ABS DATSUN B110 1969 Service Repair Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1969, Model line: B110, Model: DATSUN B110 1969Pages: 136, PDF Size: 5.64 MB

Page 5 of 136

labl8

of

Contents

Jets

60

FRONT

SUSPENSION

TlOuble

Shooting

60

f

DESCRIPTION

RECOMMENDATIONS

TROUBLE

SHOOTING

I

85

COOLING

SYSTEM

DESCRIPTION

64

STEERING

WATER

PUMP

64

Hemoval

65

DESCRIPTION

90

InstallatIOn

65

RECOMMENDATIONS

90

THERMOSTAT

65

TROUBLE

SHOOTING

91

Removal

65

InspectIOn

65

REAR

DRIVE

Installation

65

RADIATOR

66

SUSPENSION

Hemovdl

66

InspectIOn

66

REAR

AXLE

94

InstallatIOn

66

DIFFERENTIAL

94

REAR

SUSPENSION

95

REAR

SHOCK

ABSORBER

96

Replacement

96

BRAKES

InspectIOn

97

RECOMMENDATIONS

97

FRONT

DISC

BRAKE

68

BRAKE

PAD

68

Replacement

68

CLUTCH

InspectIOn

68

ReinstallatIOn

68

DESCRIPTION

CALIPER

70

CLUTCH

PEDAL

Removal

70

Removal

Disassembly

71

InspectIOn

InspectIOn

Repmr

71

ReinstallatIOn

Reassembly

72

Adjustment

ReinstallatIOn

74

CLUTCH

MASTER

CYLINDER

REAR

BRAKE

74

Removal

Hemoval

Dlsdssembly

74

DIsassembly

InspectIOn

75

InspectIOn

Reassembly

ReinstallatIOn

75

Reassembly

HAND

BRAKE

75

RemstallatlOn

Removal

75

BLEEDING

CLUTCH

SYSTEM

InspectIOn

76

RemstallatlOn

77

ADJUSTMENT

78

TRANSMISSION

Front

DI

c

Brake

78

Rear

Brake

78

4

SPEED

TRANSMISSION

Brake

Pedal

HeIght

78

3

SPEED

TRANSMISSION

Hand

Brake

79

TROUBLE

SHOOTING

BLEEPIN

HYD

AULIC

SYs

r

M

79

i

UIQM

ATJ

C

TRANSMJSSIQ

TROUBLE

SHOOTING

80

RECOMMENDATIONS

2

Page 78 of 136

pront

Suspension

Qj

@

@

I

Strut

mounting

Insulator

2

Strut

mounllng

bearing

3

Upper

pnng

o

r

at

4

Oumpu

rubblf

5

DU

tlOVU

6

P

ton

rod

7

F

ool

pring

8

Irut

embly

q

Hub

b

t

mbly

10

5pmdh

II

Ball

JOint

12

Trd

nwu

link

1

J

Tln

lon

rod

14

StJblluLr

15

SU

p

mIOn

mlmbt

r

Fig

146

Front

axle

and

suspension

assembly

I

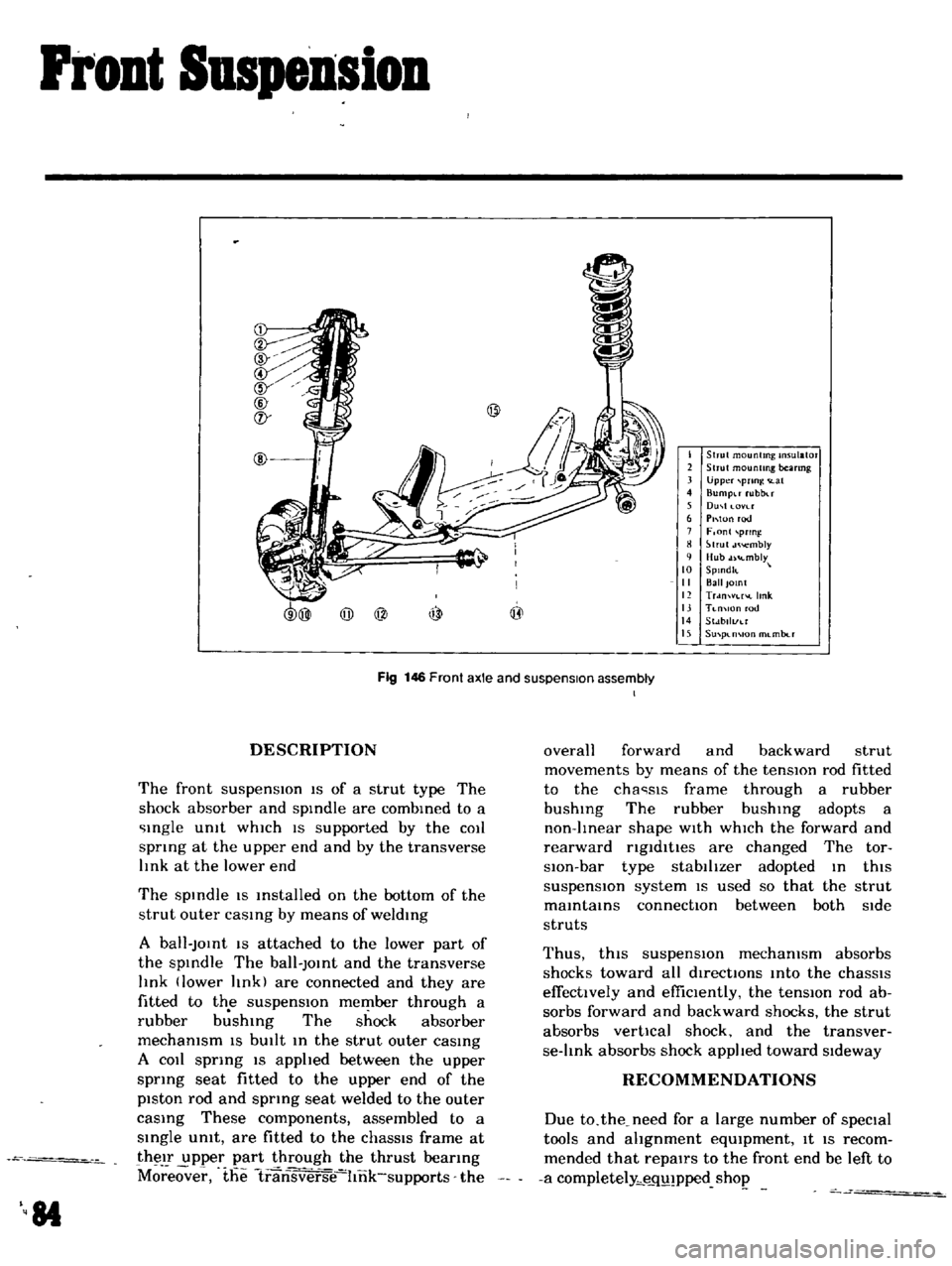

DESCRIPTION

The

front

suspensIOn

IS

of

a

strut

type

The

shock

absorber

and

spIndle

are

combIned

to

a

Ingle

Unit

whIch

IS

supported

by

the

COIl

spnng

at

the

upper

end

and

by

the

transverse

lInk

at

the

lower

end

The

spIndle

IS

Installed

on

the

bottom

of

the

strut

outer

caSIng

by

means

of

weldIng

A

ball

JOInt

IS

attached

to

the

lower

part

of

the

spIndle

The

ball

JOInt

and

the

transverse

lInk

lower

lInk

are

connected

and

they

are

fitted

to

the

suspensIOn

member

through

a

rubber

b

shIng

The

shock

absorber

mechanism

IS

bUIlt

In

the

strut

outer

caSIng

A

COIl

sprIng

IS

apphed

between

the

upper

sprIng

seat

fitted

to

the

upper

end

of

the

piston

rod

and

spring

seat

welded

to

the

outer

caSIng

These

components

assembled

to

a

SIngle

umt

are

fitted

to

the

chaSSIS

frame

at

their

upper

part

through

the

thrust

beanng

M

eover

the

1ransverse

hnk

supports

the

84

overall

forward

and

backward

strut

movements

by

means

of

the

tensIOn

rod

fitted

to

the

cha

sls

frame

through

a

rubber

bushIng

The

rubber

bushIng

adopts

a

non

lInear

shape

WIth

whICh

the

forward

and

rearward

ngldltles

are

changed

The

tor

slOn

bar

type

stabilIzer

adopted

In

thiS

suspensIOn

system

IS

used

so

that

the

strut

maIntaInS

connectIOn

between

both

Side

struts

Thus

thiS

suspensIOn

mechanism

absorbs

shocks

toward

all

directIOns

Into

the

chaSSIS

effectively

and

effiCIently

the

tensIOn

rod

ab

sorbs

forward

and

backward

shocks

the

strut

absorbs

vertical

shock

and

the

transver

se

lInk

absorbs

shock

applIed

toward

SIdeway

RECOMMENDATIONS

Due

to

the

need

for

a

large

number

of

speCial

tools

and

ahgnment

eqUIpment

It

IS

recom

mended

that

repairs

to

the

front

end

be

left

to

a

completely

e

q

pped

shop

Page 80 of 136

Pront

Suspension

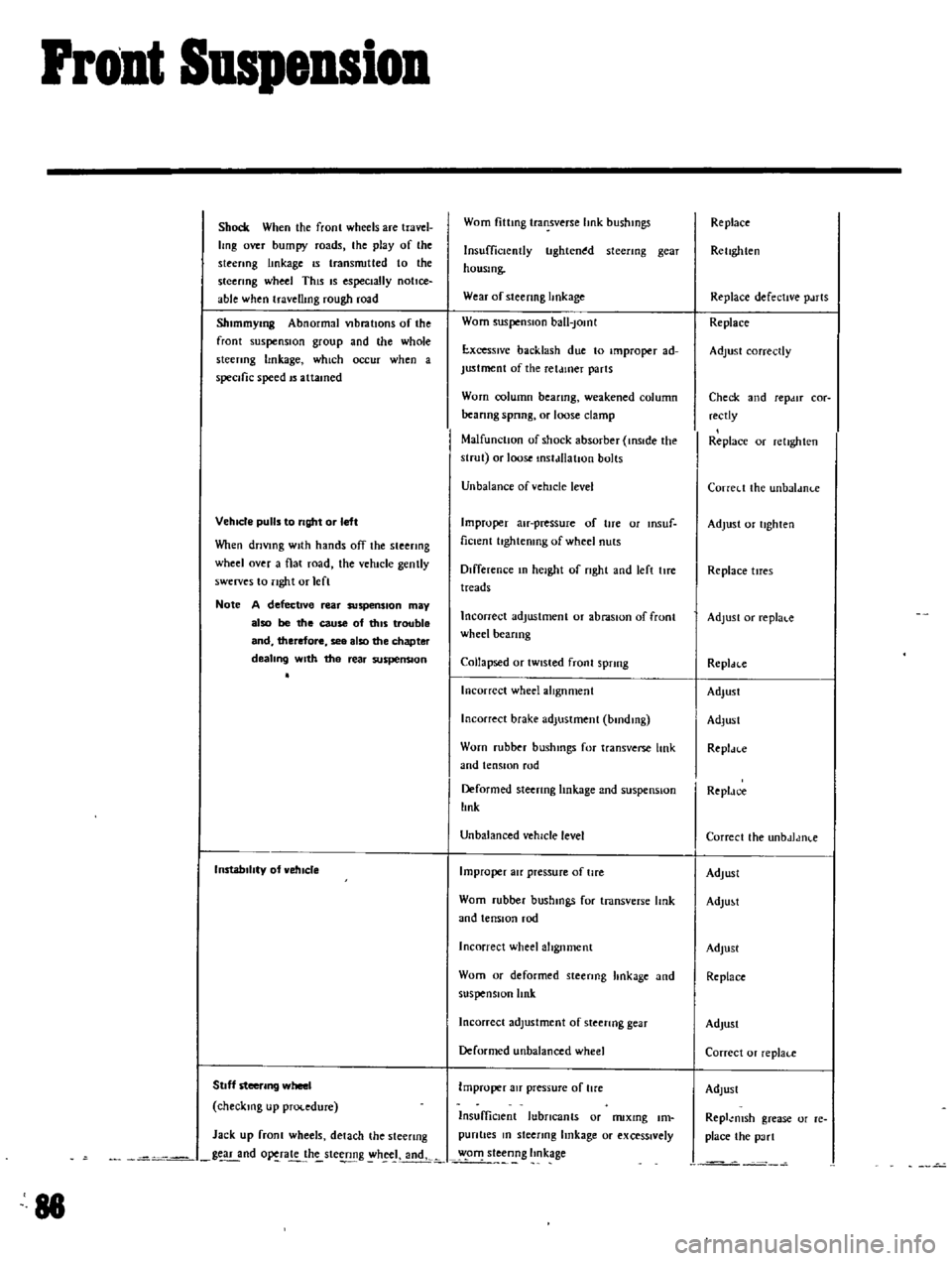

Shock

When

the

fronl

wheels

are

travel

Img

over

bumpy

roads

the

play

of

the

steenng

linkage

IS

transnutted

to

the

steering

wheel

This

IS

especially

notice

able

when

travellmg

rough

road

Shlmmymg

Abnormal

VIbratIOns

of

the

front

suspensIOn

group

and

lhe

whole

sleenng

hnkage

which

occur

when

a

specific

speed

IS

attamed

VehIcle

pulls

to

right

or

left

Vhen

driVing

With

hands

off

the

steering

wheel

over

a

flat

road

the

vehicle

gently

swerves

to

nght

or

lefl

Note

A

defective

rear

suspenSion

may

also

be

the

cause

of

tillS

trouble

and

therefore

see

also

the

chapter

dealing

With

the

rear

suspenSion

InstabilIty

of

vehIcle

Stoff

steering

wheel

checking

up

procedure

Jack

up

fronl

wheels

detach

the

steenng

g

nd

o

ra

h

ste

g

h

J

andk

88

Worn

fittmg

transverse

hnk

bushmgs

Insufficiently

tlghten

d

steenng

gear

housmg

Wear

of

steenng

hnkage

Worn

suspensIOn

ball

Jomt

E

xcesslve

backlash

due

to

improper

ad

Justment

of

the

ret

uner

parts

Worn

column

beanng

weakened

column

beanng

spnng

or

loose

clamp

MalfunctIOn

of

shock

absorber

inSIde

the

strut

or

loose

mstdllatJon

bolts

Unbalance

ofvehtcle

level

Improper

au

pressure

of

tire

or

msuf

ficlent

hghtenmg

of

wheel

nuts

Difference

In

height

of

nght

and

left

lIre

treads

Incorrect

adjustment

or

abraSIOn

of

front

wheel

beanng

Collapsed

or

tWisted

front

sprmg

Incorrect

wheel

alIgnment

Incorrect

brake

adjustment

bmdmg

Worn

rubber

bushmgs

for

transverse

link

and

tensIOn

rod

Deformed

steering

linkage

and

suspensIOn

lInk

Unbalanced

vehicle

level

Improper

au

pressure

of

tire

Worn

rubber

bushmgs

for

tmnsverse

Imk

and

tensIOn

rod

Incorrect

wheel

alignment

Worn

or

deformed

steenng

hnkage

and

suspensIOn

link

Incorrect

adjustment

of

steenng

gear

Deformed

unbalanced

wheel

Improper

au

pressure

of

lire

InsuffiCient

lubricants

or

nuxmg

Im

pun

ties

m

sleenng

linkage

or

exceSSively

o

steenng

Imkage

Replace

Rellghten

Replace

defective

p

uts

Replace

Adjust

correctly

Check

and

repdlT

cor

rectly

Replace

or

relighlen

Correl

t

the

unbaldnl

e

Adjust

or

tighten

Replace

tlTes

Adjust

or

replal

c

Repldcc

Adjust

Adlusl

Repl

n

e

Repldc

e

Correcl

the

unbdJdlKe

Adjust

AdlU

t

Adjust

Replace

AdJusl

Correcl

or

replaf

e

Adlust

Repl

msh

grease

or

re

place

the

pa

rt

Page 81 of 136

i

l

Front

SuspeDsion

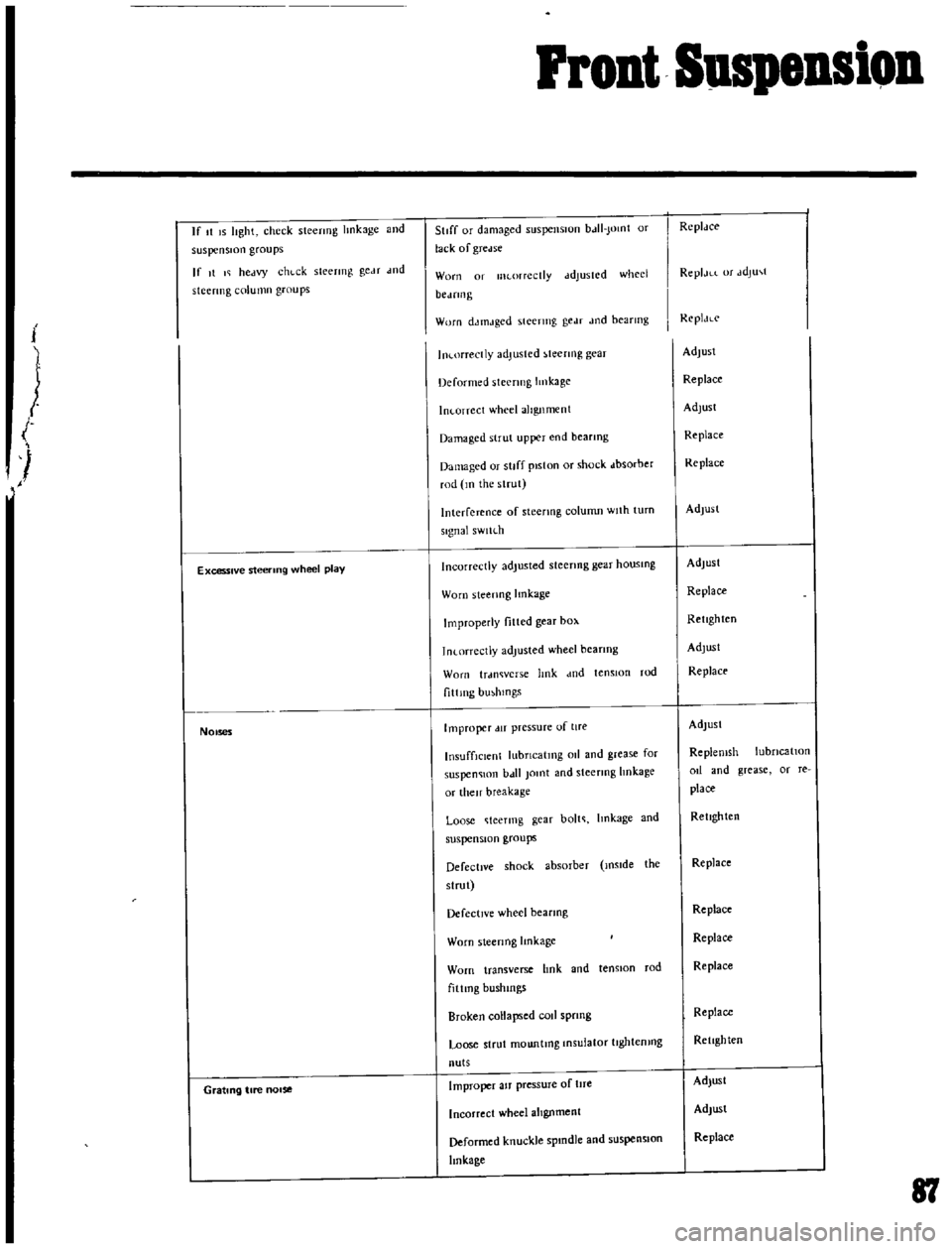

If

t

IS

lIght

check

stecrmg

hnkage

and

suspension

groups

If

It

I

hectvy

chl

ck

sleermg

geM

wd

stcermg

column

groups

Excessive

steering

wheel

play

1

NOises

Grating

tire

nOise

StIff

or

dJmaged

5llspenslUn

bJII

Jomt

or

lack

of

gTcelse

Worn

01

lIKorrcctly

ddJuSICd

whed

bCJfIll

g

Worn

dJtnJged

steering

gedf

Jod

bearmg

In

orrectly

adjusted

teenng

gear

Deformed

steering

Imkage

In

orrcct

wheel

alignment

Damaged

strut

upper

end

bearmg

Damaged

or

stiff

piston

or

shock

dbsorber

rod

m

the

strut

Interference

of

steenng

column

Wllh

turn

signal

sWlh

h

Incorrectly

adjusted

steenng

gear

housmg

Worn

steenng

lmkage

Improperly

fitted

gear

box

1n

orrectJy

adjusted

wheel

bearIng

Worn

trdl1Wcrs

e

hnk

dnd

tensIOn

rod

f1ttlllg

bmhlOgs

Improper

lIT

pressure

of

lire

InsuffiCient

lubncatmg

011

and

grease

for

suspen

lOn

b

t11

Jomt

and

steermg

hnkage

or

then

breakage

Loose

teermg

gear

bolt

Imkage

and

suspension

groups

Defective

shock

absorber

mslde

the

slrut

Defective

wheel

bearmg

Worn

sleenng

Imkage

Worn

transverse

hnk

and

tenston

rod

fiUmg

bushmgs

Broken

collapsed

rod

sprmg

Loose

strut

mountmg

Insulator

tJghtemng

nuts

Improper

aJf

pressure

of

tlfe

Incorrect

wheel

alIgnment

Deformed

knuckle

spmdle

and

suspensIOn

linkage

RcplJce

ReplJLL

or

JdJu

t

ReplJLc

AdJusl

Replace

Adlust

Replace

Replace

Adlusl

Adjust

Replace

Retighten

Adjust

Replace

Adlusl

Replemsh

lubncatlOn

od

and

grease

or

re

place

Retighten

Replace

Replace

Replace

Replace

Replace

Retighten

Adjust

Adjust

Replace

81

Page 82 of 136

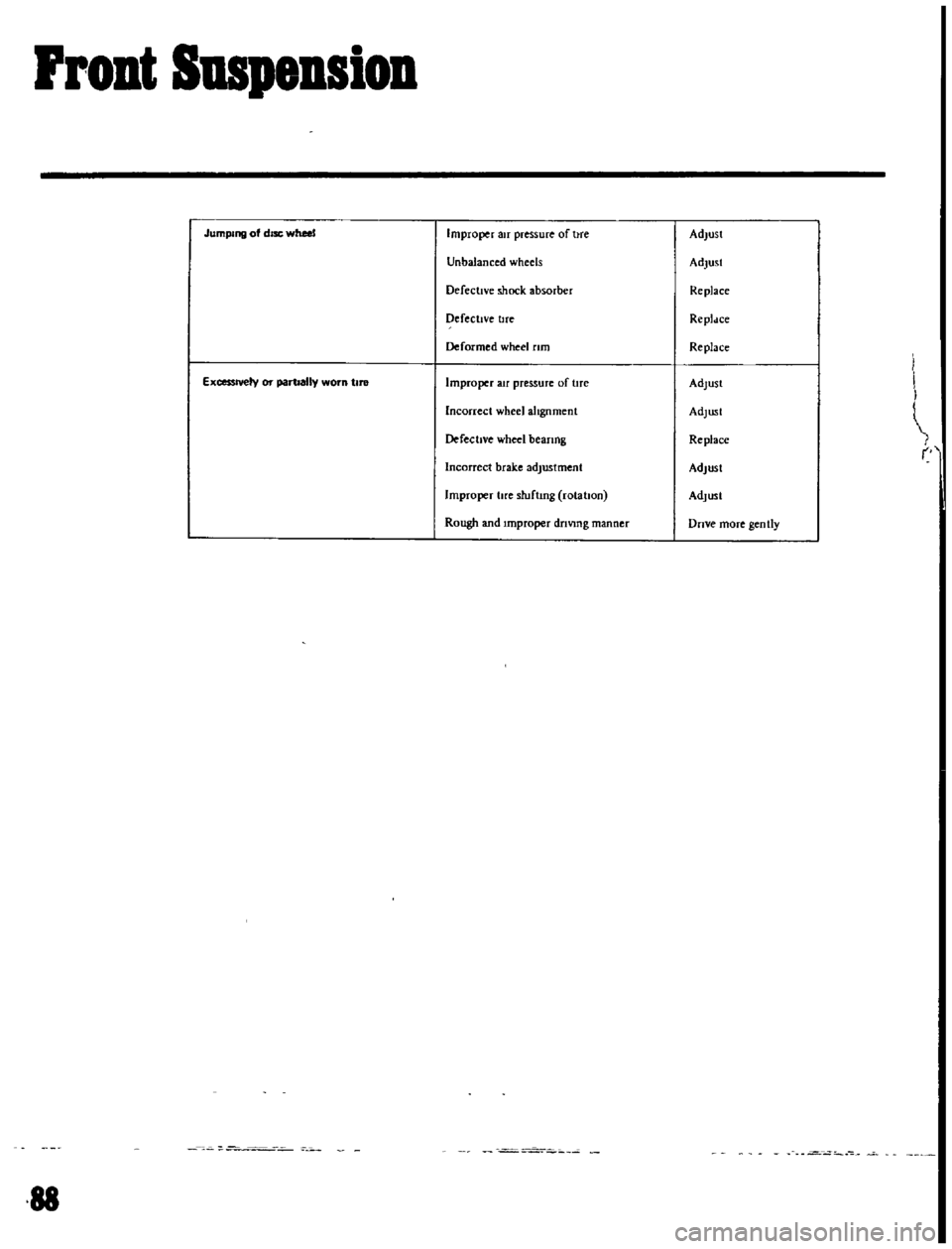

Front

Suspension

Jumping

of

disc

wheel

Improper

air

pressure

of

hre

Adjust

Unbalanced

wheels

Adjust

Defective

shock

absorber

Replace

DefectIve

tlfe

Repldce

Deformed

wheel

rim

Replace

ExcessIVely

or

partially

worn

tIre

Improper

au

pressure

of

tlfe

Adlust

Incorrect

wheel

alIgnment

Adlusl

DefectIVe

wheel

beanng

Replace

Incorrect

brake

adjustment

Adjust

Improper

lire

sluflmg

rolahon

Adlusl

Rough

and

Improper

driVing

manner

Dnve

more

gen

tly

I

88

Page 84 of 136

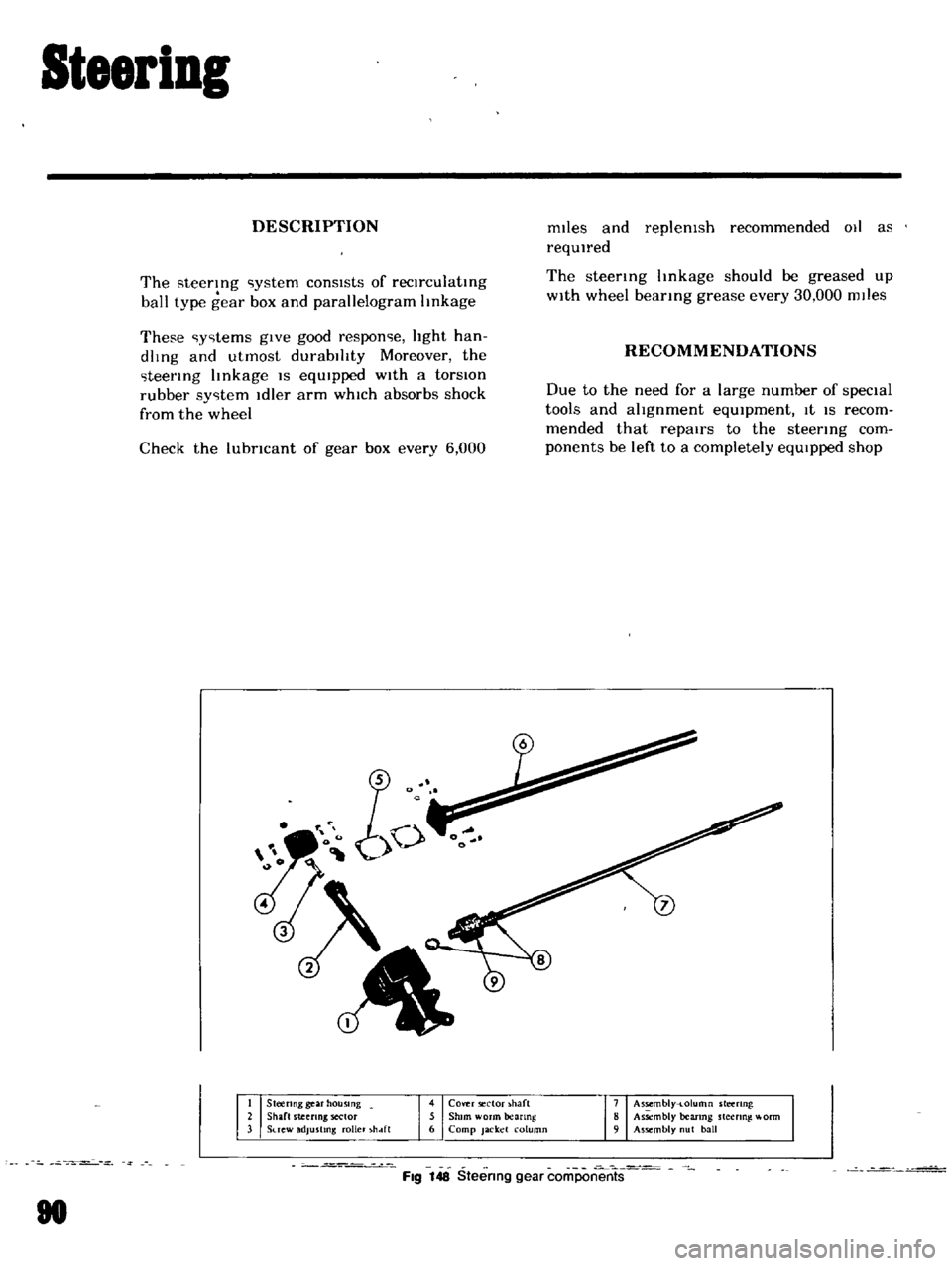

Steering

DESCRIPTION

mtles

and

replenIsh

recommended

011

as

reqUIred

The

steetlng

linkage

should

be

greased

up

WIth

wheel

bearing

grease

every

30

000

mtles

The

steering

ystem

consIsts

of

reclrculatmg

ball

type

gear

box

and

parallelogram

linkage

These

y

tems

gIve

good

respon

e

light

han

dlmg

and

utmost

durabIlity

Moreover

the

teermg

linkage

IS

eqUIpped

With

a

torsIOn

rubber

sy

tem

Idler

arm

whIch

absorbs

shock

from

the

wheel

RECOMMENDATIONS

Check

the

lubricant

of

gear

box

every

6

000

Due

to

the

need

for

a

large

number

of

specIal

tools

and

alignment

eqUIpment

It

IS

recom

mended

that

repairs

to

the

steering

com

ponents

be

left

to

a

completely

eqUIpped

shop

Steenng

gear

housing

Shaft

steeling

sector

Suew

adjusting

roller

hdft

4

Cover

ector

haft

5

Shim

worm

anng

6

Camp

Jacket

column

7

Assembly

t

olumn

steering

8

As

mbly

bearmg

steering

l

orm

9

Assembly

ut

ball

Fig

148

Steering

gear

coriiPon

rrts

80

Page 88 of 136

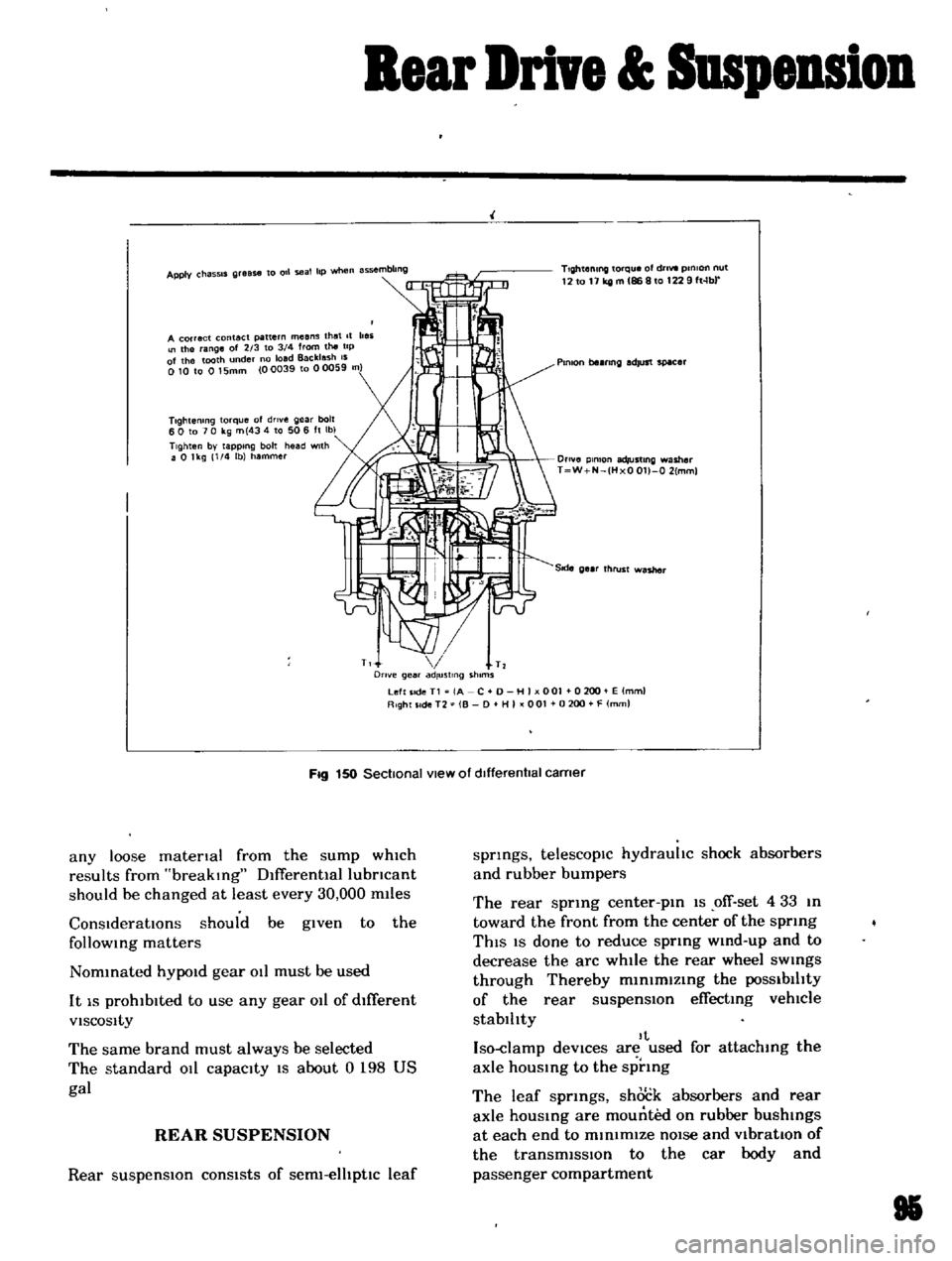

Bear

Drive

Suspension

A

correct

contact

pattern

means

that

It

beii

the

ange

of

2

3

to

3

4

from

the

tip

of

the

tooth

nder

no

load

Backlash

IS

010

to

015mm

00039

to

00059

n

Tlghtemng

torque

of

drlve

gear

bolt

60

to

70

kg

m

434

to

506

ft

Ibl

TIghten

by

tapping

bolt

head

with

a

0

lkg

1

4

lb

hammer

TIghtening

torque

of

dnvt

pmlon

nut

12

to

11

kg

m

86

8

to

1229

ft

lb

Plmon

be

nng

adjust

spacer

O

lve

plmon

adlustlng

washer

T

W

N

HxO

011

0

2

mml

T

T

Drive

gear

ad

ustlng

shims

Left

Ide

T1

jA

C

0

H

I

001

0200

E

lmml

Right

SIde

T2

B

D

HI

001

0

200

F

mml

Fig

150

Sectional

view

of

dIfferentIal

carner

any

loose

matenal

from

the

sump

which

results

from

breaking

Dlfferentlallubncant

should

be

changed

at

least

every

30

000

m11es

ConsIderatIOns

should

be

given

to

the

follOWing

matters

Nommated

hYPOld

gear

011

must

be

used

It

IS

prohibited

to

use

any

gear

011

of

dIfferent

VISCOSity

The

same

brand

must

always

be

selected

The

standard

011

capacity

IS

about

0

198

US

gal

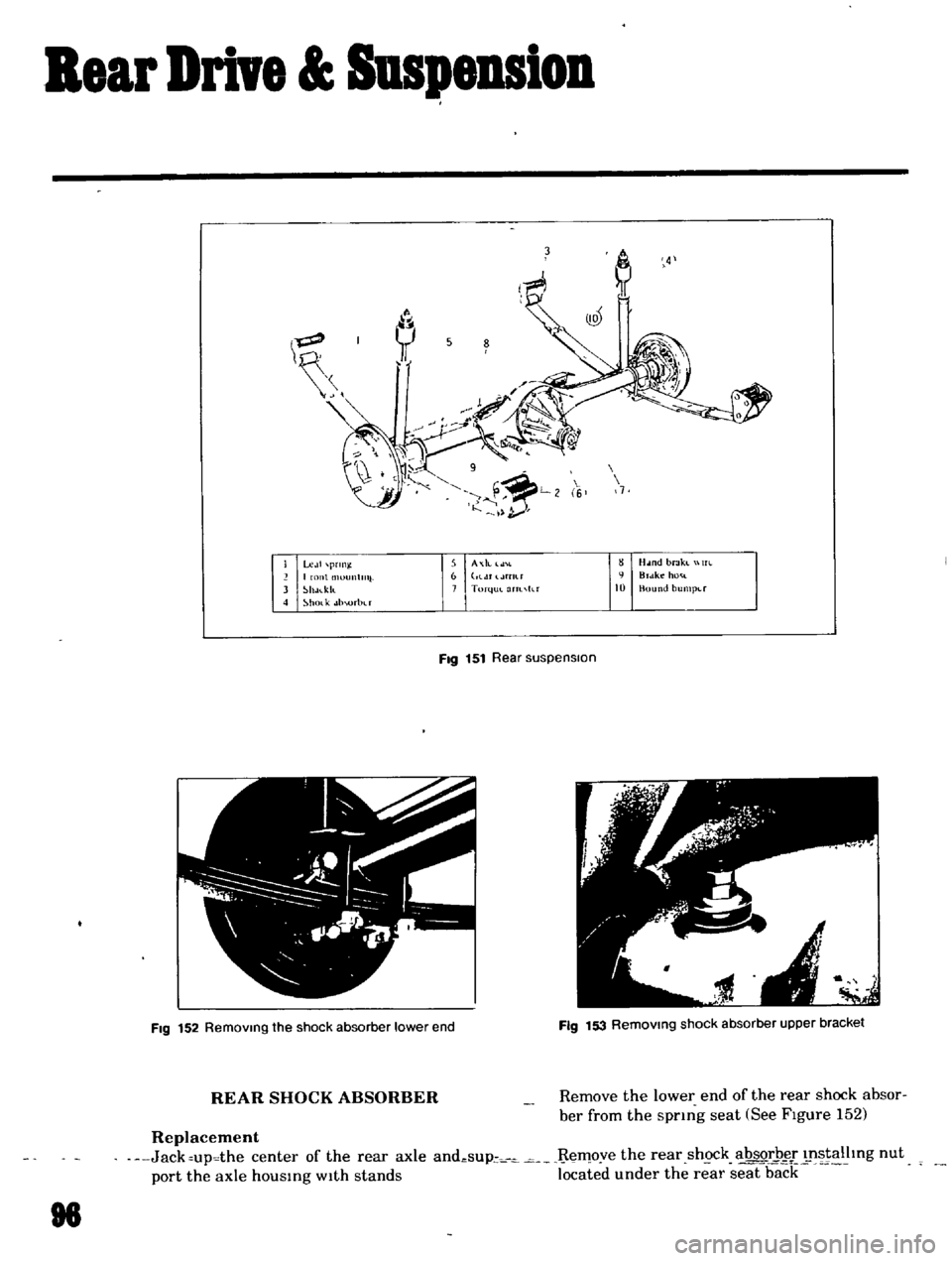

REAR

SUSPENSION

Rear

suspensIOn

consists

of

serm

elhptlc

leaf

springs

telescopIc

hydrauhc

shock

absorbers

and

rubber

bumpers

The

rear

sprmg

center

pm

1S

ofT

set

4

33

m

toward

the

front

from

the

center

of

the

sprmg

ThIS

IS

done

to

reduce

sprmg

wmd

up

and

to

decrease

the

arc

while

the

rear

wheel

sWings

through

Thereby

m1n1mlzmg

the

POSSibilIty

of

the

rear

suspensIOn

effecting

vehlCle

stablhty

It

Iso

damp

deVices

are

used

for

attachmg

the

axle

hOUSing

to

the

sprmg

The

leaf

sprmgs

shock

absorbers

and

rear

axle

housmg

are

mounted

on

rubber

bushings

at

each

end

to

minimIZe

nOIse

and

VibratIOn

of

the

transmiSSIon

to

the

car

body

and

passenger

compartment

85

Page 89 of 136

Bear

Drive

Suspension

3

4

5

B

c

16

7

Lx

ll

prill

I

It

111111

3

hJ

ddl

4

hOl

k

oIh

orbu

5

Ji

6

ldr

7

Torqw

arrl

h

r

8

H

md

brah

lrL

9

8rdk

ho

10

Hound

bumplf

Fig

151

Rear

suspension

Fig

152

Removing

the

shock

absorber

lower

end

Fig

153

Removing

shock

absorber

upper

bracket

REAR

SHOCK

ABSORBER

Remove

the

lower

end

of

the

rear

shock

absor

ber

from

the

sprmg

seat

See

FIgure

152

Replacement

Jack

upcthe

center

of

the

rear

axle

and

sup

E

ll1ove

the

rear

shock

absorJ

l

l

pstalhng

nut

port

the

axle

housmg

with

stands

located

under

the

rear

sea

back

88

Page 90 of 136

Bear

Drive

Suspension

Install

rear

shock

absorber

m

reverse

equence

of

removal

cracks

and

exceSSIve

deformatIOn

Replace

the

defectIve

parts

If

necessary

Inspection

Test

the

shock

absorber

and

replace

If

necessary

Check

for

leakage

cracks

and

the

shaft

for

straightness

Inspect

the

rubber

bushmgs

for

damage

RECOMMENDATIONS

Due

to

the

large

number

of

specIal

tools

reqUIred

and

the

advanced

knowledge

necessary

It

IS

recommended

that

the

overhaul

of

the

differential

be

left

to

a

properlv

equipped

shop

97

Page 91 of 136

Clutch

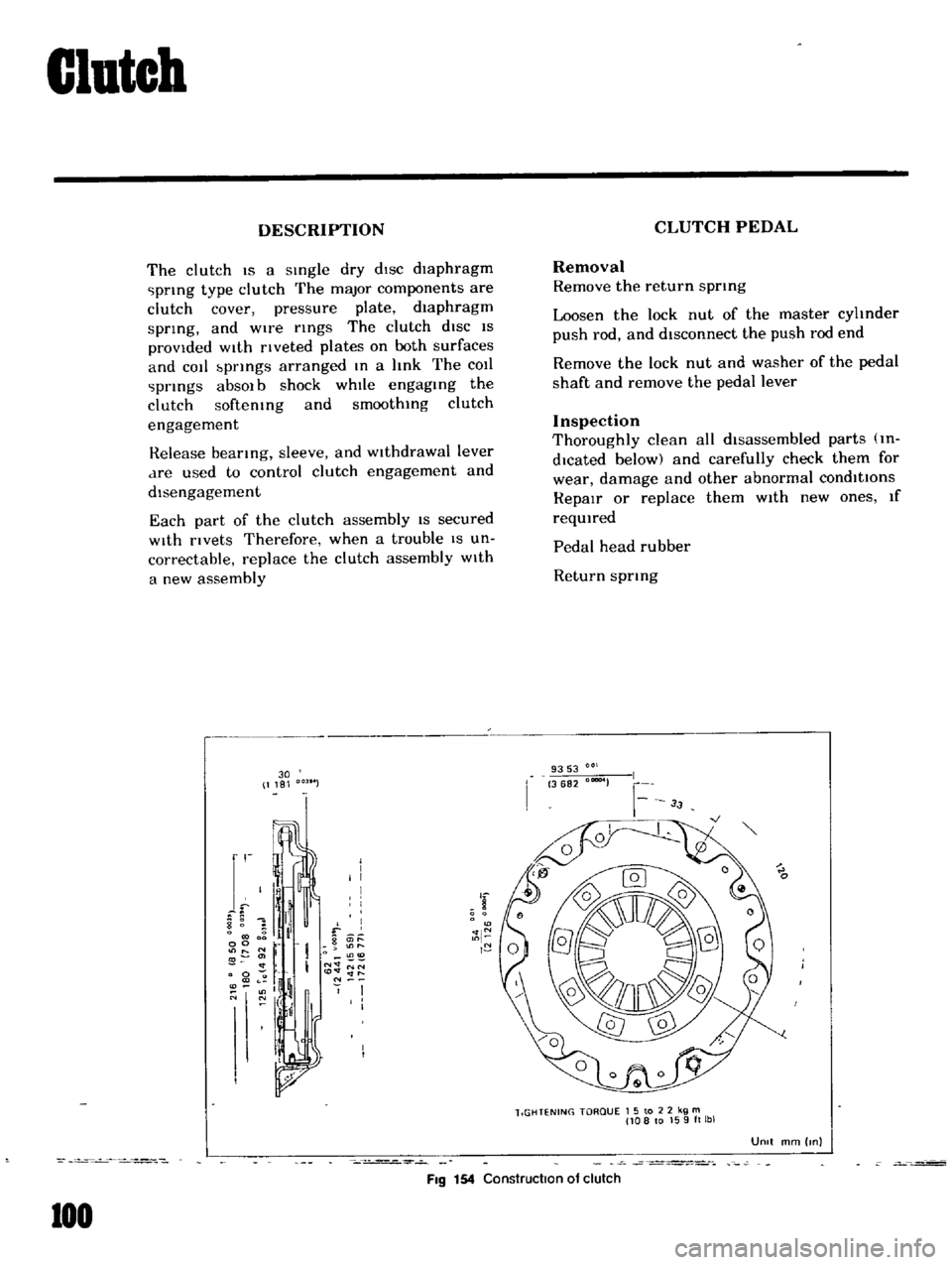

DESCRIPTION

The

clutch

IS

a

sIngle

dry

dIsc

diaphragm

prIng

type

clutch

The

major

components

are

clutch

cover

pressure

plate

diaphragm

sprIng

and

wire

rIngs

The

clutch

diSC

IS

provided

WIth

rIveted

plates

on

both

surfaces

and

cot

bprIngs

arranged

In

a

hnk

The

COIl

prIngs

absOl

b

shock

whIle

engagIng

the

clutch

softemng

and

smoothIng

clutch

engagement

Release

bearIng

sleeve

and

WIthdrawal

lever

dre

used

to

control

clutch

engagement

and

disengagement

Each

part

of

the

clutch

assembly

IS

secured

With

rivets

Therefore

when

a

trouble

IS

un

correctable

replace

the

clutch

assembly

With

a

new

assembly

30

1181

r

I

I

I

I

I

8

1

il

f

0

g

it

l

00

r

O

11

I

N

NN

0

to

lt

lt

ll

l

If

N

O

N

I

I

I

I

FIg

154

Construction

of

clutch

100

CLUTCH

PEDAL

Removal

Remove

the

return

sprmg

Loosen

the

lock

nut

of

the

master

cyhnder

push

rod

and

disconnect

the

push

rod

end

Remove

the

lock

nut

and

washer

of

the

pedal

shaft

and

remove

the

pedal

lever

Inspection

Thoroughly

clean

all

disassembled

parts

m

dlcated

below

and

carefully

check

them

for

wear

damage

and

other

abnormal

conditions

RepaIr

or

replace

them

With

new

ones

If

reqUIred

Pedal

head

rubber

Return

sprIng

9353

3682

00004

lIGHTENING

TORQUE

1

5

to

2

2

kg

m

108

to

159ft

lbl

UOIt

mm

Inl