ABS DATSUN 510 1968 Service User Guide

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1968, Model line: 510, Model: DATSUN 510 1968Pages: 252, PDF Size: 12.2 MB

Page 166 of 252

DIFFERENTIAL

REAR

AXLE

AND

REAR

SUSPENSION

161

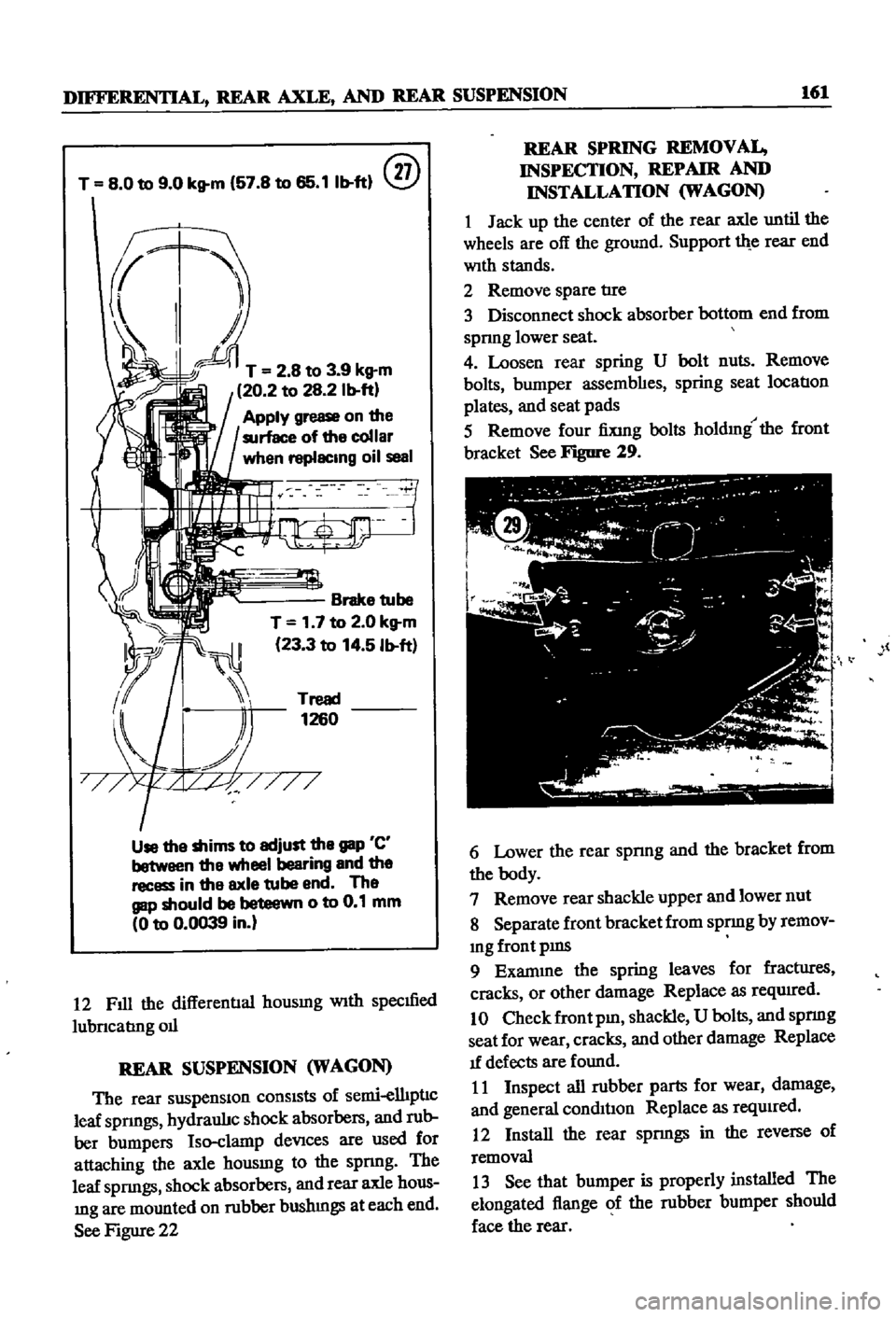

T

8

0

to

9

0

kg

m

57

8

to

65

11b

ft

@

T

2

8

to

3

9

kg

m

20

2

to

28

2

Ib

ft

Apply

grease

on

the

surface

of

the

collar

when

replacing

oil

seal

Brake

tube

T

1

7

to

2

0

kg

m

23

3

to

14

5

Ib

ft

Tread

1260

Use

the

shims

to

adjust

the

gap

C

between

the

wheel

bearing

and

the

recess

in

the

axle

tube

end

The

gap

should

be

beteewn

0

to

0

1

mm

0

to

0

0039

in

12

Fill

the

differentIal

housmg

With

specmed

lubncabng

011

REAR

SUSPENSION

WAGON

The

rear

suspensiOn

consists

of

semi

elhpnc

leaf

spnngs

hydraulJc

shock

absorbers

and

rub

ber

bumpers

Iso

clamp

deVices

are

used

for

attaching

the

axle

housmg

to

the

spnng

The

leaf

spnngs

shock

absorbers

and

rear

axle

hous

mg

are

mounted

on

rubber

bushmgs

at

each

end

See

Figure

22

REAR

SPRING

REMOVAL

INSPECTION

REPAIR

AND

INSTALLATION

WAGON

1

Jack

up

the

center

of

the

rear

axle

until

the

wheels

are

off

the

ground

Support

th

e

rear

end

With

stands

2

Remove

spare

tIre

3

Disconnect

shock

absorber

bottom

end

from

spnng

lower

seat

4

Loosen

rear

spring

U

bolt

nuts

Remove

bolts

bumper

assembhes

spring

seat

location

plates

and

seat

pads

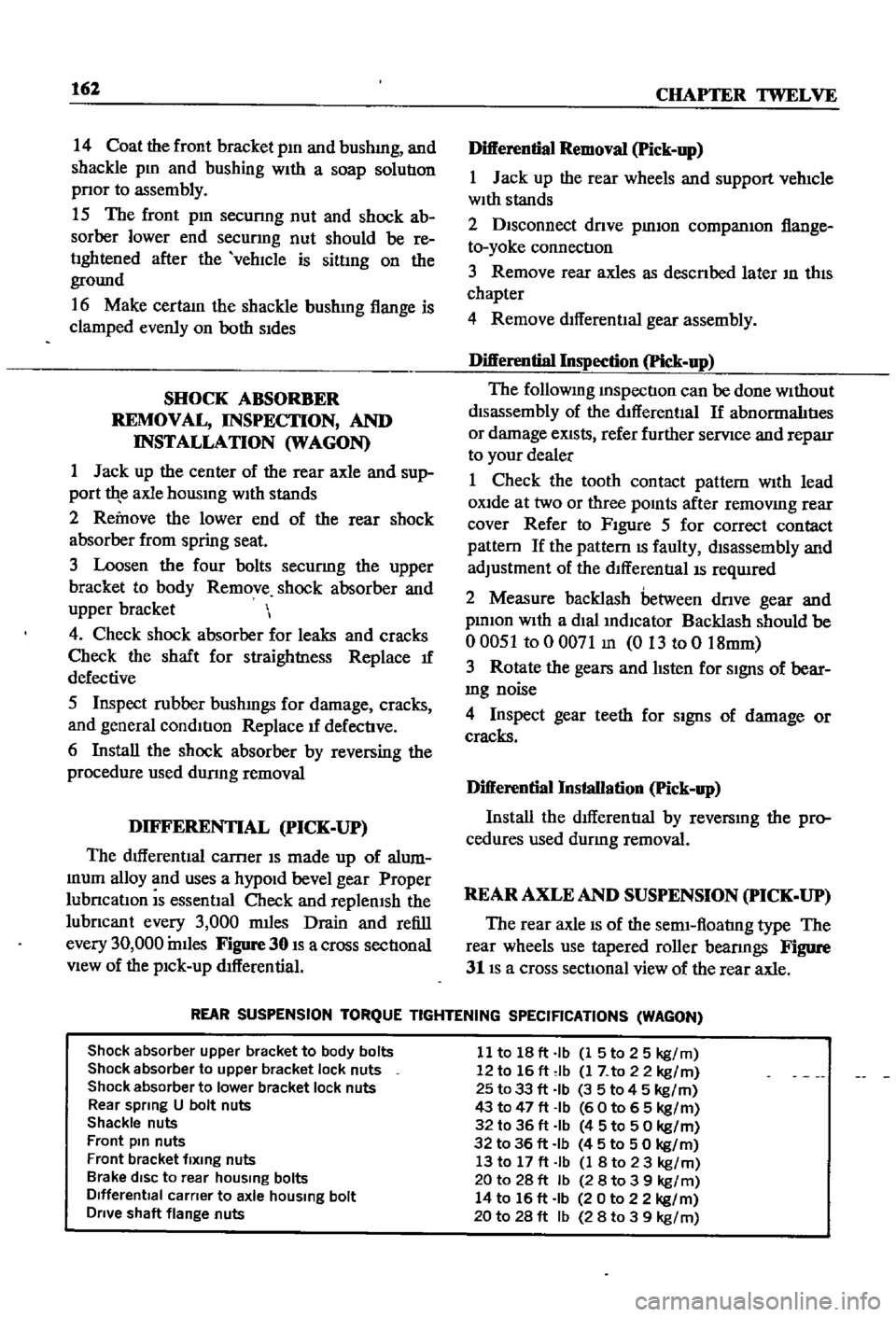

5

Remove

four

fiXing

bolts

holdmg

the

front

bracket

See

Figure

29

l

6

Lower

the

rear

spnng

and

the

bracket

from

the

body

7

Remove

rear

shackle

upper

and

lower

nut

8

Separate

front

bracket

from

spnng

by

remov

mg

front

pms

9

Exanune

the

spring

leaves

for

fractIires

cracks

or

other

damage

Replace

as

reqwred

10

Check

front

pm

shackle

U

bolts

and

spnng

seat

for

wear

cracks

and

other

damage

Replace

1f

defects

are

found

11

Inspect

all

rubber

parts

for

wear

damage

and

general

condil1on

Replace

as

reqUired

12

Install

the

rear

spnngs

in

the

reverse

of

removal

13

See

that

bumper

is

properly

installed

The

elongated

flange

of

the

rubber

bumper

should

face

the

rear

Page 167 of 252

162

CHAPTER

TWELVE

14

Coat

the

front

bracket

pm

and

bushmg

and

shackle

pm

and

bushing

With

a

soap

solution

pnor

to

assembly

15

The

front

pm

secunng

nut

and

shock

ab

sorber

lower

end

securmg

nut

should

be

re

tightened

after

the

vehicle

is

sittmg

on

the

ground

16

Make

certaJn

the

shackle

bushmg

flange

is

clamped

evenly

on

both

Sides

SHOCK

ABSORBER

REMOVAL

INSPECTION

AND

INSTALLATION

WAGON

1

Jack

up

the

center

of

the

rear

axle

and

sup

port

th

e

axle

housmg

With

stands

2

Reinove

the

lower

end

of

the

rear

shock

absorber

from

spring

seat

3

Loosen

the

four

bolts

secunng

the

upper

bracket

to

body

Remove

shock

absorber

and

upper

bracket

4

Check

shock

absorber

for

leaks

and

cracks

Check

the

shaft

for

straighmess

Replace

1f

defective

5

Inspect

rubber

bushmgs

for

damage

cracks

and

general

condition

Replace

1f

defective

6

Install

the

shock

absorber

by

reversing

the

procedure

used

durmg

removal

DIFFERENTIAL

pICK

UP

The

dlfferenl1al

carner

IS

made

up

of

alum

mum

alloy

and

uses

a

hyp01d

bevel

gear

Proper

lubncatIon

IS

essenl1al

Check

and

replemsh

the

lubncant

every

3

000

mlles

Drain

and

refill

every

30

000

inlles

Figure

30

IS

a

cross

sectional

View

of

the

pick

up

dIfferential

Difterential

Removal

Pick

up

1

Jack

up

the

rear

wheels

and

support

vehicle

With

stands

2

DIsconnect

dnve

pmlOn

companlOn

flange

to

yoke

connectIon

3

Remove

rear

axles

as

descnbed

later

m

thIS

chapter

4

Remove

dlfferenl1al

gear

assembly

Difterential

Inspection

Pick

up

The

followmg

mspection

can

be

done

Without

disassembly

of

the

d1fferenl1al

If

abnormahties

or

damage

eXiSts

refer

further

serVice

and

reparr

to

your

dealer

1

Check

the

tooth

contact

pattern

WIth

lead

OXide

at

two

or

three

pomts

after

remoVlDg

rear

cover

Refer

to

FIgure

5

for

correct

contact

pattern

If

the

pattern

IS

faulty

disassembly

and

adJustment

of

the

dIfIerentialIs

required

2

Measure

backlash

between

dnve

gear

and

pmlOn

With

a

dial

mdlcator

Backlash

should

be

00051

to

0

0071

m

013

to

0

18mm

3

Rotate

the

gears

and

lISten

for

SignS

of

bear

mg

noise

4

Inspect

gear

teeth

for

SIgnS

of

damage

or

cracks

Difterential

Installation

Pick

up

Install

the

differential

by

reversmg

the

pro

cedures

used

dunng

removal

REAR

AXLE

AND

SUSPENSION

pICK

UP

The

rear

axle

IS

of

the

semi

floatIng

type

The

rear

wheels

use

tapered

roller

beanngs

Figure

31

IS

a

cross

sectional

view

of

the

rear

axle

REAR

SUSPENSION

TORQUE

TIGHTENING

SPECIFICATIONS

WAGON

Shock

absorber

upper

bracket

to

body

bolts

Shock

absorber

to

upper

bracket

lock

nuts

Shock

absorber

to

lower

bracket

lock

nuts

Rear

spnng

U

bolt

nuts

Shackle

nuts

Front

pm

nuts

Front

bracket

flxmg

nuts

Brake

dISC

to

rear

housmg

bolts

DifferentIal

carner

to

axle

housmg

bolt

Dnve

shaft

flange

nuts

11

to

18

ft

Ib

1

5

to

2

5

kg

m

12

to

16

ft

db

17

to

2

2

kg

m

25

to

33

ft

Ib

35

to

45

kg

m

43

to

47

ft

Ib

60

to

6

5

kg

m

32

to

36

ft

Ib

45

to

50

kg

m

32

to

36

ft

Ib

45

to

5

0

kg

m

13

to

17

ft

Ib

18

to

23

kg

m

20

to

28

ft

Ib

28

to

3

9

kg

m

14

to

16

ft

Ib

20

to

2

2

kg

m

20

to

28

ft

Ib

28

to

3

9

kg

m

Page 170 of 252

DIFFERENTIAL

REAR

AXLE

AND

REAR

SUSPENSION

165

2

Check

wheel

bearmgs

for

damage

or

noise

Replace

them

If

defective

3

Be

sure

to

use

new

011

seals

and

lockwashers

4

FIt

beanng

cup

and

grease

seal

to

cage

Tap

WIth

a

brass

hammer

while

fittIng

FIll

grease

seal

IIp

With

wheel

beanng

grease

after

fittmg

5

Install

brake

diSC

and

beanng

cage

on

axle

Fit

bearmg

cone

With

brass

bar

6

Tighten

lock

nut

Place

faced

Side

of

nut

to

washer

SIde

so

that

washer

IS

not

damaged

Torque

lock

nut

to

10S

to

145

ft

lb

15

to

20

kg

m

7

Match

washer

IIp

With

groove

m

nut

tIghten

nut

and

bend

washer

carefully

to

prevent

hp

damage

S

Use

a

brass

bar

to

fit

011

seal

to

tube

end

When

fitted

apply

grease

to

the

hp

Be

careful

not

to

deform

seal

or

damage

hp

9

Completely

fill

bearmg

With

grease

10

Install

shaft

AdJust

aXial

clearance

With

shIms

See

Figure

37

Clearance

should

be

0

012

to

0

035

m

0

3

to

09mm

Standard

shIm

thickness

IS

0

059

m

1

5mm

@

11

Install

other

shaft

AdJust

aXlal

clearance

With

shIm

Clearance

should

be

0

OOOS

to

0

0059

m

002

to

0

15mm

12

Install

bolts

and

torque

to

26

to

34

ft

lb

3

6

to

4

7

kg

m

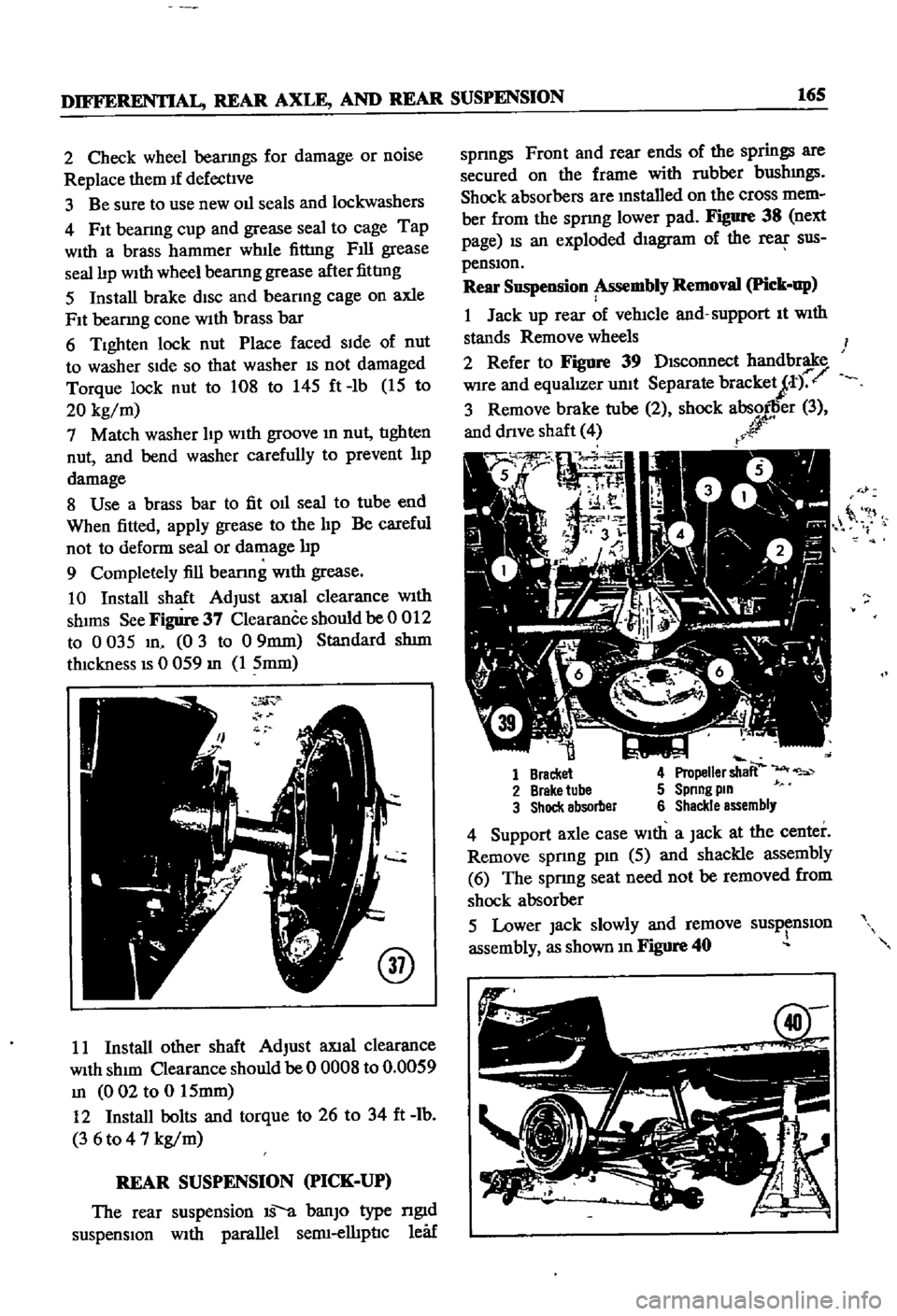

REAR

SUSPENSION

PICK

UP

The

rear

suspension

IS

a

banJO

type

ngId

suspensIOn

With

parallel

semI

elhpnc

leaf

spnngs

Front

and

rear

ends

of

the

springs

are

secured

on

the

frame

with

rubber

bushmgs

Shock

absorbers

are

mstalled

on

the

cross

mem

ber

from

the

spnng

lower

pad

Figure

38

next

page

IS

an

exploded

dIagram

of

the

rear

sus

pensIOn

Rear

Suspension

Assembly

Removal

Pick

up

1

Jack

up

rear

of

vehicle

and

support

It

With

stands

Remove

wheels

2

Refer

to

Figure

39

DIsconnect

handbrake

Wire

and

equalIZer

unit

Separate

bracketJt

r

3

Remove

brake

tube

2

shock

absorller

3

and

dnve

shaft

4

r

r

0

it

1

Bracket

4

Propeller

shaft

2

Brake

tube

5

Spnng

pm

3

Shock

absorber

6

Shackle

assembly

4

Support

axle

case

With

a

Jack

at

the

center

Remove

spnng

pm

5

aJId

shackle

assembly

6

The

sprmg

seat

need

not

be

removed

from

shock

absorber

5

Lower

Jack

slowly

and

remove

susp

nslOn

assembly

as

shown

m

Figure

40

Page 171 of 252

166

CHAPTER

TWELVE

u

@

1

Spring

helper

rubber

5

Rear

spring

outer

shackle

9

Rear

spring

mner

shackle

2

Rear

spnng

clip

6

Rear

spring

leaf

10

Rear

spring

bush

3

Rear

sprmg

pm

7

Rear

shock

absorber

11

Bumper

assembly

4

Rear

spnnglawerpad

8

Upper

rear

spring

pad

12

Rear

axle

remforcement

13

Shock

absorber

llountmg

busn

REAR

SPRING

REMOVAL

pICK

UP

1

Jack

up

vehicle

support

It

With

stands

and

remove

wheels

2

Support

axle

case

With

Jack

or

stand

3

Remove

U

bolts

and

separate

spnng

from

axle

case

4

Remove

spnng

pin

and

shackle

assembly

Remove

leaf

spring

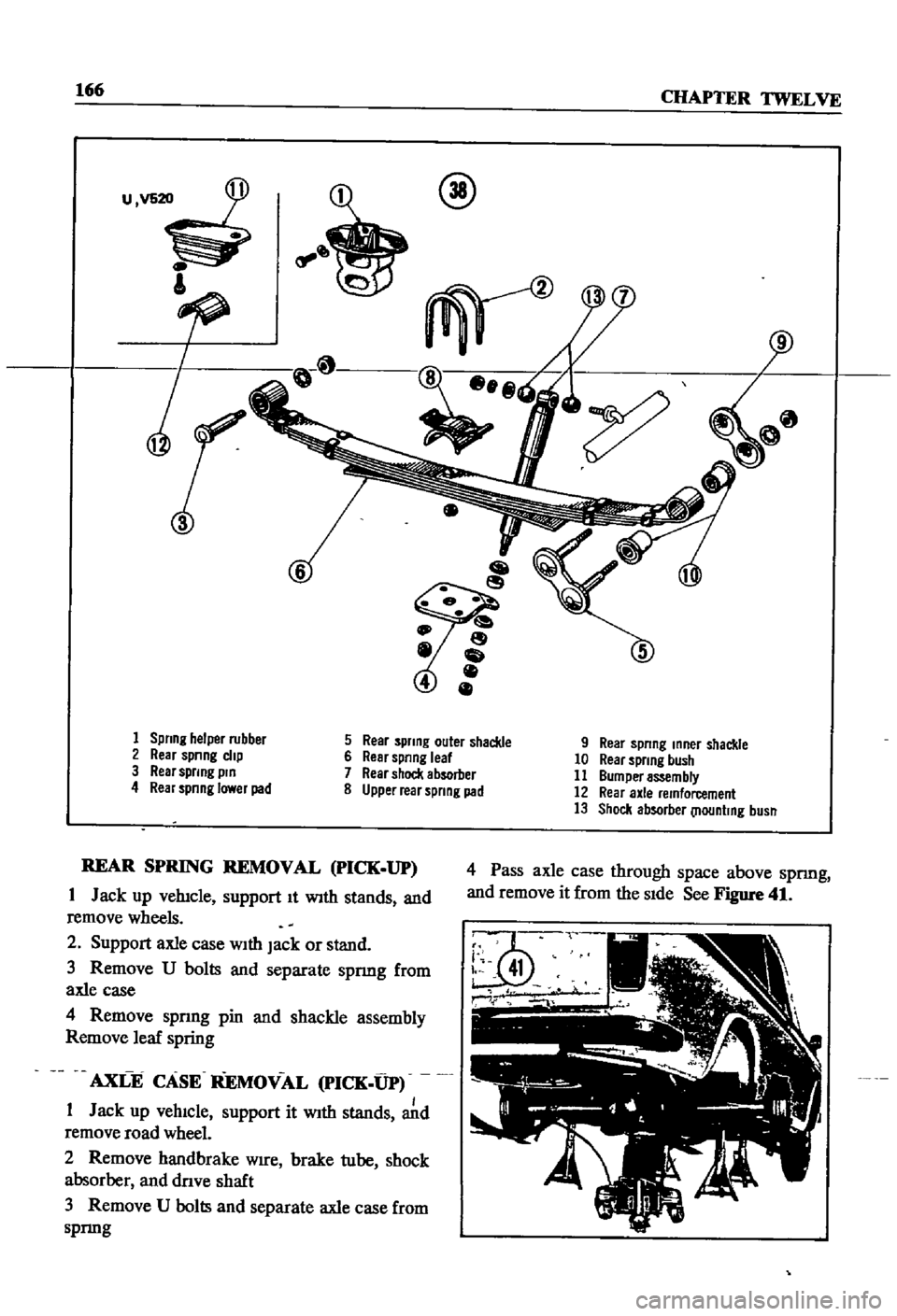

AXLE

CASE

REMOVAL

PICK

UP

1

Jack

up

vehIcle

support

it

With

stands

Jd

remove

road

wheel

2

Remove

handbrake

Wire

brake

tube

shock

absorber

and

dnve

shaft

3

Remove

U

bolts

and

separate

axle

case

from

spnng

4

Pass

axle

case

through

space

above

spnng

and

remove

it

from

the

SIde

See

Figure

41

Page 172 of 252

DIFFERENTIAL

REAR

AXLE

AND

REAR

SUSPENSION

167

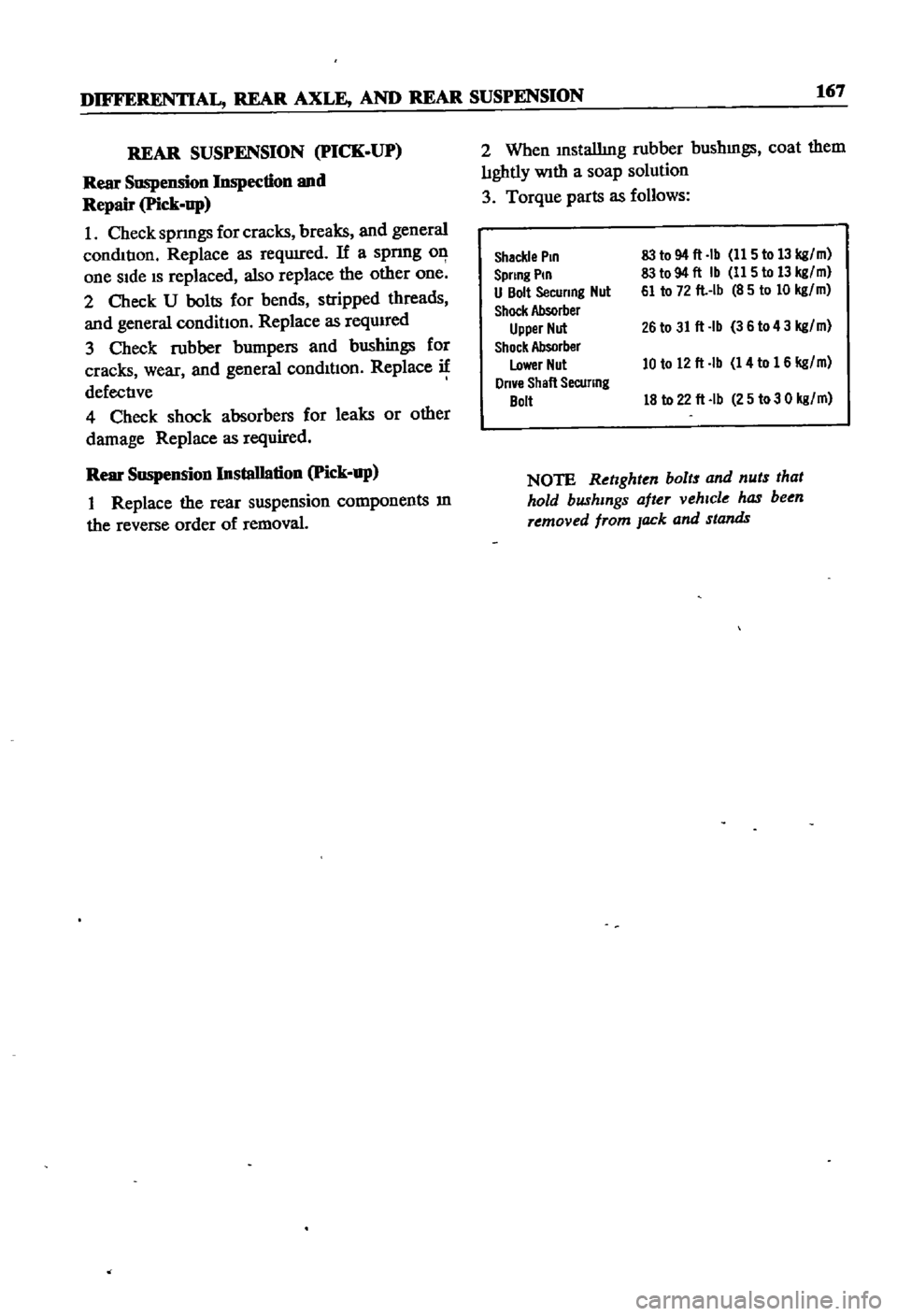

REAR

SUSPENSION

pICK

UP

Rear

Suspension

Inspection

nnd

Repair

Pick

up

1

Check

spnngs

for

cracks

breaks

and

general

conditIon

Replace

as

reqwred

If

a

spnng

on

one

Side

IS

replaced

also

replace

the

other

one

2

Check

U

bolts

for

bends

stripped

threads

and

general

conditIon

Replace

as

reqUIred

3

Check

rubber

bumpers

and

bushings

for

cracks

wear

and

general

condll1on

Replace

if

defecl1ve

4

Check

shock

absorbers

for

leaks

or

other

damage

Replace

as

required

Rear

Suspension

Installation

Pick

up

1

Replace

the

rear

suspension

components

m

the

reverse

order

of

removal

2

When

msta11mg

rubber

bushmgs

coat

them

hghtly

With

a

soap

solution

3

Torque

parts

as

follows

Shackle

Pin

Spnng

Pm

U

Bolt

Secunng

Nut

Shock

Absorber

Upper

Nut

Shock

Absorber

Lower

Nut

Dnve

Shalt

Secunng

Bolt

83

to

94

It

Ib

11

5

to

13

kg

m

83

to

94

It

Ib

115

to

13

kg

m

61

to

72

ItAb

85

to

10

kg

m

26

to

31

It

Ib

36

t04

3

kg

m

10

to

12

ft

Ib

1

4

to

1

6

kg

m

18

to

22

ft

Ib

25

to

30

kg

m

NOTE

Retighten

bolts

and

nuts

that

hold

bushmgs

after

vehicle

has

been

removed

from

Jack

and

stands

Page 173 of 252

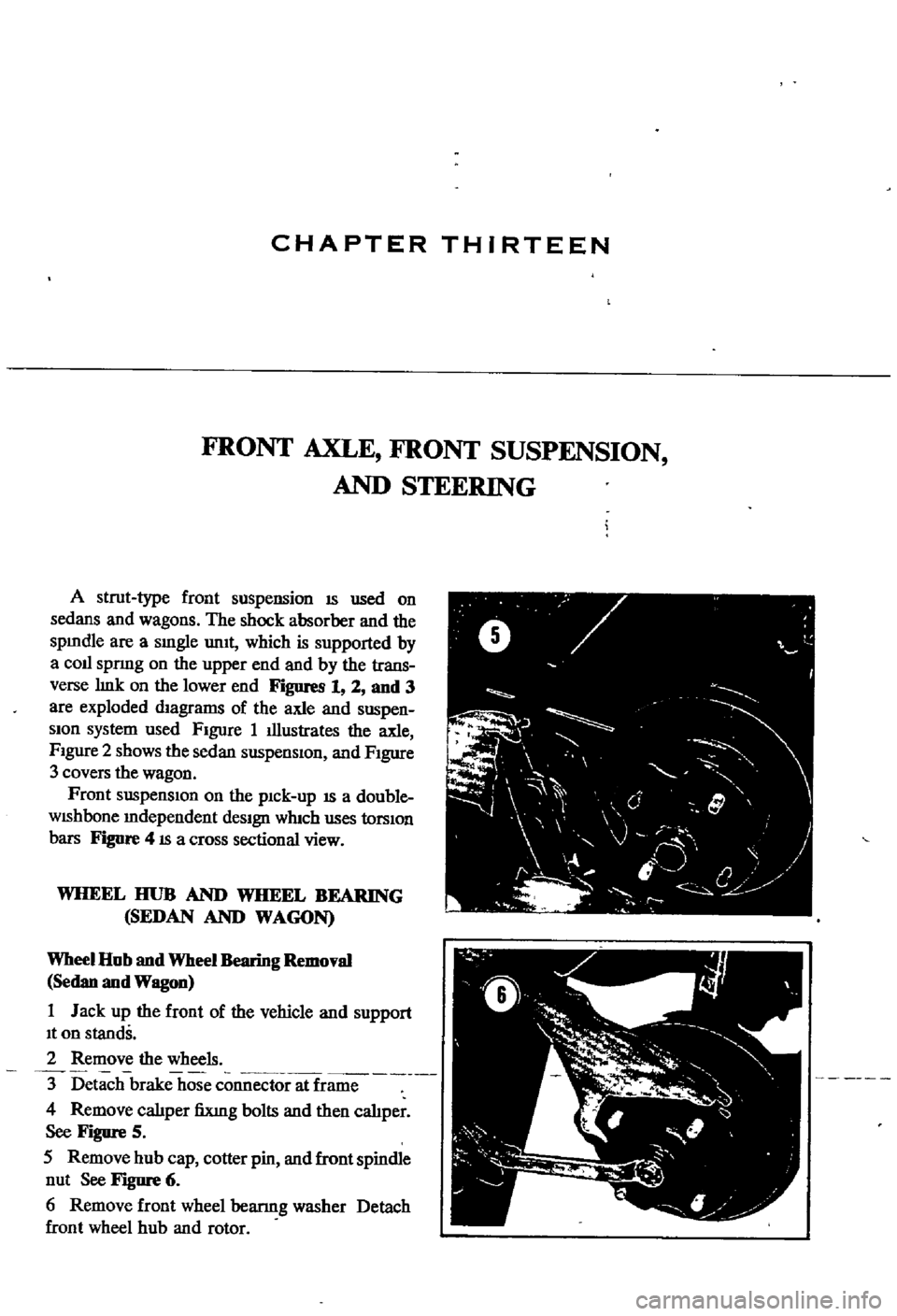

CHAPTER

THIRTEEN

FRONT

AXLE

FRONT

SUSPENSION

AND

STEERING

A

strut

type

front

suspension

IS

used

on

sedans

and

wagons

The

shock

absorber

and

the

spmdle

are

a

smgle

urnt

which

is

supported

by

a

coIl

spnng

on

the

upper

end

and

by

the

trans

verse

lInk

on

the

lower

end

Figures

1

2

nnd

3

are

exploded

dIagrams

of

the

axle

and

suspen

SIon

system

used

FIgure

1

Illustrates

the

axle

Figure

2

shows

the

sedan

suspenSlOn

and

FIgure

3

covers

the

wagon

Front

suspensIOn

on

the

pIck

up

IS

a

double

wIShbone

mdependent

deSign

which

uses

torsIon

bars

Figure

4

IS

a

cross

sectional

view

WHEEL

HUB

AND

WHEEL

BEARING

SEDAN

AND

WAGON

Wheel

Hub

nnd

Wheel

Bearing

Removal

Sednn

aud

Wagon

1

Jack

up

the

front

of

the

vehicle

and

support

It

on

stands

2

Remove

the

wheels

3

Detach

brake

hose

connector

at

frame

4

Remove

calIper

fiXlng

bolts

and

then

cahper

See

Figure

5

5

Remove

hub

cap

cotter

pin

and

front

spindle

nut

See

Figure

6

6

Remove

front

wheel

bearmg

washer

Detach

front

wheel

hub

and

rotor

ft

V

0

y

F

I

I

J

j

0

l

l

4

f

Page 175 of 252

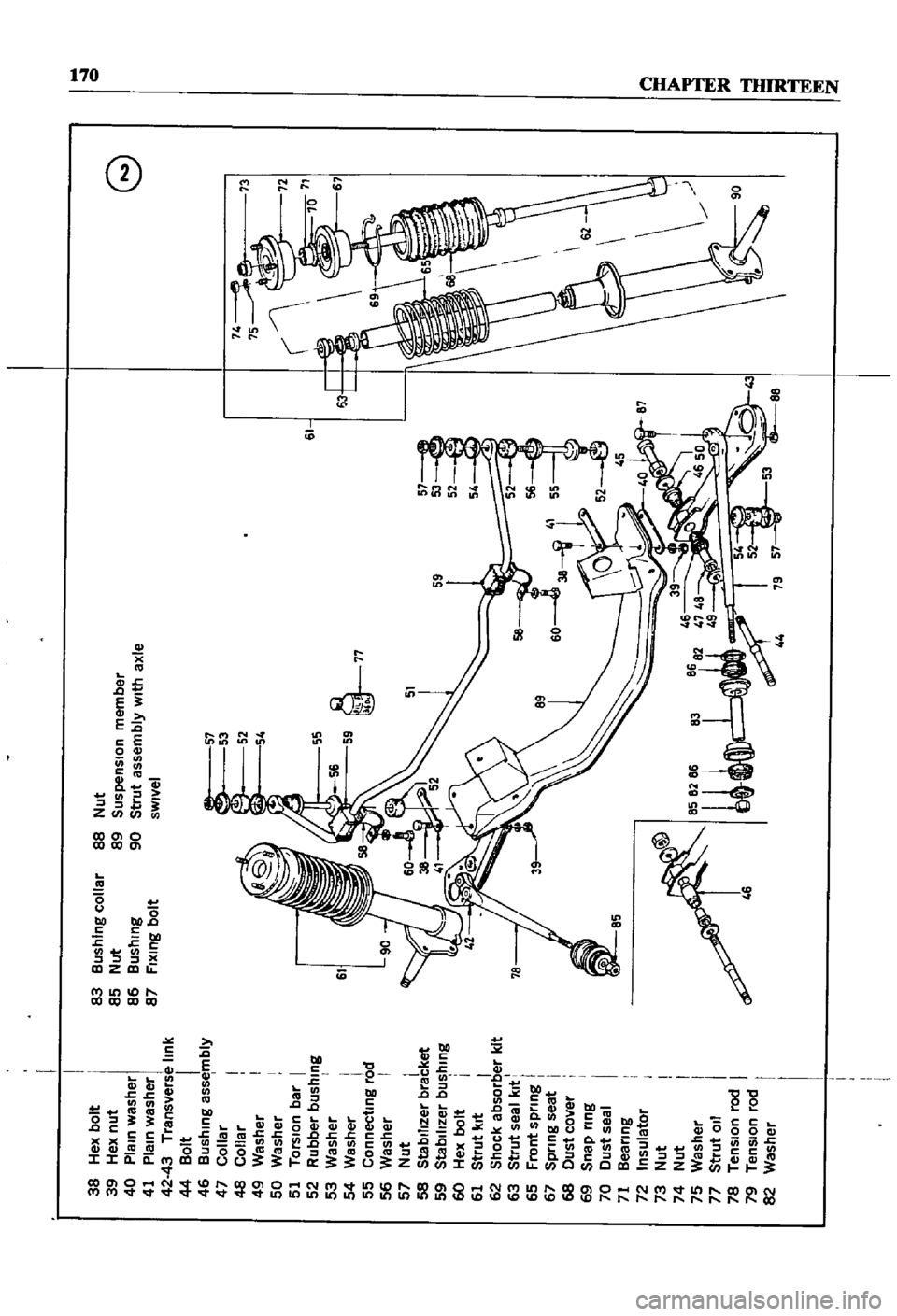

38

Hex

bolt

39

Hex

nut

40

Plain

washer

41

Plain

washer

42

43

Transverse

link

44

Bolt

I

46

Bushing

assembly

47

Collar

48

Collar

49

Washer

50

Washer

51

Torsion

bar

I

52

Rubber

bushing

53

Washer

I

54

Washer

55

Connecting

rod

56

Washer

I

57

Nut

i

58

Stabilizer

bracket

59

StabIlizer

bushing

60

Hex

bolt

i

61

Strut

kit

I

62

Shock

absorber

kit

63

Strut

sea

I

kit

I

65

Front

spnng

67

Spnng

seat

i

68

Dust

cover

69

Snap

rrng

I

70

Dust

seal

71

Bearing

72

Insulator

73

Nut

74

Nut

75

Washer

77

Strut

011

78

Tension

rod

79

Tension

rod

82

Washer

83

BushIng

collar

85

Nut

86

Bushing

87

FIxing

bolt

88

Nut

89

Suspension

member

90

Strut

assembly

with

axle

sWivel

0

61

61

55

59

11

63

46

8682

41

48

8S82

49

U

I

9

a

r

I

I

Page 176 of 252

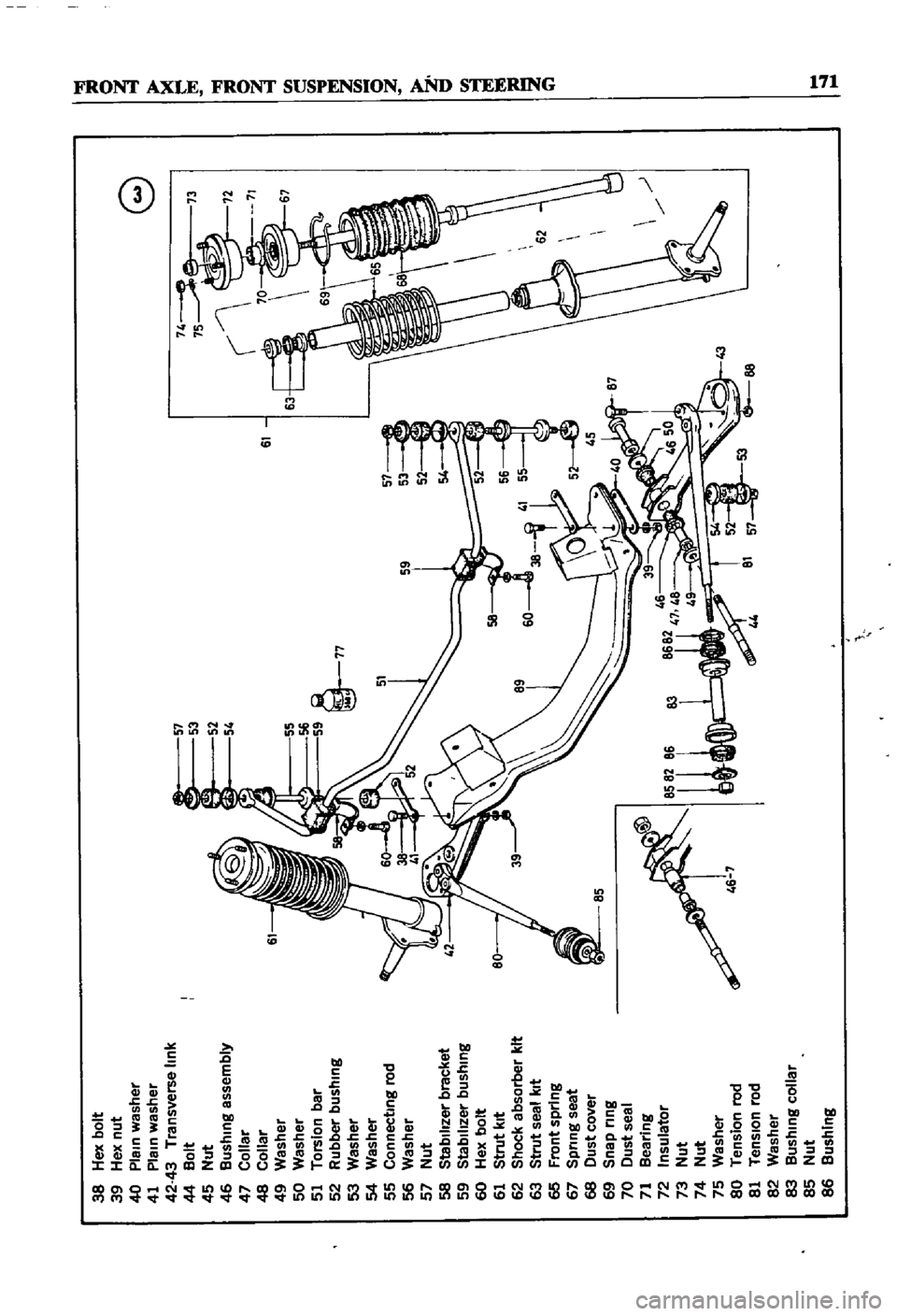

38

Hex

bolt

39

Hex

nut

40

Plain

washer

41

Plain

washer

42

43

Transverse

link

44

Bolt

45

Nut

46

Bushing

assembly

47

Collar

48

Collar

49

Washer

50

Washer

51

Torsion

bar

52

Rubber

bushing

53

Washer

54

Washer

55

Connecting

rod

56

Washer

57

Nut

58

Stabilizer

bracket

59

Stabilizer

bushing

60

Hex

bolt

61

Strut

kit

62

Shock

absorber

kit

63

Strut

seal

kit

65

Front

spring

67

Spnng

seat

68

Dust

cover

69

Snap

ring

70

Dust

seal

71

Bearing

72

Insulator

73

Nut

74

Nut

75

Washer

80

Tension

rod

81

TenSion

rod

82

Washer

83

Bushing

collar

85

Nut

86

Bushing

0

G

57

53

l

Fl

52

72

l

54

61

55

63

67

rI

l

56

c

l

59

rI

l

77

rI

l

51

57

59

53

46

8682

47

48

u

Page 177 of 252

17

CHAPTER

THIRTEEN

CD

7

Remove

bearing

collar

and

extract

the

outer

beanng

cage

8

Use

a

screwdriver

to

remove

front

hub

grease

seal

and

imIer

bearmg

cage

9

Use

a

dnft

to

punch

out

the

outer

and

mner

race

of

the

outer

bearmgs

Punch

out

imIer

bearing

10

Detach

rotor

from

wheel

hub

as

shown

in

FJgUre

7

@

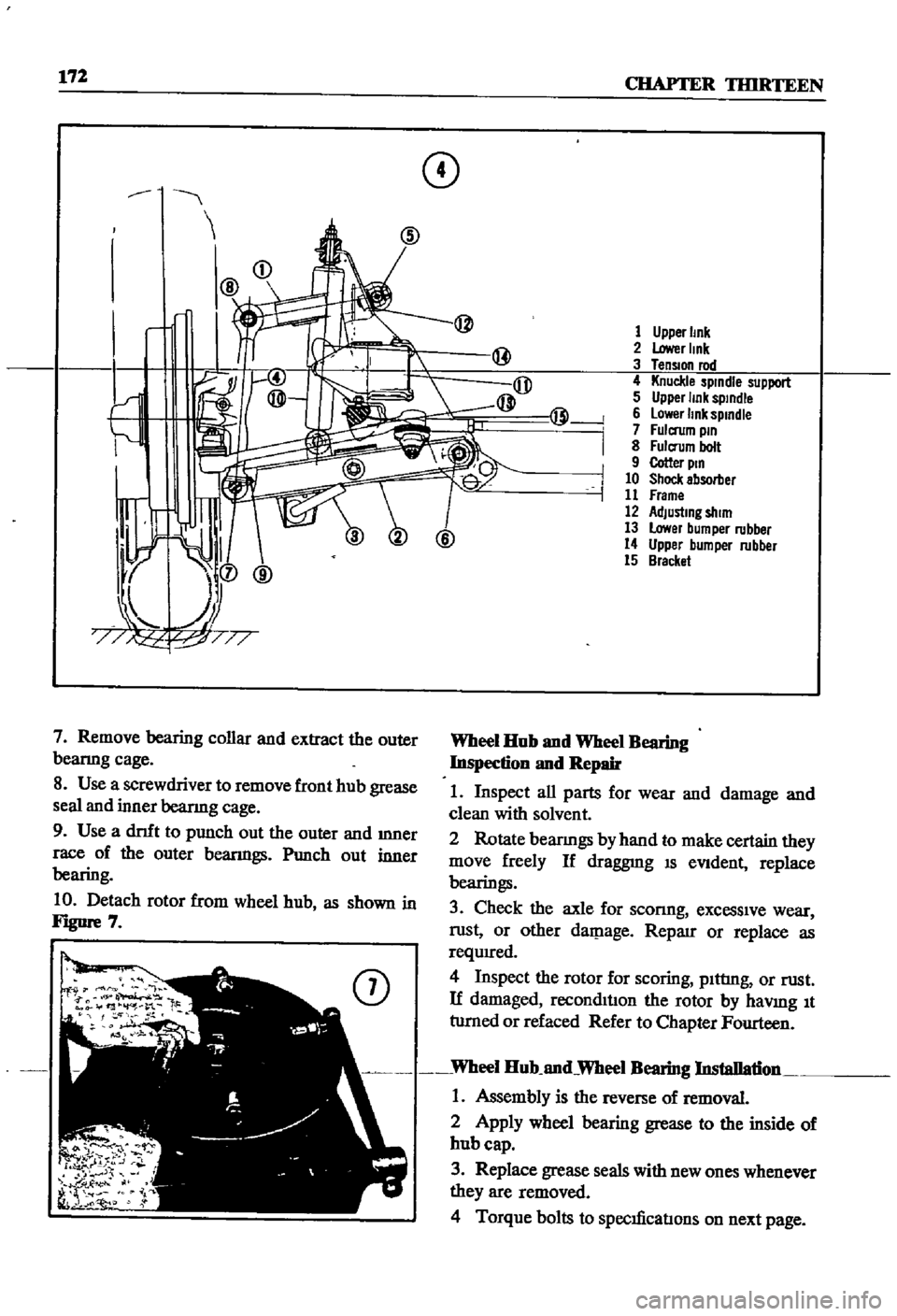

1

Upper

Imk

2

Lower

Imk

3

TenSIOn

rod

4

Knuckle

spindle

support

5

Upper

link

sptndle

6

lower

link

spmdle

7

Fulcrum

pm

8

Fulcrum

bolt

9

Cotter

ptn

10

Shock

absorber

11

Frame

12

AdJustmg

shim

13

Lower

bumper

rubber

14

Upper

bumper

rubber

15

Bracket

Wheel

Hub

nnd

Wheel

Bearing

Inspection

nnd

Repair

1

Inspect

all

parts

for

wear

and

damage

and

clean

with

solvent

2

Rotate

bearmgs

by

hand

to

make

certain

they

move

freely

If

draggnIg

IS

eVident

replace

bearings

3

Check

the

axle

for

sconng

excessive

wear

rust

or

other

daJP

age

Reparr

or

replace

as

requIred

4

Inspect

the

rotor

for

scoring

pIttIng

or

rust

If

damaged

reconditIon

the

rotor

by

haVlDg

It

tumed

or

refaced

Refer

to

Chapter

Fourteen

Wheel

Hub

nnd

Wheel

Bearing

Installation

1

Assembly

is

the

reverse

of

removal

2

Apply

wheel

bearing

grease

to

the

inside

of

hub

cap

3

Replace

grease

seals

with

new

ones

whenever

they

are

removed

4

Torque

bolts

to

specIficatIons

on

next

page

Page 183 of 252

178

CHAPTER

mIRTEEN

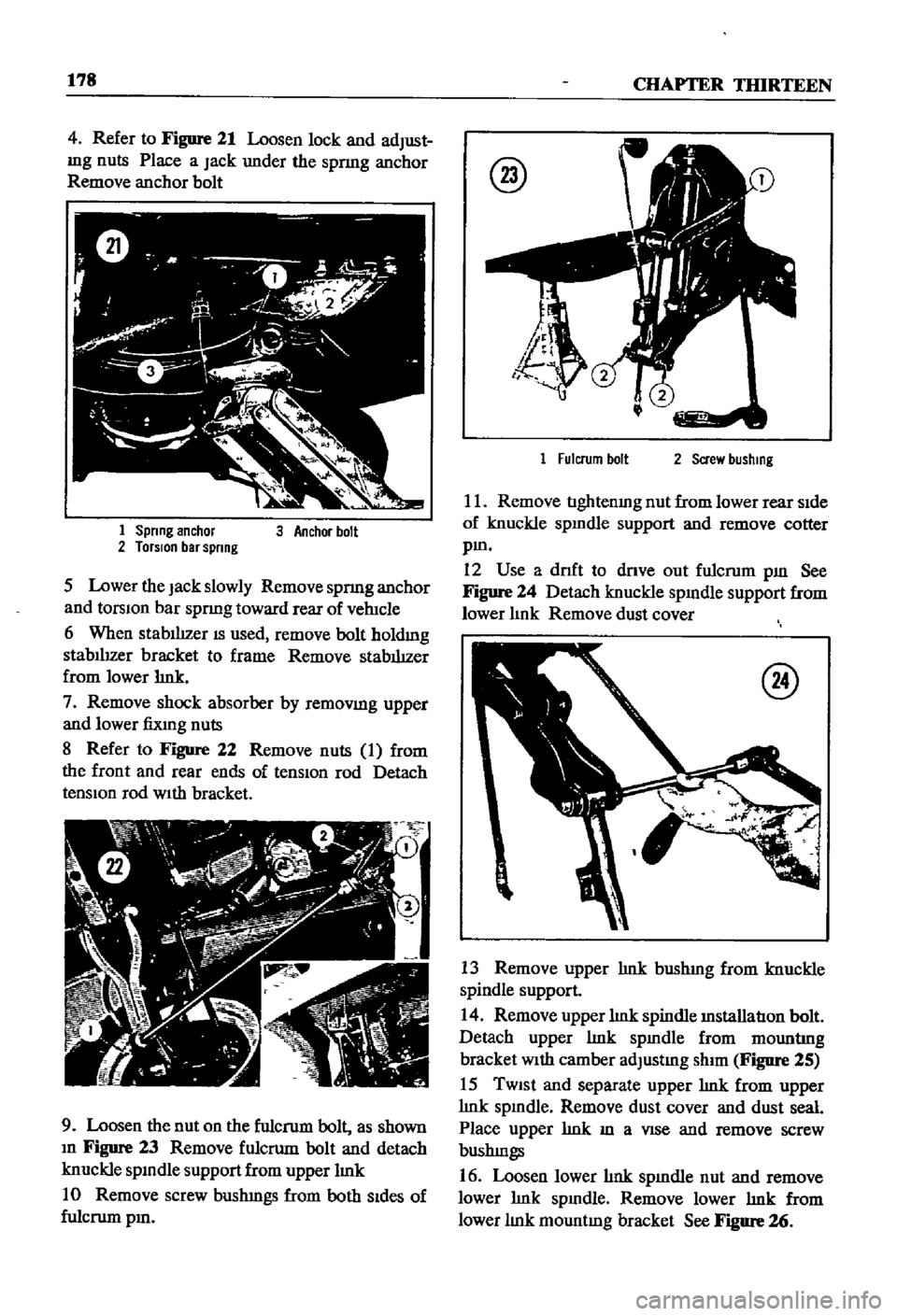

4

Refer

to

Figure

21

Loosen

lock

and

adJust

mg

nuts

Place

a

Jack

under

the

spnng

anchor

Remove

anchor

bolt

1

Spnng

anchor

2

TorSIon

bar

spnng

3

Anchor

boll

5

Lower

the

Jack

slowly

Remove

spnng

anchor

and

torsIOn

bar

spnng

toward

rear

of

vehicle

6

When

stablhzer

IS

used

remove

bolt

holdmg

stabIlIzer

bracket

to

frame

Remove

stabIlIzer

from

lower

hnk

7

Remove

shock

absorber

by

remoVlDg

upper

and

lower

fiXlng

nuts

8

Refer

to

Figure

22

Remove

nuts

1

from

the

front

and

rear

ends

of

tenSiOn

rod

Detach

tensIOn

rod

WIth

bracket

9

Loosen

the

nut

on

the

fulcrum

bolt

as

shown

m

Figure

23

Remove

fulcrum

bolt

and

detach

knuckle

spmdle

support

from

upper

hnk

10

Remove

screw

bushmgs

from

both

Sides

of

fulcrum

pm

@

1

Fulcrum

boll

2

Screw

bushmg

11

Remove

tIghtenmg

nut

from

lower

rear

SIde

of

knuckle

spmdle

support

and

remove

cotter

pm

12

Use

a

dnft

to

dnve

out

fulcrum

pm

See

Figure

24

Detach

knuckle

spmdle

support

from

lower

hnk

Remove

dust

cover

@

13

Remove

upper

hnk

bushmg

from

knuckle

spindle

support

14

Remove

upper

hnk

spindle

mstallation

bolt

Detach

upper

hnk

spmdle

from

mountIng

bracket

With

camber

adJustmg

shim

Figure

25

15

TWISt

and

separate

upper

hnk

from

upper

hnk

spmdle

Remove

dust

cover

and

dust

seal

Place

upper

hnk

m

a

VISe

and

remove

screw

bushmgs

16

Loosen

lower

hnk

spmdle

nut

and

remove

lower

hnk

spmdle

Remove

lower

hnk

from

lower

hnk

mountmg

bracket

See

FIgure

26