torque DATSUN B110 1969 Service Repair Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1969, Model line: B110, Model: DATSUN B110 1969Pages: 136, PDF Size: 5.64 MB

Page 6 of 136

fable

of

Contents

BODY

WORK

SPECIFICATIONS

I

HOOD

112

SERVICE

DATA

130

Removal

112

ENGINE

134

InstallatIOn

112

General

SpeCificatIOn

134

HOOD

LOCK

112

Tlghtemng

Torque

134

Removal

112

SpeCIficatIOn

135

Adjustment

112

Coohng

System

139

LubncatlOn

114

Fuel

System

140

TRUNK

LID

LOCK

116

Starter

142

Removal

116

Alternator

143

Adjustment

116

Regulator

144

TRUNK

LID

TORSION

BAR

116

Dlstnbutor

145

DOOR

CONSTRUCTION

117

IgnItIOn

Cot

145

WIRING

DIAGRAMS

118

CLUTCH

146

BULB

SPECIFICATIONS

120

NOTES

174

HEADLAMP

121

THERMOMETER

AND

FUEL

METER

122

OIL

PRESSURE

AND

IGNITION

WARNING

LAMPS

126

I

I

t

I

3

Page 11 of 136

l

aiDteDaDce

UDe

up

Install

a

timing

lIght

on

No

1

cyhnder

spark

plug

WIre

and

Install

a

tachometer

Set

Idhng

ipeed

to

approximately

800

rpm

Check

19mtlOn

tImmg

If

It

IS

50BTDC

Before

Top

of

Dead

Center

by

the

use

of

tlmmg

hght

If

necessary

adjust

It

as

follows

Loosen

iet

screw

to

such

an

extent

that

dlstnbutor

can

be

moved

by

hand

AdJu

it

IgmtlOn

tIming

to

50BTDC

Lock

dlstnbutor

set

screw

and

make

sure

that

tlmmg

IS

correct

IgnitIOn

tImmg

degreel

50

B

T

DC

Distributor

Breaker

Point

Check

dlstnbutor

breaker

pomts

for

abnormal

pItting

and

wear

Replace

If

necessary

Make

wre

they

are

In

correct

ahgnment

for

full

con

tact

and

that

pOint

dwell

and

gap

are

correct

Clean

and

apply

dlstnbutor

grease

to

cam

and

WIck

Note

Do

not

apply

grease

excessively

Dl

tI

IbutOl

POint

gap

0

018

to

0

022

In

Dwell

angle

49

to

55

degrees

Condenser

Clean

outlet

of

condenser

lead

WIre

and

check

for

loose

set

screw

RetIghten

If

necessary

Check

condenber

capacIty

With

a

capacity

meter

Fig

7

Checking

Igmllon

timing

Condenser

msulatlOn

resistance

may

be

also

checked

usmg

a

tester

by

adjusting

ItS

range

to

measure

large

resIstance

value

When

con

denser

IS

normal

the

tester

pomter

swmgs

largely

and

rapidly

and

moves

gradually

back

to

the

Infimte

SIde

When

the

pomter

does

not

stay

still

or

It

pomts

zero

m

reSIstance

replacement

IS

necessary

Condenser

capacIty

022

J

F

MIcro

Farad

Condenser

InsulatIOn

resIstance

5

Mn

Mega

ohms

Spark

Plugs

Remove

and

clean

plugs

In

a

sand

blast

cleaner

Inspect

each

spark

plug

Make

iure

that

they

are

of

the

specified

heat

range

In

ipect

msulator

for

cracks

and

chIps

Check

both

center

and

ground

electrodes

If

they

are

excessIVely

worn

replace

WIth

new

spark

plugs

File

center

electrode

flat

Set

the

gap

to

0031

to

0035

m

USIng

the

proper

adjustIng

tool

Tighten

plugs

to

11

0

to

150

ft

Ib

torque

CARBURETOR

Idle

mixture

adjustment

requIres

the

use

of

a

CO

meter

When

preparIng

to

adjust

Idle

mixture

It

IS

essential

to

have

the

meter

thoroughly

warmed

and

cahbrated

Warm

up

the

engme

suffiCiently

ContInue

engIne

operatIOn

for

one

mmute

un

der

ldhng

speed

I

i

I

I

I

I

I

I

ETOQ4

Fig

8

Checking

dlstnbutor

POint

gap

Page 25 of 136

Ingine

1

Cut

a

plastIgage

to

the

wIdth

of

the

bearing

and

place

It

m

parallel

with

the

crank

pm

gettmg

clear

of

the

011

hole

Install

the

cap

on

the

assembly

and

tighten

them

together

with

the

specified

torque

Tlghtentng

torque

36

to

43

ft

lb

Note

Be

sure

not

to

turn

the

crankshaft

when

the

plastIgage

is

Inserted

Remove

the

cap

and

measure

wIdth

of

the

plastlgage

at

Its

widest

part

wIth

the

scale

printed

tn

the

plastIgage

envelope

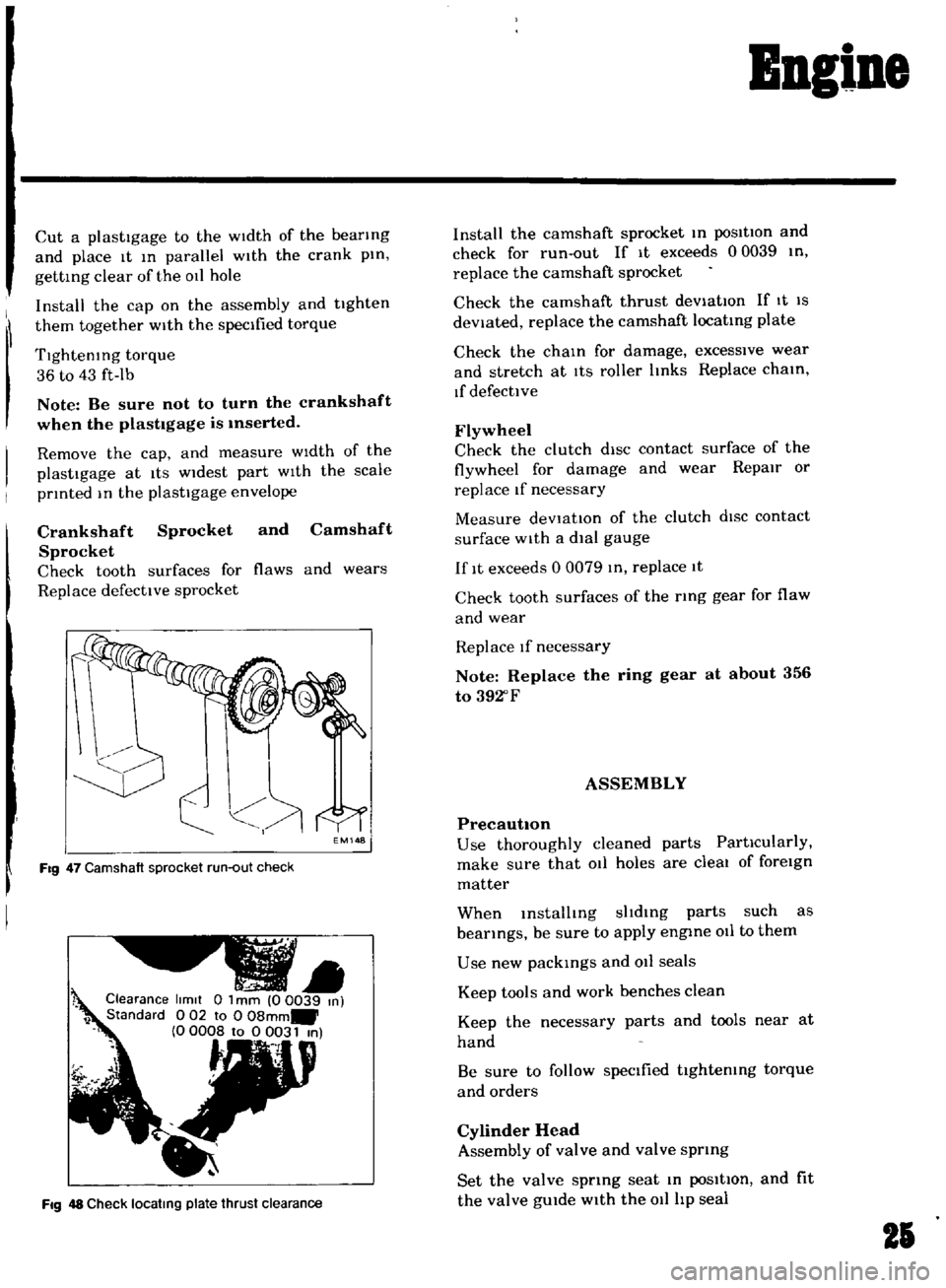

Crankshaft

Sprocket

and

Camshaft

Sprocket

Check

tooth

surfaces

for

flaws

and

wears

Replace

defective

sprocket

EM148

Fig

47

Camshaft

sprocket

run

out

check

Clearance

limit

0

1

mm

00039

m

1

Standard

0

02

to

0

08mm

0

0008

to

0

0031

m

t

Fig

48

Check

locatmg

plate

thrust

clearance

Install

the

camshaft

sprocket

m

posItion

and

check

for

run

out

If

It

exceeds

00039

tn

replace

the

camshaft

sprocket

Check

the

camshaft

thrust

deViatIOn

If

It

IS

deViated

replace

the

camshaft

locatmg

plate

Check

the

cham

for

damage

excessive

wear

and

stretch

at

ItS

roller

Imks

Replace

cham

If

defective

Flywheel

Check

the

clutch

diSC

contact

surface

of

the

flywheel

for

damage

and

wear

Repair

or

replace

If

necessary

Measure

deVtat10n

of

the

clutch

dISC

contact

surface

with

a

dial

gauge

If

It

exceeds

0

0079

m

replace

1t

Check

tooth

surfaces

of

the

ring

gear

for

flaw

and

wear

Replace

If

necessary

Note

Replace

the

ring

gear

at

about

356

to

392

F

ASSEMBLY

PrecautIOn

Use

thoroughly

cleaned

parts

PartIcularly

make

sure

that

011

holes

are

cleal

of

foreign

matter

When

mstalltng

sltdmg

parts

such

as

bearings

be

sure

to

apply

engme

011

to

them

Use

new

packmgs

and

011

seals

Keep

tools

and

work

benches

clean

Keep

the

necessary

parts

and

tools

near

at

hand

Be

sure

to

follow

specified

tIghtemng

torque

and

orders

Cylinder

Head

Assembly

of

valve

and

valve

sprmg

Set

the

valve

sprmg

seat

m

poSItIon

and

fit

the

valve

gUIde

with

the

011

hp

seal

21

Page 26 of 136

BDgiDe

Fig

49

Valve

installatIon

STl

303001

EM156

Fig

50

Piston

pin

installation

FIg

51

Piston

and

connecting

rod

assembly

Assemble

the

parts

In

order

valve

sprmg

spnng

retamer

valve

collet

and

val

ve

rocker

gUIde

28

Note

Make

sure

that

the

valve

face

is

clear

from

foreign

matters

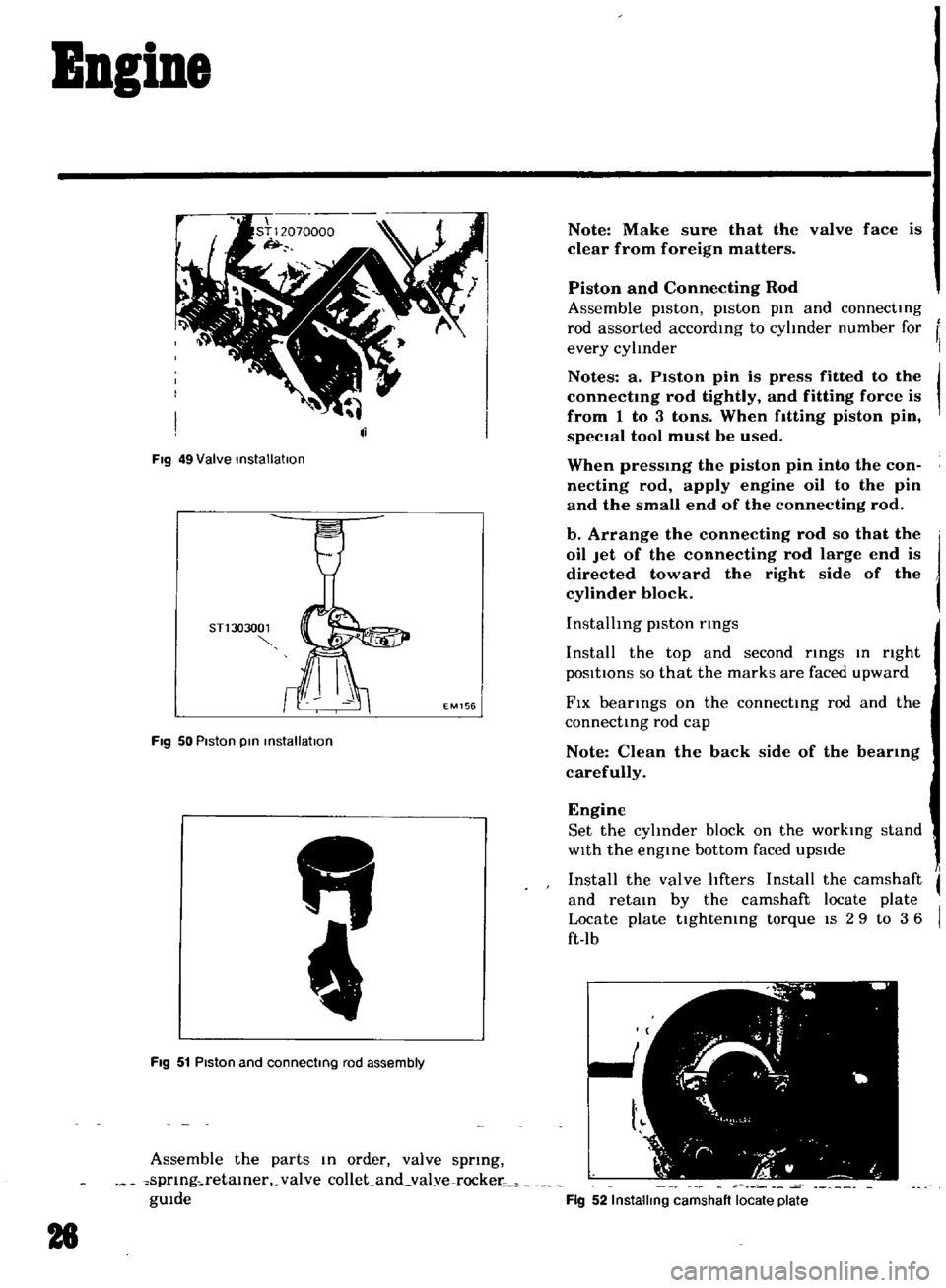

Piston

and

Connecting

Rod

Assemble

pIston

piston

pm

and

connecting

rod

assorted

accordmg

to

cyhnder

number

for

every

cylInder

Notes

a

P1ston

pin

is

press

fitted

to

the

connectmg

rod

tightly

and

fitting

force

is

from

1

to

3

tons

When

fitting

piston

pin

speCIal

tool

must

be

used

When

pressmg

the

piston

pin

into

the

con

necting

rod

apply

engine

oil

to

the

pin

and

the

small

end

of

the

connecting

rod

b

Arrange

the

connecting

rod

so

that

the

oil

Jet

of

the

connecting

rod

large

end

is

directed

toward

the

right

side

of

the

cylinder

block

InstallIng

piston

rmgs

Install

the

top

and

second

rings

In

nght

pOSItIOns

so

that

the

marks

are

faced

upward

FIX

bearings

on

the

connecting

rod

and

the

connecting

rod

cap

Note

Clean

the

back

side

of

the

bearmg

carefully

Engine

Set

the

cyhnder

block

on

the

workmg

stand

WIth

the

engine

bottom

faced

upSIde

Install

the

valve

hfters

Install

the

camshaft

and

retain

by

the

camshaft

locate

plate

Locate

plate

tightemng

torque

IS

2

9

to

3

6

ft

lb

Fig

52

Installing

camshaft

locate

plate

Page 27 of 136

Bogine

Note

Set

the

locate

plate

so

as

the

LOWER

mark

comes

to

the

engine

bot

tom

side

Set

the

maIn

bearIngR

on

theIr

posItIOns

on

the

cylinder

block

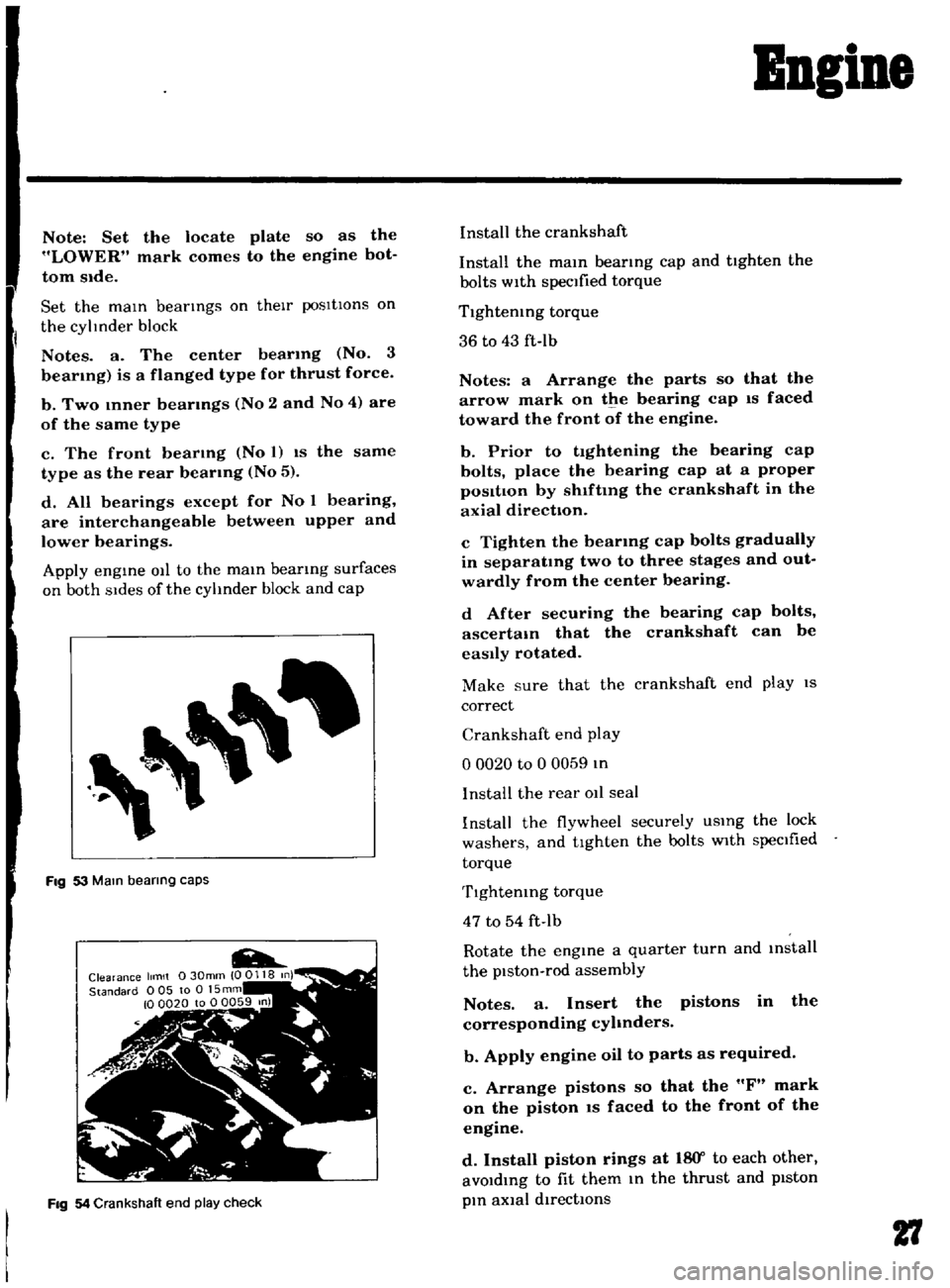

Notes

a

The

center

bearmg

No

3

bearmg

is

a

flanged

type

for

thrust

force

b

Two

lOner

bearmgs

No

2

and

No

4

are

of

the

same

type

c

The

front

bearmg

No

1

IS

the

same

type

as

the

rear

bearmg

No

5

d

All

bearings

except

for

No

I

bearing

are

interchangeable

between

upper

and

lower

bearings

Apply

engIne

OIl

to

the

mam

bearIng

surfaces

on

both

sIdes

of

the

cyltnder

block

and

cap

Fig

53

Mam

bearing

caps

Fig

54

Crankshaft

end

play

check

Install

the

crankshaft

Install

the

mam

bearmg

cap

and

tighten

the

bolts

with

specified

torque

Tlghtemng

torque

36

to

43

ft

Ib

Notes

a

Arrange

the

parts

so

that

the

arrow

mark

on

the

bearing

cap

IS

faced

toward

the

front

of

the

engine

b

Prior

to

tightening

the

bearing

cap

bolts

place

the

bearing

cap

at

a

proper

posItIon

by

shlftmg

the

crankshaft

in

the

axial

direction

c

Tighten

the

bearmg

cap

bolts

gradually

in

separatmg

two

to

three

stages

and

out

wardly

from

the

center

bearing

d

After

securing

the

bearing

cap

bolts

ascertam

that

the

crankshaft

can

be

easily

rotated

Make

sure

that

the

crankshaft

end

play

IS

correct

Crankshaft

end

play

o

0020

to

0

0059

In

I

nstalI

the

rear

011

seal

Install

the

flywheel

securely

USIng

the

lock

washers

and

tighten

the

bolts

with

specIfied

torque

Tlghtemng

torque

47

to

54

ft

Ib

Rotate

the

engine

a

quarter

turn

and

mstall

the

piston

rod

assembly

Notes

a

Insert

the

pistons

in

the

corresponding

cyhnders

b

Apply

engine

oil

to

parts

as

required

c

Arrange

pistons

so

that

the

F

mark

on

the

piston

IS

faced

to

the

front

of

the

engine

d

Install

piston

rings

at

18

Y

to

each

other

avoIdIng

to

fit

them

In

the

thrust

and

pIston

pIn

aXial

directIOns

27

Page 28 of 136

Bagine

Fig

55

ApplYing

adhesive

L

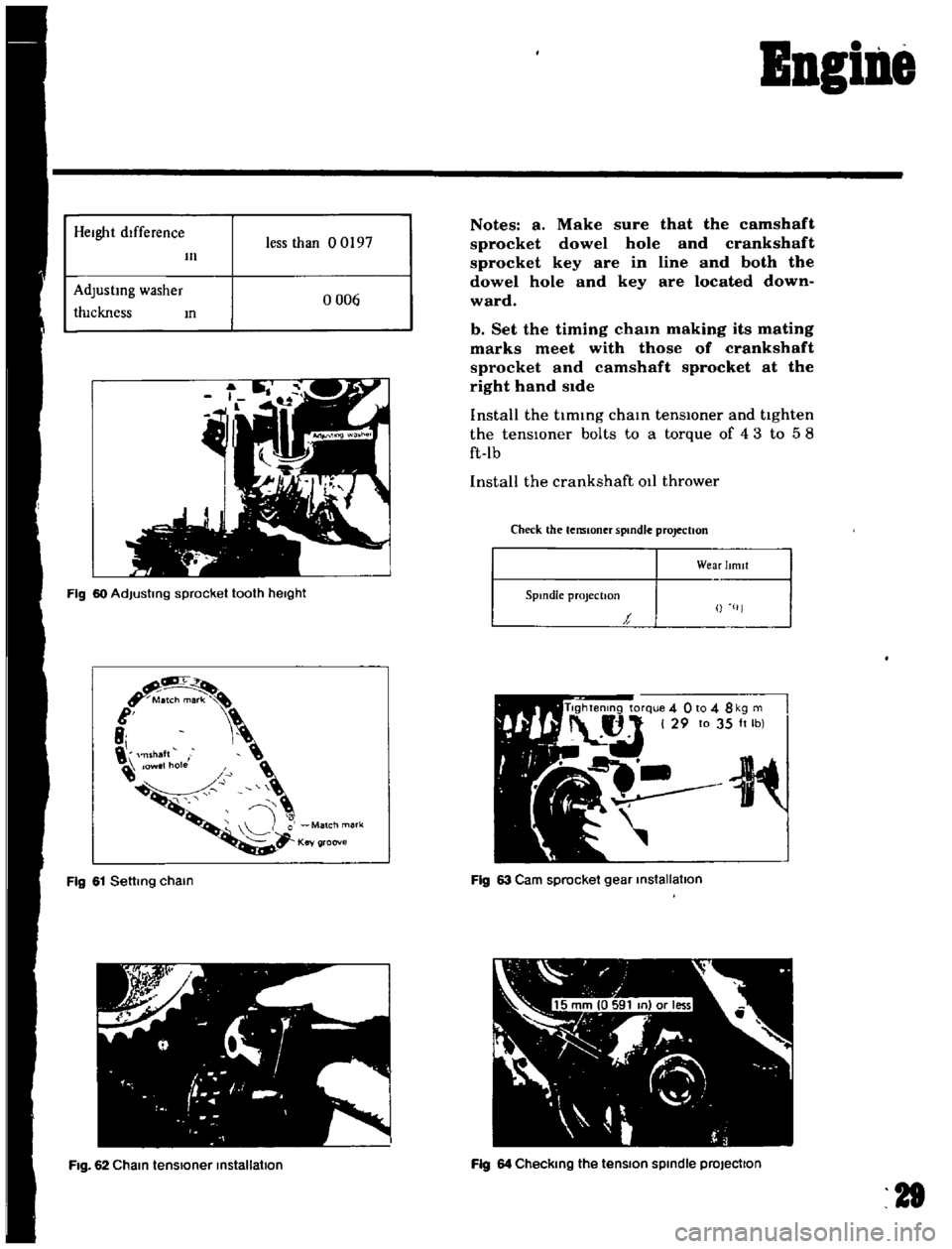

FIg

56

Flywheel

installation

c

0

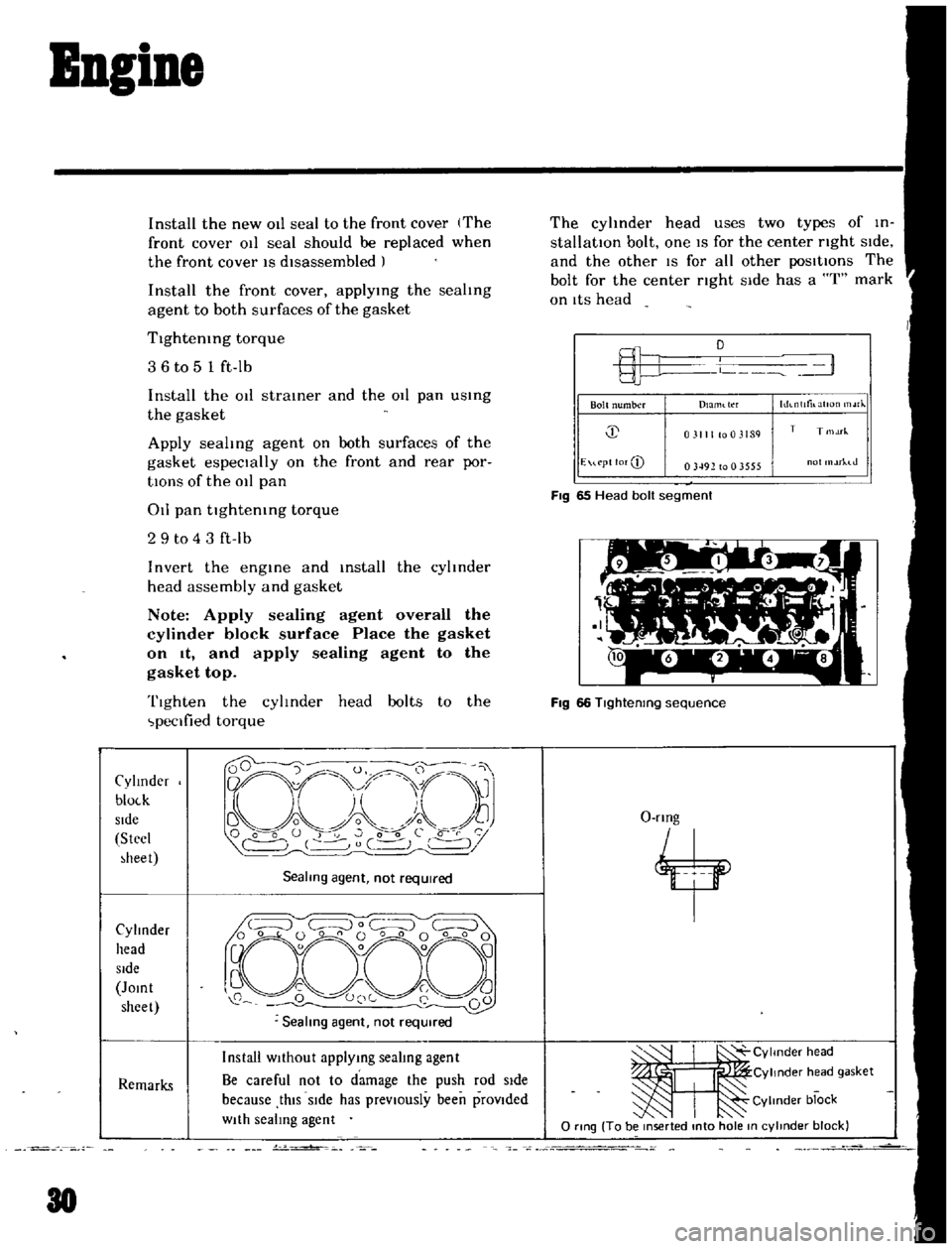

FIg

57

Piston

and

connecting

rod

assembly

installation

281

Note

Arrange

connecting

rods

and

con

necting

rod

caps

so

that

the

cylinder

num

bers

are

faced

toward

the

same

direction

Install

the

connectmg

rod

cap

Tlghtenmg

torque

23

1

to

27

5

ft

lb

Make

sure

that

end

play

of

the

connectmg

rod

large

end

IS

correct

Big

end

play

00079

to

0

0118

Install

the

camshaft

and

crankshaft

sprockets

temporarily

for

adjustment

of

the

tooth

height

by

usmg

adJustmg

washers

Install

the

tlmmg

cham

and

camshaft

sprocket

Camshaft

sprocket

tlghtemng

torque

29

to

35

ft

lb

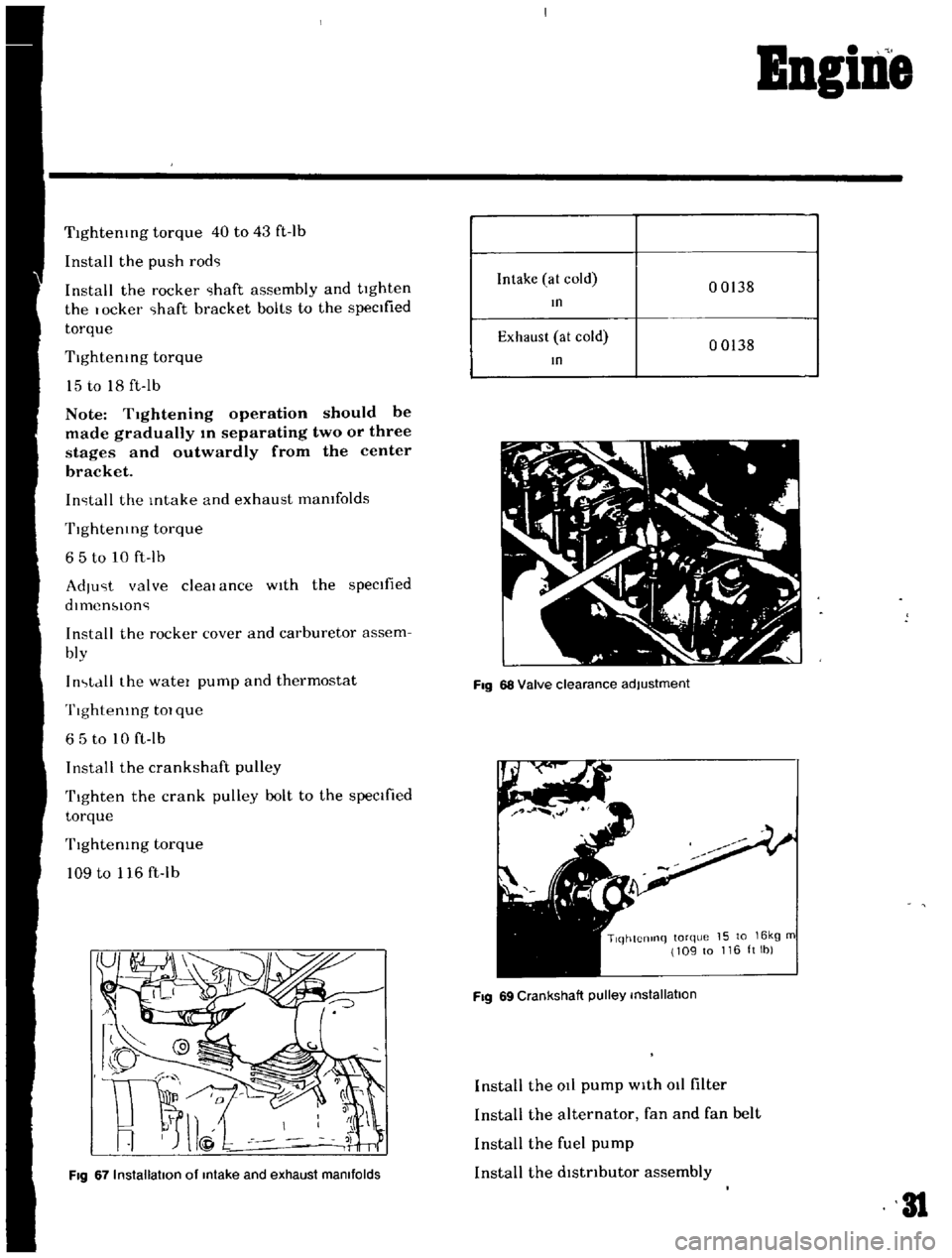

FIg

58

Connecting

rod

cap

installation

Fig

59

Big

end

play

check

Page 29 of 136

Bogine

HeIght

dIfference

less

than

0

0197

III

AdJustmg

washer

0006

tluckness

m

Fig

60

AdJustmg

sprocket

tooth

heIght

a

IT

Match

mark

e

8

Tlsnaft

0w

1

hol

0

0

0

Matohma

k

Key

groove

Fig

61

Settmg

cham

r

f

r

0

tt

I

I

l

f

I

4

Fig

62

Cham

tensloner

Installation

Notes

a

Make

sure

that

the

camshaft

sprocket

dowel

hole

and

crankshaft

sprocket

key

are

in

line

and

both

the

dowel

hole

and

key

are

located

down

ward

b

Set

the

timing

cham

making

its

mating

marks

meet

with

those

of

crankshaft

sprocket

and

camshaft

sprocket

at

the

right

hand

side

Install

the

tlmmg

cham

tenslOner

and

tighten

the

tenslOner

bolts

to

a

torque

of

43

to

58

ft

Ib

Install

the

crankshaft

011

thrower

Check

the

temloner

spondle

projection

Wear

limit

Spindle

projection

t

Fig

63

Carn

sprocket

gear

mstallatlon

Fig

64

Checkmg

the

tension

spindle

projection

21

Page 30 of 136

BDgiDe

Install

the

new

011

seal

to

the

front

cover

The

front

cover

011

seal

should

be

replaced

when

the

front

cover

IS

disassembled

Install

the

front

cover

applYing

the

seahng

agent

to

both

surfaces

of

the

gasket

Tlghtemng

torque

36

to

5

1

ft

lb

Install

the

ot

strainer

and

the

011

pan

uSing

the

gasket

Apply

seahng

agent

on

both

surfaces

of

the

gasket

especIally

on

the

front

and

rear

por

tlOns

of

the

011

pan

011

pan

tlghtemng

torque

2

9

to

4

3

ft

lb

Invert

the

engine

and

Install

the

cyhnder

head

assembly

and

gasket

Note

Apply

sealing

agent

overall

the

cylinder

block

surface

Place

the

gasket

on

It

and

apply

sealing

agent

to

the

gasket

top

Tighten

the

cylinder

head

bolts

to

the

peclfied

torque

Cylmder

bloLk

Side

Stecl

heet

Sealmg

agent

not

required

Cylinder

head

Side

Jomt

sheet

Remarks

Install

WIthout

applymg

sealing

agent

Be

careful

not

to

damage

the

push

rod

Side

because

thIS

SIde

has

prevIOusly

been

provIded

WIth

sealing

agent

J

30

v

o

The

cyhnder

head

uses

two

types

of

in

stallatIOn

bolt

one

IS

for

the

center

nght

SIde

and

the

other

IS

for

all

other

posItIOns

The

bolt

for

the

center

nght

Side

has

a

I

mark

on

ItS

head

L

1

Bolt

number

hh

nlltilatlOn

rJ

Dlaml

tl

f

j

031111003189

T

T

1M

E

u

pt

lor

CD

03492

to

0

3555

ot

rhJ

FIg

65

Head

bolt

segment

Fig

66

Tlghtenmg

sequence

O

rmg

4

ItI

CYlmder

head

Cylinder

h

ad

gasket

Cylinder

block

o

rtng

To

be

mserted

mto

hole

m

cylmder

block

Page 31 of 136

BDgiDe

TIghtening

torque

40

to

43

ft

Ib

Install

the

push

rod

Install

the

rocker

haft

assembly

and

tighten

the

I

ocker

haft

bracket

bolts

to

the

specIfied

torque

Tightening

torque

15

to

18

ft

lb

Note

TIghtening

operation

should

be

made

gradually

10

separating

two

or

three

stages

and

outwardly

from

the

center

bracket

In

tall

the

Intake

and

exhaust

mamfolds

TIghtening

torque

65

to

10

ft

lb

AdJu

t

valve

clemance

wIth

the

specIfied

dlmenblOn

Install

the

rocker

cover

and

carburetor

assem

bly

I

n

tdll

the

watel

pump

and

thermostat

Tlghtemng

tOl

que

65

to

10

ft

lb

I

nstall

the

crankshaft

pulley

Tighten

the

crank

pulley

bolt

to

the

specIfied

torque

TIghtenIng

torque

109

to

116

ft

lb

Fig

67

Installation

of

Intake

and

exhaust

manifolds

Intake

at

cold

00138

In

Exhaust

at

cold

00138

In

Fig

68

Valve

clearance

adjustment

TlqhtCnlnq

torque

15

to

16kg

m

109

to

116ltlb

Fig

69

Crankshaft

pulley

installation

Install

the

at

pump

with

011

filter

Install

the

alternator

fan

and

fan

belt

Install

the

fuel

pump

Install

the

dlstnbutor

assembly

31

Page 45 of 136

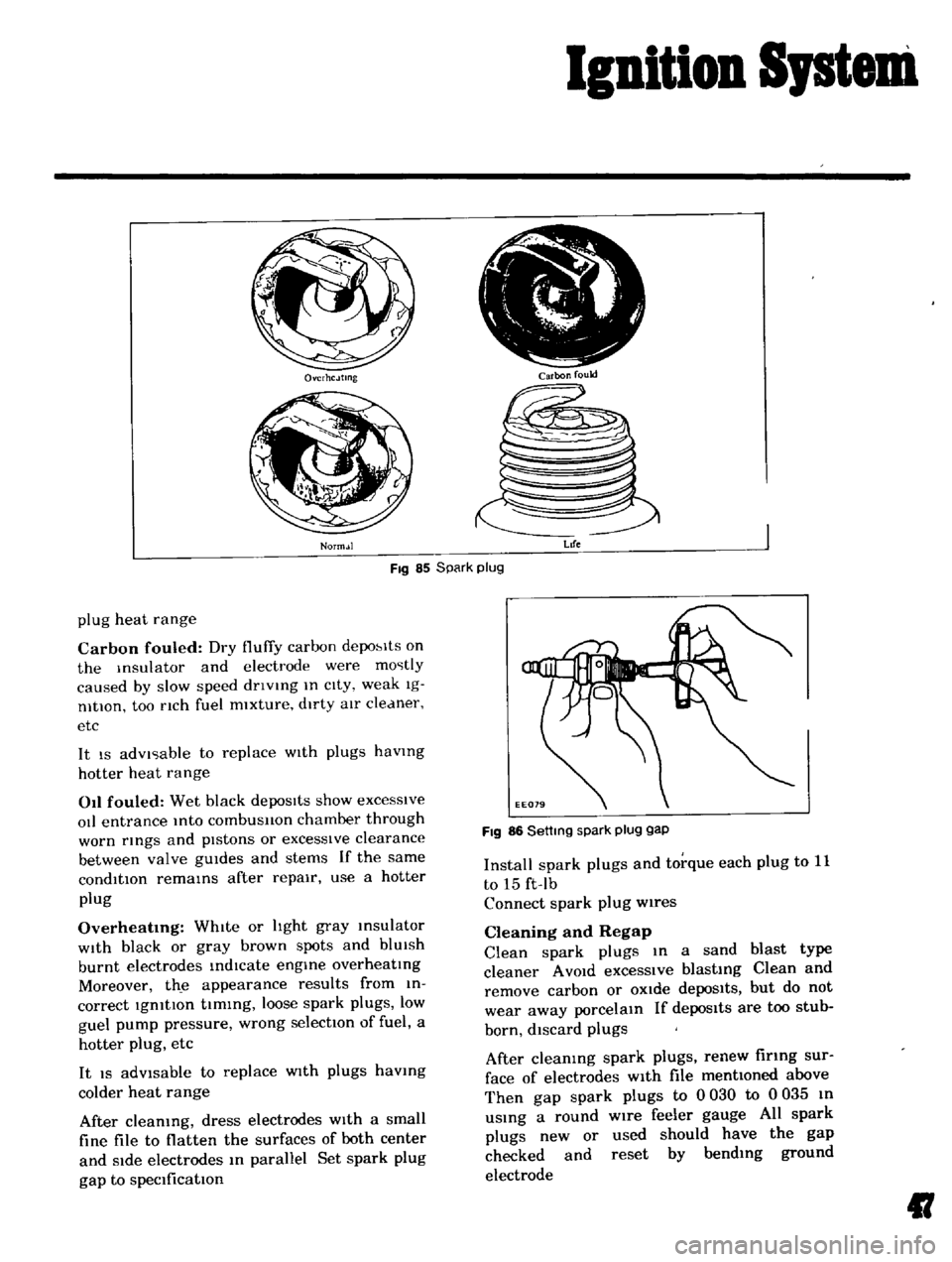

Icnition

Sptem

Ovcrhc

Jtmg

Norm

Jl

i

r

rJ

I

ttr

I

i

V

Carbon

fould

Fig

85

Spark

plug

Life

plug

heat

range

Carbon

fouled

Dry

fluffy

carbon

depo

lts

on

the

Insulator

and

electrode

were

mostly

caused

by

slow

speed

dnvlng

In

cIty

weak

Ig

nltlOn

too

nch

fuel

mixture

dirty

aIr

cleaner

etc

It

IS

advIsable

to

replace

WIth

plugs

havmg

hotter

heat

range

011

fouled

Wet

black

depoSits

show

excesSive

oIl

entrance

Into

combusllon

chamber

through

worn

rmgs

and

pIstons

or

excessIve

clearance

between

valve

gUIdes

and

stems

If

the

same

condition

remams

after

repair

use

a

hotter

plug

Overheatmg

WhIte

or

hght

gray

msulator

WIth

black

or

gray

brown

spots

and

blUIsh

burnt

electrodes

indIcate

engme

overheatIng

Moreover

th

e

appearance

results

from

in

correct

IgnitIon

tIming

loose

spark

plugs

low

guel

pump

pressure

wrong

selectIOn

of

fuel

a

hotter

plug

etc

It

IS

adVisable

to

replace

WIth

plugs

havmg

colder

heat

range

After

cleaning

dress

electrodes

With

a

small

fine

file

to

flatten

the

surfaces

of

both

center

and

Side

electrodes

In

parallel

Set

spark

plug

gap

to

specification

FIg

86

Settmg

spark

plug

gap

Install

spark

plugs

and

torque

each

plug

to

11

to

15

ft

Ib

Connect

spark

plug

wires

Cleaning

and

Regap

Clean

spark

plugs

In

a

sand

blast

type

cleaner

A

VOId

excessIve

blasting

Clean

and

remove

carbon

or

OXide

depoSits

but

do

not

wear

away

porcelain

If

depos1ts

are

too

stub

born

discard

plugs

After

cleaning

spark

plugs

renew

firing

sur

face

of

electrodes

With

file

mentioned

above

Then

gap

spark

plugs

to

0

030

to

0

035

In

uSing

a

round

wire

feeler

gauge

All

spark

plugs

new

or

used

should

have

the

gap

checked

and

reset

by

bending

ground

electrode

II