clock DATSUN B110 1973 Service Repair Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1973, Model line: B110, Model: DATSUN B110 1973Pages: 513, PDF Size: 28.74 MB

Page 20 of 513

R

range

Reverse

In

R

range

the

front

clutch

and

low

and

reverse

brake

are

applied

The

power

flow

is

through

the

input

shaft

front

clutch

connecting

sheU

and

to

the

sun

gear

Clockwise

rotatiun

of

the

sun

gear

causes

counterclockwise

rotation

of

the

rear

planetary

gears

With

the

connecting

drum

held

sta

tionary

by

the

low

and

reverse

brake

the

rear

planetary

gears

rotate

the

rear

internal

gear

and

drive

flange

counter

clockwise

The

rear

drive

flange

splined

to

the

output

shaft

rotates

the

output

shaft

counterclockwise

at

a

reduced

speed

with

an

increase

in

torque

for

reverse

gear

J

When

the

manual

valve

V

is

posi

tioned

at

R

range

the

oil

having

the

line

pressure

7

is

directed

to

the

line

pressure

circuits

5

and

6

The

pressure

in

the

circuit

ID

actuates

the

low

and

reverse

brake

after

being

introduced

into

the

line

pressure

cir

cuit

I2

through

the

lst

2nd

shift

valve

ID

The

pressure

in

the

circuit

operates

the

release

side

ofband

servo

and

the

front

clutch

after

being

led

to

the

line

pressure

circuit

10

through

the

2nd

3rd

shift

valve

@

The

throttle

pressure

16

and

the

line

pressure

6

which

vary

with

the

degree

of

the

depression

of

accelerator

pedal

both

act

on

the

pressure

regula

tor

valve

CD

and

press

its

valve

CD

increasing

the

line

pressure

7

In

R

range

the

governor

pressure

is

absent

making

all

sllch

valves

inoperative

as

the

lst

2nd

shift

valve

@

2nd

3rd

shift

valve

and

pressure

modifier

valve

@

CHASSIS

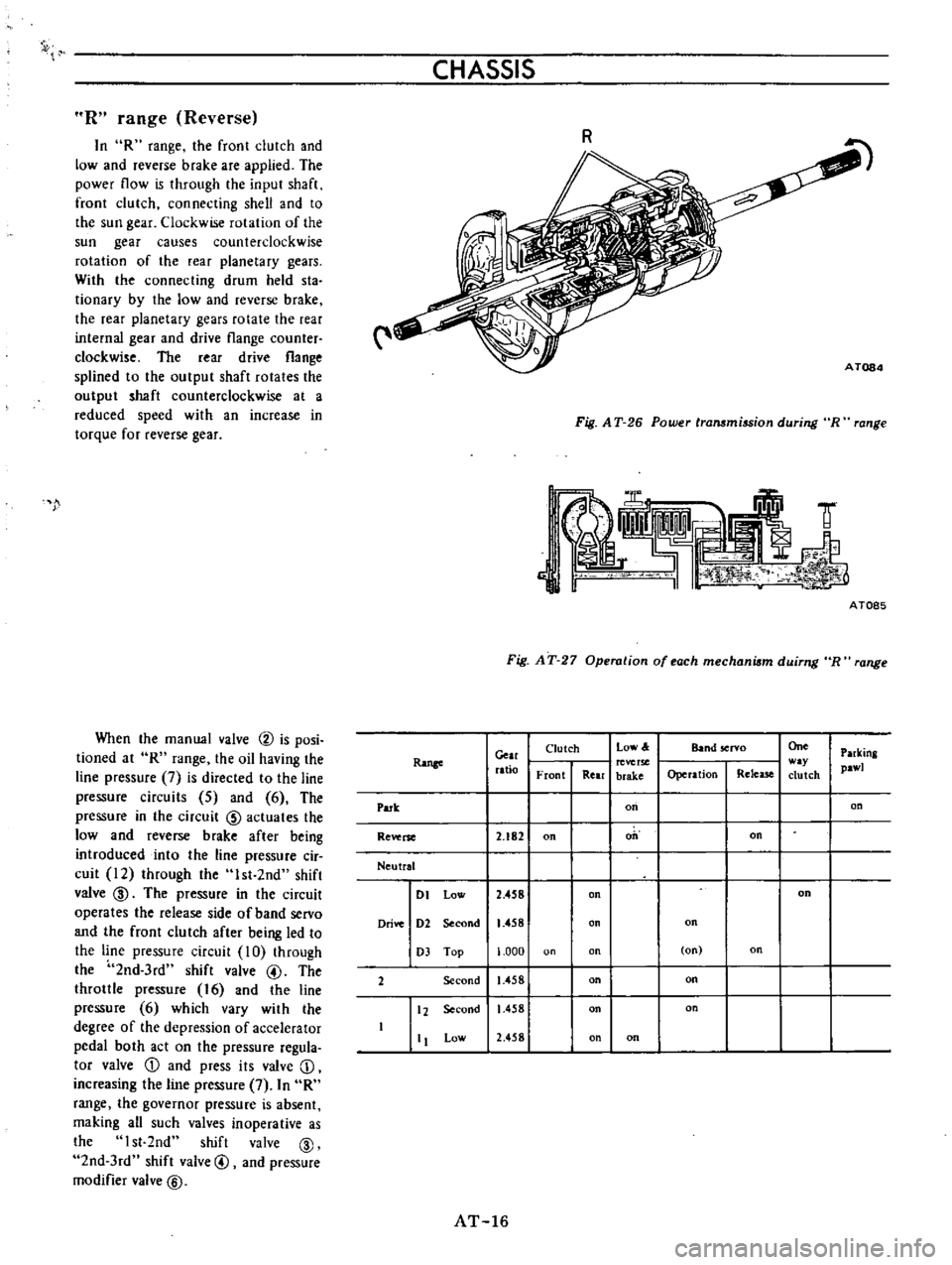

R

C

Fig

AT

26

Power

transmission

during

R

range

lI

a

Go

I

w

L

AT085

Fig

AT

27

Operation

of

each

mechani6m

duirng

OR

range

Clutch

low

Band

servo

One

Parking

Ran

Gear

ratio

reverse

way

pawl

Front

Rear

brake

Operation

Release

clutch

Park

on

on

Reverse

2

182

on

on

on

Neutral

01

low

2

458

nn

on

Drive

D2

Second

458

nn

on

OJ

Top

1

000

on

on

2

Second

458

nn

t2

Second

458

on

tt

low

2

458

on

on

AT

16

Page 24 of 513

CHASSIS

D

range

Low

gear

The

low

gear

in

D

range

is

somewhat

different

from

that

in

II

range

The

rear

clutch

is

applied

as

in

range

but

the

une

way

duldl

is

holding

the

connecling

drum

The

power

flow

is

the

same

as

in

11

range

That

is

the

power

flow

takes

place

through

Ihe

input

shaft

and

into

the

rear

clutch

The

input

shaft

is

splined

to

the

rear

clutch

drum

and

drives

it

Rotation

of

the

rear

clutch

dri

es

the

rear

clutch

hub

and

from

internal

gear

The

front

inlernal

gear

rotates

the

front

planetary

gears

clockwise

to

cause

the

sun

gear

to

rotate

counter

clockwise

Counterclockwise

rotation

of

the

sun

gear

turns

the

rear

planetary

gears

clockwise

With

the

Tear

plane

tary

carrier

held

stationary

by

the

one

way

clutch

the

clockwise

rotation

of

the

rear

planetary

gears

rotates

the

rear

internal

gear

and

drives

flange

clockwise

The

internal

drive

flange

is

splined

to

the

output

shaft

and

rotates

the

output

shaft

clockwise

When

the

manual

valve

is

posi

tioned

at

D

the

line

pressure

7

introduced

into

the

manual

valve

is

led

to

the

line

pressure

circuits

I

2

and

3

The

pressure

in

the

circuit

I

actuates

the

rear

clutch

and

the

gover

nor

and

at

the

same

time

operates

the

lst

2no

shift

valve

ID

to

change

the

speed

The

circuit

2

leads

to

the

second

lock

valve

@

The

circuit

3

actuales

the

2nd

3rd

shift

valve

0

for

the

2nd

3rd

speed

change

and

at

the

same

time

locks

the

second

lock

valve

@

The

throllIe

pressure

16

which

changes

with

the

degree

of

accelerator

pedal

depression

presses

the

pressure

regulator

valve

CD

and

increases

the

line

pressure

7

When

Ihe

speed

of

vehicle

has

increased

the

governor

pressure

J

5

inlroduced

from

the

line

pressure

circuit

ll

actuates

the

lst

2nd

shift

valve

ID

2nd

3rd

shift

valve

@

and

pressure

modifier

valve

@

When

the

governor

pressure

is

high

the

pressure

modifier

valve

CID

acts

in

such

a

direction

as

to

compress

C

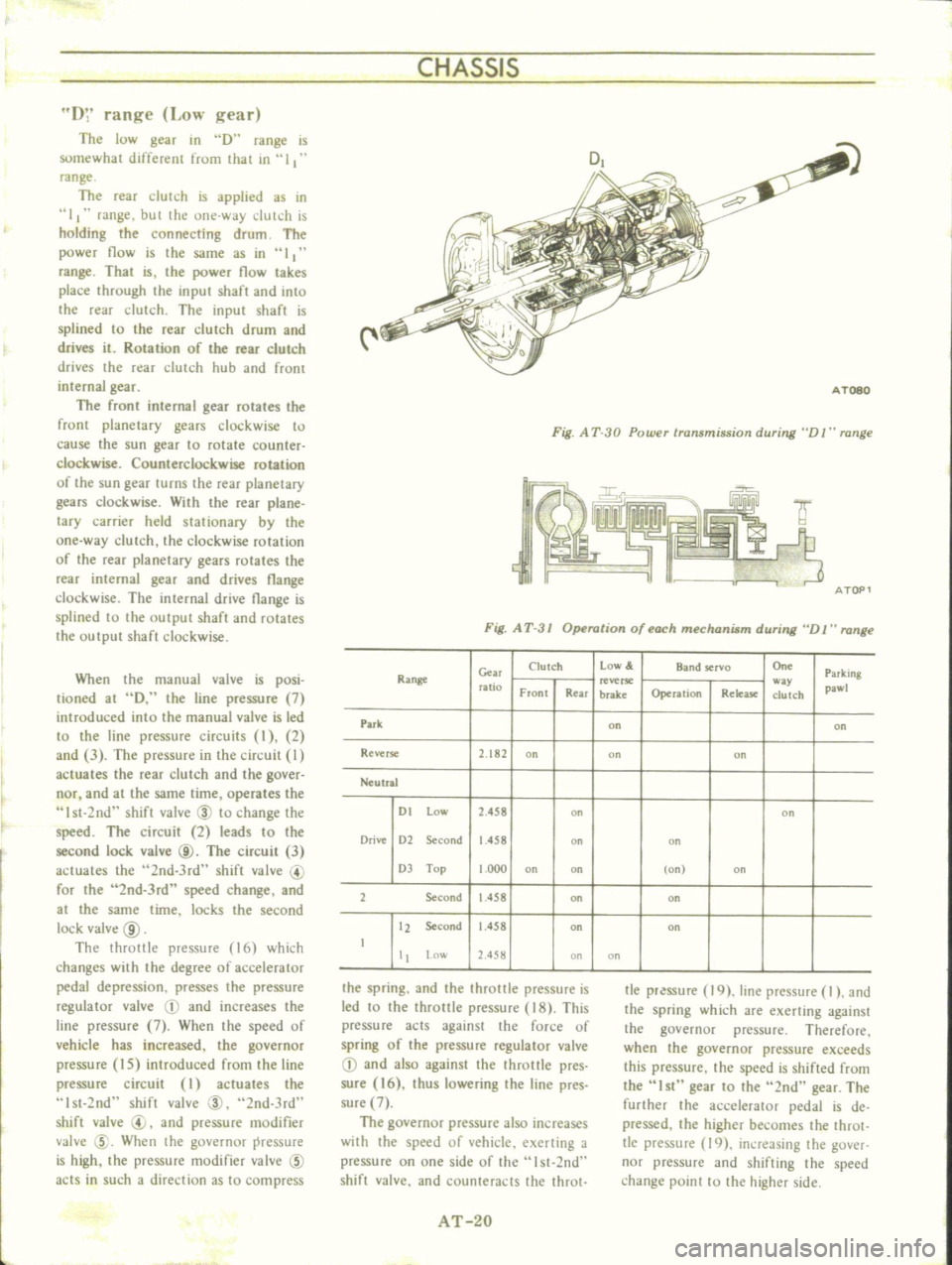

AT080

Fig

A

T

30

Power

transmission

during

V

range

ATOP1

dmifi

Fig

AT

3

Operation

of

each

mechanism

during

VI

range

G

Clutch

Low

Band

rVo

One

Parking

Ro

reverse

woy

pawl

ratio

Front

Rear

brake

Operation

Release

clutch

Park

on

on

Reverse

2

182

on

on

on

Neutral

01

low

14

8

on

on

Drive

01

Second

1

458

on

on

03

Top

1

000

on

on

on

on

1

Second

1

458

on

on

tl

Second

1

458

on

on

1

II

low

2

458

on

on

rhe

spring

and

the

throttle

pressure

is

led

10

the

throllIe

pressure

18

This

pressure

acts

againsr

the

force

of

spring

of

the

pressure

regulator

valve

CD

and

also

against

the

Ihrollle

pres

sure

16

thus

lowering

the

line

pres

sure

7

The

governor

pressure

also

increases

with

the

speed

of

vehicle

exerting

a

pressure

on

one

side

of

the

1st

2nd

shift

valve

and

counteracts

the

throt

lie

p

ssure

19

line

pressure

I

and

the

spring

which

are

exerting

against

the

governor

pressure

Therefore

when

the

governor

pressure

exceeds

this

pressure

the

speed

is

shifted

from

Ihe

I

Sl

gear

10

the

2nd

gear

The

further

the

acceleraror

pedal

is

de

pressed

the

higher

becomes

the

throt

tle

pressure

19

increasing

the

gover

nor

pressure

and

shifting

the

speed

change

point

to

the

higher

side

AT

20

Page 26 of 513

CHASSIS

D

range

2nd

gl

ar

In

this

case

the

rear

dutch

is

applied

and

the

band

brake

holds

the

front

dUh

h

drum

i

onnel

ting

shell

and

sun

gear

from

rotating

The

power

now

takes

place

through

the

input

shaft

into

the

rear

dutch

and

the

front

internal

gear

WHh

the

sun

gear

held

stationary

the

fronr

plane

lacy

gears

rotate

around

the

sun

gear

carrying

the

front

planet

carrier

with

them

The

front

planet

carrier

being

splined

to

the

output

shaft

causes

clockwise

rotation

of

the

output

shafr

at

a

reduced

speed

compared

with

the

speed

of

the

input

shaft

with

an

increase

in

torque

As

the

low

and

reverse

brake

is

not

applied

the

clock

wise

rotation

of

the

output

shaft

causes

clockwise

rotation

of

rear

inter

nal

gear

and

the

rear

planet

carrier

also

rotates

around

the

sun

gear

in

a

clockwise

direction

The

one

way

clutch

will

act

to

allow

the

clockwise

rotation

of

connecting

drum

When

the

car

speed

increases

while

running

at

D

range

1st

gear

the

st

2nd

shift

valve

4

moves

al

lowing

the

line

pressure

I

to

be

introduced

into

the

line

pressure

8

through

itself

The

line

pressure

8

is

further

led

to

the

line

pressure

9

through

the

second

lock

vaIve@

and

by

locking

the

band

servo

obtains

the

2nd

gear

condition

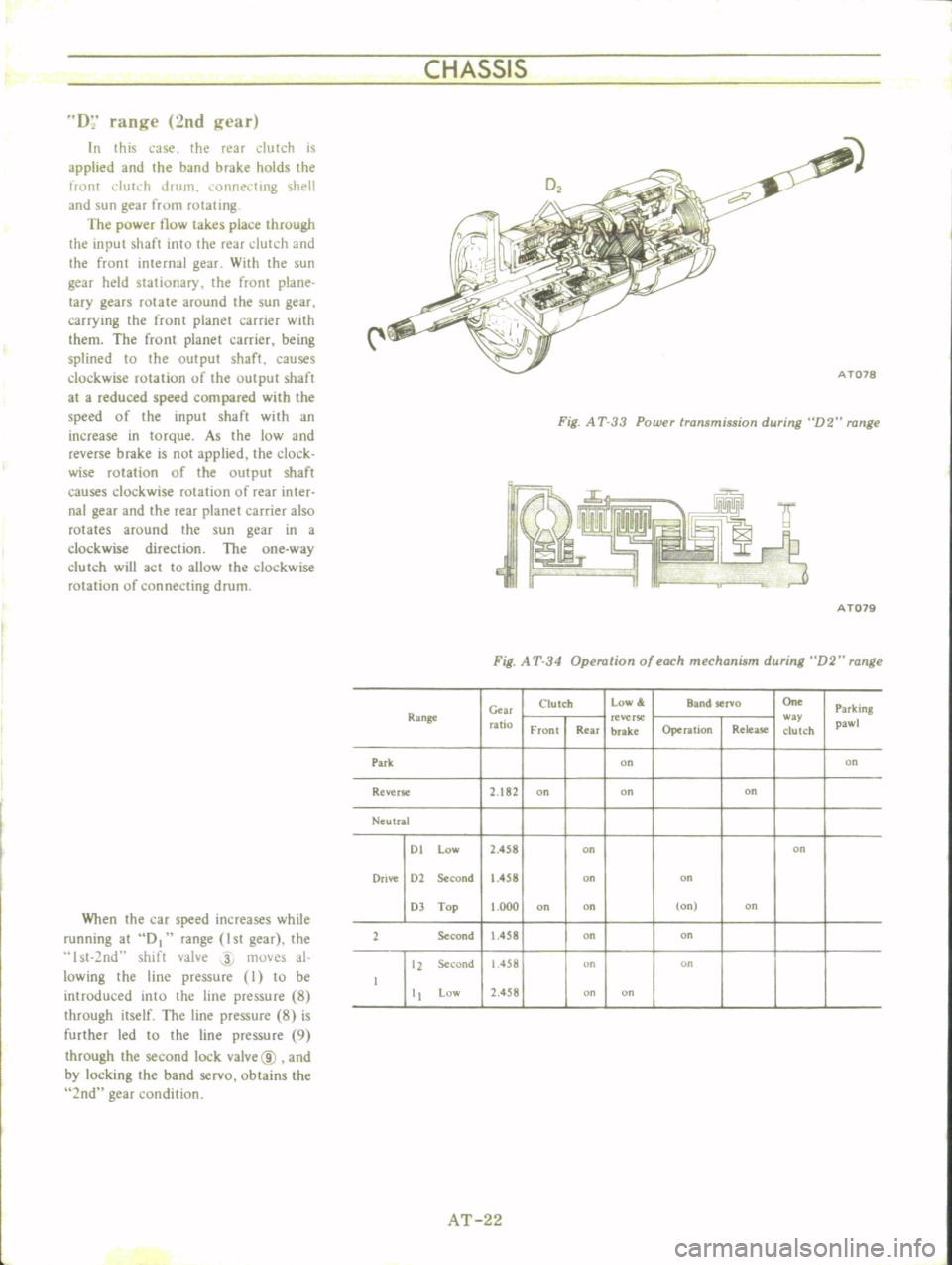

Fig

A

T

33

Power

transmission

during

D2

range

I

r

J

ITMi

A

T079

Fig

A

T

34

Operation

of

each

mechanism

during

D2

range

C

w

Clutch

low

Band

selva

On

Parking

Range

ratio

reverse

w

y

pawl

Front

Rear

brake

Operation

Rdea5e

clutch

Park

on

on

Reverse

2

182

on

on

on

Ne

ulral

01

low

2

458

on

on

Drive

01

Second

1

458

on

on

OJ

Top

000

on

on

on

on

1

Se

cond

458

on

on

11

Second

1

458

on

on

low

1

458

on

on

AT

22

Page 32 of 513

CHASSIS

2

range

2nd

gear

In

2

range

the

gear

ratio

is

locked

to

the

2nd

forward

speed

In

this

case

the

rear

clutch

is

applied

and

the

band

brake

holds

the

front

clutch

drum

connecting

shell

and

sun

gear

from

rotating

The

power

flow

takes

place

through

the

input

shaft

into

the

rear

clutch

and

the

front

internal

gear

With

the

sun

gear

held

stationary

the

front

plane

lacy

gears

rotate

around

the

sun

gear

carrying

the

front

planet

carrier

with

them

The

front

planet

carrier

being

splined

to

the

output

shaft

causes

clockwise

rotation

of

the

output

shaft

at

a

reduced

speed

compared

with

the

speed

of

the

input

shaft

with

an

increase

in

torque

As

the

low

and

reverse

brake

is

not

applied

the

clock

wise

mlation

of

the

output

shaft

causes

clockwise

rotation

of

rear

inter

nal

gear

and

the

rear

planet

carrier

also

rotates

around

the

sun

gear

in

a

clockwise

direction

The

one

way

c1urch

will

act

to

allow

the

clockwise

rotation

of

connecting

drum

When

the

manual

valve

CV

is

posi

tioned

at

2

the

line

pressure

7

is

introduced

into

the

line

pressure

cir

cuits

I

2

and

4

The

line

pressure

I

is

led

to

the

governur

rear

dutch

and

Ist

2nd

shift

valve

ID

as

in

the

case

of

D

range

The

line

pressure

2

locks

the

second

lock

valve

@

and

is

led

to

the

tightening

side

of

the

band

servo

The

2nd

gear

is

therefore

fixed

regardless

of

the

car

speed

When

DJ

range

3rd

gear

is

shifted

to

2

range

the

line

pressure

4

enters

the

throttle

back

up

valve

IJ

and

produces

a

high

pressure

in

the

circuit

17

increasing

the

throttle

pressure

16

The

line

pressure

7

is

therefore

increases

and

quickly

tightens

the

band

Note

DJ

range

3rd

gear

to

2

range

If

DJ

range

3rd

gear

is

shifted

to

2

range

during

operation

the

manual

valve

CV

is

also

shifted

to

2

position

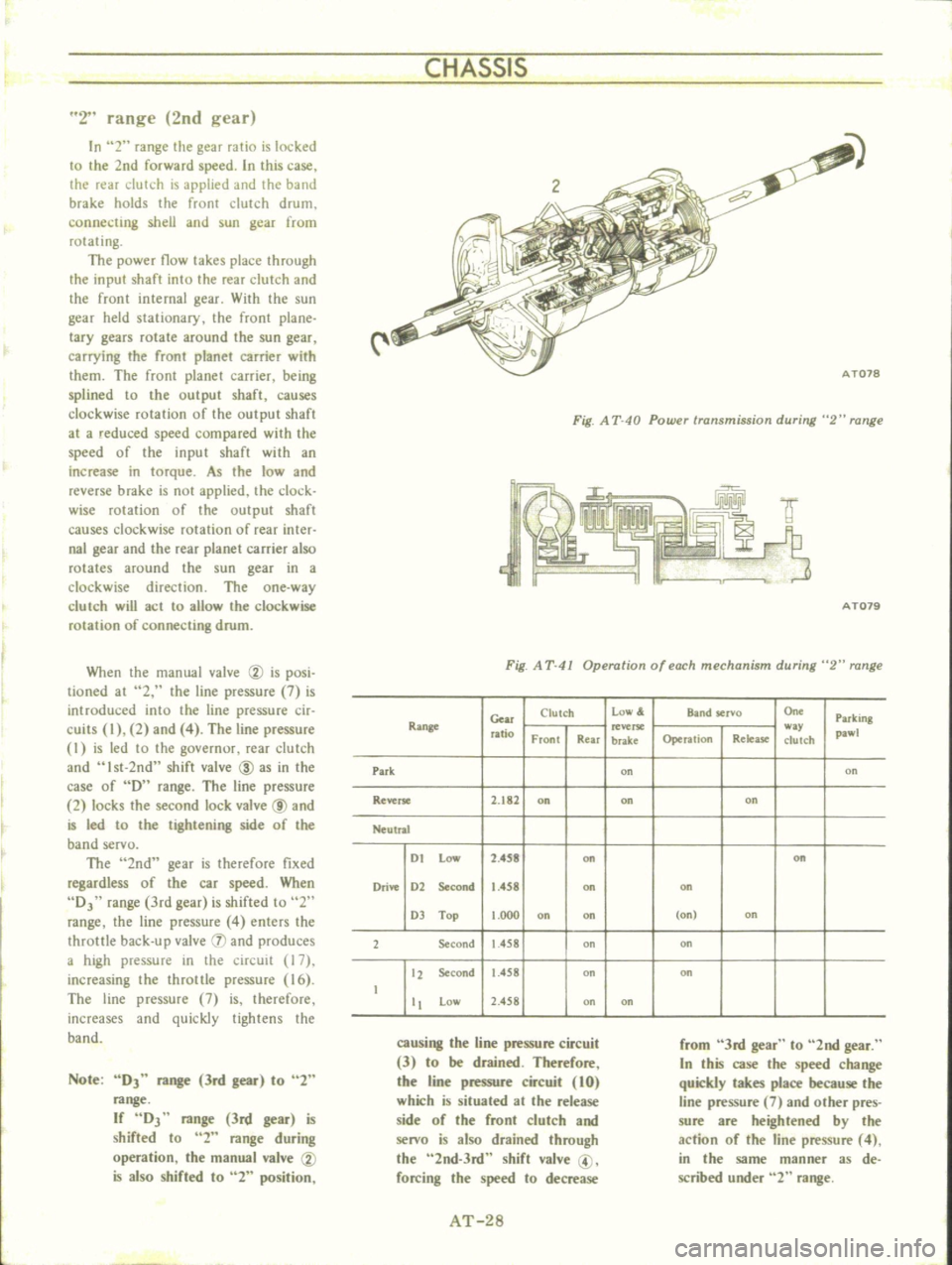

Fig

A

T

40

Powu

transmission

during

2

range

f

IY

9

3

AT079

Fig

A

T

41

Operation

of

each

mechanism

during

2

range

Gear

Clutch

low

Band

servo

On

Parking

Range

ratio

w

pawl

Front

Rear

brake

Operation

Relea

se

clutch

Park

on

on

Reverse

2

182

on

on

on

Neutral

I

t

Low

2

4S8

on

on

Drive

1

2

Second

1

458

on

on

1

Top

t

OOO

on

on

on

on

2

Second

1

458

on

on

12

Second

1

458

on

on

t

tt

Low

2

458

on

on

causing

the

line

pressure

circuit

3

to

be

drained

Therefore

the

line

pressure

circuit

10

which

is

situated

at

the

release

side

of

the

front

clutch

and

senro

is

also

drained

through

the

2nd

3rd

shift

valve

@

forcing

the

speed

to

decrease

from

3rd

gear

to

2nd

gear

In

this

case

the

speed

change

quickly

takes

place

because

the

line

pressure

7

and

other

pres

sure

are

heightened

by

the

action

of

the

line

pressure

4

in

the

same

manner

as

de

scribed

under

2

range

AT

28

Page 34 of 513

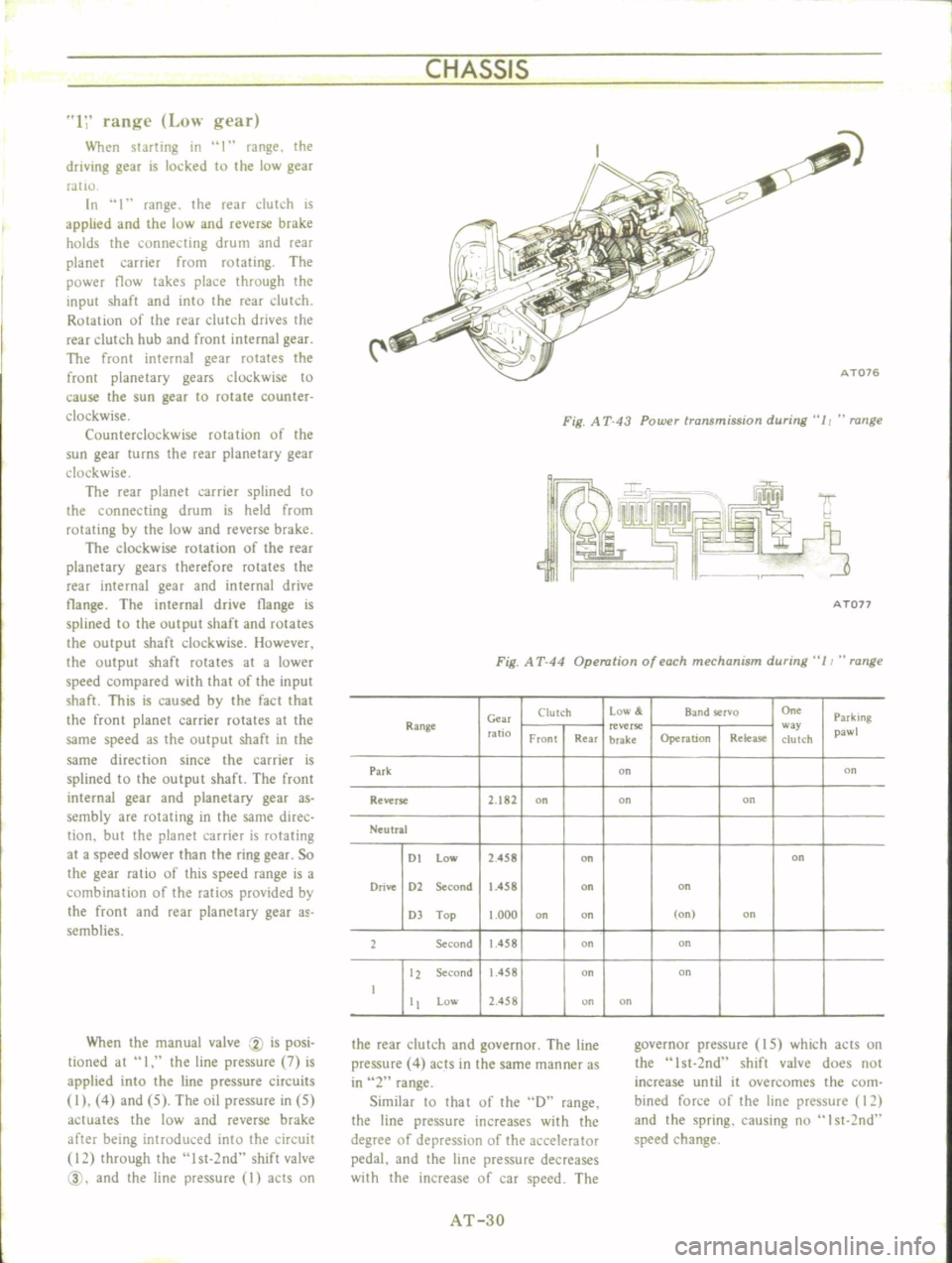

CHASSIS

1

range

Low

gear

When

starting

in

I

range

the

driving

gear

is

locked

to

the

low

gear

ratIO

In

1

range

the

reaT

dutch

is

applied

and

the

low

and

reverse

brake

holds

the

connecting

drum

and

rear

planet

carrier

from

rotating

The

power

flow

takes

place

through

the

input

shaft

and

into

the

rear

dutch

Rotation

of

the

rear

clutch

drives

the

rear

clutch

hub

and

front

internal

gear

The

front

internal

gear

rotates

the

front

planetary

gears

clockwise

to

cause

the

sun

gear

to

rotate

counter

clockwise

Counterclockwise

rotation

of

the

sun

gear

turns

the

rear

planetary

gear

clockwise

The

rear

planet

carrier

splined

to

the

connecting

drum

is

held

from

rotating

by

the

low

and

reverse

brake

The

clockwise

rotation

of

the

rear

planetary

gears

therefore

rotates

the

rear

internal

gear

and

internal

drive

tlange

The

internal

drive

tlange

is

splined

to

the

output

shaft

and

rotates

the

output

shaft

clockwise

However

the

output

shaft

rotates

at

a

lower

speed

compared

with

that

of

the

input

shaft

This

is

caused

by

the

fact

that

the

front

planet

carrier

rotates

at

the

same

speed

as

the

output

shaft

in

the

same

direction

since

the

carrier

is

splined

to

the

output

shaft

The

front

internal

gear

and

planetary

gear

as

sembly

are

rotating

in

the

same

direc

tion

but

the

planet

carrier

is

rotating

at

a

speed

slower

than

the

ring

gear

So

the

gear

ratio

of

this

speed

range

is

a

combination

of

the

ratios

provided

by

the

front

and

rear

planetary

gear

a

semblies

When

the

manual

valve

CV

is

posi

tioned

at

I

the

line

pressure

7

is

applied

into

the

line

pressure

circuits

I

4

and

5

The

oil

pressure

in

5

actuates

the

low

and

reverse

brake

after

being

introduced

into

the

circuit

12

through

the

lst

2nd

shift

valve

@

and

the

line

pressure

I

acts

on

i

C

AT076

Fig

A

T

43

Power

transmission

during

11

range

A

Ton

Fig

A

T

44

Operation

of

each

mechanism

during

11

range

Clutch

Low

Band

rvo

On

Parking

Range

Gm

ratio

reverse

w

pawl

Front

Rear

brake

Operation

Release

clutch

Park

on

on

Reverse

2

182

on

on

on

Neutral

DI

low

2

458

on

on

Drive

D2

Second

1

458

on

on

D

Top

1

000

on

on

on

on

2

Second

1

458

on

on

12

Second

1

458

on

on

I

Low

2

458

on

on

the

rear

clutch

and

governor

The

line

pressure

4

acts

in

the

same

manner

as

in

2

range

Similar

10

that

of

the

D

range

the

line

pressure

increases

with

the

degree

of

depressiun

of

the

accelerator

pedal

and

the

line

pressure

decreases

with

the

increase

of

car

speed

The

governor

pressure

IS

which

acts

on

the

Ist

2nd

shift

valve

does

not

increase

until

it

overcomes

the

com

bined

force

of

the

line

pressure

12

and

the

spring

causing

nu

I

st

2nd

speed

change

AT

3D

Page 44 of 513

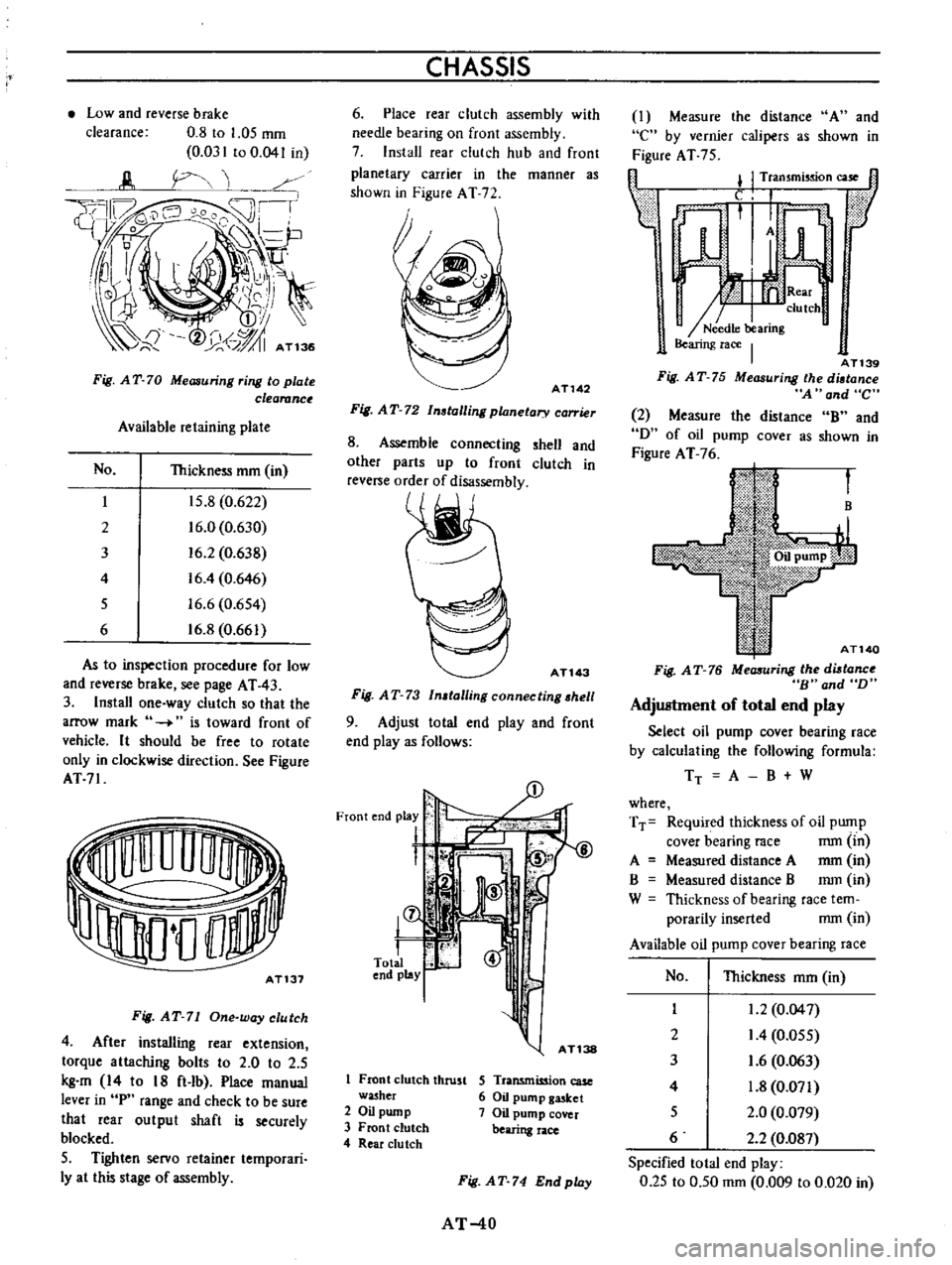

Low

and

reverse

brake

clearance

0

8

to

1

05

mm

0

031

to

0

041

in

Fig

AT

70

Measuring

ring

to

plate

clearanc

Available

retaining

plate

No

Thickness

mm

in

I

15

8

0

622

2

16

0

0

630

3

16

2

0

638

4

16

4

0

646

5

16

6

0

654

6

16

8

0

661

As

to

inspection

procedure

for

low

and

reverse

brake

see

page

AT

43

3

Install

one

way

clutch

so

that

the

arrow

mark

is

toward

front

of

vehicle

It

should

be

free

to

rotate

only

in

clockwise

direction

See

Figure

AT71

AT131

Fig

AT

71

One

way

clutch

4

After

installing

rear

extension

torque

attaching

bolts

to

2

0

to

2

5

kg

m

14

to

18

ft

lb

Place

manual

lever

in

P

range

and

check

to

be

sure

that

rear

output

shaft

is

securely

blocked

5

Tighten

servo

retainer

temporari

Iy

at

this

stage

of

assembly

CHASSIS

6

Place

rear

clutch

assembly

with

needle

bearing

on

front

assembly

7

Install

rear

clutch

hub

and

front

planetary

carrier

in

the

manner

as

shown

in

Figure

AT

72

AT142

Fig

AT

72

Installing

planetary

carrier

8

Assemble

connecting

shell

and

other

parts

up

to

front

clutch

in

reve

e

order

of

disassembly

ATl43

Fig

AT

73

In

talling

connecting

hell

9

Adjust

total

end

play

and

front

end

playas

follows

L

@

8

S

I

fT

15

l

r

1

Front

clutch

thrust

washer

2

Oil

pump

3

Front

clutch

4

Rear

du

tch

S

Transmission

case

6

Oil

pump

gasket

7

Oil

pump

cover

bearing

race

Fig

AT

74

Endplay

AT

40

I

Measure

the

distance

A

and

e

by

vernier

calipers

as

shown

in

Figure

AT

75

fl

l

I

Transmission

case

1l

Lf

ar

n

h

AT139

Fig

AT

75

Measuring

the

diltance

A

and

C

2

Measure

the

distance

B

and

D

of

oil

pump

COVer

as

shown

in

Figure

AT

76

B

AT140

Fig

AT

76

MeaJIuring

the

diltanc

B

and

D

Adjustment

of

total

end

play

Select

oil

pump

cover

bearing

race

by

calculating

the

following

formula

TT

A

B

W

where

TT

Required

thickness

of

oil

pump

cover

bearing

race

mm

in

A

Measured

distance

A

mm

in

B

Measured

distance

B

mm

in

W

Thickness

of

bearing

race

tem

porarily

inserted

mm

in

Available

oil

pump

cover

bearing

race

No

Thickness

mm

in

I

1

2

0

04

7

2

I

4

0

055

3

1

6

0

063

4

1

8

0

071

5

2

0

0

079

6

2

2

0

087

Specified

total

end

play

0

25

to

0

50

mm

0

009

to

0

020

in

Page 96 of 513

CHASSIS

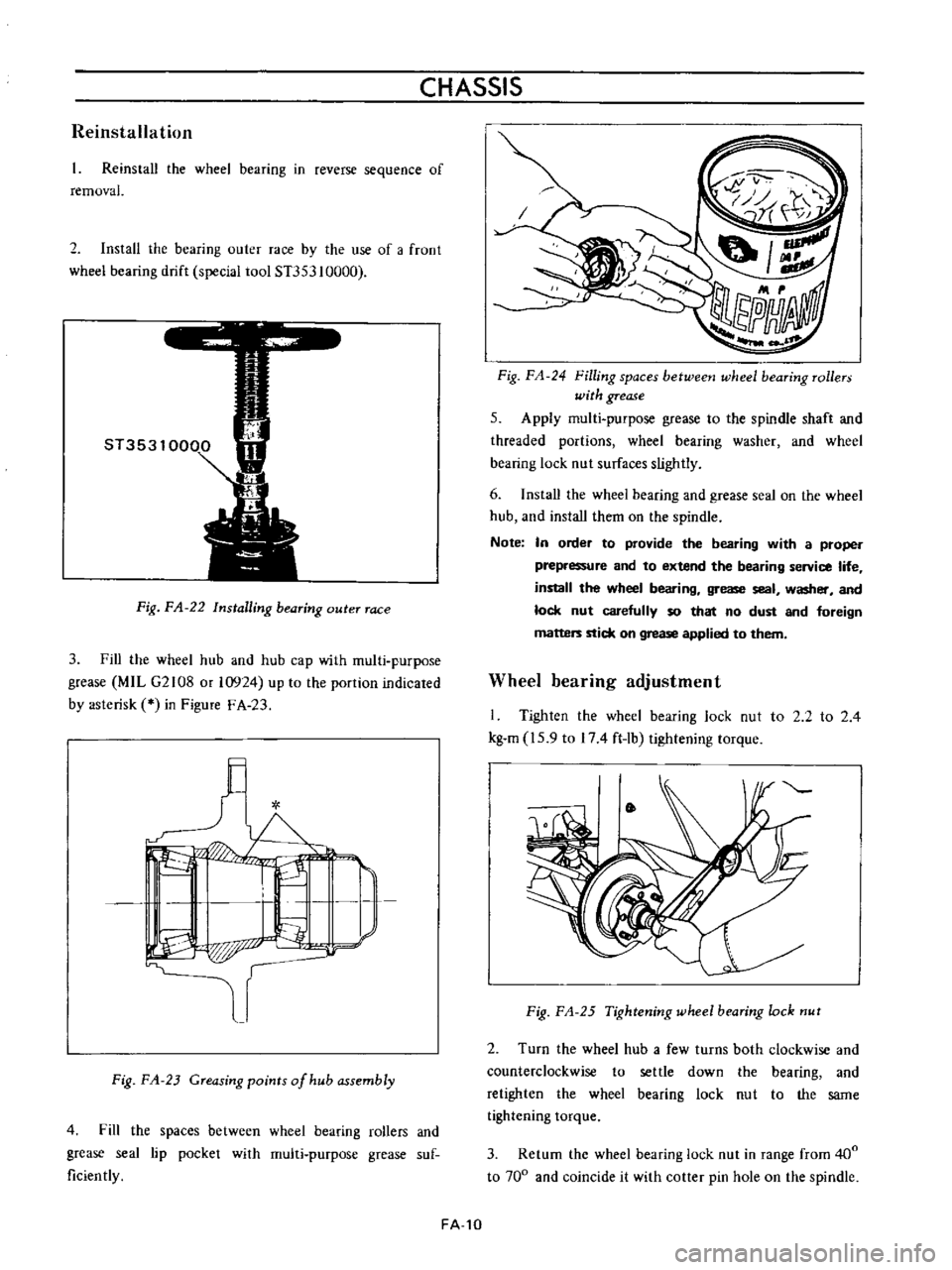

Reinstallation

Reinstall

the

wheel

bearing

in

reverse

sequence

of

removal

2

Install

the

bearing

outer

race

by

the

use

of

a

froot

wheel

bearing

drift

special

tool

ST353

10000

Fig

FA

22

Installing

bearing

outer

race

3

Fill

the

wheel

hub

and

hub

cap

with

multi

purpose

grease

MIL

G2108

or

10924

up

to

the

portion

indicated

by

asterisk

in

Figure

F

A

23

l

I

L

I

I

P

p

r

Fig

FA

23

Greasing

points

of

hub

assembly

4

Fill

the

spaces

between

wheel

bearing

rollers

and

grease

seal

lip

pocket

with

multi

purpose

grease

suf

ficiently

FA

10

Fig

FA

24

Filling

spaces

betweetJ

wheel

bearing

rollers

with

grease

5

Apply

multi

purpose

grease

to

the

spindle

shaft

and

threaded

portions

wheel

bearing

washer

and

wheel

bearing

lock

nut

surfaces

slightly

6

Install

the

wheei

bearing

and

grease

seal

on

the

wheel

hub

and

install

them

on

the

spindle

Note

In

order

to

provide

the

bearing

with

a

proper

prepressure

and

to

extend

the

bearing

service

life

install

the

wheel

bearing

grease

seal

washer

and

lock

nut

carefully

so

that

no

dust

and

foreign

matters

stick

on

grease

applied

to

them

Wheel

bearing

adjustment

I

Tighten

the

wheel

bearing

lock

nut

to

2

2

to

2

4

kg

m

15

9

to

174

ft

lb

tightening

torque

Fig

FA

25

Tightening

wheel

bearing

lock

nut

2

Turn

the

wheel

hub

a

few

turns

both

clockwise

and

counterclockwise

to

settle

down

the

bearing

and

retighten

the

wheel

bearing

lock

nut

to

the

same

tightening

torque

3

Return

the

wheel

bearing

lock

nut

in

range

from

400

to

700

and

coincide

it

with

cotter

pin

hole

on

the

spindle

Page 97 of 513

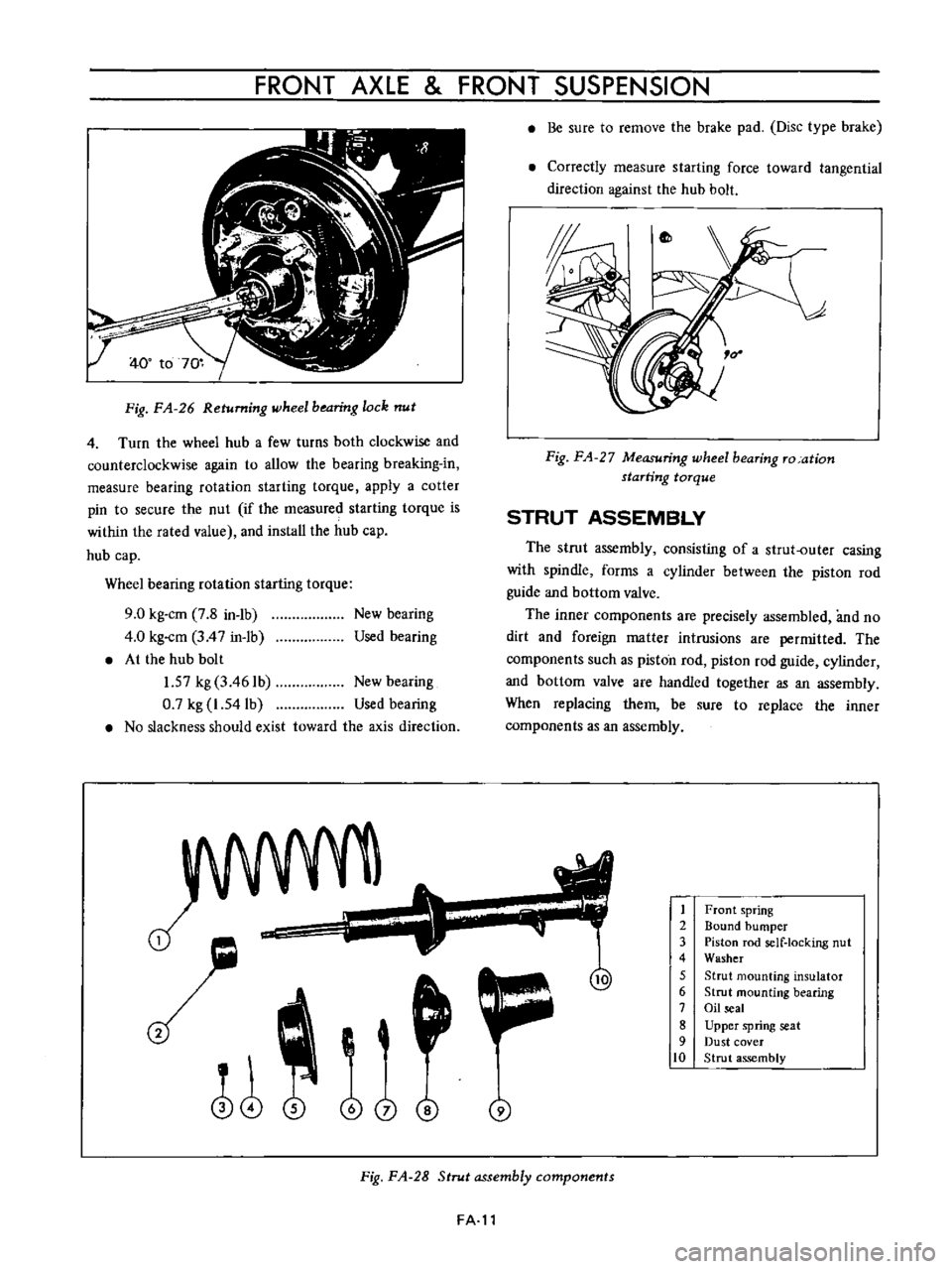

FRONT

AXLE

FRONT

SUSPENSION

t

t

Fig

FA

26

Returning

wheel

bearing

lock

nut

4

Turn

the

wheel

hub

a

few

turns

both

clockwise

and

counterclockwise

again

to

allow

the

bearing

breaking

in

measure

bearing

rotation

starting

torque

apply

a

cotter

pin

to

secure

the

nut

if

the

measured

starting

torque

is

within

the

rated

value

and

install

the

hub

cap

hub

cap

Wheel

bearing

rotation

starting

torque

9

0

kg

cm

7

8

in

1b

4

0

kg

cm

3

4

7

in

1b

At

the

hub

bolt

1

57

kg

3

461b

New

bearing

0

7

kg

1

54lb

Used

bearing

No

slackness

should

exist

toward

the

axis

direction

New

bearing

Used

bearing

J

o

i

@

j

Be

sure

to

remove

the

brake

pad

Disc

type

brake

Correctly

measure

starting

force

toward

tangential

direction

against

the

hub

bolt

Fig

FA

27

Measuring

wheel

bearing

ro

ation

starting

torque

STRUT

ASSEMBLY

The

strut

assembly

consisting

of

a

strut

outer

casing

with

spindle

forms

a

cylinder

between

the

piston

rod

guide

and

bottom

valve

The

inner

components

are

precisely

assembled

and

no

dirt

and

foreign

matter

intrusions

are

permitted

The

components

such

as

piston

rod

piston

rod

guide

cylinder

and

bottom

valve

are

handled

together

as

an

assembly

When

replacing

them

be

sure

to

replace

the

inner

components

as

an

assembly

1

2

3

4

5

6

7

8

9

10

Front

spring

Bound

bumper

Piston

rod

self

locking

nut

Washer

Strut

mounting

insulator

Strut

mounting

bearing

Oil

seal

Upper

spring

seat

Dust

cover

Strut

assembly

Fig

FA

28

Strut

assembly

components

FA

l1

Page 144 of 513

CHASSIS

4

With

the

hand

brake

lever

pulled

depress

the

push

button

and

make

sure

that

the

pawl

disengages

the

teeth

when

the

push

button

is

depressed

5

to

6

mm

0

1969

to

0

2362

in

completely

5

Make

sure

that

the

cable

dust

cover

is

not

damaged

or

warped

Reinstallation

Reinstall

the

hand

brake

in

reverse

sequence

of

removal

noting

the

following

matters

Be

careful

not

to

damage

or

twist

the

dust

cover

2

Tighten

the

hanger

strap

and

the

cable

connecting

nut

to

0

8

to

1

0

kg

m

5

8

to

7

2

ft

1b

3

When

adjusting

rear

brake

shoe

clearance

be

sure

to

loosen

the

inner

cable

sufficiently

4

Grease

the

sliding

parts

with

multi

purpose

grease

MIL

G

2108

or

G

10924

AD

JUSTMENT

Brake

shoe

clearance

Front

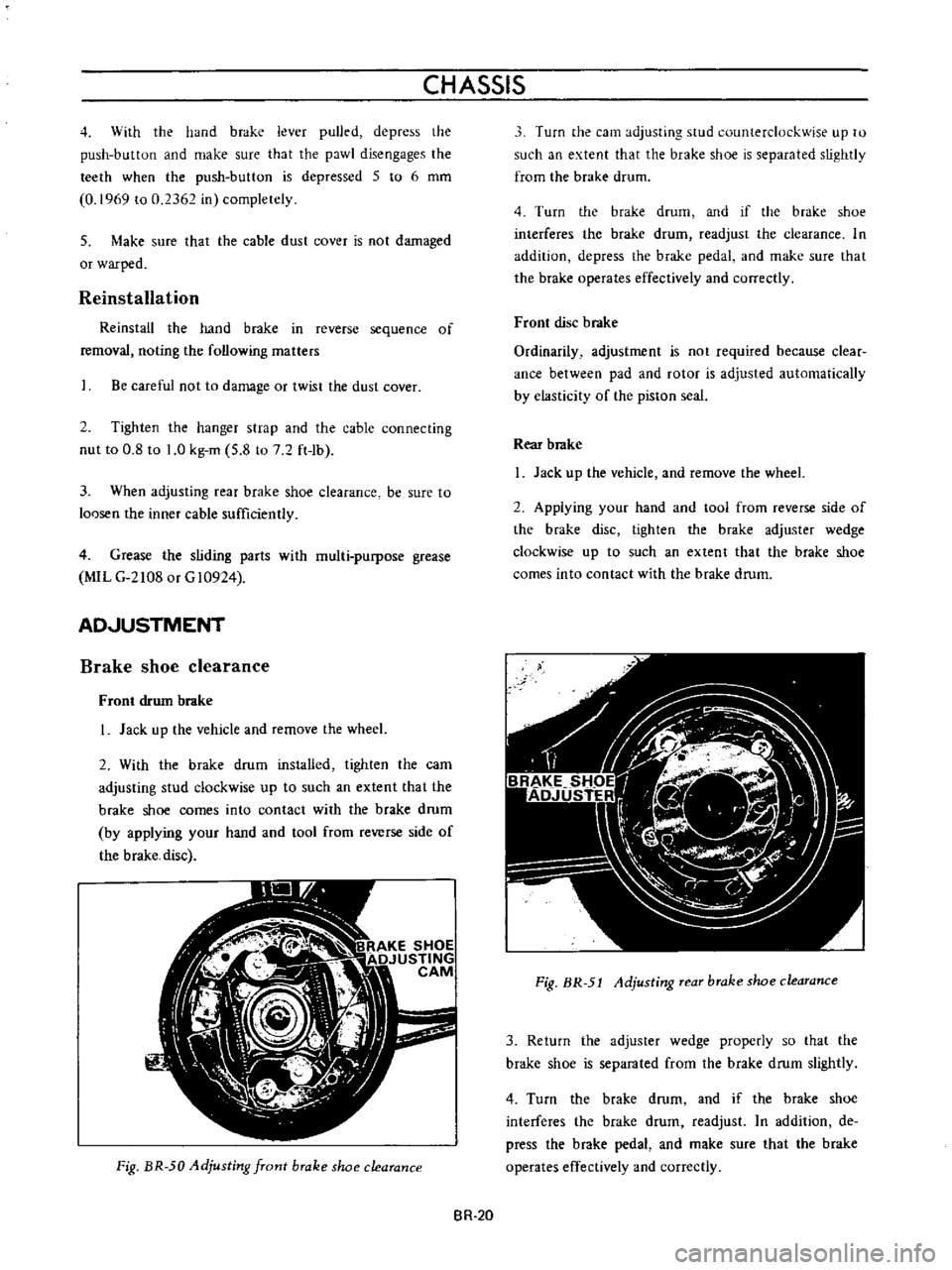

drum

brake

Jack

up

the

vehicle

and

remove

the

wheeL

2

With

the

brake

drum

installed

tighten

the

cam

adjusting

stud

clockwise

up

to

such

an

extent

that

the

brake

shoe

comes

into

contact

with

the

brake

drum

by

applying

your

hand

and

tool

from

reverse

side

of

the

brake

disc

Fig

BR

50

Adjusting

front

brake

shoe

clearance

Turn

the

cam

adjusting

5

ud

counterclockwise

up

to

such

an

extent

that

the

brake

shoe

is

separated

slightly

from

the

brake

drum

4

Turn

the

brake

drum

and

if

the

brake

shoe

interferes

the

brake

drum

readjust

the

clearance

In

addition

depress

the

brake

pedal

and

make

sure

that

the

brake

operates

effectively

and

correctly

Front

disc

brake

Ordinarily

adjustment

is

not

required

because

clear

ance

between

pad

and

rotor

is

adjusted

automatically

by

elasticity

of

the

piston

seal

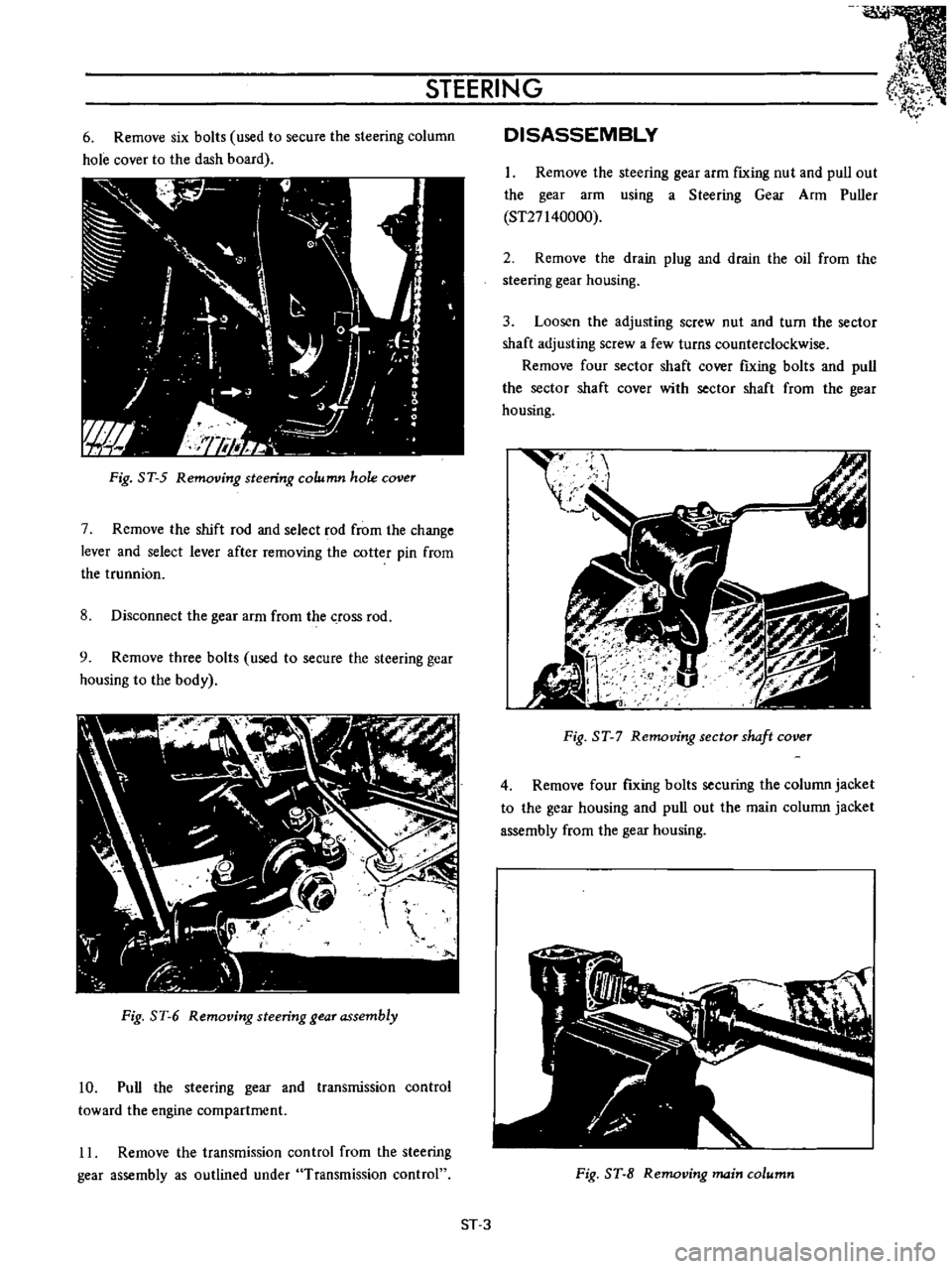

Rear

brake

Jack

up

the

vehicle

and

remove

the

wheeL

2

Appiying

your

hand

and

tool

from

reverse

side

of

the

brake

disc

tighten

the

brake

adjuster

wedge

clockwise

up

to

such

an

extent

that

the

brake

shoe

comes

into

contact

with

the

brake

drum

Fig

BR

51

Adjusting

rear

brake

shoe

clearance

3

Return

the

adjuster

wedge

properly

so

that

the

brake

shoe

is

separated

from

the

brake

drum

slightly

4

Turn

the

brake

drum

and

if

the

brake

shoe

interferes

the

brake

drum

readjust

In

addition

de

press

the

brake

pedal

and

make

sure

that

the

brake

operates

effectively

and

correctly

BR

20

Page 163 of 513

STEERING

6

Remove

six

bolts

used

to

secure

the

steering

column

hole

cover

to

the

dash

board

Fig

ST

5

Removing

steering

column

hole

cover

7

Remove

the

shift

rod

and

select

rod

from

the

change

lever

and

select

lever

after

removing

the

cotter

pin

from

the

trunnion

8

Disconnect

the

gear

arm

from

the

crOSS

rod

9

Remove

three

bolts

used

to

secure

the

steering

gear

housing

to

the

body

Fig

ST

6

Removing

steering

gear

assembly

10

Pull

the

steering

gear

and

transmission

control

toward

the

engine

compartment

11

Remove

the

transmission

control

from

the

steering

gear

assembly

as

outlined

under

Transmission

control

DISASSEMBLY

1

Remove

the

steering

gear

arm

fIxing

nut

and

pull

out

the

gear

arm

using

a

Steering

Gear

Arm

Puller

ST27140000

2

Remove

the

drain

plug

and

drain

the

oil

from

the

steering

gear

housing

3

Loosen

the

adjusting

screw

nut

and

turn

the

sector

shaft

adjusting

screw

a

few

turns

counterclockwise

Remove

four

sector

shaft

cover

fIxing

bolts

and

pull

the

sector

shaft

cover

with

sector

shaft

from

the

gear

housing

t

I

gJ

I

I

Fig

ST

7

Removing

sector

shaft

cover

4

Remove

four

fIxing

bolts

securing

the

column

jacket

to

the

gear

housing

and

pull

out

the

main

column

jacket

assembly

from

the

gear

housing

Fig

ST

8

Removing

main

column

ST

3