weight DATSUN B110 1969 Service Repair Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1969, Model line: B110, Model: DATSUN B110 1969Pages: 136, PDF Size: 5.64 MB

Page 23 of 136

Square

rmg

m

bore

by

pushing

It

mto

pos1t1on

wIth

the

head

piston

Measure

gap

between

ends

of

rmg

with

feeler

gauge

Gap

should

be

as

hsted

above

Note

a

When

the

piston

ring

only

is

to

be

replaced

without

the

cylinder

bore

bemg

corrected

measure

gap

at

the

bottom

of

the

cylinder

where

the

wear

is

minor

b

Overs1ze

piston

rings

are

avaIlable

for

service

50

100

150

oversize

Measure

the

piston

pm

hole

m

relation

to

the

outer

dIameter

of

the

pm

If

wear

exceeds

the

hmlt

replace

such

piston

pm

together

with

the

pIston

on

whIch

It

IS

mstalled

PI

ton

pill

dldmeter

06869

to

06871

PIston

pill

length

25681

to

5779

Piston

pm

hole

dta

meter

06874

to

0

6871

PIston

pm

to

piston

clearance

00002

to

OOUr

j

Interference

fit

of

piston

pm

to

connectmg

rod

o

0008

EM133

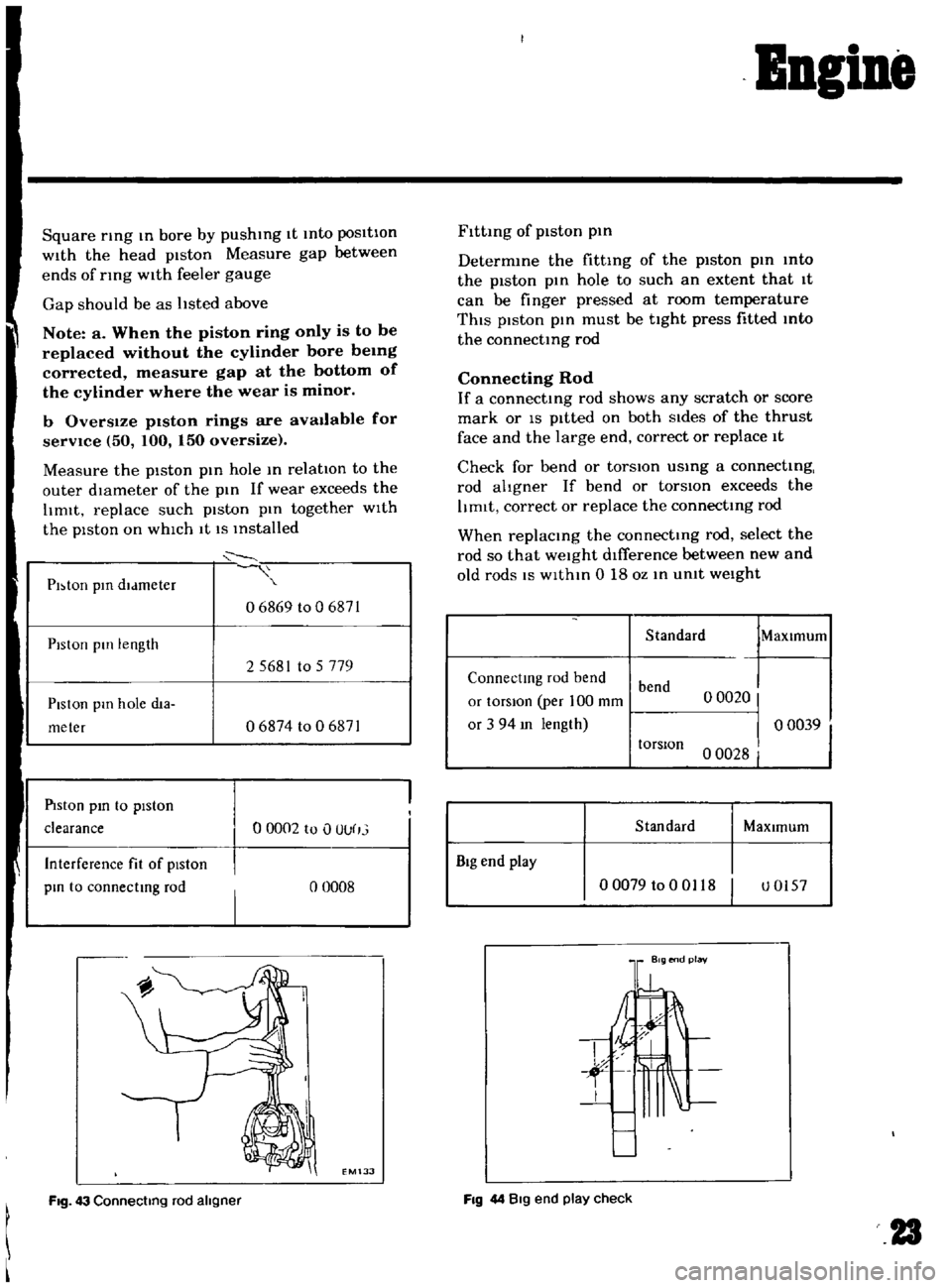

FIg

43

Connecting

rod

ahgner

Bngine

Flttmg

of

piston

pm

Determme

the

fittmg

of

the

piston

pm

mto

the

piston

pm

hole

to

such

an

extent

that

1t

can

be

finger

pressed

at

room

temperature

ThIS

piston

pm

rnust

be

tight

press

fitted

mto

the

connectmg

rod

Connecting

Rod

If

a

connectmg

rod

shows

any

scratch

or

score

mark

or

IS

pitted

on

both

Sides

of

the

thrust

face

and

the

large

end

correct

or

replace

It

Check

for

bend

or

torsIOn

usmg

a

connectmg

rod

ahgner

If

bend

or

torsIOn

exceeds

the

hmlt

correct

or

replace

the

connectmg

rod

When

replacing

the

connectmg

rod

select

the

rod

so

that

weight

difference

between

new

and

old

rods

IS

wlthm

0

18

oz

m

umt

weIght

Standard

MaXimum

Connectmg

rod

bend

bend

or

tOrsIon

per

100

mm

o

0020

or

3

94

m

length

o

00391

torsIOn

o

0028

I

Standard

MaXImum

BIg

end

play

00079

to

0

0118

I

U0157

FIg

44

Big

end

play

check

23

Page 43 of 136

Ignition

Iptem

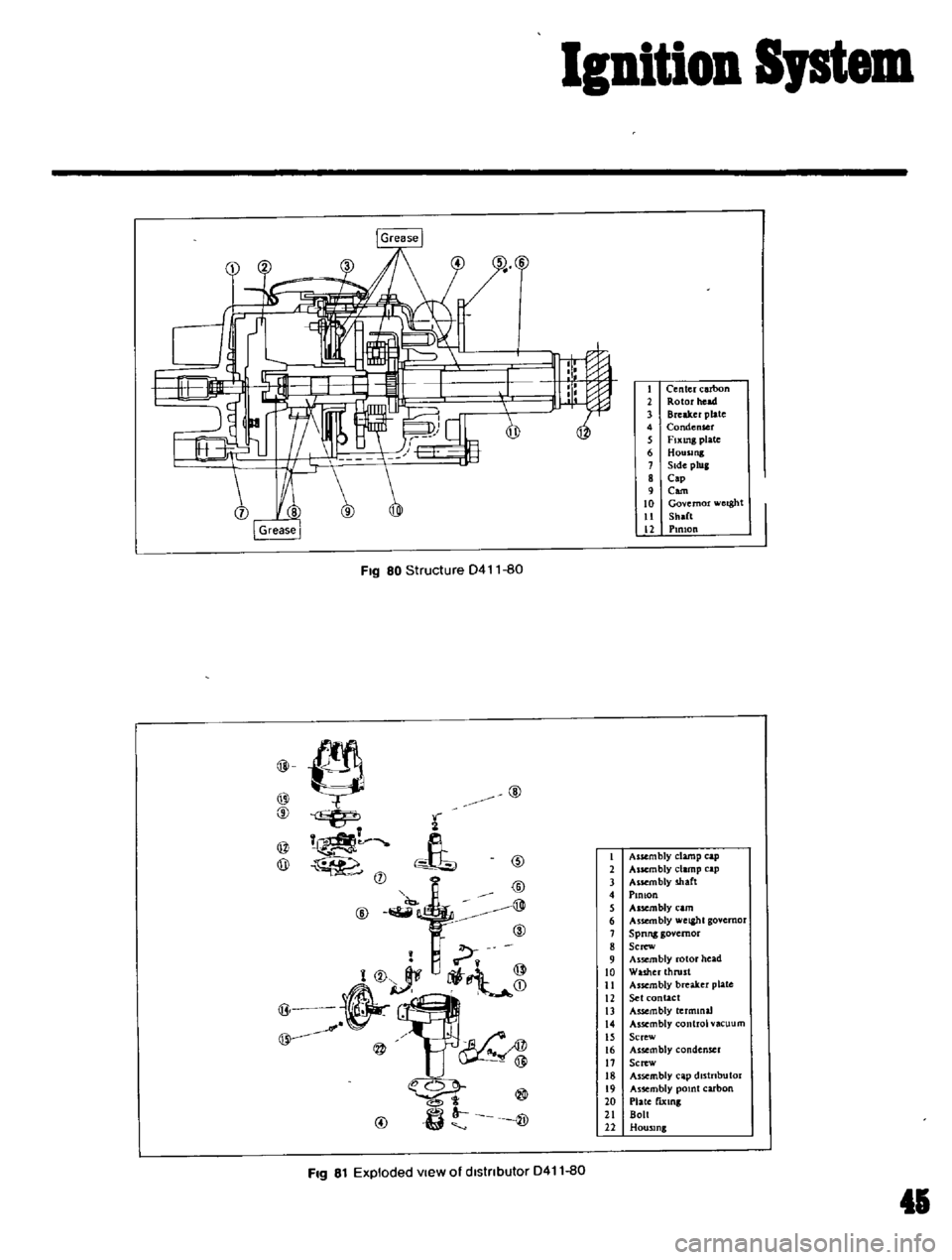

FIg

80

Structure

D411

80

CID

0

A

t

CID

l@J

rf

@

@

@

2

@

@

ID

@

FIg

81

Exploded

View

of

dlstnbutor

D411

80

1

Center

carbon

2

Rotor

head

3

Breaker

plate

4

Condenser

5

FIxing

plate

6

Housing

1

Side

plug

8

Cap

9

Com

10

Governor

werght

11

Sh

lft

l2

PIRIOn

1

Assembly

clamp

cap

2

Aucmbly

clamp

cap

3

Assembly

shaft

4

PlOlon

5

A

uembly

eam

6

Assembly

weight

governor

7

Spnng

governor

8

Screw

9

Assembly

rotor

head

10

Washer

thrust

II

Assembly

breaker

plate

12

Set

contact

13

Assembly

termmaJ

14

Assembly

control

vacuum

IS

Screw

16

AssembJy

condenser

17

Screw

J

8

Assembly

cap

dJstnbutor

19

Assembly

pomt

carbon

20

Plate

fixing

21

Bolt

22

Housing

45

Page 56 of 136

Fuel

Sptem

In

removIng

Injector

weight

piston

return

sptlng

and

ball

care

should

be

exercIsed

to

prevent

them

from

beIng

scattered

and

lost

To

check

the

accelerator

pump

the

pump

cover

IS

removed

Be

careful

not

to

lose

the

return

spring

and

mlet

valve

bal

prOVided

at

the

lower

part

of

the

piston

dUring

dIsassembly

Removal

of

bl

metal

cover

IS

a

sImple

matter

of

removmg

three

set

screws

When

It

becomes

necessary

to

take

out

float

pull

shaft

from

float

Note

Under

no

C1rcumstances

should

bl

metaI

be

moved

with

excessive

force

Since

this

may

cause

a

permanent

set

In

b1

metal

making

starting

d1fficuIt

The

thlottle

chamber

can

be

detached

from

the

float

hamber

by

removmg

three

set

screws

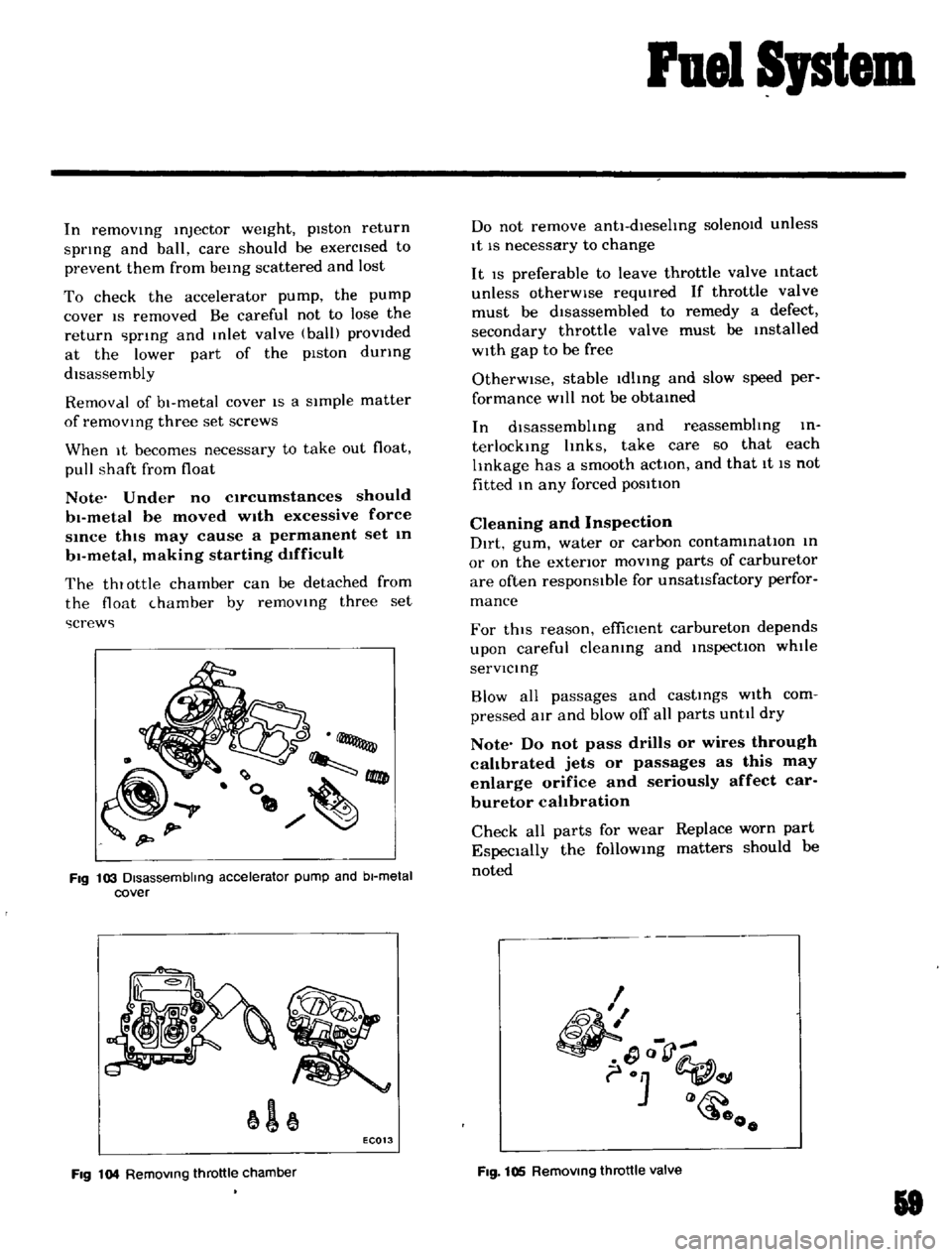

Fig

103

Disassembling

accelerator

pump

and

bl

metal

cover

1

EC013

Fig

104

RemOVing

throttle

chamber

Do

not

remove

antl

dlesehng

solenOId

unless

It

IS

necessary

to

change

It

IS

preferable

to

leave

throttle

valve

mtact

unless

otherWise

reqUIred

If

throttle

valve

must

be

dIsassembled

to

remedy

a

defect

secondary

throttle

valve

must

be

Installed

wIth

gap

to

be

free

OtherWise

stable

Idlmg

and

slow

speed

per

formance

Will

not

be

obtamed

In

dlsassembhng

and

reassembhng

in

terlockIng

hnks

take

care

so

that

each

lInkage

has

a

smooth

action

and

that

It

IS

not

fitted

m

any

forced

posltton

Cleaning

and

Inspection

Dirt

gum

water

or

carbon

contammatIon

m

or

on

the

exterior

movmg

parts

of

carburetor

are

often

responsible

for

unsattsfactory

perfor

mance

For

thiS

reason

effiCient

carbureton

depends

upon

careful

cleamng

and

InspectIOn

whtle

servlcmg

Blow

all

passages

and

castmgs

wIth

com

pressed

aIr

and

blow

off

all

parts

unttl

dry

Note

Do

not

pass

drills

or

wires

through

calibrated

jets

or

passages

as

this

may

enlarge

orifice

and

seriously

affect

car

buretor

calibration

Check

all

parts

for

wear

Replace

worn

part

EspeCially

the

followmg

matters

should

he

noted

I

1

Q

o

Fig

105

RemOVing

throttle

valve

18

Page 87 of 136

lear

Drive

Suspension

I

A

le

holft

2

SPdlU

3

Whl

c1

beanng

4

Whcd

be

mng

I

ollar

5

Oll

al

b

Hcanng

adjust

hlOl

7

Axle

a

C

8

BrJ

ke

drum

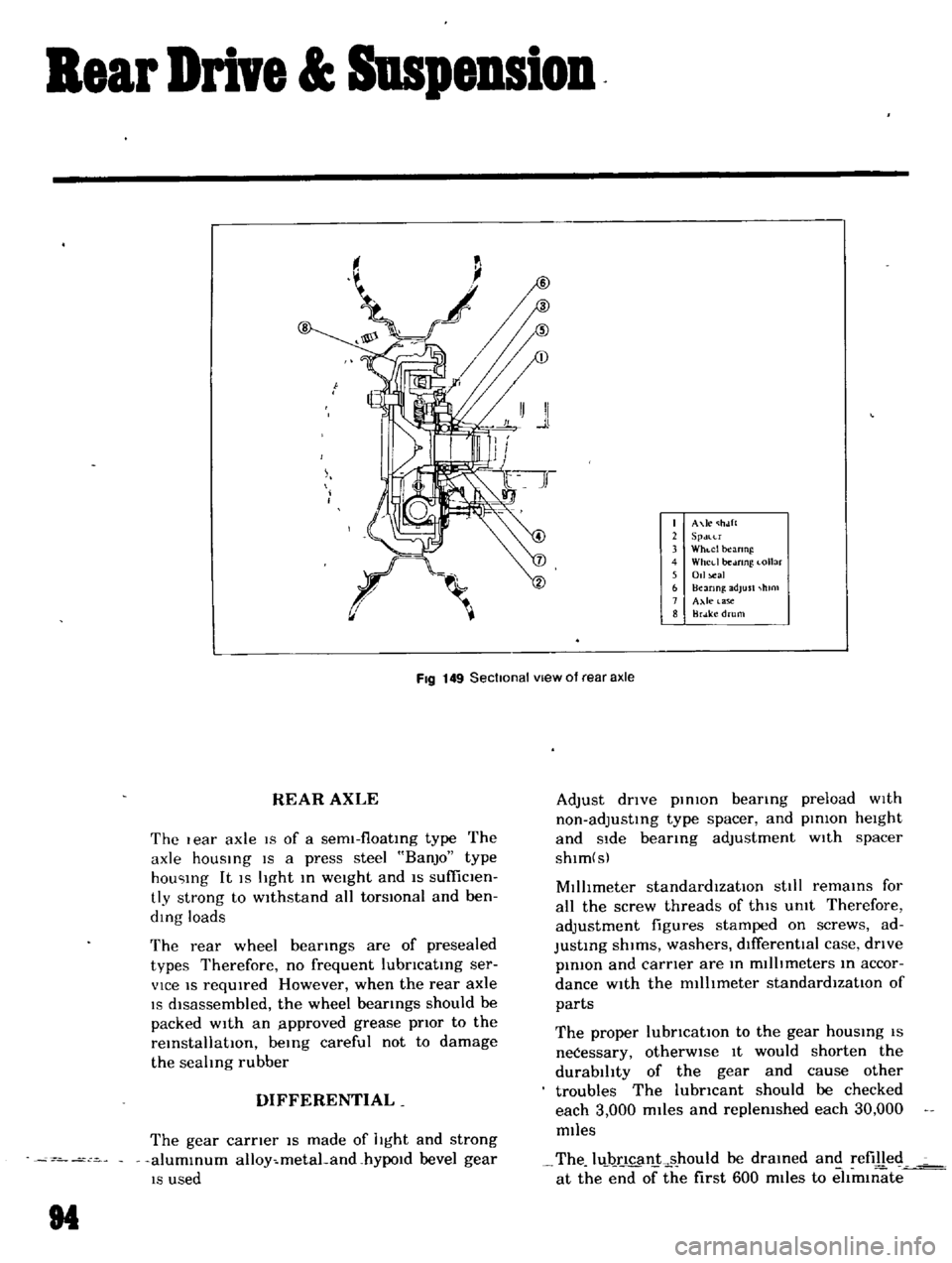

FIg

149

Sectional

vIew

of

rear

axle

REAR

AXLE

The

I

ear

axle

19

of

a

sem1

f10atIng

type

The

axle

hOUSIng

IS

a

press

steel

BanjO

type

hou

Ing

It

IS

light

In

weight

and

IS

sufficlen

tly

strong

to

wIthstand

all

torsIOnal

and

ben

ding

loads

The

rear

wheel

bearIngs

are

of

presealed

types

Therefore

no

frequent

lubncatIng

ser

vice

IS

reqUIred

However

when

the

rear

axle

IS

dIsassembled

the

wheel

bearings

should

be

packed

with

an

lpproved

grease

pnor

to

the

reInstallatIOn

beIng

careful

not

to

damage

the

sealing

rubber

DIFFERENTIAL

The

gear

carner

IS

made

of

light

and

strong

alumInum

alloy

metaLand

hYPOld

bevel

gear

IS

used

M

Adjust

dnve

pInIOn

bearIng

preload

wIth

non

adjustIng

type

spacer

and

pInion

height

and

Side

bearIng

adjustment

wIth

spacer

shlm

s

MIllimeter

standardIzatIOn

stili

remaInS

for

all

the

screw

threads

of

thIS

Unit

Therefore

adjustment

figures

stamped

on

screws

ad

JustIng

shIms

washers

dIfferentIal

case

dnve

pInIOn

and

carner

are

In

millimeters

In

accor

dance

with

the

millImeter

standardIzatIOn

of

parts

The

proper

lubncatlOn

to

the

gear

hOUSIng

IS

neCessary

otherWIse

It

would

shorten

the

durability

of

the

gear

and

cause

other

troubles

The

lubncant

should

be

checked

each

3

000

miles

and

replenished

each

30

000

miles

The

luJ

ncan

ks

hould

be

draIned

and

refilled

at

the

end

of

the

first

600

miles

to

eltm1l1ate

Page 131 of 136

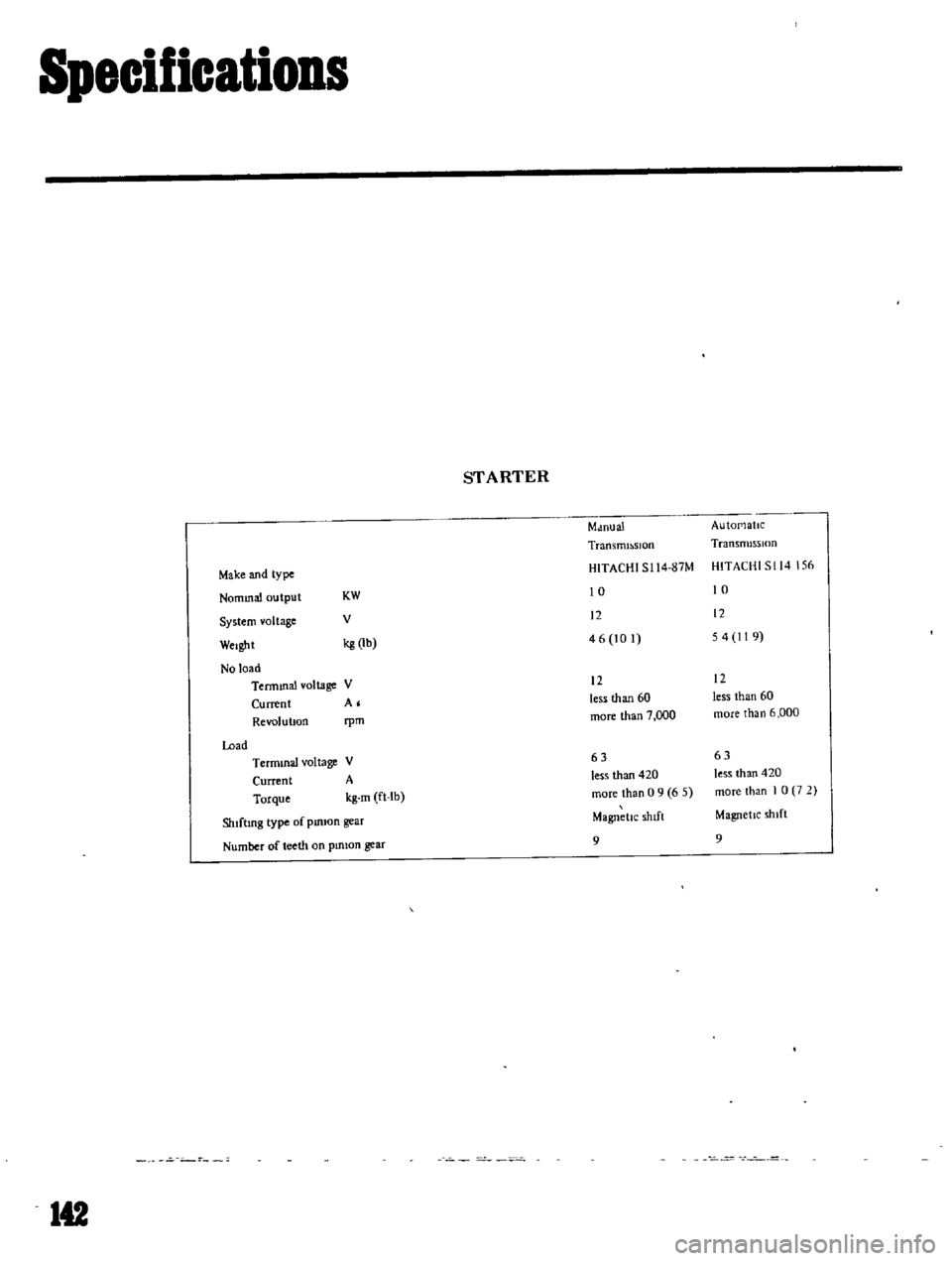

Specifications

STARTER

Make

and

type

Nommal

output

System

voltage

Weight

KW

V

J

Mdnual

Au

tOP1allc

T

ransmJ

lJSJon

TransmJsslon

HITACHI

S114

87M

HITACHI

S

114

I

S6

10

10

12

12

46

10

I

S

4

119

12

12

less

than

60

less

than

60

more

than

7

000

more

than

6

000

63

63

less

than

420

less

than

420

more

than

0

9

6

S

mare

than

1

0

7

2

MagnetiC

shift

MagnetiC

shift

9

9

kg

Ib

No

load

Tennmal

voltage

V

Current

A

RevolutIon

rpm

Load

Tennmal

voltage

Current

Torque

V

A

kg

m

ft

Ib

Sluftmg

type

of

pmlOn

gear

Number

of

teeth

on

pinion

gear

142

Page 132 of 136

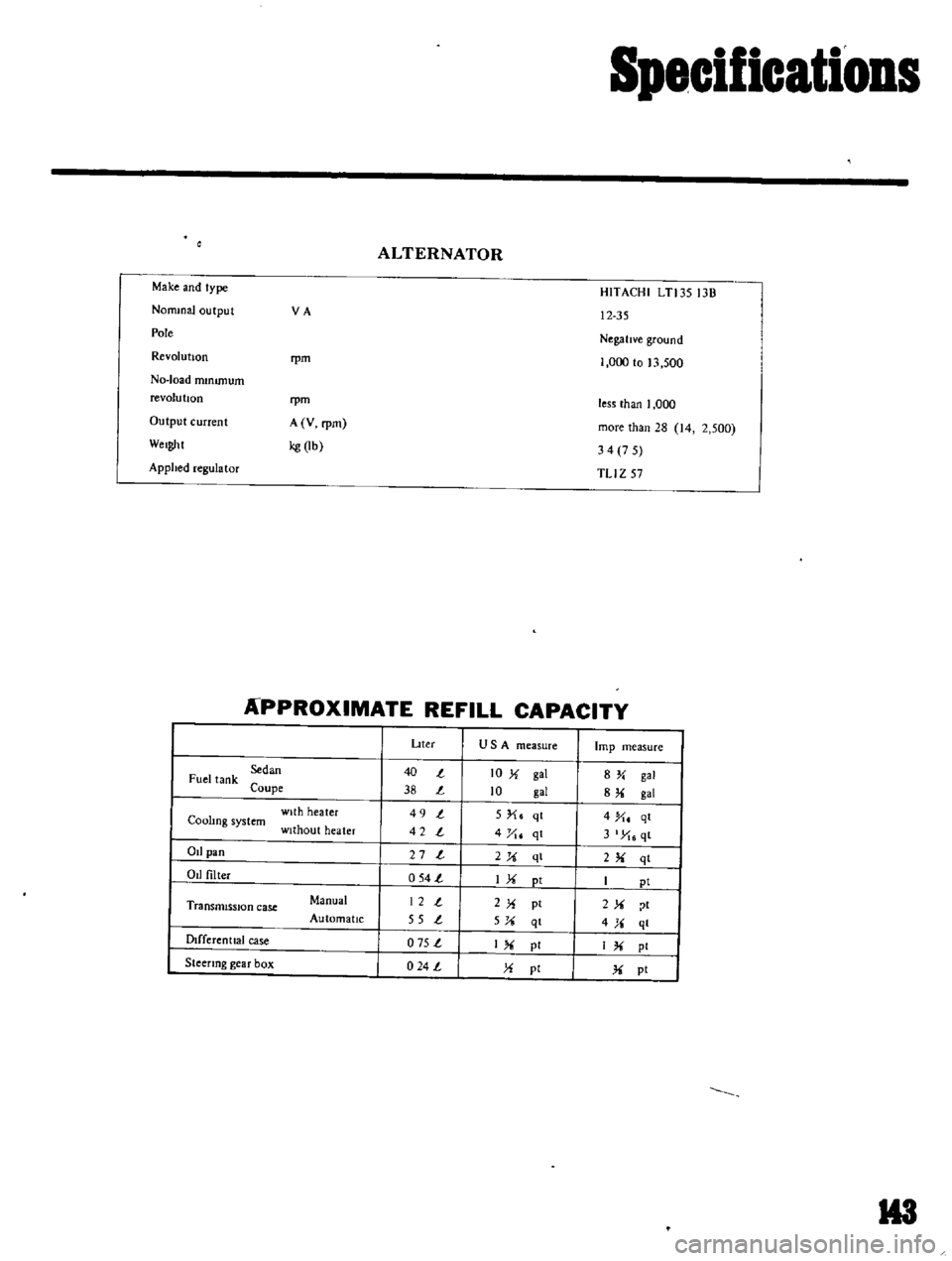

Specifications

ALTERNATOR

Make

and

type

NonunaJ

output

VA

Pole

Revolution

rpm

No

load

mmunum

revolu

bon

rpm

Output

current

A

V

rpm

Weight

kg

lb

Applied

regulator

HITACHI

LTl3S

13B

12

35

NegatIve

ground

1

000

to

13

500

less

than

I

000

more

than

28

14

2

500

34

7

5

TLI

Z

57

APPROXIMATE

REFILL

CAPACITY

Dter

USA

measure

lmp

measure

Sedan

40

t

10

X

gal

8Y

gal

Fuel

tank

Coupe

38

t

10

gal

8

gal

with

heater

49

t

5

X

qt

4

X

qt

Coohng

system

without

heater

42

t

4

yt

qt

3

X

qt

Od

pan

27

t

2X

ql

2

qt

Od

filter

054

t

IX

pt

I

pi

Transmission

case

Manual

12

t

2X

pt

2X

t

Automatic

55

t

5X

qt

4X

ql

Dlfferenttal

case

o

75

t

I

pI

IX

pI

Steenng

gear

box

024

L

X

pi

X

pt

H3