alternator DATSUN B110 1969 Service Repair Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1969, Model line: B110, Model: DATSUN B110 1969Pages: 136, PDF Size: 5.64 MB

Page 4 of 136

able

of

Contents

MAINTENANCE

TUNE

UP

DIsassembly

32

InspectIOn

RepaIr

33

VALVE

CLEARANCES

6

AdJustmg

Regulator

33

ENGINE

OIL

6

Assembly

33

OIL

FILTER

7

COOLANT

7

COMPRESSION

7

ELECTRICAL

SYSTEM

BATTERY

8

IGNITION

TIMING

8

STARTER

36

DIstributor

Breaker

Pomt

9

Removal

37

Condenser

9

InstallatIOn

37

Spark

Plugs

9

Trouble

Shootmg

37

Carburetor

9

ALTERNATOR

36

Idle

LImIter

Cap

10

Removal

37

Dash

Pot

automatic

transmISSIOn

11

InstallatIOn

37

model

only

11

REGULATOR

39

Carburetor

Return

Sprmg

11

DeSCriptIOn

39

Fuel

Filter

11

Trouble

Shootmg

40

ENGINE

IGNITION

SYSTEM

DESCRIPTION

14

DISTRIBUTOR

44

REMOVAL

14

ConstructIOn

44

INSTALLATION

14

Checkmg

and

Adjustment

44

CLEANING

INSPECTION

14

SP

ARK

PLUGS

46

DISASSEMBL

Y

14

DeSCriptIOn

46

INSPECTION

REPAIR

18

InspectIOn

46

PreparatIOn

18

Cleamng

Regap

47

Cyltnder

Head

18

Valve

Assembly

18

Valve

Spnng

19

Valve

Rocker

Shaft

Rocker

Arm

19

FUEL

SYSTEM

Valve

LIfter

Push

Rod

20

Camshaft

Camshaft

Bearmg

20

FUEL

FILTER

50

Valve

Tlmmg

20

DESCRIPTION

50

Cyltnder

Block

21

REMOVAL

50

PIston

Piston

Pm

Plsto

LRmg

21

INSTALLATION

50

Connectmg

Rod

23

FUEL

PUMP

50

Crankshaft

24

DeSCriptIOn

50

Bushmg

Bearing

24

Testmg

51

Crankshaft

Sprocket

Removal

DIsassembly

52

Camshaft

Sprocket

25

InspectIOn

52

Flywheel

25

Assembly

52

ASSEMBL

Y

25

CARBURETOR

52

PrecautIOn

25

DeSCription

52

Cyltnder

Head

25

Adjustment

53

PIston

ConnectIng

Rod

26

Removal

58

Engme

26

DIsassembly

58

OIL

PUMP

32

Cleanmg

InspectIOn

59

Removal

Engme

m

vehicle

32

Assembly

InstallatIOn

60

I

Page 6 of 136

fable

of

Contents

BODY

WORK

SPECIFICATIONS

I

HOOD

112

SERVICE

DATA

130

Removal

112

ENGINE

134

InstallatIOn

112

General

SpeCificatIOn

134

HOOD

LOCK

112

Tlghtemng

Torque

134

Removal

112

SpeCIficatIOn

135

Adjustment

112

Coohng

System

139

LubncatlOn

114

Fuel

System

140

TRUNK

LID

LOCK

116

Starter

142

Removal

116

Alternator

143

Adjustment

116

Regulator

144

TRUNK

LID

TORSION

BAR

116

Dlstnbutor

145

DOOR

CONSTRUCTION

117

IgnItIOn

Cot

145

WIRING

DIAGRAMS

118

CLUTCH

146

BULB

SPECIFICATIONS

120

NOTES

174

HEADLAMP

121

THERMOMETER

AND

FUEL

METER

122

OIL

PRESSURE

AND

IGNITION

WARNING

LAMPS

126

I

I

t

I

3

Page 14 of 136

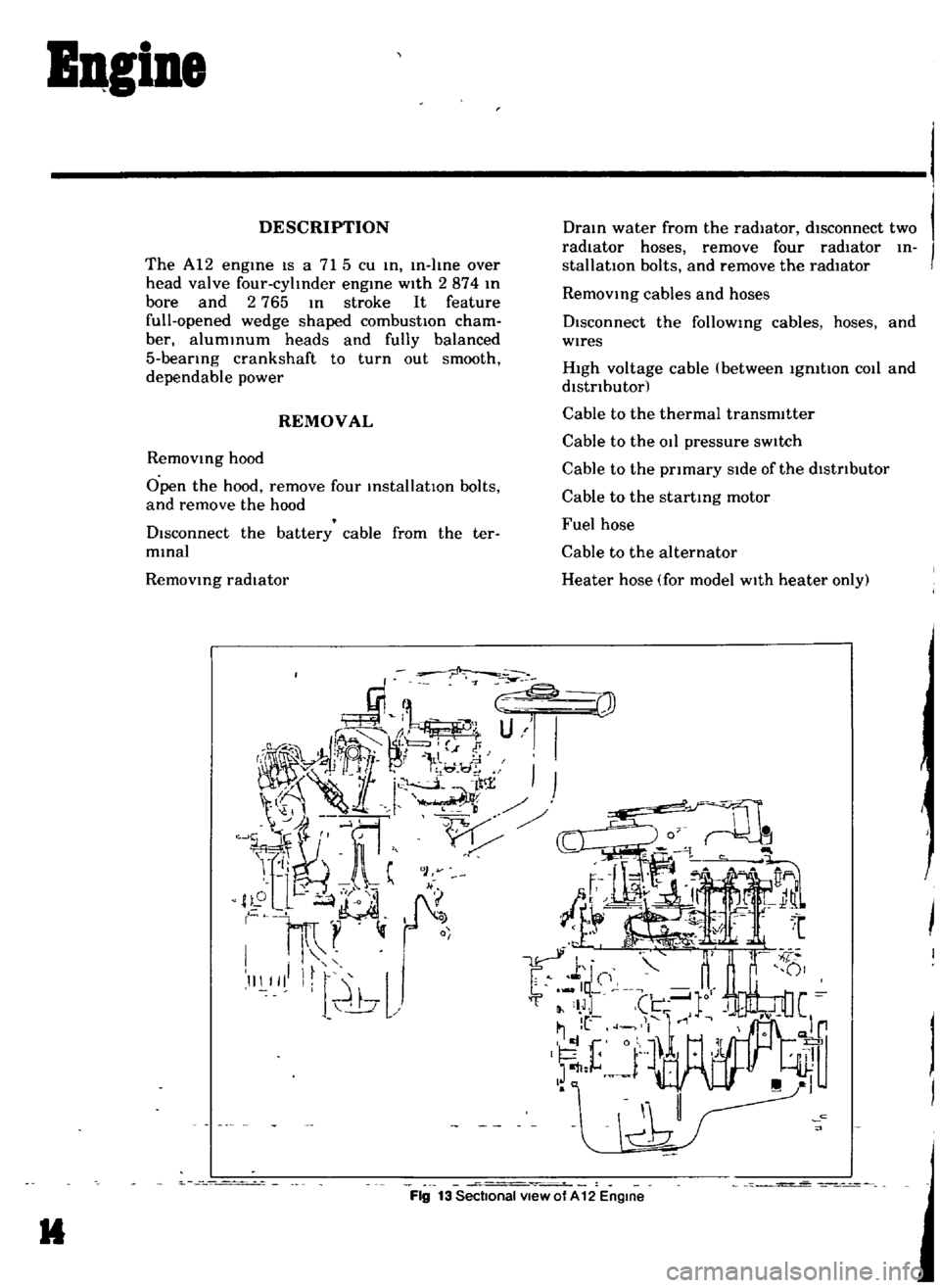

IQgiDe

DESCRIPTION

The

A12

engme

IS

a

715

cu

m

In

I

me

over

head

valve

four

cyltnder

engine

with

2874

m

bore

and

2

765

m

stroke

It

feature

full

opened

wedge

shaped

combustIOn

cham

ber

alummum

heads

and

fully

balanced

5

bearmg

crankshaft

to

turn

out

smooth

dependable

power

REMOVAL

Removmg

hood

Open

the

hood

remove

four

mstallatlOn

bolts

and

remove

the

hood

Disconnect

the

battery

cable

from

the

ter

mmal

Removmg

radIator

Dram

water

from

the

radiator

disconnect

two

radIator

hoses

remove

four

radIator

m

stallatlOn

bolts

and

remove

the

radiator

Removmg

cables

and

hoses

Disconnect

the

followmg

cables

hoses

and

wires

High

voltage

cable

between

Igmtton

COlI

and

distributor

Cable

to

the

thermal

transmitter

Cable

to

the

011

pressure

sW1tch

Cable

to

the

primary

Side

of

the

distributor

Cable

to

the

startmg

motor

Fuel

hose

Cable

to

the

alternator

Heater

hose

for

model

With

heater

only

I

Fig

13

Sectional

view

of

A

12

Engine

It

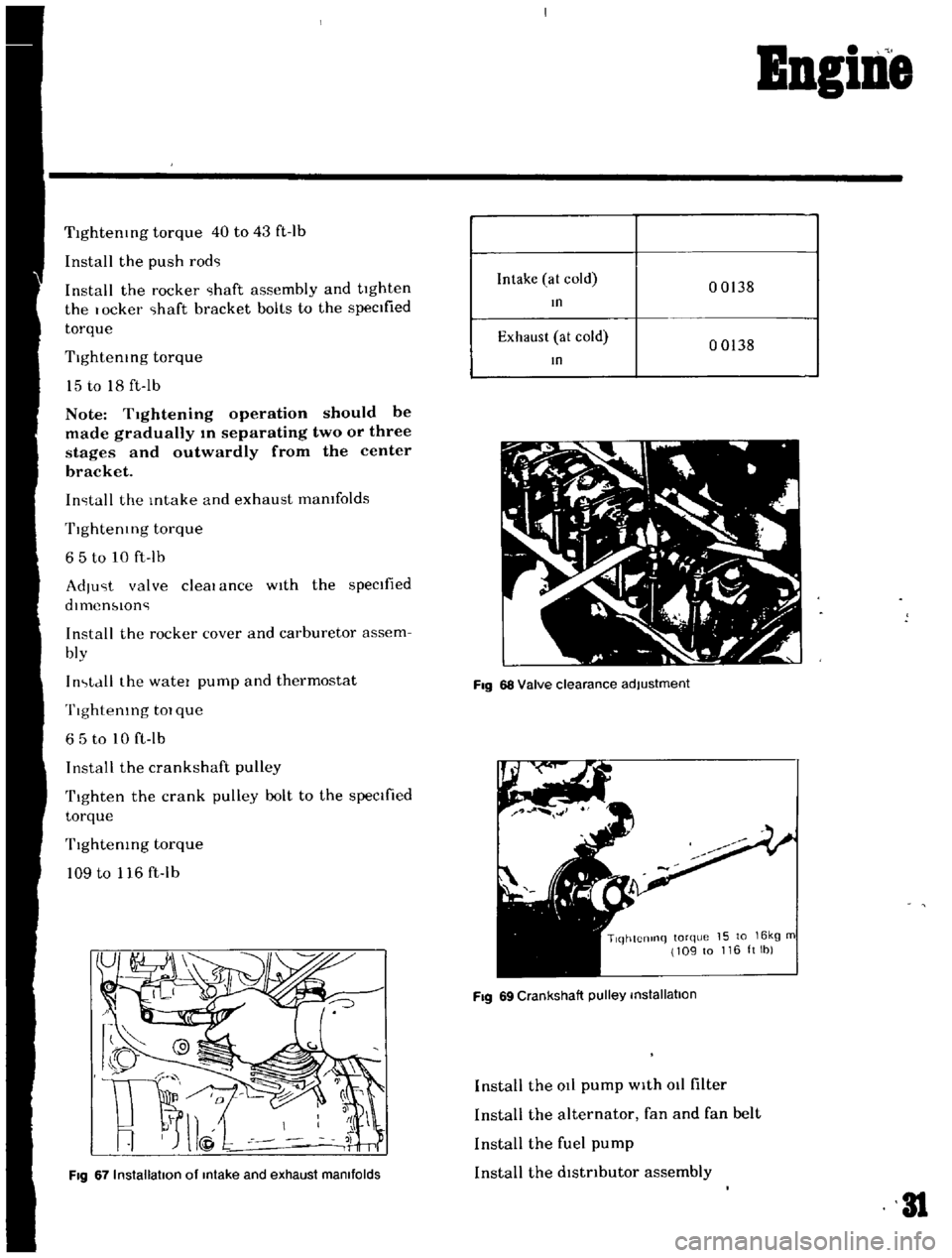

Page 31 of 136

BDgiDe

TIghtening

torque

40

to

43

ft

Ib

Install

the

push

rod

Install

the

rocker

haft

assembly

and

tighten

the

I

ocker

haft

bracket

bolts

to

the

specIfied

torque

Tightening

torque

15

to

18

ft

lb

Note

TIghtening

operation

should

be

made

gradually

10

separating

two

or

three

stages

and

outwardly

from

the

center

bracket

In

tall

the

Intake

and

exhaust

mamfolds

TIghtening

torque

65

to

10

ft

lb

AdJu

t

valve

clemance

wIth

the

specIfied

dlmenblOn

Install

the

rocker

cover

and

carburetor

assem

bly

I

n

tdll

the

watel

pump

and

thermostat

Tlghtemng

tOl

que

65

to

10

ft

lb

I

nstall

the

crankshaft

pulley

Tighten

the

crank

pulley

bolt

to

the

specIfied

torque

TIghtenIng

torque

109

to

116

ft

lb

Fig

67

Installation

of

Intake

and

exhaust

manifolds

Intake

at

cold

00138

In

Exhaust

at

cold

00138

In

Fig

68

Valve

clearance

adjustment

TlqhtCnlnq

torque

15

to

16kg

m

109

to

116ltlb

Fig

69

Crankshaft

pulley

installation

Install

the

at

pump

with

011

filter

Install

the

alternator

fan

and

fan

belt

Install

the

fuel

pump

Install

the

dlstnbutor

assembly

31

Page 35 of 136

Bleatriall

System

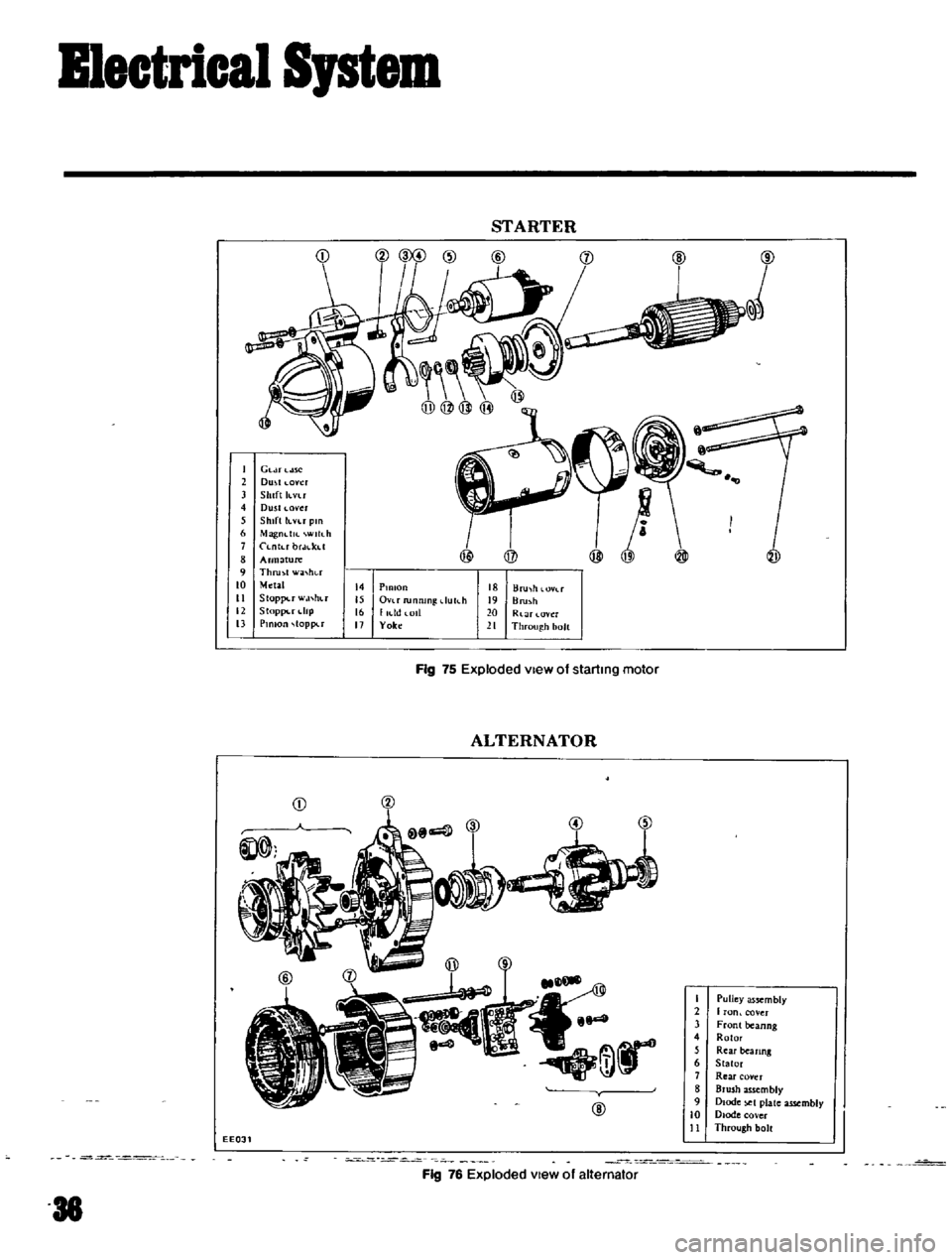

STARTER

I

Gl

U

ne

2

Dmt

oyer

3

Shift

h

vu

4

Dusll

ovcr

5

Shift

knr

pm

6

Magndlf

Wlllh

1

Lntubr

f

t

8

Arlll

ture

9

Thru

ot

w

L

ht

t

to

Metal

it

Stoppu

w

l

hu

12

Stoppt

rdlP

13

Pinion

toppu

@

@

@

@

I

15

16

17

Pmlon

Ovu

rumuRl

dukb

I

KId

lOll

Yok

18

Uru

h

19

Bru

l

b

20

Rl

ar

t

r

11

Through

bolt

Fig

75

Exploded

view

of

starting

motor

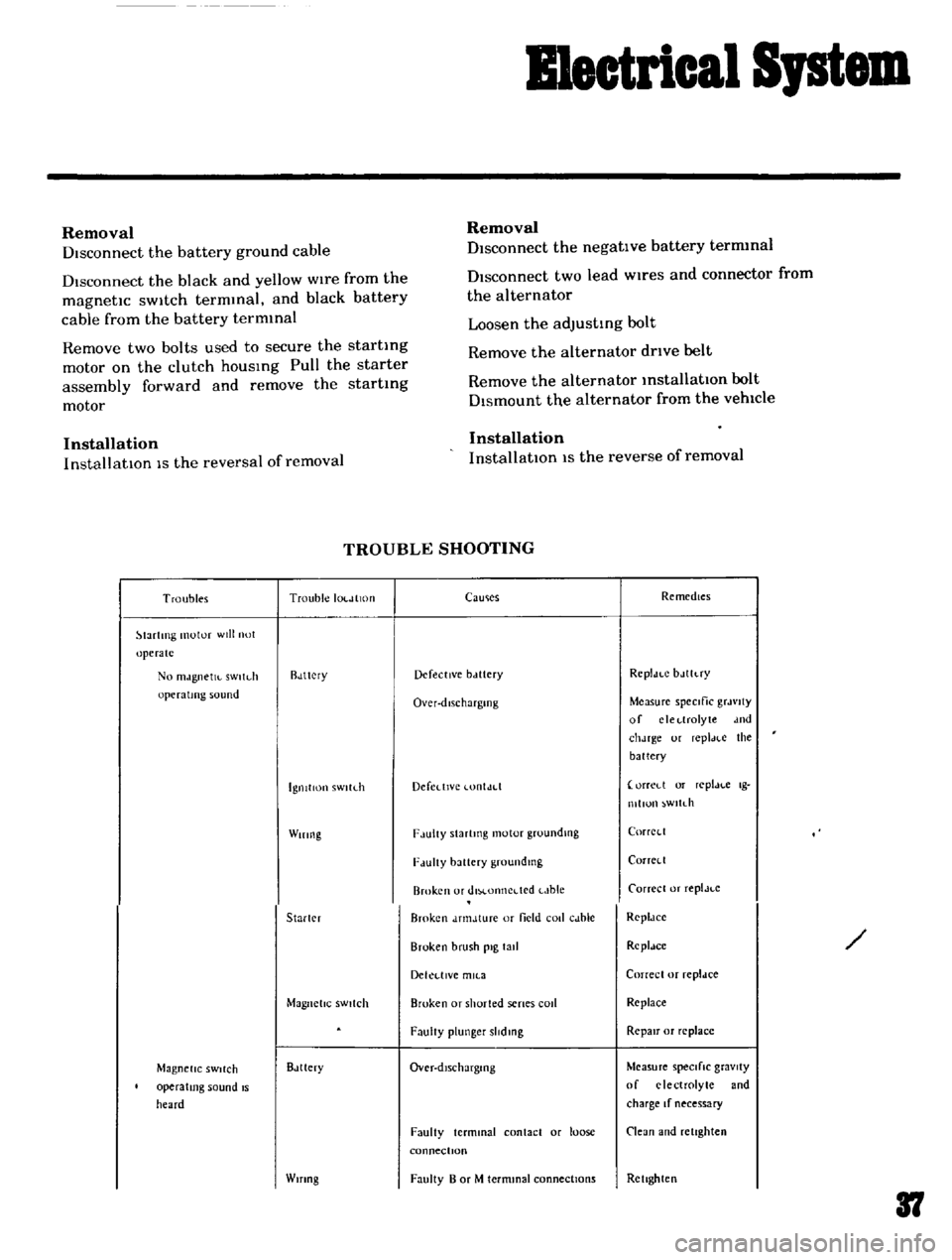

ALTERNATOR

CD

@OO

@

@

@

I

Pulley

assembly

2

f

on

cover

3

Front

beanng

4

Rotor

5

Rear

beanng

6

Stator

1

Rea

r

covet

8

Brush

assembly

9

Diode

t

plate

assembly

10

Diode

cover

11

Through

bolt

EE031

Fig

76

Exploded

view

of

alternator

Page 36 of 136

B1eetrical

Iptem

Removal

DIsconnect

the

battery

ground

cable

Disconnect

the

black

and

yellow

wIre

from

the

magnetic

sWitch

termmal

and

black

battery

cable

from

the

battery

termmal

Remove

two

bolts

used

to

secure

the

startmg

motor

on

the

clutch

housing

Pull

the

starter

assembly

forward

and

remove

the

starting

motor

Installation

InstallatlOn

IS

the

reversal

of

removal

Removal

Disconnect

the

negatIve

battery

termmal

DIsconnect

two

lead

wires

and

connector

from

the

alternator

Loosen

the

adjusting

bolt

Remove

the

alternator

drIve

belt

Remove

the

alternator

installation

bolt

Dismount

the

alternator

from

the

vehIcle

Installation

InstallatlOn

1S

the

reverse

of

removal

TROUBLE

SHOOTING

Troubles

Trouble

IOl

JlltHI

lartlTlg

motor

will

not

operate

No

mJgnetJl

sWltdl

operating

sound

Rdttcry

IgnitIon

sWltLh

Wiring

Starler

Magnetic

SWitch

Magnetic

SWitch

operating

sound

IS

heard

Bdttery

Wifing

CaUlies

Remedies

Defective

bclttery

Rcpldt

C

bJlh

ry

Over

dlschargmg

Measure

speCific

grJvlty

of

clcl

lrolyte

dnd

chJrge

ur

repl

H

e

the

battery

Defedlvc

lontJd

orreLl

or

replJl

c

Ig

mllun

wltdl

F

lulty

Slartmg

motor

groundlllg

CorrCl

l

F

lUlty

battery

groundmg

Corrcll

Broken

or

dlM

onncdcd

t

Jble

Carrece

or

replJt

c

Broken

dnnJture

or

field

coli

cJble

RcpldCC

Broken

brush

pig

tall

Rcpldce

Dekl

llVe

mll

3

Correcl

or

repldce

Broken

or

shorted

senes

cod

Replace

FaulIy

plunger

slidmg

RepaIr

or

replace

Over

dlschargmg

Measure

speCifiC

gravity

of

electrolyte

and

charge

If

necessary

Faulty

terminal

contact

or

loose

connectIOn

Clean

and

retighten

Faulty

B

or

M

termmal

connections

Rellghten

37

Page 38 of 136

llectrical

Spt

When

Harting

lWltch

I

IgllltlUn

iwltch

FJuhy

rctuflung

Repldce

set

10

OFf

the

slJrl

motor

do

nut

MJgnclK

Wltdl

Seiad

contJr

l

Repldcc

IIlg

I

op

Shorted

1

011

Replace

Faulty

plunger

slidmg

Replace

StJflillg

motOr

Pillion

does

not

dlsengJge

from

the

Repair

or

replace

nng

gedr

smoothly

Pinion

sphne

dot

110t

disengage

Repan

or

replJce

moothly

SCl7Cd

pinIOn

metal

Replace

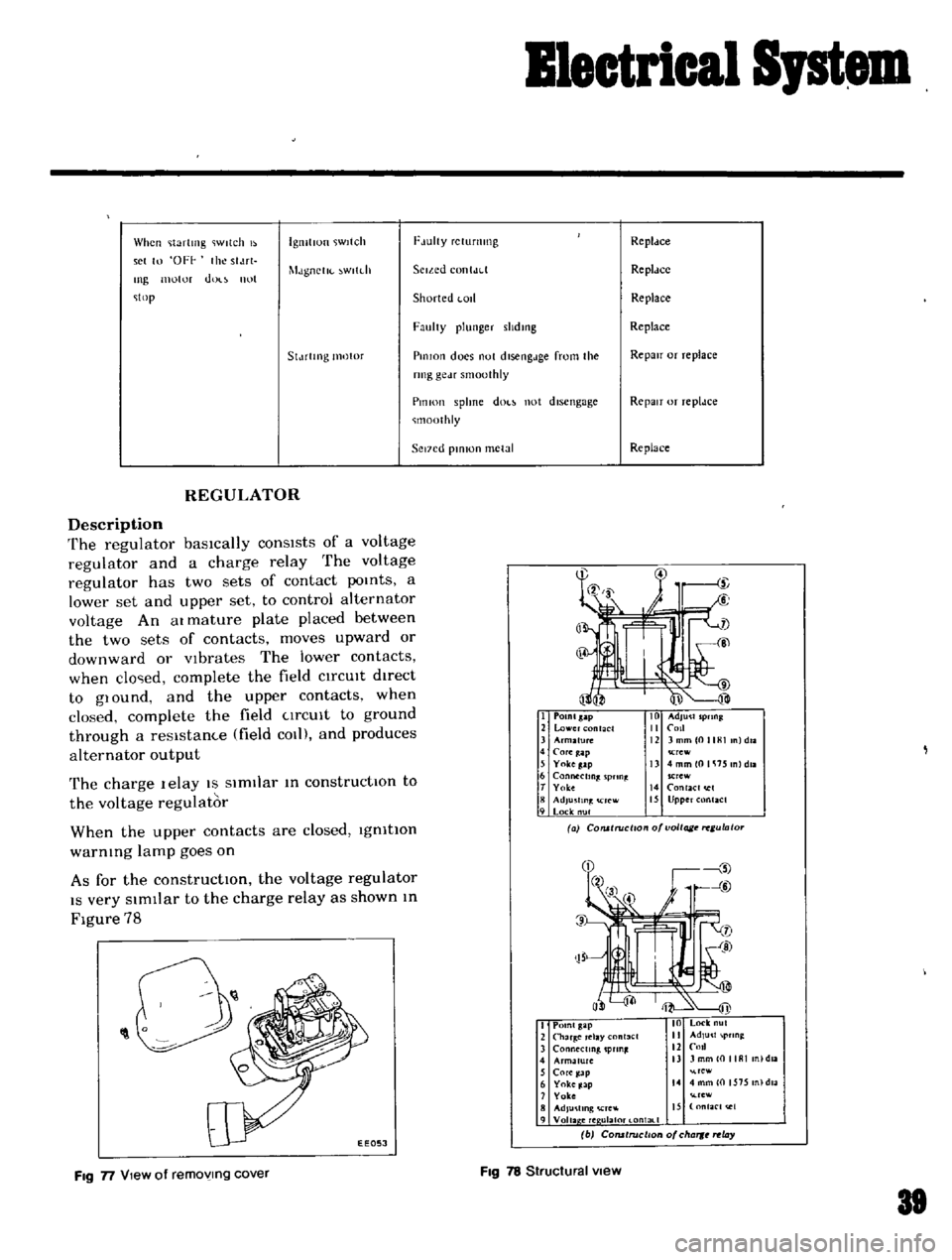

REGULATOR

Description

The

regulator

basically

consists

of

a

voltage

regulator

and

a

charge

relay

The

voltage

regulator

has

two

sets

of

contact

poInts

a

lower

set

and

upper

set

to

control

alternator

voltage

An

at

mature

plate

placed

between

the

two

sets

of

contacts

moves

upward

or

downward

or

Vibrates

The

lower

contacts

when

clo

ed

complete

the

field

CIrCUIt

dIrect

to

glOund

and

the

upper

contacts

when

closed

complete

the

field

CIrCUIt

to

ground

through

a

resIstam

e

field

COl

and

produces

alternator

output

The

charge

lelay

IS

SimIlar

In

constructIOn

to

the

voltage

regulator

When

the

upper

contacts

are

closed

IgnitIOn

warnIng

lamp

goes

on

As

for

the

constructIOn

the

voltage

regulator

IS

very

SImIlar

to

the

charge

relay

as

shown

In

Figure

78

I

POlnlsap

2

lower

nt

CI

3

Arm2fu1C

4

COfe

ap

5

Yokeg

lp

6

Connecting

pnn

t

T

Yolce

8

AdJu

fln

rcw

9

Lock

nul

Crew

13

4mmlOlli15

nldll

SCrew

14

RlaCI

I

15

Upper

Rlact

a

COlUlruci

o

o

voltage

ulato

O

0

1

EEOSJ

I

Point

gap

2

Char

Clay

nl3el

3

ConMctmg

pun

4

Armature

nl

daa

5

Core

ap

re

6

Yoke

Jap

14

4

mm

0

1575

n

dla

7

Yoke

rew

8

AdJu

llng

Cre

IS

nfaC

t

e1

9

Voila

ere

ulal0t

l

ontal

1

b

COfUtruclton

of

cha

rt

ay

FIg

n

View

of

removing

cover

FIg

78

Structural

view

81

Page 39 of 136

Blectrical

Sptem

Troubles

Trouble

locatIon

Not

output

Alternator

Regulator

WIring

Low

output

Alterndtor

Regulator

Wifing

TROUBLE

SHOOTING

Causes

Sl1ckmg

brushes

Duty

brushes

and

slIp

nngs

Loose

connections

or

broken

leads

Open

stator

coLI

Open

rotor

cotl

DefectIVe

dJodes

Shorted

rotor

Shorted

stator

Grounded

A

ternunal

Broken

fan

belt

FJulty

voltage

regulator

pomt

con

tact

Broken

cable

or

disconnectIOn

of

chargIng

CIH

UIt

StIcking

brushes

Low

brush

spring

tenSion

Duty

slIp

nngs

Partially

shorted

ground

or

open

stator

cod

Partially

shorted

or

grounded

rotor

c01l

DefectIVe

dIOde

Loose

or

worn

fan

belt

Improper

voltage

regulator

adlust

Pl

n

I

Faulty

voltage

regulator

pomt

con

t

ct

Defective

operation

Faulty

chargmg

CUI

Ult

lead

WIn

connection

Remedies

Correct

or

replace

brush

and

brush

spnng

aean

RetIghten

or

solder

connection

Replace

leads

If

necessary

6

RepaIr

or

replace

the

stator

coLi

Replace

the

rotor

Replace

the

dIOde

assembly

Replace

the

rotor

RepaIr

or

replace

the

stator

Replace

the

Insulator

Replace

the

belt

RepdU

01

replace

the

regulator

Repdtr

or

replace

Correct

or

replace

brushes

If

neces

sary

Correct

or

replace

brush

Clean

Replace

the

stator

Replace

the

rotor

Replace

the

dIode

assembly

Rettghlen

or

replace

the

belt

Check

the

voltage

regulalor

op

eratIOn

no

rep

Jr

r

J

j

required

Repair

or

replace

the

regulator

Re

olf

or

rpla

e

t

J

Loose

baltery

leririmaJ

Rettghten

1

Page 132 of 136

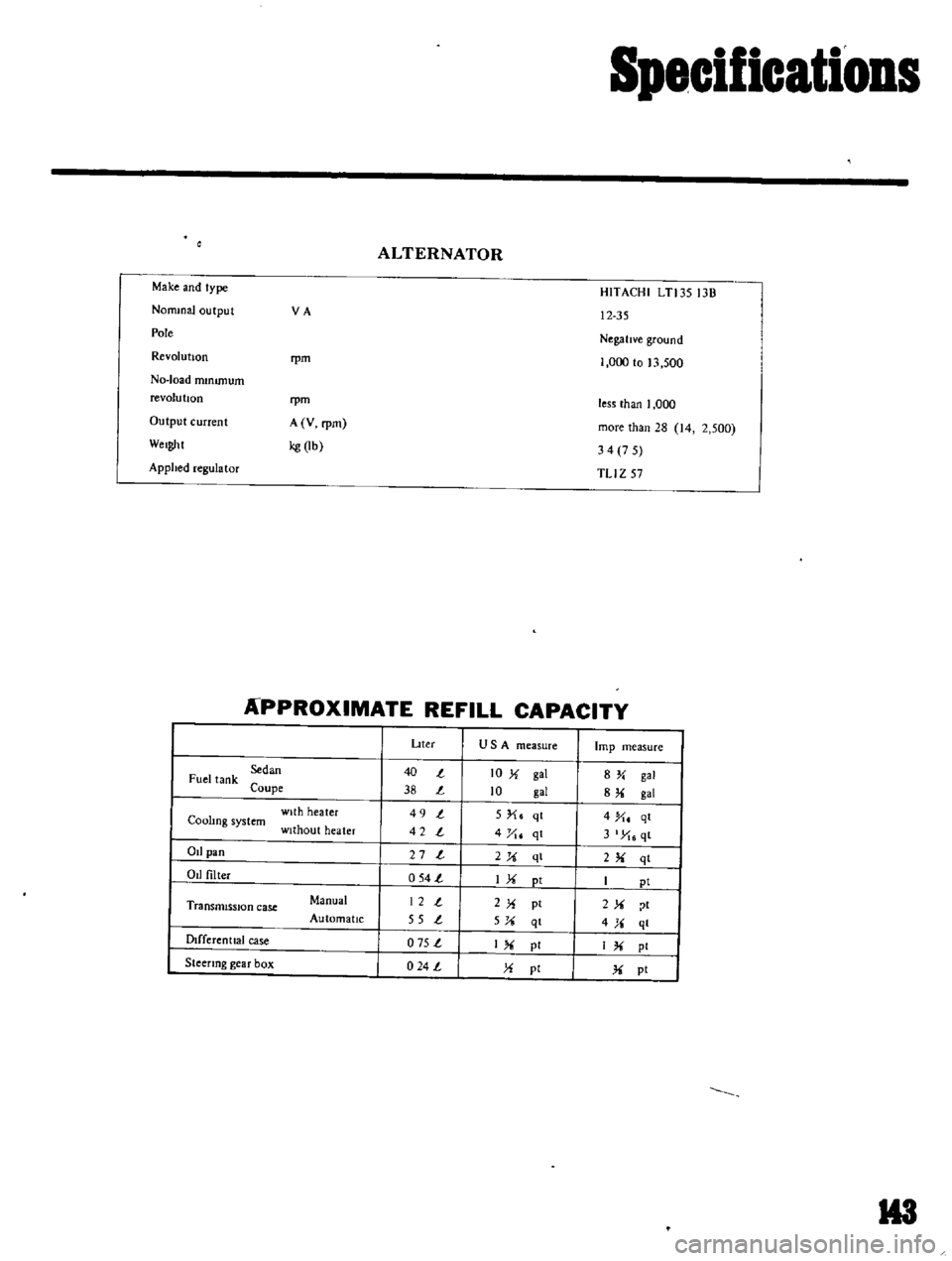

Specifications

ALTERNATOR

Make

and

type

NonunaJ

output

VA

Pole

Revolution

rpm

No

load

mmunum

revolu

bon

rpm

Output

current

A

V

rpm

Weight

kg

lb

Applied

regulator

HITACHI

LTl3S

13B

12

35

NegatIve

ground

1

000

to

13

500

less

than

I

000

more

than

28

14

2

500

34

7

5

TLI

Z

57

APPROXIMATE

REFILL

CAPACITY

Dter

USA

measure

lmp

measure

Sedan

40

t

10

X

gal

8Y

gal

Fuel

tank

Coupe

38

t

10

gal

8

gal

with

heater

49

t

5

X

qt

4

X

qt

Coohng

system

without

heater

42

t

4

yt

qt

3

X

qt

Od

pan

27

t

2X

ql

2

qt

Od

filter

054

t

IX

pt

I

pi

Transmission

case

Manual

12

t

2X

pt

2X

t

Automatic

55

t

5X

qt

4X

ql

Dlfferenttal

case

o

75

t

I

pI

IX

pI

Steenng

gear

box

024

L

X

pi

X

pt

H3