torque DATSUN B110 1969 Service User Guide

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1969, Model line: B110, Model: DATSUN B110 1969Pages: 136, PDF Size: 5.64 MB

Page 68 of 136

Brakes

Note

Be

careful

not

to

confuse

the

piston

A

with

B

Apply

rubber

grease

hghtly

to

the

shdlng

par

tlon

of

p1ston

and

Insert

the

piston

Into

the

cyhnder

Note

When

insertmg

the

piston

be

careful

not

to

insert

too

far

Install

the

boot

and

retaining

nng

Install

so

that

the

yoke

groove

of

bIas

nng

of

piston

A

COinCide

wIth

the

yoke

groove

of

cyhnder

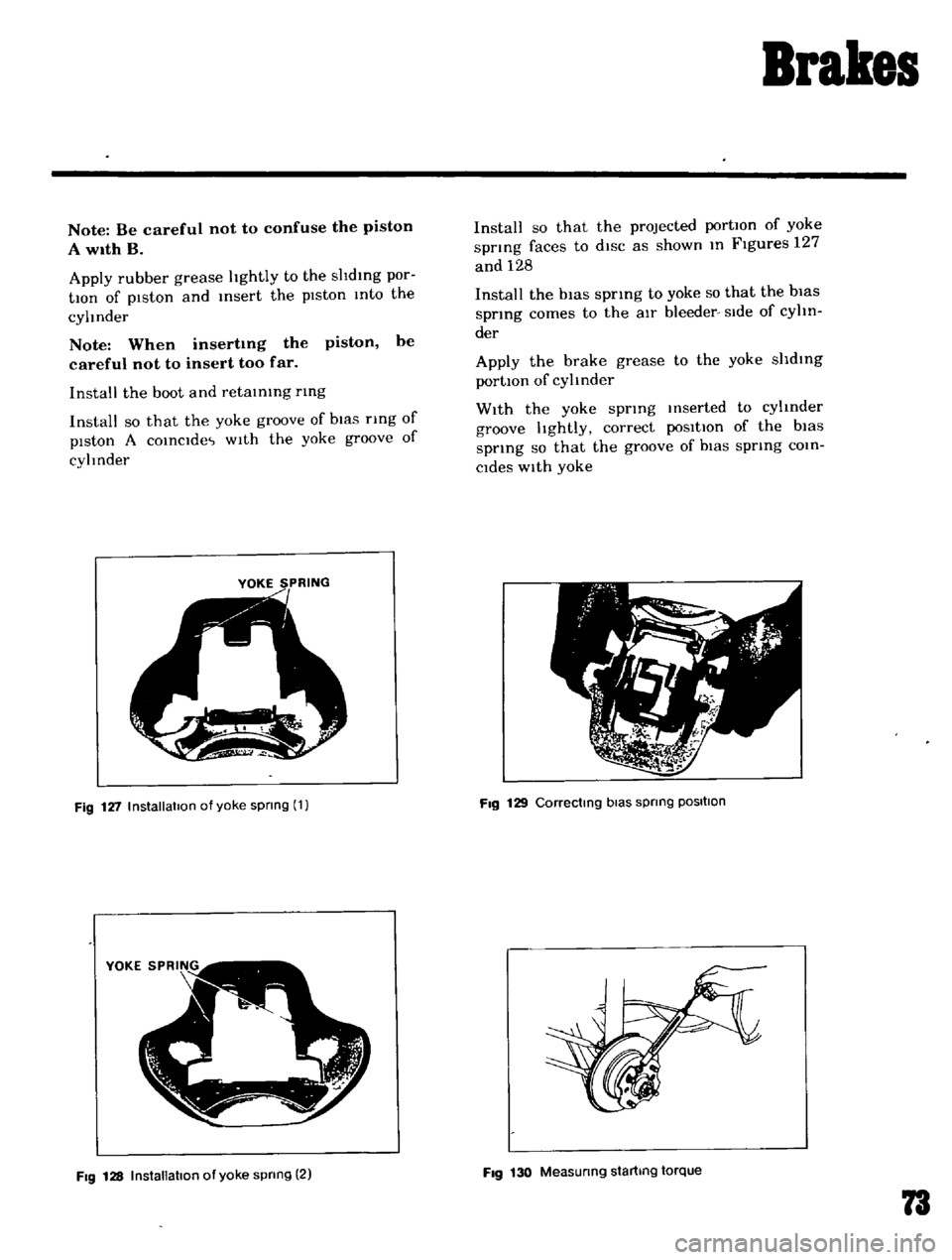

YOKE

SPRING

Fig

127

Installation

of

yoke

spnng

1

Fig

128

InstallatIOn

of

yoke

spnng

2

Install

so

that

the

projected

portIOn

of

yoke

spnng

faces

to

diSC

as

shown

In

Figures

127

and

128

Install

the

bias

spring

to

yoke

so

that

the

bias

spring

comes

to

the

aIr

bleeder

Side

of

cyhn

der

Apply

the

brake

grease

to

the

yoke

shdlng

portIOn

of

cylinder

With

the

yoke

spring

Inserted

to

cylinder

groove

hghtly

correct

poSitIOn

of

the

bias

spnng

so

that

the

groove

of

biaS

spring

COin

Cides

With

yoke

Fig

129

Correctmg

bias

spnng

POSItion

Fig

130

Measunng

startmg

torque

73

Page 69 of 136

Brakes

c

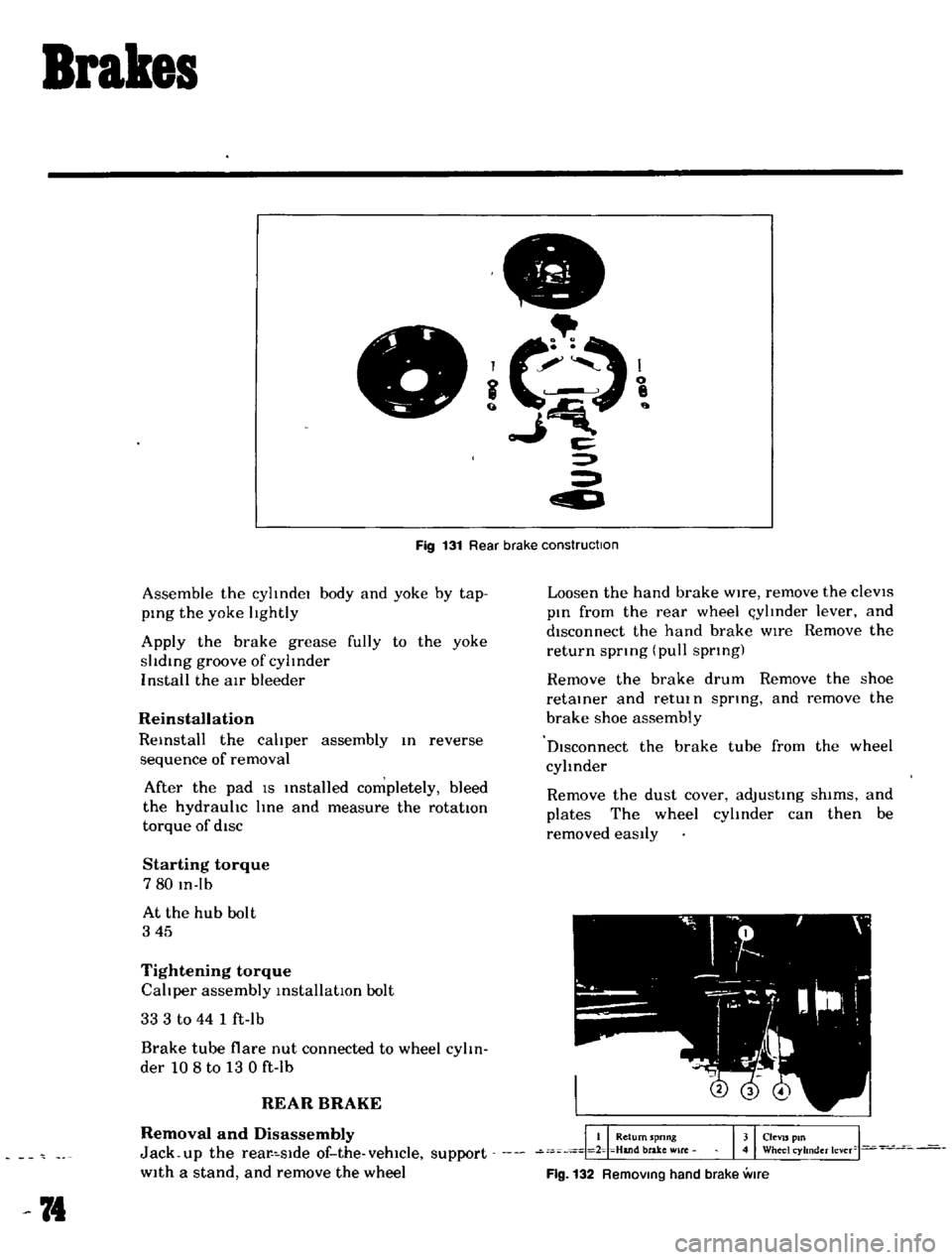

Fig

131

Rear

brake

construction

Assemble

the

cylIndel

body

and

yoke

by

tap

ping

the

yoke

lIghtly

Apply

the

brake

grease

fully

to

the

yoke

slIding

groove

of

cylInder

I

nstall

the

air

bleeder

Reinstallation

Reinstall

the

calIper

assembly

In

reverse

sequence

of

removal

After

the

pad

IS

Installed

completely

bleed

the

hydraulIc

line

and

measure

the

rotatton

torque

of

diSC

Starting

torque

780

In

Ib

At

the

hub

bolt

345

Tightening

torque

CalIper

assembly

installatIOn

bolt

33

3

to

44

1

ft

lb

Brake

tube

flare

nut

connected

to

wheel

cylIn

der

108

to

13

0

ft

lb

REAR

BRAKE

Removal

and

Disassembly

Jack

up

the

rear

slde

of

the

vehicle

support

With

a

stand

and

remove

the

wheel

74

Loosen

the

hand

brake

Wire

remove

the

cleVIS

pin

from

the

rear

wheel

l

ylInder

lever

and

disconnect

the

hand

brake

wIre

Remove

the

return

spnng

pull

spnng

Remove

the

brake

drum

Remove

the

shoe

retainer

and

retUl

n

spnng

and

remove

the

brake

shoe

assembly

DIsconnect

the

brake

tube

from

the

wheel

cylinder

Remove

the

dust

cover

adjusting

shims

and

plates

The

wheel

cylInder

can

then

be

removed

eaSily

Flg

132

RemOVing

hand

brake

vme

Page 85 of 136

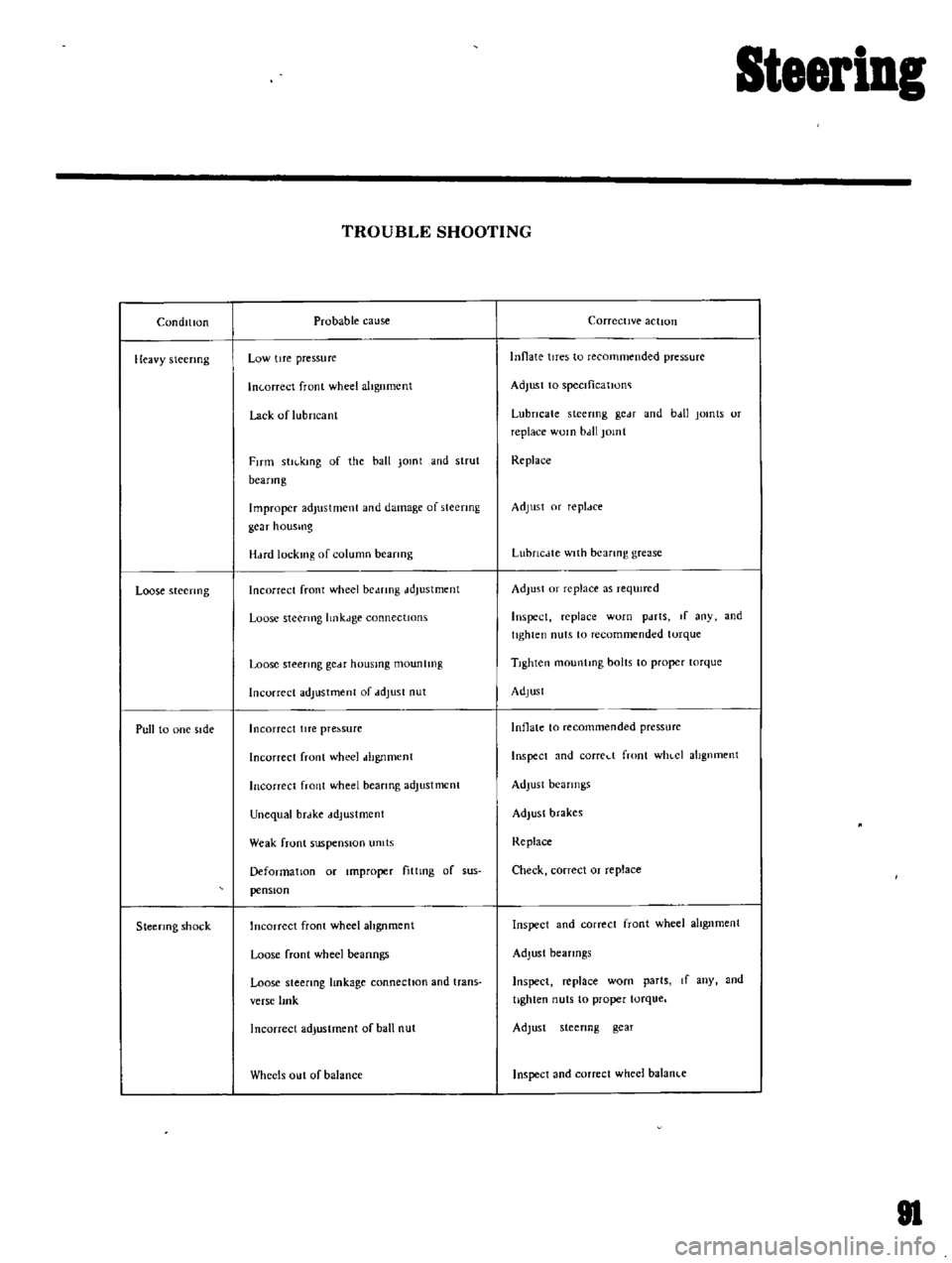

SteeriDg

ConditIon

lIeavy

steering

Loose

steenng

Pull

to

one

side

Steermg

shock

TROUBLE

SHOOTING

Probable

cause

Low

tIre

pressure

In

orreet

front

wheel

altgnmcnt

Lack

of

lubricant

FITm

stll

kmg

of

the

ball

Jomt

and

strut

beanog

Improper

adjustment

and

damage

of

steering

gcar

housmg

H

Hd

lock1l1g

of

column

beanng

Incorrect

front

wheel

be

mng

ddJustment

Loose

steermg

hnkJge

connectIOns

Loose

steermg

gCdf

housmg

mountIng

Incorrect

adjustment

of

ddJust

nut

Incorrect

lITe

pre

sure

Incorrect

front

wheel

dhgnment

Incorrect

front

wheel

beanng

adjustment

Unequal

brdke

ddJustment

Weak

front

suspensIOn

umts

Deformation

or

Improper

fittmg

of

sus

pensIOn

Incorrect

front

wheel

ahgnment

Loose

front

wheel

beanngs

Loose

steering

lmkage

connectIOn

and

trans

verse

lmk

Incorrect

adjustment

of

ball

nut

Wheels

out

of

balance

Corrective

action

Innate

tires

to

recommended

pressure

Adjust

to

speclficatJono

Lubricate

steering

gc

H

and

b

dl

jomts

or

replace

WOln

bdll

jomt

Replace

Adjust

or

repldce

LubrlcJte

with

bearing

grease

Adjust

or

replace

as

reqUired

Inspect

replace

worn

pdrts

If

any

and

tighten

nuts

to

recommended

torque

TIghten

mountmg

bolts

to

proper

torque

Adjust

Inflate

to

recommended

pressurc

Inspect

and

corred

front

WhlCI

alignment

Adjust

bearings

Adjust

brakes

Replace

Check

correct

or

replace

Inspect

and

correct

front

wheel

alIgnment

Adjust

bearings

Inspect

replace

worn

parts

If

any

and

tighten

nuts

to

proper

torque

Adjust

steenng

gear

Inspect

and

correct

wheel

balanl

e

81

Page 88 of 136

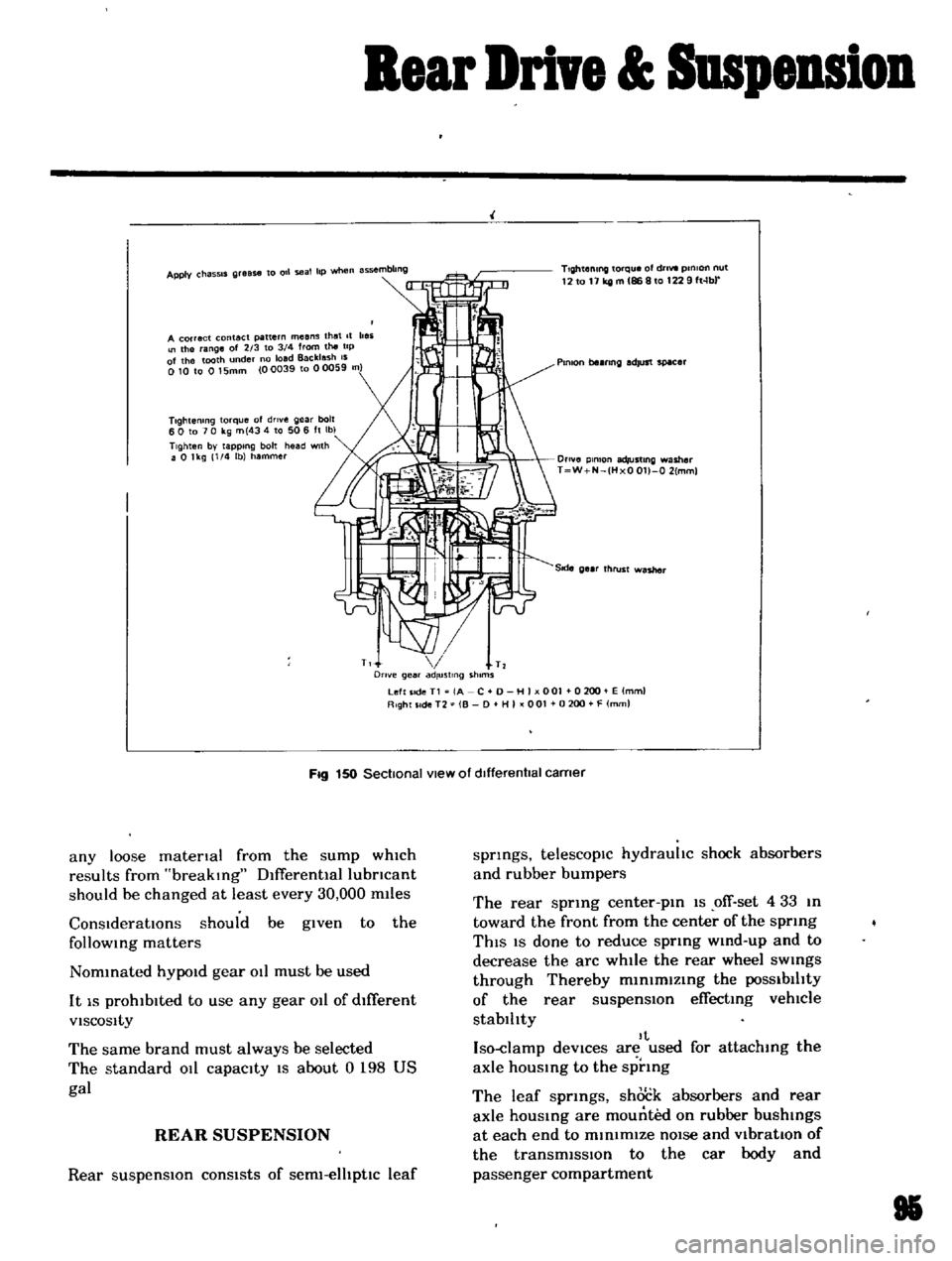

Bear

Drive

Suspension

A

correct

contact

pattern

means

that

It

beii

the

ange

of

2

3

to

3

4

from

the

tip

of

the

tooth

nder

no

load

Backlash

IS

010

to

015mm

00039

to

00059

n

Tlghtemng

torque

of

drlve

gear

bolt

60

to

70

kg

m

434

to

506

ft

Ibl

TIghten

by

tapping

bolt

head

with

a

0

lkg

1

4

lb

hammer

TIghtening

torque

of

dnvt

pmlon

nut

12

to

11

kg

m

86

8

to

1229

ft

lb

Plmon

be

nng

adjust

spacer

O

lve

plmon

adlustlng

washer

T

W

N

HxO

011

0

2

mml

T

T

Drive

gear

ad

ustlng

shims

Left

Ide

T1

jA

C

0

H

I

001

0200

E

lmml

Right

SIde

T2

B

D

HI

001

0

200

F

mml

Fig

150

Sectional

view

of

dIfferentIal

carner

any

loose

matenal

from

the

sump

which

results

from

breaking

Dlfferentlallubncant

should

be

changed

at

least

every

30

000

m11es

ConsIderatIOns

should

be

given

to

the

follOWing

matters

Nommated

hYPOld

gear

011

must

be

used

It

IS

prohibited

to

use

any

gear

011

of

dIfferent

VISCOSity

The

same

brand

must

always

be

selected

The

standard

011

capacity

IS

about

0

198

US

gal

REAR

SUSPENSION

Rear

suspensIOn

consists

of

serm

elhptlc

leaf

springs

telescopIc

hydrauhc

shock

absorbers

and

rubber

bumpers

The

rear

sprmg

center

pm

1S

ofT

set

4

33

m

toward

the

front

from

the

center

of

the

sprmg

ThIS

IS

done

to

reduce

sprmg

wmd

up

and

to

decrease

the

arc

while

the

rear

wheel

sWings

through

Thereby

m1n1mlzmg

the

POSSibilIty

of

the

rear

suspensIOn

effecting

vehlCle

stablhty

It

Iso

damp

deVices

are

used

for

attachmg

the

axle

hOUSing

to

the

sprmg

The

leaf

sprmgs

shock

absorbers

and

rear

axle

housmg

are

mounted

on

rubber

bushings

at

each

end

to

minimIZe

nOIse

and

VibratIOn

of

the

transmiSSIon

to

the

car

body

and

passenger

compartment

85

Page 91 of 136

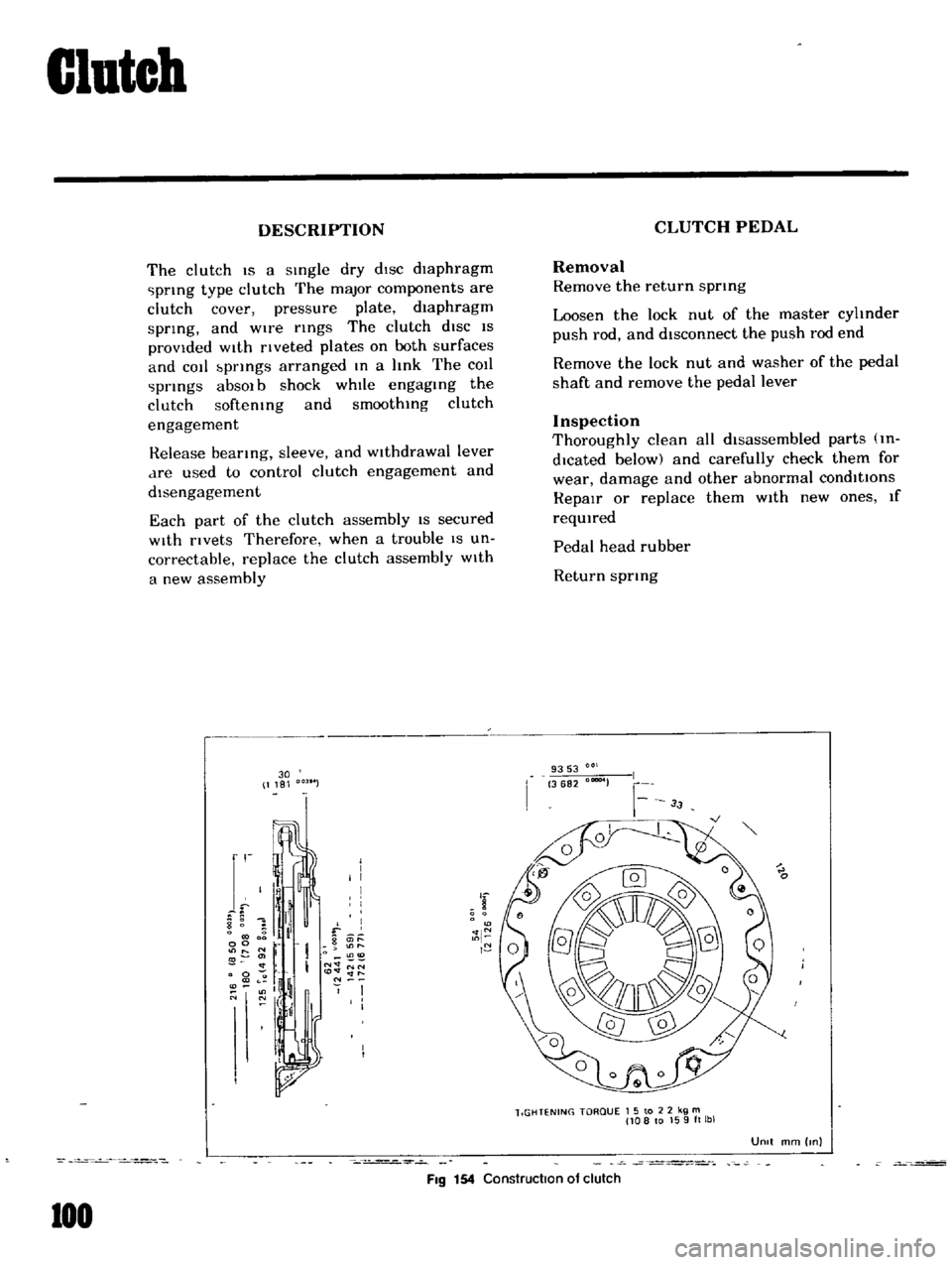

Clutch

DESCRIPTION

The

clutch

IS

a

sIngle

dry

dIsc

diaphragm

prIng

type

clutch

The

major

components

are

clutch

cover

pressure

plate

diaphragm

sprIng

and

wire

rIngs

The

clutch

diSC

IS

provided

WIth

rIveted

plates

on

both

surfaces

and

cot

bprIngs

arranged

In

a

hnk

The

COIl

prIngs

absOl

b

shock

whIle

engagIng

the

clutch

softemng

and

smoothIng

clutch

engagement

Release

bearIng

sleeve

and

WIthdrawal

lever

dre

used

to

control

clutch

engagement

and

disengagement

Each

part

of

the

clutch

assembly

IS

secured

With

rivets

Therefore

when

a

trouble

IS

un

correctable

replace

the

clutch

assembly

With

a

new

assembly

30

1181

r

I

I

I

I

I

8

1

il

f

0

g

it

l

00

r

O

11

I

N

NN

0

to

lt

lt

ll

l

If

N

O

N

I

I

I

I

FIg

154

Construction

of

clutch

100

CLUTCH

PEDAL

Removal

Remove

the

return

sprmg

Loosen

the

lock

nut

of

the

master

cyhnder

push

rod

and

disconnect

the

push

rod

end

Remove

the

lock

nut

and

washer

of

the

pedal

shaft

and

remove

the

pedal

lever

Inspection

Thoroughly

clean

all

disassembled

parts

m

dlcated

below

and

carefully

check

them

for

wear

damage

and

other

abnormal

conditions

RepaIr

or

replace

them

With

new

ones

If

reqUIred

Pedal

head

rubber

Return

sprIng

9353

3682

00004

lIGHTENING

TORQUE

1

5

to

2

2

kg

m

108

to

159ft

lbl

UOIt

mm

Inl

Page 99 of 136

Transmission

AUTOMATIC

TRANSMISSION

The

model

3N71B

automatic

transmiSSIOn

IS

a

fully

automatic

Unit

consisting

pnmanly

of

3

element

hydrauhc

torque

converter

and

two

planetary

gear

sets

Two

multiple

disc

clut

ches

a

multiple

disc

brake

a

band

brake

and

a

one

way

sprag

clutch

provide

the

fnctlon

elements

reqUired

to

obtain

the

deSired

fun

tlon

of

the

two

planetary

gear

sets

The

two

planetary

gear

sets

give

three

for

ward

ratIOs

and

one

reverse

Changing

of

the

gear

ratIOs

IS

fully

automatic

In

relation

to

vehicle

speed

and

engine

torque

Input

Vehicle

speed

and

engine

mamfold

vacuum

Signals

are

constantly

fed

to

the

transmiSSIOn

to

prOVide

the

proper

gear

ratIO

for

maximum

effiCiency

and

performance

at

all

throttle

openmgs

The

Model

3N71B

has

SIX

selector

poSitIOns

P

R

N

D

2

1

p

Park

pOSitIOn

posItively

locks

the

out

put

shaft

to

the

transmiSSIOn

case

by

means

of

a

lockmg

pawl

to

prevent

the

vehicle

from

rollmg

either

directIOn

ThiS

pOSitIOn

should

be

selected

whenever

the

dnver

leaves

the

vehicle

The

engme

may

be

started

m

Park

pOSition

R

Reverse

range

enables

the

vehicle

to

be

operated

m

a

reverse

direction

N

Neutral

pOSitIOn

enables

the

engine

to

be

started

and

run

Without

dnvIngthe

vehicle

0

Drive

range

IS

used

for

all

normal

driVing

conditions

Dnve

range

has

three

gear

ratios

from

the

startmg

ratIO

to

direct

dnve

2

2

range

prOVides

performance

for

dnvIng

onshppery

surfaces

2

range

can

also

be

used

for

engine

brakmg

2

range

can

be

selected

at

any

vehicle

speed

and

prevents

the

transmlsslOn

from

shifting

out

of

second

gear

108

Rg

162

Idenllflcatlon

number

I

1

range

can

be

selected

at

any

vehicle

speed

and

the

transmiSSIOn

will

shift

to

second

gear

and

remain

m

second

until

vehicle

speed

IS

reduced

to

approximately

25

to

31

MPH

1

range

posItion

prevents

the

transmiSSIOn

from

shlftmg

out

of

low

gear

ThiS

IS

par

tlcularly

benefiCial

for

mamtamIng

maximum

engine

brakmg

when

continUOUS

low

gear

operation

IS

deSirable

The

torque

converter

assembly

IS

of

welded

constructIOn

and

can

not

be

dlssassembled

for

service

FlUld

Recommendatwn

Use

automatic

transmiSSIOn

flUid

haVing

DEXRON

IdentificatIOns

only

m

the

3N71B

automatic

transmiSSIOn

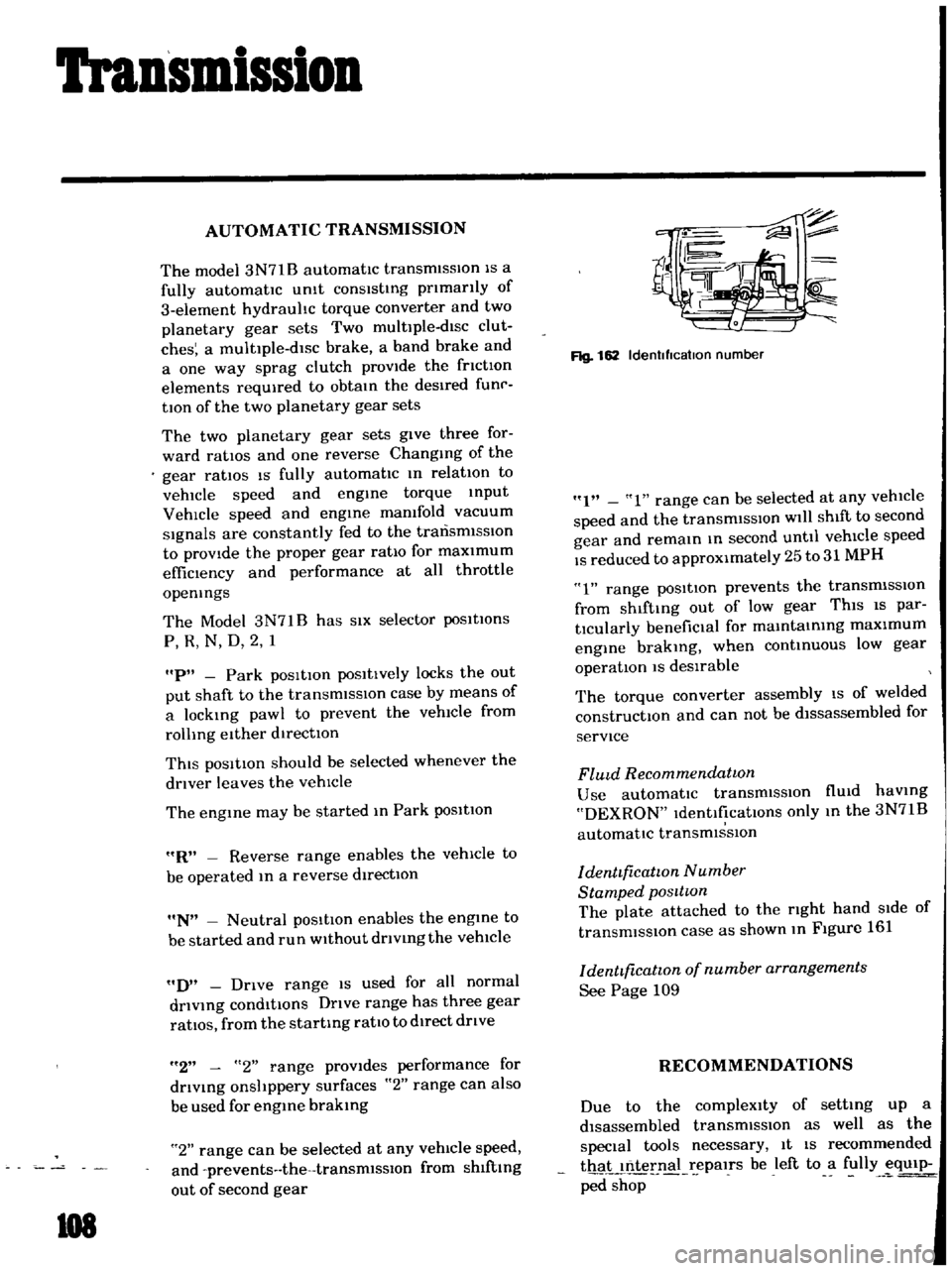

denttficatwn

Number

Stamped

posttwn

The

plate

attached

to

the

rIght

hand

Side

of

transmission

case

as

shown

m

Figure

161

denttficatwn

of

number

arrangements

See

Page

109

RECOMMENDATIONS

Due

to

the

compleXity

of

setting

up

a

disassembled

transmissIOn

as

well

as

the

special

tools

necessary

It

IS

recommended

thaL

nternal

epalrs

be

left

to

a

fully

eqUip

ped

shop

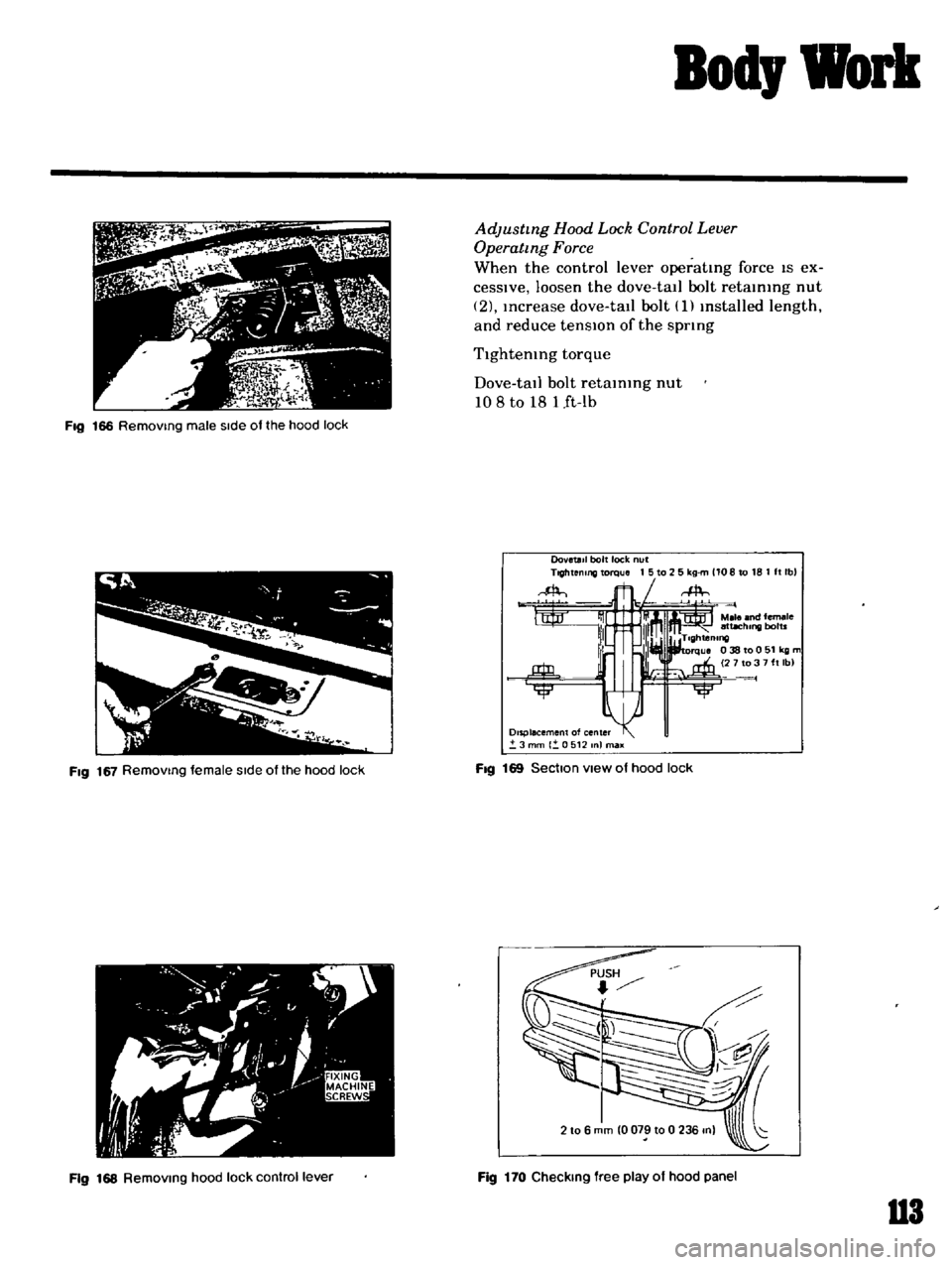

Page 103 of 136

Bod

Work

Adjusting

Hood

Lock

Control

Lever

Operating

Force

When

the

control

lever

operatmg

force

IS

ex

ceSSlve

loosen

the

dove

tail

bolt

retammg

nut

2

Increase

dove

tall

bolt

1

mstalled

length

and

reduce

tensIOn

of

the

spring

Tightening

torque

Dove

tall

bolt

retaining

nut

108

to

18

1

ft

lb

Fig

166

Removing

male

Side

of

the

hood

lock

DovetaIl

bolt

lock

nut

Ttghtenlllg

torque

1

5

to

2

5

kg

m

1108

to

18

1

It

Ib

FIg

167

Removing

female

Side

ofthe

hood

lock

FIg

169

Section

view

of

hood

lock

2

10

6

mm

0079

10

0

236

on

Fig

168

Removing

hood

lock

control

lever

Fig

170

Checking

free

play

of

hood

panel

U3

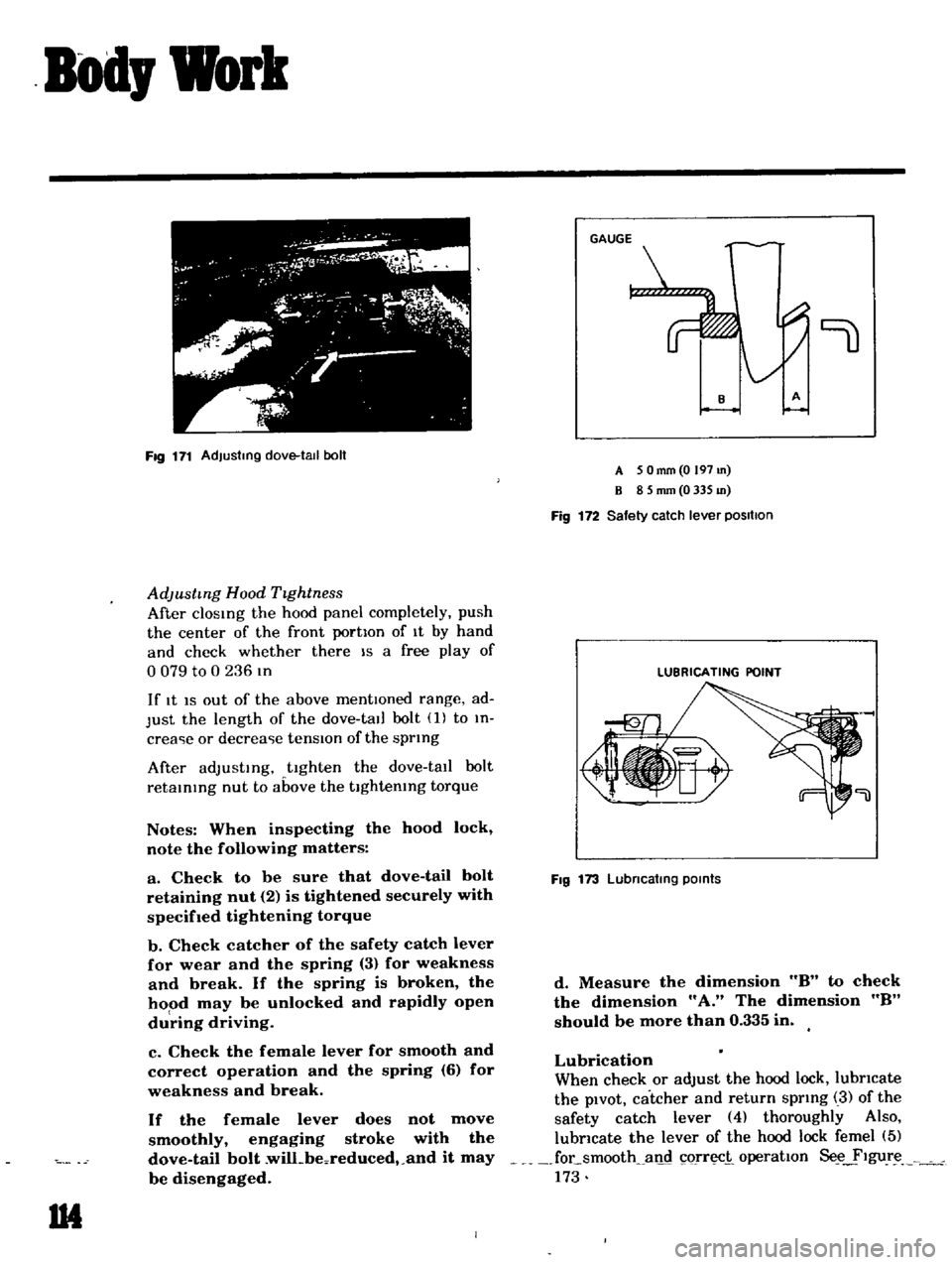

Page 104 of 136

Bod

Work

J

G

3

1

7

iJ

0

t

Fig

171

Adjusting

dove

tall

boll

AdJustmg

Hood

TIghtness

After

clOSIng

the

hood

panel

completely

push

the

center

of

the

front

portIon

of

It

by

hand

and

check

whether

there

IS

a

free

play

of

o

079

to

0

236

In

If

It

IS

out

of

the

above

mentIOned

range

ad

Just

the

length

of

the

dove

tall

bolt

1

to

In

crea

ie

or

decrea

ie

tensIOn

of

the

sprIng

After

adJustIng

tighten

the

dove

tall

bolt

retaInIng

nut

to

above

the

tIghtenIng

torque

Notes

When

inspecting

the

hood

lock

note

the

following

matters

a

Check

to

be

sure

that

dove

tail

bolt

retaining

nut

2

is

tightened

securely

with

specifIed

tightening

torque

b

Check

catcher

of

the

safety

catch

lever

for

wear

and

the

spring

3

for

weakness

and

break

If

the

spring

is

broken

the

hood

may

be

unlocked

and

rapidly

open

du

ring

driving

c

Check

the

female

lever

for

smooth

and

correct

operation

and

the

spring

6

for

weakness

and

break

If

the

female

lever

does

not

move

smoothly

engaging

stroke

with

the

dove

tail

bolt

wilLbeoreduced

and

it

may

be

disengaged

1M

9

A

5

Omm

O

197

m

B

8

5

mm

0

335

m

Fig

172

Safety

catch

lever

positIOn

LUBRICATING

POINT

Fig

173

Lubncatlng

POints

d

Measure

the

dimension

8

to

check

the

dimension

A

The

dimension

8

should

be

more

than

0

335

in

Lubrication

When

check

or

adjust

the

hood

lock

lubricate

the

pIvOt

catcher

and

return

sprIng

3

of

the

safety

catch

lever

4

thoroughly

Also

lubricate

the

lever

of

the

hood

lock

femel

5

focsmooth

all

c1

orr

i

operatIon

Se

ylgur

173

Page 106 of 136

Bod

Work

TRUNK

LID

LOCK

Removal

Loosen

m

tallatlOn

bolts

and

remove

the

tl

Iker

and

lock

from

the

body

Remove

the

leaf

chp

lu

ed

to

secure

the

trunk

hd

lock

cylmder

on

the

body

and

remove

the

trunk

lId

lock

cylIndCl

Adjustment

Sedan

When

adjustmg

engagement

between

the

lock

and

tnker

set

the

lock

statlOnanly

and

properly

adjust

stnker

poSitIOn

Adjustmg

stroke

toward

left

and

nght

SIdes

dIrectIOn

IS

0

890

m

and

03150

m

toward

vertical

dIrectIOn

VAN

j

1

II

U8

Coupe

When

adju

tmg

engagement

between

the

lock

and

stnker

adjust

stnker

poSitIOn

toward

left

and

right

Sides

adju

tmg

stroke

02362

m

and

lock

pOSitIOn

for

vertical

directIOn

ad

justmg

stroke

03

50

m

Tlghtemng

torque

Lock

and

stnker

fixmg

bolt

o

87

to

45

ft

lb

TRUNK

LID

TORSION

BAR

The

procedures

of

m

tallIng

torsIOn

bar

are

mdlcated

as

follows

Note

When

installing

the

torsion

bar

u

te

a

torsIOn

bar

wrench

J

tl

l

11

4

i

0

t

b

f

I

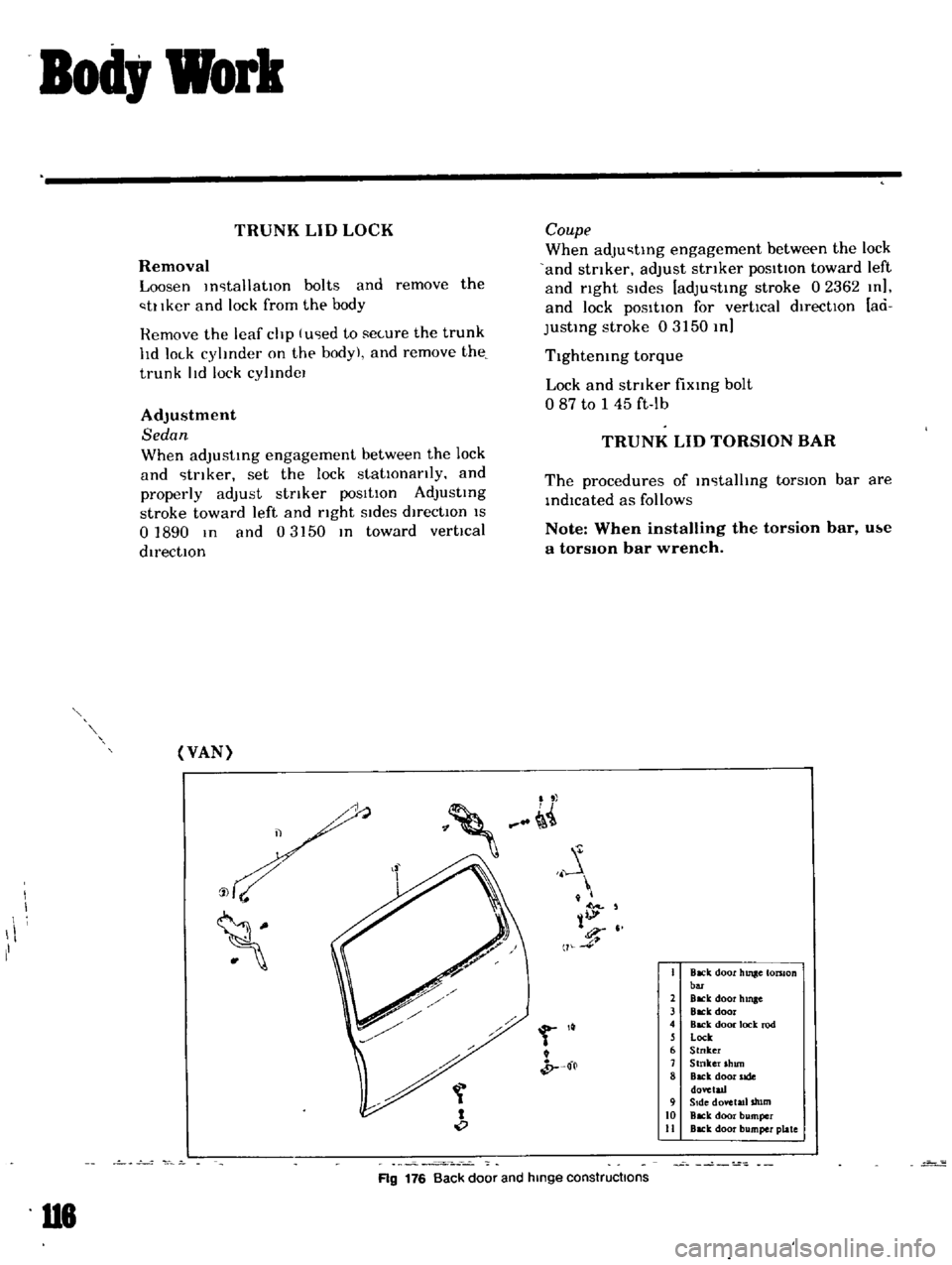

Back

door

hUlle

tomon

bOT

2

BlCk

door

hmge

3

Back

door

4

Back

door

lock

rod

l

Lock

6

Stnker

7

Stnker

shun

8

Back

door

side

dovetad

9

Side

dovetl1l

tllm

10

Back

door

bumper

II

Back

door

bumper

plate

Ag

176

Back

door

and

hinge

constructions

Page 120 of 136

Specifications

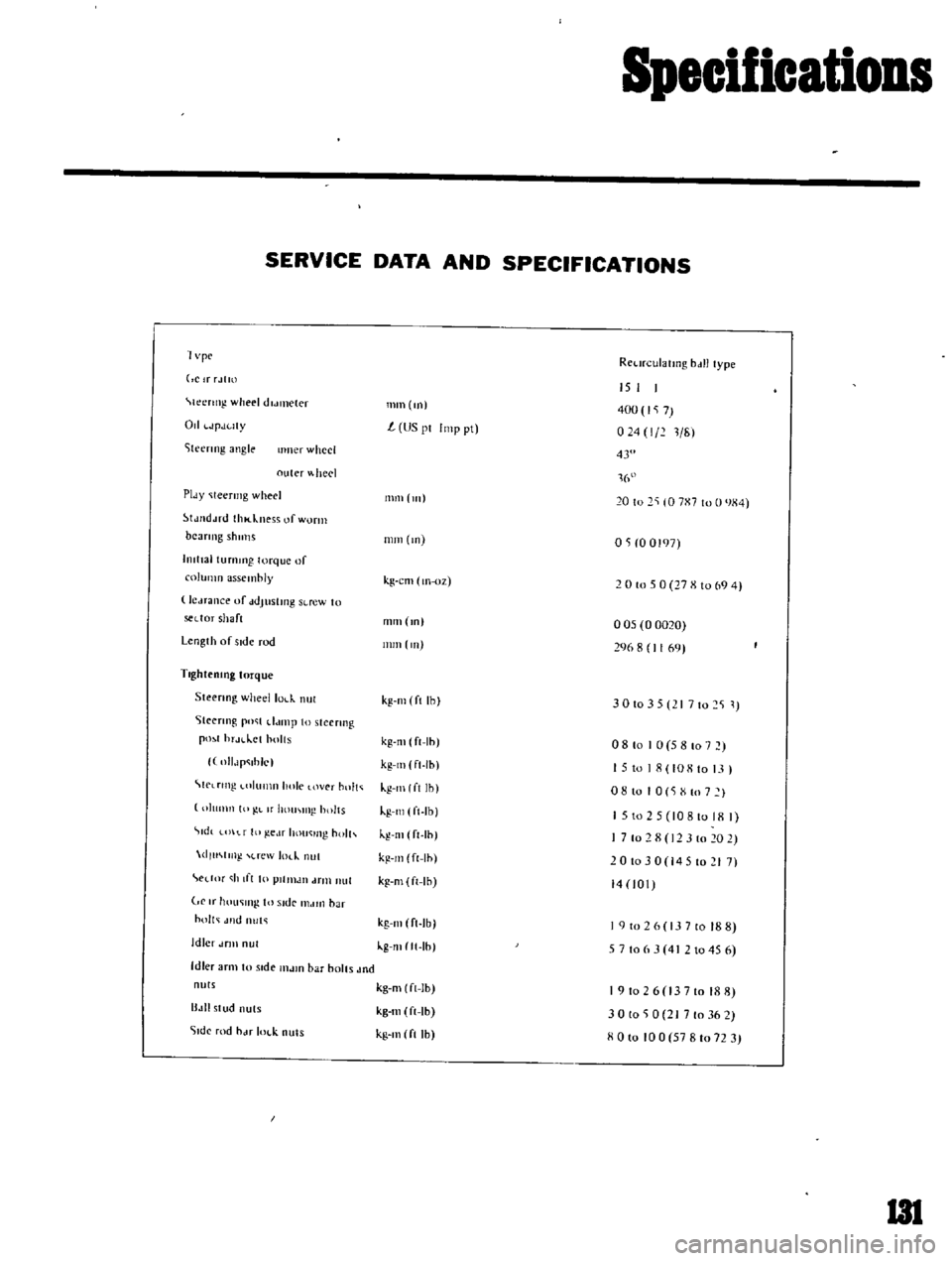

SERVICE

DATA

AND

SPECIFICATIONS

1

vpc

RCl

n

ulatlllg

bdll

type

ClrrJtm

Ieertng

wheel

dldl1lCler

Od

JpJuty

iteenng

angle

IImer

wheel

outer

heel

PIdY

Ieermg

wheel

tJJ

d

ud

thl

kness

of

worm

beaTIng

shulls

hllttal

turnmg

torque

of

column

assembly

le

Hance

uf

ddJustmg

SLrew

to

sedor

shaft

Length

of

side

rod

TlghteolOg

torque

Steenng

wheellol

k

nul

Steenng

po

t

d

unp

to

steermg

pO

1

hr

H

lct

holts

llIlJp

ihlc

C

lrtng

llImn

hole

over

hnlt

IllImn

10

L

If

hOUI

IIl

holts

tdt

t

f

III

ge

lf

hou

lIl

holh

dlu

m

l

rew

m

nut

edM

h

If

I

10

plllllJIl

drill

nut

If

hOll

lI1g

In

Side

I1MIIl

bar

holt

Jlld

nut

Idler

dflll

nul

Idler

arm

to

stde

l1lJlO

bar

bolts

Jnd

nuts

B

III

stud

nuts

51dc

rod

hJf

IOl

k

nuts

mm

m

15

I

400

7

024

1

211

L

US

pI

Imp

pt

43

1

16

111111

111

20

to

2

10

7X7

to

0

JX4

mm

m

OS

0

0197

kg

cm

lIl

oz

2

0

to

5

0

27

X

10

69

4

mm

m

005

0

0020

296

8

1169

nun

Ill

kg

Ill

ft

Ihl

3

0

10

3

5

I

7

10

2

S

1

kg

m

ft

Ih

kg

Ill

ft

Ih

kg

Ill

I

ft

Ih

kg

Ill

ft

Ib

kg

Ill

ft

Ih

kg

m

ft

Ih

kg

m

ft

Ih

08

to

I

0

5

8

107

15

to

18

108

to

13

I

o

8

10

I

0

S

X

to

7

I

1

5

to

2

5

10810

18

I

7

10

2

8

12

3

10

20

2

201030

14510217

14

101

kg

Ill

ft

Ib

kg

mltt

Ih

I

9

to

2

6

13

7

to

18

8

5

7

106

3

4

2

1045

6

kg

m

ft

Ib

kg

m

ft

Ib

kg

Ill

ft

Ih

191026

13710188

30

to

0

21

7

to

36

2

XOlo

100

57810723

I3l