ABS DATSUN 510 1968 Service Owner's Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1968, Model line: 510, Model: DATSUN 510 1968Pages: 252, PDF Size: 12.2 MB

Page 184 of 252

FRONT

AXLE

FRONT

SUSPENSION

AND

STEERING

179

17

Remove

lower

lmk

torque

arm

and

torque

arm

bolt

Separate

torque

arm

from

lower

lmk

18

Dnve

out

lower

lmk

bushmg

from

bracket

Front

Suspension

Inspection

and

Repair

1

Check

the

shock

absorber

for

011

leakage

and

general

conditIon

Replace

1f

defects

are

found

2

Check

upper

and

lower

bushmgs

Replace

If

defective

or

worn

3

Install

screw

bushmg

to

upper

lmk

spmdle

and

fulcrum

pm

Measure

end

play

m

aXial

dIrection

If

end

play

exceeds

000

38

m

0

033mm

replace

upper

lmk

spmdle

fulcrum

pm

and

or

screw

bushmg

4

Check

dust

cover

for

damage

and

detenora

tIon

Replace

as

reqUIred

5

Check

threads

of

upper

lmk

spmdle

fulcrum

pm

and

screw

bushmg

RepaIr

or

replace

If

defective

6

Check

lower

lmk

and

upper

lmk

bushmgs

for

general

condition

and

wear

Replace

1f

defective

7

Check

torsion

bar

for

distortion

weakness

bends

and

general

conmtIon

Replace

If

de

fectIve

8

Check

tensIOn

rod

for

dIStortion

If

the

threaded

part

is

damaged

replace

9

Check

tenSiOn

bar

cushIOn

rubber

Replace

if

defective

10

Check

dust

seal

for

wear

and

damage

Re

place

as

requIred

11

Check

threaded

part

of

upper

lmk

spmdle

fulcrum

pm

and

screw

bushmgs

for

wear

and

damage

Replace

as

required

2

Check

lower

hnk

bushmg

and

upper

hnk

bushmg

for

SignS

of

wear

or

damage

Replace

as

reqwred

13

Check

torsIOn

bar

for

dlstorllon

and

general

condition

Replace

as

reqwred

14

Replace

rubber

bumper

If

weakened

or

damaged

15

Check

upper

and

lower

lmks

for

cracks

thread

damage

and

general

condition

RepaIr

or

replace

If

defectIve

Front

Suspension

Installation

1

Fit

lower

lmk

bushmg

to

lower

lmk

mountmg

bracket

usmg

a

SUItable

drlft

and

hanmIer

2

Install

torque

arm

on

lower

lmk

Torque

bolts

as

follows

181

to

224

fl

lb

25to31

kg

m

58

to

8

7

fl

Ib

08

to

12

kg

m

4

Tighten

screw

bushmg

on

upper

lmk

Install

grease

seal

and

dust

cover

Torque

to

173

5

to

1808

ft

lb

24

to

25

kg

m

5

Refer

to

Figure

27

Fill

upper

lmk

screw

bushmg

With

multi

purpose

grease

as

mdlcated

by

the

m

the

Illustration

Apply

grease

to

bush

mg

mtenor

Thread

on

upper

lmk

spmdle

to

the

dimenSIOn

mdIcated

6

Screw

front

and

rear

lInks

agaJnst

upper

hnk

spmdle

to

the

openmg

Width

mdlcated

Remove

the

filler

plug

while

fittIng

the

front

and

rear

lmks

Check

to

make

cectam

that

the

upper

link

spmdle

operates

smoothly

7

Remove

filler

plug

mstall

grease

mpple

and

inJect

grease

untIl

It

comes

out

from

dust

cover

Reinstall

filler

plug

Arm

Head

Serration

Boss

Page 186 of 252

FRONT

AXLE

FRONT

SUSPENSION

AND

STEERING

181

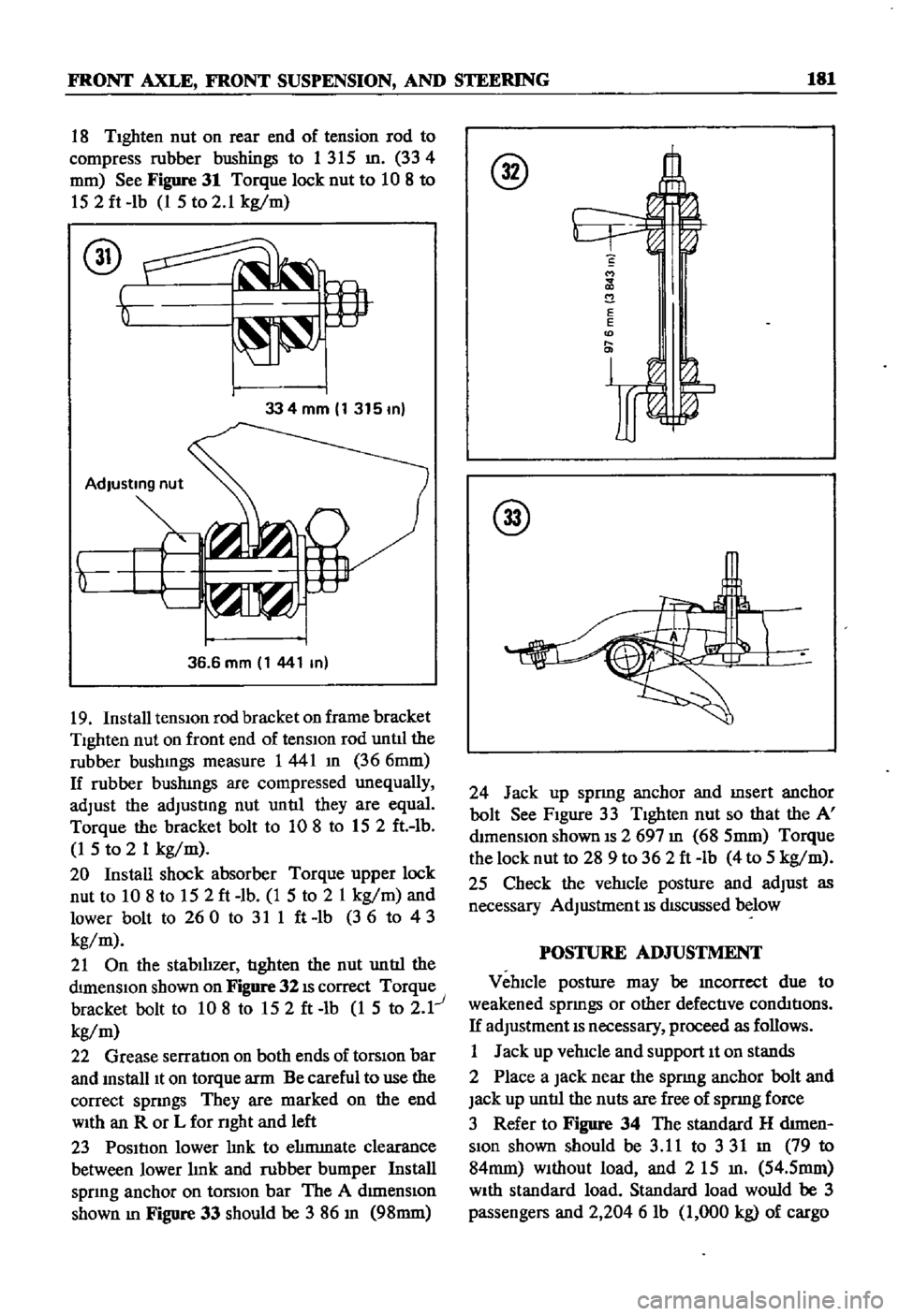

18

TIghten

nut

on

rear

end

of

tension

rod

to

compress

rubber

bushings

to

1

315

m

334

fi2

mm

See

Figure

31

Torque

lock

nut

to

10

8

to

152ft

lb

1

5

to

2

1

kg

m

334mm

1315m

36

6

mm

1

441

m

19

Install

tensiOn

rod

bracket

on

frame

bracket

Tighten

nut

on

front

end

of

tensIOn

rod

untll

the

rubber

bushmgs

measure

1441

m

366mm

If

rubber

bushmgs

are

compressed

unequally

adJust

the

adJusting

nut

until

they

are

equal

Torque

the

bracket

bolt

to

108

to

152

ft

lb

1

5

to

2

1

kg

m

20

Install

shock

absorber

Torque

upper

lock

nut

to

10

8

to

152ft

lb

1

5

to

2

1

kg

m

and

lower

bolt

to

260

to

311ft

lb

36

to

43

kg

m

21

On

the

stabilizer

tighten

the

nut

until

the

dimenSIOn

shown

on

Figure

32

IS

correct

Torque

bracket

bolt

to

10

8

to

152ft

lb

1

5

to

2

1

kg

m

22

Grease

serratIon

on

both

ends

of

torSiOn

bar

and

mstalllt

on

torque

arm

Be

careful

to

use

the

correct

spnngs

They

are

marked

on

the

end

WIth

an

R

or

L

for

nght

and

left

23

Position

lower

hnk

to

ehmmate

clearance

between

lower

hnk

and

rubber

bumper

Install

spnng

anchor

on

torsIOn

bar

The

A

dImenSiOn

shown

m

Figure

33

should

be

3

86

m

98mm

S

M

2

E

E

D

@

24

Jack

up

spnng

anchor

and

msert

anchor

bolt

See

Figure

33

Tighten

nut

so

that

the

A

mmenslon

shown

IS

2

697

m

68

5mm

Torque

the

lock

nut

to

28

9

to

362ft

lb

4

to

5

kg

m

25

Check

the

vehicle

posture

and

adJust

as

necessary

AdJustment

IS

dIScussed

below

POSTURE

AD

JUSTMENT

Vehicle

posture

may

be

mcorrcct

due

to

weakened

sprmgs

or

other

defective

conmtions

If

adJustment

IS

necessary

proceed

as

follows

1

Jack

up

vehicle

and

support

It

on

stands

2

Place

a

Jack

near

the

sprmg

anchor

bolt

and

Jack

up

until

the

nuts

are

free

of

spnng

force

3

Refer

to

Figure

34

The

standard

H

d1men

Slon

shown

should

be

3

11

to

331

m

79

to

84mm

Without

load

and

2

15

m

54

5mm

WIth

standard

load

Standard

load

would

be

3

passengers

and

2

204

6

lb

1

000

kg

of

cargo

Page 245 of 252

l

INDEX

239

Rear

suspensIOn

wagon

Removal

40

92

Servlcmg

161

Termmals

94

Tightening

torques

162

Test

diagnosIs

97

Testmg

96

Troubleshootmg

10

5

Steenng

also

see

Suspension

front

I

Exploded

views

182

185

L

Seats

SpecIfications

186

DescnptIon

228

Troubleshooting

16

Exploded

View

front

4

door

sedan

232

SuspensIOn

front

pick

up

Exploded

VIew

front

pick

up

228

Axle

removal

175

Service

hmts

4

Inspection

and

repair

179

Shock

absorbers

sedan

154

Installation

179

Shock

absorbers

wagon

162

Posture

adjustment

181

Spark

plugs

Removal

177

CondlllOn

chart

21

Wheel

abgnment

182

InspectIon

and

servlcmg

21

Wheel

bearmg

adjustment

177

Recommended

types

112

Suspension

front

sedan

and

wagon

SpecificatIOns

and

tables

Inspection

and

repair

176

Adjustment

and

wheel

alignment

175

InstallatIOn

177

Brake

service

data

203

204

Lower

ball

Jomt

174

Brakes

203

204

Spnng

and

strut

assembly

173

Camshaft

beanngs

48

Stabilizer

173

Caster

and

camber

sedan

and

wagon

175

TenSIOn

rod

173

Clutch

134

Transverse

bnk

174

Clutch

service

data

134

Wheel

beanngs

177

Connectmg

rod

beanng

underslzes

52

Wheel

hubs

and

bearmgs

168

173

Dlstnbutor

112

SWItches

Dnveshaft

147

DescnptIon

205

Dnveshaft

service

dala

147

Exploded

View

through

1969

208

Engme

60

61

Exploded

view

1970

1972

207

Engme

service

data

60

61

General

4

Mam

bearmg

underslzes

52

T

Piston

rmg

gap

50

Rear

suspenSIOn

pick

up

167

Tail

gate

228

233

Rear

suspensIOn

torques

wagon

162

TenSIOn

rod

sedan

and

wagon

173

Steermg

186

Thermostat

TransmiSSion

manual

144

DescnptIon

89

TransmiSSion

service

data

manual

144

Inspection

and

replacement

89

Valve

spnng

47

Removal

89

Sprmg

and

strut

assembly

sedan

and

wagon

173

Tires

Spnngs

sedan

154

Wear

analYSIS

17

Stabilizer

sedan

and

wagon

173

TransmiSSion

automatic

Starter

Downshift

solenOid

147

Armature

95

Inhlbllor

SWItch

148

Beanngs

96

Kick

down

SWitch

147

Brush

holder

96

Lmkage

mspectIon

and

adjustment

148

Brushes

and

lead

WIre

95

011

checks

147

Cleaning

mspectIon

and

repair

94

Oil

leakage

147

Construcllon

92

TransmiSSion

manual

Disassembly

92

DescnptIon

134

Exploded

View

93

Disassembly

138

Field

COIl

94

Exploded

view

138

Magnetic

SWItch

96

Gear

assembly

exploded

view

139

Magnetic

SWItch

assembly

test

97

Inspection

and

repair

141

Operation

91

Installation

143

Overrunnmg

clutch

96

Reassembly

and

adjustment

142

Reassembly

96

Removal

134