radio DATSUN B110 1973 Service Repair Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1973, Model line: B110, Model: DATSUN B110 1973Pages: 513, PDF Size: 28.74 MB

Page 232 of 513

BODY

INSTRUMENT

PANEL

CONTENTS

REMOVAL

BF

42

REMOVAL

Fig

BF

88

Removing

instrument

panel

Note

There

are

two

types

of

instrument

panel

square

type

and

round

type

However

both

of

them

are

removed

and

reinstalled

in

the

same

manner

Disconnect

the

battery

cable

at

the

battery

terminal

2

Disconnect

the

wiring

harness

connector

units

Disconnect

the

instrument

harness

from

the

engine

compartment

harness

Disconnect

the

instrument

harness

from

the

turn

signal

switch

Disconnect

the

instrument

harness

frorn

the

body

harness

Disconnect

the

instrumen

t

harness

connected

to

the

door

switch

stop

lamp

switch

flasher

unit

and

passing

light

relay

option

REINSTALLATION

BF

43

Note

When

disconnecting

the

wiring

harness

recom

mend

to

use

tags

for

identifying

their

relationship

3

Disconnect

cables

for

radio

antenna

and

speaker

4

Remove

the

package

tray

the

shell

cover

and

turn

signal

switch

Note

Work

may

be

carried

out

without

removing

die

steering

wheel

However

it

is

recommended

to

remove

the

steering

wheel

50

that

work

can

be

carried

out

more

easily

5

Disconnect

the

speedometer

cable

from

the

speedometer

unit

6

Disconnect

the

heater

control

cable

at

the

heater

side

Fig

BF

89

Removing

imtrument

panel

Ii

BF

42

Page 235 of 513

DATSUN

1200

MODEL

B

11

0

SERIES

I

NISSAN

I

NISSAN

MOTOR

CO

LTD

TOKYO

JAPAN

SECTION

BE

BODY

ELECTRICAL

WIRING

FUSE

LIGHTING

SYSTEM

HORN

METERS

AND

GAUGES

WINDSHIELD

WIPER

AND

WASHER

IGNITION

SWITCH

AND

STEERING

LOCK

CLOCK

RADIO

HEATER

BE

1

BE

6

BE

7

BE

15

BE

18

BE

26

BE

29

BE

31

BE

32

BE

34

Page 253 of 513

BODY

METERS

AND

GAUGES

CONTENTS

CLUSTER

LID

Oescri

ption

Removal

SPEEDOMETER

Replacement

FUEL

GAUGE

AND

TEMPERATURE

GAUGE

Description

Replacement

BE

1B

BE

18

BE

18

BE

19

BE

19

BE

19

BE

19

BE

20

CLUSTER

LID

Description

The

cluster

lid

holds

various

rneters

indicators

and

clock

located

around

the

speedorneter

Printed

circuit

board

is

used

at

the

back

of

the

meter

as

shown

in

Figure

BE

38

and

the

printed

circuit

board

is

connected

with

multiple

connectors

Thus

the

meters

Can

be

inspected

and

serviced

extremely

easily

Except

for

the

speed

ometer

all

rneters

are

operated

electrically

The

fuel

gauge

and

therrnometer

are

very

reliable

and

they

are

equipped

with

bimetal

devices

F

a

o

ill

I

1

a

a

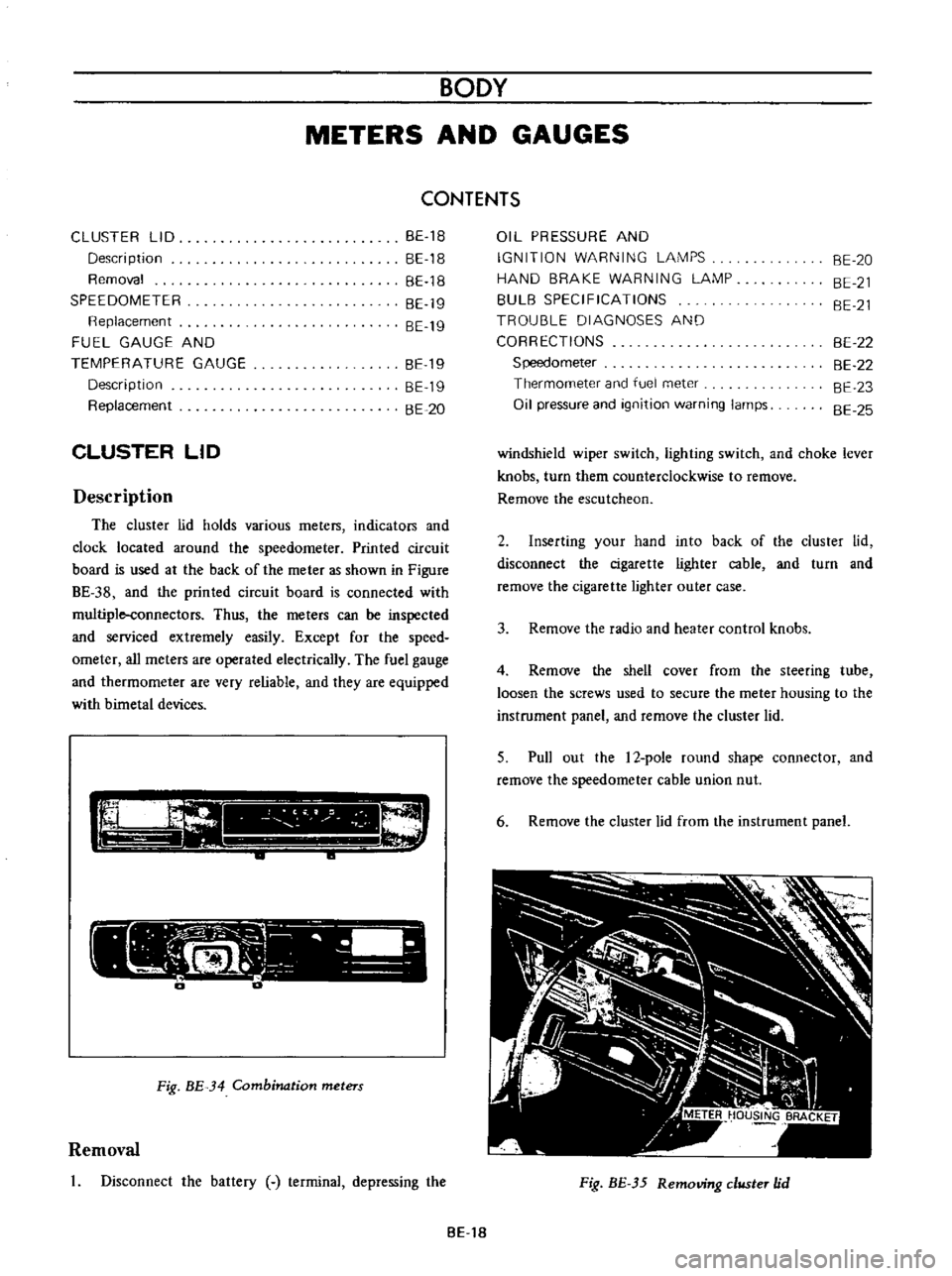

Fig

BE

34

Combination

meters

Removal

Disconnect

the

battery

terminal

depressing

the

OIL

PRESSURE

AND

IGNITION

WARNING

LAMPS

HAND

BRAKE

WARNING

LAMP

BULB

SPECIFICATIONS

TROUBLE

DIAGNOSES

AND

CORRECTIONS

Speedometer

Thermometer

and

fuel

meter

Oil

pressure

and

ignition

warning

lamps

BE

20

BE

21

BE

21

BE

22

BE

22

BE

23

BE

25

windshield

wiper

switch

lighting

switch

and

choke

lever

knobs

turn

them

counterclockwise

to

remove

Remove

the

escutcheon

2

Inserting

your

hand

into

back

of

the

cluster

lid

disconnect

the

cigarette

lighter

cable

and

turn

and

remove

the

cigarette

lighter

outer

case

3

Remove

the

radio

and

heater

control

knobs

4

Remove

the

shell

cover

from

the

steering

tube

loosen

the

screws

used

to

secure

the

meter

housing

to

the

instrument

panel

and

remove

the

cluster

lid

5

Pull

out

the

l2

pole

round

shape

connector

and

remove

the

speedometer

cable

union

nut

6

Remove

the

cluster

lid

from

the

instrument

panel

Fig

BE

35

Removing

clllSter

jd

BE

18

Page 267 of 513

BODY

RADIO

Removal

Remove

he

cluster

lid

2

Disconnect

the

lead

wires

from

the

radio

3

Remove

two

nuts

used

to

install

the

front

side

of

the

radio

on

the

instrument

panel

4

Loosen

two

screws

as

shown

in

the

Figure

BE

55

and

remove

the

bracket

used

to

install

the

rear

side

of

the

radio

on

the

instrument

panel

5

Remove

the

radio

Noise

prevention

chart

Run

the

engine

raise

the

antenna

set

volume

to

Condition

Apparent

cause

Ignition

system

Noise

occurs

when

engine

is

oper

High

tension

code

ated

Ignition

coil

i

O

i

M

1

iiJ

1

7

L

l

o

f

I

ft

V

r

1

1

v

I

I

t

i

J

iL

1

Power

soutee

cable

Blue

white

cable

of

harness

2

Power

source

cable

Radio

3

Speaker

cables

4

Antenna

cable

5

Single

pole

fuse

6

Spare

fuse

7

Attaching

screws

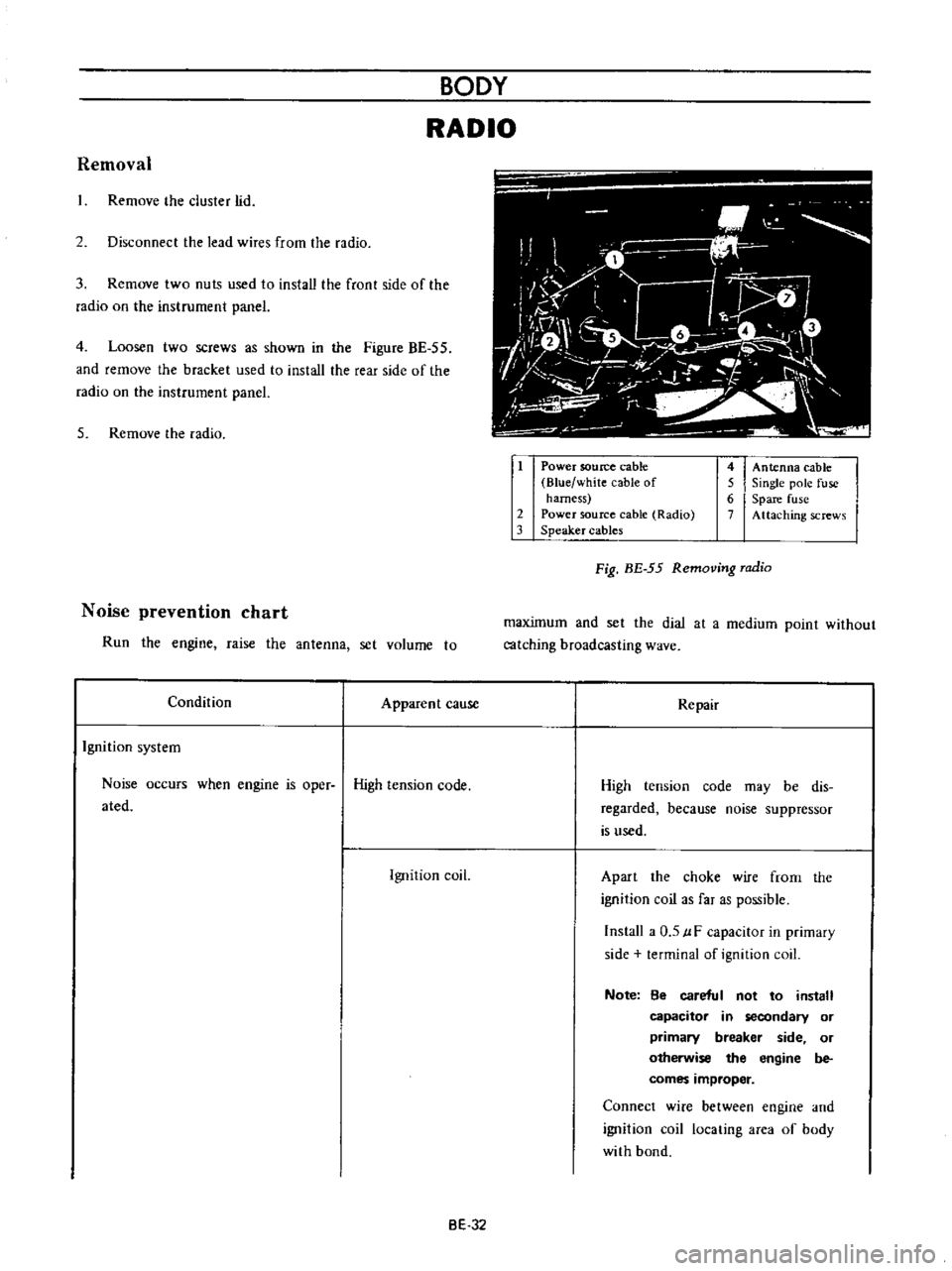

Fig

BE

55

Removing

radio

maximum

and

set

the

dial

at

a

medium

point

without

catching

broadcasting

wave

Repair

High

tension

code

may

be

dis

regarded

because

noise

suppressor

is

used

Apart

the

choke

wire

frorn

the

ignition

coil

as

far

as

possible

Install

a

0

5

uF

capacitor

in

primary

side

terminal

of

ignition

coil

Note

8e

careful

not

to

install

capacitor

in

secondary

or

primary

breaker

side

or

otherwise

the

engine

be

comes

improper

Connect

wire

between

engine

and

ignition

coil

locating

area

of

body

with

bond

BE

32

Page 444 of 513

ENGINE

MEASUREMENT

OF

REGULATING

VOLTAGE

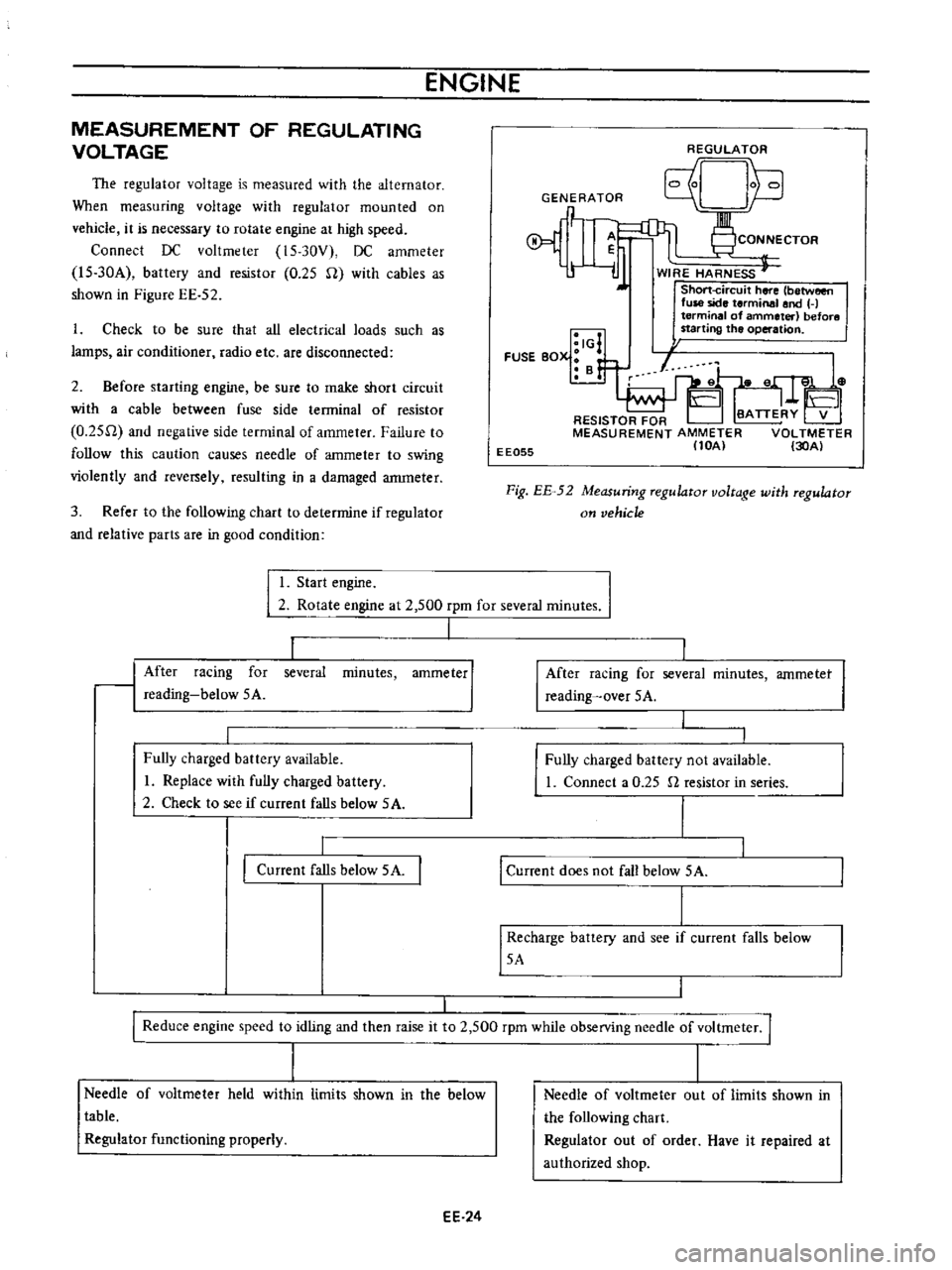

The

regulator

voltage

is

measured

with

the

alternator

When

measuring

voltage

with

regulator

mounted

on

vehicle

it

is

necessary

to

rotate

engine

at

high

speed

Connect

DC

voltmeter

15

30V

DC

ammeter

l5

30A

battery

and

resistor

0

25

U

with

cables

as

shown

in

Figure

EE

52

1

Check

to

be

sure

that

all

electrical

loads

such

as

lamps

air

conditioner

radio

etc

are

disconnected

2

Before

starting

engine

be

sure

to

make

short

circuit

with

a

cable

between

fuse

side

terminal

of

resistor

O

25U

and

negative

sIde

terminal

of

ammeter

Failure

to

follow

this

caution

causes

needle

of

ammeter

to

swing

violently

and

rever

ely

resulting

in

a

damaged

anuneter

3

Refer

to

the

following

chart

to

determine

if

regulator

and

relative

parts

are

in

good

condition

REGULATOR

Unh

GENERATOR

q

P

1

CONNECTOR

r

l

ij

WIRE

HARNESS

J

Short

circuit

here

between

fuse

side

terminal

and

H

terminal

of

ammeter

before

starting

the

operation

I

I

I

IG

FUSE

BOX

B

f

EE055

Fig

EE

52

Measuring

regulator

voltage

with

regulator

on

vehicle

I

Start

engine

I

2

Rotate

engine

at

2

500

rpm

for

several

minutes

I

1

minutes

ammeter

I

After

racing

for

reading

below

5A

several

Fully

charged

battery

available

I

Replace

with

fully

charged

battery

2

Check

to

see

if

current

falls

below

5A

Current

falls

below

5A

I

After

racing

for

several

reading

over

5A

minutes

ammetet

I

Fully

charged

battery

not

available

1

Connect

a

0

25

n

resistor

in

series

I

Current

does

not

fall

below

5A

I

Recharge

battery

and

see

if

current

falls

below

5A

I

I

Reduce

engine

speed

to

idling

and

then

raise

it

to

2

500

rpm

while

observing

needle

of

voltmeter

I

I

I

Needle

of

voltmeter

held

within

limits

shown

in

the

below

table

Regulator

functioning

properly

EE

24

Needle

of

voltmeter

out

of

limits

shown

in

the

following

chart

Regulator

out

of

order

Have

it

repaired

at

authorized

shop