tow bar DATSUN B110 1969 Service Repair Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1969, Model line: B110, Model: DATSUN B110 1969Pages: 136, PDF Size: 5.64 MB

Page 78 of 136

pront

Suspension

Qj

@

@

I

Strut

mounting

Insulator

2

Strut

mounllng

bearing

3

Upper

pnng

o

r

at

4

Oumpu

rubblf

5

DU

tlOVU

6

P

ton

rod

7

F

ool

pring

8

Irut

embly

q

Hub

b

t

mbly

10

5pmdh

II

Ball

JOint

12

Trd

nwu

link

1

J

Tln

lon

rod

14

StJblluLr

15

SU

p

mIOn

mlmbt

r

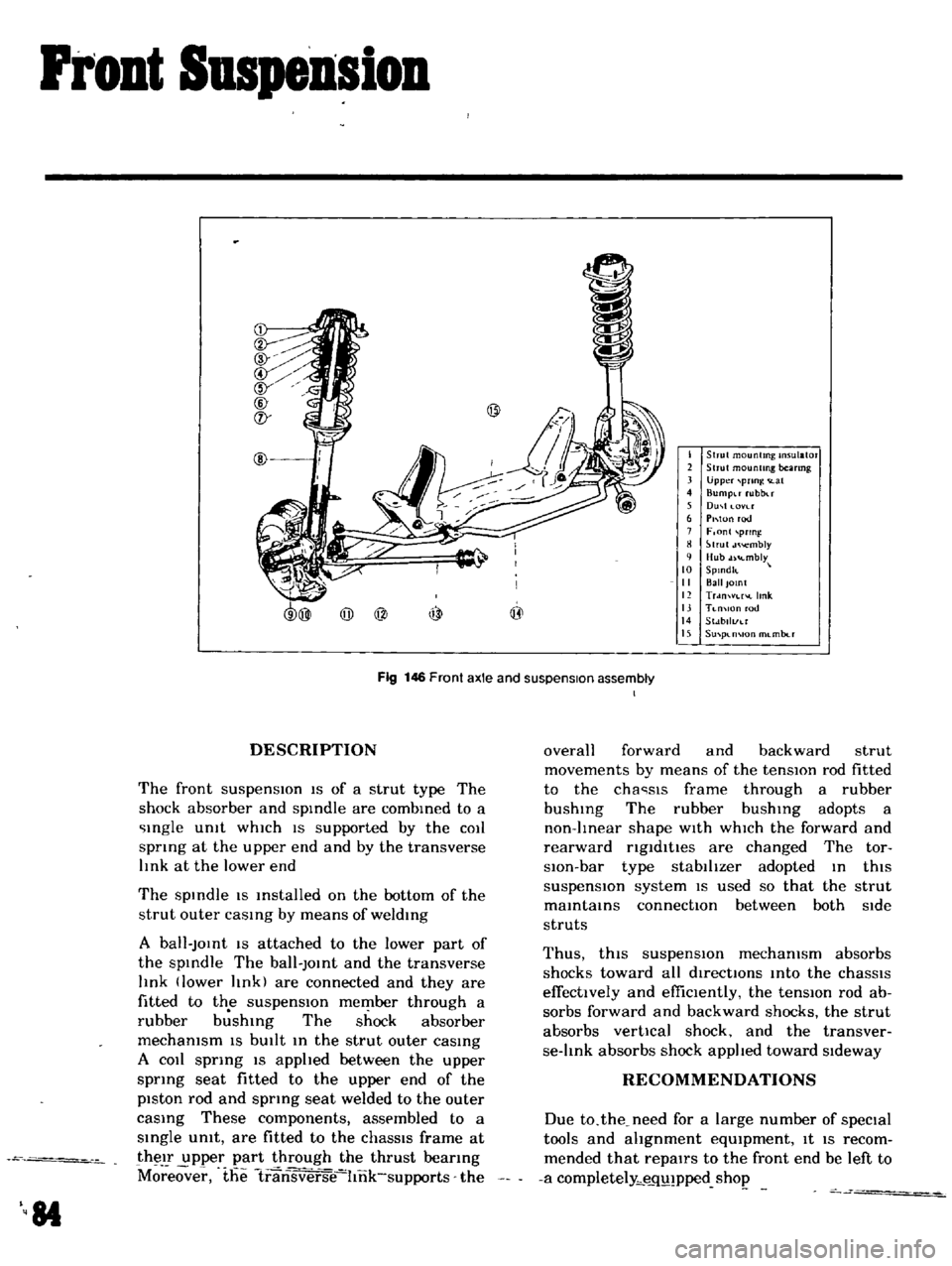

Fig

146

Front

axle

and

suspension

assembly

I

DESCRIPTION

The

front

suspensIOn

IS

of

a

strut

type

The

shock

absorber

and

spIndle

are

combIned

to

a

Ingle

Unit

whIch

IS

supported

by

the

COIl

spnng

at

the

upper

end

and

by

the

transverse

lInk

at

the

lower

end

The

spIndle

IS

Installed

on

the

bottom

of

the

strut

outer

caSIng

by

means

of

weldIng

A

ball

JOInt

IS

attached

to

the

lower

part

of

the

spIndle

The

ball

JOInt

and

the

transverse

lInk

lower

lInk

are

connected

and

they

are

fitted

to

the

suspensIOn

member

through

a

rubber

b

shIng

The

shock

absorber

mechanism

IS

bUIlt

In

the

strut

outer

caSIng

A

COIl

sprIng

IS

apphed

between

the

upper

sprIng

seat

fitted

to

the

upper

end

of

the

piston

rod

and

spring

seat

welded

to

the

outer

caSIng

These

components

assembled

to

a

SIngle

umt

are

fitted

to

the

chaSSIS

frame

at

their

upper

part

through

the

thrust

beanng

M

eover

the

1ransverse

hnk

supports

the

84

overall

forward

and

backward

strut

movements

by

means

of

the

tensIOn

rod

fitted

to

the

cha

sls

frame

through

a

rubber

bushIng

The

rubber

bushIng

adopts

a

non

lInear

shape

WIth

whICh

the

forward

and

rearward

ngldltles

are

changed

The

tor

slOn

bar

type

stabilIzer

adopted

In

thiS

suspensIOn

system

IS

used

so

that

the

strut

maIntaInS

connectIOn

between

both

Side

struts

Thus

thiS

suspensIOn

mechanism

absorbs

shocks

toward

all

directIOns

Into

the

chaSSIS

effectively

and

effiCIently

the

tensIOn

rod

ab

sorbs

forward

and

backward

shocks

the

strut

absorbs

vertical

shock

and

the

transver

se

lInk

absorbs

shock

applIed

toward

SIdeway

RECOMMENDATIONS

Due

to

the

need

for

a

large

number

of

speCial

tools

and

ahgnment

eqUIpment

It

IS

recom

mended

that

repairs

to

the

front

end

be

left

to

a

completely

e

q

pped

shop

Page 106 of 136

Bod

Work

TRUNK

LID

LOCK

Removal

Loosen

m

tallatlOn

bolts

and

remove

the

tl

Iker

and

lock

from

the

body

Remove

the

leaf

chp

lu

ed

to

secure

the

trunk

hd

lock

cylmder

on

the

body

and

remove

the

trunk

lId

lock

cylIndCl

Adjustment

Sedan

When

adjustmg

engagement

between

the

lock

and

tnker

set

the

lock

statlOnanly

and

properly

adjust

stnker

poSitIOn

Adjustmg

stroke

toward

left

and

nght

SIdes

dIrectIOn

IS

0

890

m

and

03150

m

toward

vertical

dIrectIOn

VAN

j

1

II

U8

Coupe

When

adju

tmg

engagement

between

the

lock

and

stnker

adjust

stnker

poSitIOn

toward

left

and

right

Sides

adju

tmg

stroke

02362

m

and

lock

pOSitIOn

for

vertical

directIOn

ad

justmg

stroke

03

50

m

Tlghtemng

torque

Lock

and

stnker

fixmg

bolt

o

87

to

45

ft

lb

TRUNK

LID

TORSION

BAR

The

procedures

of

m

tallIng

torsIOn

bar

are

mdlcated

as

follows

Note

When

installing

the

torsion

bar

u

te

a

torsIOn

bar

wrench

J

tl

l

11

4

i

0

t

b

f

I

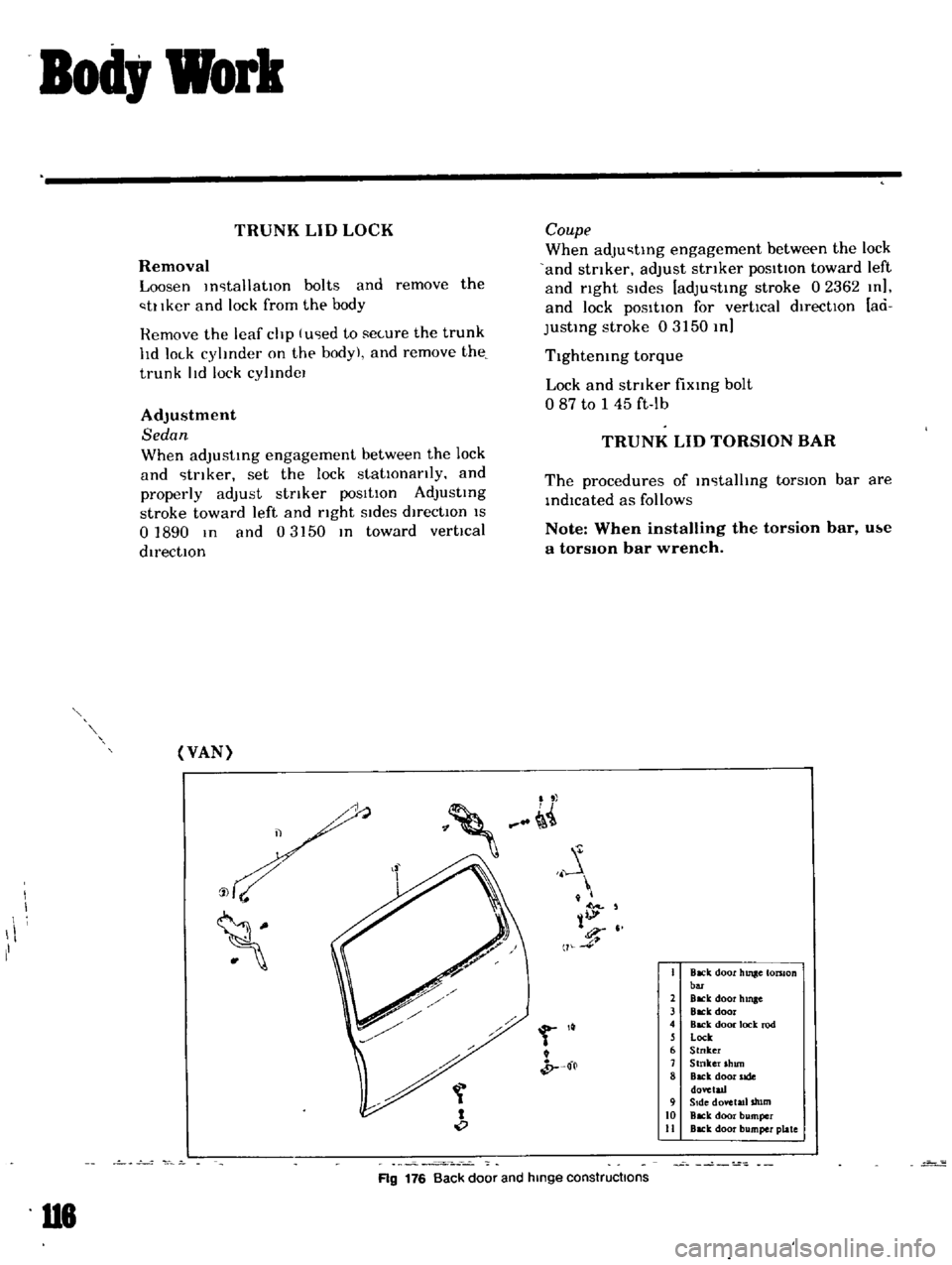

Back

door

hUlle

tomon

bOT

2

BlCk

door

hmge

3

Back

door

4

Back

door

lock

rod

l

Lock

6

Stnker

7

Stnker

shun

8

Back

door

side

dovetad

9

Side

dovetl1l

tllm

10

Back

door

bumper

II

Back

door

bumper

plate

Ag

176

Back

door

and

hinge

constructions