brakes DATSUN 510 1968 Service Repair Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1968, Model line: 510, Model: DATSUN 510 1968Pages: 252, PDF Size: 12.2 MB

Page 3 of 252

CON1EN1S

CHAPTER

ONE

GENERAL

INFORMATION

Introduction

Model

Identification

CHAPTER

TWO

PERIODIC

MAINTENANCE

RoutIne

checks

Pen

odic

checks

CHAPTER

THREE

TROUBLESHOOTING

EqUIpment

Starter

ChargIng

system

EngIne

Igmtlon

system

Fuel

system

Exhaust

emIssIon

control

CHAPTER

FOUR

ENGINE

AND

IGNITION

TUNE

UP

EqUIpment

Battery

Spark

plugs

DIstrIbutor

Igmtlon

timIng

CHAPTER

FIVE

ENGINE

LUBRICATION

SYSTEM

Descnptlon

Lubncation

cIrcuIt

SpecIficatiOns

and

dImensIons

EngIne

lubncation

and

maIntenance

Recommended

lubncants

Clutch

TransmIssiOn

Brakes

Steenng

and

suspension

TIre

wear

analysIs

Wheel

balancIng

Idle

speed

and

Idle

mIXture

Dwell

angle

setting

CompressIon

test

Valve

clearance

adjustment

AddlllOnal

checks

Oil

pump

I

6

t

1

4

V

9

t

1

20

27

Page 5 of 252

CHAPTER

TWELVE

DIFFERENTIAL

REAR

AXLE

AND

REAR

SUSPENSION

149

DIfferentIal

Rear

axle

and

suspension

Codspnng

Shock

absorber

Rear

suspensIOn

arm

Rear

axle

shaft

Wheel

beanngs

Seals

Rear

spnng

Axle

case

SpecificatIons

CHAPTER

THIRTEEN

FRONT

AXLE

FRONT

SUSPENSION

AND

STEERING

168

Wheel

hub

and

bearmg

StabilIzer

TenSion

rod

Spnng

and

strut

assembly

Transverse

lInk

Lower

ball

Jomt

Front

suspension

adjustment

Wheel

alignment

Posture

adJustment

Steenng

system

SpeCificatIons

CHAPTER

FOURTEEN

BRAKES

187

Brake

pedal

Master

cylInder

Front

diSC

brakes

Rear

brakes

Front

drum

brakes

Wheel

cylInders

Brake

system

bleedIng

Handbrake

Service

data

and

speCificatIons

CHAPTER

FIFTEEN

BODY

ELECTRICAL

SYSTEM

Wmng

SWitches

and

fuses

Instrument

meters

and

panels

Heater

205

Wmdshleld

wipers

Wmdslueld

washers

Headlamps

WIrIng

diagrams

CHAPTER

SIXTEEN

BODY

223

Front

body

trIm

Bumpers

Hood

lock

control

Doors

Door

locks

and

regulators

Trunk

lId

and

rear

bumper

Seats

Tad

gate

INDEX

235

I

Page 21 of 252

16

CHAPTER

TIlREE

sary

Also

check

all

parts

for

mlSaltgnment

and

uneven

wear

TRANSMISSION

1

Difficult

to

mesh

gears

Make

certam

the

clutch

pressure

plate

and

re

lease

beanng

are

m

good

condItion

The

trouble

can

be

caused

by

worn

gears

shaft

and

or

bear

mgs

DISassemble

and

repaIr

as

requIred

Also

can

be

caused

by

msufficlent

operatmg

stroke

due

to

worn

or

loose

sltdmg

parts

or

a

defective

synchronIZer

DIsassemble

carefully

InSpect

and

replace

as

requIred

2

Gears

slip

out

of

mesh

Generally

thIS

trouble

occurs

when

the

mterlock

plunger

check

ball

and

or

spnng

IS

weakened

or

worn

The

trouble

can

also

be

caused

by

worn

fork

rod

ball

groove

damaged

bearings

or

dam

aged

gears

DIsassemble

carefully

mspect

and

replace

as

required

3

NOIse

If

nOISes

are

heard

wIth

the

engme

idlmg

and

the

clutch

disengaged

the

nOIse

IS

probably

conung

from

the

transmISSIOn

Several

Items

can

cause

nOISes

either

smgly

or

m

combmatIon

Check

the

qualIty

and

quantity

of

lubrIcant

in

the

trans

mISSIon

Replace

or

replenISh

as

necessary

Worn

bearIngs

wIll

usually

produce

a

lugh

humming

at

hIgh

speed

and

a

cycltc

knockIng

sound

at

low

speed

Worn

or

damaged

splInes

and

bushmgs

will

also

cause

nOIse

BRAKES

1

Brake

pedal

goes

to

floor

There

are

numerous

causes

for

thIS

includIng

excessIvely

worn

Itnmgs

aIr

in

the

hydraultc

sys

tem

leaky

brake

lmes

leaky

wheel

cylmders

or

leaky

or

worn

master

cylmder

Check

for

leaks

and

thIn

brake

linmgs

Bleed

and

adjust

the

brakes

If

thIS

doesn

t

cure

the

trouble

rebwld

wheel

cylmders

a

nd

or

master

cylmder

2

Spongy

pedal

Normally

caused

by

aIr

m

the

system

blee

d

and

adjust

the

brakes

3

Brakes

pull

Check

brake

adjustment

Also

check

for

contam

inated

brake

Itmngs

from

leaks

leaky

wheel

cyltnders

loose

caltpers

frozen

or

seIZed

pIstons

and

restrIcted

brake

lmes

or

hoses

In

addItion

check

front

end

alignment

and

suspensIOn

dam

age

such

as

broken

front

or

rear

sprmgs

shocks

etc

Check

condItIon

of

tIres

4

Brakes

squeal

or

chatter

Check

brake

lmmg

thickness

and

brake

drum

roundness

Ensure

that

the

shoes

have

cham

ferred

ends

and

are

not

loose

Inspect

the

condI

tion

of

the

rotors

on

the

front

wheel

dISC

brakes

to

make

certain

they

are

not

scored

or

damaged

Clean

away

all

dIrt

on

shoes

pads

rotors

or

drums

5

Draggmg

brakes

Check

brake

adjustment

includmg

handbrake

Check

for

broken

or

weak

shoe

return

springs

swollen

rubber

parts

due

to

unproper

brake

flUId

or

other

contammatIon

Clean

or

replace

de

fectIve

parts

6

Hard

pedal

Check

brake

linmgs

for

contammation

Also

check

for

restrIcted

brake

lines

and

hoses

7

High

speed

fade

Check

for

dIstorted

or

out

of

round

drums

and

contamInated

brake

lmmgs

Make

certam

the

recommended

brake

flUId

IS

used

Dram

entIre

system

and

refill

If

In

doubt

8

Pulsatmg

pedal

Check

for

dIStorted

or

out

of

round

drums

or

rotors

Check

for

excessIVe

brake

dISC

run

out

STEERING

AND

SUSPENSION

NOTE

Unusual

steermg

pullmg

or

wandermg

IS

usually

caused

by

bent

or

otherwise

mIsaligned

suspenszon

parts

Because

of

the

speCialized

equIp

ment

reqUired

to

evaluate

and

correct

these

faults

It

IS

recommended

t

tat

servIce

to

the

steermg

and

suspension

system

be

referred

to

your

Datsun

dealer

oca

quallfied

specrallst

m

thiS

field

1

VibratIOn

felt

m

steermg

wheel

VIbratIon

can

be

caused

by

several

thmgs

includ

ing

lll1proper

aIr

pressure

m

tIres

uneven

wear

Page 152 of 252

CLUTCH

TRANSMISSION

AND

DRIVESHAFI

147

SERVICE

DATA

AND

SPECIFICATIONS

Table

3

gives

the

service

data

and

specIfica

tIons

for

the

dnveshaft

AUTOMATIC

TRANSMISSION

CHECKS

AND

ADJUSTMENTS

Whlle

removal

and

repair

of

the

automatic

transmisSIOn

IS

not

recommended

the

follo

VlIlg

checks

and

adjustments

should

help

prevent

costly

repatrs

Transmission

Oil

Check

Check

the

automatIc

transmission

oil

level

at

least

every

3

000

mlles

Replemsh

With

hIgh

qualIty

automatIc

transmISSIon

flUId

as

reqUIred

Be

careful

not

to

overfill

as

damage

to

the

seals

can

result

To

check

the

011

level

proceed

as

follows

1

Start

the

engme

and

nm

it

untIl

normal

oper

atrng

temperature

IS

reached

2

Apply

brakes

and

move

the

transmission

shut

lever

through

all

drive

pOSItions

and

place

lever

In

park

position

3

WIth

engme

running

remove

tranSmISSIon

dIp

StIck

clean

It

WIth

a

lInt

free

cloth

or

paper

and

return

it

to

the

transmission

4

Remove

dIp

stIck

agam

and

examine

level

on

dIp

stIck

gauge

It

should

be

between

the

low

and

full

marks

Replenish

as

necessary

5

VIsually

InSpect

the

color

and

condItIon

of

the

OIl

on

the

dIp

stIck

Normal

color

of

the

OIl

IS

red

If

the

color

IS

abnormal

dram

and

re

place

If

the

011

has

detenorated

to

a

vamlsh

lIke

qualIty

It

may

cause

the

control

valve

to

stIck

Blackened

oil

may

mdlcate

a

burned

clutch

or

brake

band

6

Should

the

above

condItIons

exist

refer

mamtenance

to

a

transmISSIon

specIalIst

Transmission

Oil

Leakage

Check

011

leakage

may

occur

at

the

Junction

of

the

transmissIon

and

rear

extensIon

011

tube

con

nectors

011

pan

OIl

pressure

mspectIon

holes

downshIft

solenoid

or

breather

pipe

Abnormal

OIl

usage

usually

mdlcates

leaks

that

should

be

stopped

before

severe

damage

IS

done

To

mspect

for

011

leaks

proceed

as

follows

1

LIft

car

up

on

hOISt

or

Jack

up

and

place

on

stands

2

Clean

outsIde

of

transmISSIon

case

With

cleanIng

solvent

to

remove

dIrt

and

011

accumu

latIons

3

Start

engme

and

nm

untIl

operating

temper

ature

is

reached

4

ShIft

gear

lever

to

dnve

to

Increase

011

pres

sure

and

CIrculatIon

WIthin

tranSmISsion

5

Inspect

pOInts

mentIoned

above

for

SIgnS

of

leakage

Leakage

of

transrmSSIOn

011

IS

dIStrnC

tIve

by

its

reddISh

color

6

If

leaks

are

detected

refer

servIce

and

reparr

to

qualIfied

transrmssion

specialISt

Kick

down

Switch

and

Downshift

Solenoid

Checks

and

Adjustment

When

ktck

down

operatIon

IS

not

correct

or

the

speed

changmg

pomt

IS

too

high

check

the

klck

down

SWItch

downshIft

solenOId

and

the

wlDng

between

them

Figure

45

shows

the

loca

tIOn

of

these

parts

To

check

operatIon

proceed

as

follows

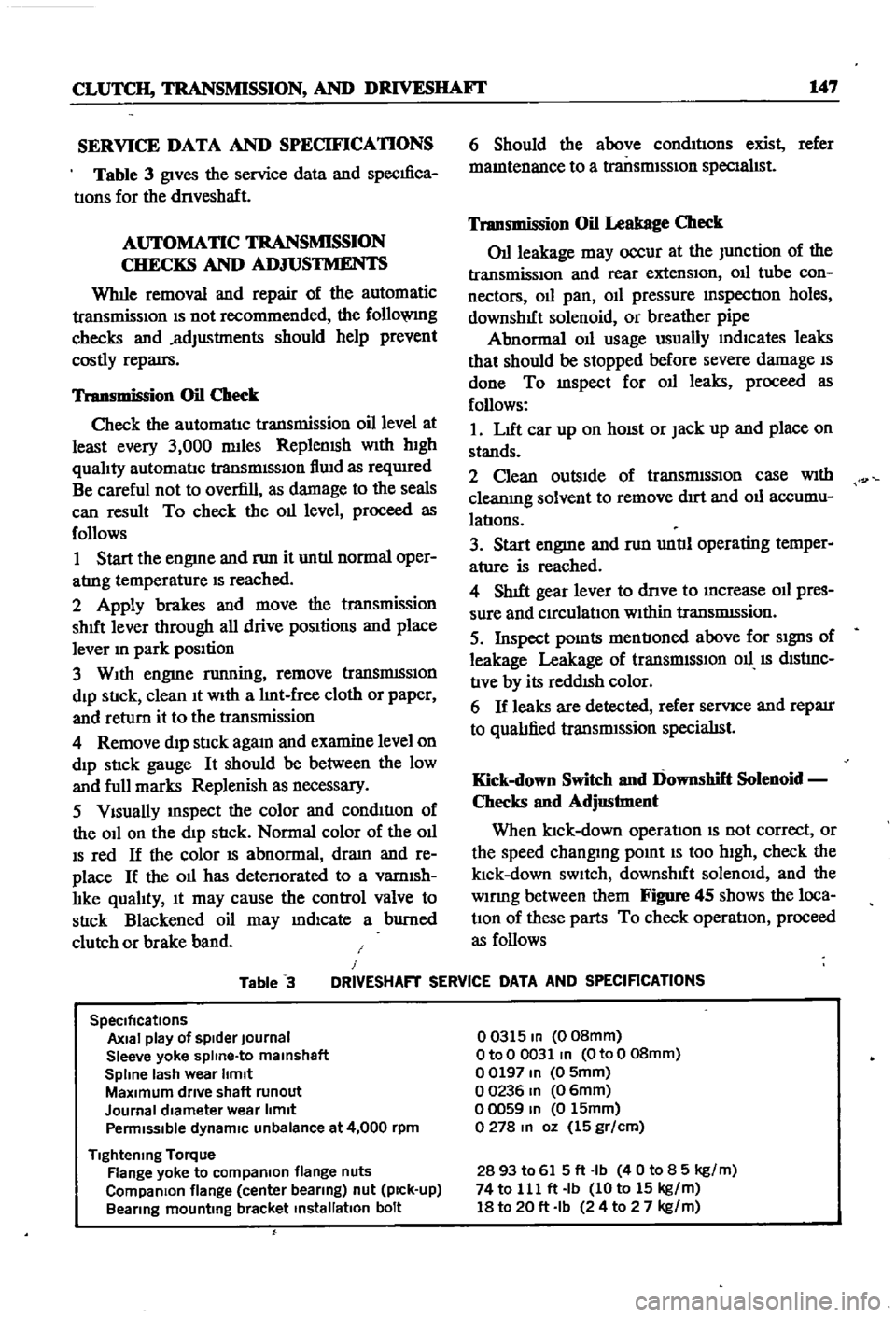

Table

3

J

DRIVESHAFT

SERVICE

DATA

AND

SPECIFICATIONS

SpeCifications

Axial

play

of

spider

Journal

Sleeve

yoke

spltne

to

malnshaft

Spline

lash

wear

Itmlt

MaXimum

drive

shaft

runout

Journal

diameter

wear

limit

Penmlsslble

dynamiC

unbalance

at

4

000

rpm

Tightening

Torque

Flange

yoke

to

compaRlon

flange

nuts

CompaRlon

flange

center

bearing

nut

pick

up

Bearing

mounting

bracket

installation

bolt

00315

In

008mm

OtoO

0031

In

OtoO

08mm

00197

In

0

5mm

00236

In

06mm

00059

In

0

15mm

0278

In

oz

15

gr

cm

2893

to

615ft

Ib

40

to

8

5

kg

m

74

to

111

ft

Ib

10

to

15

kg

m

18

to

20

ft

Ib

24

to

2

7

kg

m

Page 192 of 252

CHAPTER

FOURTEEN

BRAKES

The

sedan

and

station

wagon

are

equipped

With

disc

brakes

on

the

front

wheels

drum

brakes

on

the

rear

wheeis

and

a

tandem

master

cyhnder

The

pIck

up

has

drum

brakes

on

all

four

wheels

and

a

single

master

cylmder

All

vehicles

have

a

mechanIcal

handbrake

that

works

on

the

rear

wheels

only

BRAKE

PEDAL

Figures

1

and

2

show

the

mounting

location

and

the

components

of

the

brake

pedal

for

sedans

and

wagons

The

pick

up

is

smlliar

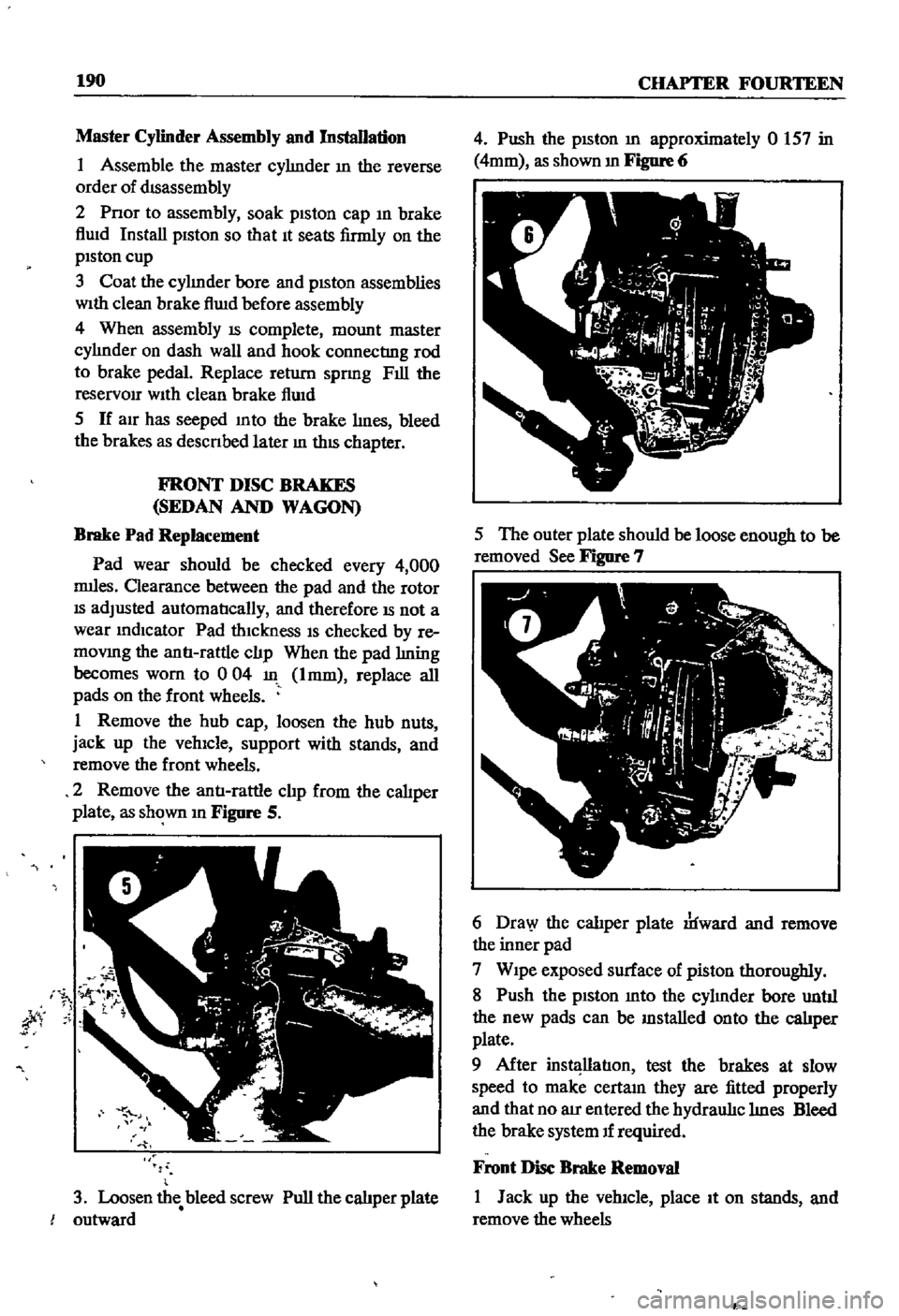

Brake

Pedal

Removal

1

Remove

pedal

return

spring

2

Remove

cleViS

pm

on

the

push

rod

CD

3

Disconnect

brake

pedal

from

the

master

cyhnder

4

Remove

the

fulcrum

pm

Remove

the

brake

pedal

Brake

Pedal

Inspection

nnd

Repair

Check

all

parts

for

wear

damage

and

defor

matIon

Replace

defective

parts

as

reqwred

Page 195 of 252

190

CHAPTER

FOURTEEN

Master

Cylinder

Assembly

and

Installation

I

Assemble

the

master

cyhnder

m

the

reverse

order

of

dIsassembly

2

Pnor

to

assembly

soak

piston

cap

m

brake

flwd

Install

piston

so

that

It

seats

firmly

on

the

piston

cup

3

Coat

the

cyhnder

bore

and

pISton

assemblies

With

clean

brake

flwd

before

assembly

4

When

assembly

IS

complete

mount

master

cylmder

on

dash

wall

and

hook

connecting

rod

to

brake

pedal

Replace

return

sprmg

Fill

the

reservOir

With

clean

brake

flUid

5

If

aIr

has

seeped

mto

the

brake

Imes

bleed

the

brakes

as

descnbed

later

m

thIS

chapter

FRONT

DISC

BRAKES

SEDAN

AND

WAGON

Brake

Pad

Replacement

Pad

wear

should

be

checked

every

4

000

nuIes

Clearance

between

the

pad

and

the

rotor

IS

adjusted

automatIcally

and

therefore

IS

not

a

wear

mdlcator

Pad

thiCknesS

IS

checked

by

re

movmg

the

antI

rattle

clJp

When

the

pad

hning

becomes

worn

to

0

04

Imm

replace

all

pads

on

the

front

wheels

I

Remove

the

hub

cap

loosen

the

hub

nuts

jack

up

the

vehicle

support

with

stands

and

remove

the

front

wheels

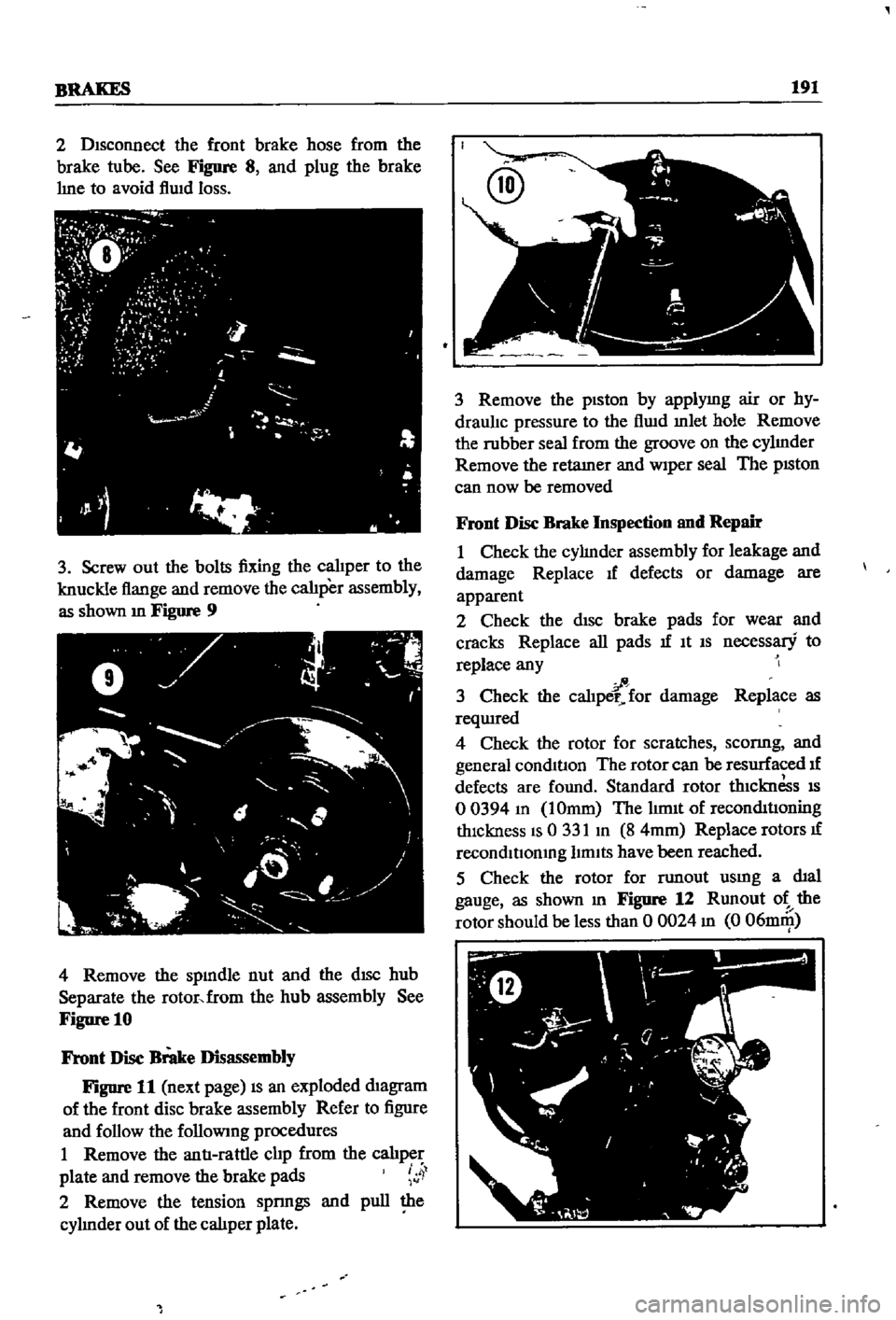

2

Remove

the

antI

rattle

clJp

from

the

caliper

plate

as

shown

m

Figure

S

jty

3

Loosen

the

bleed

screw

Pull

the

calJper

plate

outward

4

Push

the

pISton

m

approximately

0

157

in

4mm

as

shown

m

Figure

6

5

The

outer

plate

should

be

loose

enough

to

be

removed

See

Figure

7

6

Dra

y

the

calJper

plate

rlfward

and

remove

the

inner

pad

7

Wipe

exposed

surface

of

piston

thoroughly

8

Push

the

piston

mto

the

cyhnder

bore

untJI

the

new

pads

can

be

mstalled

onto

the

calJper

plate

9

After

instl

llatIon

test

the

brakes

at

slow

speed

to

make

certam

they

are

fitted

properly

and

that

no

au

entered

the

hydraul1c

hnes

Bleed

the

brake

system

If

required

Front

Disc

Brake

Removal

I

Jack

up

the

vehicle

place

It

on

stands

and

remove

the

wheels

P

Page 196 of 252

BRAKES

191

2

Disconnect

the

front

brake

hose

from

the

brake

tube

See

Figure

8

and

plug

the

brake

hne

to

avoid

flwd

loss

3

Screw

out

the

bolts

fixing

the

calJper

to

the

knuckle

flange

and

remove

the

calJper

assembly

as

shown

m

Figure

9

4

Remove

the

spmdle

nut

and

the

dISC

hub

Separate

the

rotor

from

the

hub

assembly

See

Figure

10

Front

Disc

Brake

Disassembly

Figure

11

next

page

IS

an

exploded

diagram

of

the

front

disc

brake

assembly

Refer

to

figure

and

follow

the

followmg

procedures

I

Remove

the

antI

rattle

clip

from

the

calJper

plate

and

remove

the

brake

pads

4

2

Remove

the

tension

spnngs

and

pull

the

cyhnder

out

of

the

caliper

plate

3

Remove

the

piston

by

applymg

air

or

hy

draulJc

pressure

to

the

flwd

mlet

hole

Remove

the

rubber

seal

from

the

groove

on

the

cyhnder

Remove

the

retamer

and

Wiper

seal

The

pISton

can

now

be

removed

Front

Disc

Brake

Inspection

and

Repair

I

Check

the

cyhnder

assembly

for

leakage

and

damage

Replace

If

defects

or

damage

are

apparent

2

Check

the

disc

brake

pads

for

wear

and

cracks

Replace

all

pads

If

It

IS

necessary

to

replace

any

fi

3

Check

the

caliper

for

damage

Replace

as

reqUIred

4

Check

the

rotor

for

scratches

sconng

and

general

conditIon

The

rotor

can

be

resurfaced

If

defects

are

found

Standard

rotor

thiCknesS

IS

o

0394

m

IOmm

The

hm1t

of

reconditIOning

thickness

IS

0

331

m

8

4mm

Replace

rotors

If

recondltIomng

limits

have

been

reached

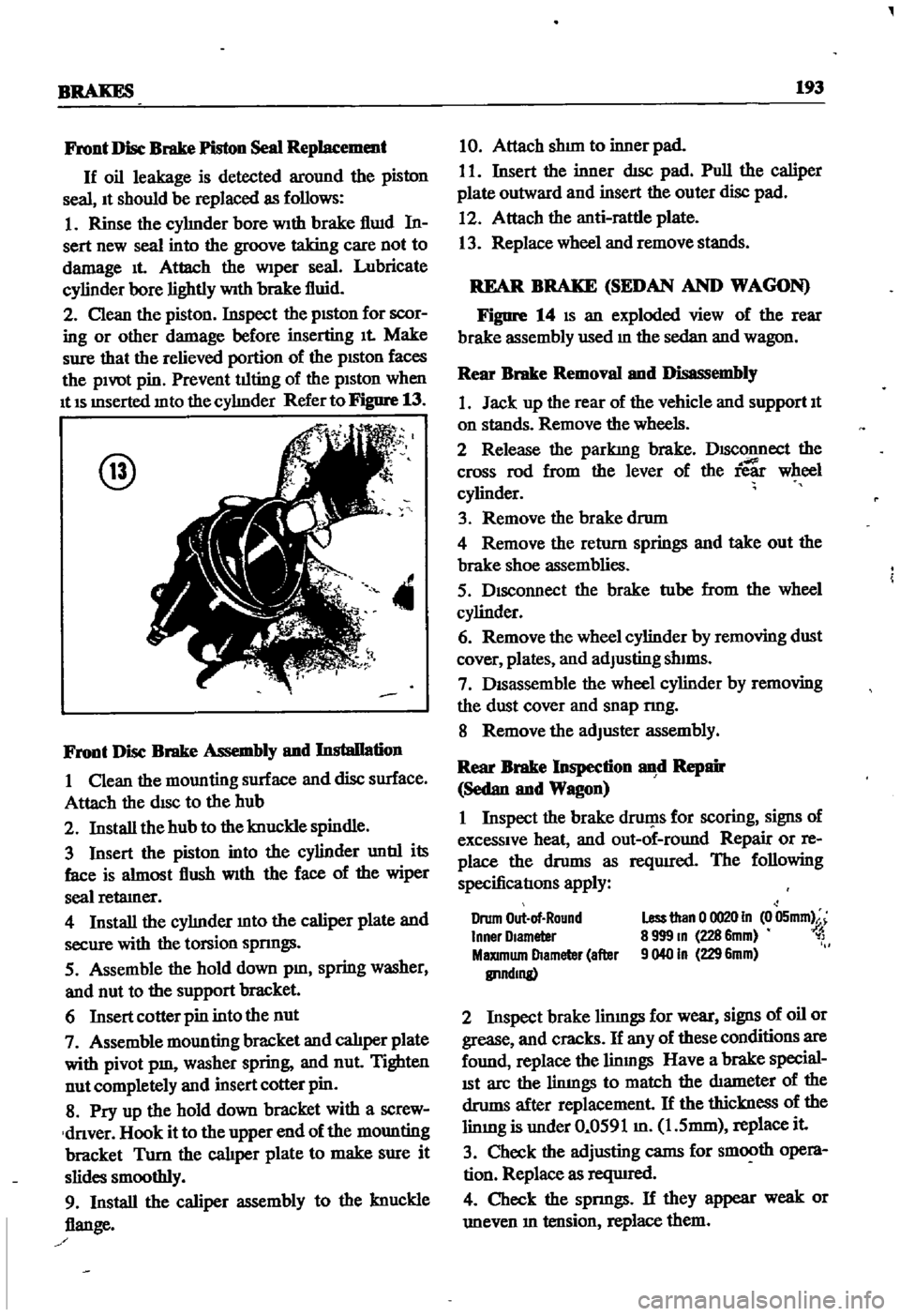

5

Check

the

rotor

for

TWlout

usmg

a

dial

gauge

as

shown

m

Figure

12

Rnnout

ot

the

rotor

should

be

less

than

0

0024

m

0

06DlIll

Page 198 of 252

BRAKES

193

Front

Disc

Brake

Piston

Seal

Replacement

If

oil

leakage

is

detected

around

the

piston

seal

It

should

be

replaced

as

follows

I

Rinse

the

cyhnder

bore

With

brake

flwd

In

sert

new

seal

into

the

groove

taking

care

not

to

damage

It

Attach

the

wiper

seal

Lubricate

cylinder

bore

lightly

With

brake

fluid

2

Clean

the

piston

Inspect

the

pISton

for

scor

ing

or

other

damage

before

inserting

It

Make

sure

that

the

relieved

portion

of

the

pISton

faces

the

pivot

pin

Prevent

tilting

of

the

piston

when

It

IS

mserted

mto

the

cyhnder

Refer

to

Figure

13

@

4

Front

Disc

Brake

Assembly

and

Installation

I

Clean

the

mounting

surface

and

disc

surface

Attach

the

disc

to

the

hub

2

Install

the

hub

to

the

knuckle

spindle

3

Insert

the

piston

into

the

cylinder

untIl

its

face

is

almost

flush

With

the

face

of

the

wiper

seal

retamer

4

Install

the

cyhnder

mto

the

caliper

plate

and

secure

with

the

torsion

spnngs

5

Assemble

the

hold

down

pm

spring

washer

and

nut

to

the

support

bracket

6

Insert

cotter

pin

into

the

nut

7

Assemble

mounting

bracket

and

calJper

plate

with

pivot

pm

washer

spring

and

nut

Tighten

nut

completely

and

insert

cotter

pin

8

Pry

up

the

hold

down

bracket

with

a

screw

dnver

Hook

it

to

the

upper

end

of

the

mounting

bracket

Turn

the

cal1per

plate

to

make

sure

it

slides

smoothly

9

Install

the

caliper

assembly

to

the

knuckle

flange

10

Attach

shun

to

inner

pad

I

I

Insert

the

inner

dIsc

pad

Pull

the

caliper

plate

outward

and

insert

the

outer

disc

pad

12

Attach

the

anti

rattle

plate

13

Replace

wheel

and

remove

stands

REAR

BRAKE

SEDAN

AND

WAGON

Figure

14

IS

an

exploded

view

of

the

rear

brake

assembly

used

m

the

sedan

and

wagon

Rear

Brake

Removal

and

Disassembly

1

Jack

up

the

rear

of

the

vehicle

and

support

It

on

stands

Remove

the

wheels

2

Release

the

parkIng

brake

DISConnect

the

cross

rod

from

the

lever

of

the

ie

wheel

cylinder

3

Remove

the

brake

drum

4

Remove

the

return

springs

and

take

out

the

brake

shoe

assemblies

5

Disconnect

the

brake

tube

from

the

wheel

cylinder

6

Remove

the

wheel

cylinder

by

removing

dust

cover

plates

and

adJusting

shIms

7

DISassemble

the

wheel

cylinder

by

removing

the

dust

cover

and

snap

nng

8

Remove

the

adJuster

assembly

Rear

Brake

Inspection

d

Repair

Sedan

and

Wagon

I

Inspect

the

brake

druf

1s

for

scoring

signs

of

excessive

heat

and

out

of

round

Repair

or

re

place

the

drums

as

reqUIred

The

following

specificatIons

apply

Drum

Out

of

Round

Inner

Olameter

MaXImum

Diameter

after

IlI1ndmg

Less

than

0

0020

In

0

05mm

8

999

m

228

6mm

1

9040

In

229

6mm

2

Inspect

brake

limngs

for

wear

signs

of

oil

or

grease

and

cracks

If

any

of

these

conditions

are

found

replace

the

linmgs

Have

a

brake

special

ISt

arc

the

limngs

to

match

the

diameter

of

the

drums

after

replacement

If

the

thickness

of

the

limng

is

under

0

0591

m

1

5mm

replace

it

3

Check

the

adjusting

cams

for

smooth

opera

tion

Replace

as

reqUIred

4

Check

the

spnngs

If

they

appear

weak

or

uneven

m

tension

replace

them

Page 199 of 252

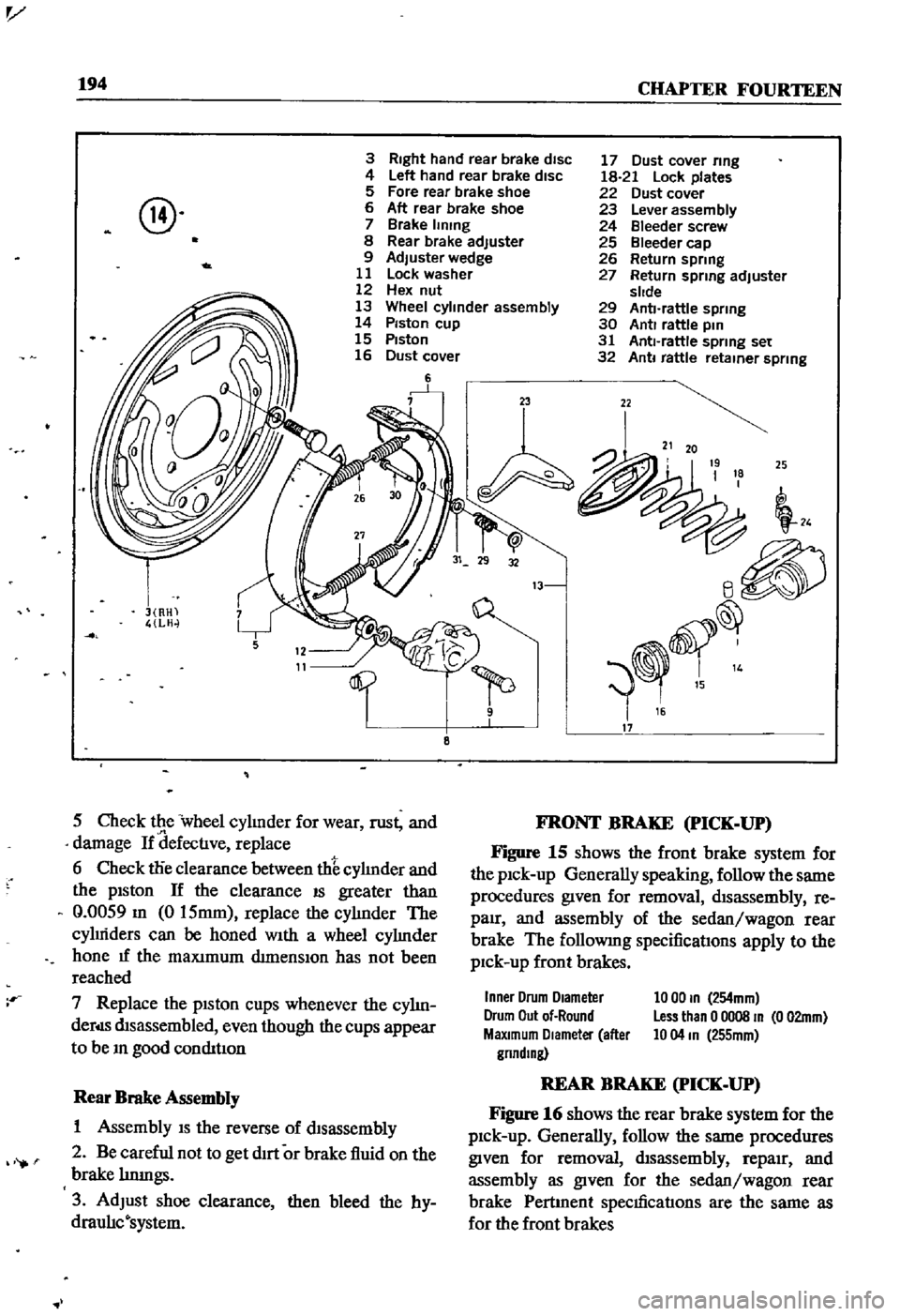

v

194

CHAPTER

FOURTEEN

3

Right

hand

rear

brake

disc

4

Left

hand

rear

brake

disc

5

Fore

rear

brake

shoe

6

Aft

rear

brake

shoe

7

Brake

IImng

8

Rear

brake

adjuster

9

Adjuster

wedge

11

Lock

washer

12

Hex

nut

13

Wheel

cylinder

assembly

14

Piston

cup

15

Piston

16

Dust

cover

6

@

5

Check

the

wheel

cylinder

for

wear

rust

and

damage

If

defectIve

replace

6

Check

die

clearance

between

th

cyhnder

and

the

piston

If

the

clearance

18

greater

than

Q

0059

m

0

15mm

replace

the

cylinder

The

cyluiders

can

be

honed

With

a

wheel

cyhnder

hone

If

the

maXImum

dimensIOn

has

not

been

reached

7

Replace

the

piston

cups

whenever

the

cyhn

derds

disassembled

even

though

the

cups

appear

to

be

m

good

condition

Rear

Brake

Assembly

1

Assembly

IS

the

reverse

of

disassembly

2

Be

careful

not

to

get

dirt

or

brake

fluid

on

the

brake

hnnlgs

3

AdJust

shoe

clearance

then

bleed

the

hy

draulIc

system

17

Dust

cover

ring

18

21

Lock

plates

22

Dust

cover

23

Lever

assembly

24

Bleeder

screw

25

Bleeder

cap

26

Return

spring

27

Return

spring

adjuster

slide

29

Anti

rattle

spring

30

Anti

rattle

pin

31

Anti

rattle

spring

set

32

Anti

rattle

retainer

spring

23

22

24

e

17

a

25

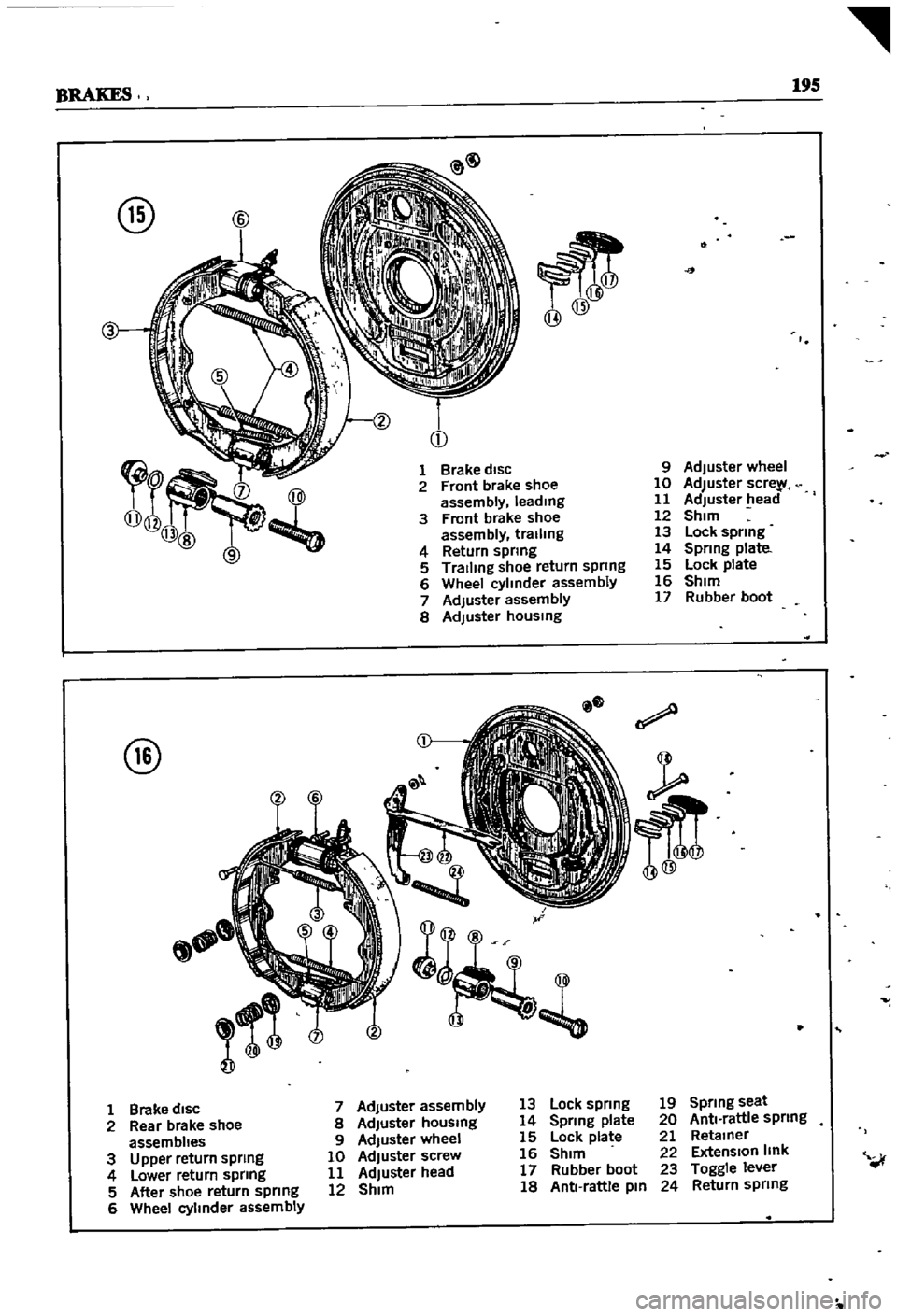

FRONT

BRAKE

pICK

UP

Figure

15

shows

the

front

brake

system

for

the

pick

up

Generally

speaking

follow

the

same

procedures

given

for

removal

disassembly

re

pair

and

assembly

of

the

sedan

wagon

rear

brake

The

followmg

specifications

apply

to

the

pick

up

front

brakes

Inner

Drum

Diameter

Drum

Out

of

Round

MaXimum

DIameter

after

gnndlng

10

00

In

254mm

Less

than

0

0008

In

0

02mm

10

04

In

255mm

REAR

BRAKE

pICK

UP

Figure

16

shows

the

rear

brake

system

for

the

pick

up

Generally

follow

the

same

procedures

given

for

removal

disassembly

repaIr

and

assembly

as

given

for

the

sedan

wagon

rear

brake

Pertment

specificatIons

are

the

same

as

for

the

front

brakes

Page 200 of 252

BRAKES

195

@

@

r

@

I

1

Brake

disc

9

Adjuster

wheel

2

Front

brake

shoe

10

Adjuster

scre

assembly

leadmg

11

Adjuster

lead

3

Front

brake

shoe

12

Shim

assembly

trallmg

13

Lock

spring

4

Return

spring

14

Spring

plate

5

Trailing

shoe

return

spring

15

Lock

plate

6

Wheel

cylinder

assembly

16

Shim

7

Adjuster

assembly

17

Rubber

boot

8

Adjuster

housmg

@

j

@@

1

Brake

disc

7

Adjuster

assembly

13

Lock

spring

19

Spring

seat

2

Rear

brake

shoe

8

Adjuster

housmg

14

Sprmg

plate

20

Ant

rattle

spring

assemblies

9

Adjuster

wheel

15

Lock

plate

21

Retamer

3

Upper

return

spring

10

Adjuster

screw

16

Shim

22

Extension

link

i

l

4

Lower

return

spring

11

Adjuster

head

17

Rubber

boot

23

Toggle

lever

5

After

shoe

return

sprmg

12

Shim

18

Anti

rattle

pm

24

Return

spring

6

Wheel

cylinder

assembly