automatic transmission fluid DATSUN 210 1979 Service Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1979, Model line: 210, Model: DATSUN 210 1979Pages: 548, PDF Size: 28.66 MB

Page 9 of 548

Erigine

crankcase

EI

gine

cooling

system

Transmission

case

Final

drive

case

housing

Steering

gear

box

Fuel

tank

Air

conditioning

system

Refrigerant

Compressor

oil

f

tl

It

J

4

i

1

protect

the

catalytic

cop

verter

froitr

contamination

t

n

General

Information

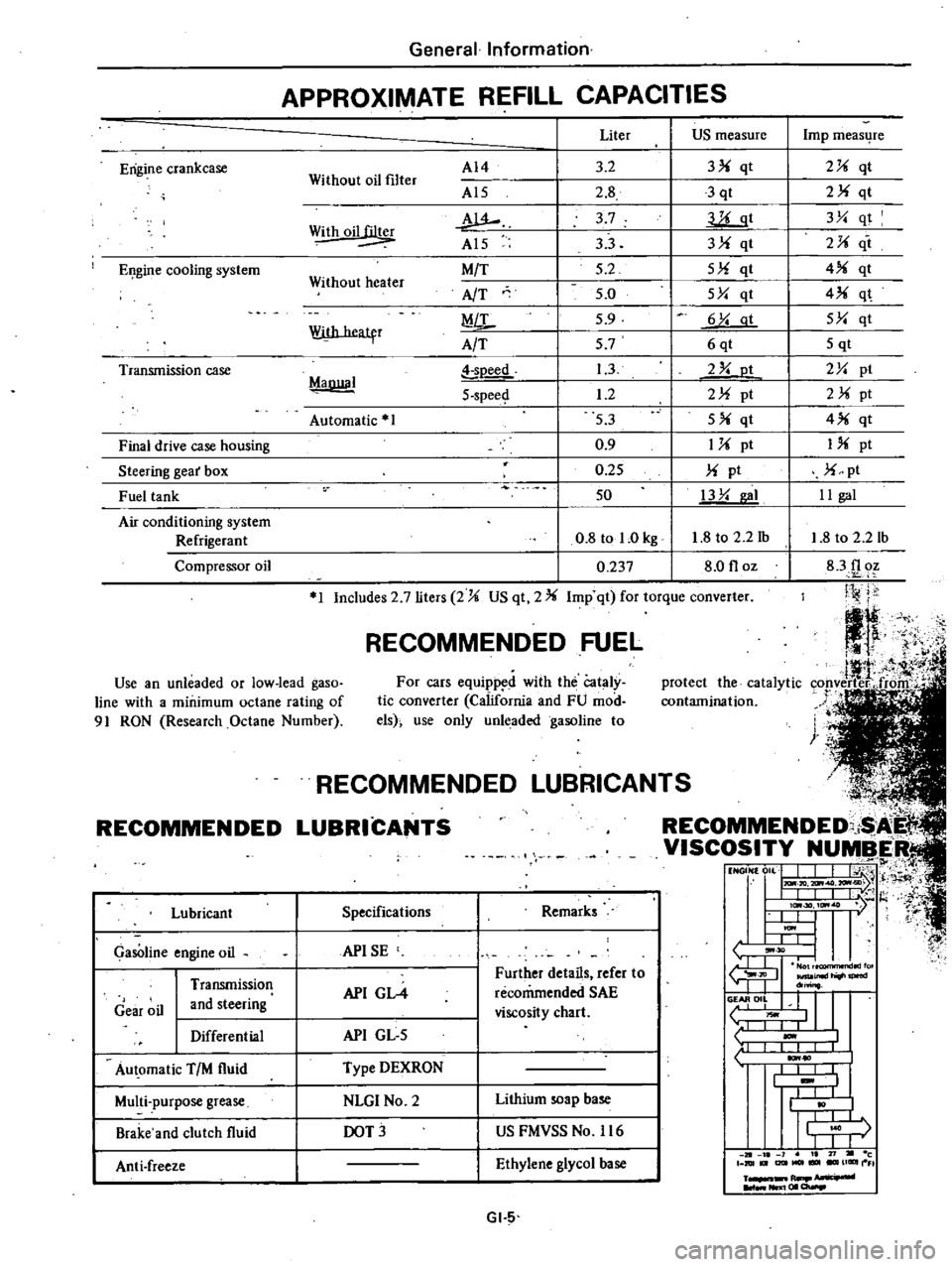

APPROXIMATE

REFILL

CAPACITIES

Without

oil

filter

AI4

Al5

w

Al5

M

T

AfT

MiL

A

T

Liter

US

measure

3

2

3

qt

2

8

3

qt

3

7

llLgt

33

3

qt

5

2

5

qt

5

0

5Y

qt

5

9

6

Y

at

57

6qt

1

3

2

Y

ot

1

2

2

pt

53

5

qt

0

9

1

pt

0

25

pt

50

13

Y

I

0

8

tol

Okg

1

8

to

2

2

1b

0

237

8

0

floz

Withoil

Without

heater

With

heatfr

MaDllal

soeed

5

spee

Automatic

1

1

Includes

2

7

liters

2

US

qt

2

Imp

qt

for

torque

converter

RECOMMENDED

FUEL

Use

an

unleaded

or

low

lead

gaso

line

with

a

minimum

octane

rating

of

91

RON

Research

Octane

Number

For

cars

equipp

d

with

the

Cataly

tic

converter

California

and

FU

mod

els

use

only

unleaded

gasoline

to

RECOMMENDED

Lubricant

GasOline

engine

oil

Gear

oil

Transmission

and

steering

Differential

Au

omatic

TIM

fluid

Multi

purpose

grease

Brake

and

clutch

fluid

Anti

freeze

L

NDED

LUBRICAN

COMMENDED

i

I

VISCOSITY

NUMBER

t1

NGON

0

L

J

I

j

H

I

IlL

I

t

l

I

lc

30

ItM

7

l

t

U

I

ItM

I

L

L

tJ

30

I

I

fu

JIl

inld

do

o

II

L

liOwl

1

I

I

1

10

I

I

I

I

t

I

I

j

r

I

I

J

1

21

l

1

I

71

c

DIUt

I2lItMOl

UGIIII

FI

R

NIl

I

01

a

Specifications

Remarks

APISE

API

GL4

Further

details

refer

to

recommended

SAE

viscosity

chart

API

GL

5

Type

DEXRON

NLGI

No

2

Lithium

soap

base

DOT

US

FMVSS

No

116

Ethylene

glycol

base

GI

5

Imp

meas4re

2

qt

2

qt

3Y

qt

2

it

4

qt

4

q

5Y

qt

5

qt

2Y

pt

2

pt

4

qt

I

pt

pt

II

gal

1

8

to

2

2

lb

83f1

oz

Ji

j

j

Page 149 of 548

gear

box

I

Disconnect

a

pair

of

lead

wires

2

Unscrew

the

switch

body

itself

The

switch

can

then

be

taken

out

3

Installation

is

in

the

reverse

se

quence

of

removal

dl

Tightening

torque

Top

cietectingswitch

2

0

to

3

0

kll

m

14

to

22

fHbl

@

EC892

Fig

EC

89

Remouing

Top

Detecting

Switch

Top

detecting

switch

For

AfT

models

The

top

detecting

switch

is

installed

on

the

side

face

of

the

gear

box

I

Disconnect

a

lead

wire

for

top

switch

2

Loosen

switch

itself

Switch

can

then

be

taken

out

Note

When

the

switch

is

remo

ed

automatic

transmission

fluid

flows

out

Prepare

some

rugs

to

prevent

the

fluid

rom

flowing

out

EC169A

Fig

EC

90

Remouing

Top

Detecting

Switch

An

models

3

Insta

tion

is

in

the

reverse

se

quence

of

removal

Emission

Control

System

dl

r

ingtorq

Top

detecting

switch

2

0

to

3

0

kll

m

14

to

22

ft

bl

Thermal

vacuum

valve

3

port

type

The

thermal

vacuum

valve

is

instal

led

on

the

rear

end

of

the

engine

cylinder

head

I

Drain

engine

coolant

about

one

liter

lUllS

qt

Ulmp

qt

2

Remove

manifold

nut

securing

heat

shi

eld

plate

r

l

EC170A

Fig

EC

91

Remouing

Hoot

Shield

Pwte

3

Disconnect

3

vacuum

hoses

and

unscrew

valve

itself

Valve

can

then

be

taken

out

4

Install

thermal

vacuum

valve

in

the

reverse

sequence

of

removal

At

this

time

the

valve

should

be

tighten

ed

to

a

tilt

angle

of

300

Note

Be

sure

to

apply

oealer

to

threads

o

the

valve

prior

to

instal

ling

new

valve

t

J

T1g11taning

torqUe

Thermal

cuum

waive

Less

than

2

2

kll

m

16

ft

bl

Manifold

nut

1

5

to

2

0kg

m

11

to

14

ft

bl

From

distributor

From

B

P

T

valve

From

air

cleaner

ECl71A

Fig

EC

92

mtalling

Thermal

Vacuum

Value

3

port

type

Vacl

ul11

delay

valVe

The

vacuum

delay

Valve

is

installed

on

the

midway

o

the

vacuum

tube

between

the

carburetor

and

distributor

vacuum

advance

mechanism

In

installing

the

valve

make

sure

that

the

brown

face

sid

is

connected

to

the

carburetor

side

Carburetor

sid

C

r

i

J

EG

30

Distributor

side

One

way

umbreDa

valve

Sintered

metal

disc

EC277

Fig

EC

93

In

tolling

Vacuum

Deloy

Value

Page 254 of 548

The

3N71

B

trammission

is

a

fully

automatic

unit

consisting

primarily

of

a

3

element

hydraulic

torque

converter

and

two

planetary

gear

sets

Two

multiple

disc

c1utclies

a

multiple

disc

brake

brake

band

and

one

way

clutch

provide

the

friction

elements

necessary

to

obtain

the

desired

function

of

the

two

planetary

gear

ets

A

hydraulic

control

system

is

used

to

operate

the

friction

elements

and

automatic

shift

controls

TORQUE

CONVERTER

The

torque

converter

is

attached

to

the

crankshaft

through

a

flexible

drive

plate

Heat

generat

in

the

t

rque

converter

is

dissipated

by

circulating

the

transmission

fluid

through

an

oil

to

water

type

cooler

in

the

radiator

lower

tank

The

welded

comtruction

of

the

torque

co

verter

prevents

di

3

ssembly

or

service

unless

highly

specialized

equipment

is

available

Qj

gJ

Autpmatic

Trimsmissi6n

DEScRIPTION

FLUID

RECOMMENDAnON

Use

DEXRON

type

automatic

transmission

fluid

only

IDENTIFICATION

NUMBER

Stamped

position

The

plate

is

attached

to

the

right

han

side

of

transmission

case

AT

M

Fig

AT

l

Identification

Number

Identification

of

number

arranaemanta

JAPAJllUTOIlATlC

TRAJISIIISSIO

C8

Ull

MODEL

X

0

12

3

NO

7

6

0

1

2

34

Number

designation

76

0

I

2

34

L

Serial

productioo

number

for

the

month

Month

of

production

1

Jan

2

Feb

X

Oct

Y

Nov

Z

Dec

Lut

IJgUre

denotins

the

year

A

D

IJ

III

J

W

f

r

lrr

G

1

Transmission

case

2

Oil

pump

3

Front

clutch

4

Band

brake

5

Rear

dutch

6

Front

planetary

geat

7

Rear

planetary

gear

8

One

way

clutch

9

Low

4

Reverse

brake

10

Oil

distributor

11

Governor

12

utput

shaft

13

Rear

extension

14

Oil

pan

IS

Control

valve

16

Input

shaft

17

Torque

converter

18

Converter

housi

19

Drive

pia

te

Tightening

torque

T

of

bolts

and

nuts

kg

m

ft

lb

@

T

4

to

5

29

to

36

@

T

14

to

16

101

to

116

@

T

4

5

to

5

5

33

to

40

@

T

0

6

to

0

8

4

3

to

5

8

@

T

0

5

to

0

7

3

6

to

5

1

T

2

0

to

2

5

14

to

18

@

T

1

3

to

1

8

9

to

13

@

T

0

55

ta

0

75

4

0

to

5

4

CD

T

0

25

to

0

35

1

8

to

2

5

AT312

Fig

AT

2

3N71B

Automatic

Trammiuion

AT

2

Page 255 of 548

Automatic

Transmission

HYDRAULIC

CONTROL

UNIT

AND

VALVES

The

hydraulic

or

a

tomatic

control

system

is

comprised

of

four

4

basic

groups

the

pressure

supply

system

the

pressure

regulating

system

the

flow

control

valves

and

the

friction

elements

PRESSURE

SUPPLY

SYSTEM

The

pressure

supply

system

consists

of

a

gear

type

oil

pwnp

driven

by

the

engine

through

the

torque

converter

The

pump

provides

pressure

for

aU

hydraulic

and

lubrication

needs

PRESSURE

REGULATOR

VALVES

The

pressure

regulating

valves

con

trol

the

output

pressure

of

the

oil

pump

Pre

ure

rellulator

valve

The

pressure

regulator

valve

con

trois

mainline

pressure

based

on

throttle

opening

for

the

operation

of

the

band

clutches

and

brake

Governor

valve

The

governor

valve

transmits

re

gulated

pressure

based

on

car

peed

to

the

shift

valves

to

control

upshifts

and

downshifts

Vacuum

throttle

valve

The

vacuum

throttle

valve

transmits

regulated

pressure

based

on

engine

load

vacuum

This

pressure

controls

the

pressure

regulator

valve

Also

this

pressure

is

applied

to

one

end

of

the

shift

valves

in

opposition

to

governor

pressure

which

acts

on

the

other

end

of

the

shift

valves

controlling

upshift

and

downshift

speeds

FLOW

CONTROL

VALVES

Manual

valve

The

manual

valve

is

moved

manual

Iy

by

the

car

operator

to

select

the

different

drive

ranges

1

2

ShHt

valve

The

1

2

shift

valve

automaticaIly

shifts

the

transmission

from

first

to

second

or

from

second

to

first

depend

ing

upon

governor

and

throttle

pres

sure

along

with

accelerator

position

solenoid

downshift

valve

See

Hy

draulic

Control

Circuits

Drive

2

2

3

ShHt

valve

The

2

3

shift

valve

automaticaIly

shifts

the

transmission

from

second

to

top

gear

or

from

top

to

second

de

pending

upon

governor

and

throttle

pressure

or

accelerator

position

sole

noid

downshift

valve

See

Hydraulic

Control

Circuits

Drive

3

Range

2

3

Tlmlnll

valve

For

2

3

shifts

a

restrictive

orifice

slows

the

application

fluid

to

the

front

clutch

while

the

slower

reacting

band

is

allowed

to

release

This

prevents

a

hard

2

3

or

3

2

shift

Under

heavy

load

however

the

engine

will

tend

to

run

away

during

the

2

3

or

3

2

shift

pause

therefore

a

2

3

timing

valve

using

throttle

and

governor

pressure

is

used

to

bypass

the

restrictive

orifice

during

such

heavy

load

conditions

Solenoid

down

hHt

valve

The

solenoid

downshift

valve

is

activated

electrically

when

the

ac

celerator

is

f1oor

d

causing

a

forced

downshift

from

top

to

second

top

to

first

or

second

to

first

gear

depending

upon

car

speed

governor

pressure

AT

3

Pre

ure

modified

valve

The

pressure

modifier

valve

assists

the

mainline

pressure

regulator

valve

in

lowering

mainline

pressure

during

high

speed

light

load

conditions

such

as

steady

speed

cruise

Governor

pres

sure

working

against

a

spring

opens

the

valve

which

aUows

modified

throt

tle

pressure

to

work

against

the

pres

sure

regulator

valve

spring

lowering

mainline

pressure

Lower

operating

pressure

under

light

load

reduces

oil

temperature

and

increases

transmis

sian

life

Throttle

back

up

valve

The

throttle

back

up

valve

assists

the

vacuum

throttle

valve

to

increase

line

pressure

when

the

manual

valve

is

shifted

either

to

2

or

I

range

Second

lock

valve

The

second

lock

valve

is

used

to

bypa

the

1

2

shift

valve

to

maintain

the

band

apply

pressure

in

2

posi

tion

The

valve

is

also

used

as

an

oil

passage

for

the

1

2

shift

valve

band

apply

pressure

in

D2

D3

and

12

Range

CLUTCHES

AND

BAND

SERVOS

The

servo

pistons

of

the

clutches

low

reverse

brake

and

band

are

moved

hydraulically

to

engage

the

clutches

brake

and

apply

the

band

The

clutch

and

brake

istons

are

released

by

spring

tension

and

band

piston

is

released

by

spring

tension

and

hy

draulic

pressure

Page 264 of 548

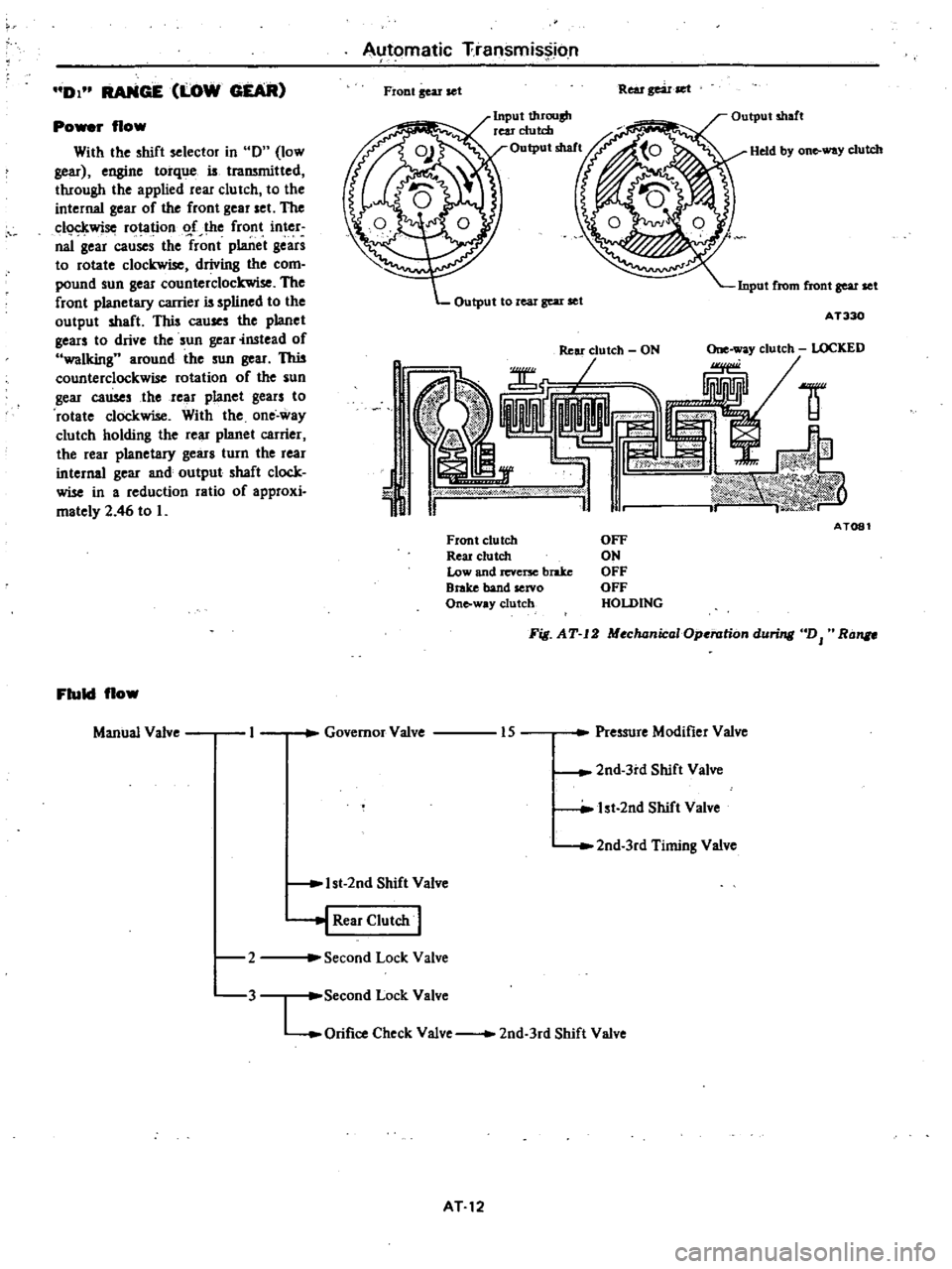

DI

RANGE

LOW

GEAR

Po

r

flow

With

the

shift

selector

in

0

low

gear

engine

torque

is

traJWnitted

through

the

applied

rear

clu

tch

to

the

internal

gear

of

the

front

gear

set

The

c1o

kwise

rotation

o

f

the

front

inter

naI

gear

causes

the

front

planet

gears

to

rotate

clockwise

driving

the

com

pound

sun

gear

counterclockwise

The

front

planetary

carrier

is

splined

to

the

output

shaft

This

cau

the

planet

gears

to

drive

the

sun

gear

instead

of

walking

around

the

sun

gear

This

counterclockwise

rotation

of

the

sun

gear

causes

the

rear

planet

gears

to

rotate

clockwise

With

the

one

way

clutch

holding

the

rear

planet

carrier

the

rear

planetary

gears

turn

the

rear

internal

gear

and

output

shaft

clock

wise

in

a

reduction

ratio

of

approxi

mately

2

46

to

L

Fluid

flow

Manual

Valve

2

3

Automatic

Transmission

Fiont

gear

set

Rear

gear

set

Input

t1uOllsh

rear

clutch

Output

shaft

Held

by

on

way

clutch

Input

from

front

gear

set

Output

to

real

gear

set

AT330

1

J

ld

AT081

Front

clutch

Reu

clutch

Low

and

revcrx

brake

Brake

band

servo

Onto

way

clutch

OFF

ON

OFF

OFF

HOLDING

Fig

AT

12

MochanicaIOp

rationduri

DJ

Ra

Governor

Valve

Pressure

Modifier

Valve

15

2nd

3rd

Shift

Valve

lst

2nd

Shift

Valve

2nd

3rd

Timing

Valve

1st

2nd

Shift

Valve

j

Rear

Clutch

I

Second

Lock

Valve

Second

Lock

Valve

LOrifice

Check

Valve

2nd

3rd

Shift

Valve

AT12

Page 268 of 548

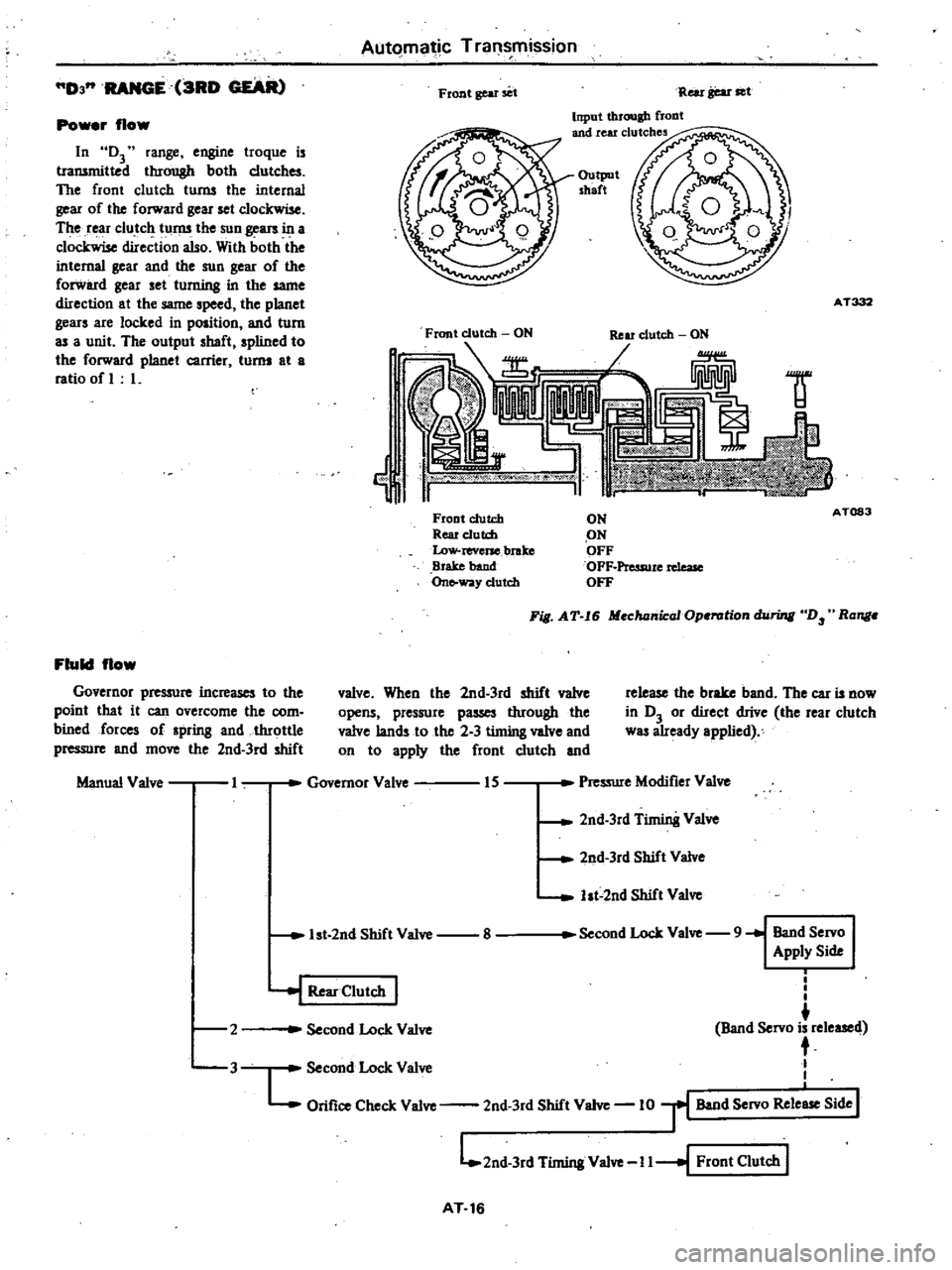

Automatic

Transmission

D3

RANGE

3RD

GEAR

Front

gear

set

Rei

r

gear

set

Input

through

flODt

and

rear

clutches

Power

flow

In

D3

range

engine

troque

is

transmitted

through

both

clutches

The

front

clutch

turns

the

internal

gear

of

the

forward

gear

set

clockwise

The

rear

clutch

turns

the

sun

gears

in

a

clockwise

direction

also

With

both

the

internal

gear

and

the

sun

gear

of

the

forward

gear

set

turning

in

the

same

direction

at

the

same

speed

the

planet

gears

are

locked

in

position

and

turn

as

a

unit

The

output

shaft

spIined

to

the

forward

planet

carrier

turns

at

a

ratio

of

L

Output

shaft

AT332

Front

clutch

ON

Ij

1f

Front

clutch

Rear

e1utd

Low

reverse

brake

Brake

band

On

way

clutch

ON

ON

OFF

OFF

Pressure

rdeaJe

OFF

A

T083

Fill

AT

I6

Mechanical

Operation

hiring

D

Ronge

Fluid

flow

Governor

pre

ure

increases

to

the

poinl

that

it

can

overcome

the

com

bined

forces

of

spring

and

throttle

pressure

and

move

the

2nd

3rd

shift

valve

When

the

2nd

3rd

shift

valve

opens

pressure

passes

through

the

valve

lands

to

the

2

3

timing

valve

and

on

to

apply

the

front

clutch

and

release

the

brake

band

The

car

is

now

in

D3

or

direct

drive

the

rear

clutch

was

already

applied

Manual

Valve

I

Governor

Valve

IS

Pressure

Modifier

Valve

2nd

3rd

Timin8

Valve

2nd

3rd

Shift

Valve

ht

2nd

Shift

Valve

1st

2nd

Shift

Valve

8

Second

Lock

Valve

9

Band

Servo

Apply

Side

2

i

I

I

Band

Servo

is

released

t

Second

Lock

Valve

L

Orifice

Check

Valve

2nd

3rd

Shift

Valve

10

r

Band

Servo

Rele

Side

I

L

2nd

3rd

Timing

Valve

I

I

I

Front

Clutch

I

J

Second

Lock

Valve

I

Rear

Clutch

I

3

AT

16

Page 272 of 548

Automatic

Transmission

2

RANGE

2ND

GEAR

The

range

2

position

is

used

to

lock

the

car

in

2nd

gear

preventing

upshifts

or

downshifts

under

any

con

ditions

Fluid

flow

opening

the

valVe

and

alloWing

pr

sure

to

p

into

the

line

of

the

throttle

valve

thus

assuring

adequate

throttle

pressure

even

during

decelera

tion

J

he

downshift

solenoid

valve

is

used

as

a

passage

for

line

pre

re

to

lock

the

1

2

and

2

3

shift

valves

Po

r

flow

Power

flow

in

2

raogo

is

the

same

as

in

D2

range

Uoe

pressure

from

the

manual

valve

opens

the

second

lock

valve

against

spring

pressure

As

this

valve

opens

pressure

the

passes

to

apply

the

band

servo

Une

pressure

also

flows

to

the

throttle

back

up

valve

UlllV

I

Governor

Valve

IS

Pressure

Modifier

Valve

2nd

3rd

Timing

Valve

2nd

3rd

Shift

Valve

1st

2nd

Shift

Valve

1st

2nd

Shift

Valve

j

Rear

Clutch

2

1

Band

Servo

Apply

Side

l

Solenoid

Downshift

Vilve

1312nd

3rd

Shift

Valve

1st

2nd

Shift

Valve

Second

Lock

Valve

9

4

Throttle

Back

up

Valve

17

Vacuwn

Throttle

Vilve

16

l

Jre

ModifJerVilve

2nd

3rd

Shift

Valve

2nd

3rd

Timing

Valve

Throttle

Drain

Valve

Pressure

Regulator

Valve

AT

20

Page 274 of 548

Automatic

Transmission

l

RANGE

LOW

AND

2ND

GEAR

second

12

afwvernor

preSsure

pre

vents

the

I

2

shift

valve

from

closing

The

range

1

position

is

used

to

lock

the

car

in

1st

gear

preventing

any

upshifts

If

the

selector

lever

is

moved

to

the

I

position

while

the

car

is

moving

at

high

speeds

the

transmis

sion

w

ill

not

shift

into

first

gear

until

car

speed

slows

to

approxiniately

55

km

h

35

mph

Instead

it

will

shift

to

Po

r

flow

The

power

flow

in

11

differs

slight

ly

from

01

in

that

the

low

and

reverse

band

is

applied

to

hold

the

rear

gear

set

planet

carrier

providing

engine

hraking

Power

flow

in

12

is

the

same

a

io02

Manual

Valve

Governor

Valve

15

Pressure

Modifier

Valve

I

Fluid

flow

Lolft

ar

Manual

pressure

passing

through

the

1

2

shift

valve

is

used

to

close

the

1

2

shift

valve

preventing

a

1

2

up

shift

Manual

pressure

pusing

through

the

downshift

valve

lock

the

2

3

siuit

valve

closed

along

with

applying

addi

tional

closing

pressure

to

the

I

2

shift

valve

2nd

3rd

Timing

Valve

2nd

3rd

Shift

Valve

lst

2ndSti

ft

Valve

1st

2nd

Shift

Valve

iRea

Clutcb

I

4

Solenoid

Downshift

Valve

13

I2nd

3rd

Shift

Valve

ht

2nd

Shift

Valve

Throttle

Back

up

Valve

5

C

1st

2nd

Shift

Valve

12

I

Throttle

Back

up

Valve

y

Low

Reverse

Bra1ce

I

Fluid

flow

2nd

ar

Manual

Valve

Governor

Valve

15

Preuurc

Modjfier

Valve

2nd

3rd

Timing

Valve

2nd

3rd

Shift

Valve

1st

2nd

Shift

Valve

8

1st

2nd

Shift

Valve

Second

Lock

Valve

9

I

Band

Servo

I

Apply

Side

4

t

Rear

Clutch

I

Solenoid

Downshift

Valve

13

I

2nd

3rd

Shift

Valve

ht

2nd

Shift

Valve

Throttle

Back

up

Valve

17

PreSlure

Modifier

Valve

2nd

3rd

Shift

Valve

2nd

3rd

Timing

Valve

Throttle

Drain

Valve

s

ht

2nd

Shift

Valve

Pressure

Regulator

Valve

AT

22

Page 278 of 548

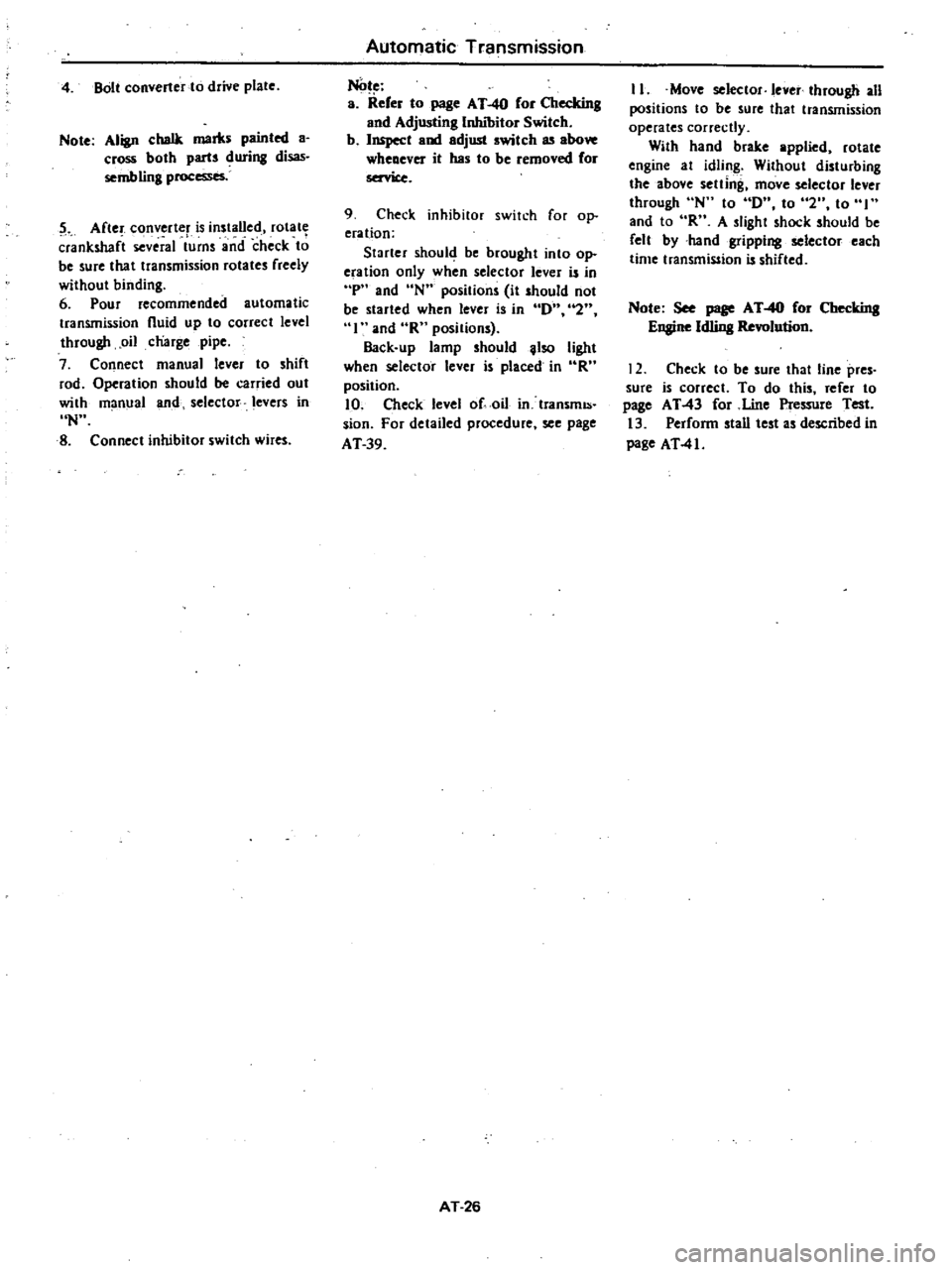

4

Bolt

converter

to

drive

plate

Note

Align

chalk

mark

painted

a

cro5S

both

parts

during

disas

sembling

p

S

After

converter

is

installed

rotat

r

nkshait

veral

turns

and

check

to

be

sure

that

transmission

rotates

freely

without

binding

6

Pour

recommended

automatic

transmission

fluid

up

to

correct

level

through

oil

charge

pipe

7

Connect

manual

lever

to

shift

rod

Operation

should

be

carried

out

with

m

mual

and

selector

levers

in

N

8

Connect

inhibitor

switch

wires

Automatic

Transmission

NOte

a

Refer

to

page

AT40

for

Checking

and

Adjusting

Inhibitor

Switch

b

Inspect

end

edjust

switch

as

abo

whe

ever

it

has

to

be

removed

for

servi

e

9

Check

inhibitor

switch

for

op

eration

Starter

should

be

brought

into

op

eration

only

when

selector

lever

is

in

P

and

N

positions

it

should

not

be

started

when

lever

is

in

D

n

and

Ru

positions

Back

up

lamp

should

Iso

light

when

selector

lever

is

placed

in

R

position

10

Check

level

of

oil

in

transm

sion

For

detailed

procedure

see

page

AT39

AT

26

II

Move

selector

leve

through

all

positions

to

be

sure

that

transmission

operates

correctly

With

hand

brake

applied

rotate

engine

at

idling

Without

disturbing

the

above

seUlng

move

selector

lever

through

N

to

D

to

2

to

I

and

to

R

A

slight

shock

should

be

reU

by

handgripping

selector

each

time

transmission

is

shifted

Note

See

page

AT40

for

Checking

Engine

Idling

Revolution

12

Check

to

be

sure

that

line

pres

sure

is

correct

To

do

this

refer

to

page

AT

43

for

Line

Pressure

Test

13

Perform

stan

test

as

described

in

page

AT41

Page 284 of 548

Insp

ctIon

I

Check

for

signs

of

wear

or

dam

age

to

clutch

drive

plate

facing

If

found

worn

or

damaged

excessively

discard

Drive

plm

th

Standen

1

5

to

1

66mm

0

059

to

O

Inl

Allowable

limit

1A

mm

0

065

inl

2

Check

fOI

weer

on

snap

ring

and

for

weakened

or

broken

coil

spring

If

necessary

replace

with

new

ones

Spring

retainer

should

also

be

in

spected

fOI

warpage

sembi

1

Assembly

is

in

reverse

the

order

of

disassembly

Dip

all

parts

in

clean

automatic

transmission

fluid

before

installing

Fig

AT

56

l

ting

Clutch

PIlIte

2

After

clutch

is

a

embled

make

sure

th

t

clearance

between

snap

ring

CD

and

retaining

plate

V

is

held

within

specified

limits

If

necessary

lIy

with

other

retaining

plate

having

different

thickness

until

correct

clear

ance

is

obteined

S

1

deerence

1

6

to

2

0

mm

0

063

to

0

079

inl

Automatic

Transmission

Awilable

reteiningplate

Thickness

mm

in

10

6

0

417

10

8

0

425

11

0

0

433

11

2

0441

II

4

0

449

11

6

0

457

AT151

Fig

AT

67

Me

ring

Ring

to

PIlIte

Cleo

3

Testing

front

clutch

With

front

clutch

assembled

on

oil

pump

cover

direct

a

jet

of

air

into

hole

in

clutch

drum

for

definite

clutch

operation

AT152

Fig

AT

58

Taring

Front

Clutch

AT

32

REAR

a

UTCH

D1

mbl

AT313

1

Rear

clutch

drum

6

Snap

rina

2

Piston

7

SpriDa

3

Dished

plate

8

SDap

riJlI

4

Coil

sprina

9

Dri

plate

5

Rctainins

plate

10

Iltmm

plate

Fig

AT

59

Sectional

VielD

0

Rear

Clutch

1

Take

out

snap

ring

@

retaining

plate

@

drivc

plate

@

driven

plate

@

and

dished

plate

ID

Same

tech

nique

can

be

applied

as

in

disas

sembling

front

clutch

2

Remove

snap

ring

from

coil

spring

retainer

ST2S3200l

X

Fi6

AT

60

Remouing

SruJP

Ring