air filter DATSUN B110 1973 Service User Guide

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1973, Model line: B110, Model: DATSUN B110 1973Pages: 513, PDF Size: 28.74 MB

Page 403 of 513

ENGINE

Step

system

The

construction

of

this

system

corresponds

to

the

idling

and

slow

system

of

the

primary

system

This

system

aims

at

the

power

filling

up

of

the

gap

when

fuel

supply

is

transferred

from

the

primary

system

to

the

secondary

system

The

step

port

is

located

near

the

auxiliary

valve

in

its

fully

closed

state

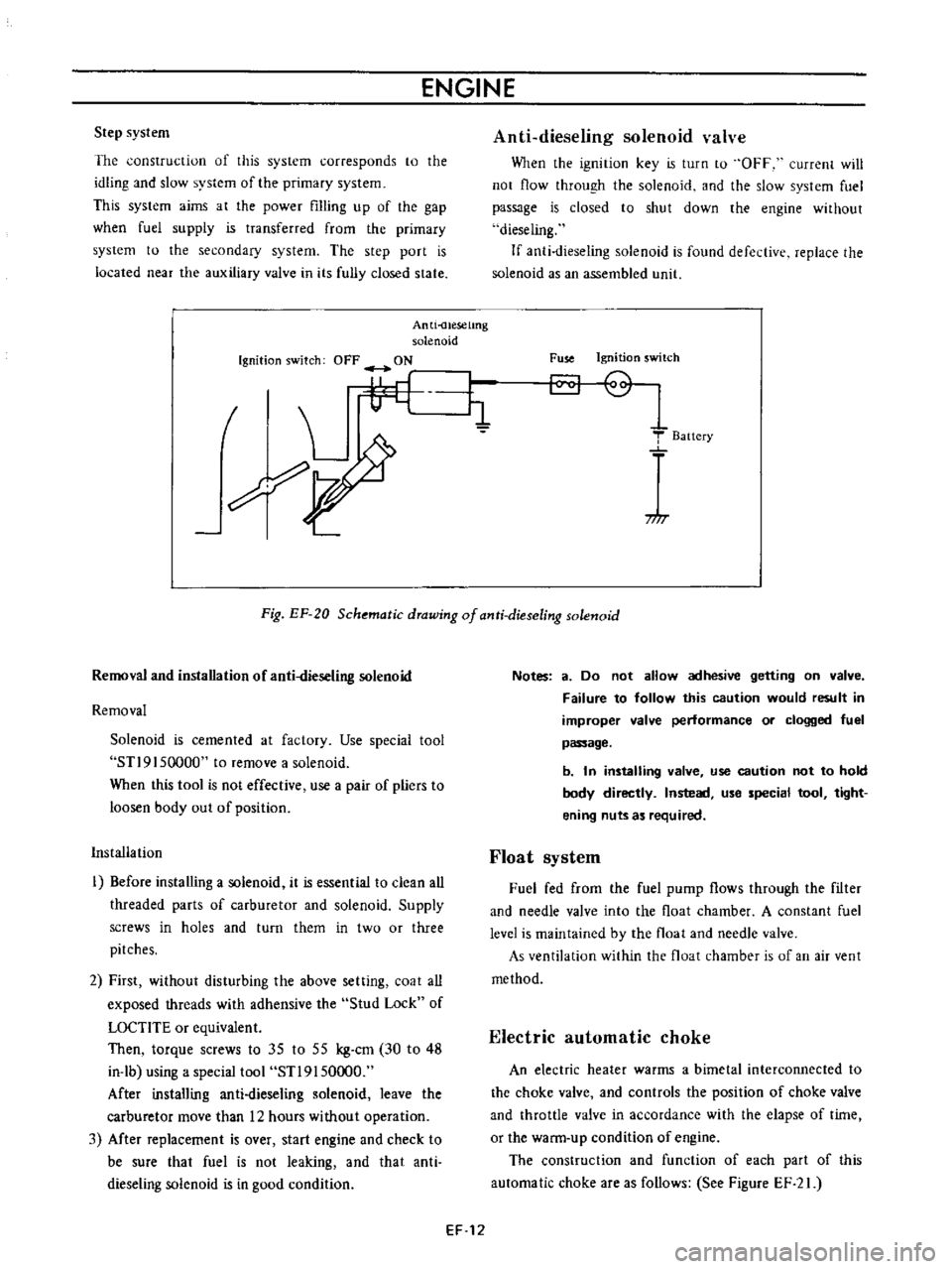

Anti

uesetmg

solenoid

Ignition

switch

OFF

ON

I

L

i1

7

I

Anti

dieseling

solenoid

valve

When

the

ignition

key

is

turn

to

OFF

current

will

not

flow

through

the

solenoid

and

the

slow

system

fuel

passage

is

closed

to

shut

down

the

engine

without

dieseling

If

anti

dieseling

solenoid

is

found

defective

replace

the

solenoid

as

an

assembled

llnit

Fuse

Ignition

switch

T

Baitery

717

Fig

EF

20

Schematic

drawing

of

anti

dieseling

solenoid

Removal

and

installation

of

anti

dieseling

solenoid

Removal

Solenoid

is

cemented

at

factory

Use

special

tool

STl9

I

50000

to

remove

a

solenoid

When

this

tool

is

not

effective

use

a

pair

of

pliers

to

loosen

body

out

of

position

Installation

I

Before

installing

a

solenoid

it

is

essential

to

clean

all

threaded

parts

of

carburetor

and

solenoid

Supply

screws

in

holes

and

turn

them

in

two

or

three

pitches

2

First

without

disturbing

the

above

setting

coat

all

exposed

threads

with

adhensive

the

Stud

Lock

of

LOCTlTE

or

equivalent

Then

torque

screws

to

35

to

55

kg

cm

30

to

48

in

lb

using

a

special

tool

STl9150000

After

installing

anti

dieseling

solenoid

leave

the

carburetor

move

than

12

hours

without

operation

3

Mter

replacement

is

over

start

engine

and

check

to

be

sure

that

fuel

is

not

leaking

and

that

anti

dieseling

solenoid

is

in

good

condition

Notes

a

Do

not

allow

adhesive

getting

on

valve

Failure

to

follow

this

caution

would

result

in

improper

valve

performance

or

clogged

fuel

passage

b

In

installing

valve

use

caution

not

to

hold

body

directly

Instead

use

special

tool

tight

ening

nuts

as

required

Float

system

Fuel

fed

from

the

fuel

pump

flows

through

the

filter

and

needle

valve

into

the

float

chamber

A

constant

fuel

level

is

maintained

by

the

float

and

needle

valve

As

ventilation

within

the

float

chamber

is

of

an

air

vent

method

Electric

automatic

choke

An

electric

heater

warms

a

bimetal

interconnected

to

the

choke

valve

and

controls

the

position

of

choke

valve

and

throttle

valve

in

accordance

with

the

elapse

of

time

or

the

warm

up

condition

of

engine

The

construction

and

function

of

each

part

of

this

automatic

choke

are

as

follows

See

Figure

EF

21

EF

12

Page 411 of 513

ENGINE

Y

Q

0

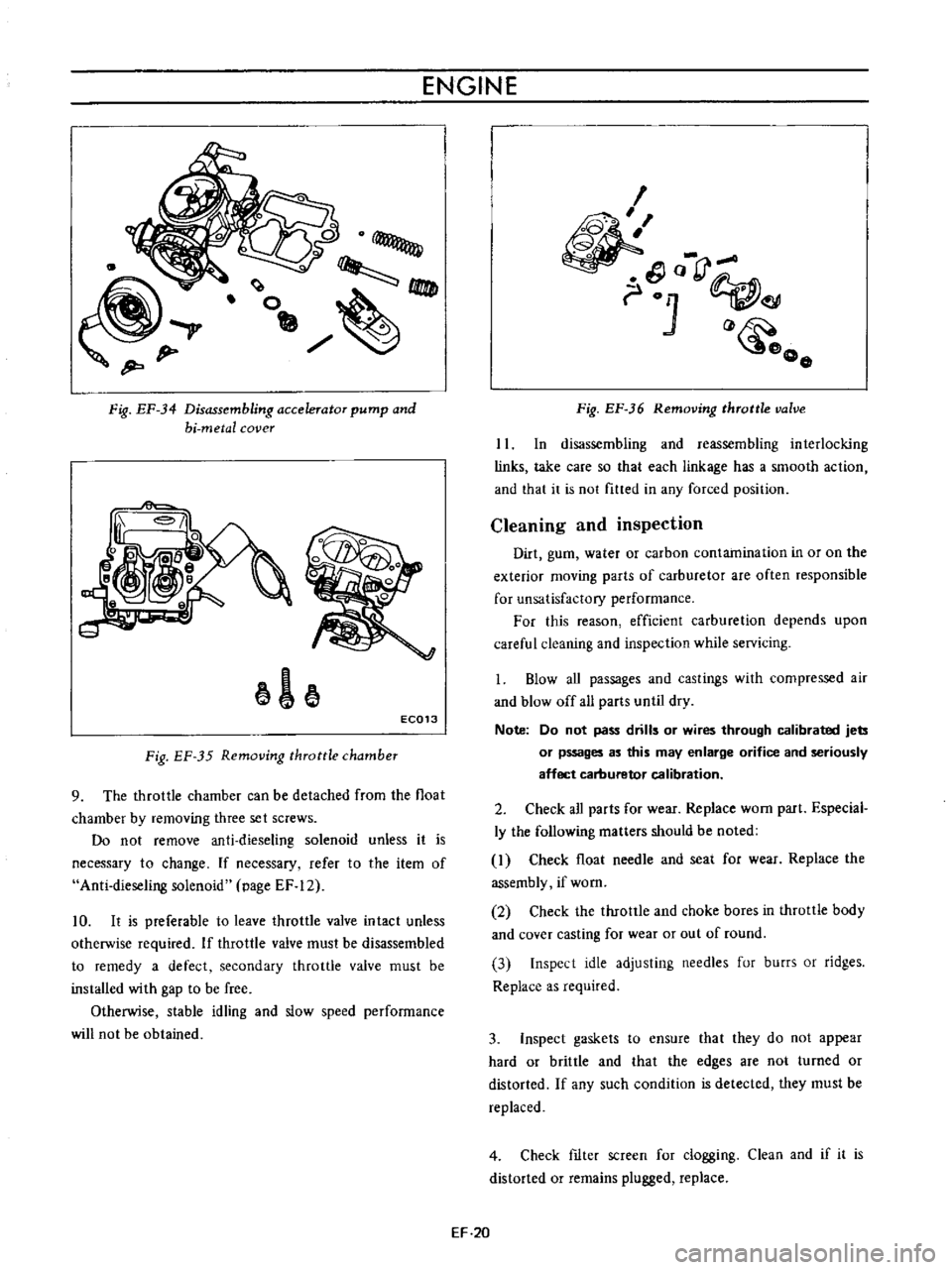

Fig

EF

34

Disassembling

accelerator

pump

and

hi

metal

cover

1

EC013

Fig

EF

35

Removing

throttle

chamber

9

The

throttle

chamber

can

be

detached

from

the

float

chamber

by

removing

three

set

screws

Do

not

remove

anti

dieseling

solenoid

unless

it

is

necessary

to

change

If

necessary

refer

to

the

item

of

Anti

dieseling

solenoid

page

EF

12

10

It

is

preferable

to

leave

throttle

valve

intact

unless

otherwise

required

If

throttle

valve

must

be

disassembled

to

remedy

a

defect

secondary

throttle

valve

must

be

installed

with

gap

to

be

free

Otherwise

stable

idling

and

slow

speed

performance

will

not

be

obtained

I

o

rJ

01

o

o

Fig

EF

36

Removing

throttle

valve

II

In

disassembling

and

reassembling

interlocking

links

take

care

so

that

each

linkage

has

a

smooth

action

and

that

it

is

not

fitted

in

any

forced

position

Cleaning

and

inspection

Dirt

gum

water

or

carbon

contamination

in

or

on

the

exterior

moving

parts

of

carburetor

are

often

responsible

for

unsatisfactory

performance

For

this

reason

efficient

carburetion

depends

upon

careful

cleaning

and

inspection

while

servicing

1

Blow

aU

passages

and

castings

with

compressed

air

and

blow

off

all

parts

until

dry

Note

Do

not

pass

drills

or

wires

through

calibrated

jets

or

pssages

as

this

may

enlarge

orifice

and

seriously

affect

carburetor

calibration

2

Check

all

parts

for

wear

Replace

worn

part

Especial

ly

the

following

matters

should

be

noted

I

Check

float

needle

and

seat

for

wear

Replace

the

assembly

if

worn

2

Check

the

throttle

and

choke

bores

in

throttle

body

and

cover

casting

for

wear

or

out

of

round

3

Inspect

idle

adjusting

needles

fur

burrs

or

ridges

Replace

as

required

3

Inspect

gaskets

to

ensure

that

they

do

not

appear

hard

or

brittle

and

that

the

edges

are

not

turned

or

distorted

If

any

such

condition

is

detected

they

must

be

replaced

4

Check

fIlter

screen

for

clogging

Clean

and

if

it

is

distorted

or

remains

plugged

replace

EF

20