height adjustment DATSUN 210 1979 Service Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1979, Model line: 210, Model: DATSUN 210 1979Pages: 548, PDF Size: 28.66 MB

Page 51 of 548

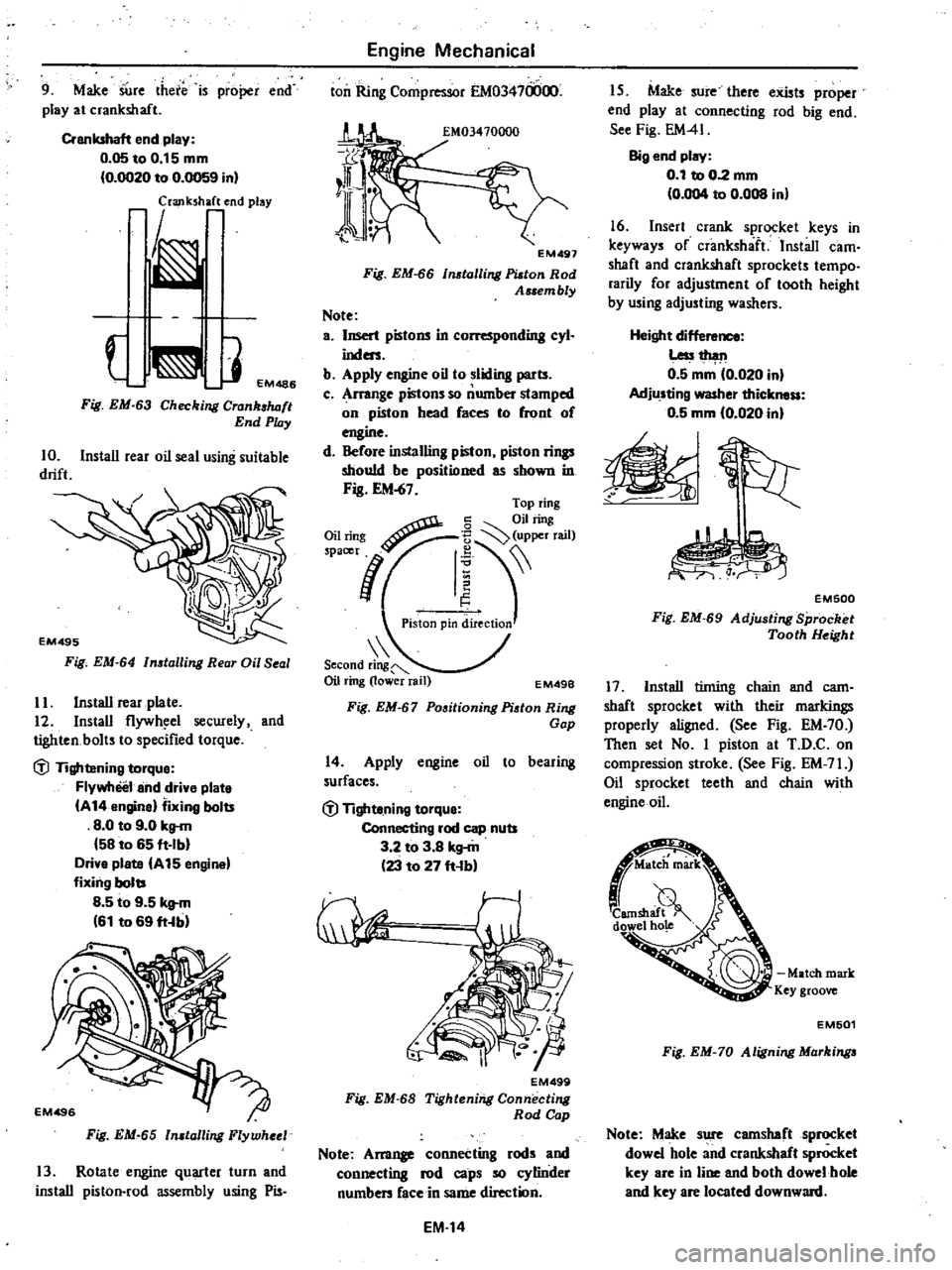

9

Make

SUre

there

is

proper

end

play

at

crankshaft

Crankshaft

end

play

0

05toO

15mm

0

OO20

to

0

0059

in

laJlk

h

end

play

J

EM486

Fig

EM

63

Checking

Crank

luJft

End

Play

10

Install

rear

oil

seal

using

suitable

drift

Fig

EM

64

n

talling

Rear

Oil

Seal

II

Install

rear

plate

12

Install

flywh

el

secwely

and

tighten

bolts

to

specified

torque

dl

Tightening

torque

Flywheel

and

drive

plate

A

14

engine

fixing

bolts

8

0

to

9

0

kg

m

58

to

65

ft

Ib

Drive

plate

A

15

engine

fixing

bolts

8

5

to

9

5

kg

m

61

to

69

ft

b

Fig

EM

65

n

talling

Flywheel

13

Rotate

engine

quarter

turn

and

install

piston

rod

assembly

using

Pis

Engine

Mechanical

ton

Ring

Compressor

EM03470000

EM497

Fig

EM

66

tolling

Platon

Rod

Assem

bly

Note

a

Insert

pistons

in

L

r

nding

cyl

inders

b

Apply

engine

oil

to

sliding

parts

c

Arrange

pistons

so

number

stamped

on

piston

head

faces

to

front

of

engine

d

Before

installing

piston

piston

rings

should

be

positioned

as

shown

in

Fig

EM

67

Second

ring

Oil

ring

lower

rail

EM49B

Fig

EM

67

Positioning

Piston

Ring

Gap

14

Apply

engine

oil

to

bearing

surfaces

dl

Tighte

ning

torque

Connecting

rod

cap

nuts

3

2

to

3

8

kg

m

23

to

27

ft

b

EM499

Fig

EM

68

Tightening

Connecting

Rod

Cap

Note

Am11

connecting

rods

and

connecting

rod

caps

so

cylinder

numben

face

in

same

direction

EM

14

I

S

Make

sure

there

exists

proper

end

play

at

connecting

rod

big

end

See

Fig

EM41

Big

end

play

0

1

to

0

2

mm

0

004

to

0

008

in

16

Insert

crank

sprocket

keys

in

keyways

of

crankshaft

Install

cam

shaft

and

crankshaft

sprockets

tempo

rarily

for

adjustment

of

tooth

height

by

using

adjusting

washers

Height

dif

Less1

h

l11

0

5

mm

0

020

in

Adjusting

washer

thickness

0

5

mm

10

020

in

EM500

Fig

EM

69

Adju

ting

Sprocket

Tooth

Height

17

Install

tinting

chain

and

cam

shaft

sprocket

with

their

markings

properly

aligned

See

Fig

EM

70

Then

set

No

I

piston

at

T

D

C

on

compression

stroke

See

Fig

EM

71

Oil

sprocket

teeth

and

chain

with

engine

oil

Match

mark

Key

groove

EM501

Fig

EM

70

Aligning

Markinga

Note

Make

sure

camshaft

sprocket

dowel

hole

and

crankshaft

sprocket

key

are

in

line

and

both

dowel

hole

and

key

are

located

downward

Page 56 of 548

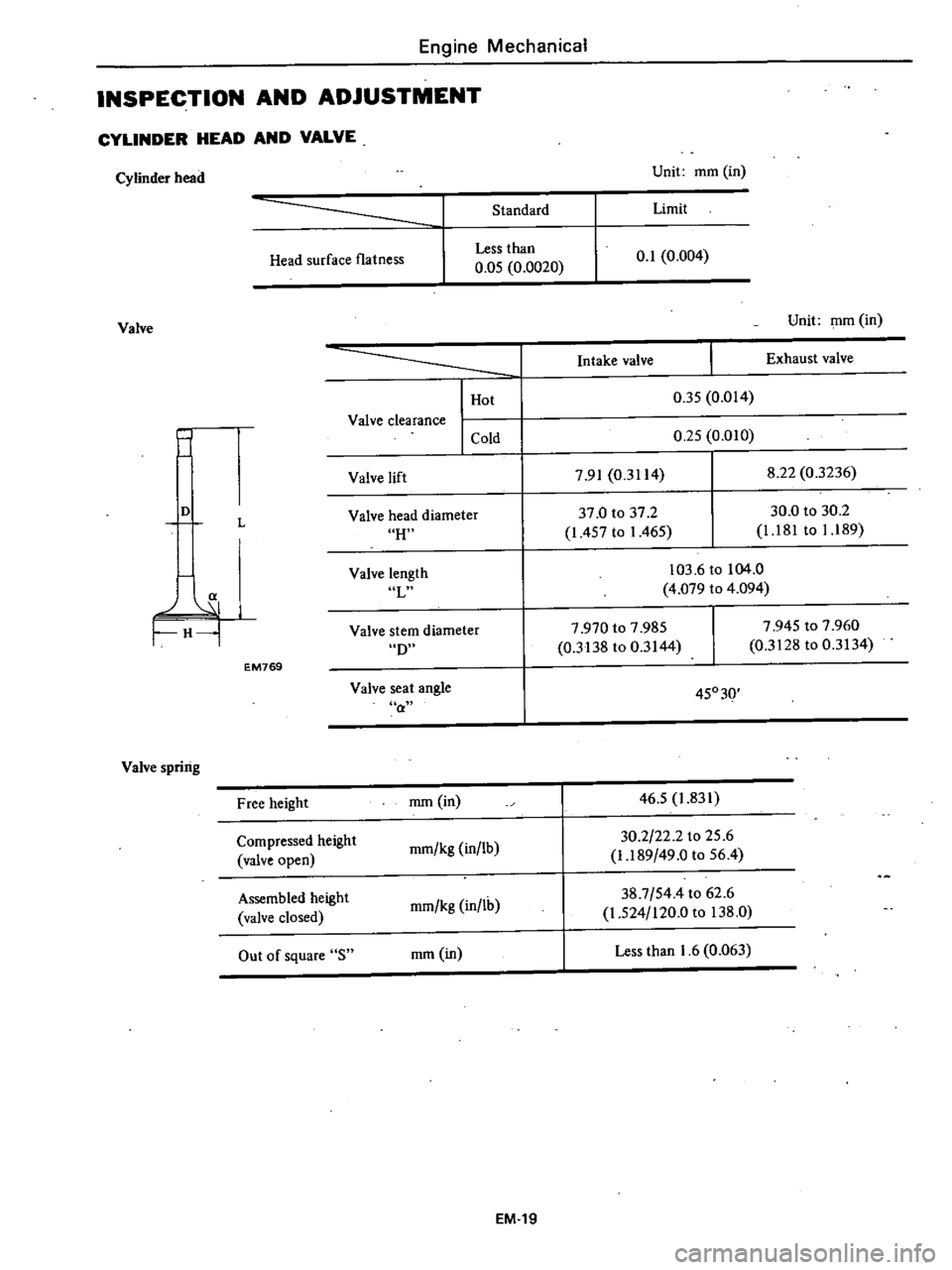

Engine

Mechanical

INSPECTION

AND

ADJUSTMENT

CYLINDER

HEAD

AND

VALVE

Cylinder

head

Unit

mm

in

Standard

Limit

Head

surface

flatness

Less

than

0

05

0

0020

0

1

0

004

Valve

Unit

mm

in

j

I

Hot

Valve

clearance

I

Cold

Intake

valve

Exhaust

valve

0

35

0

014

0

25

0

010

Valve

lift

7

91

0

3114

8

22

0

3236

H

37

0

to

37

2

1

457

to

1

465

30

0

to

30

2

1

181

to

1

189

D

L

Valve

head

diameter

a

H

Valve

length

L

103

6

to

104

0

4

079

to

4

094

D

7

970

to

7

985

0

3138

to

0

3144

7

945

to

7

960

0

3128

to

0

3134

Valve

stem

diameter

EM769

Valve

seat

angle

a

45030

Valve

spring

Free

height

mm

in

46

5

1

831

Compressed

height

mm

kg

in

lb

30

2

22

2

to

25

6

valve

open

1

189

49

0

to

56

4

Assembled

height

mm

kg

in

lh

38

7

544

to

62

6

valve

closed

1

524

120

0

to

138

0

Out

of

square

S

mm

in

Less

than

1

6

0

063

EM

19

Page 203 of 548

DATSUN

210

Model

8310

Series

SECTIONCL

CLUTCH

CONTENTS

ADJUSTMENT

CLUTCH

PEDAL

HEIGHT

CLUTCH

PEDAL

FREE

TRAVEL

BLEEDING

CLUTCH

SYSTEM

CLUTCH

CONTROL

CLUTCH

PEDAL

CLUTCH

MASTER

CYLINDER

OPERATING

CYLINDER

CLUTCH

LINE

CLUTCH

UNIT

CLUTCH

DISC

AND

COVER

CL

2

CL

2

CL

2

CL

2

CL

3

CL

3

CL

4

CL

5

CL

6

CL

7

CL

7

RELEASE

BEARING

PILOT

BUSHING

SERVICE

DATA

AND

SPECIFICATIONS

GENERAL

SPECIFICATIONS

INSPEctiON

AND

ADJUSTMENT

TIGHTENING

TORQUE

TROUBLE

DIAGNOSES

AND

I

ECTIONS

SPECIAL

SERVICE

TOOLS

CL

8

CL

9

CL

10

CL

10

CL10

CL

11

CL

12

CL

14

Page 204 of 548

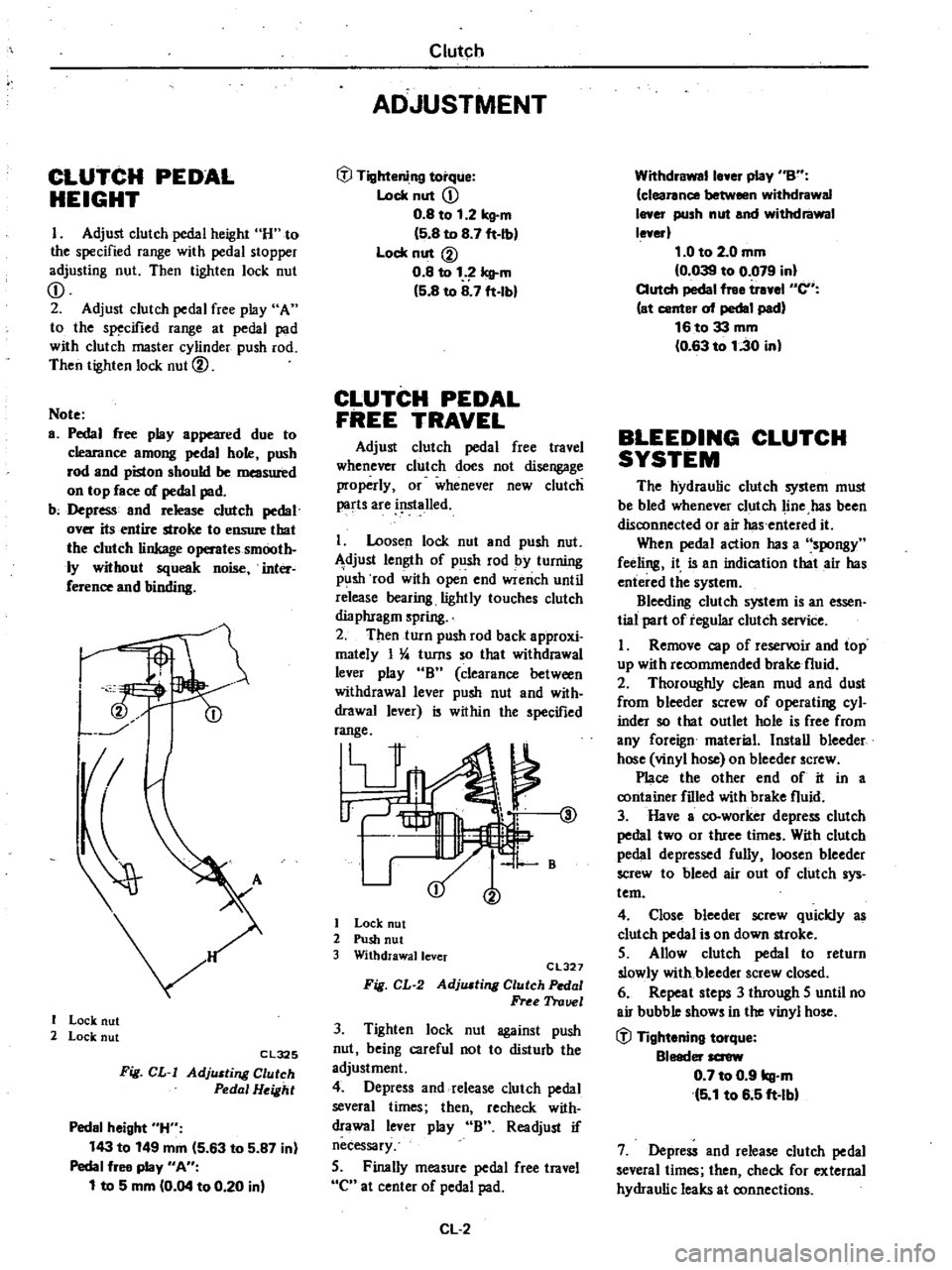

CLUTCH

PEDAL

HEIGHT

I

Adjust

clutch

pedal

height

H

to

the

specified

range

with

pedal

stopper

adjusting

nut

Then

tighten

lock

nut

CD

2

Adjust

clutch

pedal

free

play

A

to

the

specified

range

at

pedal

pad

with

clutch

master

cylinder

push

rod

Then

tighten

lock

nut

@

Note

a

Pedal

free

play

appeared

due

to

clearance

among

pedal

hole

push

rod

and

piston

should

be

measured

on

top

face

of

pedal

pad

b

Depress

and

release

clutch

pedal

over

its

entire

stroke

to

ensure

that

the

clutch

linkage

operates

smooth

ly

without

squeak

noise

inter

ference

and

binding

I

I

Lock

nut

2

Lock

nut

Cl325

Fig

CL

I

AdjlUting

Clutch

Pedal

Height

Pedal

height

H

143

to

149

mm

5

63

to

5

87

in

Pedal

free

play

An

1

to

5

mm

0

04

to

0

20

in

Clutch

ADJUSTMENT

tfl

Tightening

torque

Lock

nut

CD

0

8

to

1

2

kg

m

5

8

to

8

7

ft

Ib

Lock

nut

@

0

8

to

1

Icll

m

5

8

to

8

7

ft

lbl

CLUTCH

PEDAL

FREE

TRAVEL

Adjust

clutch

pedal

free

travel

whenever

clutch

does

not

disengage

properly

or

whenever

new

clutch

parts

are

i

lslalled

I

Loosen

lock

nut

and

push

nut

djust

length

of

push

rod

by

turning

p

lsh

rod

with

open

end

wrench

until

release

bearing

lightly

touches

clutch

dia

phragm

spring

2

Then

turn

push

rod

back

approxi

mately

I

4

turns

so

that

withdrawal

lever

play

B

clearance

between

withdrawal

lever

push

nut

and

with

drawal

lever

is

within

the

specified

range

V

@

1

B

I

Lock

nut

2

Push

nut

3

Withdrawallcver

CL327

Fig

CL

2

AdjlUting

Clutch

Pedal

Free

Trauel

3

Tighten

lock

nut

against

push

nut

being

careful

not

to

disturb

the

adjustment

4

Depress

and

release

clutch

pedal

several

times

then

recheck

with

drawal

lever

play

B

Readjust

if

necessary

5

Finally

measure

pedal

free

travel

C

at

center

of

pedal

pad

CL

2

Withdrawalle

er

play

nBn

clearance

between

withdrawal

I

er

push

nut

and

withdrawal

le

erl

1

0

to

2

0

mm

0

039

to

0

079

in

Clutch

pedal

free

tr

el

en

at

center

of

pedal

pad

16to33

mm

0

63

to

1

30

in

BLEEDING

CLUTCH

SYSTEM

The

hydraulic

clutch

system

must

be

bled

whenever

clutch

line

has

been

disconnected

or

air

has

entered

it

When

pedal

action

has

a

spongy

feeling

it

is

an

indication

that

air

has

entered

the

system

Bleeding

clutch

system

is

an

essen

tial

part

of

regular

clutch

service

I

Remove

cap

of

reservoir

and

top

up

with

recommended

brake

fluid

2

Thoroughly

clean

mud

and

dust

from

bleeder

screw

of

operating

cyl

inder

so

that

outlet

hole

is

free

from

any

foreign

material

Install

bleeder

hose

vinyl

hose

on

bleeder

screw

Place

the

other

end

of

it

in

a

container

filled

with

brake

fluid

3

Have

a

co

worker

depress

clutch

pedal

two

or

three

times

With

clutch

pedal

depressed

fully

loosen

bleeder

screw

to

bleed

air

out

of

clutch

sys

tem

4

Close

bleeder

screw

quickly

as

clutch

pedal

is

on

down

stroke

5

Allow

clutch

pedal

to

return

slowly

with

bleeder

screw

closed

6

Repeat

steps

3

through

5

until

no

air

bubble

shows

in

the

vinyl

hose

tfl

Tightening

torque

Bleeder

screw

0

7

to

0

9

kg

m

5

1

to

6

5

ft

lbl

7

Depress

and

release

clutch

pedal

several

times

then

check

for

external

hydraulic

leaks

at

connections

Page 207 of 548

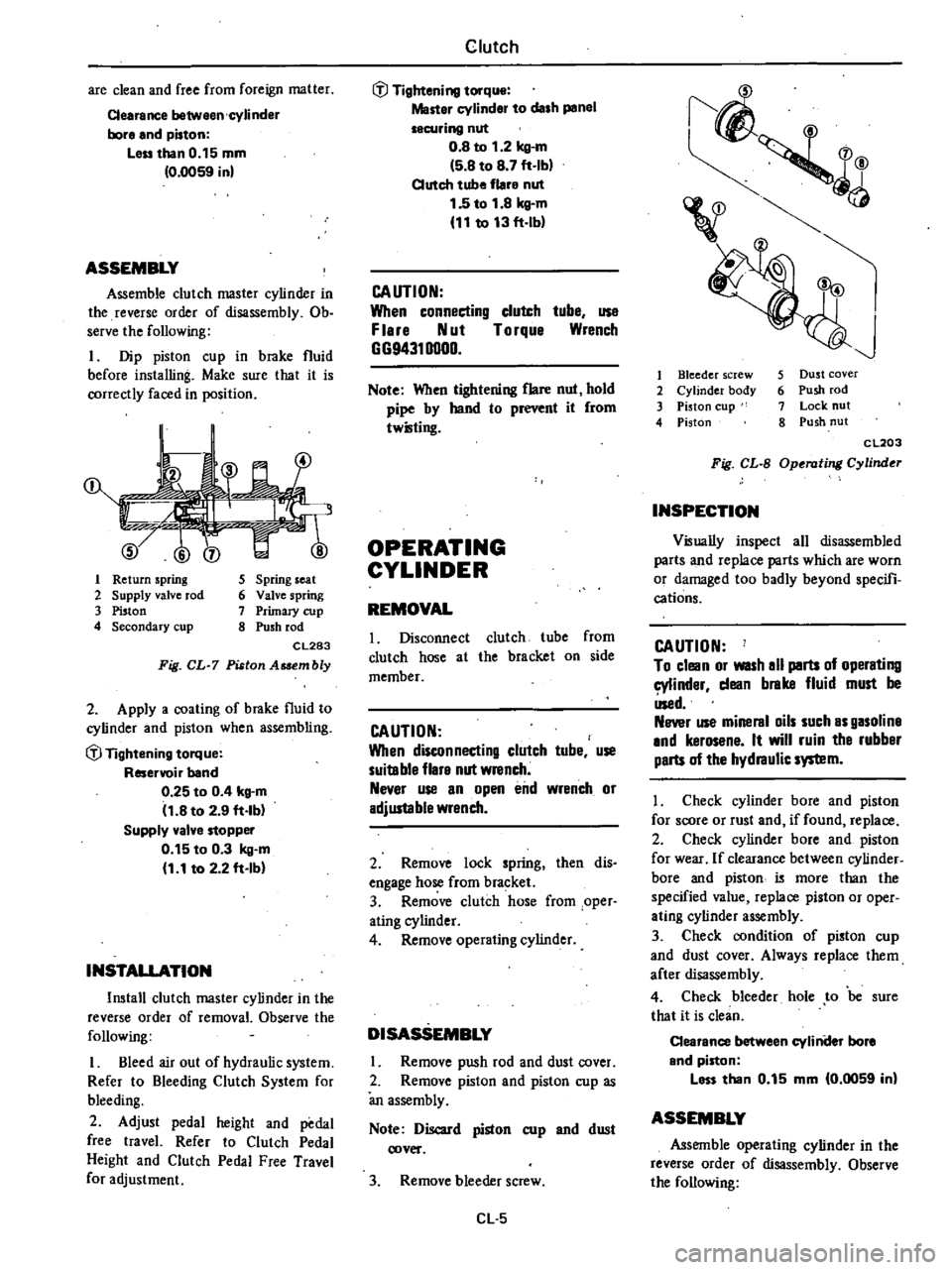

are

clean

and

free

from

foreign

matter

Cearance

between

cylinder

bore

and

piston

Leu

than

0

15

mm

0

0059

in

ASSEMBLY

Assemble

clutch

master

cylinder

in

the

reverse

order

of

disassembly

Ob

serve

the

following

I

Dip

piston

cup

in

brake

fluid

before

installing

Make

sure

that

it

is

correctly

faced

in

position

1

Return

spring

2

Supply

valve

rod

3

Piston

4

Secondary

cup

5

Spring

seat

6

Valve

spring

7

Primary

cup

8

Push

rod

CL283

Fig

CL

7

Piston

Asaembly

2

Apply

a

coating

of

brake

fluid

to

cylinder

and

piston

when

assembling

if

Tightening

torque

Reservoir

band

0

25

to

0

4

kg

m

11

8

to

2

9

ft

lb

Supply

valve

stopper

0

15

to

0

3

kg

m

1

1

to

2

2

ft

Ib

INSTALLATION

Install

clutch

master

cylinder

in

the

reverse

order

of

removal

Observe

the

following

I

Bleed

air

out

of

hydraulic

system

Refer

to

Bleeding

Clutch

System

for

bleeding

2

Adjust

pedal

height

and

pedal

free

travel

Refer

to

Clutch

Pedal

Height

and

Clutch

Pedal

Free

Travel

for

adjustment

Clutch

if

Tightening

torque

Master

cylinder

to

dash

panel

securing

nut

0

8

to

1

2

kg

m

5

8

to

8

7

ft

Ib

Clutch

tube

flare

nut

1

5

to

1

8

kg

m

11

to

13

ft

lb

CAUTION

When

connecting

clutch

tube

use

F

lere

Nut

Torque

Wrench

GG94310000

Note

When

tightening

flare

nut

hold

pipe

by

hand

to

r

it

from

twilling

OPERATING

CYLINDER

REMOVAL

I

Disconnect

clutch

tube

from

clutch

hose

at

the

bracket

on

side

member

CAUTION

When

disconnecting

clutch

tube

use

suitable

flare

nut

wrench

Never

use

an

open

end

wrench

or

adjustable

wrench

2

Remove

lock

spring

then

dis

engage

hose

from

bracket

3

Remove

clutch

hose

from

oper

ating

cylinder

4

Remove

operating

cylinder

DISASSEMBLY

Remove

push

rod

and

dust

cover

2

Remove

piston

and

piston

cup

as

an

assembly

Note

Discard

piston

cup

and

dust

cover

3

Remove

bleeder

screw

Cl

5

1

4

v

I

Bleeder

screw

2

Cylinder

body

3

Piston

cup

4

Piston

5

Dust

cover

6

Push

rod

7

Lock

nut

8

Push

nut

CL203

Fig

CL

B

Operating

Cylinder

INSPECTION

Visually

inspect

all

disassembled

parts

and

replace

parts

which

are

worn

or

damaged

too

badly

beyond

specifi

cations

CAUTION

To

clean

or

WISh

all

parts

of

operating

cylinder

dean

brake

fluid

must

be

Used

Never

use

mineral

oils

such

as

gasoline

and

kerosene

It

will

ruin

the

rubber

parts

of

the

hydraulic

system

I

Check

cylinder

bore

and

piston

for

score

or

rust

and

if

found

replace

2

Check

cylinder

bore

and

piston

for

wear

If

clearance

between

cylinder

bore

and

piston

i5

more

than

the

specified

value

replace

piston

or

oper

ating

cylinder

assembly

3

Check

condition

of

piston

cup

and

dust

cover

Always

replace

them

after

disassembly

4

Check

bleeder

hole

to

be

sure

that

it

is

clean

Clearance

between

cyliniler

bore

and

piston

less

than

0

15

mm

0

0059

in

ASSEMBLY

Assemble

operating

cylinder

in

the

reverse

order

of

disassembly

Observe

the

following

Page 212 of 548

Clutch

SERVICE

DATA

AND

SPECIFICATIONS

ENERALSPECIFICATIONS

Clutch

control

system

Type

of

clutch

control

Clutch

master

cylinder

Diameter

Clutch

operating

cylinder

Type

Diameter

Clutch

disc

Type

Facing

size

Outer

dia

x

Inner

dia

x

Thickness

Thicmess

of

disc

assembly

Free

Installed

Number

of

torsion

springs

Clutch

cover

Type

FuU

load

Hydraulic

mill

in

15

88

mm

in

Adjustable

1746

180CBL

mrn

in

180

x

125

x

3

5

7

09

x

4

92

x

0

138

mm

in

mm

in

8

5

to

9

2

0

335

to

0

362

7

6

to

8

0

0

299

to

0

315

6

kg

Ob

CI80S

335

to

385

739

to

849

INSPECTION

AND

ADJUSTMENT

Clutch

pedal

Pedal

height

H

Pedal

free

play

A

Withdiawallever

play

B

Pedalfree

travel

C

Clutch

master

cylinder

Maximum

clearance

between

cylinder

bore

and

piston

Clutch

operating

cylinder

Maximum

clearance

belween

cylinder

bore

and

piston

Clutch

disc

Wear

liinit

of

facing

Depth

of

rivet

head

below

facing

surface

Runoullimit

Distance

of

runout

checking

point

from

the

hub

center

Maximum

backlash

of

spline

at

outer

edge

of

disc

mm

in

mm

in

mm

in

mm

in

143

to

149

5

63

to

5

87

1

to

5

0

04

to

0

20

1

0

to

2

0

0

039

to

0

079

16

to

33

0

63

to

1

30

mm

in

Less

than

0

15

0

0059

mm

in

Less

than

0

15

0

0059

mm

in

mm

in

0

3

0

012

0

5

0

020

mm

in

85

3

35

mm

in

0

4

0

016

CLIO

Page 214 of 548

Condition

Clutch

slips

Clutch

drags

Clutch

TROUBLE

DIAGNOSES

AND

CORRECTIONS

Probable

cause

and

testing

Corrective

action

Slipping

of

clutch

may

be

noticeable

when

any

of

the

following

symptoms

is

encountered

during

operation

I

Car

will

not

respond

to

erigine

speed

during

acceleration

2

Insufficient

car

speed

3

Lack

of

power

during

uphill

driving

Some

of

the

above

conditions

may

also

be

attributable

to

engine

problem

First

determine

whether

engine

or

clutch

is

causing

the

problem

If

slipping

clutch

is

left

unheeded

wear

and

or

overheating

will

occur

on

clutch

facing

to

such

an

extent

that

it

is

no

longer

serviceable

TO

TEST

FOR

SLIPPING

CLurCH

proceed

as

follows

During

upgrade

havelling

run

engine

at

about

40

to

50

km

h

25

to

31

MPH

with

gear

shift

lever

in

3rd

speed

position

shift

into

highest

gear

and

t

the

same

time

rev

up

engine

If

clutch

is

slipping

car

willnot

readily

respond

to

depression

of

accelerator

pedal

Clutch

facing

warn

excessively

Oil

or

grease

on

clutch

facing

Warped

clutch

cover

or

pressure

plate

Replace

Replace

Repair

or

replace

Dragging

clu

tch

is

particularly

noticeable

when

shifting

gears

especially

into

low

gear

TO

TEST

FOR

DRAGGING

CLurCH

proceed

as

follows

I

Start

engine

Disengage

clutch

Shift

into

reverse

gear

and

then

into

Neutral

Gradually

increase

engine

speed

and

again

shift

into

reverse

gear

If

clutch

is

dragging

gear

grating

is

heard

when

shifting

gears

from

Neutral

into

Reverse

2

Stop

engine

and

shift

gears

Conduct

this

test

at

each

gear

position

3

In

step

2

gears

are

shifted

smoothly

except

1st

speed

position

at

idling

a

If

dragging

is

encountered

at

the

end

of

shifting

check

condition

of

synchro

mechanism

in

transmission

b

If

dragging

is

encountered

at

the

beginning

of

shifting

proceed

to

step

4

below

4

Push

change

lever

toward

Reverse

ide

depress

pedal

to

check

for

free

travel

of

pedal

a

If

pedal

can

be

depressed

further

check

clutch

for

condition

b

If

pedal

cannot

be

depressed

further

proceed

to

step

5

below

5

Check

clutch

control

pedal

height

pedal

free

play

free

travel

withdrawal

lever

play

etc

If

any

abnormal

condition

does

not

exist

and

if

pedal

cannot

be

depressed

further

check

clutch

for

condition

Clutch

disc

runout

or

warped

Wear

or

rust

on

hub

splines

in

clutch

disc

Diaphragm

spring

toe

height

out

of

adjustment

or

toe

tip

worn

Worn

or

improperly

installed

parts

Replace

Clean

and

lubricate

with

grease

or

replace

Adjust

or

replace

Repair

or

replace

CL12

Page 307 of 548

DATSUN

2JO

Model

83

J

0

Series

SECTIONPD

PROPELLER

SHAFT

DIFFERENTIAL

CARRIER

CONTENTS

PROPELLER

SHAFT

INSPECTION

GENERAL

INSPECTION

PROPEllER

SHAFT

VIBRATION

REMOVAL

AND

INSTAllATION

REMOVAL

INSTAllATION

DIFFERENTIAL

CARRIER

REMOVAL

PRE

DISASSEMBl

Y

INSPECTION

DISASSEMBLY

FINAL

DRIVE

ASSEMBLY

DIFFERENTIAL

CASE

INSPECTION

ASSEMBl

Y

AND

ADJUSTMENT

PRECAUTIONS

IN

REASSEMBLY

ASSEMBLY

OF

DIFFERENTIAL

CASE

ADJUSTMENT

OF

DRIVE

PINION

HEIGHT

ADJUSTMENT

OF

DRIVE

PINION

PRELOAD

PD

2

PD

2

PD

2

PD

2

PD

2

PD

2

PD

2

PD

3

PD

3

PD

3

PD

4

PD

4

PD

4

PD

4

PD

5

PD

5

PD

5

PD

6

PD

6

AQJUSTMENT

OF

SIDE

BEARING

SHIMS

INSTAllATION

REPLACEMENT

OF

FRONT

Oil

SEAL

SERVICE

DATA

AND

SPECIFICATIONS

PROPEllER

SHAFT

GENERAL

SPECIFICATIONS

SERVICE

DATA

TIGHTENING

TORQUE

DIFFERENTIAL

CARRIER

GENERAL

SPECIFICATIONS

SERVICE

DATA

TIGHTENING

TORQUE

TROUBLE

DIAGNOSES

AND

CORRECTIONS

PROPEllER

SHAFT

DIFFERENTIAL

CARRIER

SPECIAL

SERVICE

TOOLS

PD

7

PD

9

PD

9

PD

lO

PD

lO

PD

lO

PD

lO

PD

lO

PD

l0

PD

lO

PD

ll

PD

ll

PD

12

PD

12

PD

13

PD

15

Page 312 of 548

ADJUSTMENT

OF

DRIVE

PINION

HEIGHT

Adjust

the

pinion

height

with

wash

er

provided

between

rear

bearing

inner

race

and

the

back

of

piliion

gear

J

Press

fit

front

and

rear

bearing

outer

races

into

gear

carrier

using

Drive

Pinion

Outer

Race

Drift

STJ070

I

000

and

Bar

ST30611000

2

Fit

rear

bearing

on

gear

carrier

and

install

Dwnmy

Shaft

on

rear

bear

ing

and

place

Height

Gauge

on

gear

carrier

STJII21000

Height

gauge

KV38

103500

Height

gauge

spacer

ST3

II

22000

Dummy

shaft

KV3gl03600

Dummy

shaft

spacer

ST3112tOOO

PD461

Fig

PD

14

AqjUlting

Pinion

Height

3

Measure

the

clearance

N

be

tween

the

tip

end

of

height

gauge

and

the

end

surface

of

dummy

shaft

using

a

thickness

gauge

P0322

Fig

PD

15

Meo

uring

Clearance

4

The

proper

thickness

of

pinion

height

adjusting

washers

can

be

obtain

ed

from

the

following

formula

Propeller

Shaft

Differential

Carrier

T

W

N

HxO

01

OJ8

Where

T

Required

thickness

of

pinion

heightedjusting

w

shers

W

Thickness

of

temporarily

insert

ed

washer

mm

Be

sure

to

use

washer

of

2

74

0

1079

or

2

77

0

1091

or

2

80

0

1102

mm

in

thick

ness

N

Measured

clearance

between

height

gauge

and

dummy

shaft

face

mm

H

Figure

marked

on

the

drive

pinion

head

Note

e

Figure

H

is

e

dimensional

variation

in

units

of

1

100

mm

egainst

stand

ard

measurement

b

If

value

signifying

H

is

not

given

regard

it

as

zero

and

compute

Head

number

Hl

P0186

Set

number

Fig

PD

16

Variation

Number

on

Drive

Pinion

Examples

of

calculation

EX

I

W

2

74mmN

0

30mmH

1

T

W

N

H

x

0

01

0

18

2

74

0

30

I

x

0

01

OJ8

3

04

0

19

2

85

The

correct

washer

thickness

is

2

86

mm

EX

2

W

2

77

mm

N

0

21

mm

H

0

T

W

N

HxO

01

OJ8

2

77

0

21

OxO

0I

OJ8

2

98

0

18

2

80

The

correct

washer

thickness

is

2

g0

mm

PD

6

EX

3

W

2

80

mm

N

0

48

mm

H

2

T

W

N

HxO

OI

OJg

2

80

OA8

2

x

0

01

OJ8

3

28

0

20

3

08

The

correct

washer

thickness

is

3

07

mm

Pinion

height

adjusting

washer

Thickness

mm

in

2

74

OJ

079

3

01

0

1185

2

77

OJ09I

3

04

0

1197

2

80

OJ

102

3

07

0

1209

2

83

0

1114

3

10

0

1220

2

86

OJ

126

3J3

0

1232

2

89

0

1138

3

16

0

1244

2

92

OJ

150

3

19

0

1256

2

95

0

1161

3

22

OJ

268

2

98

0

1173

3

25

O

l2g0

5

Fit

detennined

pinion

height

ad

justing

washer

in

drive

pinion

and

press

fit

rear

bearing

inner

race

in

it

using

Drive

Pinion

Bearing

Drift

Bar

STJ0600000

Note

After

assembly

check

to

see

thet

tooth

contact

is

correct

If

Dot

readjust

ADJUSTMENT

OF

DRIVE

PINION

PRELOAD

Adjust

the

preload

of

drive

pinion

with

collapsible

spacer

This

procedure

has

nothing

to

do

with

thickness

of

pinion

height

ad

justing

washer

Note

Collapsible

spacer

oil

seal

and

pinion

nut

cannot

be

reused

I

After

adjusting

pinion

height

lubricate

front

bearing

with

gear

oil

and

place

it

in

gear

carrier

2

Install

a

new

oil

seal

in

gear

carrier

using

Oil

Seal

Fitting

Tool

ST33400001

Lubricate

cavity

between

seal

lips

with

recommended

multi

purpose

grease

when

installing

3

Place

a

new

collapsible

spacer

on

Page 354 of 548

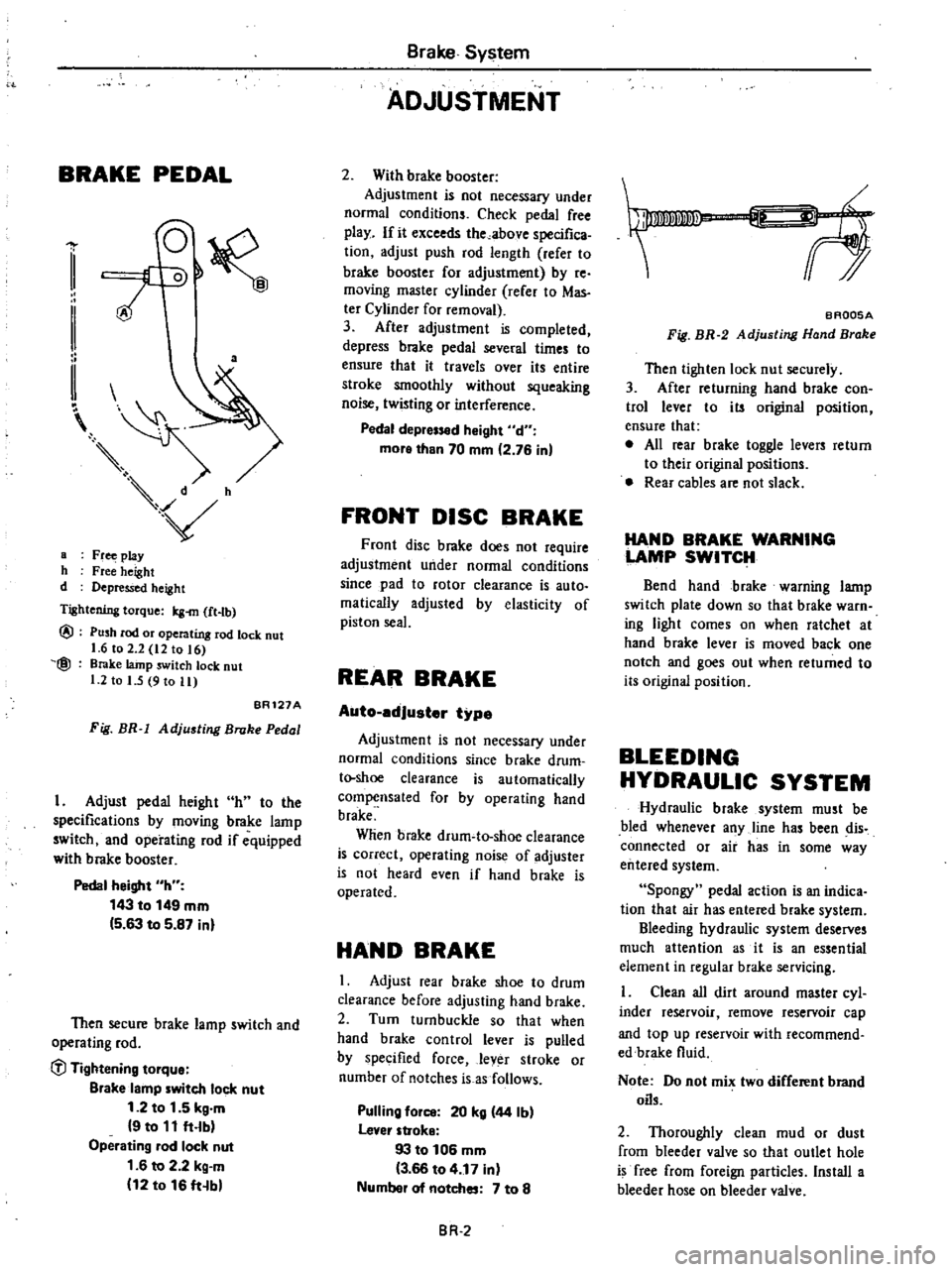

BRAKE

PEDAL

a

a

Fr

play

h

Free

height

d

Depressed

height

Tightening

torque

Icg

m

ft

tb

@

@

Push

rod

or

operating

rod

lock

nut

1

6

to

2

2

12

to

16

Brake

lainp

switch

lock

nut

1

2

to

I

5

9

to

11

BR121A

Fig

BR

1

Adjusting

Broke

Pedal

I

Adjust

pedal

height

h

to

the

specifications

by

moving

brake

lamp

switch

and

operating

rod

if

equipped

with

brake

booster

Pedal

height

h

143

to

149

mm

5

63

to

5

87

inl

Then

secure

brake

lamp

switch

and

operating

rod

C

l

Tightening

tOlque

Blake

lamp

witch

lock

nut

1

2

to

1

5

kg

m

9

to

11

ft

lb

Operating

lad

lock

nut

1

6

to

2

2

kg

m

12

to

16

ft

b

Brake

System

ADJUSTMENT

2

With

brake

booster

Adjustment

is

not

necessary

under

normal

conditions

Check

pedal

free

play

If

it

exceeds

the

above

specifica

tion

adjust

push

rod

length

refer

to

brake

booster

for

adjustment

by

re

moving

master

cylinder

rerer

to

Mas

ter

Cylinder

for

removal

3

After

adjustment

is

completed

depress

brake

pedal

several

times

to

ensure

that

it

travels

over

its

entire

stroke

smoothly

without

squeaking

noise

twisting

or

interference

Pedal

depr

d

Might

d

more

than

70

mm

2

76

in

FRONT

DISC

BRAKE

Front

disc

brake

does

not

require

adjustment

under

normal

conditions

since

pad

to

rotor

clearance

is

auto

malically

adjusted

by

elasticity

of

piston

seal

REAR

BRAKE

Auto

edJuster

type

Adjustment

is

not

necessary

under

normal

conditions

since

brake

drum

t

shoe

clearance

is

automatically

compensated

for

by

operating

hand

brake

Wlien

brake

drum

to

shoe

clearance

is

correct

operating

noise

of

adjuster

is

not

heard

even

if

hand

brake

is

operated

HAND

BRAKE

I

Adjust

rear

brake

shoe

to

drum

clearance

before

adjusting

hand

brake

2

Turn

turnbuckle

so

that

when

hand

brake

control

lever

is

pulled

by

specified

force

lever

stroke

or

number

of

notches

is

as

follows

Pulling

fOil

20

kg

44

Ib

lever

stroke

93

to

106

mm

3

66

to

4

17

in

Numbel

of

notches

7

to

8

BR

2

f

BAQ05A

Fig

BR

2

Adjusting

Hand

Brake

Then

tighten

lock

nut

securely

3

After

returning

hand

brake

con

trol

lever

to

its

original

position

ensure

that

e

All

rear

brake

toggle

levers

return

to

their

original

positions

Rear

cables

are

not

slack

HAND

BRAKE

WARNING

LAMP

SWITCH

Bend

hand

brake

warning

lamp

switch

plate

down

so

that

brake

warn

ing

light

comes

on

when

ratchet

at

hand

brake

lever

is

moved

back

one

notch

and

goes

out

when

returned

to

its

original

position

BLEEDING

HYDRAULIC

SYSTEM

Hydraulic

brake

system

must

be

bled

whenever

any

line

has

been

dis

connected

or

air

has

in

some

way

entered

system

Spongy

pedal

action

is

an

indica

tion

that

air

has

entered

brake

system

Bleeding

hydraulic

system

deserves

much

attention

as

it

is

an

essential

element

in

regular

brake

servicing

Clean

all

dirt

around

master

cyl

inder

reservoir

remove

reservoir

cap

and

top

up

reservoir

with

recommend

edbrake

fluid

Note

Do

not

mix

two

different

brand

oils

2

Thoroughly

clean

mud

or

dust

from

bleeder

valve

so

that

outlet

hole

is

free

from

foreign

particles

Install

a

bleeder

hose

on

bleeder

valve