end

of

lower

jacket

tube

When

jacket

tube

is

crushed

dimen

sion

A

is

reduced

Column

length

A

191

mm

7

52

in

1

Jacket

tube

2

Column

clamp

ST669

Fig

ST

l1

Standard

Dimension

on

Collapsible

Column

2

Column

clamp

Measure

dimension

0

as

shown

in

Fig

ST

12

When

jacket

tube

is

crushed

dimen

sion

0

is

increased

Length

1J

Column

bracket

o

mm

0

in

Steering

System

r

1

Steering

wheel

side

1

Column

clamp

2

Block

ST679

Fig

ST

12

Standard

Dimension

B

3

Steering

wheel

Check

steering

wheel

for

axial

play

When

steering

jacket

shaft

is

crush

ed

axial

play

exists

j

Axial

direction

ST194

Fig

ST

13

mpecting

Steering

Wheel

for

Axial

Play

4

Sector

shaft

When

collision

occurs

abnormal

strength

is

applied

to

gear

arm

As

a

result

of

this

serration

of

sector

shaft

is

apt

to

be

distorted

1

Serration

of

sector

shaft

2

Gear

arm

ST195

Fig

ST

14

mpeeting

Serration

of

Sector

S

IuJft

for

Deformation

STEERING

GEAR

RB4SL

Removal

I

Remove

clutch

operating

cylinder

manual

transmission

equipped

models

only

Note

Do

not

remove

clutch

hose

from

8

cylinder

2

Remove

nuts

securing

front

tube

to

exhaust

manifold

ST

5

3

Remove

bolt

securing

V

bolt

housing

clamp

to

gusset

catalytic

con

verter

equipped

models

only

STa6l

Fig

ST

5

Clutch

Operating

Cylinder

and

Front

Tube

4

Remove

bolt

securing

front

tube

to

exhaust

mounting

bracket

1

Q

I

II

@

J

111111

ST862

Fig

ST

16

Exhau

t

Mounting

Bracktt

5

Remove

front

tube

from

exhaust

manifold

Note

Do

not

remove

front

exhaust

tube

assembly

from

catalytic

con

verter

or

muffler

assembly

Refer

to

Section

FE

ST863

Fig

ST

7

Removal

of

Front

Tube