clock DATSUN B110 1973 Service User Guide

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1973, Model line: B110, Model: DATSUN B110 1973Pages: 513, PDF Size: 28.74 MB

Page 235 of 513

DATSUN

1200

MODEL

B

11

0

SERIES

I

NISSAN

I

NISSAN

MOTOR

CO

LTD

TOKYO

JAPAN

SECTION

BE

BODY

ELECTRICAL

WIRING

FUSE

LIGHTING

SYSTEM

HORN

METERS

AND

GAUGES

WINDSHIELD

WIPER

AND

WASHER

IGNITION

SWITCH

AND

STEERING

LOCK

CLOCK

RADIO

HEATER

BE

1

BE

6

BE

7

BE

15

BE

18

BE

26

BE

29

BE

31

BE

32

BE

34

Page 243 of 513

n

YR

f

f1

JC

1

r

8bD

l

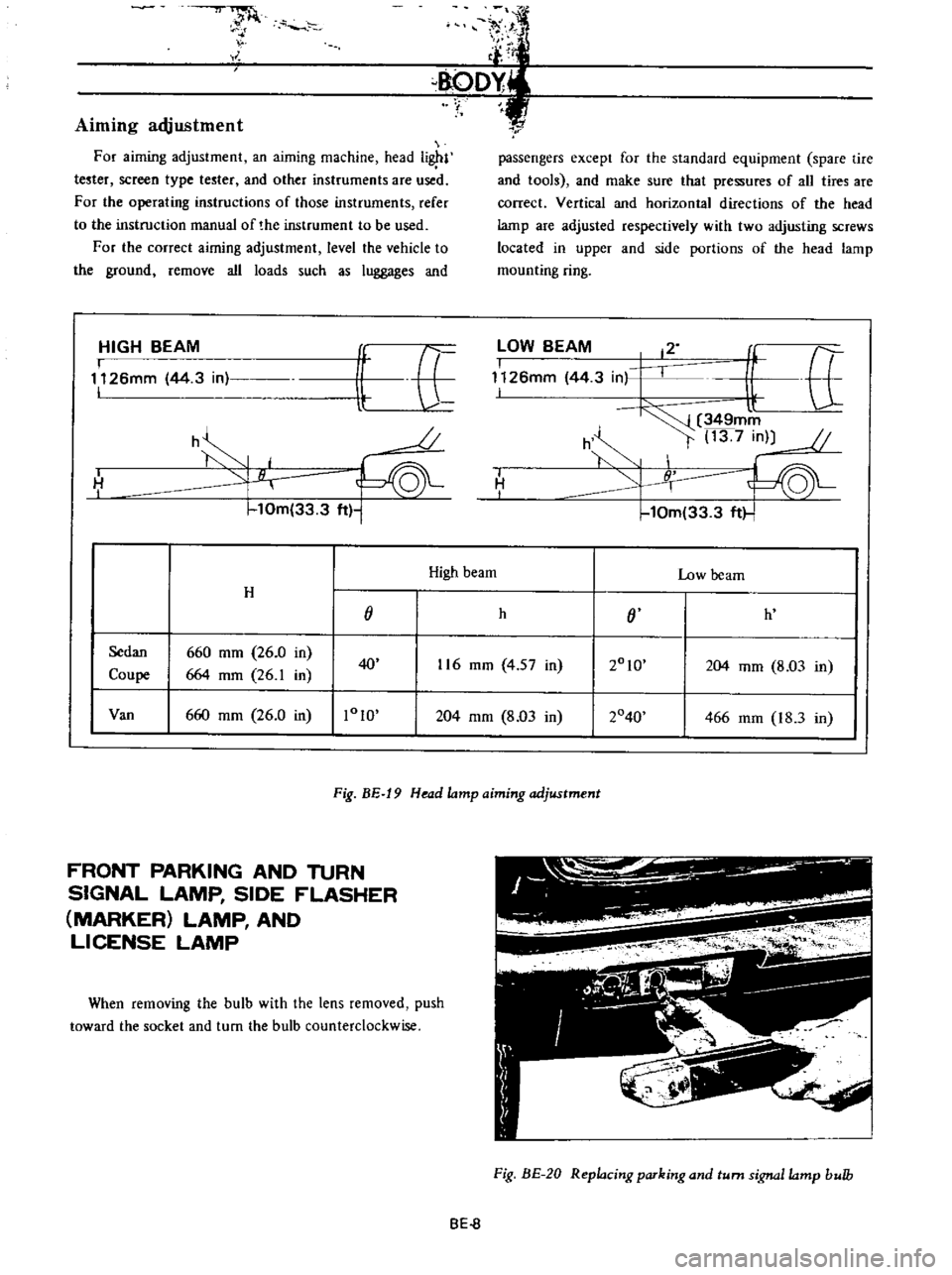

Aiming

adjustment

For

aiming

adjustment

an

aiming

machine

head

i

l

tester

screen

type

tester

and

other

instruments

are

used

For

the

operating

instructions

of

those

instruments

refer

to

the

instruction

manual

of

the

instrument

to

be

used

For

the

correct

airning

adjustment

level

the

vehicle

to

the

ground

remove

all

loads

such

as

luggages

and

HIGH

BEAM

I

1126mm

44

3

in

I

it

E

U

o

h

H

I

10m

33

3

ft

1

r

passengers

except

for

the

standard

equipment

spare

tire

and

tools

and

make

sure

that

pressures

of

all

tires

are

correct

Vertical

and

horizontal

directions

of

the

head

lamp

are

adjusted

respectively

with

two

adjusting

screws

located

in

upper

and

side

portions

of

the

head

lamp

mounting

ring

lOW

BEAM

12

I

f

tt

1126mm

44

3

in

I

l

349mm

h

t

13

7

in

10m

33

3

ft

I

H

I

High

beam

Low

beam

H

j

h

j

h

Sedan

660

mm

26

0

in

2010

Coupe

664

mm

26

1

in

40

116

mm

4

57

in

204

mm

8

03

in

Van

660

mm

26

0

in

1010

204

mm

8

03

in

2040

466

mm

18

3

in

Fig

BE

19

Head

lamp

aiming

adjustment

FRONT

PARKING

AND

TURN

SIGNAL

LAMP

SIDE

FLASHER

MARKER

LAMP

AND

LICENSE

LAMP

When

removing

the

bulb

with

the

lens

removed

push

toward

the

socket

and

turn

the

bulb

counterclockwise

Fig

BE

20

Replacing

parking

and

turn

signa

lamp

bulb

BE

8

Page 244 of 513

r

BODY

ELECTRICAL

Fig

BE

21

Replacing

side

lasher

lamp

bulb

Fig

BE

22

Replacing

license

lamp

bulb

REAR

COMBINATION

LAMPS

When

removing

the

bulb

turning

it

counterclockwise

remove

the

socket

from

the

lamp

housing

and

rernove

the

bulb

from

the

socket

Fig

BE

23

Replacing

rear

combination

lamp

bulb

r

oving

the

rear

combination

lamp

assembly

remove

the

socket

from

the

lamp

housing

remove

fixing

nuts

and

remove

the

combination

lamp

assembly

1

0

Fig

BE

24

Removing

rear

combination

lamp

sedan

1

I

Combination

lamp

RH

2

Body

earth

I

J

I

Tail

harness

Fig

BE

25

Removing

Tear

combination

lamp

van

Fig

BE

26

Remavinit

r

ar

combirwtioH

lamI

coupe

BE

9

Page 246 of 513

BODY

ELECTRICAL

8

G

J

r

ICENSE

LAMPS

10

0

I

I

g

N

Ap

KING

10

00

01

2

I

NATION

J

J

r

j

a

iii

a

g

Lv

F

a

G

G

Lo

o

0

I

I

m

L

J

HER

UNIT

DIMMER

SWITCH

TURN

SIONAl

SWITCH

I

I

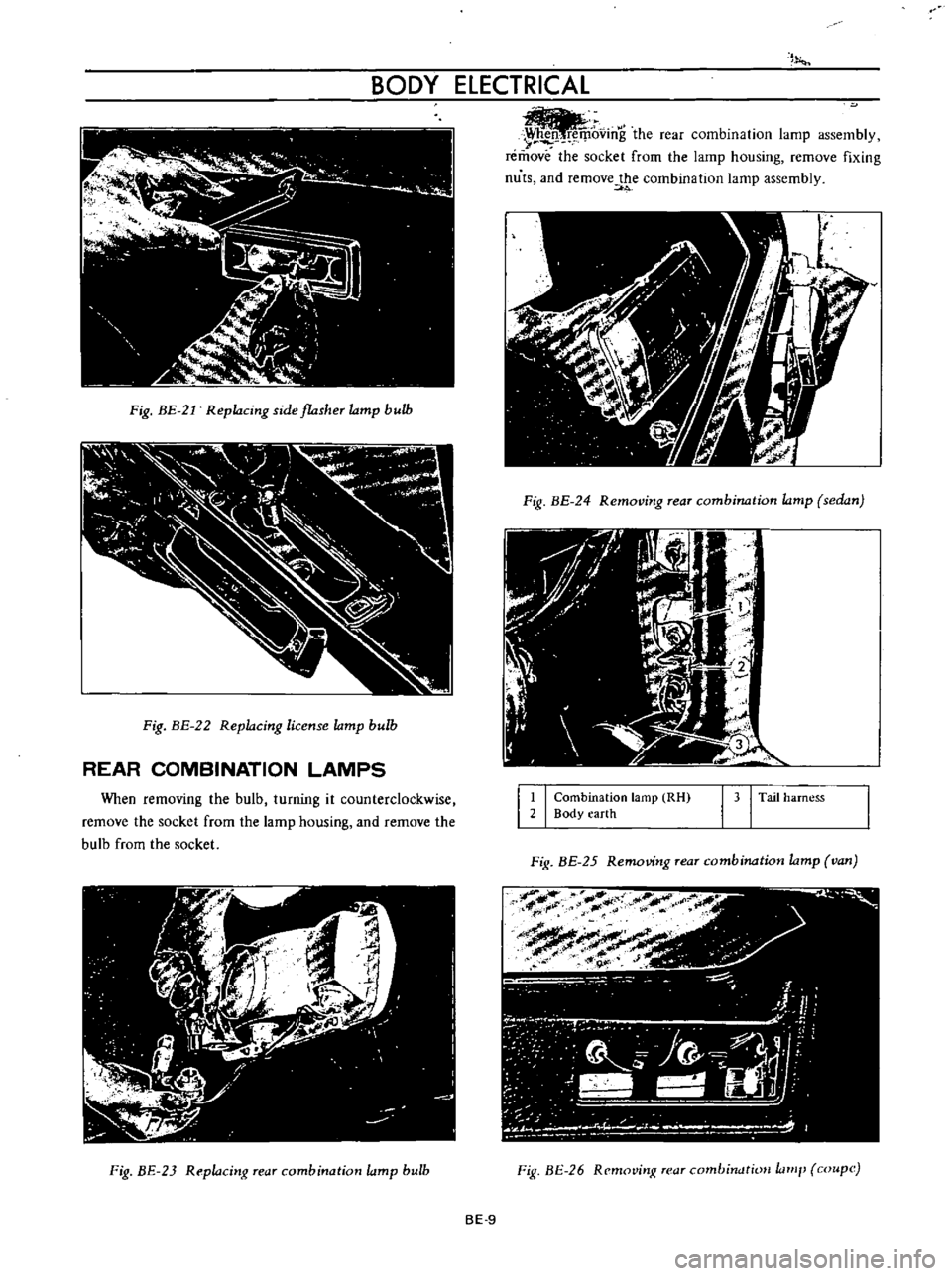

Fig

BE

28

Circuit

diagram

for

turn

signal

and

dimmer

switch

system

LIGHTING

SWITCH

HAZARD

WARNING

SWITCH

Removal

The

hazard

lamp

system

4

way

flasher

consists

of

hazard

warning

switch

and

flasher

unit

When

the

hazard

warning

switch

is

turned

on

all

signal

lamps

flash

simultaneously

telling

other

drivers

that

the

vehicle

is

stopped

When

the

turn

signal

lamps

flash

the

pilot

lamps

on

the

instrument

panel

also

flash

telling

you

of

hazard

lamp

operation

1

Rernove

the

connector

from

back

of

the

lighting

switch

2

Depressing

the

lighting

switch

knob

turn

it

counter

clockwise

and

remove

it

3

Loosen

the

escutcheon

switch

frorn

the

cluster

lid

and

remove

the

lighting

IGNITION

SWITCH

EZ

L

I

U

I

JJ

u

HAZARD

UNIT

Ip

FLASHER

UNIT

HAZARD

WARNING

SWITCH

161

6

6

g

Q

a

ll

Zll

Zll

CE

O

a

We

a

l

e

rY

1

LEFT

SiDE

RIGHT

SIDE

Fig

BE

29

Circuit

diagram

for

hazard

lamp

system

BE

11

Page 251 of 513

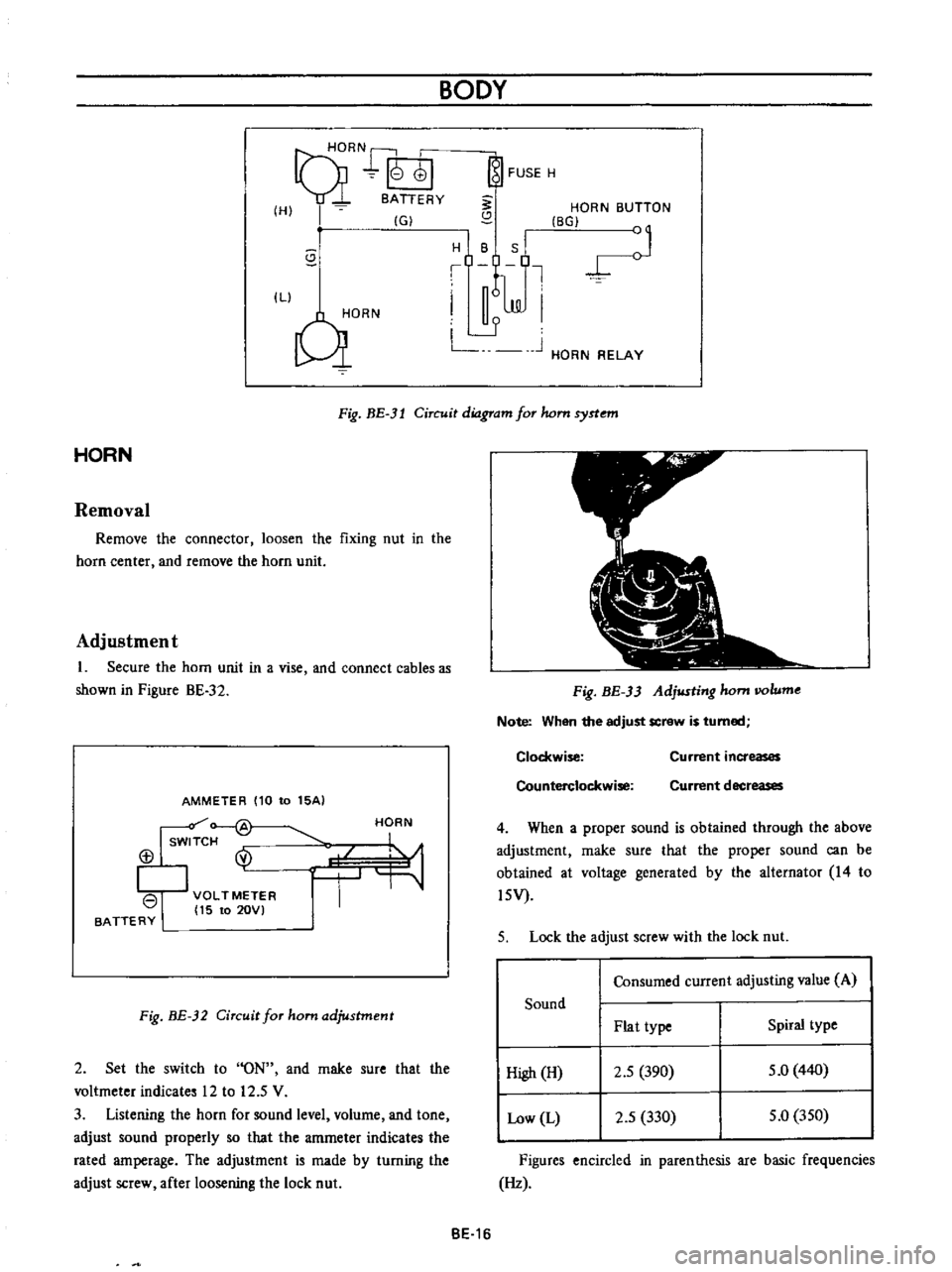

9HORN

r

I

01

8ATTERY

HI

IGI

s

ILl

C

iORN

BODY

FUSE

H

S

HORN

BUTTON

BGI

J

H

B

S

Il

I

n6lm

I

L

J

L

HORN

RELAY

Fig

BE

3l

Circuit

diagram

for

hom

syrtem

HORN

Removal

Remove

the

connector

loosen

the

fixing

nut

in

the

horn

center

and

remove

the

horn

unit

Adjustment

1

Secure

the

horn

unit

in

a

vise

and

connect

cables

as

shown

in

Pigure

BE

32

AMMETER

110

to

15AI

Isw

f

@

113

I

VOLTMETER

I

15

to

20VI

BATTERY

HORN

Fig

BE

32

Circuit

for

ham

adjustment

2

Set

the

switch

to

ON

and

rnake

sure

that

the

voltmeter

indicates

12

to

12

5

V

3

Listening

the

horn

for

sound

level

volurne

and

tone

adjust

sound

properly

so

that

the

amrneter

indicates

the

rated

amperage

The

adjustment

is

made

by

turning

the

adjust

screw

after

loosening

the

lock

nut

Fig

BE

33

Adjusting

hom

IIOlume

Note

When

the

adjust

screw

is

turned

Clockwise

Counterclockwise

Current

increases

Current

decreases

4

When

a

proper

sound

is

obtained

through

the

above

adjustment

rnake

sure

that

the

proper

sound

can

be

obtained

at

voltage

generated

by

the

alternator

14

to

l5V

5

Lock

the

adjust

screw

with

the

lock

nut

Consumed

current

adjusting

value

A

Sound

Plat

type

Spiral

type

High

H

2

5

390

5

0

440

Low

L

2

5

330

5

0

350

Figures

encircled

in

parenthesis

are

basic

frequencies

Hz

BE

16

Page 253 of 513

BODY

METERS

AND

GAUGES

CONTENTS

CLUSTER

LID

Oescri

ption

Removal

SPEEDOMETER

Replacement

FUEL

GAUGE

AND

TEMPERATURE

GAUGE

Description

Replacement

BE

1B

BE

18

BE

18

BE

19

BE

19

BE

19

BE

19

BE

20

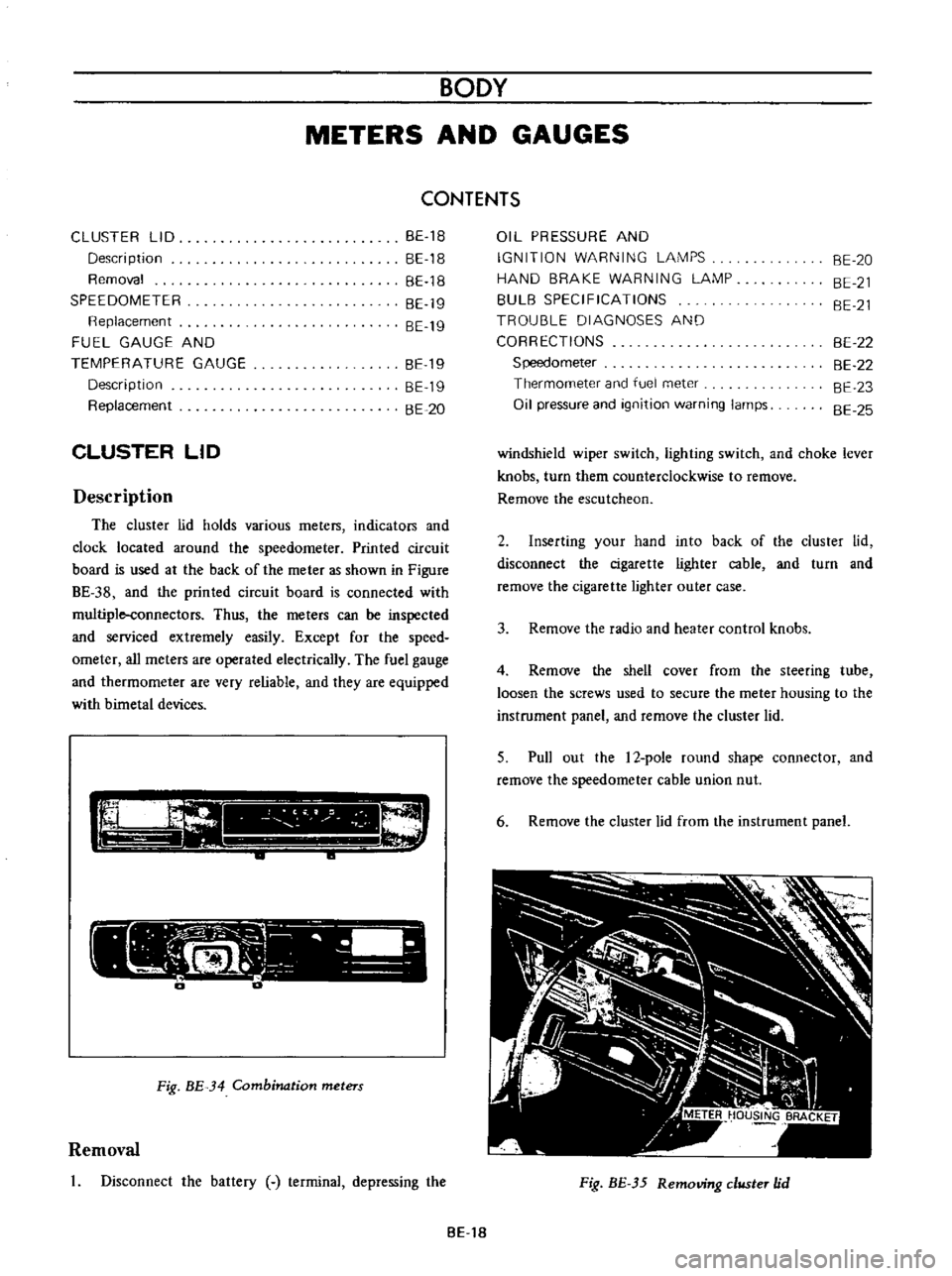

CLUSTER

LID

Description

The

cluster

lid

holds

various

rneters

indicators

and

clock

located

around

the

speedorneter

Printed

circuit

board

is

used

at

the

back

of

the

meter

as

shown

in

Figure

BE

38

and

the

printed

circuit

board

is

connected

with

multiple

connectors

Thus

the

meters

Can

be

inspected

and

serviced

extremely

easily

Except

for

the

speed

ometer

all

rneters

are

operated

electrically

The

fuel

gauge

and

therrnometer

are

very

reliable

and

they

are

equipped

with

bimetal

devices

F

a

o

ill

I

1

a

a

Fig

BE

34

Combination

meters

Removal

Disconnect

the

battery

terminal

depressing

the

OIL

PRESSURE

AND

IGNITION

WARNING

LAMPS

HAND

BRAKE

WARNING

LAMP

BULB

SPECIFICATIONS

TROUBLE

DIAGNOSES

AND

CORRECTIONS

Speedometer

Thermometer

and

fuel

meter

Oil

pressure

and

ignition

warning

lamps

BE

20

BE

21

BE

21

BE

22

BE

22

BE

23

BE

25

windshield

wiper

switch

lighting

switch

and

choke

lever

knobs

turn

them

counterclockwise

to

remove

Remove

the

escutcheon

2

Inserting

your

hand

into

back

of

the

cluster

lid

disconnect

the

cigarette

lighter

cable

and

turn

and

remove

the

cigarette

lighter

outer

case

3

Remove

the

radio

and

heater

control

knobs

4

Remove

the

shell

cover

from

the

steering

tube

loosen

the

screws

used

to

secure

the

meter

housing

to

the

instrument

panel

and

remove

the

cluster

lid

5

Pull

out

the

l2

pole

round

shape

connector

and

remove

the

speedometer

cable

union

nut

6

Remove

the

cluster

lid

from

the

instrument

panel

Fig

BE

35

Removing

clllSter

jd

BE

18

Page 256 of 513

BODY

ElECTRICAL

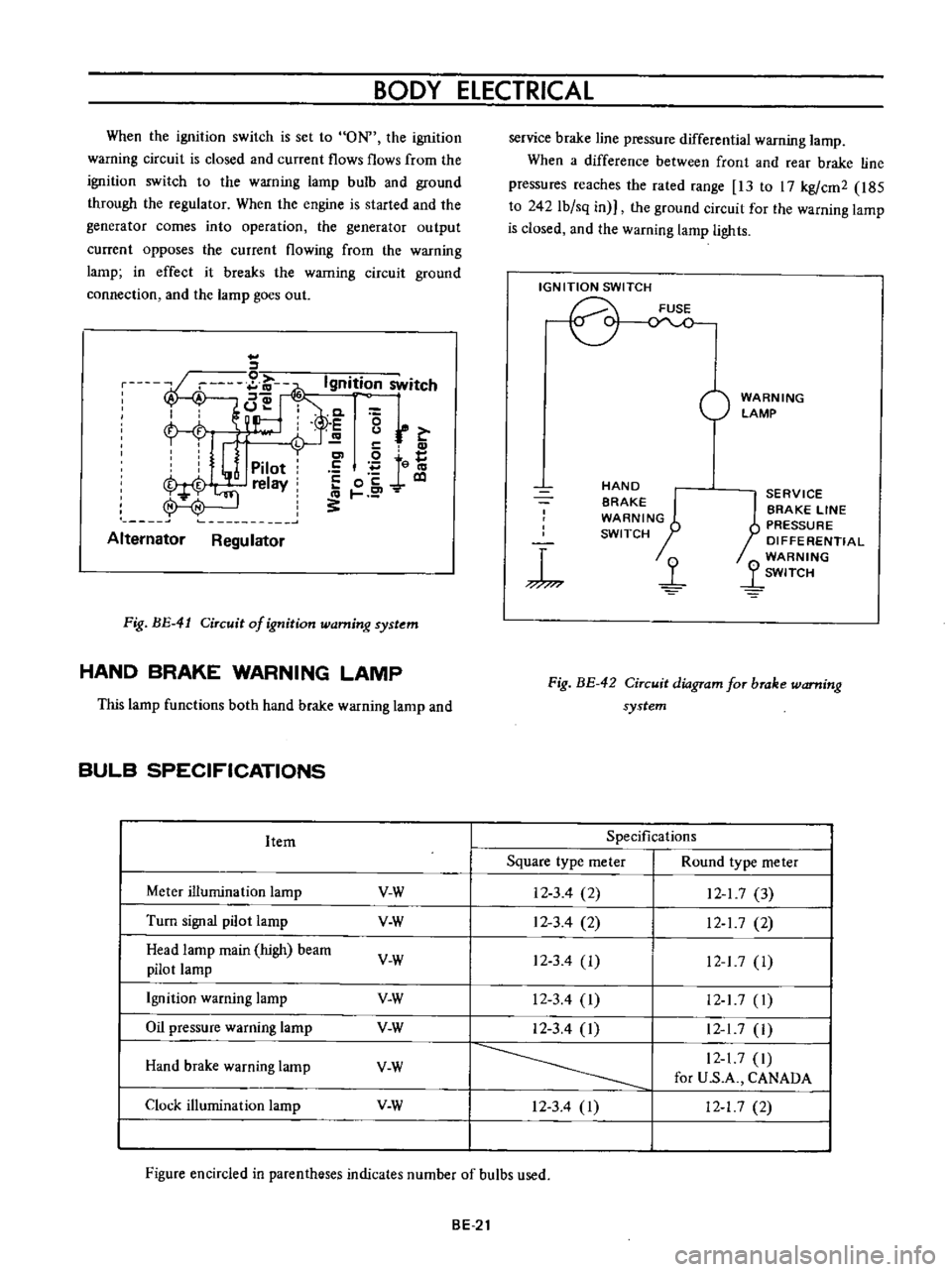

When

the

ignition

switch

is

set

to

ON

the

ignition

wa

rning

circuit

is

closed

and

current

flows

flows

from

the

ignition

switch

to

the

warning

lamp

bulb

and

ground

through

the

regulator

When

the

engine

is

started

and

the

generator

comes

into

operation

the

generator

output

current

opposes

the

current

flowing

from

the

warning

lamp

in

effect

it

breaks

the

warning

circuit

ground

connection

and

the

lamp

goes

out

l

r

hffi

u

z

Ignition

switch

I

Q

6

I

0

c

M

1

E

8

ca

i

L

g

PI

lot

c

P

I

j

co

rt

0

relay

E

0

5

y

y

1

N

N

3

Alternator

Regulator

Fig

BE

41

Circuit

of

ignition

warning

system

HAND

BRAKE

WARNING

LAMP

This

lamp

functions

both

hand

brake

warning

larnp

and

BULB

SPECIFICATIONS

service

brake

line

pressure

differential

warning

lamp

When

a

difference

between

front

and

rear

brake

line

pressures

reaches

the

rated

range

13

to

17

kgfcm2

185

to

242

lb

sq

in

the

ground

circuit

for

the

warning

lamp

is

closed

and

the

warning

lamp

lights

IGNITION

SWITCH

WARNING

LAMP

L

E

WARNING

SWITCH

1

SERVICE

BRAKE

LINE

PRESSU

R

E

DIFFERENTIAL

WARNING

J

SWITCH

Fig

BE

42

Circuit

diagram

for

brake

warning

system

tern

Specifications

Square

type

meter

Round

type

meter

Meter

illumination

larnp

VoW

12

3

4

2

12

1

7

3

Turn

signal

pilot

lamp

VoW

12

3

4

2

12

1

7

2

Head

lamp

main

high

beam

VoW

12

3

4

I

12

17

1

pilot

lamp

Ignition

warning

lamp

VoW

123

4

I

12

17

1

Oil

pressure

warning

lamp

VoW

12

3

4

1

12

1

7

1

Hand

brake

warning

lamp

VoW

12

1

7

1

for

U

S

A

CANADA

Clock

illumination

lamp

VoW

123

4

I

12

17

2

Figure

encircled

in

parentheses

indicates

number

of

bulbs

used

BE

21

Page 262 of 513

BODY

ELECTRICAL

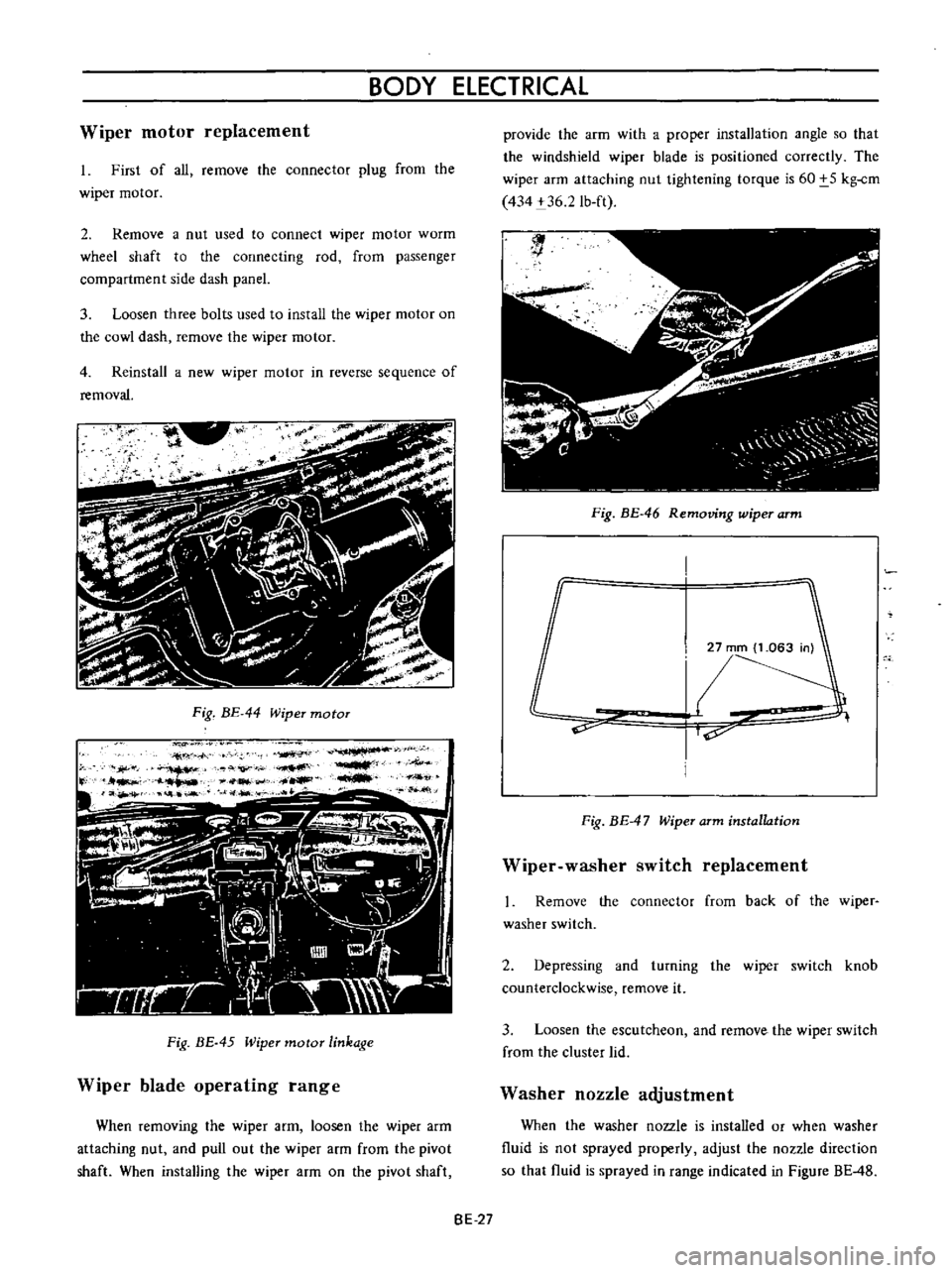

Wiper

motor

replacement

First

of

all

remove

the

connector

plug

from

the

wiper

motoI

2

Remove

a

nut

used

to

connect

wiper

motor

worm

wheel

shaft

to

the

connecting

rod

from

passenger

compartment

side

dash

panel

3

Loosen

three

bolts

used

to

install

the

wiper

motor

on

the

cowl

dash

remove

the

wiper

motor

4

Reinstall

a

new

wiper

motor

in

reverse

sequence

of

removal

Fig

BE

44

Wiper

motor

Q

V

rt

ir

o

y

At

Jllif

Fig

BE

45

Wiper

motor

linkage

Wiper

blade

operating

range

When

removing

the

wiper

arm

loosen

the

wiper

arm

attaching

nut

and

pull

out

the

wiper

arm

from

the

pivot

shaft

When

installing

the

wiper

arm

on

the

pivot

shaft

provide

the

arm

with

a

proper

installation

angle

so

that

the

windshield

wiper

blade

is

positioned

correctly

The

wiper

arm

attaching

nut

tightening

torque

is

60

5

kg

m

434

36

2lb

ft

Fig

BE

46

Removing

wiper

arm

00

I

i

Fig

BE

47

Wiper

arm

installation

Wiper

washer

switch

replacement

Remove

the

connector

from

back

of

the

wiper

washer

switch

2

Depressing

and

turning

the

wiper

switch

knob

counterclockwise

remove

it

3

Loosen

the

escutcheon

and

remove

the

wiper

switch

from

the

cluster

lid

Washer

nozzle

adjustment

When

the

washer

nozzle

is

installed

or

when

washer

fluid

is

not

sprayed

properly

adjust

the

nozzle

direction

so

that

fluid

is

sprayed

in

range

indicated

in

Figure

BE

48

BE

27

Page 266 of 513

BODY

ELECTRICAL

CLOCK

Installation

upper

portion

of

the

instrument

panel

Connect

red

blue

cable

or

red

green

cable

for

illumi

nation

lamp

of

the

clock

to

the

terminals

on

the

printed

circuit

board

for

illumination

lamp

on

the

meter

housing

Ground

the

clock

ground

cable

In

the

case

of

a

square

type

clock

tighten

the

ground

cable

together

with

the

meter

housing

installation

screw

1

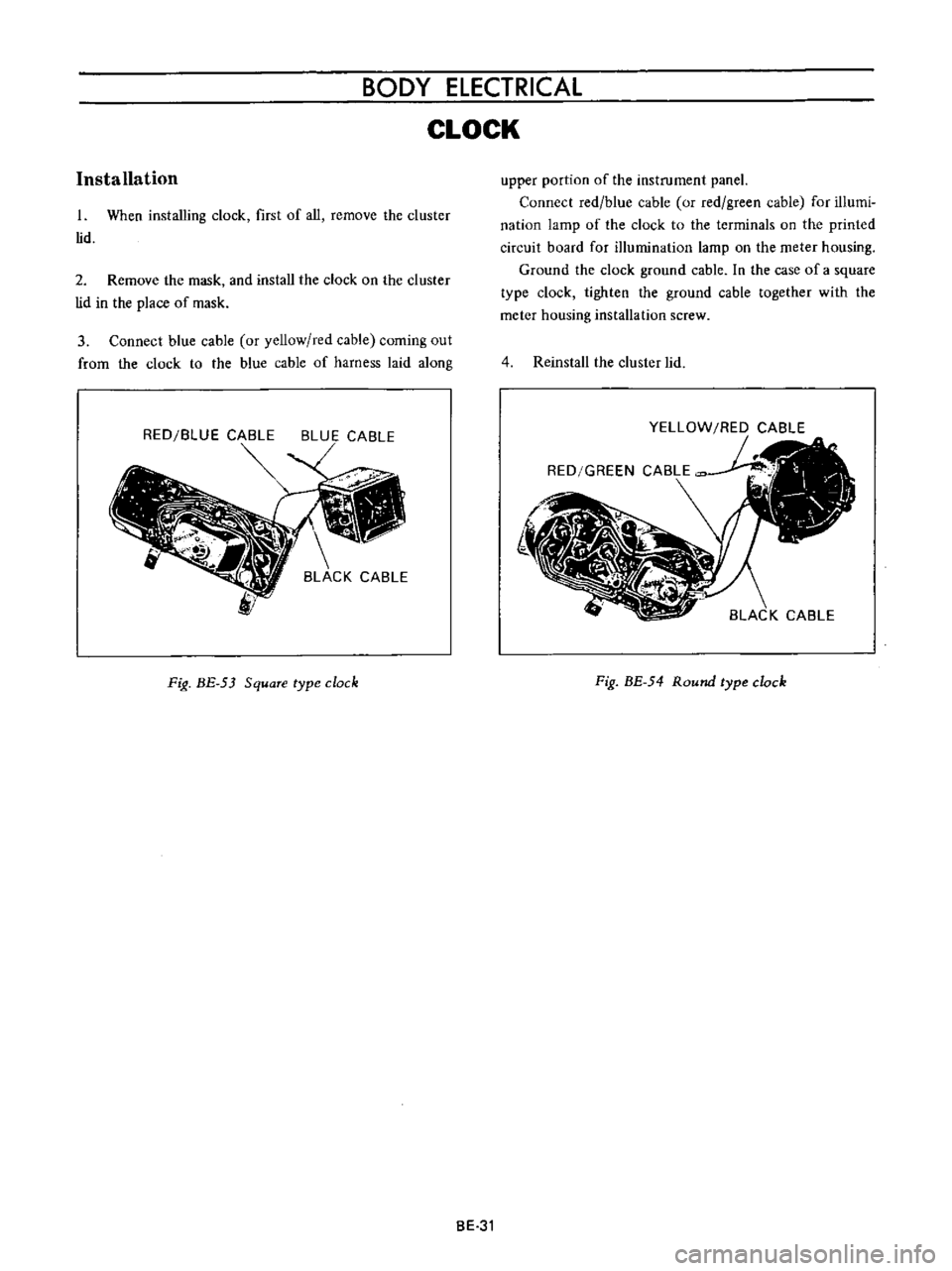

When

installing

clock

first

of

all

remove

the

cluster

lid

2

Remove

the

mask

and

install

the

clock

on

the

cluster

lid

in

the

place

of

mask

3

Connect

blue

cable

or

yellow

red

cable

coming

out

from

the

clock

to

the

blue

cable

of

harness

laid

along

4

Reinstall

the

cluster

lid

RED

BLUE

CABLE

BLUE

CABLE

Fig

BE

53

Square

type

clock

Fig

BE

54

Round

type

clock

BE

31

Page 314 of 513

EMISSION

CONTROL

AND

TUNE

UP

Checking

and

adjusting

dash

pot

automatic

transmission

model

only

Check

operation

of

dash

pot

It

should

not

be

cracked

or

bound

It

is

also

essential

to

check

to

be

certain

that

it

is

in

correct

adjustment

L

Check

to

be

sure

that

dash

pot

contacts

stopper

lever

when

engine

speed

reaches

1

900

to

2

000

rpm

2

Engine

should

be

slowed

down

from

3

000

to

1

000

rpm

within

a

few

seconds

Readjust

dash

pot

or

replace

it

with

a

new

one

if

it

fails

to

meet

the

above

conditions

Checking

carburetor

return

spring

Check

throttle

return

spring

for

sign

of

damage

wear

or

squareness

Discard

spring

if

found

with

any

of

above

excessively

beyond

use

Checking

choke

mechanism

choke

valve

and

linkage

1

Check

choke

valve

and

mechanism

for

free

operation

and

clean

or

replace

if

necessary

A

binding

condition

may

have

developed

from

petro

leum

gum

for

motion

on

choke

shaft

or

from

damage

2

Check

bimetal

cover

setting

position

The

index

mark

of

bimetal

cover

is

usually

aligned

at

the

middle

point

of

the

scale

Note

When

somewhat

over

choked

turn

bimetal

caver

clockwise

slightly

3

Prior

to

starting

check

to

be

sure

that

choke

valve

closes

automatically

when

pressing

down

on

accelerator

pedal

Should

it

fail

to

close

automatically

the

likelihood

is

that

fast

idle

cam

is

out

of

proper

adjustment

or

that

bimetal

is

not

properly

adjusted

calling

for

adjustment

Refer

to

Carburetor

in

Section

EF

Page

EF

15

Checking

anti

dieseling

solenoid

If

engine

will

not

stop

when

ignition

switch

is

turned

off

this

indicates

a

striking

closed

solenoid

valve

shutting

off

supply

of

fuel

to

engine

If

harness

is

in

good

condition

replace

solenoid

as

a

unit

To

replace

proceed

as

follows

Removal

and

installation

of

anti

dieseling

solenoid

Removal

Solenoid

is

cemented

at

factory

Use

special

tool

STl

91

50000

to

remove

a

solenoid

When

this

tool

is

not

effective

use

a

pair

of

pliers

to

loosen

body

out

of

position

lnstalltion

I

Before

installing

a

solenoid

it

is

essential

to

clean

all

threaded

parts

of

carburetor

and

solenoid

Supply

screws

in

holes

and

turn

them

in

two

or

three

pitches

2

First

without

disturbing

the

above

setting

coat

all

exposed

threads

with

adhensive

the

Stud

Lock

of

LOCTlTE

or

equivalent

Then

torque

screws

to

35

to

55

kg

cm

30

to

48

in

lb

using

a

special

tool

STl9150000

After

installing

anti

dieseling

solenoid

leave

the

carbu

retor

more

than

12

hours

without

operation

3

After

replacement

is

over

start

engine

and

check

to

be

sure

that

fuel

is

not

leaking

and

that

anti

dieseling

solenoid

is

in

good

condition

Notes

a

Do

not

allow

adhesive

getting

on

valve

Failure

to

follow

this

caution

would

result

in

improper

valve

performance

or

clogged

fuel

passage

b

I

n

installing

valve

use

caution

not

to

hold

body

directly

Instead

use

special

tool

tighten

ing

nuts

as

required

ET

9