length DATSUN 510 1968 Service Repair Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1968, Model line: 510, Model: DATSUN 510 1968Pages: 252, PDF Size: 12.2 MB

Page 9 of 252

4

CHAPTER

ONE

chassIs

number

Write

the

numbers

down

and

carry

them

ill

your

wallet

Service

Hints

Throughout

thIs

manual

keep

two

conven

bons

ill

mmd

Front

refers

to

the

front

of

the

vehicle

The

left

and

nght

sides

of

the

ve

hicle

refer

to

a

person

sittIng

ill

the

car

facing

forward

For

example

the

steenng

wheelIS

on

the

left

hand

Side

All

dimensIOns

and

capacities

are

expressed

ill

units

fanuhar

to

a

Umted

States

mechaniC

such

as

illches

and

pounds

Metric

measurements

are

also

given

Metnc

tools

are

reqUITed

to

work

on

the

Datsun

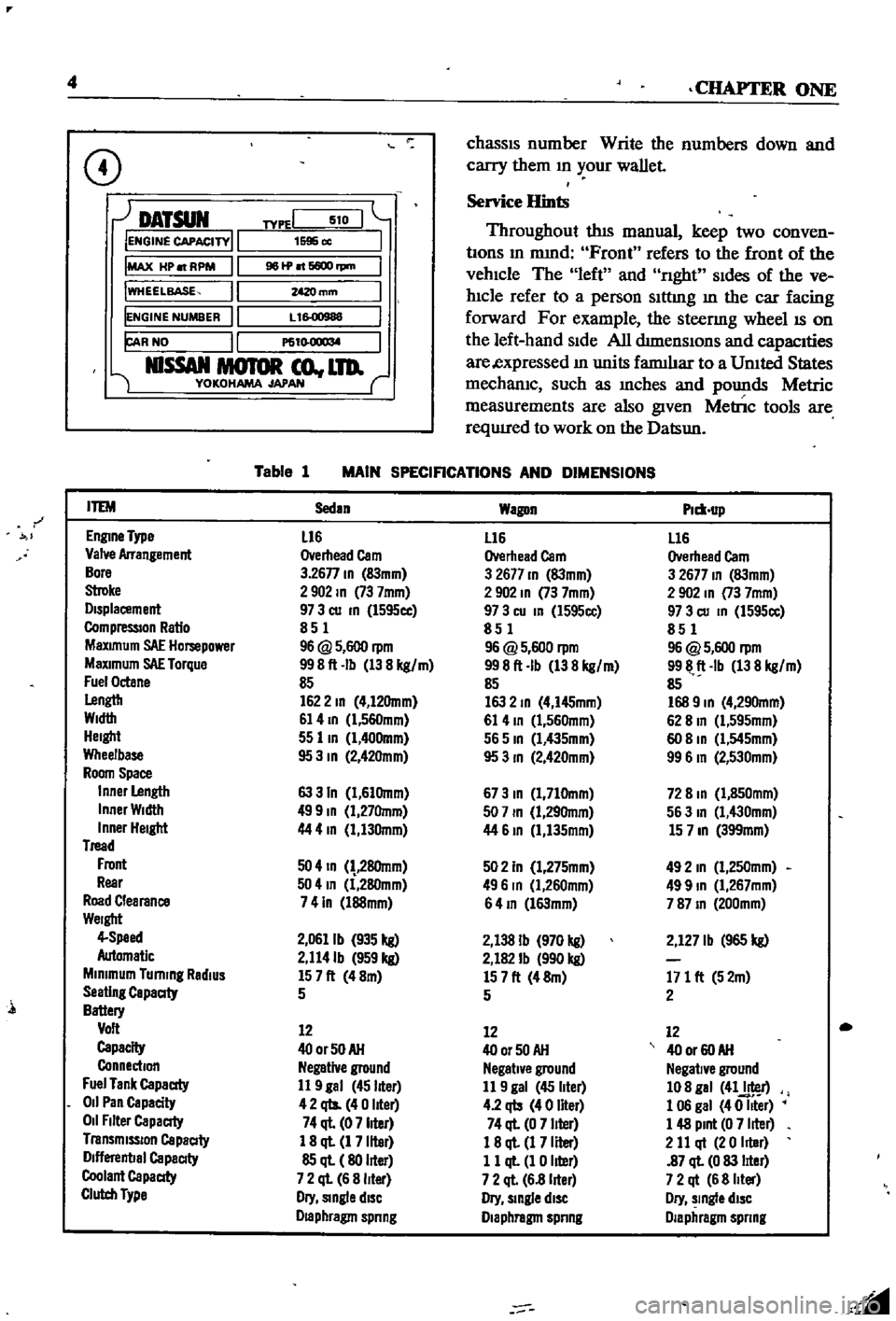

CD

DATSUN

IENGINE

CAPACITY

IMAX

HP

RPM

IWHEELBASE

IENGINE

NUMBER

FAR

NO

NlSSAN

MOTOR

co

LTD

YOKOHAMA

JAPAN

TYPEI

510

1595

cc

961P

6600

rpm

mm

L

1

00988

P61

l

O

1

l

M

Table

1

MAIN

SPECIFICATIONS

AND

DIMENSIONS

r

ITEM

Sedan

Wagon

Plm

up

EnglDe

Type

L16

L16

L16

Valve

Arrangement

Overhead

Cam

Overhead

Cam

Overhead

Cam

Bore

3

26n

ID

83mm

3

2677

ID

83mm

3

2677

ID

83mm

Stroke

2902

ID

73

7mm

2

902

ID

73

7mm

2

902

In

73

7mm

Displacement

97

3

cu

ID

l595cc

97

3

cu

In

l595cc

97

3

cu

ID

1595cc

CompressIOn

Ratio

851

851

851

MaXimum

SAE

Hompower

96

@

5

600

rpm

96

@

5

600

rpm

96

@

5

600

rpm

MaXimum

SAE

Torque

998ft

Ib

138

kg

m

998ft

Ib

138

kg

m

9911

ft

Ib

138

kg

m

Fuel

Octane

85

85

85

Lengtb

1622

ID

4

12Omm

163

2

ID

4

I45mm

168

9

ID

4

290mm

Width

61

4

ID

l

560mm

61

4

ID

1

560mm

62

8

In

Cl

595mm

Height

55

lID

1

400mm

565

ID

Cl

435mm

60

8

ID

Cl

545mm

Wheelbase

95

3

ID

2

42Omm

95

3

ID

2

420mm

99

6

In

2

530mm

Room

Space

Inner

Length

63

3

In

1

61Omm

673

ID

1

710mm

72

8

ID

1

850mm

Inner

Width

499

ID

1

27Omm

507

ID

1

29Omm

563

In

1

430mm

Inner

Height

44

4

In

1

130mm

44

61D

1

135mm

15

7

ID

399mm

Tread

Front

50

4

ID

28Omm

502

In

1

275mm

492

In

1

250mm

Rear

504

In

1

280mm

496

In

Cl

260mm

499

ID

1

267mm

Road

Clearance

741n

l88mm

64

ID

l63mm

787

ID

200mm

Weight

4

Speed

2

0611b

935

kg

2

138

Ib

970

kg

2

127

Ib

965

kg

Automatic

2

114Ib

959

kg

2

182

Ib

990

kg

Minimum

Turning

RadiUS

157ft

48m

157ft

48m

171

ft

52m

Seating

Capaaty

5

5

2

Battery

Volt

12

12

12

Capacity

400rSOAH

400r50AH

40

or

60

AH

Connection

Negative

ground

Negative

ground

Negative

ground

Fuel

Tank

Capaaty

11

9

gal

45

liter

11

9

gal

45

liter

108

gal

41J

r

011

Pan

Capacity

42

qts

40

liter

4

2

qb

40

liter

1

06

gal

40

Iller

011

Filter

Capaaty

74

ql

07

liter

74

ql

0

7

liter

1

48

Pint

0

7

liter

Transmission

Capaaty

1

8

ql

1

7

liter

18

ql

1

7

Iller

2

11

qt

20

Iller

Dlflerenbal

Capaaty

85

ql

80

liter

11

ql

1

0

liter

87

ql

0

83

lIter

Coolant

Capaaty

7

2

ql

6

8

liter

7

2

ql

6

8

lIter

7

2

qt

6

8

Iller

Clutch

Type

Dry

Single

diSC

Dry

slDgle

diSC

Dry

slDgle

diSC

Draphragm

spnng

Diaphragm

spnng

Diaphragm

spnng

l

Page 33 of 252

28

CHAPTER

FIVE

011

gallery

supphes

011

to

the

crankshaft

mam

beanngs

Dnlled

passages

m

the

crankshaft

direct

oil

from

the

mam

bearings

to

the

con

nectmg

rod

beanngs

011

mJected

from

jet

holes

in

the

connectIng

rods

IS

directed

to

the

cylmder

walls

and

piston

pins

0U

dlstnbuted

from

the

mam

gallery

enters

the

cham

tensioner

The

pad

IS

held

against

the

cham

by

011

pressure

and

spnng

tension

The

tmung

chain

receives

011

through

the

Jet

located

near

It

LubncatIon

IS

supphed

to

the

cyhnder

head

mam

011

gallery

through

the

crankshaft

center

beanngs

Camshaft

beanngs

on

the

cyhnder

head

are

fed

directly

from

the

cyhnder

head

mam

gallery

The

rocker

arms

and

valves

are

lubncated

intermittently

by

the

camshaft

011

gallery

and

the

small

channel

at

the

base

CIrcle

portIon

of

each

cam

OllIS

supphed

to

the

cam

shaft

011

gallery

through

the

No

2

and

No

3

camshaft

bearings

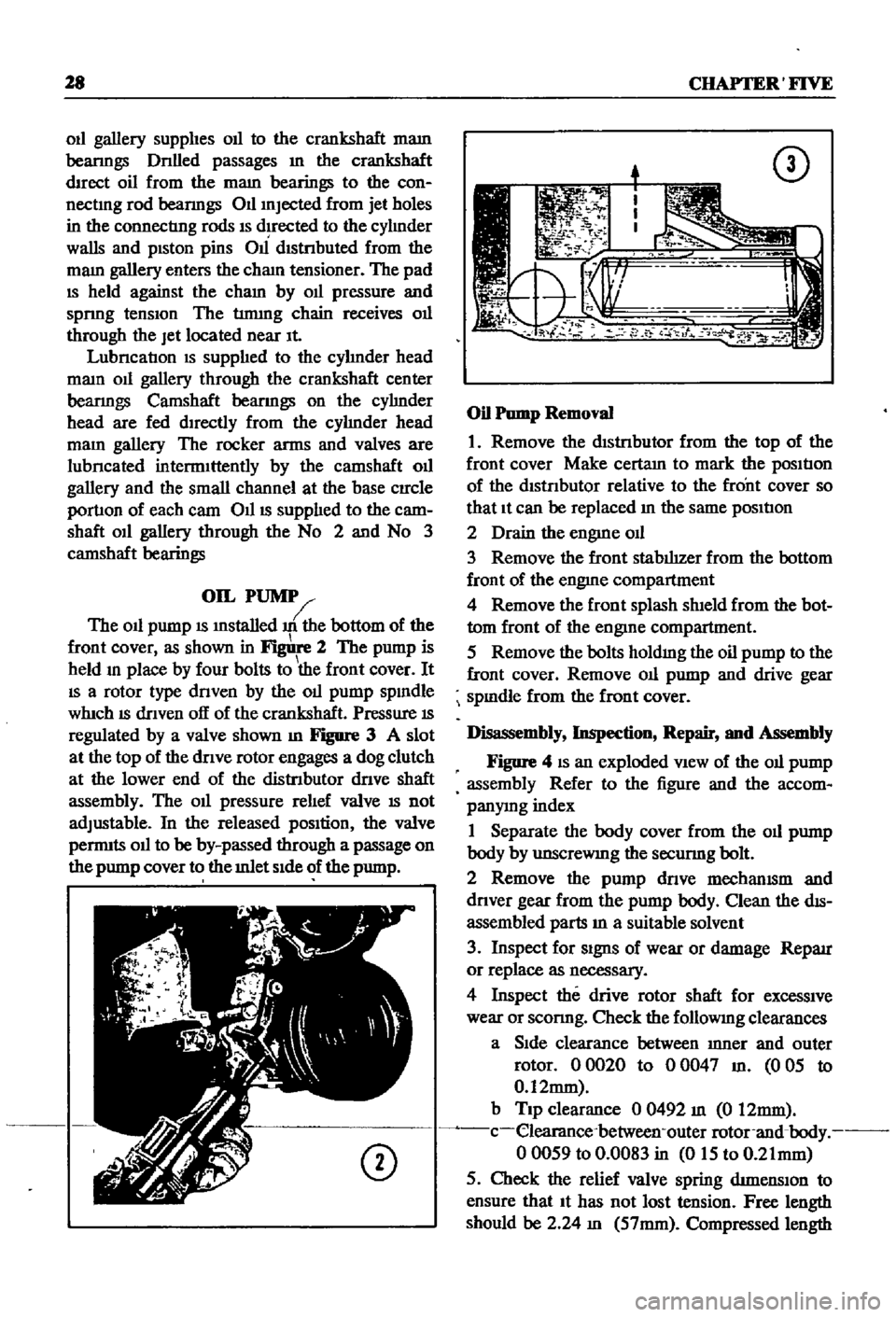

OIL

PUMP

The

011

pump

IS

mstalled

m

the

bottom

of

the

front

cover

as

shown

in

2

The

pump

is

held

m

place

by

four

bolts

to

the

front

cover

It

IS

a

rotor

type

dnven

by

the

011

pump

spmdle

whIch

IS

dnven

off

of

the

crankshaft

Pressure

IS

regulated

by

a

valve

shown

m

Figure

3

A

slot

at

the

top

of

the

dnve

rotor

engages

a

dog

clutch

at

the

lower

end

of

the

distnbutor

dnve

shaft

assembly

The

011

pressure

rehef

valve

IS

not

adjustable

In

the

released

pOSition

the

valve

pernnts

011

to

be

by

passed

through

a

passage

on

the

pump

cover

to

the

mlet

Side

of

the

pump

CD

CD

Oil

Pump

Removal

1

Remove

the

dIStnbutor

from

the

top

of

the

front

cover

Make

certam

to

mark

the

posItIon

of

the

dtstnbutor

relative

to

the

front

cover

so

that

It

can

be

replaced

m

the

same

posItIon

2

Drain

the

engme

od

3

Remove

the

front

stabIhzer

from

the

bottom

front

of

the

engme

compartment

4

Remove

the

front

splash

shIeld

from

the

bot

tom

front

of

the

engine

compartment

5

Remove

the

bolts

holdmg

the

oil

pump

to

the

front

cover

Remove

011

pump

and

drive

gear

spmdle

from

the

front

cover

Disassembly

Inspection

Repair

and

Assembly

Figure

4

IS

an

exploded

VIew

of

the

011

pump

assembly

Refer

to

the

figure

and

the

accom

panymg

index

1

Separate

the

body

cover

from

the

011

pump

body

by

unscreWIng

the

secunng

bolt

2

Remove

the

pump

dnve

mechamsm

and

dnver

gear

from

the

pump

body

Clean

the

dIS

assembled

parts

m

a

suitable

solvent

3

Inspect

for

Signs

of

wear

or

damage

Reparr

or

replace

as

necessary

4

Inspect

the

drive

rotor

shaft

for

excessive

wear

or

sconng

Check

the

followmg

clearances

a

Side

clearance

between

mner

and

outer

rotor

00020

to

00047

m

005

to

0

12mm

b

Tip

clearance

0

0492

m

0

12mm

c

elearance

between

outer

rotor

and

body

00059

to

0

0083

in

015

to

0

21mm

5

Check

the

relief

valve

spring

dtmenslOn

to

ensure

that

It

has

not

lost

tension

Free

length

should

be

2

24

m

57mm

Compressed

length

Page 52 of 252

ENGINE

47

allowable

warpage

IS

0

0039

in

0

I

mm

Standard

should

be

less

than

0

0012

in

O

03mm

In

the

event

the

measurements

are

out

of

tolerance

the

cylmder

head

surface

should

be

milled

or

resurfaced

3

Verify

that

all

water

and

011

passages

are

free

of

foreign

matena

Use

compressed

aIr

to

clean

passages

after

scraping

4

Note

the

condition

of

all

studs

in

the

cylinder

head

Replace

damaged

ones

Valve

Assembly

I

Check

intake

and

exhaust

valve

assembhes

for

worn

damaged

or

deformed

valve

caps

and

stems

Correct

or

replace

the

valve

If

excessive

defects

exist

2

Measure

valve

stem

diameter

WIth

a

micro

meter

as

shown

in

Fignre

36

Figure

37

gives

cnncal

drmensions

@

@

Y

lm

1

0

515

r

3

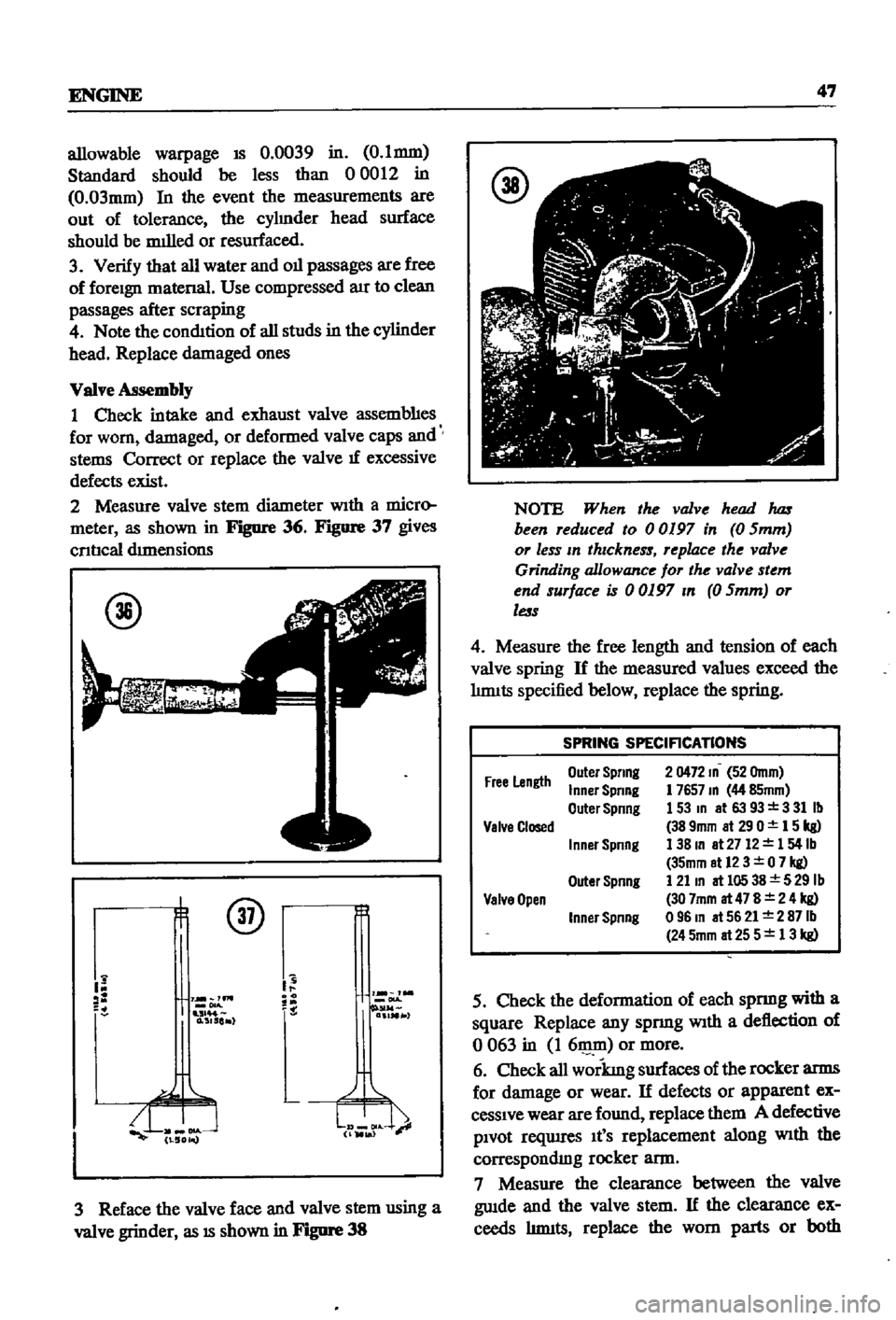

Reface

the

valve

face

and

valve

stem

using

a

valve

grinder

as

18

shown

in

Fignre

38

NOTE

When

the

valve

head

1uzs

been

reduced

to

00197

in

0

Smm

or

less

In

thIckness

replace

the

valve

Grinding

allowance

for

the

valve

stem

end

surface

is

00197

In

0

Smm

or

less

4

Measure

the

free

length

and

tension

of

each

valve

spring

If

the

measured

values

exceed

the

hnuts

specified

below

replace

the

spring

SPRING

SPECIFICATIONS

Free

Length

Outel

Spring

Inner

Spring

Outer

Spring

2

0472

10

52

Omm

1

765710

44

85mm

153m

at6393

331Ib

389mm

at290

15kg

138m

at

2712

154lb

35mm

at12

3

0

7

kg

121

10

at

105

38

5

29

Ib

30

7mm

at

47

8

2

4

kg

09610

at5621

2871b

245mm

at

25

5

13

kg

Valve

Closed

I

nner

Spring

Outer

Spnng

Valve

Open

Inner

Spnng

5

Check

the

deformation

of

each

spnng

with

a

square

Replace

any

spnng

WIth

a

deflection

of

o

063

in

I

611lID

or

more

6

Check

all

workmg

surfaces

of

the

rocker

arms

for

damage

or

wear

If

defects

or

apparent

ex

cessIve

wear

are

found

replace

them

A

defective

PIvot

reqwres

It

S

replacement

along

WIth

the

correspondIng

rocker

ann

7

Measure

the

clearance

between

the

valve

gwde

and

the

valve

stem

If

the

clearance

ex

ceeds

hnuts

replace

the

worn

parts

or

both

Page 55 of 252

50

CHAPTER

SIX

3

Pull

up

on

the

spnng

scale

If

the

force

re

qurred

to

pull

the

feeler

gauge

out

IS

more

than

3

3

lbs

or

less

than

0

44

Ibs

the

piston

skirt

IS

either

too

large

or

small

for

the

cyhnder

and

must

be

replaced

With

a

pISton

of

the

proper

size

EIther

that

or

the

cyhnder

must

be

rebored

or

a

new

cyhnder

hner

mstalled

Piston

Piston

Pin

and

Piston

Ring

1

Inspect

all

parts

carefully

for

signs

of

clups

cracks

and

general

wear

2

Measure

the

side

clearance

oLeac

ring

in

It

S

appropnate

groove

as

shown

in

Figure

45

Clearances

should

be

witlun

the

following

tol

erances

Top

Ring

00018

through

00031

In

0045

through

0

078mm

00012

through

0

0025

In

0030

through

0063mm

00010

through

0

0025

In

0025

through

0063mm

Middle

Ring

011

Ring

bottom

@

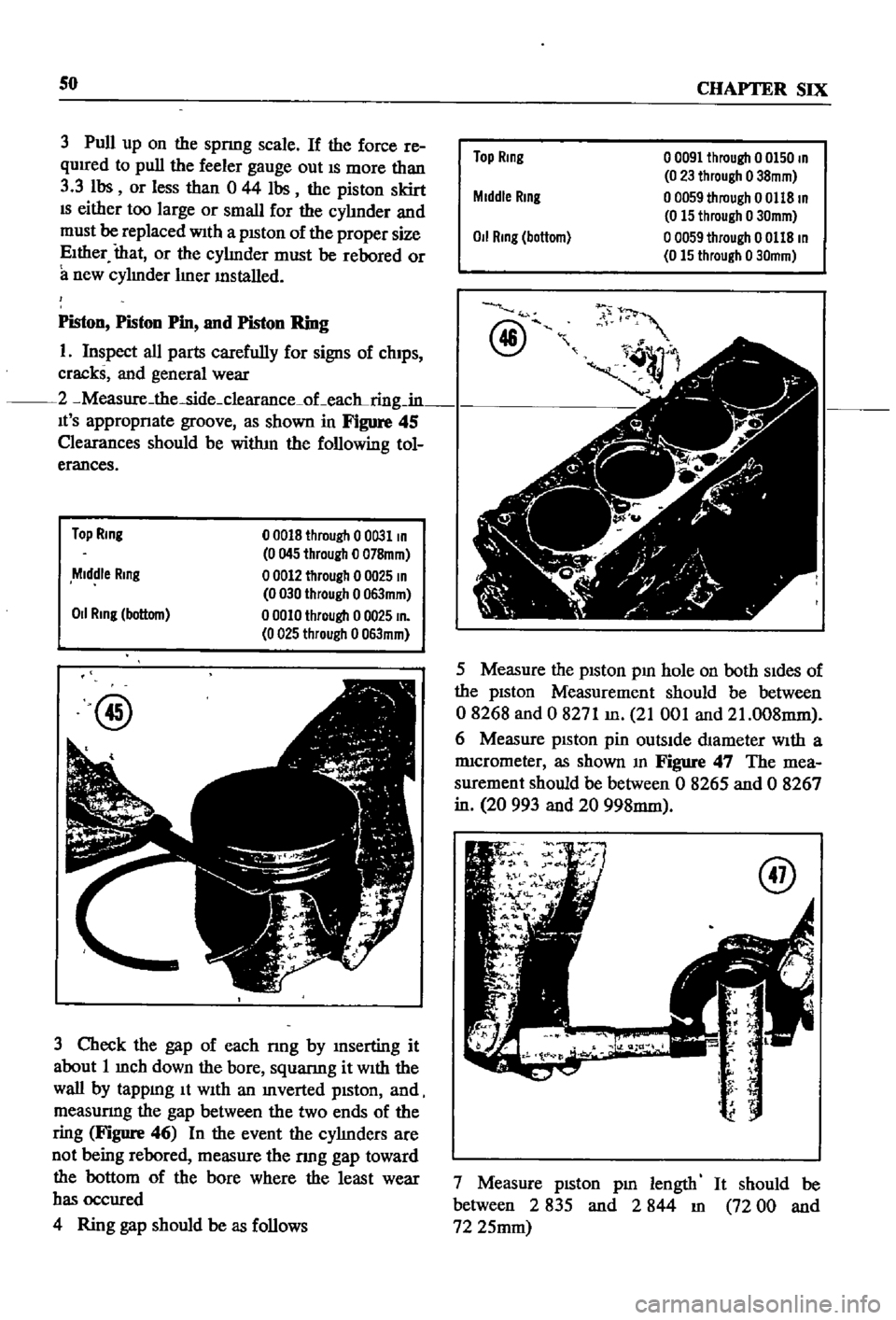

3

Check

the

gap

of

each

nng

by

mserting

it

about

1

mch

down

the

bore

squanng

it

With

the

wall

by

tappmg

It

WIth

an

mverted

pIston

and

measunng

the

gap

between

the

two

ends

of

the

ring

Figure

46

In

the

event

the

cyhnders

are

not

being

rebored

measure

the

nng

gap

toward

the

bottom

of

the

bore

where

the

least

wear

has

occured

4

Ring

gap

should

be

as

follows

Top

Ring

00091

through

0

0150

In

0

23

through

o

38mm

o

0059

through

0

0118

In

0

15

through

0

30mm

o

0059

through

0

0118

In

0

15

through

0

30mm

Middle

Rmg

0

1

Rmg

bottom

@

fJ

t

1

v

5

Measure

the

pIston

pm

hole

on

both

SIdes

of

the

pIston

Measurement

should

be

between

08268

and

0

8271

m

21

001

and

21

008mm

6

Measure

pISton

pin

outsIde

dIameter

With

a

nucrometer

as

shown

m

Figure

47

The

mea

surement

should

be

between

0

8265

and

0

8267

in

20

993

and

20

998mm

7

Measure

pIston

pm

length

It

should

be

between

2

835

and

2

844

m

72

00

and

72

25mm

Page 56 of 252

ENGINE

51

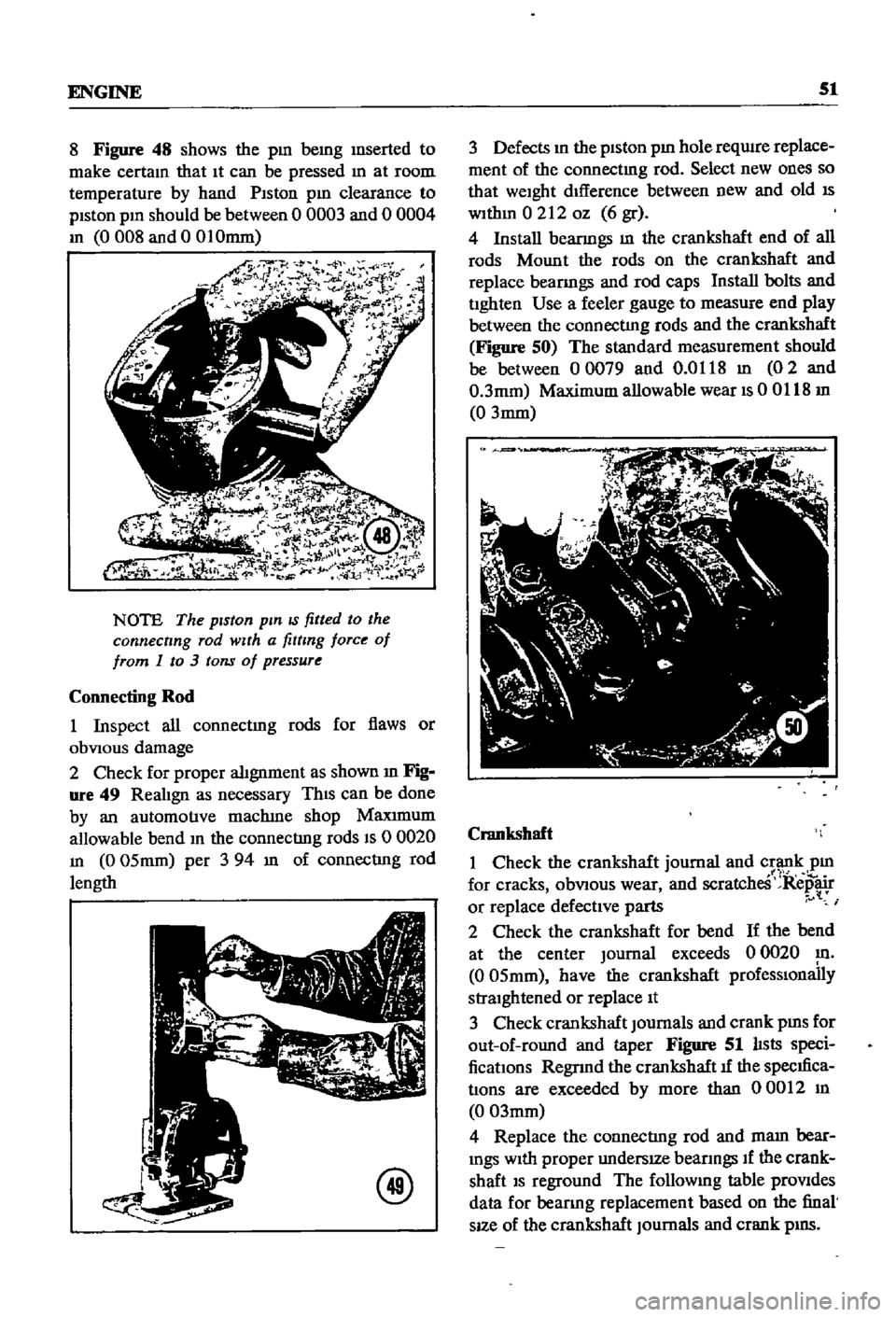

8

Figure

48

shows

the

pm

bemg

mserted

to

make

certam

that

It

can

be

pressed

m

at

room

temperature

by

hand

Piston

pm

clearance

to

piston

pm

should

be

between

0

0003

and

0

0004

m

0008

and

0

01Omm

NOTE

The

piston

pin

IS

fitted

to

the

connecting

rod

with

a

fitting

force

of

from

1

to

3

tons

of

pressure

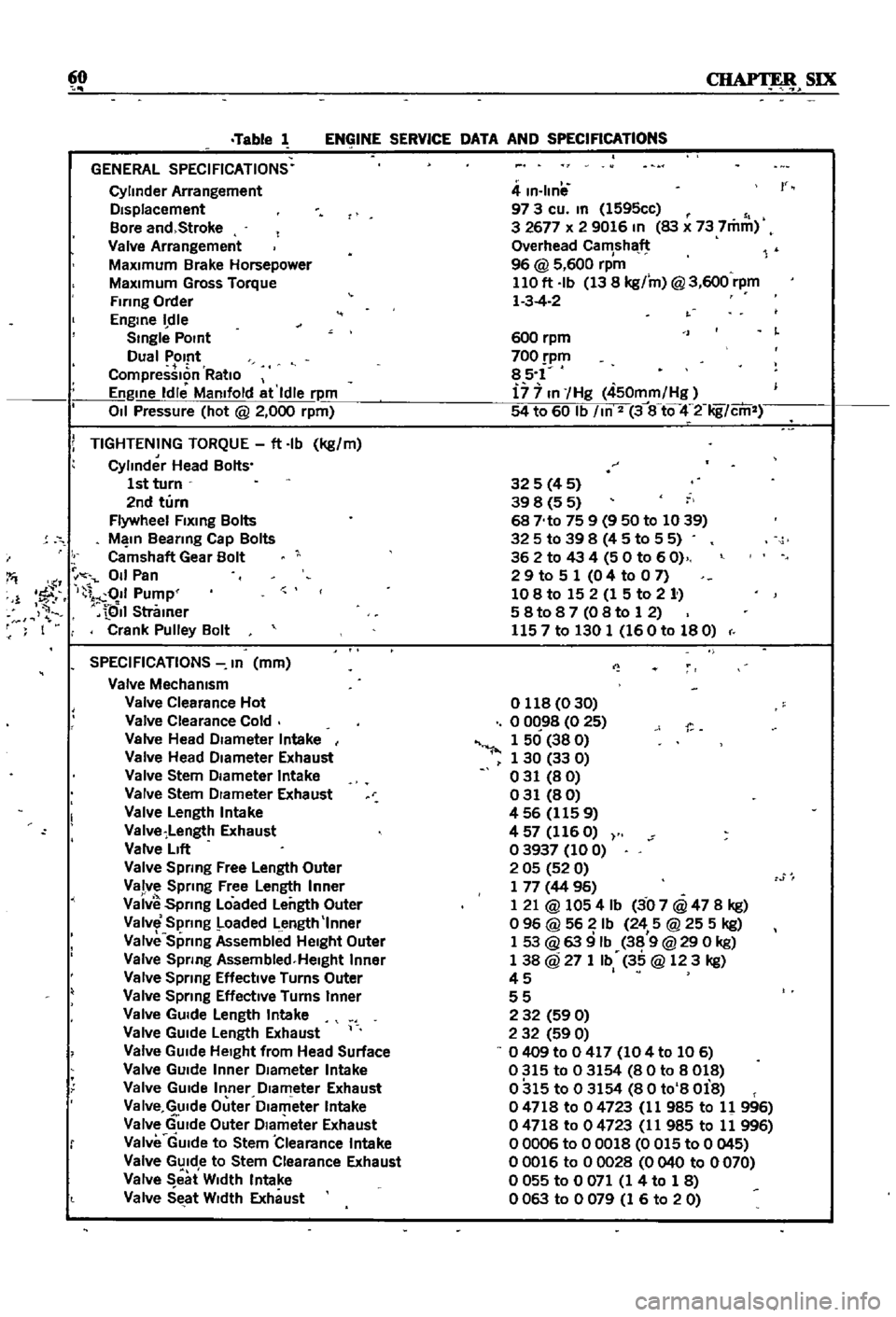

Connecting

Rod

1

Inspect

all

connectmg

rods

for

flaws

or

obVIOUS

damage

2

Check

for

proper

alignment

as

shown

m

Fig

ure

49

RealIgn

as

necessary

ThIS

can

be

done

by

an

automotive

maclune

shop

Maxrmum

allowable

bend

m

the

connecting

rods

IS

0

0020

m

0

05mm

per

3

94

m

of

connecting

rod

length

@

3

Defects

m

the

piston

pm

hole

reqwre

replace

ment

of

the

connectmg

rod

Select

new

ones

so

that

weight

dIfference

between

new

and

old

IS

wlthm

0212

oz

6

gr

4

Install

beanngs

m

the

crankshaft

end

of

all

rods

Mount

the

rods

on

the

crankshaft

and

replace

beanngs

and

rod

caps

Install

bolts

and

tighten

Use

a

feeler

gauge

to

measure

end

play

between

the

connecting

rods

and

the

crankshaft

Figure

50

The

standard

measurement

should

be

between

00079

and

0

0118

m

02

and

0

3mm

Maximum

allowable

wear

IS

00118

m

0

3mm

Crankshaft

1

Check

the

crankshaft

journal

and

crank

pm

1

1

for

cracks

obVIOUS

wear

and

scratcheS

Repair

or

replace

defective

parts

I

2

Check

the

crankshaft

for

bend

If

the

bend

at

the

center

Journal

exceeds

0

0020

m

0

05mm

have

the

crankshaft

prOfeSSIOnally

straightened

or

replace

It

3

Check

crankshaft

Journals

and

crank

pms

for

out

of

round

and

taper

Figure

51

lIsts

speci

fications

Regnnd

the

crankshaft

1f

the

specIfica

tions

are

exceeded

by

more

than

00012

m

0

03mm

4

Replace

the

connecting

rod

and

mam

bear

mgs

With

proper

undersIZe

beanngs

If

the

crank

shaft

IS

reground

The

followmg

table

prOVides

data

for

beanng

replacement

based

on

the

final

sIZe

of

the

crankshaft

Journals

and

crank

pIllS

Page 65 of 252

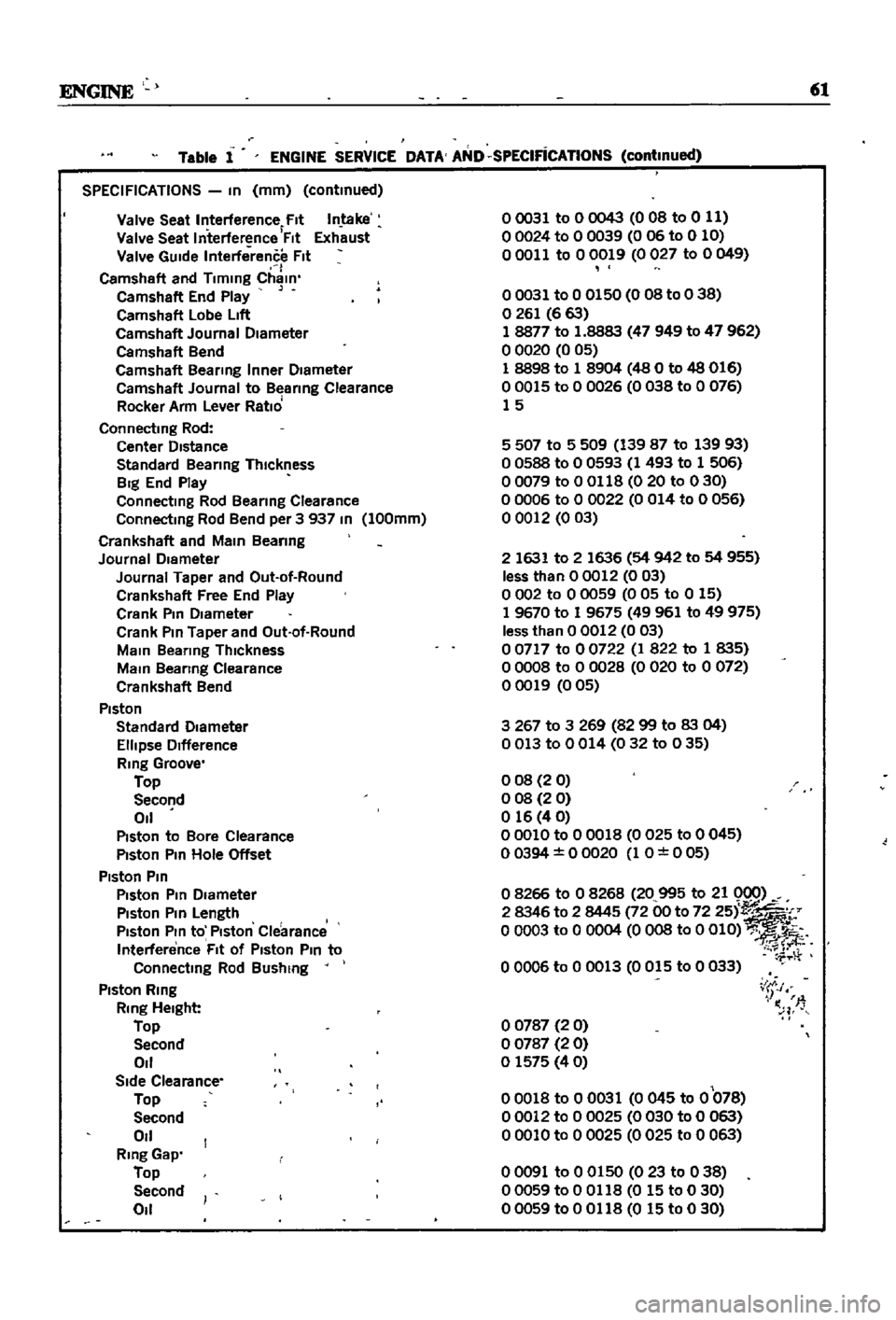

60

SIX

Table

1

ENGINE

SERVICE

DATA

AND

SPECIFICATIONS

GENERAL

SPECIFICATIONS

Cylinder

Arrangement

DIsplacement

Bore

and

Stroke

Valve

Arrangement

MaxImum

Brake

Horsepower

MaxImum

Gross

Torque

Firing

Order

Engme

dle

Smgle

POint

Dual

Pomt

CompressIon

RatIo

Engme

Idle

Mamfold

at

Idle

rpm

011

Pressure

hot

@

2

000

rpm

i

TIGHTENING

TORQUE

ft

Ib

kg

m

Cylinder

Head

Bolts

1st

turn

2nd

turn

Flywheel

Flxmg

Bolts

M

In

Beanng

Cap

Bolts

Camshaft

Gear

Bolt

I

011

Pan

1

1

fF

I

011

Pump

QII

Stramer

F

I

Crank

Pulley

Bolt

SPECIFICATIONS

In

mm

Valve

Mechamsm

Valve

Clearance

Hot

Valve

Clearance

Cold

Valve

Head

DIameter

Intake

Valve

Head

DIameter

Exhaust

Valve

Stem

DIameter

Intake

Valve

Stem

DIameter

Exhaust

Valve

Length

Intake

Valve

Length

Exhaust

Valve

LIft

Valve

Spring

Free

Length

Outer

Valve

Sprmg

Free

Length

Inner

Vaiv

Spnng

Loaded

Length

Outer

Valve

Spring

Loaded

Length

Inner

Valve

Sprmg

Assembllld

HeIght

Outer

Valve

Spnng

Assembled

Helght

Inner

Valve

Spnng

Effective

Turns

Outer

Valve

Sprmg

EffectIve

Turns

Inner

Valve

GUIde

Length

Intake

Valve

GUIde

Length

Exhaust

Valve

GUIde

HeIght

from

Head

Surface

Valve

GUIde

Inner

DIameter

Intake

Valve

GUIde

Inner

DIameter

Exhaust

Va

Ive

GUIde

Outer

Dlam

eter

Intake

Valve

GUIde

Outer

DIameter

Exhaust

Valve

GUIde

to

Stem

Clearance

Intake

Valve

GUIde

to

Stem

Clearance

Exhaust

Valve

eat

W

dth

Intake

Valve

SEtat

WIdth

Exhaust

4

m

Ilnil

97

3

cu

m

1595cc

3

2677

x

2

9016

In

83

x

73

7mm

Overhead

Camshaft

96

@

5

600

rpm

110

ft

Ib

13

8

kg

m

@

3

600

rpm

1

3

4

2

r

600

rpm

700

pm

85

1

i7

7

In

Hg

450mm

Hg

54

to

60

Ib

m

2

3

8

tQ

4

2

Iig

cm

325

4

5

39

8

5

5

68

No

75

9

9

50

to

1039

325

to

39

8

4

5

to

5

5

362

to

43

4

50

to

60

2

9

to

5

1

0

4

to

0

7

108

to

15

2

1

5

to

2

1

58t087

08to

12

1157

to

130

1

160

to

180

o

118

0

30

o

0C

98

0

25

1

50

38

0

1

30

33

0

031

80

031

80

456

1159

4

57

116

O

03937

100

2

05

52

0

1

77

44

96

1

21

@

1054

Ib

3

07

@

47

8

kg

o

96

@

56

Ib

24

5

@

25

5

kg

1

53

@

63

9

Ib

38

9

@

29

0

kg

1

38

@

27

1

Ib

35

@

123

kg

45

I

55

2

32

59

0

2

32

59

0

0409

to

0

417

104

to

106

0315

to

03154

80

to

8018

0315

to

03154

80

to

8

Oi8

04718

to

04723

11

985

to

11

996

04718

to

04723

11

985

to

11

996

00006

to

00018

0

015

to

0

045

00016

to

00028

0040

to

0070

o

055

to

0

071

1

4

to

1

8

0063

to

0079

1

6

to

20

Page 66 of 252

ENGINE

61

SPECIFICATIONS

In

mm

continued

Valve

Seat

Interference

Fit

Intake

Valve

Seat

Interference

Flt

Exh

ust

Valve

GUide

Interference

fit

I

Camshaft

and

Timing

Chain

Ca

mshaft

End

Play

Camshaft

Lobe

LIft

Camshaft

Journal

Diameter

Camshaft

Bend

Camshaft

Bearing

Inner

Diameter

Camshaft

Journal

to

B

arlng

Clearance

Rocker

Arm

Lever

Ratio

Connecting

Rod

Center

Distance

Standard

Bearing

Thickness

Big

End

Play

Connectmg

Rod

Beanng

Clearance

Connecting

Rod

Bend

per

3

937

In

100mm

Crankshaft

and

Main

Beanng

Journal

Diameter

Journal

Taper

and

Out

ot

Round

Crankshaft

Free

End

Play

Crank

Pin

Diameter

Crank

Pin

Taper

and

Out

ot

Round

Main

Bearing

Thickness

Main

Beanng

Clearance

Crankshaft

Bend

Piston

Standard

Diameter

Ellipse

Difference

Ring

Groove

Top

Second

011

Piston

to

Bore

Clearance

Piston

Pm

Hole

Offset

Piston

Pin

Piston

Pin

Diameter

Piston

Pin

Length

Piston

Pin

to

Piston

Clearance

Interference

Fit

ot

Piston

Pin

to

Connecting

Rod

Bushing

Piston

Ring

Ring

Height

Top

Second

011

Side

Clearance

Top

Second

011

Ring

Gap

Top

Second

011

Table

1

ENGINE

SERVICE

DATA

AND

SPECIFicATIONS

continued

00031

to

0

0043

0

OB

to

0

11

00024

to

0

0039

006

to

0

10

00011

to

00019

0027

to

0049

00031

to

0

0150

0

08

to

0

38

o

261

6

63

18877

to

1

8883

47

949

to

47

962

o

0020

0

05

1

8898

to

1

8904

48

0

to

48

016

00015

to

0

0026

0038

to

0

076

15

5

507

to

5

509

139

87

to

139

93

o

0588

to

0

0593

1

493

to

1

506

00079

to

0

0118

0

20

to

030

o

0006

to

0

0022

0

014

to

0

056

o

0012

003

2

1631

to

2

1636

54

942

to

54

955

less

than

00012

003

o

002

to

0

0059

0

05

to

0

15

1

9670

to

1

9675

49961

to

49

975

less

than

0

0012

0

03

o

0717

to

0

0722

1

822

to

1

835

o

0008

to

0

0028

0

020

to

0

072

00019

005

3267

to

3

269

8299

to

83

04

0013

to

0014

032

to

035

008

20

o

08

2

0

o

16

4

0

00010

to

0

0018

0

025

to

0

045

00394

0

0020

1

O

0

05

o

8266

to

0

8268

20

995

to

21

0

0

2

8346

to

2

8445

72

00

to

72

251

o

0003

to

0

0004

0

OOS

to

0

OlD

00006

to

0

0013

0015

to

0

033

o

0787

2

0

o

0787

2

0

o

1575

40

00018

to

00031

0

045

to

0

078

00012

to

0

0025

0030

to

0

063

00010

to

00025

0025

to

0

063

i

J

I

n

T

00091

to

0

0150

023

to

038

00059

to

0

0118

0

15

to

0

30

00059

to

0

0118

0

15

to

0

30

Page 100 of 252

ENGINE

ELECI

RlCAL

SYSTEM

9S

@

@

4

Test

the

COIls

for

shorts

by

unsoldermg

the

connectIons

of

each

coIl

and

repeatlng

the

test

given

m

step

3

If

a

defectIve

coil

IS

found

It

must

be

replaced

BRUSHES

AND

BRUSH

LEAD

WIRE

1

Check

condItIon

of

the

brush

contact

surface

and

general

wear

of

the

brush

If

the

brush

is

worn

to

under

02362

In

60mm

m

length

replace

It

Inspect

all

connectIons

carefully

for

looseness

or

cracks

Replace

or

reparr

as

re

qUIred

2

Check

the

connectIon

of

the

lead

clIp

and

WIre

3

Check

brush

holders

and

sprmg

clIps

for

damage

Replace

1f

they

will

not

hold

the

brushes

agaInst

the

commutator

properly

Clean

all

brushes

aIld

brush

holders

thoroughly

4

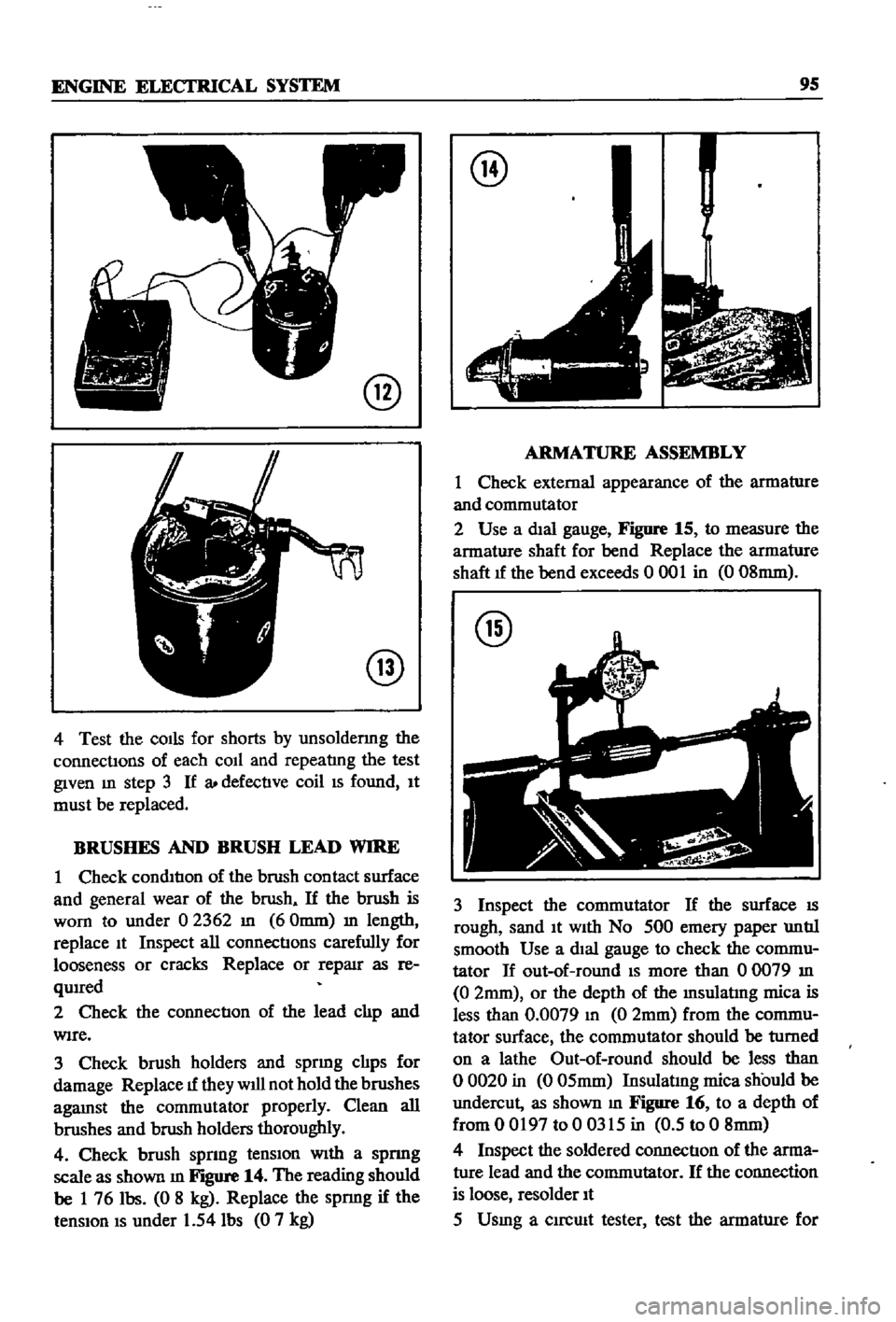

Check

brush

sprmg

tenSIon

WIth

a

spnng

scale

as

shown

m

Figure

14

The

reading

should

be

1

76

Ibs

0

8

kg

Replace

the

spnng

if

the

tenSIon

IS

under

1

54

Ibs

0

7

kg

@

ARMATURE

ASSEMBLY

1

Check

external

appearance

of

the

armature

and

commutator

2

Use

a

dIal

gauge

Figure

15

to

measure

the

armature

shaft

for

bend

Replace

the

armature

shaft

1f

the

bend

exceeds

0

001

in

0

08mm

@

3

Inspect

the

commutator

If

the

surface

IS

rough

sand

It

With

No

500

emery

paper

untIl

smooth

Use

a

dIal

gauge

to

check

the

commu

tator

If

out

of

round

IS

more

than

00079

In

0

2mm

or

the

depth

of

the

Insulatlng

mica

is

less

than

0

0079

In

0

2mm

from

the

commu

tator

surface

the

commutator

should

be

turned

on

a

lathe

Out

of

round

should

be

less

than

o

0020

in

0

05mm

Insulatmg

mica

should

be

undercut

as

shown

m

Figure

16

to

a

depth

of

from

0

0197

to

0

0315

in

0

5

to

0

8mm

4

Inspect

the

soldered

connectIon

of

the

arma

ture

lead

and

the

commutator

If

the

connection

is

loose

resolder

It

5

Usmg

a

clrcmt

tester

test

the

armature

for

Page 135 of 252

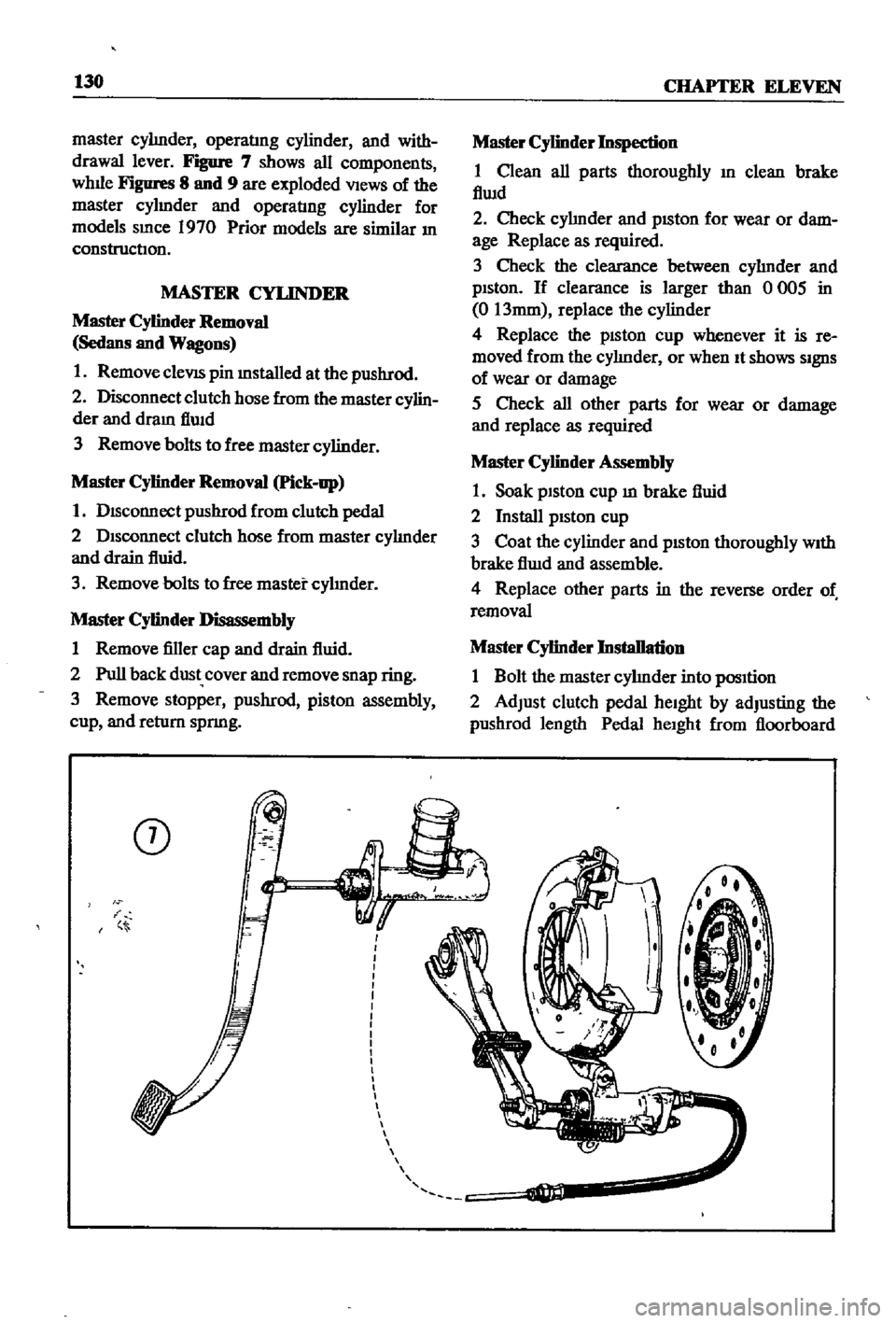

130

CHAPTER

ELEVEN

master

cylInder

operatlng

cylinder

and

with

drawal

lever

Figure

7

shows

all

components

whlle

Figures

8

and

9

are

exploded

VIews

of

the

master

cylmder

and

operatIng

cylinder

for

models

smce

1970

Prior

models

are

similar

In

construction

MASTER

CYLINDER

Master

Cylinder

Removal

Sedans

and

Wagons

1

Remove

cleVIS

pin

mstalled

at

the

pushrod

2

Disconnect

clutch

hose

from

the

master

cylin

der

and

dram

flwd

3

Remove

bolts

to

free

master

cylinder

Master

Cylinder

Removal

Pick

up

1

DIsconnect

pushrod

from

clutch

pedal

2

DIsconnect

clutch

hose

from

master

cylInder

and

drain

fluid

3

Remove

bolts

to

free

master

cylInder

Master

Cylinder

Disassembly

1

Remove

filler

cap

and

drain

fluid

2

Pull

back

dust

cover

and

remove

snap

ring

3

Remove

stopper

pushrod

piston

assembly

cup

and

return

spnng

CD

i

Master

Cylinder

Inspection

1

Clean

all

parts

thoroughly

In

clean

brake

flwd

2

Check

cylInder

and

pISton

for

wear

or

dam

age

Replace

as

required

3

Check

the

clearance

between

cylInder

and

pIston

If

clearance

is

larger

than

0

005

in

0

13mm

replace

the

cylinder

4

Replace

the

pISton

cup

whenever

it

is

re

moved

from

the

cylInder

or

when

It

shows

SIgnS

of

wear

or

damage

5

Check

all

other

parts

for

wear

or

damage

and

replace

as

required

Master

Cylinder

Assembly

1

Soak

piston

cup

m

brake

fluid

2

Install

pIston

cup

3

Coat

the

cylinder

and

pIston

thoroughly

WIth

brake

flwd

and

assemble

4

Replace

other

parts

in

the

reverse

order

of

removal

Master

Cylinder

Installation

1

Bolt

the

master

cylInder

into

pOSItion

2

Adjust

clutch

pedal

heIght

by

adjusting

the

pushrod

length

Pedal

heIght

from

floorboard

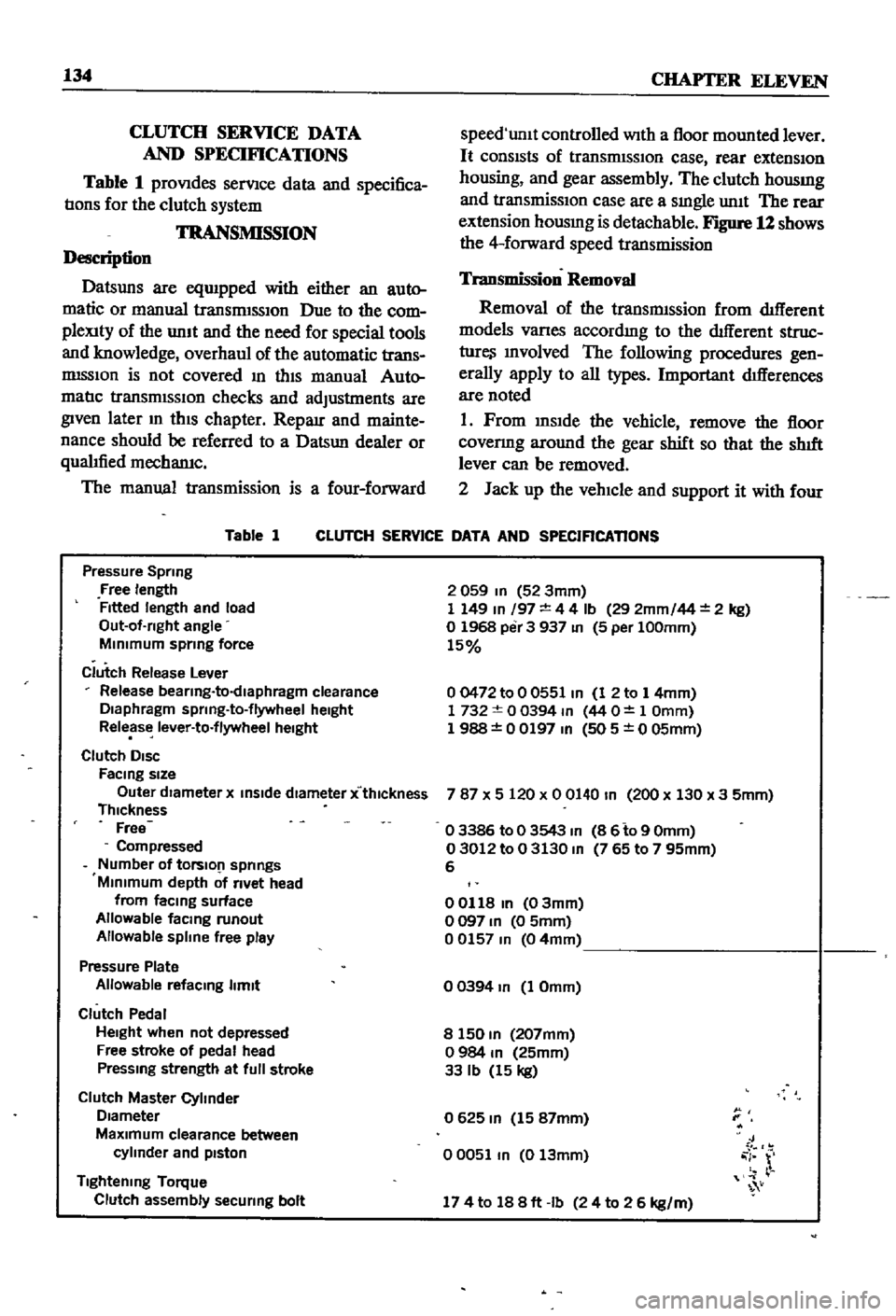

Page 139 of 252

134

CHAPTER

ELEVEN

CLUTCH

SERVICE

DATA

AND

SPECIF1CATIONS

Table

1

proVIdes

serVIce

data

and

specifica

tIons

for

the

clutch

system

TRANSMISSION

Description

Datsuns

are

eqUIpped

with

either

an

auto

matic

or

manual

transrmSSIOn

Due

to

the

com

pleXity

of

the

unIt

and

the

need

for

special

tools

and

knowledge

overhaul

of

the

automatic

trans

mISSIon

is

not

covered

In

thIS

manual

Auto

matIc

transmISSIOn

checks

and

adjustments

are

given

later

m

thIS

chapter

Reparr

and

mainte

nance

should

be

referred

to

a

Datsun

dealer

or

qualIfied

mechamc

The

manual

transmission

is

a

four

forward

Table

1

speed

unlt

controlled

With

a

floor

mounted

lever

It

consIsts

of

transrmSSIOn

case

rear

extensIOn

housing

and

gear

assembly

The

clutch

housmg

and

transmissIOn

case

are

a

sIngle

unIt

The

rear

extension

housmg

is

detachable

Figure

12

shows

the

4

forward

speed

transmission

Transmission

Removal

Removal

of

the

transmIssion

from

dIfferent

models

Varles

accordmg

to

the

dIfferent

struc

ture

Involved

The

following

procedures

gen

erally

apply

to

all

types

Important

dIfferences

are

noted

1

Prom

InsIde

the

vehicle

remove

the

floor

covenng

around

the

gear

shift

so

that

the

shIft

lever

can

be

removed

2

Jack

up

the

vehIcle

and

support

it

with

four

CLUTCH

SERVICE

DATA

AND

SPECIFICATIONS

Pressure

Spring

Free

length

Fitted

length

and

load

Out

of

rlght

angle

MInimum

sprmg

force

Clutch

Release

Lever

Release

bearlng

to

dlaphragm

clearance

Diaphragm

sprlng

to

flywheel

height

Release

lever

to

flywheel

height

Clutch

DISC

FaCing

size

Outer

dIameter

x

inSide

diameter

x

thlckness

Thickness

Free

Compressed

Number

of

tOrslO

1

springs

Minimum

depth

of

rivet

head

from

faCing

surface

Allowable

facmg

runout

Allowable

spline

free

play

Pressure

Plate

Allowable

refacmg

limit

Clutch

Pedal

Height

when

not

depressed

Free

stroke

of

pedal

head

Pressmg

strength

at

full

stroke

Clutch

Master

Cylinder

Diameter

MaXimum

clearance

between

cylinder

and

pIston

Tightening

Torque

Clutch

assembly

securing

bolt

2

059

In

52

3mm

1

149

In

197

4

4

Ib

29

2mm

44

2

kg

o

1968

per

3

937

In

5

per

100mm

15

00472

to

0

0551

In

1

2

to

1

4mm

1732

0

0394

m

44

O

1

Omm

1

988

0

0197

In

505

0

05mm

787

X

5

120

x

0

0140

In

200

x

130

x

3

5mm

o

3386

to

0

3543

m

8

6

to

9

Omm

03012

to

0

3130

m

765

to

7

95mm

6

00118

In

03mm

o

097

In

0

5mm

00157

m

04mm

o

0394

In

1

Omm

8

150

m

207mm

o

984

m

25mm

33

Ib

15

kg

0625

m

15

87mm

00051

m

0

13mm

J

i

r

174

to

188ft

Ib

24

to

2

6

kg

m