lock DATSUN B110 1969 Service Owner's Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1969, Model line: B110, Model: DATSUN B110 1969Pages: 136, PDF Size: 5.64 MB

Page 71 of 136

Brakes

Remove

the

lock

plate

located

Immediately

III

front

of

the

turn

buckle

remove

the

clip

III

the

passenger

compartment

SIde

and

discon

nect

the

front

cable

I

Spong

balancer

G

Wheel

cyhnder

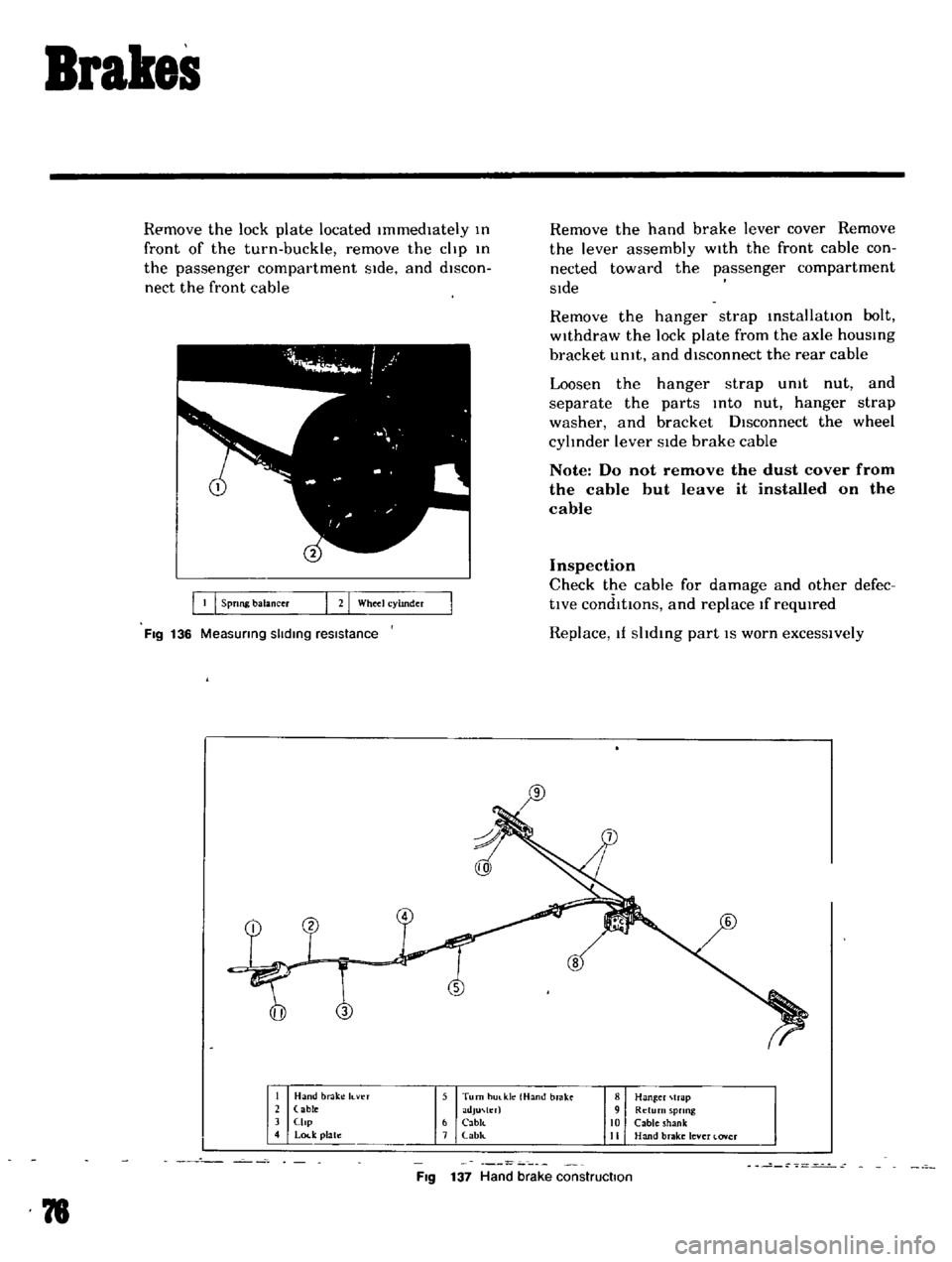

FIg

136

Measunng

slidIng

resistance

Remove

the

hand

brake

lever

cover

Remove

the

lever

assembly

wIth

the

front

cable

con

nected

toward

the

passenger

compartment

SIde

Remove

the

hanger

strap

installatIOn

bolt

withdraw

the

lock

plate

from

the

axle

hOUSIng

bracket

umt

and

disconnect

the

rear

cable

Loosen

the

hanger

strap

umt

nut

and

separate

the

parts

Into

nut

hanger

strap

washer

and

bracket

DIsconnect

the

wheel

cylinder

lever

SIde

brake

cable

Note

Do

not

remove

the

dust

cover

from

the

cable

but

leave

it

installed

on

the

cable

Inspection

Check

the

cable

for

damage

and

other

defec

tlve

condlttons

and

replace

If

reqUIred

Replace

If

shdIng

part

IS

worn

excessively

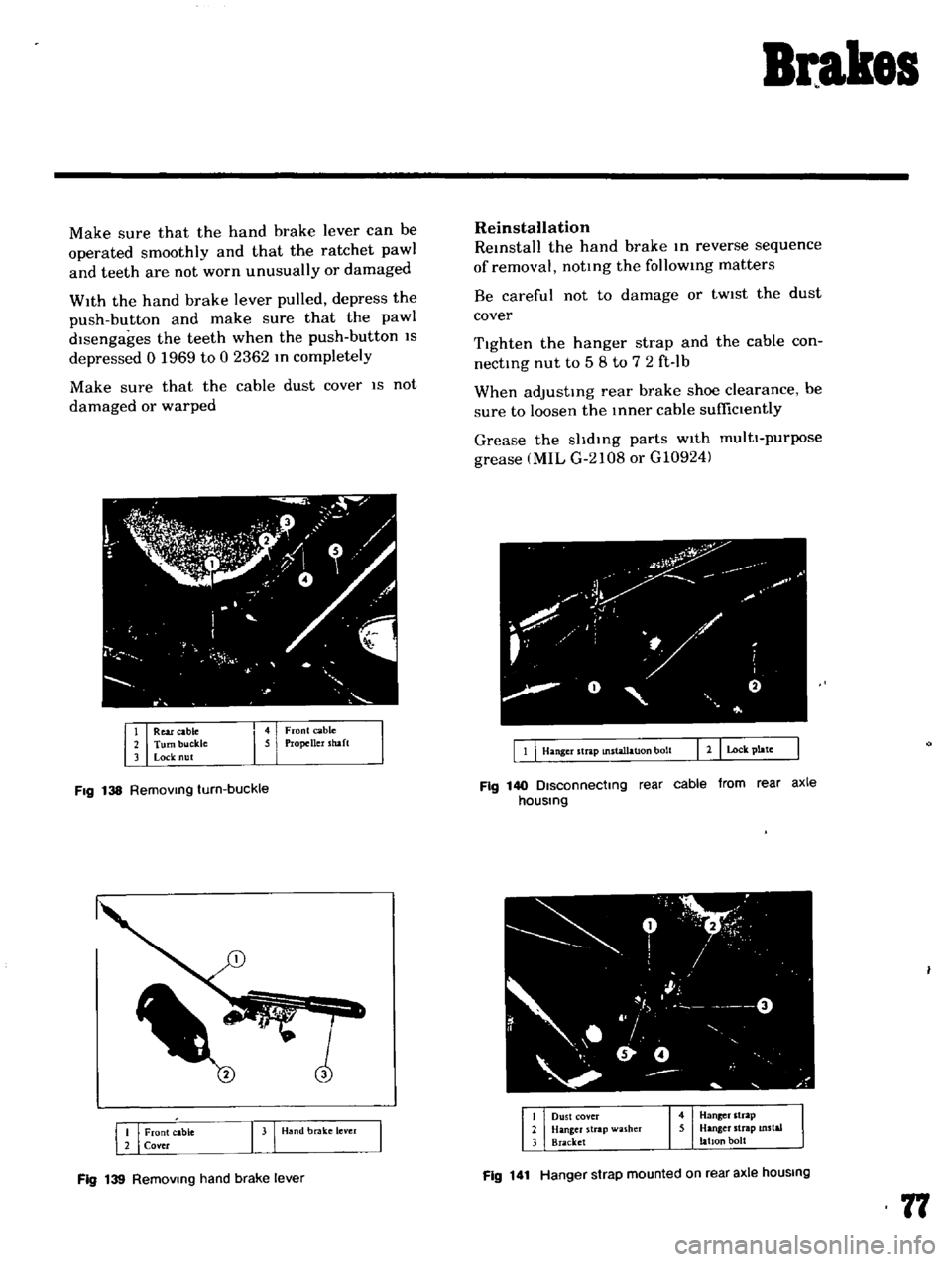

1

Hand

brake

It

ver

2

able

J

Clip

4

Lock

plate

5

Turn

hUlkle

Hand

brake

adJU

h

r

6

CabJc

7

abk

8

Han

er

trap

9

Return

sprmg

10

Cable

shank

II

Hand

brake

lever

lover

FIg

137

Hand

brake

construction

78

Page 72 of 136

Brakes

Make

sure

that

the

hand

brake

lever

can

be

operated

smoothly

and

that

the

ratchet

pawl

and

teeth

are

not

worn

unusually

or

damaged

With

the

hand

brake

lever

pulled

depress

the

push

button

and

make

sure

that

the

pawl

disengages

the

teeth

when

the

push

button

IS

depressed

0

1969

to

0

2362

In

completely

Make

sure

that

the

cable

dust

cover

1S

not

damaged

or

warped

FIg

138

Removing

turn

buckle

I

Front

cabl

2

Cover

CI

H

nd

brok

1

Ye

Fig

139

Removing

hand

brake

lever

Reinstallation

Remstall

the

hand

brake

m

reverse

sequence

of

removal

notmg

the

folloWIng

matters

Be

careful

not

to

damage

or

tW1St

the

dust

cover

TIghten

the

hanger

strap

and

the

cable

con

nectmg

nut

to

5

8

to

7

2

ft

lb

When

adJustmg

rear

brake

shoe

clearance

be

sure

to

loosen

the

mner

cable

sufficIently

Grease

the

shdmg

parts

w1th

multI

purpose

grease

MIL

G

2108

or

G10924l

o

Lock

plate

Fig

140

Disconnecting

rear

cable

from

rear

axle

housing

i

O

j

0

I

J

i

Ii

0

j

0

0

V

I

Dust

cover

Hanger

strap

washer

Bracket

I

Fig

141

Hanger

strap

mounted

on

rear

axle

hOUSing

77

Page 73 of 136

Brakes

ADJUSTMENT

Front

Disc

Brake

Ordinarily

adJu

tment

IS

not

requIred

because

clearance

between

pad

and

rotor

IS

adjusted

automattcally

by

elasttclty

of

the

pIston

seal

I

iJ

1

el

i

C

1

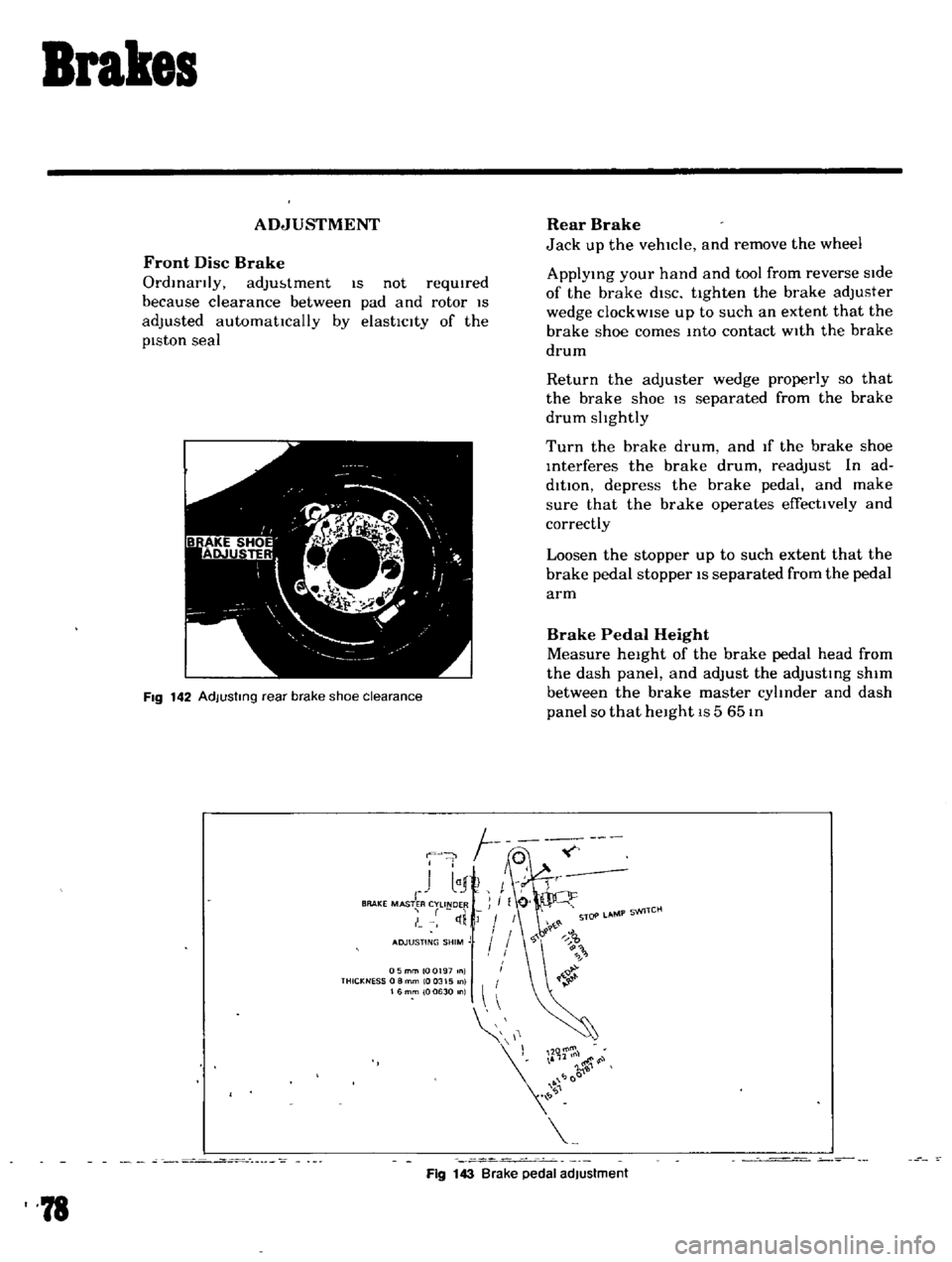

FIg

142

AdJustmg

rear

brake

shoe

clearance

F

J

I

1

I

r

BRAKE

MASTER

CYLINDER

I

tI

Rear

Brake

Jack

up

the

vehicle

and

remove

the

wheel

ApplYing

your

hand

and

tool

from

reverse

side

of

the

brake

diSC

ttghten

the

brake

adjuster

wedge

clockWise

up

to

such

an

extent

that

the

brake

shoe

comes

Into

contact

With

the

brake

drum

Return

the

adjuster

wedge

properly

so

that

the

brake

shoe

IS

separated

from

the

brake

drum

slIghtly

Turn

the

brake

drum

and

If

the

brake

shoe

Interferes

the

brake

drum

readjust

In

ad

dition

depress

the

brake

pedal

and

make

sure

that

the

brake

operates

effecttvely

and

correctly

Loosen

the

stopper

up

to

such

extent

that

the

brake

pedal

stopper

IS

separated

from

the

pedal

arm

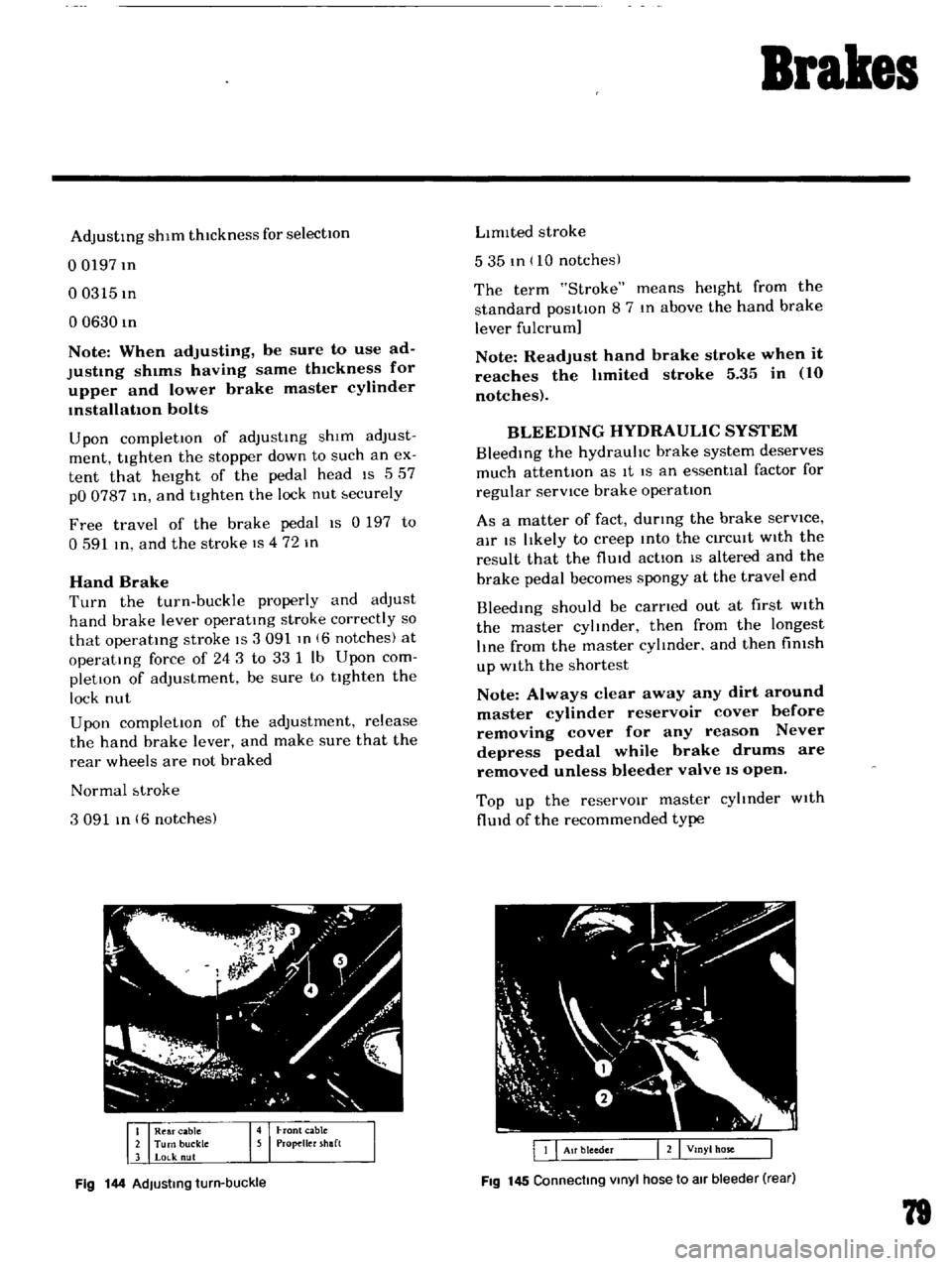

Brake

Pedal

Height

Measure

height

of

the

brake

pedal

head

from

the

dash

panel

and

adjust

the

adjusting

shim

between

the

brake

master

cylInder

and

dash

panel

so

that

height

IS

5

65

In

05mmlOQ197

nl

THICKNESS

0

8

mm

10

0315

0

16mm

100630

n

11

r

l00

Fig

143

Brake

pedal

adjustment

78

Page 74 of 136

Brakes

Adjusting

shIm

thickness

for

selectIOn

o

0197

In

00315

In

o

0630

In

Note

When

adjusting

be

sure

to

use

ad

Jusbng

sh1ms

having

same

th1ckness

for

upper

and

lower

brake

master

cylinder

IOstallahon

bolts

Upon

completIOn

of

adjusting

shIm

adjust

ment

tighten

the

stopper

down

to

such

an

ex

tent

that

heIght

of

the

pedal

head

IS

5

57

pO

0787

In

and

tighten

the

lock

nut

becurely

Free

travel

of

the

brake

pedal

IS

0

197

to

0591

tn

and

the

stroke

IS

4

72

In

Hand

Brake

Turn

the

turn

buckle

properly

and

adjust

hand

brake

lever

operatmg

stroke

correctly

so

that

operatmg

stroke

IS

3

091

m

16

notches

at

operatIng

force

of

243

to

331

Ib

Upon

com

pletIOn

of

adjustment

be

sure

to

tIghten

the

lock

nut

Upon

completIOn

of

the

adjustment

release

the

hand

brake

lever

and

make

sure

that

the

rear

wheels

are

not

braked

Normal

btroke

3091

In

6

notches

Fig

144

AdJusting

turn

buckle

LImIted

stroke

535

tn

10

notches

The

term

Stroke

means

heIght

from

the

standard

posItIon

8

7

In

above

the

hand

brake

lever

fulcrum

Note

Readjust

hand

brake

stroke

when

it

reaches

the

hmited

stroke

5

35

in

10

notches

BLEEDING

HYDRAULIC

SYSTEM

BleedIng

the

hydrauhc

brake

system

deserves

much

attentIOn

as

It

IS

an

e

senttal

factor

for

regular

servICe

brake

operatIon

As

a

matter

of

fact

durmg

the

brake

serVice

air

IS

lIkely

to

creep

Into

the

CirCUIt

WIth

the

result

that

the

flUId

actIon

IS

altered

and

the

brake

pedal

becomes

spongy

at

the

travel

end

Bleedmg

should

be

carned

out

at

first

WIth

the

master

cylmder

then

from

the

longest

lIne

from

the

master

cylmder

and

then

fimsh

up

With

the

shortest

Note

Always

clear

away

any

dirt

around

master

cylinder

reservoir

cover

before

removing

cover

for

any

reason

Never

depress

pedal

while

brake

drums

are

removed

unless

bleeder

valve

IS

open

Top

up

the

reservOIr

master

cyltnder

With

flUId

of

the

recommended

type

Fig

145

Connecting

Vinyl

hose

to

air

bleeder

rear

79

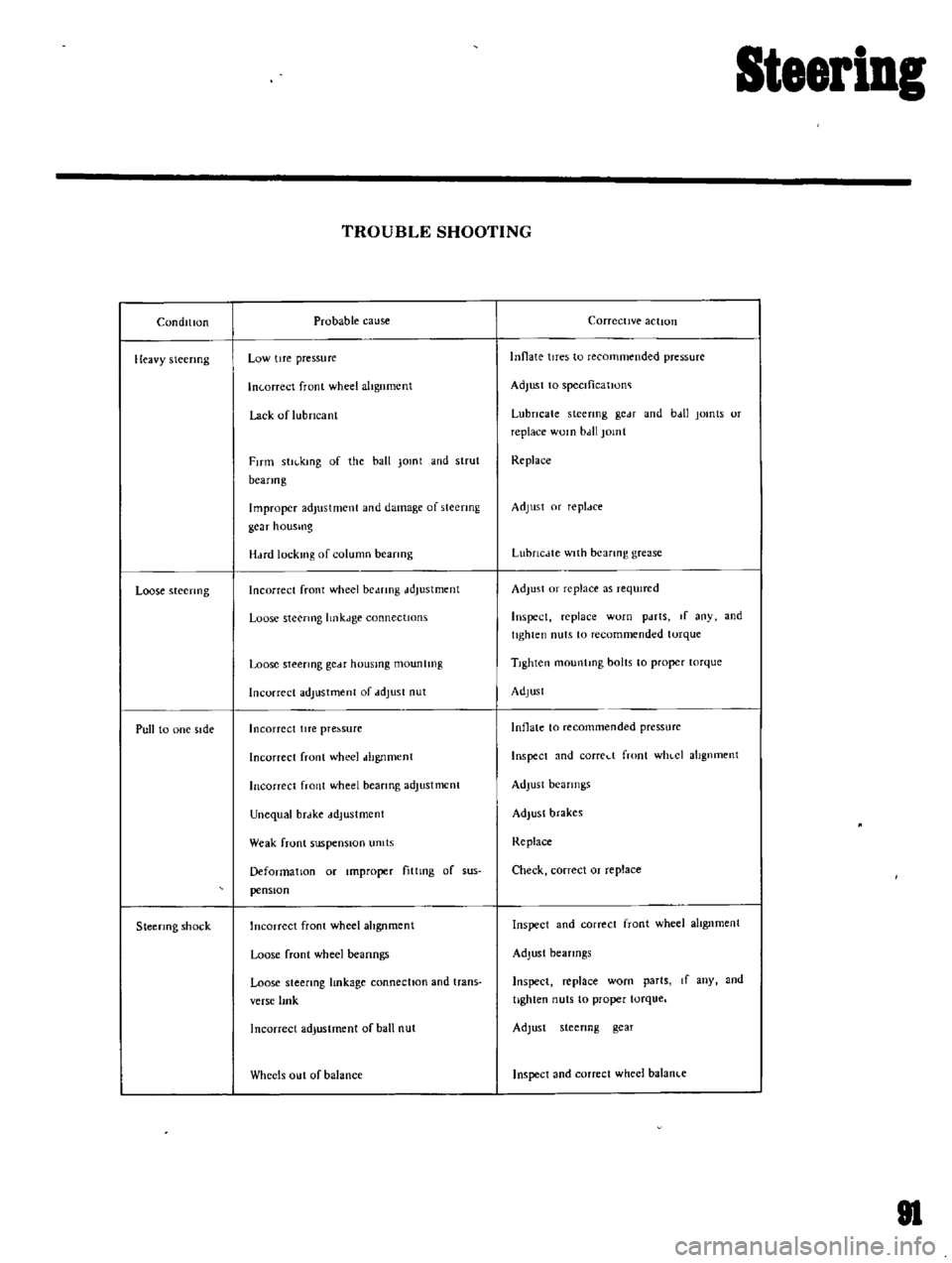

Page 85 of 136

SteeriDg

ConditIon

lIeavy

steering

Loose

steenng

Pull

to

one

side

Steermg

shock

TROUBLE

SHOOTING

Probable

cause

Low

tIre

pressure

In

orreet

front

wheel

altgnmcnt

Lack

of

lubricant

FITm

stll

kmg

of

the

ball

Jomt

and

strut

beanog

Improper

adjustment

and

damage

of

steering

gcar

housmg

H

Hd

lock1l1g

of

column

beanng

Incorrect

front

wheel

be

mng

ddJustment

Loose

steermg

hnkJge

connectIOns

Loose

steermg

gCdf

housmg

mountIng

Incorrect

adjustment

of

ddJust

nut

Incorrect

lITe

pre

sure

Incorrect

front

wheel

dhgnment

Incorrect

front

wheel

beanng

adjustment

Unequal

brdke

ddJustment

Weak

front

suspensIOn

umts

Deformation

or

Improper

fittmg

of

sus

pensIOn

Incorrect

front

wheel

ahgnment

Loose

front

wheel

beanngs

Loose

steering

lmkage

connectIOn

and

trans

verse

lmk

Incorrect

adjustment

of

ball

nut

Wheels

out

of

balance

Corrective

action

Innate

tires

to

recommended

pressure

Adjust

to

speclficatJono

Lubricate

steering

gc

H

and

b

dl

jomts

or

replace

WOln

bdll

jomt

Replace

Adjust

or

repldce

LubrlcJte

with

bearing

grease

Adjust

or

replace

as

reqUired

Inspect

replace

worn

pdrts

If

any

and

tighten

nuts

to

recommended

torque

TIghten

mountmg

bolts

to

proper

torque

Adjust

Inflate

to

recommended

pressurc

Inspect

and

corred

front

WhlCI

alignment

Adjust

bearings

Adjust

brakes

Replace

Check

correct

or

replace

Inspect

and

correct

front

wheel

alIgnment

Adjust

bearings

Inspect

replace

worn

parts

If

any

and

tighten

nuts

to

proper

torque

Adjust

steenng

gear

Inspect

and

correct

wheel

balanl

e

81

Page 91 of 136

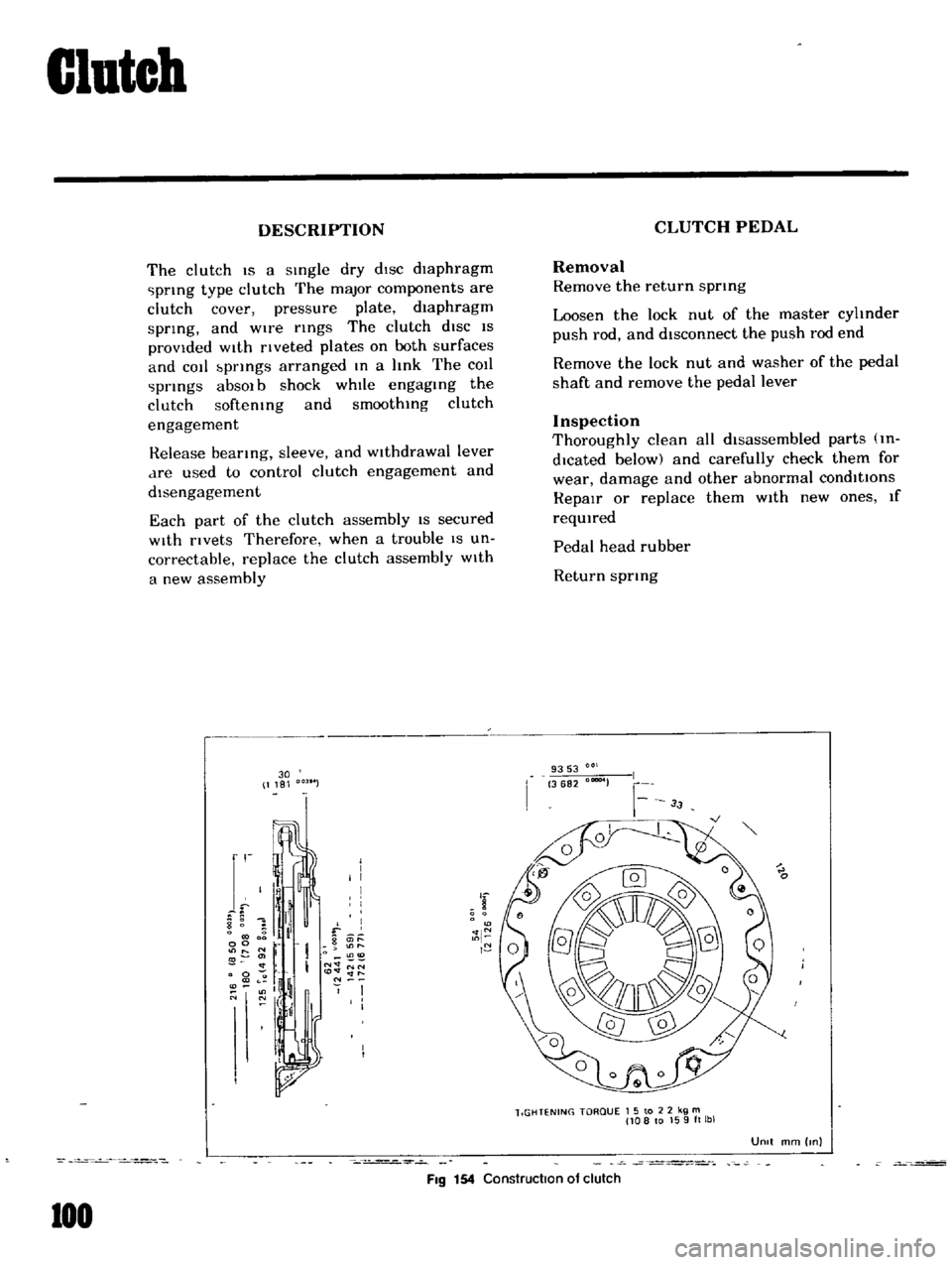

Clutch

DESCRIPTION

The

clutch

IS

a

sIngle

dry

dIsc

diaphragm

prIng

type

clutch

The

major

components

are

clutch

cover

pressure

plate

diaphragm

sprIng

and

wire

rIngs

The

clutch

diSC

IS

provided

WIth

rIveted

plates

on

both

surfaces

and

cot

bprIngs

arranged

In

a

hnk

The

COIl

prIngs

absOl

b

shock

whIle

engagIng

the

clutch

softemng

and

smoothIng

clutch

engagement

Release

bearIng

sleeve

and

WIthdrawal

lever

dre

used

to

control

clutch

engagement

and

disengagement

Each

part

of

the

clutch

assembly

IS

secured

With

rivets

Therefore

when

a

trouble

IS

un

correctable

replace

the

clutch

assembly

With

a

new

assembly

30

1181

r

I

I

I

I

I

8

1

il

f

0

g

it

l

00

r

O

11

I

N

NN

0

to

lt

lt

ll

l

If

N

O

N

I

I

I

I

FIg

154

Construction

of

clutch

100

CLUTCH

PEDAL

Removal

Remove

the

return

sprmg

Loosen

the

lock

nut

of

the

master

cyhnder

push

rod

and

disconnect

the

push

rod

end

Remove

the

lock

nut

and

washer

of

the

pedal

shaft

and

remove

the

pedal

lever

Inspection

Thoroughly

clean

all

disassembled

parts

m

dlcated

below

and

carefully

check

them

for

wear

damage

and

other

abnormal

conditions

RepaIr

or

replace

them

With

new

ones

If

reqUIred

Pedal

head

rubber

Return

sprIng

9353

3682

00004

lIGHTENING

TORQUE

1

5

to

2

2

kg

m

108

to

159ft

lbl

UOIt

mm

Inl

Page 93 of 136

Clutch

Pedal

lever

bush

Fulcrum

pedal

pIn

etc

Remstallation

Reinstall

the

clutch

pedal

In

reverse

sequence

of

removal

Adjustment

Adjust

pedal

pad

heIght

to

565

In

Without

stopper

The

adjustment

IS

made

by

selectmg

and

applYIng

shlm

s

haVing

adequate

thIckness

Be

Ule

to

use

shIms

haVIng

same

thIckness

for

both

upper

and

lower

Next

adjust

the

pedal

stopper

properly

so

that

the

pedal

pad

height

IS

557

In

and

secure

the

pOSitIOn

WIth

lock

nut

Note

Make

sure

that

chaSSIS

grease

has

been

applied

to

the

CG

marked

portions

two

places

Grease

if

reqUired

CLUTCH

MASTER

CYLINDER

Removal

DIsconnect

the

push

rod

from

the

cleVIS

DIsconnect

the

clutch

lIne

from

the

master

cylinder

and

draIn

flUid

Remove

the

ecunng

bolts

and

remove

the

master

cyhnder

assembly

from

the

vehIcle

DIsassembly

Remove

the

filler

cap

and

draIn

flUId

Pull

back

the

dust

cover

and

remove

the

snap

rIng

The

stopper

push

rod

pIston

assembly

pnmary

cup

and

return

sptlng

assembly

can

be

removed

Inspection

Thoroughly

clean

all

parts

With

brake

flUId

before

InspectIOn

Check

the

cyhnder

and

piston

for

uneven

wear

or

damage

Replace

If

required

When

clearance

between

the

cylinder

and

pIston

IS

more

than

O

0059

In

replace

the

cyhnder

102

Replace

the

pIston

cup

pnmanly

whenever

the

master

cyhnder

IS

dIsassembled

It

must

also

be

replaced

when

wear

or

deformatIOn

due

to

fatIgue

or

damage

IS

found

Check

the

dust

cover

OIl

reservOIr

filler

cap

and

clutch

lIne

for

damage

or

deformatIOn

If

abnormal

condItIOn

IS

found

replace

With

new

one

Reassembly

Reassemble

the

master

cylInder

assembly

In

reverse

sequence

of

dIsassembly

notIng

the

follOWIng

matters

The

pIston

cup

should

be

soaked

In

brake

flUId

before

reassembly

Install

the

pIston

cup

carefully

so

that

It

IS

correctly

faced

Apply

brake

flUId

suffiCIently

to

the

cyhnder

and

pIston

and

assemble

them

Reinstallation

ReInstall

the

master

cyhnder

assembly

In

reverse

sequence

of

removal

and

adjust

as

follows

Adjust

the

pedal

heIght

by

changmg

the

push

rod

length

Bleed

air

out

of

the

hydrauhc

system

BLEEDING

CLUTCH

SYSTEM

Remove

the

bleed

screw

dust

cap

from

the

operatIng

cyhnder

Open

the

bleed

screw

approximately

three

quarters

of

a

turn

Attach

a

tube

Immer

SIng

the

open

end

mto

a

clean

contaIner

which

contaInS

a

small

amount

of

brake

flUId

Fill

the

master

cyhnder

reservOIr

With

the

recommended

flUId

Depress

the

clutch

pedal

qUIckly

while

keepIng

It

down

retighten

the

bleed

screw

and

allow

It

to

return

slowly

Repeat

thiS

pumpIng

actIOn

unttl

the

flUId

entenng

the

contaIner

IS

free

from

air

bubbles

Screw

up

the

bleed

screw

on

a

down

stroke

of

the

pedal

remove

the

bleec

t1

1

nd

rel1lace

the

dust

cap

Page 97 of 136

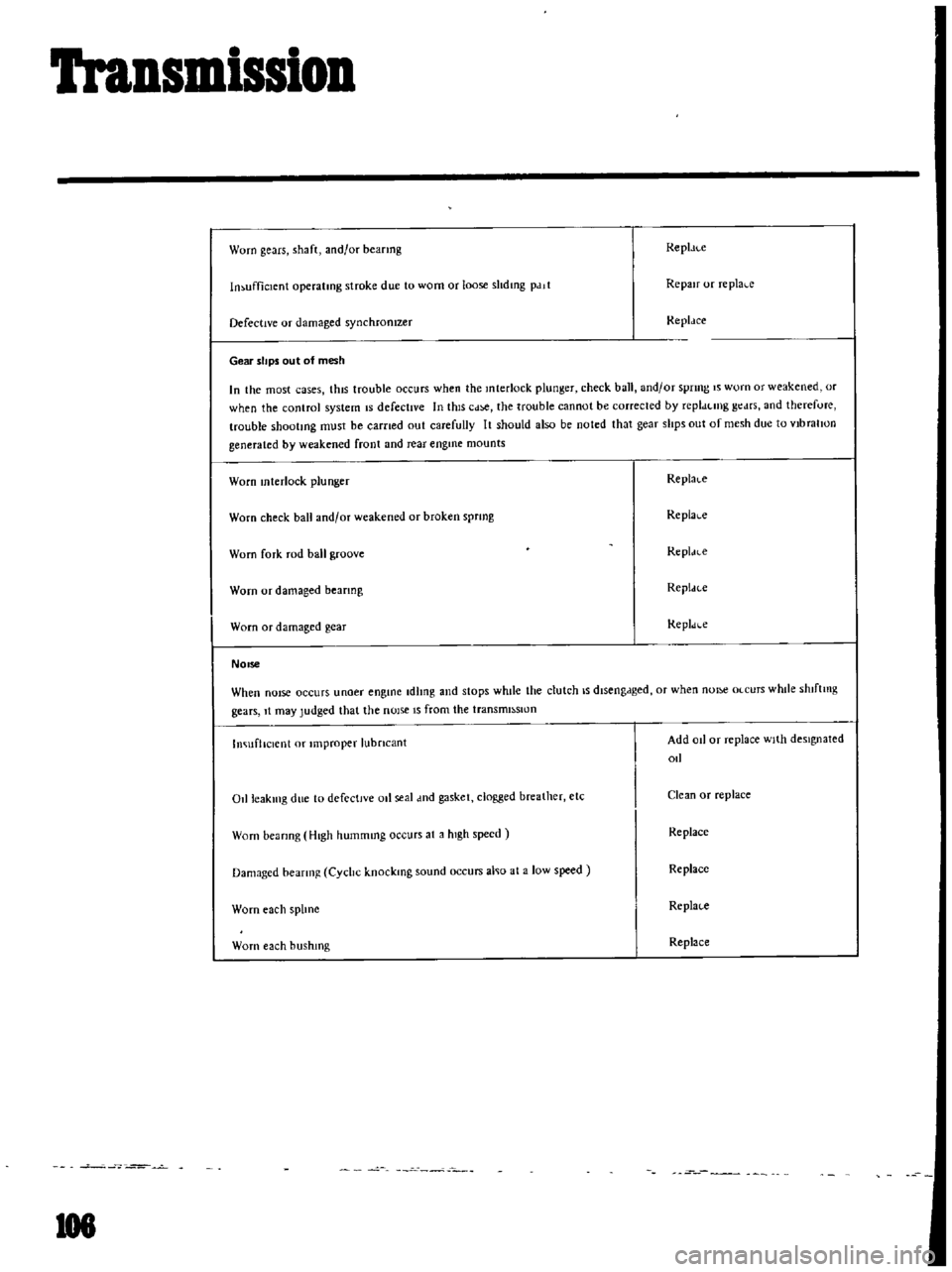

Transmission

Worn

gears

shaft

and

or

heanng

Repl

ll

c

In

ufficlcnt

operatmg

stroke

due

to

worn

or

loose

shdmg

pdll

Repair

or

replal

c

Defective

or

damaged

synchronIzer

Replace

Gear

slips

out

of

mesh

In

the

most

cases

thiS

trouble

occurs

when

the

Interlock

plunger

check

ball

and

or

spnng

IS

worn

or

weakened

or

when

the

control

system

IS

defectIve

In

thiS

Cd

the

trouble

cannot

be

corrected

by

repldtlllg

gt

drs

and

therefore

trouble

shootmg

must

be

earned

out

carefully

It

should

also

be

noted

that

gear

slips

out

of

mesh

due

to

vlbralIon

generated

by

weakened

front

and

rear

engme

mounts

Worn

mterlock

plunger

Replal

c

Worn

check

hall

and

or

weakened

or

broken

sprmg

Replal

c

Worn

fork

rod

ball

groove

RepI

H

e

Worn

or

damaged

beanng

Repldce

Worn

or

damaged

gear

Repldl

c

NOise

When

nOIse

occurs

unoer

engine

Idling

and

stops

whde

the

clutch

IS

dlseng

lged

or

when

nOI

Olcurs

while

shlftmg

gears

It

may

Judged

that

the

nOIse

IS

from

the

tranSmll

lSIUn

Ino

ufllclenl

or

1mproper

lubncant

Add

od

or

replace

With

deSignated

oIl

Ollleaklllg

due

to

defectIve

011

seal

md

gasket

clogged

breather

etc

Clean

or

replace

Worn

beanng

High

hummmg

occurs

at

a

high

speed

Replace

Damaged

beanng

Cychc

knockmg

sound

occurs

alllo

at

a

low

speed

Replace

Worn

each

sphne

Replace

Worn

each

hushmg

Replace

108

Page 99 of 136

Transmission

AUTOMATIC

TRANSMISSION

The

model

3N71B

automatic

transmiSSIOn

IS

a

fully

automatic

Unit

consisting

pnmanly

of

3

element

hydrauhc

torque

converter

and

two

planetary

gear

sets

Two

multiple

disc

clut

ches

a

multiple

disc

brake

a

band

brake

and

a

one

way

sprag

clutch

provide

the

fnctlon

elements

reqUired

to

obtain

the

deSired

fun

tlon

of

the

two

planetary

gear

sets

The

two

planetary

gear

sets

give

three

for

ward

ratIOs

and

one

reverse

Changing

of

the

gear

ratIOs

IS

fully

automatic

In

relation

to

vehicle

speed

and

engine

torque

Input

Vehicle

speed

and

engine

mamfold

vacuum

Signals

are

constantly

fed

to

the

transmiSSIOn

to

prOVide

the

proper

gear

ratIO

for

maximum

effiCiency

and

performance

at

all

throttle

openmgs

The

Model

3N71B

has

SIX

selector

poSitIOns

P

R

N

D

2

1

p

Park

pOSitIOn

posItively

locks

the

out

put

shaft

to

the

transmiSSIOn

case

by

means

of

a

lockmg

pawl

to

prevent

the

vehicle

from

rollmg

either

directIOn

ThiS

pOSitIOn

should

be

selected

whenever

the

dnver

leaves

the

vehicle

The

engme

may

be

started

m

Park

pOSition

R

Reverse

range

enables

the

vehicle

to

be

operated

m

a

reverse

direction

N

Neutral

pOSitIOn

enables

the

engine

to

be

started

and

run

Without

dnvIngthe

vehicle

0

Drive

range

IS

used

for

all

normal

driVing

conditions

Dnve

range

has

three

gear

ratios

from

the

startmg

ratIO

to

direct

dnve

2

2

range

prOVides

performance

for

dnvIng

onshppery

surfaces

2

range

can

also

be

used

for

engine

brakmg

2

range

can

be

selected

at

any

vehicle

speed

and

prevents

the

transmlsslOn

from

shifting

out

of

second

gear

108

Rg

162

Idenllflcatlon

number

I

1

range

can

be

selected

at

any

vehicle

speed

and

the

transmiSSIOn

will

shift

to

second

gear

and

remain

m

second

until

vehicle

speed

IS

reduced

to

approximately

25

to

31

MPH

1

range

posItion

prevents

the

transmiSSIOn

from

shlftmg

out

of

low

gear

ThiS

IS

par

tlcularly

benefiCial

for

mamtamIng

maximum

engine

brakmg

when

continUOUS

low

gear

operation

IS

deSirable

The

torque

converter

assembly

IS

of

welded

constructIOn

and

can

not

be

dlssassembled

for

service

FlUld

Recommendatwn

Use

automatic

transmiSSIOn

flUid

haVing

DEXRON

IdentificatIOns

only

m

the

3N71B

automatic

transmiSSIOn

denttficatwn

Number

Stamped

posttwn

The

plate

attached

to

the

rIght

hand

Side

of

transmission

case

as

shown

m

Figure

161

denttficatwn

of

number

arrangements

See

Page

109

RECOMMENDATIONS

Due

to

the

compleXity

of

setting

up

a

disassembled

transmissIOn

as

well

as

the

special

tools

necessary

It

IS

recommended

thaL

nternal

epalrs

be

left

to

a

fully

eqUip

ped

shop

Page 102 of 136

Bod

Work

HOOD

Removal

DI

connect

the

WInd

hwld

washer

hose

at

the

nozzle

In

order

to

protect

the

hood

from

damaging

place

rag

In

hoth

Ide

of

the

hood

rear

end

loosen

the

hood

hinge

installatIOn

bolts

and

remove

the

hood

UPPOl

tIng

It

from

both

SIdes

as

shown

In

the

follOWing

figure

Two

workers

are

required

Installation

Install

the

hood

In

reverse

sequence

of

removal

carefully

so

that

the

hood

IS

flush

FIg

163

Removmg

hood

hmge

Fig

164

Removmg

hood

U2

with

the

fender

top

and

clearance

between

the

hood

and

fender

IS

aligned

evenly

toward

overall

circumference

of

the

hood

when

the

hood

IS

closed

HOOD

LOCK

Removal

Remove

the

radiator

gnlle

loosen

the

in

stallation

bolts

and

remove

the

male

Side

of

the

hood

lock

Disconnect

the

hood

lock

wire

from

the

female

Side

of

the

hood

lock

and

remove

the

female

Side

of

the

hood

lock

Remove

three

screws

and

remove

the

hood

lock

control

lever

Adjustment

Centermg

the

Hood

Lock

The

male

Side

hook

lock

IS

prOVided

with

a

o

118

In

adjusting

stroke

toward

left

and

nght

Sides

of

the

vehicle

and

the

female

SIde

with

a

0118

In

adjustIng

stroke

toward

front

and

rear

Sides

of

the

vehicle

Loosen

the

in

stallatIOn

bolts

and

align

the

center

correctly

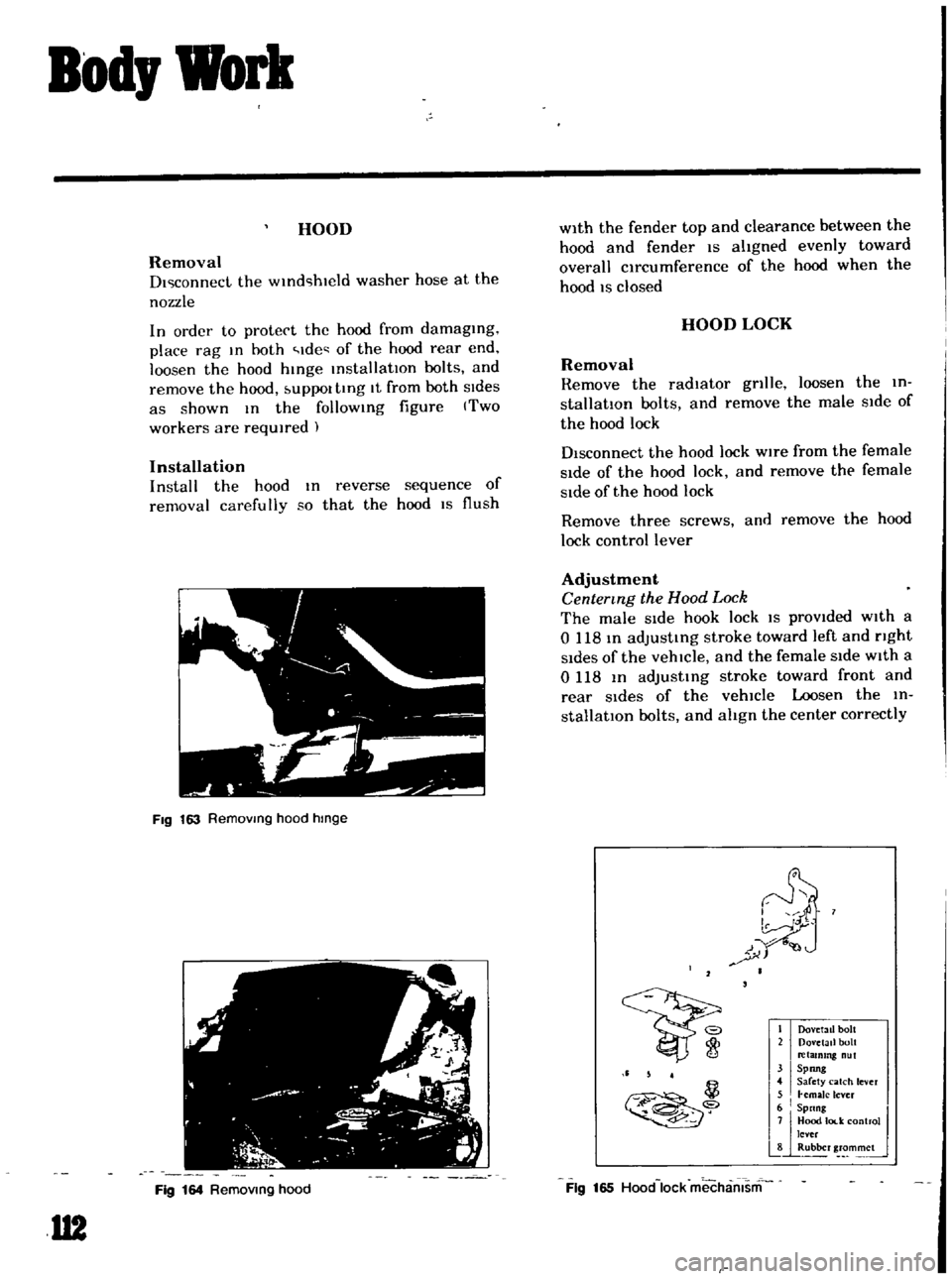

I

Dov

tall

bolt

2

Dovetail

bolt

retammg

nut

31

Spong

4

Sarety

catch

lever

5

I

hmaJc

lever

6

Spnng

j

7JjHood

lod

control

lever

8

Rubber

grommet

Ii

5

4

il

Fig

165

Hood

lock

mechamsm