cooling DATSUN B110 1973 Service User Guide

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1973, Model line: B110, Model: DATSUN B110 1973Pages: 513, PDF Size: 28.74 MB

Page 330 of 513

EMISSION

CONTROL

AND

TUNE

UP

SERVICE

DATA

AND

SPECIFICATIONS

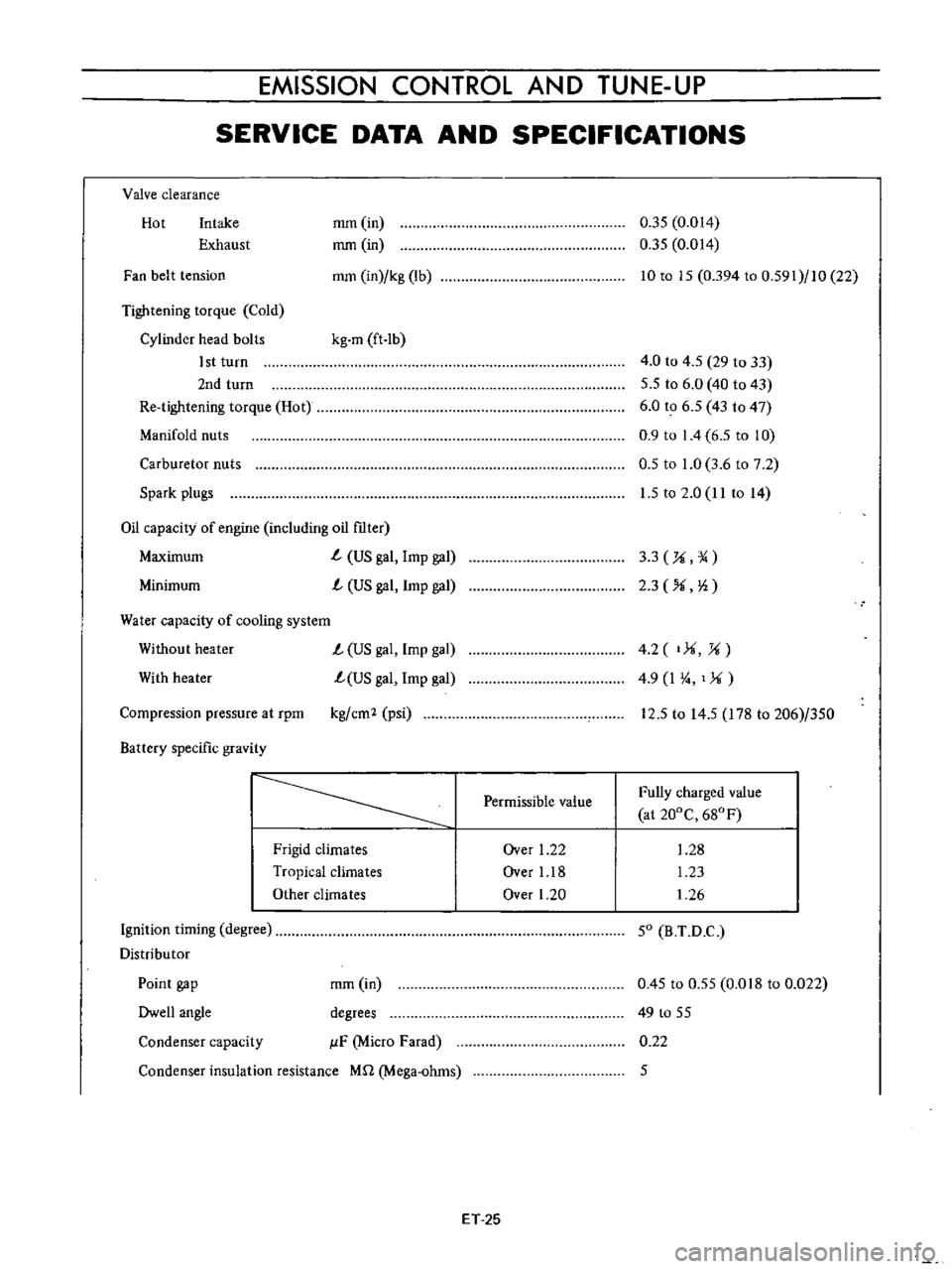

Valve

clearance

Hot

Intake

Exhaust

mm

in

rom

in

rom

in

kg

lb

0

35

0

014

0

35

0

014

10

to

15

0

394

to

0

591

10

22

Fan

belt

tension

Tightening

torque

Cold

Cylinder

head

bolts

kg

m

ft

lb

1st

turn

2nd

turn

Re

tightening

torque

Hot

Manifold

nuts

Carburetor

nuts

4

0

to

4

5

29

to

33

5

5

to

6

0

40

to

43

6

0

to

6

5

43

to

47

0

9

to

I

4

6

5

to

10

0

5

to

1

0

3

6

to

7

2

1

5

to

2

0

II

to

14

Spark

plugs

Oil

capacity

of

engine

including

oil

ftIter

Maximum

L

US

gal

Imp

gal

L

US

gal

Imp

gal

3

3

U

14

2

3

Ii

Minimum

Water

capacity

of

cooling

system

Without

heater

L

US

gal

Imp

gal

With

heater

L

US

gal

Imp

gal

4

2

1

U

4

9

I

4

11

12

5

to

14

5

I78

to

206

350

Compression

pressure

at

rpm

kg

em

psi

Battery

specific

gravity

Permissible

value

Fully

charged

value

at

200C

680F

Frigid

climates

Tropical

climates

Other

elima

tes

Over

1

22

Over

1

18

Over

1

20

1

28

1

23

1

26

Ignition

timing

degree

Distributor

50

B

T

D

C

Condenser

capacity

mm

in

degrees

IlF

Micro

Farad

0

45

to

0

55

0

018

to

0

022

49

to

55

0

22

5

Point

gap

Dwell

angle

Condenser

insulation

resistance

Mil

Mega

ohms

ET

25

Page 335 of 513

Air

intake

system

in

trouble

Overheating

Overcooling

Others

NOISY

ENGINE

Car

knocking

Car

knock

when

coasting

ENGINE

Diny

ur

clogged

fuel

strainer

Fuel

pump

will

not

work

properly

Clogged

carburetor

jets

Clogged

air

cleaner

Air

inhaling

from

manifold

gasket

or

carbu

retor

gasket

Insufficient

coolant

Loosened

fan

belt

Worn

or

defective

fan

belt

Defective

thermostat

Defective

water

pump

Clogged

or

leaky

radiator

Defective

radiator

filler

cap

Air

mixing

into

cooling

system

Improper

grade

engine

oil

Incorrect

ignition

timing

Defective

carburetor

lean

mixture

Defective

thermostat

Low

octane

fuel

Improper

tire

pressure

Dragging

brake

Slipping

clutch

Overloading

to

engine

Carbon

knocking

Timing

knocking

Fuel

knocking

Preignition

misusing

of

spark

plug

Incorrect

throttle

opener

adjustment

Trouble

in

PCV

valve

ET

30

Replace

Repair

or

replace

Disassemble

and

clean

Replace

element

Replace

gasket

Replenish

Adjust

Replace

Replace

Replace

Flush

repair

or

replace

Replace

Retighten

each

part

of

cooling

system

Replace

with

proper

grade

oil

Adjust

Overhaul

carburetor

Replace

Replace

with

specified

octane

fuel

Adjust

to

the

specified

pressure

Adjust

Adjust

Use

right

gear

in

driving

Disassemble

cylinder

head

and

remove

carbon

Adjust

ignition

timing

Use

specified

octane

fuel

Use

specified

spark

plug

Adjust

throttle

opener

Replace

PCV

valve

Page 342 of 513

ENGINE

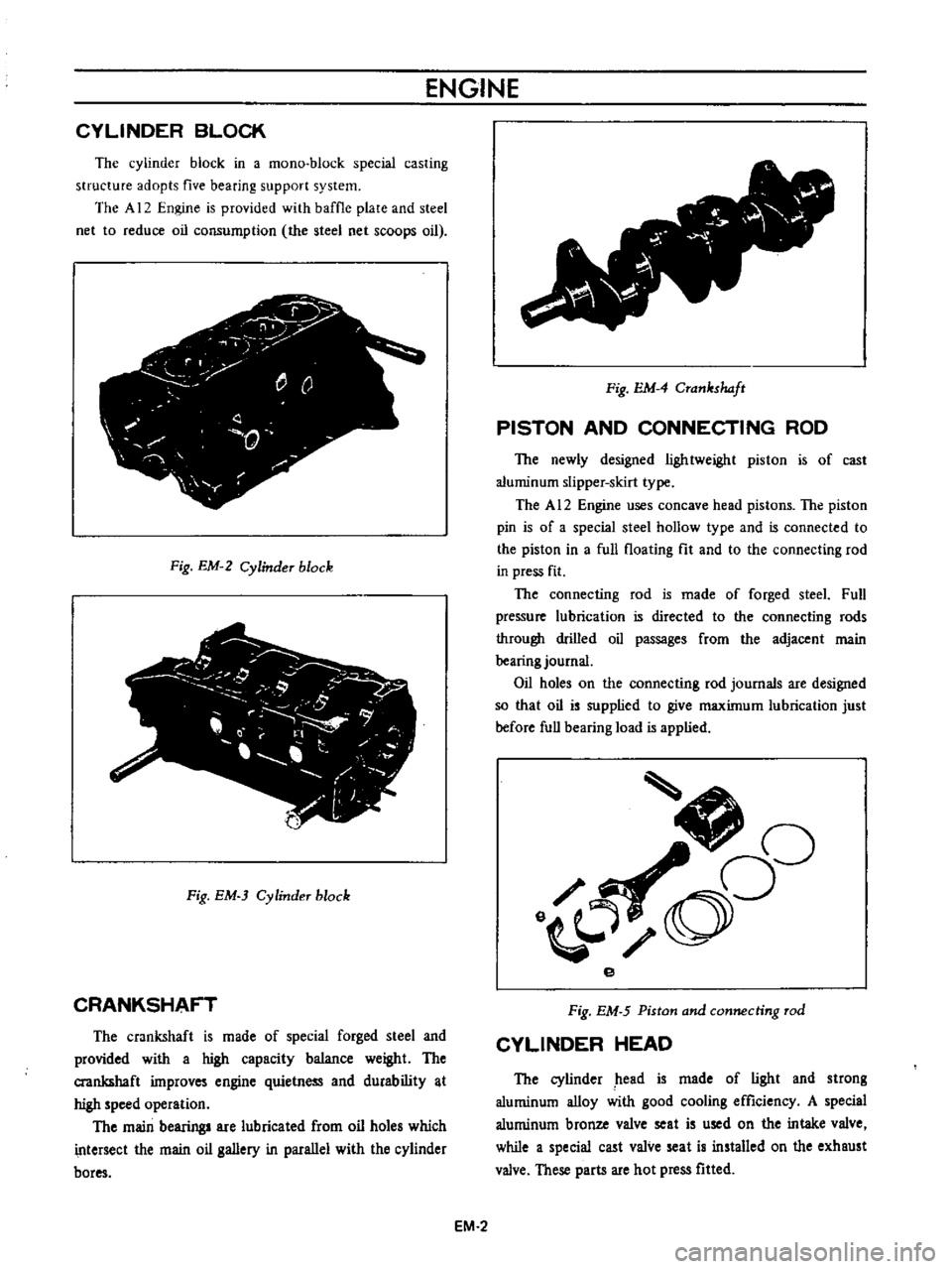

CYLINDER

BLOCK

The

cylinder

block

in

a

mono

block

special

casting

structure

adopts

five

bearing

support

system

The

A

12

Engine

is

provided

with

baffle

plate

and

steel

net

to

reduce

oil

consumption

the

steel

net

scoops

oil

j

y

r

0

Q

0

T

Fig

EM

2

Cylinder

block

Fig

EM

3

Cylinder

block

CRANKSHAFT

The

crankshaft

is

made

of

special

forged

steel

and

provided

with

a

high

capacity

balance

weight

The

crankshaft

improves

engine

quietness

and

durability

t

high

speed

operation

The

main

bearing

are

lubricated

from

oil

holes

which

intersect

the

main

oil

gallery

in

parallel

with

the

cylinder

bores

v

Fig

EM

4

Crankshaft

PISTON

AND

CONNECTING

ROD

The

newly

designed

lightweight

piston

is

of

cast

aluminum

slipper

skirt

type

The

A

12

Engine

uses

concave

head

pistons

The

piston

pin

is

of

a

special

steel

hollow

type

and

is

connected

to

the

piston

in

a

full

floating

fit

and

to

the

connecting

rod

in

press

fit

The

connecting

rod

is

made

of

forged

steeL

Full

pressure

lubrication

is

directed

to

the

connecting

rods

through

drilled

oil

passages

from

the

adjacent

main

bearing

journal

Oil

holes

on

the

connecting

rod

journals

are

designed

so

that

oil

is

supplied

to

give

maximum

lubrication

just

before

full

bearing

load

is

applied

J

oO

o

e

Fig

EM

5

Piston

and

connecting

rod

CYLINDER

HEAD

The

cylinder

head

is

made

of

light

and

strong

aluminum

alloy

with

good

cooling

efficiency

A

special

aluminum

bronze

valve

seat

is

used

on

the

intake

valve

while

a

special

cast

valve

seat

is

installed

on

the

exhaust

valve

These

parts

are

hot

press

fitted

EM

2

Page 386 of 513

r

r

J

j

r

I

1

Bi

l

it

1

J

f

J

f

f

r

c

i

I

i

f

4

Y

fj

r

i

SER

V

E

o

r

irJ

fl

i

rt

r

f

c

V

A

M

I

I

U

I

L

WI

F

or

i

7

v

I

1II

i

r

JIt

l

W

1

pI

r

r

1

r

0

j

j

j

t

r

7

f

of

JI

p

Xjlf

ii

i

t

oI

c

J

SECTION

CO

DATSUN

1200

MODEL

8110

SERIES

COOLING

SYSTEM

LNISSAN

I

NI55AN

MOTOR

CO

LTD

TOKYO

JAPAN

COOLING

SYSTEM

co

1

Page 387 of 513

COOLING

SYSTEM

COOLING

SYSTEM

CONTENTS

DESCRIPTION

WATER

PUMP

Removal

THERMOSTAT

Removal

Inspection

CO

1

CO

2

CO

2

CO

2

CO

2

CO

2

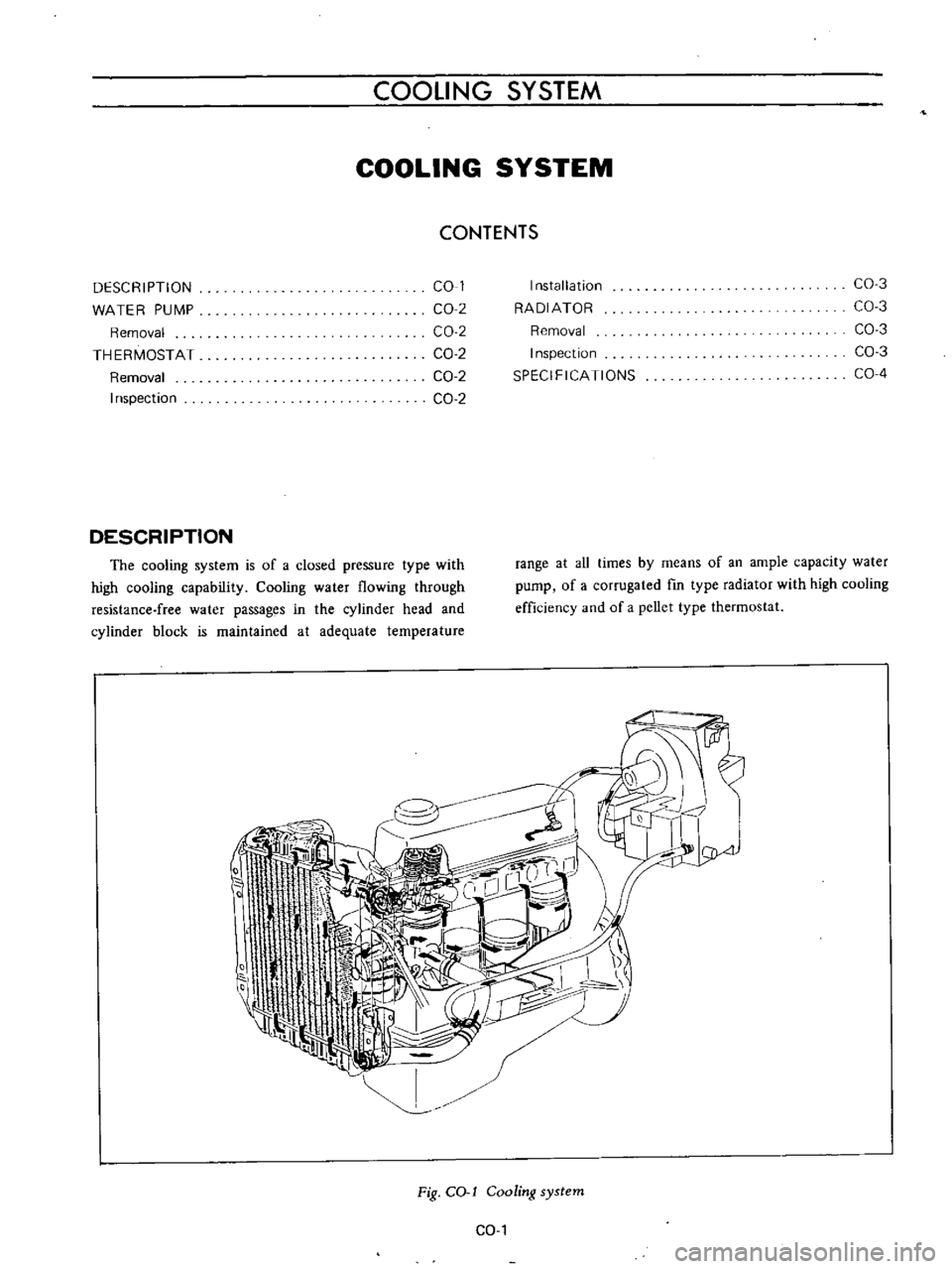

DESCRIPTION

The

cooling

system

is

of

a

closed

pressure

type

with

high

cooling

capability

Cooling

water

flowing

through

resistance

free

water

passages

in

the

cylinder

head

and

cylinder

block

is

maintained

at

adequate

temperature

Installation

RADIATOR

Removal

Inspection

SPECIFICATIONS

CO

3

CO

3

CO

3

CO

3

CO

4

range

at

aU

times

by

means

of

an

ample

capacity

water

pump

of

a

corrugated

fm

type

radiator

with

high

cooling

efficiency

and

of

a

pellet

type

thermostat

I

I

I

0

Jrl

oA

Fig

COol

Cooling

system

CO

I

Page 388 of 513

ENGINE

WATER

PUMP

The

water

pump

is

a

centrifugal

type

water

pump

with

an

aluminum

die

cast

pump

body

The

volute

chamber

is

built

into

the

front

cover

assembly

and

a

high

pressure

sealing

mechanism

is

adopted

to

prevent

the

water

leakage

and

noise

completely

Note

The

water

pump

must

not

be

disassembled

since

the

bearings

are

shrinkage

fitted

to

their

bores

If

any

part

of

water

pump

is

found

defective

replace

pump

assembly

o

C0026

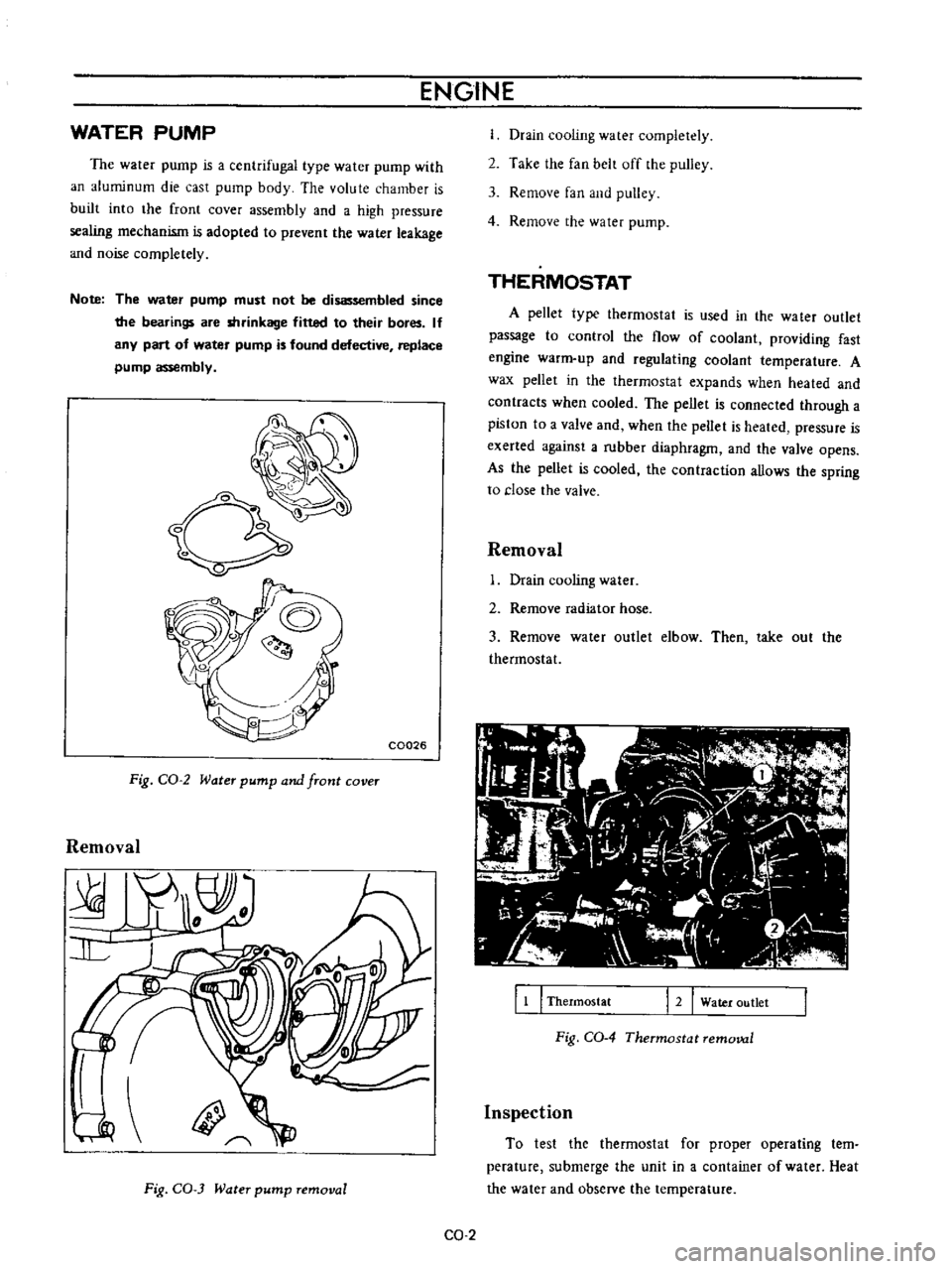

Fig

CO

2

Water

pump

and

front

cover

Removal

Fig

CO

3

Water

pump

removal

Drain

cooling

water

completely

2

Take

the

fan

belt

off

the

pulley

3

Remove

fan

and

pulley

4

Remove

the

water

pump

THERMOSTAT

A

pellet

type

thermostat

is

used

in

the

wa

ter

outlet

passage

to

control

the

flow

of

coolant

providing

fast

engine

warm

up

and

regulating

coolant

temperature

A

wax

pellet

in

the

thermostat

expands

when

heated

and

contracts

when

cooled

The

pellet

is

connected

through

a

piston

to

a

valve

and

when

the

peUet

is

heated

pressure

is

exerted

against

a

rubber

diaphragm

and

the

valve

opens

As

the

pellet

is

cooled

the

contraction

allows

the

spring

to

close

the

valve

Removal

Drain

cooling

water

2

Remove

radiator

hose

3

Remove

water

outlet

elbow

Then

take

out

the

thermostat

11

I

Thermostat

12

Water

outlet

Fig

CO

4

Thermostat

removal

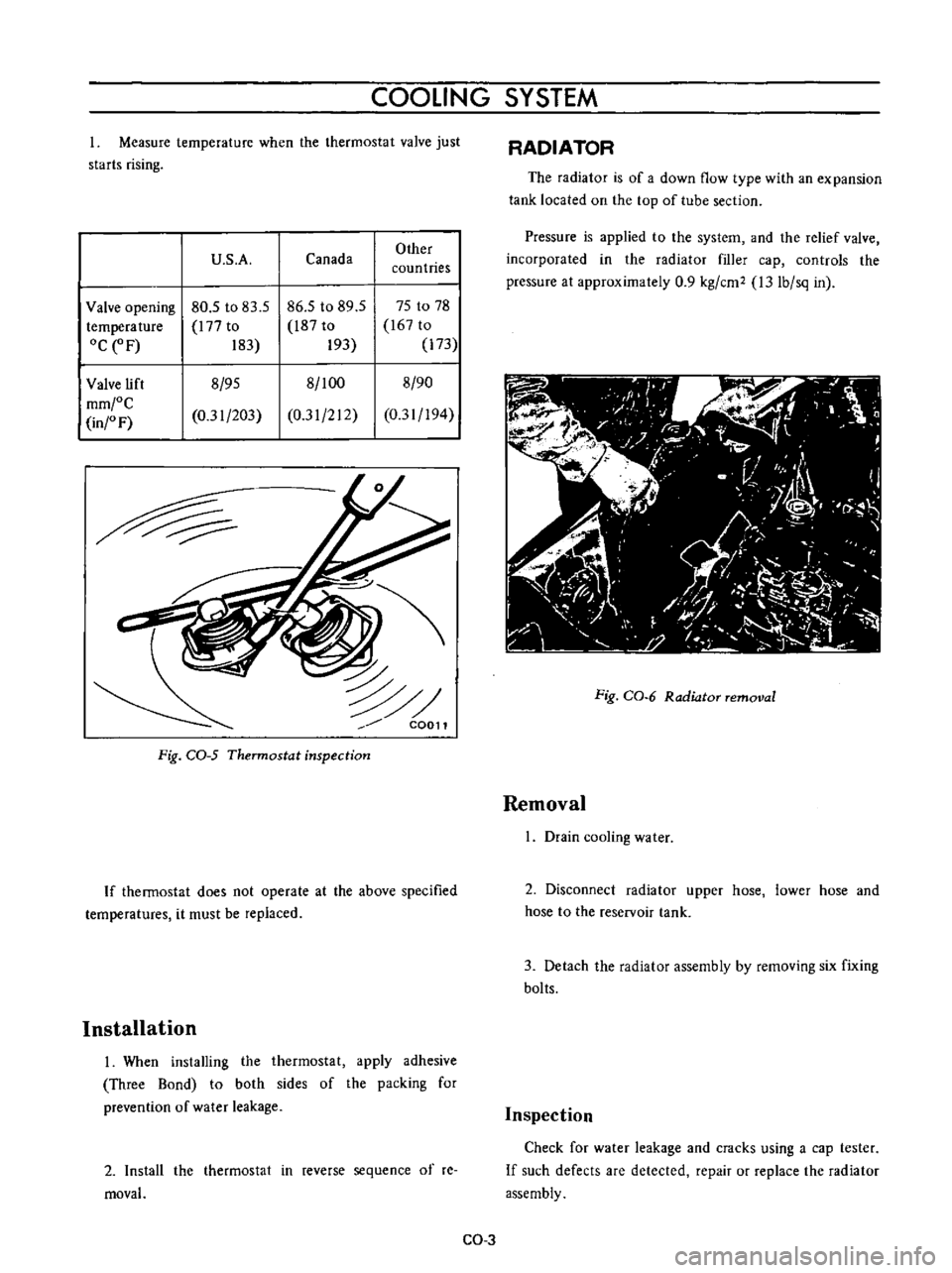

Inspection

To

test

the

thermostat

for

proper

operating

tern

perature

submerge

the

unit

in

a

container

of

water

Heat

the

water

and

observe

the

temperature

CO

2

Page 389 of 513

COOLING

SYSTEM

Measure

temperature

when

the

thermostat

valve

just

starts

rising

U

S

A

Canada

Other

countries

Valve

opening

80

5

to

83

5

86

5

to

89

5

75

to

78

temperature

l77

to

l87

to

167

to

OCeF

183

193

173

Valve

lift

8

95

8

100

8

90

mm

C

0

31

203

0

31

212

0

31

194

in

F

C0011

Fig

CQ

5

Thermostat

inspection

If

thermostat

does

not

operate

at

the

above

specified

temperatures

it

must

be

replaced

Installation

I

When

installing

the

thermostat

apply

adhesive

Three

Bond

to

both

sides

of

the

packing

for

prevention

of

water

leakage

2

Install

the

thermostat

in

reverse

sequence

of

re

moval

RADIATOR

The

radiator

is

of

a

down

flow

type

with

an

expansion

tank

located

on

the

top

of

tube

section

Pressure

is

applied

to

the

system

and

the

relief

valve

incorporated

in

the

radiator

filler

cap

controls

the

pressure

at

approximately

0

9

kg

cm2

l3

Ib

sq

in

Fig

CO

6

Radiator

removal

Removal

I

Drain

cooling

water

2

Disconnect

radiator

upper

hose

lower

hose

and

hose

to

the

reservoir

tank

3

Detach

the

radiator

assembly

by

removing

six

fixing

bolts

Inspection

Check

for

water

leakage

and

cracks

using

a

cap

tester

If

such

defects

are

detected

repair

or

replace

the

radiator

assembly

CO

3