fuse DATSUN B110 1973 Service User Guide

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1973, Model line: B110, Model: DATSUN B110 1973Pages: 513, PDF Size: 28.74 MB

Page 250 of 513

Flashing

cycle

varies

BODY

ELECTRICAL

Faulty

contact

of

power

supply

circuit

from

ignition

switch

to

fuse

Tail

and

stop

lamp

license

lamp

back

up

lamp

Condition

Both

left

and

right

lamps

do

not

light

Probable

cause

Blown

off

fuse

or

faulty

contact

Defective

stop

larnp

switch

or

backup

lamp

switch

or

faulty

contact

Stop

larnps

and

backup

lamp

only

Faulty

grounding

Only

one

side

lamp

Burnt

out

lamp

bulb

f1lament

lights

Brightness

of

one

side

lamp

differs

from

the

other

HORN

Removal

Adjustment

Faulty

contact

of

connector

ter

minal

and

or

socket

Faulty

contact

of

connector

ter

minal

and

or

socket

BE

16

BE

16

BE

16

When

the

windshield

wiper

which

uses

the

ignition

for

power

supply

is

operated

flashing

cycle

and

brightness

change

Method

of

inspection

Check

the

fuse

for

fusing

and

faulty

contact

When

two

lead

wires

of

the

switch

are

connected

and

the

lamp

lights

the

larnp

and

circuit

are

normal

All

rear

combination

lamps

do

not

light

HORN

CONTENTS

TROUBLE

DIAGNOSES

AND

CORRECTIONS

BE

15

Repair

as

required

Corrective

action

When

the

fuse

is

fused

detect

and

COf

rect

the

cause

and

replace

the

fuse

Replace

the

switch

or

repair

the

connector

terrninal

Repair

the

grounding

cable

contact

Replace

the

larnp

with

a

new

one

Repair

or

replace

Repair

or

replace

if

required

BE

17

Page 251 of 513

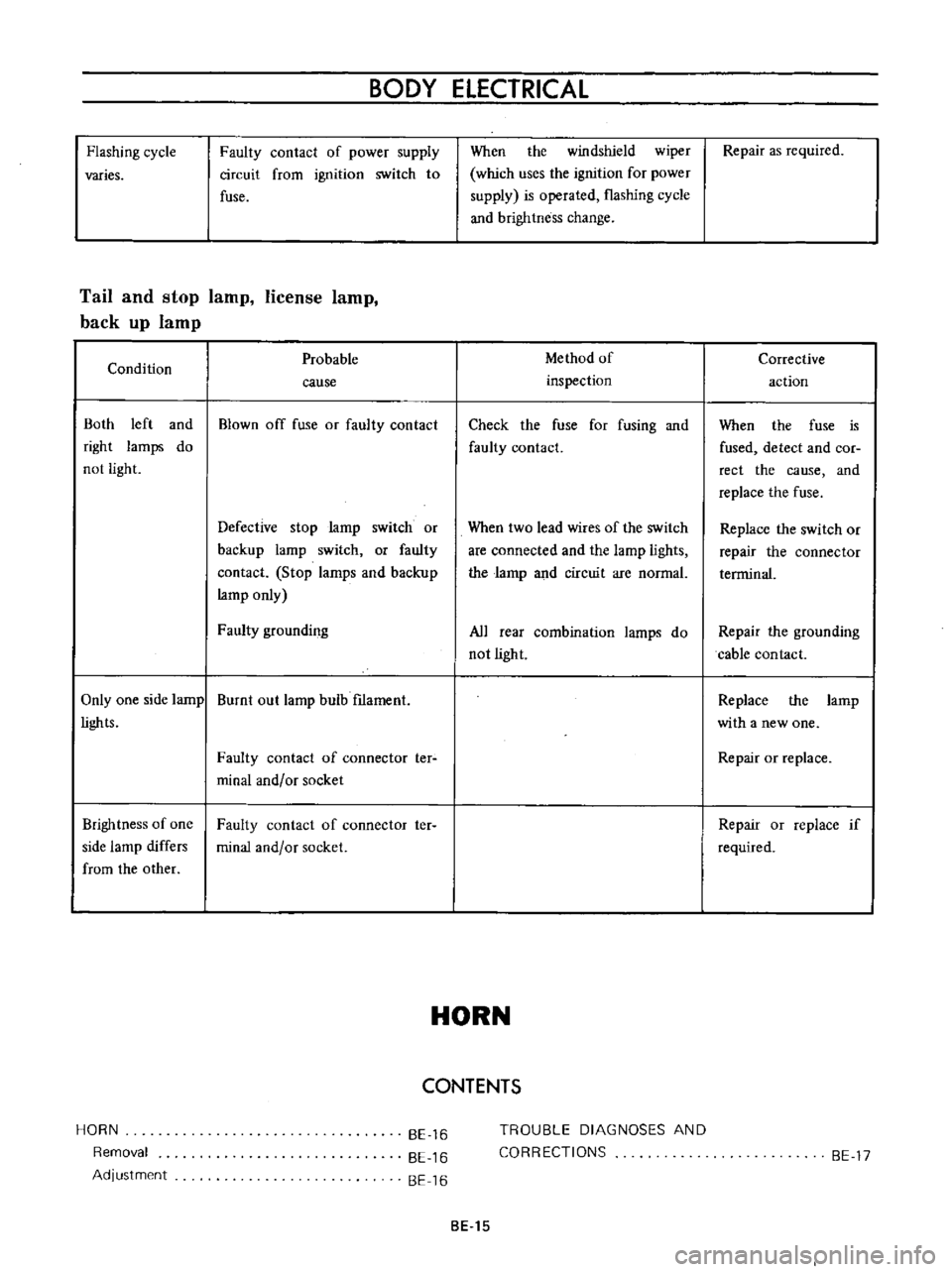

9HORN

r

I

01

8ATTERY

HI

IGI

s

ILl

C

iORN

BODY

FUSE

H

S

HORN

BUTTON

BGI

J

H

B

S

Il

I

n6lm

I

L

J

L

HORN

RELAY

Fig

BE

3l

Circuit

diagram

for

hom

syrtem

HORN

Removal

Remove

the

connector

loosen

the

fixing

nut

in

the

horn

center

and

remove

the

horn

unit

Adjustment

1

Secure

the

horn

unit

in

a

vise

and

connect

cables

as

shown

in

Pigure

BE

32

AMMETER

110

to

15AI

Isw

f

@

113

I

VOLTMETER

I

15

to

20VI

BATTERY

HORN

Fig

BE

32

Circuit

for

ham

adjustment

2

Set

the

switch

to

ON

and

rnake

sure

that

the

voltmeter

indicates

12

to

12

5

V

3

Listening

the

horn

for

sound

level

volurne

and

tone

adjust

sound

properly

so

that

the

amrneter

indicates

the

rated

amperage

The

adjustment

is

made

by

turning

the

adjust

screw

after

loosening

the

lock

nut

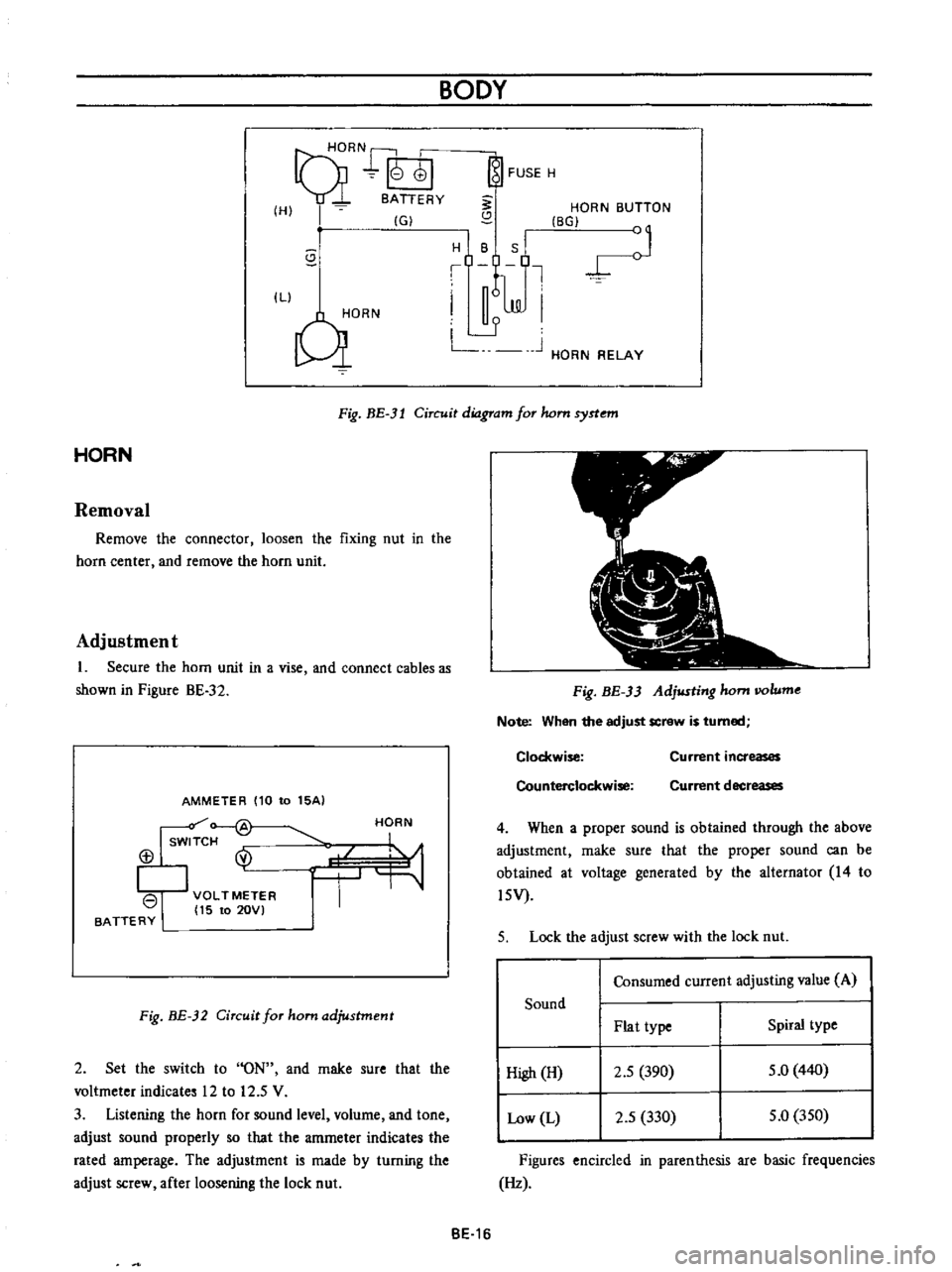

Fig

BE

33

Adjusting

hom

IIOlume

Note

When

the

adjust

screw

is

turned

Clockwise

Counterclockwise

Current

increases

Current

decreases

4

When

a

proper

sound

is

obtained

through

the

above

adjustment

rnake

sure

that

the

proper

sound

can

be

obtained

at

voltage

generated

by

the

alternator

14

to

l5V

5

Lock

the

adjust

screw

with

the

lock

nut

Consumed

current

adjusting

value

A

Sound

Plat

type

Spiral

type

High

H

2

5

390

5

0

440

Low

L

2

5

330

5

0

350

Figures

encircled

in

parenthesis

are

basic

frequencies

Hz

BE

16

Page 252 of 513

BODY

ELECTRICAL

TROUBLE

DIAGNOSES

AND

CORRECTIONS

Condition

The

horn

does

not

operate

The

horn

sounds

continuously

Reduced

volume

and

or

tone

quali

ty

Probalbe

cause

Excessively

discharged

battery

Blown

off

fuse

Improper

horn

button

contact

Defective

horn

relay

Defective

horn

Defective

horn

relay

Short

circuited

horn

button

and

horn

relay

terminal

S

Improper

fuse

wire

contact

Broken

cable

Improper

horn

button

contact

Method

of

inspection

Measure

specific

gravity

of

electro

lyte

Corrective

action

Charge

if

required

Check

the

fuse

for

fusing

and

im

Replace

fuse

proper

contact

The

horn

sounds

though

the

horn

relay

terrninal

S

is

grounded

Check

and

repair

horn

button

The

horn

sounds

though

the

horn

Replace

horn

relay

relay

terrninals

B

and

H

are

short

circuited

The

horn

does

not

sound

though

Replace

horn

the

horn

relay

terminals

B

and

H

are

short

circuited

and

the

porn

still

does

not

sound

though

the

battery

terminal

is

con

nected

to

the

horn

terminal

direct

ly

The

horn

does

not

stop

though

the

Replace

horn

relay

horn

relay

S

terminal

is

discon

nected

When

the

horn

stops

through

the

above

disconnection

check

the

horn

button

unit

particularly

care

fully

BE

17

Repair

horn

relay

terminal

S

Replace

horn

button

Correct

Repair

or

replace

if

required

Repair

d

Page 255 of 513

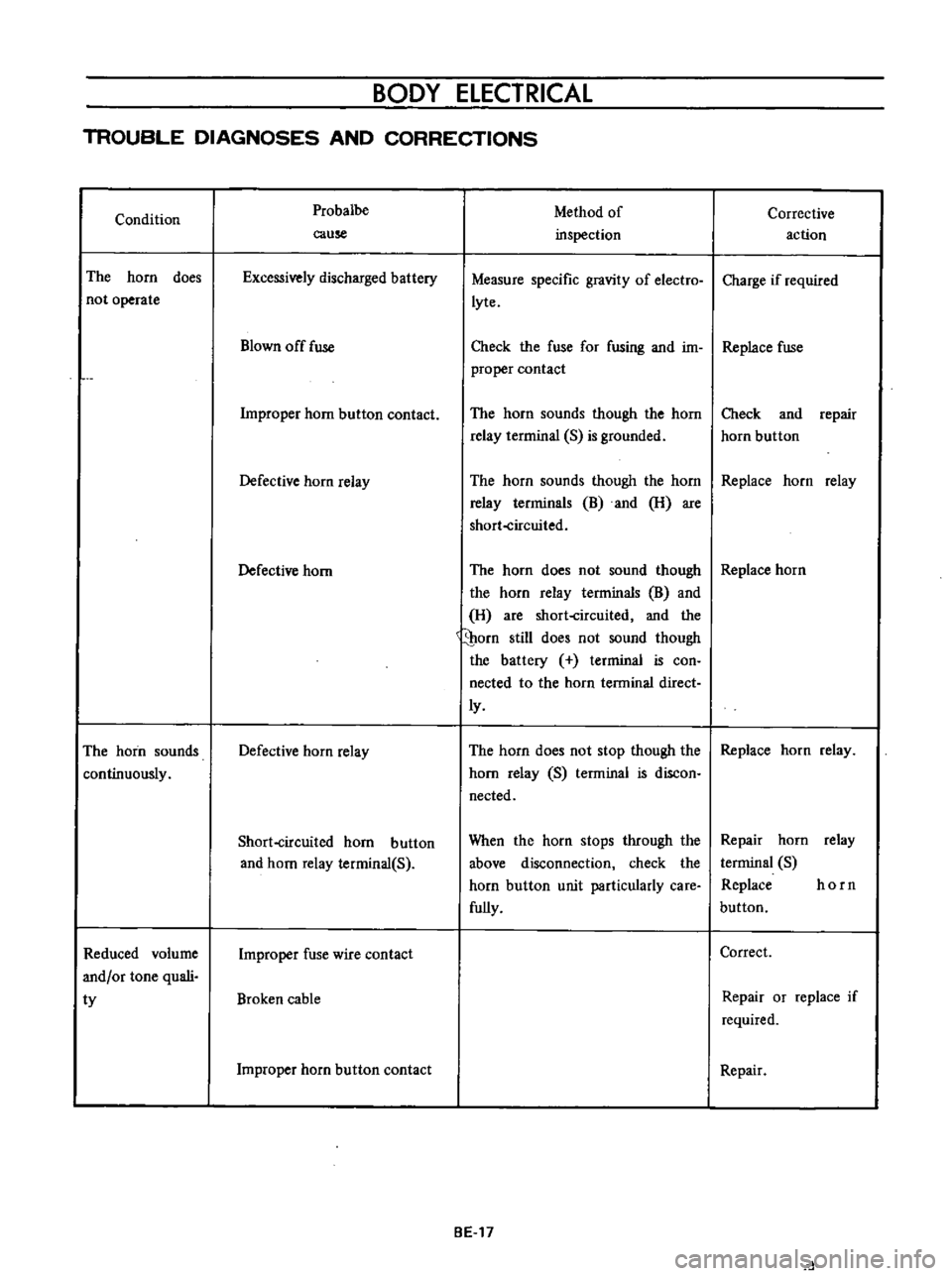

BODY

REGULATOR

FUSE

M

TEMPE

RATURE

GAUGE

IGNITION

SWITCH

Lf

I

iT

Ji

1M

THERMAL

TRANSMITTER

I

J

0

I

GAUGE

TANK

UNIT

FUEL

TANK

Fig

BE

38

Circuit

diagram

for

fuel

gauge

temperature

gauge

and

voltage

regulator

Replacement

Remove

the

cluster

lid

first

2

Unscrew

two

screws

and

remove

the

thermometer

or

fuel

meter

from

the

combination

meter

housing

3

Reinstall

a

new

meter

in

reverse

sequence

of

removal

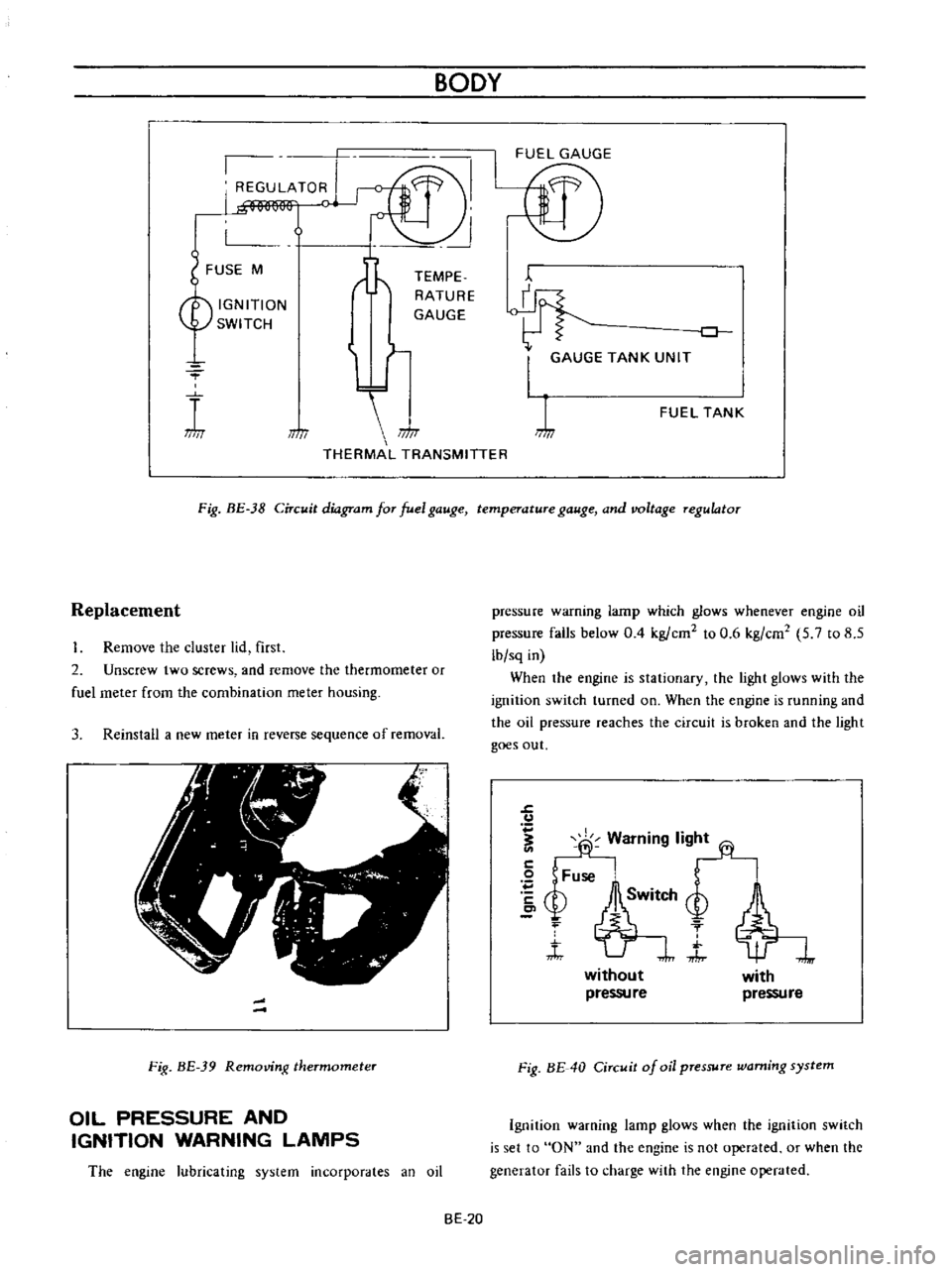

Fig

BE

39

Removing

thermometer

OIL

PRESSURE

AND

IGNITION

WARNING

LAMPS

The

engine

lubricating

system

incorporates

an

oil

pressure

warning

lamp

which

glows

whenever

engine

oil

pressure

falls

below

0

4

kg

ern

to

0

6

kg

em

5

7

to

8

5

lb

sq

in

When

the

engine

is

stationary

the

light

glows

with

the

ignition

switch

turned

on

When

the

engine

is

running

and

the

oil

pressure

reaches

the

circuit

is

broken

and

the

light

goes

out

J

u

fj

Warning

lig

2

Fuse

bSM

Q

f

t

J

without

pressu

re

with

pressure

Fig

BE

40

Circuit

of

oil

pressure

warning

system

Ignition

warning

lamp

glows

when

the

ignition

switch

is

set

to

ON

and

the

engine

is

not

operated

or

when

the

generator

fails

to

charge

with

the

engine

operated

BE

20

Page 258 of 513

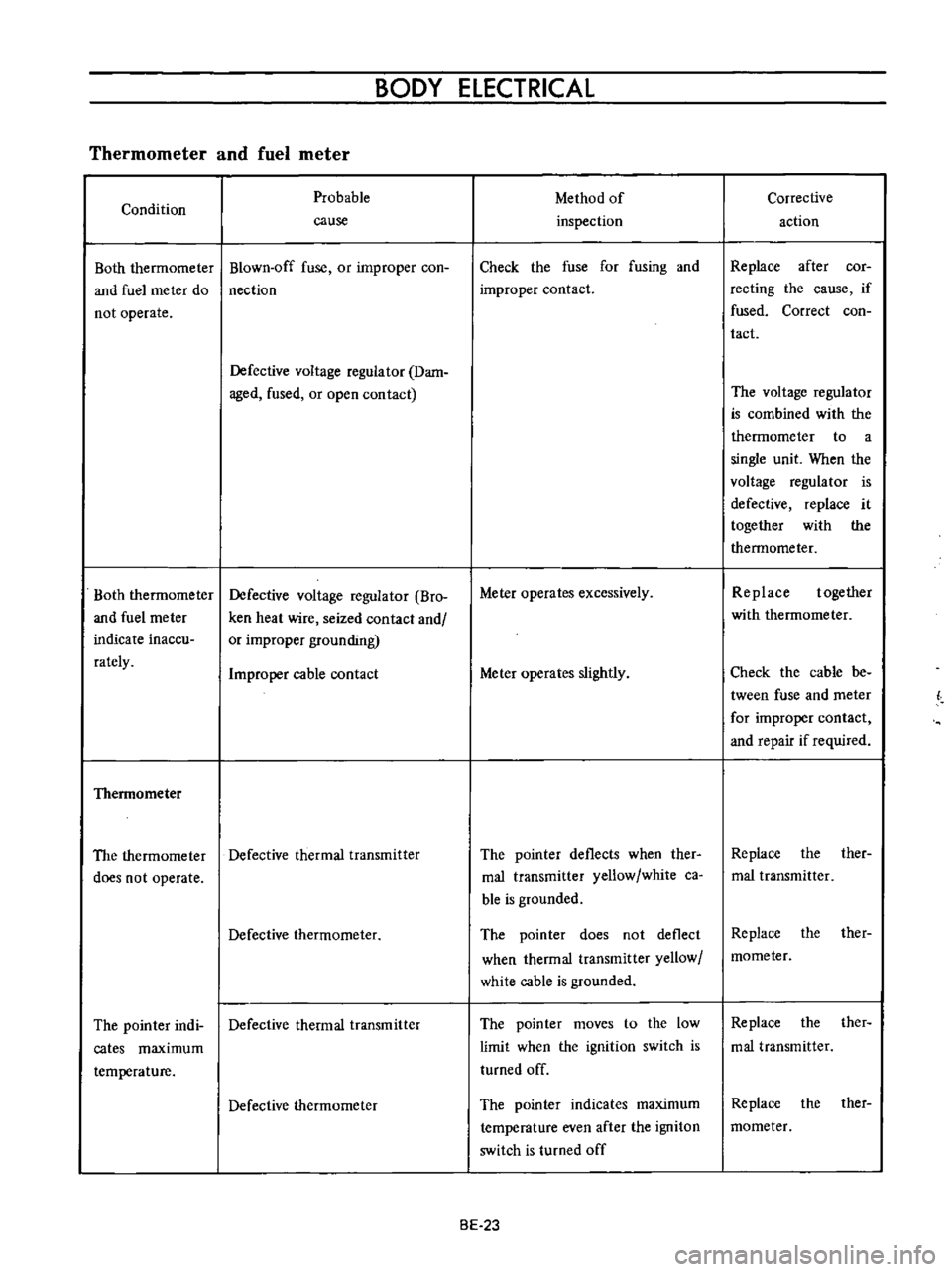

BODY

ELECTRICAL

Thermometer

and

fuel

meter

Condition

Both

therrnorneter

and

fuel

rneter

do

not

operate

Both

thermorneter

and

fuel

rneter

indicate

inaccu

rately

Thennometer

Probable

cause

Blown

off

fuse

or

improper

coo

nection

Defective

voltage

regulator

Dam

aged

fused

or

open

contact

Defective

voltage

regulator

Bro

ken

heat

wire

seized

contact

and

or

improper

grounding

Improper

cable

contact

The

thermometer

Defective

thermal

transmitter

does

not

operate

Defective

thermometer

The

pointer

indi

Defective

thermal

transmitter

cates

maximum

temperature

Defective

thermometer

Method

of

inspection

Check

the

fuse

for

fusing

and

improper

contact

Meter

operates

excessively

Meter

operates

slightly

The

pointer

deflects

when

ther

mal

transrnitter

yellow

white

ca

ble

is

grounded

The

pointer

does

not

deflect

when

thermal

transmitter

yellow

white

cable

is

grounded

The

pointer

moves

to

the

low

limit

when

the

ignition

switch

is

turned

off

The

pointer

indicates

maximum

temperature

even

after

the

ignitoD

switch

is

turned

off

BE

23

Corrective

action

Replace

after

cor

recting

the

cause

if

fused

Correct

coo

tact

The

voltage

regulator

is

combined

with

the

thermometer

to

a

single

unit

When

the

voltage

regulator

is

defective

replace

it

together

with

the

thermometer

Replace

together

with

thermometer

Check

the

cable

be

tween

fuse

and

meter

for

improper

contact

and

repair

if

required

Replace

the

ther

mal

transmitter

Replace

the

ther

mometer

Replace

the

ther

mal

transmitter

Replace

the

ther

mometer

Page 260 of 513

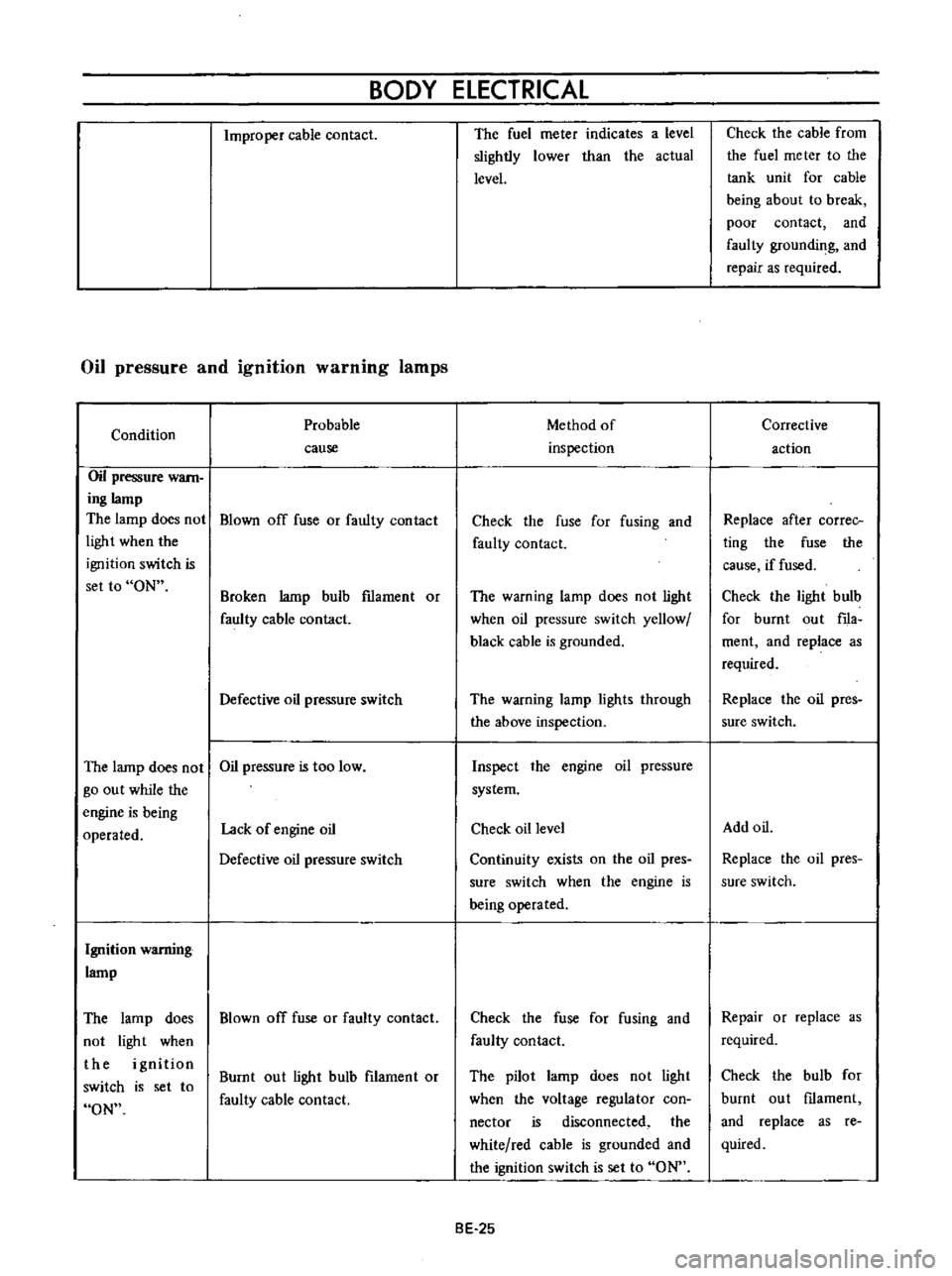

BODY

ELECTRICAL

Improper

cable

contact

Oil

pressure

and

ignition

warning

lamps

Condition

Oil

pressure

Want

ing

lamp

The

lamp

does

not

ligh

t

when

the

ignition

switch

is

set

to

ON

Probable

cause

Blown

off

fuse

or

faulty

contact

Broken

lamp

bulb

fIlarnent

or

faulty

cable

contact

Defective

oil

pressure

switch

The

lamp

does

not

Oil

pressure

is

too

low

go

out

while

the

engine

is

being

operated

Lack

of

engine

oil

Defective

oil

pressure

switch

Ignition

warning

lamp

The

lamp

does

not

light

when

the

ignition

switch

is

set

to

ON

Blown

off

fuse

or

faulty

contact

Burnt

out

light

bulb

filarnent

or

faulty

cable

contact

The

fuel

rneter

indicates

a

level

slightly

lower

than

the

actual

level

Method

of

inspection

Check

the

fuse

for

fusing

and

faulty

contact

The

warning

lamp

does

not

light

when

oil

pressure

switch

yellow

black

cable

is

grounded

The

warning

lamp

lights

through

the

above

inspection

Inspect

the

engine

oil

pressure

system

Check

oil

level

Continuity

exists

on

the

oil

pres

sure

switch

when

the

engine

is

being

operated

Check

the

fuse

for

fusing

and

faulty

contact

The

pilot

lamp

does

not

light

when

the

voltage

regulator

con

nector

is

disconnected

the

white

red

cable

is

grounded

and

the

ignition

switch

is

set

to

ON

BE

25

Check

the

cable

from

the

fuel

meter

to

the

tank

unit

for

cable

being

about

to

break

poor

contact

and

faulty

grounding

and

repair

as

required

Corrective

action

Replace

after

corree

ting

the

fuse

the

cause

if

fused

Check

the

light

bulb

for

burnt

out

fIla

ment

and

replace

as

required

Replace

the

oil

pres

sure

switch

Add

oil

Replace

the

oil

pres

sure

switch

Repair

or

replace

as

required

Check

the

bulb

for

burnt

out

fIlament

and

replace

as

re

quired

Page 261 of 513

The

lamp

does

not

go

out

when

the

engine

is

started

Faulty

charging

system

BODY

Inspect

the

charging

system

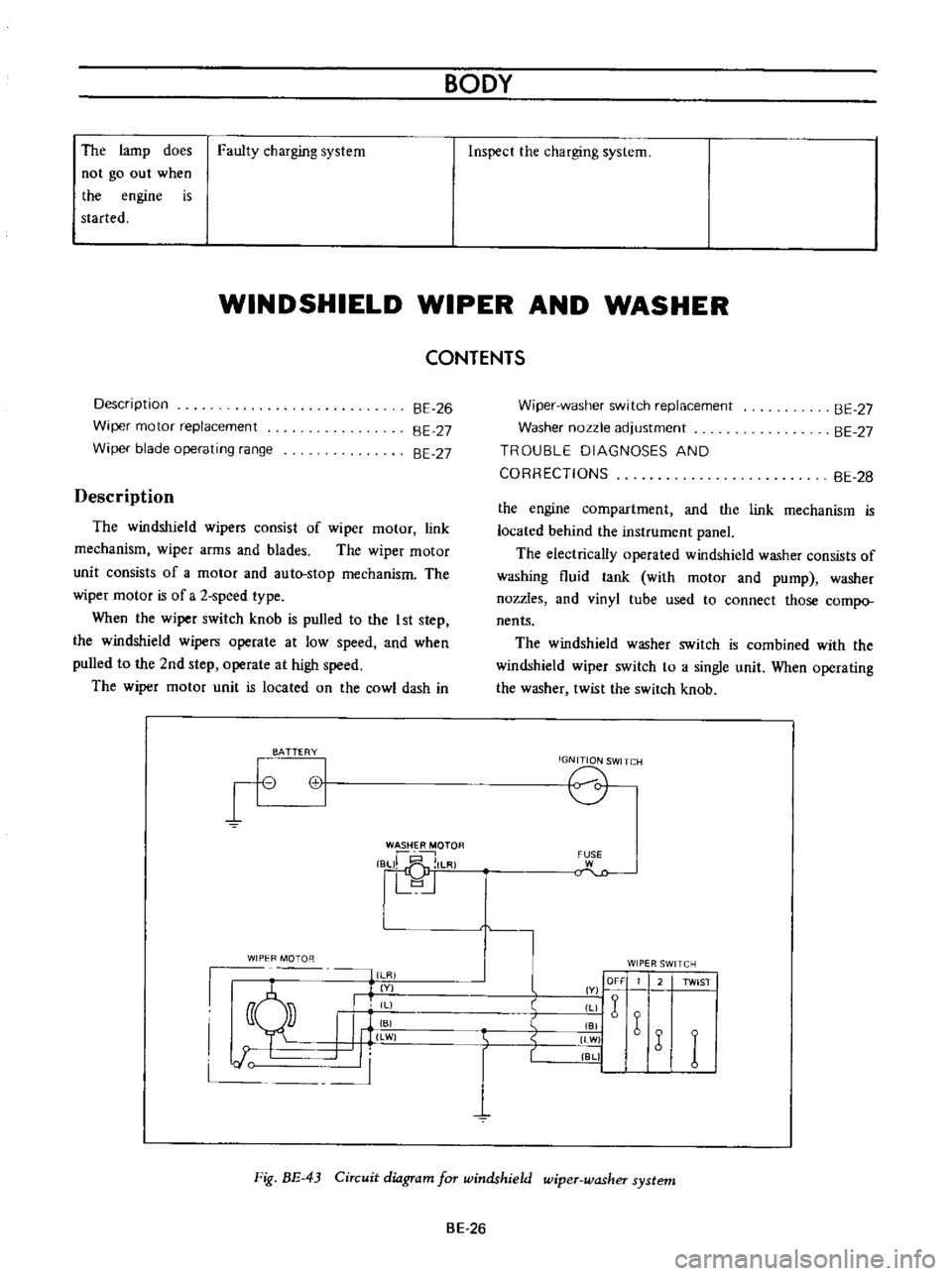

WINDSHIELD

WIPER

AND

WASHER

Description

Wiper

motor

replacement

Wiper

blade

operating

range

CONTENTS

BE

26

BE

27

BE

27

Description

The

windshield

wipers

consist

of

wiper

motor

link

mechanism

wiper

arms

and

blades

The

wiper

motor

unit

consists

of

a

motor

and

auto

stop

mechanism

The

wiper

rnotor

is

of

a

2

speed

type

When

the

wiper

switch

knob

is

pulled

to

the

I

st

step

the

windshield

wipers

operate

at

low

speed

and

when

pulled

to

the

2nd

step

operate

at

high

speed

The

wiper

motor

unit

is

located

on

the

cowl

dash

in

BATTERY

Cl

WIPER

MOTOR

rrQ

J

WASHER

MOTOR

IB

ILRI

L

CJ

LA

t

Y

I

Ll

j

IBI

1

f

I

LW

I

Wiper

washer

switch

replacement

Washer

nozzle

adjustment

TROUBLE

OIAGNOSES

ANO

CORRECTIONS

BE

27

BE

27

BE

28

the

engine

compartment

and

the

link

mechanism

is

located

behind

the

instrument

panel

The

electrically

operated

windshield

washer

consists

of

washing

fluid

lank

with

rnotor

and

pump

washer

nozzles

and

vinyl

tube

used

to

connect

those

compo

nents

The

windshield

washer

switch

is

combined

with

the

windshield

wiper

switch

to

a

single

unit

When

operating

the

washer

twist

the

switch

knob

IG

FUSE

W

v

l

i

f

WIPER

SWITCH

10FFI

I

2

I

TWIST

I

y

ILl

I

b

I

J

6

I

BLII

Fig

BE

43

Circuit

diagram

for

windshield

wiper

washer

system

BE

26

Page 263 of 513

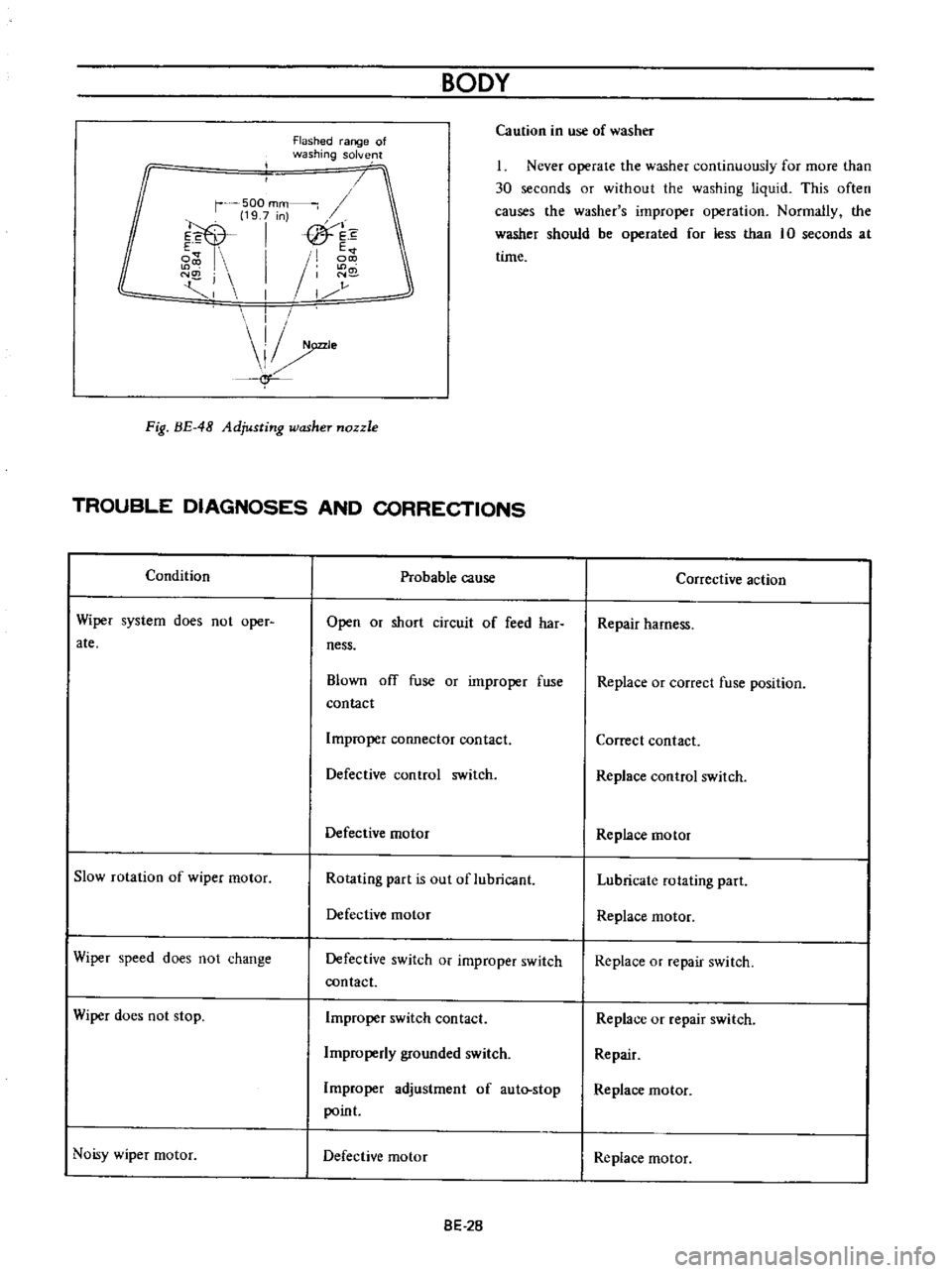

BODY

Flashed

range

of

washing

solve

lt

Ca

ution

in

use

of

washer

r

500

mm

19

7

n

E

I

fTh

e

i

E

I

I

N

j

1

N

I

1

r

j

I

I

e

f

1

Never

operate

the

washer

continuously

for

more

than

30

seconds

or

without

the

washing

liquid

This

often

causes

the

washer

s

improper

operation

Normally

the

washer

should

be

operated

for

less

than

10

seconds

at

time

Fig

BE

48

Adjusting

washer

nozzle

TROUBLE

DIAGNOSES

AND

CORRECTIONS

Condition

Probable

cause

Corrective

action

Wiper

system

does

not

oper

ate

Open

or

short

circuit

of

feed

har

ness

Repair

harness

Blown

ofT

fuse

or

improper

fuse

contact

Replace

or

correct

fuse

position

Improper

connector

contact

Correct

contact

Defective

control

switch

Replace

control

switch

Defective

motor

Replace

motor

Slow

rotation

of

wiper

motor

Rotating

part

is

out

of

lubricant

Lubricate

rotating

part

Defective

motor

Replace

rnotor

Wiper

speed

does

not

change

Defective

switch

or

improper

switch

contact

Replace

or

repair

switch

Wiper

does

not

stop

Improper

switch

contact

Replace

or

repair

switch

Irnproperly

grounded

switch

Repair

Improper

adjustment

of

aut

stop

point

Replace

motor

Noisy

wiper

motor

Defective

motor

Replace

motor

8E

2B

Page 265 of 513

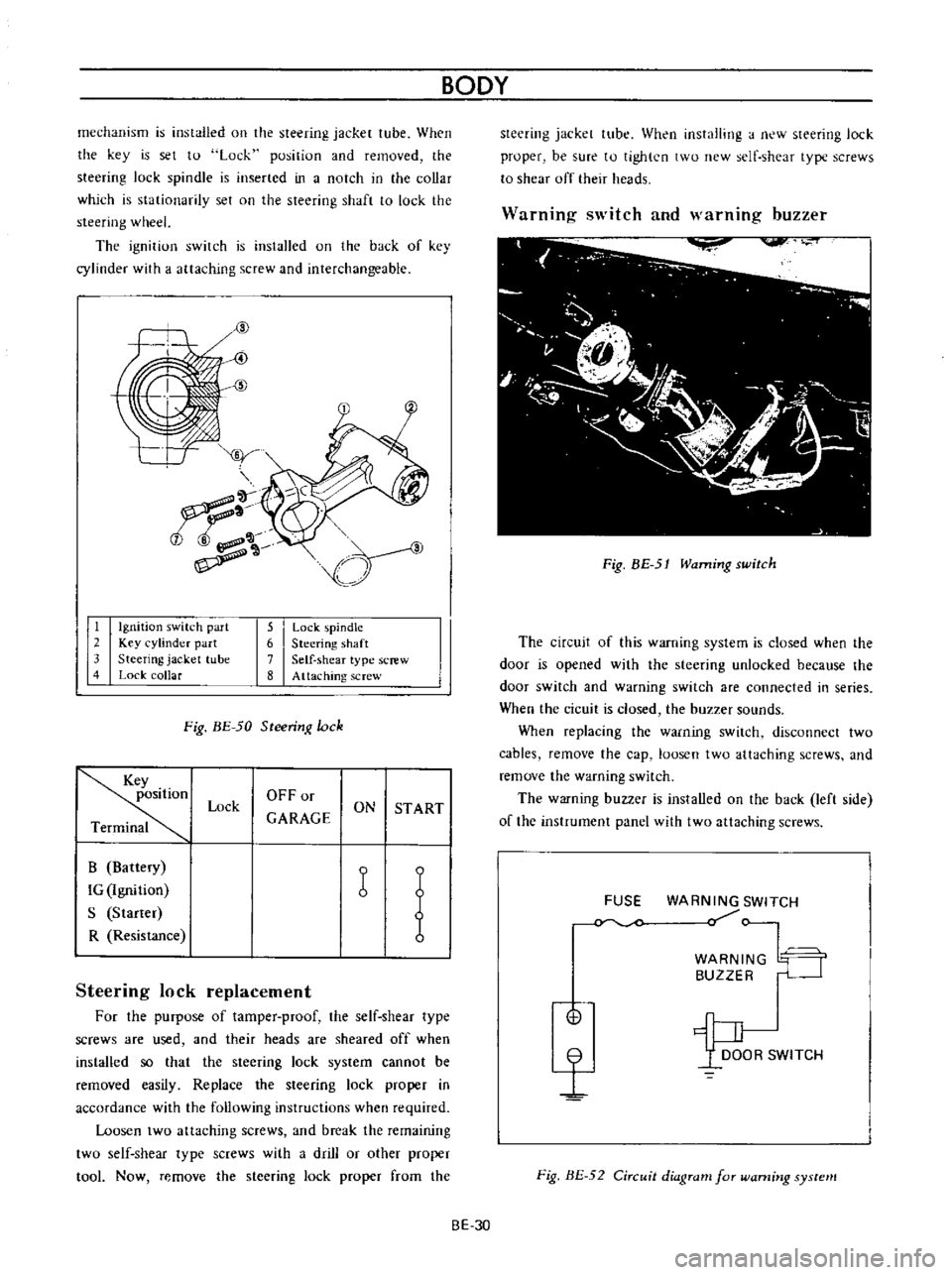

mechanism

is

installed

on

the

steering

jacket

tube

When

the

key

is

set

to

Lock

position

and

removed

the

steering

lock

spindle

is

inserted

in

a

notch

in

the

collar

which

is

stationarity

set

on

the

steering

shaft

to

lock

the

steering

wheel

The

ignitiun

switch

is

installed

on

the

back

of

key

cylinder

with

a

attaching

screw

and

interchangeable

tf

iY

t

7

a

1

Ignition

switch

part

2

Key

cylinder

part

3

Steering

jacket

tube

4

Lock

collar

5

Lock

pindle

6

Steering

shaft

7

Self

shear

type

screw

8

Attaching

screw

Fig

BE

50

Steering

lock

Key

position

Terminal

OFFor

GARAGE

Lock

ON

ST

ART

B

Battery

IG

Ignition

S

Starter

R

Resistance

b

1

Steering

lock

replacement

For

the

purpuse

of

tamper

proof

the

self

shear

type

screws

are

used

and

their

heads

are

sheared

off

when

installed

so

that

the

steering

lock

system

cannot

be

removed

easily

Replace

the

steering

lock

proper

in

accordance

with

the

following

instructions

when

required

Loosen

two

attaching

screws

and

break

the

remaining

twu

self

shear

type

screws

with

a

drill

or

other

proper

tool

Now

remove

the

steering

lock

proper

from

the

BODY

BE

30

steering

jacket

tube

When

installing

a

new

steering

lock

proper

be

sure

tu

tighten

two

new

self

shear

type

screws

to

shear

off

their

heads

Warning

switch

and

warnmg

buzzer

Fig

BE

51

Warning

switch

The

circuit

of

this

warning

system

is

closed

when

the

door

is

opened

with

the

steering

unlocked

because

the

door

switch

and

warning

switch

are

connected

in

series

When

the

cicuit

is

closed

the

buzzer

sounds

When

replacing

the

warning

switch

disconnect

two

cables

remove

the

cap

loosen

two

attaching

screws

and

remove

the

warning

switch

The

warning

buzzer

is

installed

on

the

back

left

side

of

the

instrument

panel

with

two

attaching

screws

FUSE

WARNING

SWITCH

WARN

BUZZ

G

n

WITCH

t

Fig

BE

52

Circuit

diagram

for

warning

system

Page 267 of 513

BODY

RADIO

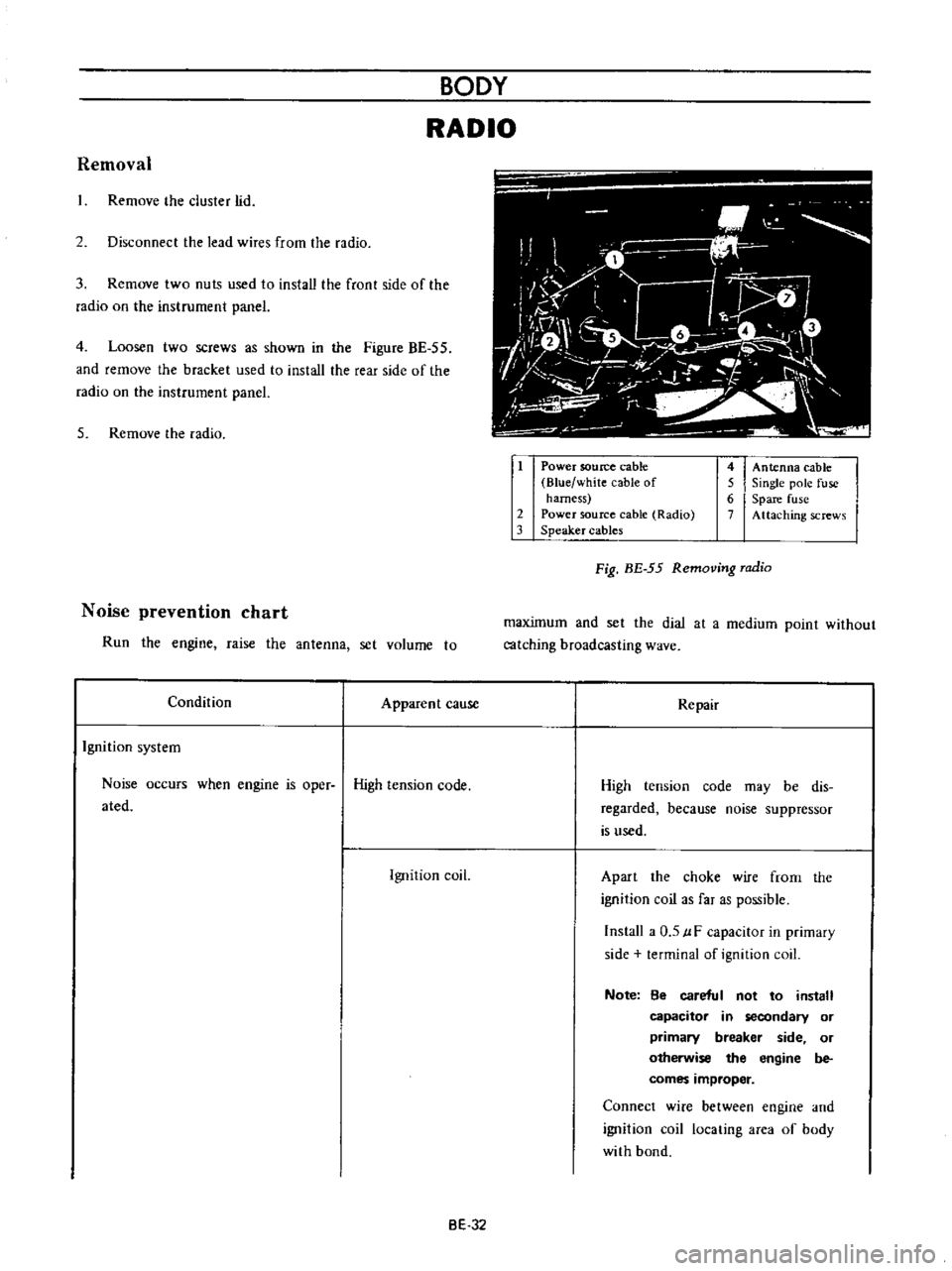

Removal

Remove

he

cluster

lid

2

Disconnect

the

lead

wires

from

the

radio

3

Remove

two

nuts

used

to

install

the

front

side

of

the

radio

on

the

instrument

panel

4

Loosen

two

screws

as

shown

in

the

Figure

BE

55

and

remove

the

bracket

used

to

install

the

rear

side

of

the

radio

on

the

instrument

panel

5

Remove

the

radio

Noise

prevention

chart

Run

the

engine

raise

the

antenna

set

volume

to

Condition

Apparent

cause

Ignition

system

Noise

occurs

when

engine

is

oper

High

tension

code

ated

Ignition

coil

i

O

i

M

1

iiJ

1

7

L

l

o

f

I

ft

V

r

1

1

v

I

I

t

i

J

iL

1

Power

soutee

cable

Blue

white

cable

of

harness

2

Power

source

cable

Radio

3

Speaker

cables

4

Antenna

cable

5

Single

pole

fuse

6

Spare

fuse

7

Attaching

screws

Fig

BE

55

Removing

radio

maximum

and

set

the

dial

at

a

medium

point

without

catching

broadcasting

wave

Repair

High

tension

code

may

be

dis

regarded

because

noise

suppressor

is

used

Apart

the

choke

wire

frorn

the

ignition

coil

as

far

as

possible

Install

a

0

5

uF

capacitor

in

primary

side

terminal

of

ignition

coil

Note

8e

careful

not

to

install

capacitor

in

secondary

or

primary

breaker

side

or

otherwise

the

engine

be

comes

improper

Connect

wire

between

engine

and

ignition

coil

locating

area

of

body

with

bond

BE

32