fuel pump DATSUN 610 1969 User Guide

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1969, Model line: 610, Model: DATSUN 610 1969Pages: 171, PDF Size: 10.63 MB

Page 126 of 171

N

Engme

SYMPTOMS

I

Trouble

Shooting

Lubrication

System

SYMPTOMS

bed

t

f

I

h

i

1m

0

p

q

r

I

I

II

bed

t

f

I

h

Ii

I

m

n

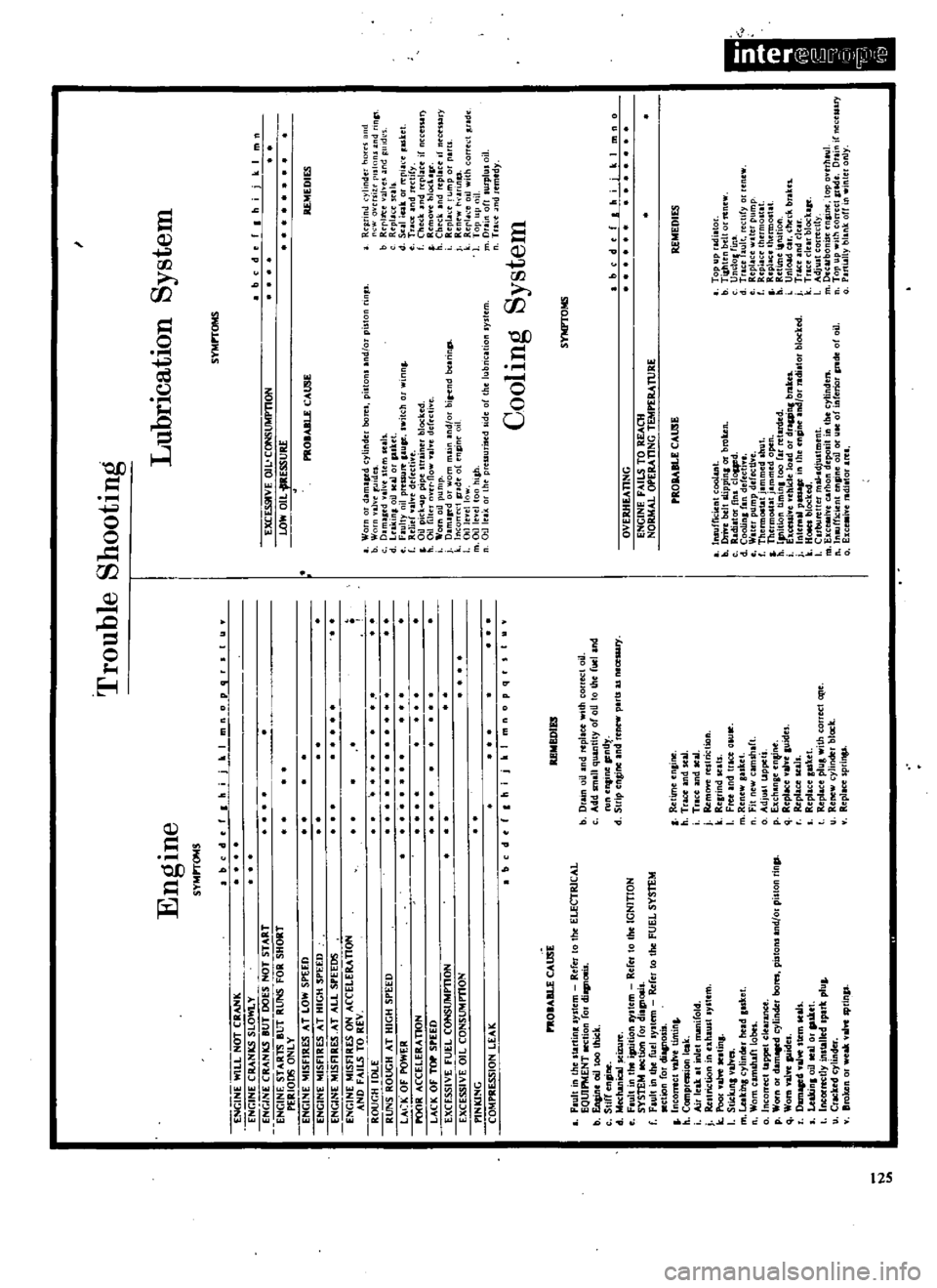

ENGINE

WILL

NOT

CRANK

ENGINE

CRANKS

SLOWLY

ENGINE

CRANkS

BUT

OOES

NOT

START

ENGINE

STARTS

BUT

RUNS

FOR

SHORT

PERIODS

aNL

Y

ENGINE

I

tISFIRES

AT

LOW

SPEED

ENGINE

MISFIRES

AT

HIGH

SPEED

ENGINE

MISFIRES

AT

ALL

SPEEDS

ENGINE

MISFIRES

ON

ACCELERATION

AND

FAILS

TO

REV

ROUGH

IDLE

RUNS

ROUGH

AT

HIGH

SPEED

lACK

OF

POWER

POOR

CCElERA

nON

LACK

OF

TOP

SPEED

EXCESSIVE

FUEL

CONSUMmON

EXCESSIVE

OIL

CONSUMmON

PINKING

COMPRESSION

LEAK

PROIABLE

CAUSE

Faull

In

th

e

ltartinll

IYltem

Refer

to

the

ELECTRICAL

EQUIPMENT

leetion

fOI

dilllflOlIll

b

Eft

ineoiltoothick

Stiffenpne

d

Mechanieal

scimre

Flult

In

lhe

IpUlion

I

ltem

Refer

to

the

IGNITION

SYSTEM

IeCtion

for

di

I

f

Flult

the

fuellYlltm

Refer

to

the

FUEL

SYSTEM

Clion

or

di

l

OIII

Incomcl

tllvetlmln

h

ComprellllllIU

IClk

Air

leak

IRlel

JIlIIni

old

j

Reltriction

nhlu5t5ylltm

Ie

Poor

alYe

WIIIIIJ

I

Stick

tnlvall

n

m

Lclklnl

cylinder

held

Illke

Womcamlhlft

lobel

IncolTe

ttappetclurance

p

Worn

dlm

ed

cylinder

born

pUlon5

Ind

or

pll

f1np

q

Wom

nl

fC

paides

Damaced

a1wlttmseal

LeWnloilwaI

pu

e

Incorrectly

installed

apark

plu

CrICked

cylinder

Broken

weakv

w

sprinp

EXCES9lVE

OIL

CONSUMPTION

WW

OIL

ilRESSURE

PROIABLE

CAUSE

REMEDIES

I

Worn

dlmalJl

dcyhnderbon

P

v

lnd

orpulu

nnr

s

b

WorJl

valve

r

uides

C

D

m

led

valve

lIemluls

d

Lnlunr

oil

ul

pillet

e

Flulty

nil

P

uu

IluP

Iwnch

wmn

f

Relief

valve

defecuve

011

pick

up

pipellfline

blocked

h

011

filler

nver

flow

yaJYe

dcffe

WO

n

oil

pump

J

Dlmllfd

om

maUl

Ind

or

bl

nd

b

lnnll

l

lncorreCllndeofentpneoil

l

Oil

level

10

m

Oillevel

tnnhllh

Oillelk

the

preuunled

Ilde

of

the

lubn

IYSfem

p

Tldc

Rel1

f1nd

yllOde1

ne

OVCntZl

nd

nnJ

b

Rcpltte

v

lve

and

Iltd

c

Repl

cc

5c

l

d

Sullu

rt

pl

cp

aI

kCl

e

Trice

Ind

rtClify

f

heel

lod

replace

if

nccess

T

RemoYcblQChJC

h

Chcck

Ind

repllcclfncct

i

ry

i

Repll

e

rump

J

Renew

nnp

k

Rerl

ec

OIl

with

l

Top

up

oil

m

DTllnofllurpIUloil

Tn

ndremedy

Coolmg

System

b

r

h

j

I

m

p

q

d

REMEDIES

SYMI

IOMS

b

Drlm

oiJ

nd

rcpl

ce

with

ot

Add

smlll

quanllty

n

oil

to

the

fuel

Ind

rune

lmeFnd

d

SlfIpenJine

Ind

renew

p

ru

asn

celllry

I

bed

t

f

I

h

I

i

k

I

mn

0

OVERHEATING

ENGINE

FAILS

TO

REAOI

NORMAL

OPERATING

TEMPERAt

lRE

PROIAILE

CAUSE

REMEDIES

I

RetUne

enJine

h

Trace

ndseal

Tr

Ind

seal

j

RemO

f

t

rellnction

k

Relnnd

sel

I

Freelnd

trice

C

UIe

m

Renewguke

Fit

new

clmlhlrt

AdJult

t

appeti

p

bch

ngeenfin

q

Replacevalnluldes

Rtplace

seall

Repllccgukel

Repllcc

plulwlth

correct

Cl

Ie

Renew

cyhndcrblock

Repllce

5prLnp

I

IlIIIIfficien

coolant

b

DriYebellllippinIOfbrobn

c

RldiatOf

fUll

cloq

ed

d

Coo

inlflndefeclln

e

Wit

pl1mpdtfectlve

f

ThelTllOllatj

mmed

Ihul

Thermost

j

mmed

open

r

t

eti

I

kt

r

re

a

q

brake

j

lntel1laJp

se

lheenpne

ndforradi

torbloeked

11

HOItI

blocked

I

Carburetterm

djullmem

m

Excellive

arbon

depolit

in

thecylinden

In

ffici

enpneoil

uae

of

inferior

p1Ide

of

oil

Exce

inrldi

lorlrea

I

Topupradil

v

b

Ti

htenbdtorftnc

I

t

rmify

e

Repl

cwaterpump

f

Rcpll

e

thermoltll

I

Replleclhermolt

t

h

RetimeiaTUlion

i

Unload

ear

check

brl

ktt

j

Trace

ndclu

k

TfI

cdUrblockaae

L

AdjUllcorrc

cth

m

Decarbonise

fO

tne

top

overh

uJ

Top

up

wlth

correct

rade

Dr

inifneceUlry

PUIl

lly

blink

off

in

winter

only

Page 127 of 171

Trouble

Shooting

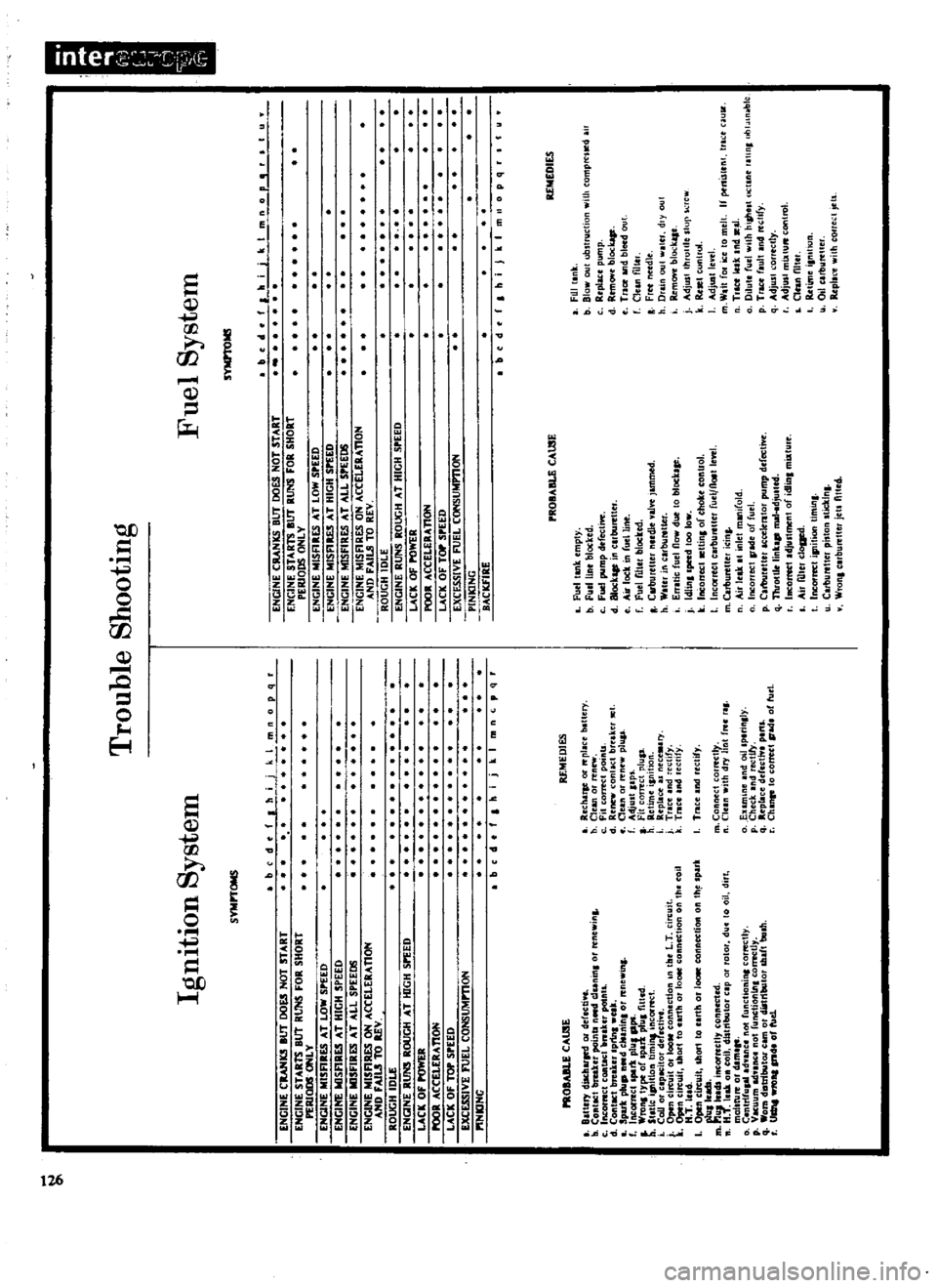

Ignition

System

SYMnONS

be

d

t

f

I

h

ENGINE

CRANKS

IUT

DOES

NOT

nART

ENGINE

STARTS

BUT

RUNS

FOR

SHORT

PERIODS

ONLY

ENGINE

MISfiRES

AT

LOW

SPEED

ENCINE

WlSflRES

AT

HIGH

SPEED

ENGINE

MISFIRES

AT

ALL

SPEEDS

ENCINE

MISfiRES

ON

ACCELERATION

AND

FAI

TO

REV

ROUGH

IDLE

ENGINE

RUNS

ROUCH

AT

toGH

SPEED

UCK

OF

POWER

POOR

ACCELERAnON

LACK

OF

TOP

SPEED

EXCESSIVE

FUEL

CONSUMmON

PlNKlNC

PROBABLE

CAU5E

t

Bani

dilcharFd

01

defective

b

COJlIllCl

nabr

poinb

nCiCCl

c1Unlftl

renewlna

c

Incorrect

cantlel

ltn

ktr

potftu

d

ConllCt

maker

Iprtn

wuk

Spark

plup

n

d

ch

ntnl

nnewlJIl

r

Jncorrec

llpulpl1llPpI

WronllypeoCap

rtpllllflttad

h

Slltlc

I

lllon

limina

Incorrect

I

Coli

c

plCilor

defC

tl

t

g

o

o

c

o

c

t1o

t

n

h

CllIl

the

toil

H

T

lud

I

Open

cimail

lIlort

nnh

1

conneclion

Ih

spart

m

l

1ulludslnCClfRcllyc

oIIJlCC

tcd

H

T

Ink

coil

dbtribulor

elp

due

oil

din

mol

t

I

o

d

ml

C

ntrlfuplld

anee

not

unetionln

eOll

lctly

p

VKuum

Id

e

not

funclionill

cOIYKtly

q

om

datrlbutw

elm

Or

4iltributor

dldt

bluh

I

UllntWJlOlllpldl

off

ld

L

i

k

I

m

no

p

q

I

b

m

q

f

h

i

j

REMEDIES

I

aceh

tJe

oc

pllce

blHery

b

Clean

01

n

c

Fi

wrrecl

poin

d

Renew

blnker

ll

t

Clea

l

l

ne

plllll

f

Adjull

pt

Fit

cor

c

plu

l

h

aetUne

i

mtlon

I

a

plaCf

I

nece

r

j

Trice

Ind

recury

k

True

ndlecfity

Tnee

nd

leclity

m

Con

c

cOI

ct1r

Clca

wIth

dry

hn

fne

rl

EllImlne

and

Oillpllln

ly

p

Cheek

Ind

rectlly

q

aepllccddectkol

plnl

r

Chlnp

comct

Il

adl

of

fuel

Fuel

System

ENGINE

CRANKS

8lTf

DOES

NOT

START

ENGINE

STARTS

BUT

RUNS

FOR

SHORT

PERIODS

ONLY

ENGINE

MISARES

AT

LOW

SPEED

ENGINE

MISflRE5

AT

HIGH

SPEED

ENGINE

MISFIRES

AT

ALL

SPEEDS

ENGINE

MISAKES

ON

ACCELERA110N

AND

FAILS

TO

REV

ROUGH

IDLE

ENGINE

RUNS

ROUGH

AT

HIGH

SPEED

LACK

OF

POWER

POOR

ACCELERA110N

LACK

OF

TOP

SPEED

EXCESSIVE

flJEL

CONSUMmON

PINKING

BACKFIRE

PROBABLE

CAU5E

Fuel

tank

empty

b

Fu

llinc

blocked

Fuel

pumpd

fectiYe

d

Block

in

cllburene

Air

lock

in

fuel

line

f

Fuel

rut

r

blocked

I

Cuburetter

needle

nlve

jammed

h

Wile

CI

buRlt

r

Errltic

fllel

now

due

blocka

j

IdlinJlpeed

too

low

k

InConectlCtllnlofcttoke

conllol

1

lncorrectcarbuntterfuel

nOltlewl

m

C

muretler

Itlna

Ail

leak

It

Inlet

mlrurold

Incorrect

pade

offuet

p

Carburetter

accelerator

pumpdefect

e

q

Throlll

lintl

rrlIIl

djUlled

IncofftCl

Idjullmenl

of

IdlmJ

mutU

e

Aif

nltef

elogcd

Incorm

t

lpiitiOlluminJ

Clrburellel

Pll

un

lIitkln

Wron

cllburenerjetl

Atled

YMPtO

I

bell

f

1

h

I

j

k

I

m

nOli

I

I

I

0

b

f

h

i

J

k

I

m

REMEDIES

q

FLllllnk

b

Blow

ObSIf1rCllUll

ilh

compl

t

lIed

R

pll

pump

d

RemO

l

e

blockaJe

Trace

Uld

bleed

QUI

r

CIUl1fi1tef

K

Fretne

dle

h

Drlln

d

yout

Removeblockq

J

Adju

throlllelfOl

k

Reset

conllol

1

AdjUSlle

e

m

Wlit

fOI

melt

If

pt

nLS

n

nu

Tlact

lelklndse

a1

Dllu

e

fuel

with

hlah

I

rllln

ubl

ln

blc

p

Trace

fault

and

reeufy

q

AdjuII

correelly

Adju

mutufWconlrol

Clnnnlttr

Retjme

Ilftn

OdClrbulelle

Repllce

Wllh

Je

Page 134 of 171

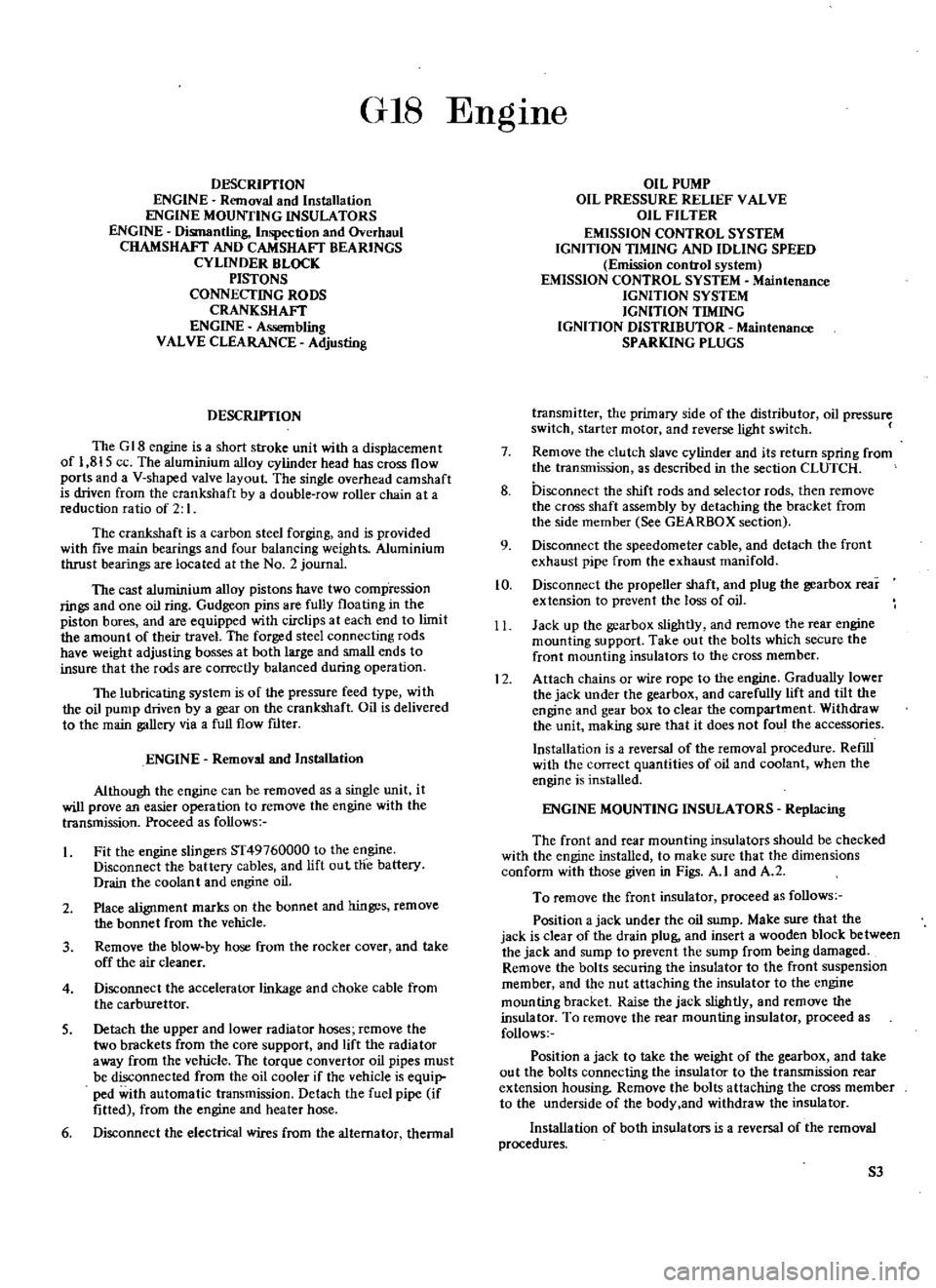

GIS

DESCRIYfION

ENGINE

Removal

and

Installation

ENGINE

MOUNTING

INSULATORS

ENGINE

Dismantling

Inspection

and

Overhaul

CHAMSHAFT

AND

CAMSHAFT

BEARINGS

CYLINDER

BLOCK

PISTONS

CONNECTING

RODS

CRANKSHAFT

ENGINE

Assembling

VALVE

CLEARANCE

Adjusting

DESCRIYfION

The

G

18

engine

is

a

short

stroke

unit

with

a

displacement

of

1

815

ce

The

aluminium

alloy

cylinder

head

has

cross

flow

ports

and

a

V

shaped

valve

layout

The

single

overhead

camshaft

is

driven

from

the

crankshaft

by

a

double

row

roller

chain

at

a

reduction

ratio

of

2

I

The

crankshaft

is

a

carbon

steel

forging

and

is

provided

with

five

main

bearings

and

four

balancing

weights

Aluminium

thrust

bearings

are

located

at

the

No

2

journal

The

cast

aluminium

alloy

pistons

have

two

comp

ression

rings

and

one

oil

ring

Gudgeon

pins

are

fully

floating

in

the

piston

bores

and

are

equipped

with

circlips

at

each

end

to

limit

the

amount

of

their

travel

The

forged

steel

connecting

rods

have

weight

adjusting

bosses

at

both

large

and

small

ends

to

insure

that

the

rods

are

correctly

balanced

during

operation

The

lubricating

system

is

of

the

pressure

feed

type

with

the

oil

pump

driven

by

a

gear

on

the

crankshaft

Oil

is

delivered

to

the

main

gallery

via

a

full

flow

ftlter

ENGINE

Removal

and

Installation

Although

the

engine

can

be

removed

as

a

single

unit

it

will

prove

an

easier

operation

to

remove

the

engine

with

the

transmission

Proceed

as

follows

Fit

the

engine

slingers

ST49760000

to

the

engine

Disconnect

the

battery

cables

and

lift

out

the

battery

Drain

the

coolant

and

engine

oil

2

Place

alignment

marks

on

the

bonnet

and

hinges

remove

the

bonnet

from

the

vehicle

3

Remove

the

blow

by

hose

from

the

rocker

cover

and

take

off

the

air

cleaner

4

Disconnect

the

accelerator

linkage

and

choke

cable

from

the

carburettor

S

Detach

the

upper

and

lower

radiator

hoses

remove

the

two

brackets

from

the

core

support

and

lift

the

radia

tor

away

from

the

vehicle

The

torque

convertor

oil

pipes

must

be

disconnected

from

the

oil

cooler

if

the

vehicle

is

equip

ped

with

automatic

transmission

Detach

the

fuel

pipe

if

fitted

from

the

engine

and

heater

hose

6

Disconnect

the

electrical

wires

from

the

alternator

thennal

EngIne

OIL

PUMP

OIL

PRESSURE

RELIEF

VALVE

OIL

FILTER

EMISSION

CONTROL

SYSTEM

IGNITION

TIMING

AND

IDLING

SPEED

Emission

control

system

EMISSION

CONTROL

SYSTEM

Maintenance

IGNITION

SYSTEM

IGNITION

TIMING

IGNITION

DISTRIBUTOR

Maintenance

SPARKING

PLUGS

transmitter

the

primary

side

of

the

distributor

oil

pressure

switch

starter

motor

and

reverse

light

switch

7

Remove

the

clutch

slave

cylinder

and

its

return

spring

from

the

transmission

as

described

in

the

section

CLUTCH

8

Disconnect

the

shift

rods

and

selector

rods

then

remove

the

cross

shaft

assembly

by

detaching

the

bracket

from

the

side

member

See

GEARBOX

section

9

Disconnect

the

speedometer

cable

and

detach

the

front

exhaust

pipe

from

the

exhaust

manifold

10

Disconnect

the

propeller

shaft

and

plug

the

gearbox

rear

extension

to

prevent

the

loss

of

oil

11

Jack

up

the

gearbox

slightly

and

remove

the

rear

engine

mounting

support

Take

out

the

bolts

which

secure

the

front

mounting

insulators

to

the

cross

member

12

Attach

chains

or

wire

rope

to

the

engine

Gradually

lower

the

jack

under

the

gearbox

and

carefully

lift

and

tilt

the

engine

and

gear

box

to

clear

the

compartment

Withdraw

the

unit

making

sure

that

it

does

not

foul

the

accessories

Installation

is

a

reversal

of

the

removal

procedure

RefIll

with

the

correct

quantities

of

oil

and

coolant

when

the

engine

is

installed

ENGINE

MOUNTING

INSULATORS

Replacing

The

front

and

rear

mounting

insulators

should

be

checked

with

the

engine

installed

to

make

sure

that

the

dimensions

conform

with

those

given

in

Figs

A

I

and

A

2

To

remove

the

front

insulator

proceed

as

follows

Position

a

jack

under

the

oil

sump

Make

sure

that

the

jack

is

clear

of

the

drain

plug

and

insert

a

wooden

block

between

the

jack

and

sump

to

prevent

the

sump

from

being

damaged

Remove

the

bolts

securing

the

insulator

to

the

front

suspension

member

and

the

nut

attaching

the

insulator

to

the

engine

mounting

bracket

Raise

the

jack

slightly

and

remove

the

insulator

To

remove

the

rear

mounting

insulator

proceed

as

follows

Position

a

jack

to

take

the

weight

of

the

gearbox

and

take

out

the

bolts

connecting

the

insulator

to

the

transmission

rear

extension

housing

Remove

the

bolts

attaching

the

cross

member

to

the

underside

of

the

body

and

withdraw

the

insulator

Installation

of

both

insulators

is

a

reversal

of

the

removal

procedures

S3

Page 144 of 171

carrying

out

extensive

tests

with

the

necessary

equipment

The

hoses

and

connectors

can

of

course

be

checked

for

signs

of

leakage

and

corrected

as

necessary

Also

the

tension

of

the

air

pump

belt

IGNITION

TIMING

AND

IDLING

SPEED

Emission

control

system

The

ignition

timing

should

be

set

and

the

idling

speed

mixture

adjusted

in

the

folloWing

manner

Run

the

engine

until

it

reaches

its

normal

operating

tem

perature

Connect

an

ignition

tachometer

and

timing

light

observ

ing

the

manufacturers

instructions

NOTE

If

the

vehicle

is

equipped

with

automatic

transmission

make

sure

that

the

dashpot

does

not

prevent

the

throttle

from

closing

Turn

the

throttle

shaft

arm

adjusting

screw

anti

clock

wise

so

that

the

tip

of

the

screw

is

clear

of

the

throttle

shaft

arm

see

Fig

A

26

Turn

the

throttle

adjusting

screw

to

set

the

idling

speed

to

700

r

p

m

650

rpm

for

automatic

transmission

Adjust

the

ignition

timing

to

5

A

T

D

C

Refererence

should

be

made

to

the

instructions

given

in

the

section

IGNITION

SYSTEM

for

the

L14

L16

and

LI8

engines

for

ignition

timing

details

Turn

the

idling

adjustment

screw

and

throttle

adjusting

screw

until

the

engine

runs

smoothly

a

t

the

correct

idling

speed

Turn

the

idling

adjustment

screw

clockwise

until

the

engine

speed

starts

to

drop

as

a

weaker

mix

ture

is

obtained

Now

turn

the

idling

adjustment

screw

anti

clockwise

by

one

turn

one

and

a

half

turns

for

automatic

transmission

to

obtain

a

richer

mix

ture

Adjust

the

idling

speed

to

700

rpm

650

rpm

for

automatic

transmission

by

turning

the

throttle

adjusting

screw

Make

sure

that

the

ignition

timing

remains

at

50

A

T

D

C

Turn

the

throttle

shaft

ann

adjusting

screw

clockwise

until

the

tip

of

the

screw

just

contacts

the

throttle

shaft

ann

The

screw

must

not

exert

pressure

on

the

throttle

shaft

arm

EMISSION

CONTROL

SYSTEM

Maintenance

The

system

should

be

inspected

and

serviced

every

I

2

months

or

20

000

km

12

000

miles

whichever

comes

fIrst

to

make

sure

that

the

exhaust

emissions

are

maintained

at

the

minimum

level

Check

the

carburettor

choke

setting

and

adjust

as

described

in

the

section

FUEL

SYSTEM

Check

the

carburettor

idling

speed

mixture

and

adjust

if

necessary

as

described

under

the

heading

IGNITION

TIMING

AND

IDLING

SPEED

in

this

section

2

Check

the

distributor

earn

dwell

angle

and

also

the

condi

tion

of

the

contact

breaker

points

Check

the

ignition

timing

and

adjust

if

necessary

The

distributor

dwell

angle

should

be

adjusted

to

49

55

degrees

and

the

points

gap

to

0

45

0

55

mm

0

0177

0

0217

in

3

Remove

and

clean

the

sparking

plugs

Renew

any

plug

with

badly

worn

electrodes

Set

the

plug

gaps

to

0

80

0

90

mm

0

0315

0

0355

in

by

adjusting

the

earth

electrode

IGNITION

SYSTEM

The

maintenance

and

servicing

procedures

for

the

compo

nents

of

the

ignition

system

on

vehicles

fitted

with

the

GIS

engine

are

basically

similar

to

the

instructions

previously

given

for

the

Ll4

LI6

and

LIS

engines

The

distributor

is

however

of

a

different

type

Either

an

Hitachi

0416

57

distributor

being

fitted

or

an

Hitachi

0423

53

if

the

vehicle

is

equipped

with

an

emission

control

system

The

distributors

have

different

advance

curve

characteristics

as

shown

in

Technical

Data

IGNITION

TIMING

Check

the

ignition

timing

with

a

timing

light

as

previously

described

for

the

LI4

L16

and

L

8

engines

Disconnect

the

distributor

vacuum

line

and

run

engine

at

idling

speed

or

slightly

below

The

timing

should

be

set

at

8

BTDCj600

rpm

for

the

D416

57

distributor

or

at

5

ATDCj600

rpm

for

the

D423

53

distributor

fItted

to

engines

with

emission

control

systems

IGNITION

DISTRIBUTOR

Maintenance

Maintenance

instructions

are

similar

to

those

given

for

the

L14

LI6

and

L18

engines

Set

the

contact

breaker

points

gap

to

0

45

0

55

mm

0

0177

0

0217

in

as

previously

described

SPARKING

PLUGS

The

sparking

plugs

should

be

inspected

and

cleaned

at

regular

intervals

and

renewed

at

approximately

20

000

kIn

12

000

miles

Clean

the

plugs

thoroughly

and

make

sure

they

are

of

the

same

type

and

heat

range

File

the

centre

electrode

nat

before

adjusting

the

gap

Set

the

gap

to

0

8

0

9mm

0

031

0

035

in

if

the

engine

is

fItted

with

emission

control

system

or

to

0

7

0

8

mm

0

028

0

031

in

if

emission

control

is

not

fitted

Adjustment

must

always

be

made

by

bending

the

earth

electrode

TechnIcal

Data

GENERAL

SPECIFICATION

GI8

Engine

Cylinders

Bore

and

stroke

Displacemen

t

Valve

arrangemen

t

Firing

order

Engine

idler

speed

Compression

ratio

Oil

pressure

at

3000

r

p

m

4

in

line

85x80

mm

3

346x3

150

in

1

815

cc

110

8

cu

in

OHC

134

2

600

r

p

m

STD

8

3

I

4

7

to

5

5

kgjsq

cm

66

8

to

78

2

Ibjsq

in

LIQUID

PACKING

APPLICATION

Cylinder

block

2

Cylinder

head

Oil

gallery

blind

plug

Expansion

plug

Gas

breather

guide

Rear

bearing

cap

fitting

surface

Rear

bearing

cap

side

seal

both

ends

Expansion

plug

Rubber

plug

Rea

Manifold

heat

pipe

3

Chain

cover

gasket

both

sides

S13

Page 148 of 171

Fan

coupling

Pulley

ratio

fan

and

water

pump

Tuning

data

Basic

timing

Idling

speed

Distributor

dwell

angle

Spark

plug

gap

Choke

setting

CO

percent

setting

Fan

rpm

water

pump

rpm

3

300

4

000

120

103

Ll71

50

A

T

D

C

700

rpm

650

rpm

automatic

490

550

at

0

02

in

breaker

gap

0

8IJ

0

90

mm

0

03

I

5

0

0355

in

Manual

6

0

I

0

5

air

supply

hose

disconnected

Air

pump

drive

belt

tensioning

Permissible

slackness

of

8

0

12

0

mm

0

3

15

0

4

72

in

under

a

load

of7

1O

kg

1

54

2

20

lb

IGNITION

SYSTEM

DISTRIBUTOR

Type

Firing

order

Rotation

Igntion

timing

Without

emission

control

With

emission

control

Dwell

angle

Condenser

capacity

Advance

characteristics

D416

57

distributor

Hitachi

D416

57

Hitachi

D423

53

with

emission

control

system

134

2

Anti

clockwise

80

B

T

D

C

at

600

rpm

50

A

T

D

C

at

600

r

p

m

49

to

55

degreos

0

20

0

24

1

F

Centrifugal

Start

Maximum

degree

r

p

m

Vacuum

Start

Maximum

degree

r

p

m

Advance

characteristics

D423

53

distributor

Centrifugal

Start

Maximum

degree

r

p

m

Vacuum

Start

Maximum

degree

r

p

m

IGNITION

COIL

Type

Primary

voltage

Spark

gap

Primary

resistance

Secondary

resistance

SPARKING

PLUGS

Type

Gap

Fuel

Systenl

DESCRIPTION

FUEL

PUMP

Testing

FUEL

PUMP

Removing

and

Dismantling

CARBURETTOR

Idling

adjustment

FUEL

LEVEL

Adjusting

STARTING

INTERLOCK

VALVE

OPENING

THROTTLE

VALVE

INTERLOCK

OPENING

CARBURETIOR

Removing

and

Dismantling

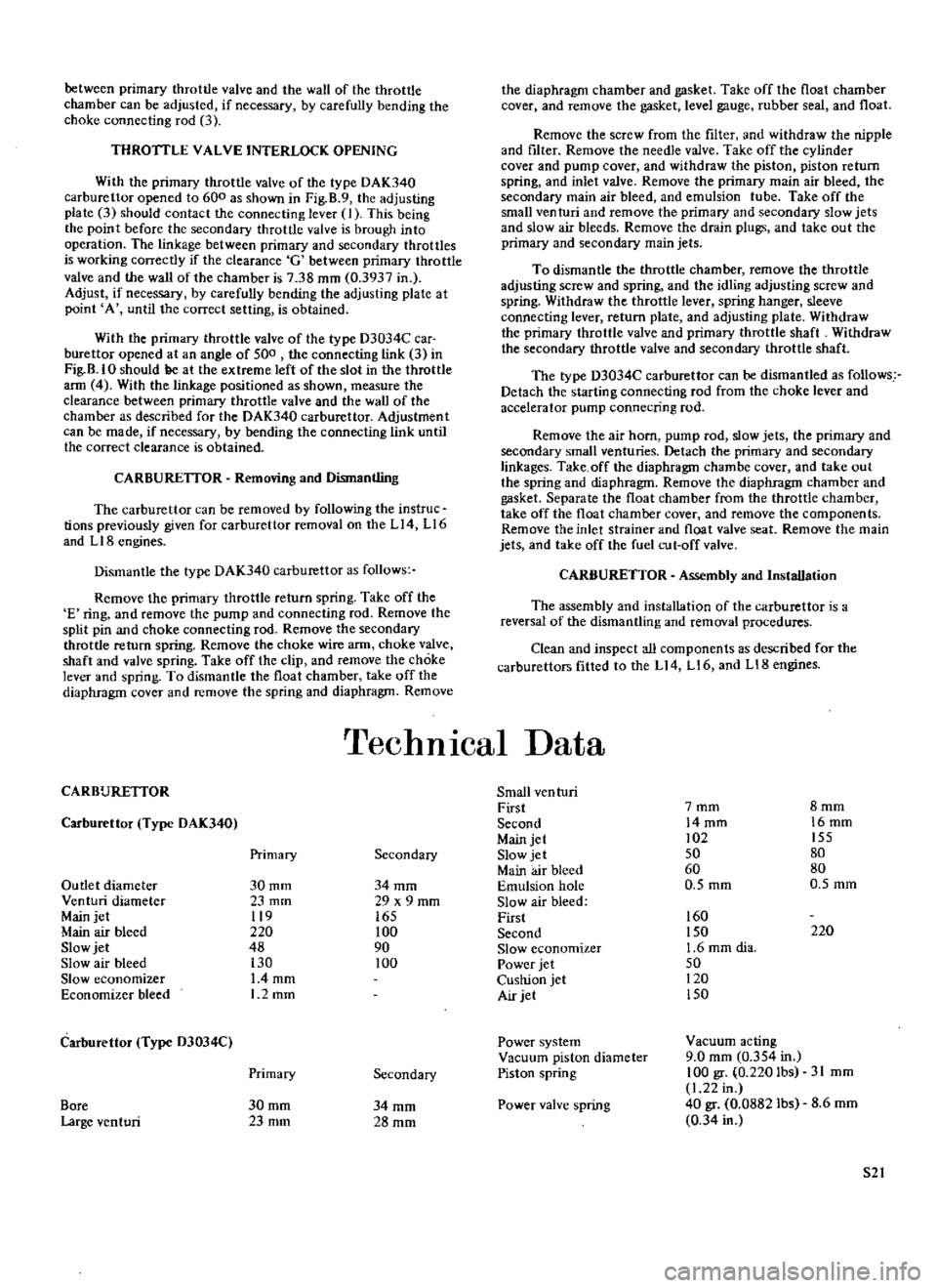

DESCRIPTION

A

dual

barrel

down

draught

type

carburettor

is

fitted

to

vehicles

with

the

G

18

engine

A

Stromberg

type

D3034C

carburet

tor

is

installed

on

engines

with

exhaust

emission

controL

and

a

Solex

type

DAK340

carburettor

on

engines

not

equipped

with

this

type

of

system

Both

types

of

carburettors

incorporate

a

550

r

p

m

01

50

at

I

400

16

50

at

2

800

80

mmHg

6

50

at

200

r

p

m

475

r

p

m

01

50

at

1

000

23

50

at

2

600

80

mm

Hg

30

at

120

r

p

m

go

at

400

r

p

m

Hanshin

HM

12F

or

HP5

I

OE

with

emission

control

system

12

volts

more

than

6

mm

0

2362

in

3

8

ohms

at

200C

I

1

2

I

6

8

ohms

at

200

C

NGK

BP

6E

0

7

0

8

mm

0

028

0

031

in

or

0

80

9

mm

0

031

0

035

in

with

emission

control

system

primary

system

for

normal

running

and

a

secondary

system

for

full

load

running

a

float

assembly

which

supplies

fuel

to

both

primary

and

secondary

systems

a

starting

mechanism

and

accelerator

pump

which

provides

a

richer

mixture

on

accelera

tion

SI7

Page 149 of 171

1

D

1

1

I

i

l

I

1

j

j

w

n

I

UJ

1

j

e

tOll

i

j25z

t2JZ2

21

1

S

Mizin

nozzk

2

S

SmtzJJ

v

nturi

3

S

Main

air

bleed

4

S

Slow

jet

5

S

Slow

air

bleed

6

Needle

WIlve

7

Float

8

S

Emulsion

tube

9

S

Mainjd

10

S

Jly

paD

hol

11

S

Throttle

alve

12

Chob

I1tzhe

13

P

Main

air

bleed

14

P

Afuin

nozzle

15

Economizer

bleed

16

P

Slow

jet

17

Slow

onomiur

18

P

Slow

air

bleed

19

Airl

e

nt

20

Lnel

gauge

21

PMainjel

22

Idle

limitler

23

1dl

24

P

Jly

pa

hol

2S

P

Throttle

vahe

Fig

B

l

Sectional

view

of

the

DAK340

carburettor

Coil

Piiton

Strainer

v

cero

Fig

S

3

Electrical

fuel

pump

SI8

A

It

I

IL

o

l

Cfd

rj

1

l

o

j

11

111

r

J

l

l

b

I

1

1

F700

t

vahle

2

Vacuum

piJton

3

P

Slow

air

bleed

4

Slow

jtt

5

Slow

onomUt

T

6

P

Slow

air

bleM

7

Air

Fent

8

P

Main

air

bl

d

9

P

MiJin

nozzle

10

P

SmaU

venturi

1

J

Ozokt

valPe

12

Pumpnozzk

13

Pump

wd6h1

14

Discharft

check

valve

15

S

SnwU

venturi

17

S

Main

air

bleed

18

Step

air

bleed

19

Pump

arm

Fig

B

2

Sectional

view

of

the

D3034C

carburet

tor

fitted

to

engines

with

emiss

ion

control

5Y5tem

20

Step

jet

21

Pump

plunger

22

Inlet

c1r

k

l

aIve

23

S

Mizin

jet

24

lRtzp

uaun

25

lRtzplrragm

26

Step

port

27

Idle

port

28

P

T1vottk

valve

29

Idk

port

30

S

Dw

port

31

Idkadjust

screw

32

P

MiIin

jet

33

Po

NU

jet

34

Float

I

Ul

l

2

1

Fibre

mat

Nvlon

6

Fig

B

4

Fuel

strainer

Fig

Ii

s

Removing

the

fuel

pump

cover

1

Page 150 of 171

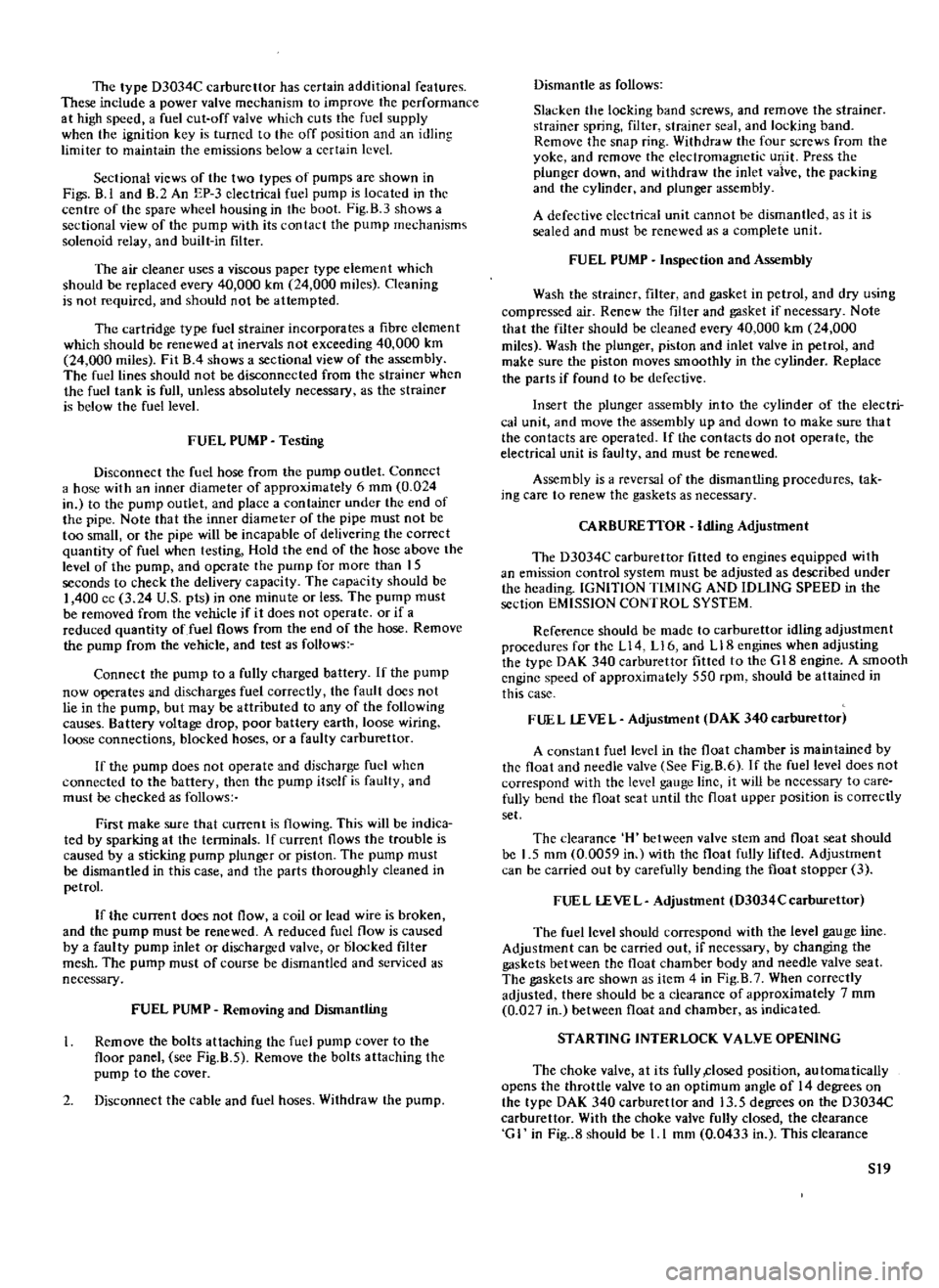

The

type

D3034C

carburettor

has

certain

additional

features

These

include

a

power

valve

mechanism

to

improve

the

performance

at

high

speed

a

fuel

cut

off

valve

which

cuts

the

fuel

supply

when

the

ignition

key

is

turned

to

the

off

position

and

an

idling

limiter

to

maintain

the

emissions

below

a

certain

level

Sectional

views

of

the

two

types

of

pumps

are

shown

in

Figs

8

1

and

B

2

An

EP

3

electrical

fuel

pump

is

located

in

the

centre

of

the

spare

wheel

housing

in

the

boot

Fig

B

3

shows

a

sectional

view

of

the

pump

with

its

contact

the

pump

mechanisms

solenoid

relay

and

built

in

filter

The

air

cleaner

uses

a

viscous

paper

type

element

which

should

be

replaced

every

40

000

km

24

000

miles

Cleaning

is

not

required

and

should

not

be

attempted

The

cartridge

type

fuel

strainer

incorporates

a

fibre

clement

which

should

be

renewed

at

inervals

not

exceeding

40

000

km

24

000

miles

Fit

B

4

shows

a

sectional

view

of

the

assembly

The

fuel

lines

should

not

be

disconnected

from

the

strainer

when

the

fuel

tank

is

full

unless

absolutely

necessary

as

the

strainer

is

below

the

fuel

level

FUEL

PUMP

Testing

Disconnect

the

fuel

hose

from

the

pump

outlet

Connect

a

hose

with

an

inner

diameter

of

approximately

6

mm

0

024

in

to

the

pump

outlet

and

place

a

container

under

the

end

of

the

pipe

Note

that

the

inner

diameter

of

the

pipe

must

not

be

too

small

or

the

pipe

will

be

incapable

of

delivering

the

correct

quantity

of

fuel

when

testing

Hold

the

end

of

the

hose

above

the

level

of

the

pump

and

operate

the

pump

for

more

than

IS

seconds

to

check

the

delivery

capacity

The

capacity

should

be

I

400

cc

3

24

U

S

pts

in

one

minute

or

less

The

pump

must

be

removed

from

the

vehicle

if

it

does

not

operate

or

if

a

reduced

quantity

of

fuel

flows

from

the

end

of

the

hose

Remove

the

pump

from

the

vehicle

and

test

as

follows

Connect

the

pump

to

a

fully

charged

battery

If

the

pump

now

operates

and

discharges

fuel

correctly

the

fault

does

not

lie

in

the

pump

but

may

be

attributed

to

any

of

the

following

causes

Battery

voltage

drop

poor

battery

earth

loose

wiring

loose

connections

blocked

hoses

or

a

faulty

carburettor

If

the

pump

does

not

operate

and

discharge

fuel

when

connected

to

the

battery

then

the

pump

itself

is

faulty

and

must

be

checked

as

follows

First

make

sure

that

current

is

flowing

This

will

be

indica

ted

by

sparking

at

the

tenninals

If

current

flows

the

trouble

is

caused

by

a

sticking

pump

plunger

or

piston

The

pump

must

be

dismantled

in

this

case

and

the

parts

thoroughly

cleaned

in

petrol

If

the

current

does

not

flow

a

coil

or

lead

wire

is

broken

and

the

pump

must

be

renewed

A

reduced

fuel

flow

is

caused

by

a

faulty

pump

inlet

or

discharged

valve

or

blocked

filter

mesh

The

pump

must

of

course

be

dismantled

and

serviced

as

necessary

FUEL

PUMP

Removing

and

Dismantling

Remove

the

bolts

attaching

the

fuel

pump

cover

to

the

floor

panel

see

Fig

B

S

Remove

the

bolts

attaching

the

pump

to

the

cover

2

Disconnect

the

cable

and

fuel

hoses

Withdraw

the

pump

Dismantle

as

follows

Slacken

the

locking

band

screws

and

remove

the

strainer

strainer

spring

filter

strainer

seal

and

locking

band

Remove

the

snap

ring

Withdraw

the

four

screws

from

the

yoke

and

remove

the

electromagnetic

ulJ

it

Press

the

plunger

down

and

withdraw

the

inlet

vaive

the

packing

and

the

cylinder

and

plunger

assembly

A

defective

eledrical

unit

cannot

be

dismantled

as

it

is

sealed

and

must

be

renewed

as

a

complete

unit

FUEL

PUMP

Inspection

and

Assembly

Wash

the

strainer

filter

and

gasket

in

petrol

and

dry

using

compressed

air

Renew

the

filter

and

gasket

if

necessary

Note

that

the

filter

should

be

cleaned

every

40

000

km

24

000

miles

Wash

the

plunger

piston

and

inlet

valve

in

petrol

and

make

sure

the

piston

moves

smoothly

in

the

cylinder

Replace

the

parts

if

found

to

be

defective

Insert

the

plunger

assembly

into

the

cylinder

of

the

electri

cal

unit

and

move

the

assembly

up

and

down

to

make

sure

tha

t

the

contacts

are

operated

If

the

contacts

do

not

operate

the

electrical

unit

is

faulty

and

must

be

renewed

Assembly

is

a

reversal

of

the

dismantling

procedures

tak

ing

care

to

renew

the

gaskets

as

necessary

CARBURETIOR

Idling

Adjustment

The

D3034C

carburettor

fitted

to

engines

equipped

with

an

emission

control

system

must

be

adjusted

as

described

under

the

heading

IGNITION

TIMING

AND

IDLING

SPEED

in

the

section

EMISSION

CONTROL

SYSTEM

Reference

should

be

made

to

carburettor

idling

adjustment

procedures

for

the

L14

L16

and

LI8

engines

when

adjusting

the

type

DAK

340

carburettor

fitted

to

the

G

18

engine

A

smooth

engine

speed

of

approximately

550

rpm

should

be

attained

in

this

case

FUEL

lEVEL

Adjustment

DAK

340earburettor

A

constant

fuellevcl

in

the

float

chamber

is

maintained

by

the

float

and

needle

valve

See

Fig

8

6

If

the

fuel

level

does

not

correspond

with

the

level

gauge

line

it

will

be

necessary

to

care

fully

bend

the

float

seat

until

the

float

upper

position

is

correctly

set

The

clearance

H

between

valve

stem

and

float

seat

should

be

I

5

mm

0

0059

in

with

the

float

fully

lifted

Adjustment

can

be

carried

out

by

carefully

bending

the

float

stopper

3

FUEL

lEVEL

Adjustment

D3034Ccarburettnr

The

fuel

level

should

correspond

with

the

level

gauge

line

Adjustment

can

be

carried

out

if

necessary

by

changing

the

gaskets

between

the

float

chamber

body

and

needle

valve

seat

The

gaskets

are

shown

as

item

4

in

Fig

B

7

When

correctly

adjusted

there

should

be

a

clearance

of

approximately

7

mm

0

027

in

between

float

and

chamber

as

indicated

STARTING

INTERLOCK

VALVE

OPENING

The

choke

valve

at

its

fully

closed

position

automatically

opens

the

throttle

valve

to

an

optimum

angle

of

14

degrees

on

the

type

DAK

340

carburettor

and

13

5

degrees

on

the

D3034C

carburettor

With

the

choke

valve

fully

closed

the

clearance

G

I

in

Fig

8

should

be

1

I

mm

0

0433

in

This

clearance

S19

Page 152 of 171

between

primary

throttle

valve

and

the

wall

of

the

throttle

chamber

can

be

adjusted

if

necessary

by

carefully

bending

the

choke

connecting

rod

3

THROTILE

VALVE

INTERLOCK

OPENING

With

the

primary

throttle

valve

of

the

type

DAK340

carburettor

opened

to

600

as

shown

in

Fig

B

9

the

adjusting

plate

3

should

contact

the

connecting

lever

J

This

being

the

point

before

the

secondary

throttle

valve

is

brough

into

operation

The

linkage

between

primary

and

secondary

throttles

is

working

correctly

if

the

clearance

G

between

primary

throttle

valve

and

the

wall

of

the

chamber

is

738

mm

0

3937

in

Adjust

if

necessary

by

carefully

bending

the

adjusting

plate

at

point

A

until

the

correct

setting

is

obtained

With

the

primary

throttle

valve

of

the

type

D3034C

car

burettor

opened

at

an

angle

of

500

the

connecting

link

3

in

Fig

B

IO

should

ge

at

the

extreme

left

of

the

slot

in

the

throttle

ann

4

With

the

linkage

positioned

as

shown

measure

the

clearance

between

primary

throttle

valve

and

the

wall

of

the

chamber

as

described

for

the

DAK340

carburettor

Adjustment

can

be

made

if

necessary

by

bending

the

connecting

link

until

the

correct

clearance

is

obtained

CARBURElTOR

Removing

and

Dismantling

The

carburettor

can

be

removed

by

following

the

instruc

tions

previously

given

for

carburettor

removal

on

the

Ll4

L16

and

LIB

engines

Dismantle

the

type

DAK340

carburettor

as

follows

Remove

the

primary

throttle

return

spring

Take

off

the

E

ring

and

remove

the

pump

and

connecting

rod

Remove

the

split

pin

and

choke

connecting

rod

Remove

the

secondary

throttle

return

spring

Remove

the

choke

wire

arm

choke

valve

shaft

and

valve

spring

Take

off

the

clip

and

remove

the

choke

lever

and

spring

To

dismantle

the

float

chamber

take

off

the

diaphragm

cover

and

remove

the

spring

and

diaphragm

Remove

the

diaphragm

chamber

and

gasket

Take

off

the

float

chamber

cover

and

remove

the

gasket

level

gauge

rubber

seal

and

float

Remove

the

screw

from

the

filter

and

withdraw

the

nipple

and

filter

Remove

the

needle

valve

Take

off

the

cylinder

cover

and

pump

cover

and

withdraw

the

piston

piston

return

spring

and

inlet

valve

Remove

the

primary

main

air

bleed

the

secondary

main

air

bleed

and

emulsion

tube

Take

off

the

small

venturi

and

remove

the

primary

and

secondary

slow

jets

and

slow

air

bleeds

Remove

the

drain

plugs

and

take

out

the

primary

and

secondary

main

jets

To

dismantle

the

throttle

chamber

remove

the

throttle

adjusting

screw

and

spring

and

the

idling

adjusting

screw

and

spring

Withdraw

the

throttle

lever

spring

hanger

sleeve

connecting

lever

return

plate

and

adjusting

plate

Withdraw

the

primary

throttle

valve

and

primary

throttle

shaft

Withdraw

the

secondary

throttle

valve

and

secondary

throttle

shaft

The

type

D3034C

carburettor

can

be

dismantled

as

follows

Detach

the

starting

connecting

rod

from

the

choke

lever

and

accelerator

pump

connecting

rod

Remove

the

air

horn

pump

rod

slow

jets

the

primary

and

secondary

small

venturies

Detach

the

primary

and

secondary

linkages

Take

off

the

diaphragm

chambe

cover

and

take

out

the

spring

and

diaphragm

Remove

the

diaphragm

chamber

and

gasket

Separate

the

float

chamber

from

the

throttle

chamber

take

off

the

float

chamber

cover

and

remove

the

components

Remove

the

inlet

strainer

and

float

valve

seat

Remove

the

main

jets

and

take

off

the

fuel

cut

off

valve

CARBURETTOR

Assembly

and

Installation

The

assembly

and

installation

of

the

carburettor

is

a

reversal

of

the

dismantling

and

removal

procedures

Clean

and

inspect

all

components

as

described

for

the

carburettors

fitted

to

the

Ll4

Ll6

and

LI8

engines

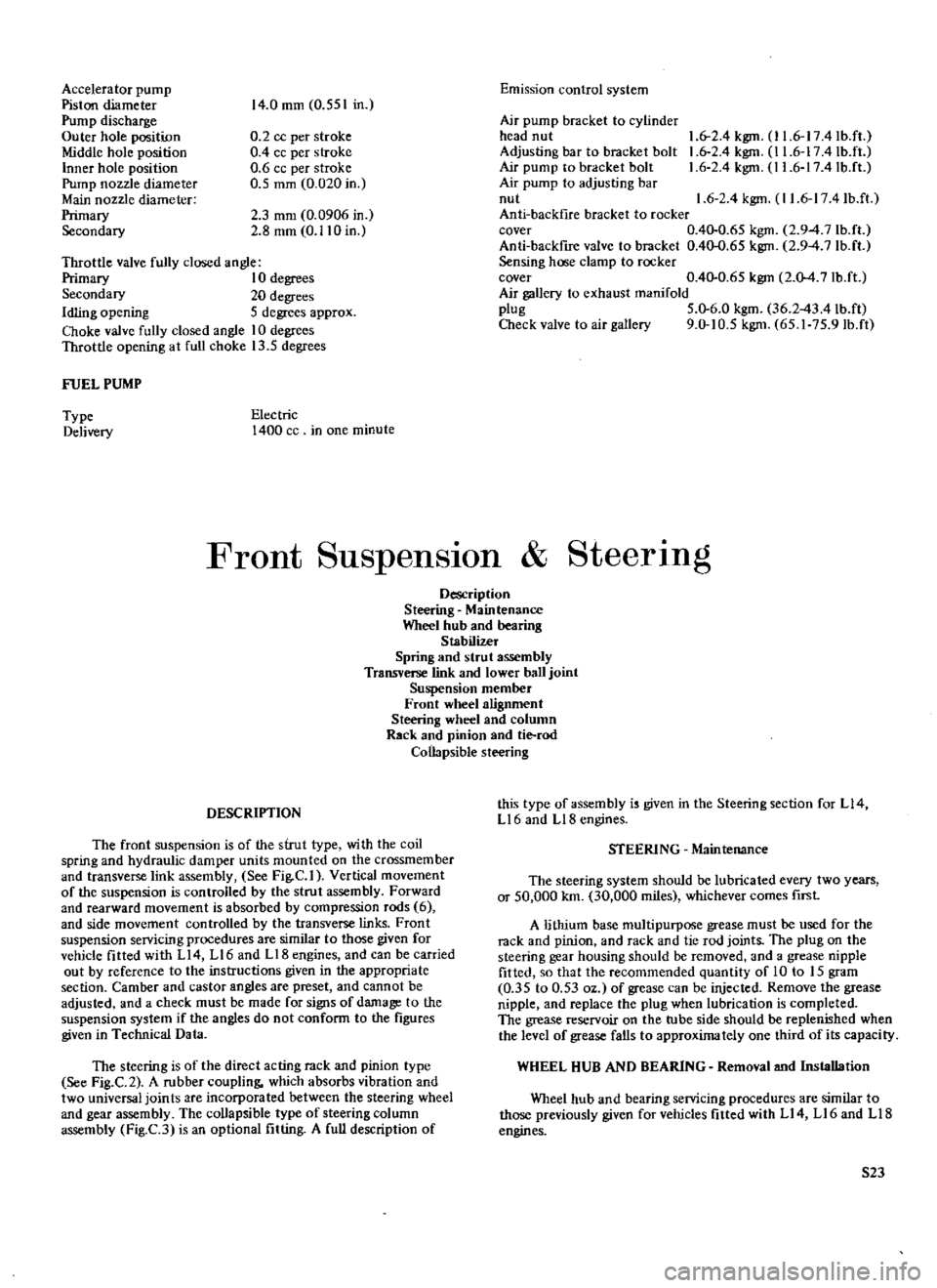

TechnIcal

Data

CARBURETIOR

Small

ven

turi

First

7mm

8mm

Carburettor

Type

DAK340

Second

14mm

16mm

Main

jet

02

155

Primary

Secondary

Slow

jet

50

80

Main

air

bleed

60

80

Outlet

diameter

30mm

34mm

Emulsion

hole

0

5

mm

O

5mm

Venturi

diameter

23

mm

29

x

9

mm

Slow

air

bleed

Main

jet

119

165

First

160

Main

air

bleed

220

100

Second

150

220

Slow

jet

48

90

Slow

economizer

1

6

mm

dia

Slow

air

bleed

130

100

Power

jet

50

Slow

economizer

L4mm

Cushion

jet

120

Economizer

bleed

1

2mm

Air

jet

150

Carburettor

Type

D3034C

Power

system

Vacllum

acting

Vacuum

piston

diameter

9

0

mm

0

354

in

Primary

Secondary

Piston

spring

100

gr

0

220

Ibs

31

mm

1

22

in

Bore

30mm

34mm

Power

valve

spring

40

gr

0

0882

lbs

8

6mm

Large

venturi

23mm

28mm

0

34

in

52

Page 154 of 171

Accelerator

pump

Piston

diameter

Pump

discharge

Outer

hole

position

Middle

hole

position

Inner

hole

position

Pump

nozzle

diameter

Main

nozzle

diameter

Primary

Secondary

14

0

mm

0

551

in

0

2

cc

per

stroke

0

4

cc

per

stroke

0

6

cc

per

stroke

0

5

mm

0

020

in

2

3

mm

0

0906

in

2

8

mm

0

110

in

Throttle

valve

fully

closed

angle

Primary

10

degrees

Secondary

20

degrees

Idling

opening

5

degrees

approx

Choke

valve

fully

closed

angle

10

degrees

Throttle

opening

at

full

choke

13

5

degrees

FUEL

PUMP

Type

Delivery

Electric

1400

cc

in

one

minute

Emission

control

system

Air

pump

bracket

to

cylinder

head

nut

Adjusting

bar

to

bracket

bolt

Air

pump

to

bracket

bolt

Air

pump

to

adjusting

bar

nut

Anti

backfrre

bracket

to

rocker

cover

0

4Q

0

65

kgm

2

94

7

lb

ft

Anti

backfire

valve

to

bracket

0

4Q

O

65

kgm

2

94

7

lb

ft

Sensing

hose

clamp

to

rocker

cover

0

4Q

0

65

kgm

2

M

7

Ib

ft

Air

gallery

to

exhaust

manifold

plug

5

Q

6

0

kgm

36

243

4lb

ft

Check

valve

to

air

gallery

9

0

10

5

kgm

65

1

75

9Ib

ft

1

6

2

4

kgm

I

1

6

17

4Ib

ft

1

6

2

4

kgm

I

1

6

17

4Ib

ft

1

6

2

4

kgm

I

1

6

17

4

lb

ft

1

6

2

4

kgm

11

6

17

4Ib

ft

Front

SuspensIon

SteerIng

Description

Steering

Maintenance

Wheel

hub

and

bearing

Stabilizer

Spring

and

strut

assembly

Transverse

link

and

lower

ball

joint

Suspension

member

Front

wheel

alignment

Steering

wheel

and

column

Rack

and

pinion

and

tie

rod

Collapsible

steering

DESCRIPTION

The

front

suspension

is

of

the

strut

type

with

the

coil

spring

and

hydraulic

damper

units

mounted

on

the

crossmember

and

transverse

link

assembly

See

Fig

C

I

Vertical

movement

of

the

suspension

is

controlled

by

the

strut

assembly

Forward

and

rearward

movement

is

absorbed

by

compression

rods

6

and

side

movement

controlled

by

the

transverse

links

Front

suspension

servicing

procedures

are

similar

to

those

given

for

vehicle

fitted

with

L14

Ll6

and

LIB

engines

and

can

be

carried

out

by

reference

to

the

instructions

given

in

the

appropriate

section

Camber

and

castor

angles

are

preset

and

cannot

be

adjusted

and

a

check

must

be

made

for

signs

of

damage

to

the

suspension

system

if

the

angles

do

not

confonn

to

the

figures

given

in

Technical

Data

The

steering

is

of

the

direct

acting

rack

and

pinion

type

See

Fig

C

2

A

rubber

coupling

which

absorbs

vibration

and

two

universal

join

ts

are

incorpora

ted

between

the

steering

wheel

and

gear

assembly

The

collapsible

type

of

steering

column

assembly

Fig

C3

is

an

optional

fitting

A

full

description

of

this

type

of

assembly

i

given

in

the

Steering

section

for

L14

L16

and

L18

engines

STEERING

Maintenance

The

steering

system

should

be

lubricated

every

two

years

or

50

000

km

30

000

miles

whichever

comes

fIrst

A

lithium

base

multipurpose

grease

must

be

used

for

the

rack

and

pinion

and

rack

and

tie

rod

joints

The

plug

on

the

steering

gear

housing

should

be

removed

and

a

grease

nipple

fitted

so

that

the

recommended

quantity

of

10

to

15

gram

0

35

to

0

53

oz

of

grease

can

be

injected

Remove

the

grease

nipple

and

replace

the

plug

when

lubrication

is

completed

The

grease

reservoir

on

the

tube

side

should

be

replenished

when

the

level

of

grease

falls

to

approximately

one

third

ofits

capacity

WHEEL

HUB

AND

BEARING

Removal

and

Installation

Wheel

hub

and

bearing

servicing

procedures

are

similar

to

those

previously

given

for

vehicles

fitted

with

L14

LI6

and

LIB

engines

S23

Page 168 of 171

MO

MI

1224

D

I

KM

f

fMn

n

r

A

A

JP

I

I

T

I

I

I

Drain

ill

Changeelemenl

I

42

Cleantlement

3

I

II

r

I

Check

il

topup

4

I

Chinnloil

511

1

11

41

Gle

nelern

n

Ii

I

Orainlluid

7

I

I

I

I

Clunertmtn

81

1

I

I

I

I

I

27

Check

ailltop

up

Jf71

r

I

JIO

WI

28

Change

il

I

ill

limittdSlip

DiHlranti

1

Clleck

ilftopup

1J

I

I

I

Changelil

11

i

ill

ShdmgJolntt

Df

YlShlft

Check

11IIOpup

n

II

I

I

ChangeDl1

1

I

I

I

I

SHOCKASSORBERS

Check

Il

topup

5

PROP

DRIVESHAFTISI

lubncate

Hi

1

GREASE

GUN

POINTS

lubnCIl

it

PEOAlSHAFT

Sj

Lubrlc

te

18

HANDBHAKE

lubnc

1t

I

I

r

1

t

R

IINKAl

iF

luhncll

2u

I

I

i

I

ARlUWIORED

WHEELS

FREE

1m

I

I

i

1121

wHEE

L

tll

AHINli

ronl

HepitCk

211

t

f

WHEEl

BEARINGS

Rur

Repack

77

U

I

BRAKE

FLUID

R

nfWfbletd

1

I

lf

13

117

I

t

I

AH

UUWI

f

t1UN

11Itl

ih1tl

1

i

lcl

Check

oillevtl

B

l

r1i

BI1I1I1

r

Cap

Cleen

1ifj

j

I

Air

Cluner

Service

el

m

nt

l

J7

4

Replace

element

l

l

B

L

5

Cteenfilter

1

C

l

I

I

I

4

Clun

va

vellllR

I

I1

I

I

I

Repl

cH

lve

1

I

I

I

I

Cleen

jets

bOM

R

t

I

Top

liP

pisl

dempe

l

I

r

L

LlIbncatelinkages

I

I

L

Ctean

replace

5

j

I

Ch

ckoill

ve1

Ei

l

j

16

Clun

replac

n

11

R

fill

witll

fluid

38

I

Check

fluid

levll

IlL

t

I

CI

ign

toil

t

i

I

t

1

l

9

CheCk

top

u

p

10

Flulhryst

m

y

Cllecksolullon

44

Chltk

45

Lubrlc

tt

46

i

Clleck

top

up

L

L

Check

topup

4

aJdM

Cllltkspet

gl1vity

i

CI

en

gr

1S

liD

116

Lubriclt

1il

If

I

II

Clleck

topup

52

1

i

Chtck

topuplluid

3

I

I

Gre

rlm

4

I

1

I

I

I

Clunfiltlr

55

L

I

I

I

Chick

top

up

fluid

I6

w

W

e

I

ofi

Ldtir

1

Renewfiltlr

58

I

Check

topupflu

d

i91

i

I

i

Renrwfluid

I

I

I

I

I

ilinlil1r

11

I

I

I

I

I

I

CAR

DOWN

E

TERNAL

j

II

1

I

1

lOCKS

HINGES

Ell

Lubrictt

S21

r

1

el

L

Door

Dram

Hol

l

Clun

f

J

I

I

WIPER

SPINDLES

lubrictt

64

W

I

I

En

in

Dil

Filwr

GttrbOK

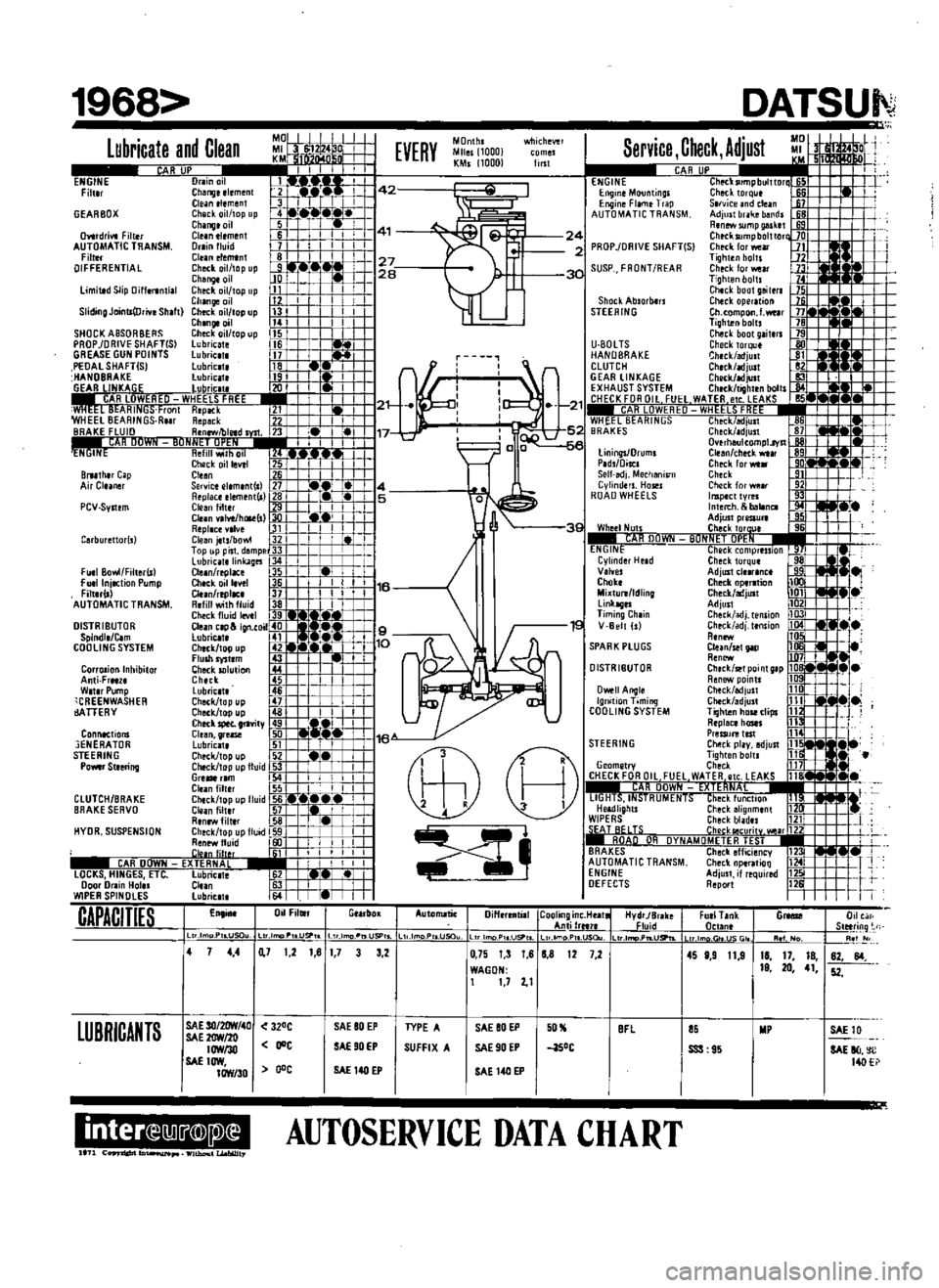

1968

Lubricate

and

Clean

ENGINE

Filt

r

GEARBOX

Dvttdrivt

Filt

r

AUTOMATIC

TRANSM

Filt

r

DIFFERENTIAL

PCV

Syllem

rburettor

s

FUll

Bowl

Filter

S1

Fu

llnjectionPump

Fittll

ll

AUTOMATIC

TRANSM

DISTRIBUTOR

Spindl

Ctm

COOLING

SYSTEM

CorrDlionlnllibitor

Anti

Frltl

W

t

rPump

CREENWASHER

ArrERY

Connections

3ENERATOR

STEERING

POMrStlering

CLUTCH

BRAKE

BRAKE

SERVO

HYDR

SUSPENSION

CAPACITIES

LUBRICANTS

Il

D

P

LUSClu

Service

Check

Adjust

CAR

UP

I

l

lletksumpbulttortM

1

Clled

rque

i6

ServiceJndclean

J1

Adjult

brake

bandl

tB

RtnMsumpgal

tt

fiS

Check

llJmpbnlttort

PROP

lOAIVE

SHAFT

S

Check

lor

wear

JJ

Tiglltenbolu

Jl

Check

tor

wear

n

Tiglltenboltl

Clllckbootgeiltrl

Clleckoperltion

Ch

CQmpon

l

welr

Tighten

bolts

Clleclbootgaiterl

Checktorqu

Gheck

edjult

Clllck

ljust

CIIRCk

adjult

Clleck

tighltnbolts

W

M

KSI

1

t

heCklMliiili

86

Check

ldjust

81

Overllllulcompl

rvll

Cleen

chltkwtlr

R9

Check

for

wear

0

Check

9

Checkforwp

lr

192

Il1Ipecttyrel

1IJ