light DATSUN 610 1969 Owner's Guide

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1969, Model line: 610, Model: DATSUN 610 1969Pages: 171, PDF Size: 10.63 MB

Page 164 of 171

or

C

c

i

CI

7

vc

1

j

k

t

V

f

l

7D

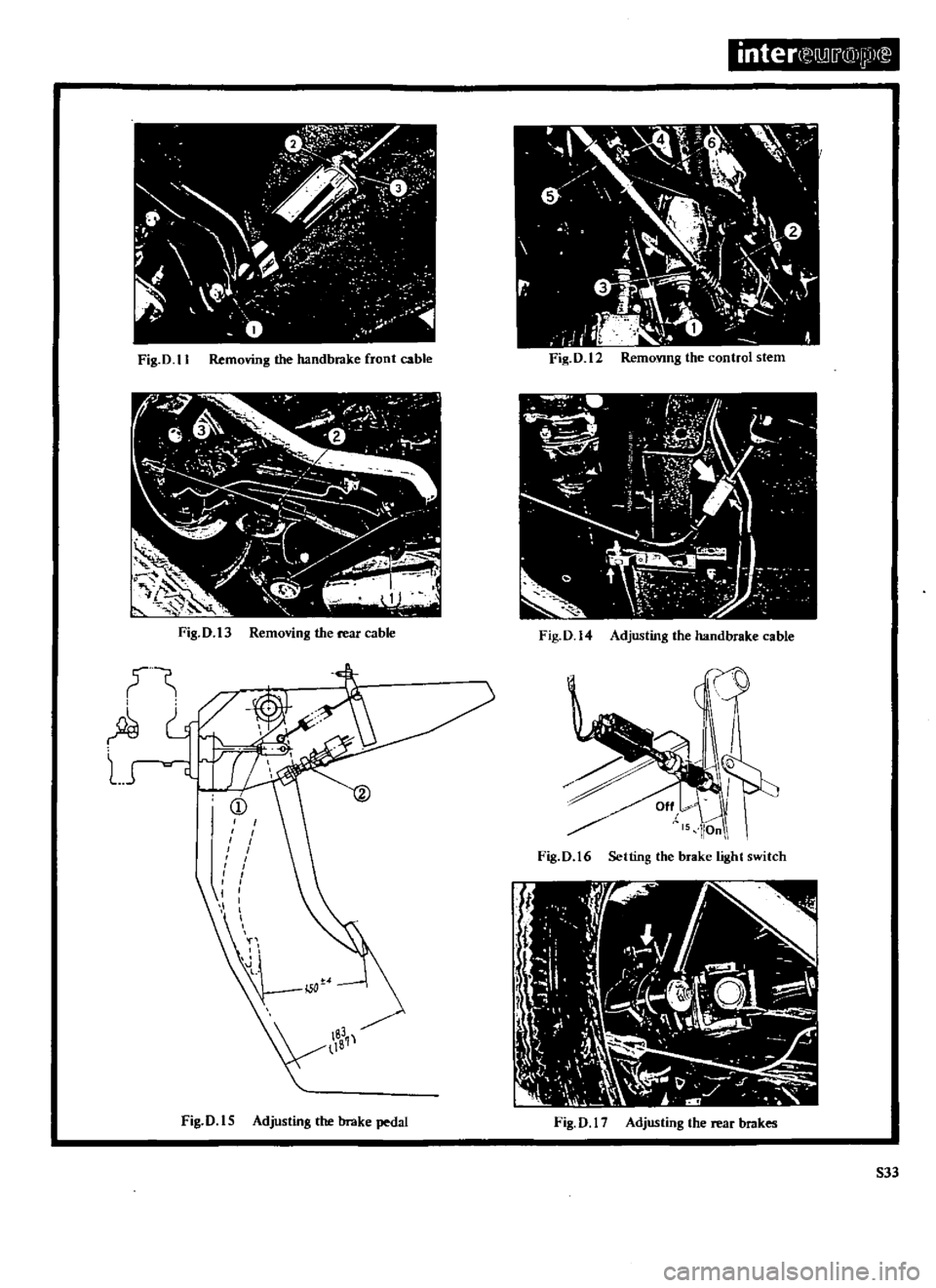

Fig

D

l

t

Removing

the

handbrake

front

cable

Fig

D

13

Removing

the

rear

cable

Jt

A

G

L

J

CD

I

I

I

I

I

I

I

I

I

I

1

l

I

lSOt4

831

B

Fig

D

S

Adjusting

the

brnke

pedal

J

Fig

D

14

Adjusting

the

handbrake

cable

Fig

D

16

Setting

the

brake

light

switch

Fig

D

I7

Adjusting

the

rear

brakes

S33

Page 165 of 171

Clamp

the

flange

and

bolt

assembly

in

a

vice

Push

the

rear

shell

and

stud

assembly

down

and

turn

it

anti

clockwise

to

release

Take

care

not

to

drop

the

valve

body

and

di

phrd

gm

plate

which

will

be

detached

at

the

same

time

Remove

the

retainer

and

detach

the

bearing

and

seal

from

the

rear

shelL

A

needle

can

be

used

to

remove

the

retainer

Pull

the

diaphragm

from

the

groove

in

the

diaphragm

plate

Remove

the

valve

body

guard

and

the

air

silencer

See

Fig

0

8

Remove

the

valve

plunger

stop

key

Fig

D

9

detach

the

valve

rod

and

plunger

assembly

and

the

air

silencer

fllter

from

the

valve

body

and

diaphragm

plate

Pull

out

the

reaction

di

c

To

dismantle

the

front

shell

and

stud

assembly

first

pull

out

the

push

rod

then

remove

the

plate

and

seal

and

the

check

valve

MASfER

V

AC

SERVO

UNIT

Assembling

inspect

the

components

and

replace

any

which

show

signs

of

wear

or

damage

As

previously

stated

the

repair

kit

contains

a

number

of

items

which

must

be

used

to

replace

the

original

parts

Assembly

is

a

reversal

of

the

dismantling

procedure

but

the

following

components

should

be

lubricated

with

silicon

grease

Grease

the

lip

and

face

of

the

seal

the

lip

of

the

poppet

both

faces

of

the

reaction

disc

Grease

the

diaphragm

edge

in

contact

with

the

front

and

rear

shell

Grease

the

face

of

the

plate

and

seal

assembly

which

con

tacts

the

front

shell

and

push

rod

the

face

of

the

check

valve

in

contact

with

the

packing

and

also

the

push

rod

at

the

point

of

contact

with

the

diaphragm

plate

Check

the

clearance

between

the

master

cylinder

and

push

rod

after

assembling

The

clearance

should

be

4

0

0

5

0

mm

ot

575

0

0197

0

in

and

can

be

adjusted

if

necessary

by

altering

the

length

of

the

push

rod

Installation

of

the

Master

Vac

unit

is

a

reversal

of

the

removal

procedure

HANDBRAKE

CABLES

Removing

The

cables

of

the

mechanical

handbrake

See

Fig

D

3

can

be

removed

in

the

following

manner

Front

cable

1

Release

the

hand

brake

and

disconnect

the

front

cable

by

removing

the

clevis

pin

1

in

Fig

D

I

0

at

the

handbrake

equalizer

Screw

out

the

adjusting

nut

2

to

disconnect

the

cable

from

the

handbrake

lever

2

Straighten

the

cable

clamp

I

in

Fig

D

II

and

pullout

the

the

lock

plate

2

to

extract

the

cable

from

the

retainer

3

Detach

the

cable

outer

casing

from

the

handbrake

control

bracket

then

pull

out

the

front

cable

Control

Stem

Removal

of

the

control

stem

is

a

straight

forward

opera

tion

Refer

to

Fig

D

12

and

take

out

the

clevis

pin

I

connect

ing

the

yoke

2

to

the

lever

3

Remove

the

clevis

pin

4

secur

ing

the

guide

5

to

the

bracket

6

then

withdraw

the

control

stem

S34

Re

lf

rnble

Remove

the

nut

from

the

adjuster

and

disconnect

the

left

hand

rear

cable

Disconnect

the

rear

cables

from

the

wheel

cylinders

Refer

to

Fig

D

13

pull

out

the

lock

plates

1

and

2

andremove

the

clevis

pin

HANDBRAKE

CABLES

Inspection

and

Installation

lnspect

the

cables

and

replace

them

if

any

of

the

wires

have

broken

Cables

which

have

stretched

must

be

renewed

as

it

will

no

longer

be

possible

to

adjust

the

handbrake

correctly

Check

the

springs

and

renew

them

if

they

have

weakened

or

broken

Oteck

the

centre

lever

trunnion

pin

and

equalizer

and

replace

as

necessary

Installation

is

a

reversal

of

the

removal

procedure

Grease

all

sliding

parts

and

adjust

the

handbrake

as

described

below

HANDBRAKE

Adjusting

Release

the

handbrake

and

adjust

the

rear

brake

shoes

as

described

under

the

appropriate

heading

Adjust

the

front

and

rear

cables

to

give

a

handbrake

lever

stroke

of

85

to

95

mm

0

35

to

3

74

in

by

setting

the

adjust

ing

nuts

shown

arrowed

in

Fig

D

14

BRAKE

PEDAL

Adjusting

Adjust

the

length

of

the

master

cylinder

push

rod

until

the

brake

pedal

pad

is

set

to

a

height

of

187

0

mm

7

36

in

with

the

brake

light

switch

free

from

the

pedal

stopper

Lock

the

push

rod

by

tightening

the

locknut

l

in

Fig

D

15

Screw

in

the

brake

light

switch

until

the

screwed

shaft

of

the

switch

makes

contact

with

the

stopper

brJ

cket

bolt

then

retighten

the

locknut

Adjust

the

stopper

bolt

2

until

the

brake

pedal

pad

is

set

to

a

height

of

183

0

mm

7

2

in

then

retighten

the

locknut

The

full

stroke

of

the

brake

pedal

should

now

be

set

to

150

0

mm

5

9

in

The

brake

lamps

should

light

up

when

the

pedal

is

depressed

15

0

mm

0

6

in

see

Fig

D

16

Lubricate

all

sliding

parts

with

bearing

grease

REAR

DRUM

BRAKE

Adjusting

Jack

up

the

vehicle

at

the

rear

and

release

the

handbrake

Depress

the

brake

pedal

several

times

and

turn

the

adjuster

clockwise

until

the

drum

is

locked

See

Fig

D

I

Turn

the

adjuster

in

the

opposite

direction

until

the

shoes

arc

just

dear

of

the

drum

and

the

wheel

can

be

turned

freely

by

hand

Repeat

the

operation

on

the

other

adjuster

and

then

depress

the

brake

pedal

to

make

sure

the

brakes

are

working

correctly

BLEEDING

THE

HYDRAULIC

SYSTEM

Refer

to

the

section

BRAKING

SYSTEM

for

L14

Ll6

and

LIS

engines

and

follow

the

instructions

given

under

the

appropriate

heading

Page 168 of 171

MO

MI

1224

D

I

KM

f

fMn

n

r

A

A

JP

I

I

T

I

I

I

Drain

ill

Changeelemenl

I

42

Cleantlement

3

I

II

r

I

Check

il

topup

4

I

Chinnloil

511

1

11

41

Gle

nelern

n

Ii

I

Orainlluid

7

I

I

I

I

Clunertmtn

81

1

I

I

I

I

I

27

Check

ailltop

up

Jf71

r

I

JIO

WI

28

Change

il

I

ill

limittdSlip

DiHlranti

1

Clleck

ilftopup

1J

I

I

I

Changelil

11

i

ill

ShdmgJolntt

Df

YlShlft

Check

11IIOpup

n

II

I

I

ChangeDl1

1

I

I

I

I

SHOCKASSORBERS

Check

Il

topup

5

PROP

DRIVESHAFTISI

lubncate

Hi

1

GREASE

GUN

POINTS

lubnCIl

it

PEOAlSHAFT

Sj

Lubrlc

te

18

HANDBHAKE

lubnc

1t

I

I

r

1

t

R

IINKAl

iF

luhncll

2u

I

I

i

I

ARlUWIORED

WHEELS

FREE

1m

I

I

i

1121

wHEE

L

tll

AHINli

ronl

HepitCk

211

t

f

WHEEl

BEARINGS

Rur

Repack

77

U

I

BRAKE

FLUID

R

nfWfbletd

1

I

lf

13

117

I

t

I

AH

UUWI

f

t1UN

11Itl

ih1tl

1

i

lcl

Check

oillevtl

B

l

r1i

BI1I1I1

r

Cap

Cleen

1ifj

j

I

Air

Cluner

Service

el

m

nt

l

J7

4

Replace

element

l

l

B

L

5

Cteenfilter

1

C

l

I

I

I

4

Clun

va

vellllR

I

I1

I

I

I

Repl

cH

lve

1

I

I

I

I

Cleen

jets

bOM

R

t

I

Top

liP

pisl

dempe

l

I

r

L

LlIbncatelinkages

I

I

L

Ctean

replace

5

j

I

Ch

ckoill

ve1

Ei

l

j

16

Clun

replac

n

11

R

fill

witll

fluid

38

I

Check

fluid

levll

IlL

t

I

CI

ign

toil

t

i

I

t

1

l

9

CheCk

top

u

p

10

Flulhryst

m

y

Cllecksolullon

44

Chltk

45

Lubrlc

tt

46

i

Clleck

top

up

L

L

Check

topup

4

aJdM

Cllltkspet

gl1vity

i

CI

en

gr

1S

liD

116

Lubriclt

1il

If

I

II

Clleck

topup

52

1

i

Chtck

topuplluid

3

I

I

Gre

rlm

4

I

1

I

I

I

Clunfiltlr

55

L

I

I

I

Chick

top

up

fluid

I6

w

W

e

I

ofi

Ldtir

1

Renewfiltlr

58

I

Check

topupflu

d

i91

i

I

i

Renrwfluid

I

I

I

I

I

ilinlil1r

11

I

I

I

I

I

I

CAR

DOWN

E

TERNAL

j

II

1

I

1

lOCKS

HINGES

Ell

Lubrictt

S21

r

1

el

L

Door

Dram

Hol

l

Clun

f

J

I

I

WIPER

SPINDLES

lubrictt

64

W

I

I

En

in

Dil

Filwr

GttrbOK

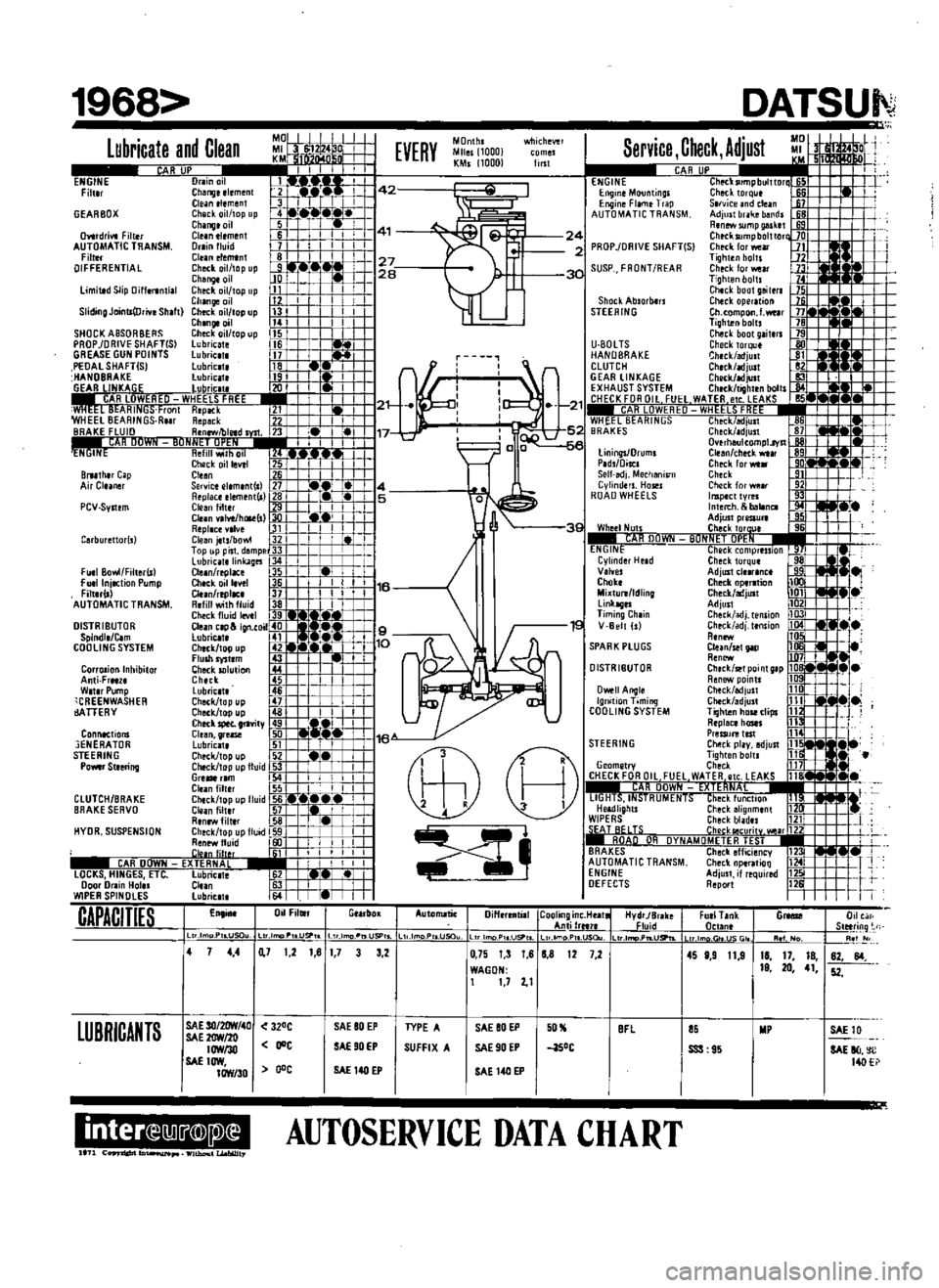

1968

Lubricate

and

Clean

ENGINE

Filt

r

GEARBOX

Dvttdrivt

Filt

r

AUTOMATIC

TRANSM

Filt

r

DIFFERENTIAL

PCV

Syllem

rburettor

s

FUll

Bowl

Filter

S1

Fu

llnjectionPump

Fittll

ll

AUTOMATIC

TRANSM

DISTRIBUTOR

Spindl

Ctm

COOLING

SYSTEM

CorrDlionlnllibitor

Anti

Frltl

W

t

rPump

CREENWASHER

ArrERY

Connections

3ENERATOR

STEERING

POMrStlering

CLUTCH

BRAKE

BRAKE

SERVO

HYDR

SUSPENSION

CAPACITIES

LUBRICANTS

Il

D

P

LUSClu

Service

Check

Adjust

CAR

UP

I

l

lletksumpbulttortM

1

Clled

rque

i6

ServiceJndclean

J1

Adjult

brake

bandl

tB

RtnMsumpgal

tt

fiS

Check

llJmpbnlttort

PROP

lOAIVE

SHAFT

S

Check

lor

wear

JJ

Tiglltenbolu

Jl

Check

tor

wear

n

Tiglltenboltl

Clllckbootgeiltrl

Clleckoperltion

Ch

CQmpon

l

welr

Tighten

bolts

Clleclbootgaiterl

Checktorqu

Gheck

edjult

Clllck

ljust

CIIRCk

adjult

Clleck

tighltnbolts

W

M

KSI

1

t

heCklMliiili

86

Check

ldjust

81

Overllllulcompl

rvll

Cleen

chltkwtlr

R9

Check

for

wear

0

Check

9

Checkforwp

lr

192

Il1Ipecttyrel

1IJ

Illte

II

blIl1nCl

Adjultpres

lure

Cllecktorul

liON

ET

OPE

l

heckcompression

Checktorqul

AdjUltclttr

nc

CheckoptTltion

Check

lIljLllt

AdjUlI

Clleck

alIj

tension

adj

t

nsion

I

Clun

selpp

jt1

Renew

Chetk

tPoint

tp

Renew

pointl

Check

6djult

110

J

Check

edjult

ill

i

ii

j

Tiglltenhoseclips

112

R

plece

lIastl

ill

PreSSIJ

test

114

1

STEERING

Clleek

play

adjust

ill

j

i

itl

e

Ti9htenboltl

ill

ii

Geometry

Check

U1L

H

CHECK

FOR

Oil

FUEL

WATER

etc

LEAKS

1181

I

I

R

DOWN

FXIE

HNA

11

1

1

lIGHTS

If

isfHUMt

NTS

Check

flll

C

lOn

f

3

Headlights

Checkllhgnmlnt

112Cr

WIPERS

Checkbladu

11111

J

TS

r

h

kIl

CII

I

Jrl7

iI

An

UH

OVNAUOMFTER

I

ST

I

BRAKES

CheCkemCienCY

1

I

AUTOMATIC

TRANSM

Clleek

op

rttioQ

T

ENGINE

Adjust

if

required

12

DEFECTS

Report

12

EVERY

MOnthl

Miles

1000

KMs

1000

lIBt

wtJichewl

ENGINE

EngmlMountings

Engine

Film

Trap

AUTOMATIC

TRANSM

24

2

30

SUSP

FRONT

REAR

Shock

Ablorb

rs

STEERING

1

21

5

1

c

e

U

80lTS

HANDBRAKE

CLUTCH

GEAR

LINKAGE

EXHAUST

SYSTEM

f

HFf

K

FOR

Oil

FllE

1

CAH

LUWI

RI

If

WHEEL

BEARINGS

BRAKES

UningsJDruml

Plds

Discl

Selhdj

Meclleni5l11

Cylinders

Hosel

ROAD

WHEELS

3S

Whe

1

Nun

AHllIIWN

ENGINE

Cyllnd

r

Held

Vllyes

Clloke

MiKtulli

ldling

linkagel

Timing

Ch

in

16

V

Belt

Is

SPARK

PLUGS

OISTRIBUTOR

Owell

Angle

Ignition

Timing

COOLING

SYSTEM

8

X

Automatic

Diffrrrntill

ICoolinginc

Ht

lltel

AntilrH1f

Ltr

lmoP

Ugo

IL

dmo

PII

U

Ou

HydrJBrak

Fluid

4

7

1

21

81

7

ULlma

II

USP

ULlmD

USP

L

L

tmoP

USQu

127

2

4

4

SAE

3O

2OW

411

SAE

lfrN

2fJ

IOWI3O

SAE1OW

IOW

30

320C

JOe

o

e

SAE80

EP

SAE90EP

SAE

140

EP

mmDIIIII

Ifn

c

ID

WIthDv

1

LI

obWt7

3

LtrJ

PtLUSPtL

3

2

0

75

T

3

1

8

B

8

WAGON

1

1

72

1

TYPE

A

SUFFIX

A

SAE80

EP

SAE90EP

SAE

140EP

0

aSoC

BFl

AUTOSERVICE

DATA

CHART

DATSUI

D

FurlT

nk

n

tln

G

0

Slltring

Re

I

lm

r

JSGI

11

1

No

4S

8

9

11

9

11

17

18

19

20

41

82

84

52

SSS

95

SAElll

SAE

80

c

14O

Page 170 of 171

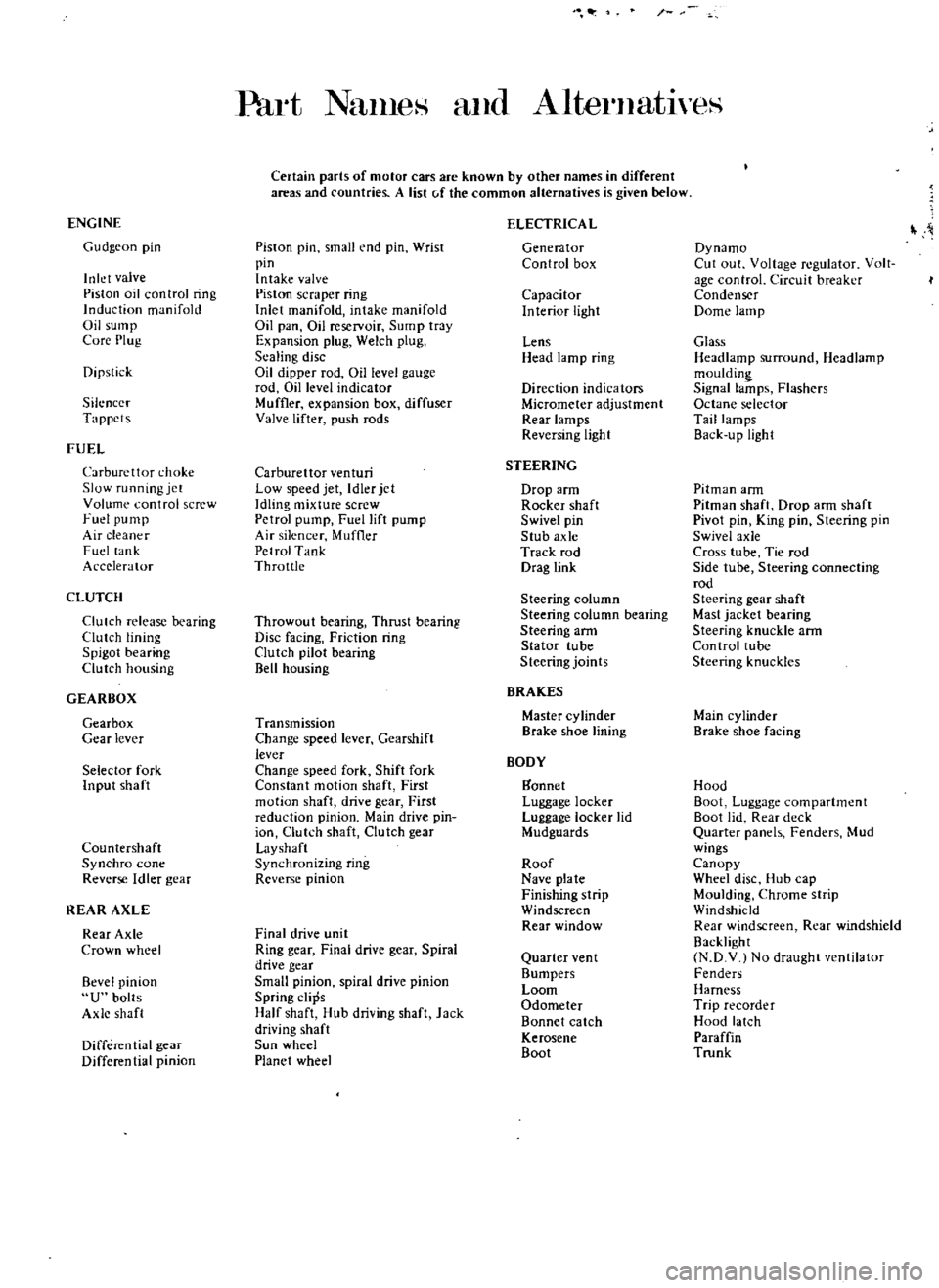

Part

NanleH

and

AlternatlyeS

Certain

parts

of

motor

cars

are

known

by

other

names

in

different

areas

and

countries

A

list

c

f

the

common

alternatives

is

given

below

ENGINE

ELECTRICA

L

Gudgeon

pin

Piston

pin

small

end

pin

Wrist

Generator

Dynamo

pin

Control

box

Cut

out

Voltage

regulator

Volt

Inlet

valve

Intake

valve

age

control

Circuit

breaker

Piston

oil

control

ring

Piston

scraper

ring

Capacitor

Condenser

Induction

manifold

Inlet

manifold

intake

manifold

Interior

light

Dome

lamp

Oil

sump

Oil

pan

Oil

reservoir

Sump

tray

Core

Plug

Expansion

plug

Welch

plug

Lens

Glass

Sealing

disc

Head

lamp

ring

Headlamp

surround

Headlamp

Dipstick

Oil

dipper

rod

Oil

level

gauge

mouldin

rod

Dillevel

indicator

Direction

indicators

Signal

lamps

Flashers

Silencer

Muffler

expansion

box

diffuser

Micrometer

adjustment

Octane

selector

Tappets

Valve

lifter

push

rods

Rear

lamps

Tail

lamps

Reversing

light

Back

u

pUgh

t

FUEL

Carburettor

choke

Carburettor

venturi

STEERING

Slow

running

jet

Low

speed

jet

Idler

jet

Drop

arm

Pitman

ann

Volume

control

screw

Idling

mixture

screw

Rocker

shaft

Pitman

shaft

Drop

ann

shaft

Fuel

pump

Petrol

pump

Fuel

lift

pump

Swivel

pin

Pivot

pin

King

pin

Steering

pin

Air

cleaner

Air

silencer

Muffler

Stub

axle

Swivel

axle

Fuel

lank

Petrol

Tank

Track

rod

Cross

tube

Tie

rod

Accelerator

Throttle

Drag

link

Side

tube

Steering

connecting

rod

CLUTCH

Steering

column

Steering

gear

shaft

Clutch

release

bearing

Throwout

bearing

Thrust

bearing

Steering

column

bearing

Mast

jacket

bearing

Clutch

lining

Disc

facing

Friction

ring

Steering

arm

Steering

knuckle

ann

Spigot

bearing

Clutch

pilot

bearing

Stator

tube

Control

tube

Clutch

housing

Bell

housing

Steering

joints

Steering

knuckles

GEARBOX

BRAKES

Gearbox

Transmission

Master

cylinder

Main

cylinder

Gear

lever

Change

speed

lever

Gearshift

Brake

shoe

lining

Brake

shoe

facing

lever

BODY

Selector

fork

Change

speed

fork

Shift

fork

Input

shaft

Constant

motion

shaft

First

gannet

Hood

motion

shaft

drive

gear

First

Luggage

locker

Boot

Luggage

compartment

reduction

pinion

Main

drive

pin

Luggage

locker

lid

Boot

lid

Rear

deck

ion

Clutch

shaft

Clutch

gear

Mudguards

Quarter

panels

Fenders

Mud

Countershaft

Layshaft

wings

Synchro

cone

Synchronizing

ring

Roof

Canopy

Reverse

Idler

gear

Reverse

pinion

Nave

plate

Wheel

disc

Hub

cap

Finishing

strip

Moulding

Chrome

strip

REAR

AXLE

Windscreen

Windshield

Rear

Axle

Final

drive

unit

Rear

window

Rear

windscreen

Rear

windshield

Crown

wheel

Ring

gear

Final

drive

gear

Spiral

Backlight

drive

gear

Quarter

ven

t

N

D

V

No

draught

ventilator

Bevel

pinion

Small

pinion

spiral

drive

pinion

Bumpers

Fenders

Loom

Harness

U

bolts

Spring

clips

Odometer

Trip

recorder

Axle

shaft

Half

shaft

Hub

driving

shaft

Jack

Bonnet

catch

Hood

latch

driving

shaft

Kerosene

Paraffin

Differential

gear

Sun

wheel

Boot

Trunk

Differential

pinion

Planet

wheel