fuse DATSUN B110 1973 Service Repair Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1973, Model line: B110, Model: DATSUN B110 1973Pages: 513, PDF Size: 28.74 MB

Page 48 of 513

Assembly

I

Prior

10

assemlbing

dip

all

parts

in

clean

automatic

transmission

fluid

Reverse

disassembly

procedure

to

assemble

brake

2

Use

extreme

care

to

avoid

dam

aging

rubber

ring

when

installing

seal

lace

3

Blow

under

pressure

air

from

apply

side

of

piston

to

lislen

for

defi

nite

piston

operation

as

shown

in

Figure

AT

93

4

With

appIy

side

of

piston

plugged

with

thumb

blow

air

under

pressure

into

cylinder

from

release

side

as

shown

in

Figure

AT

94

If

retainer

is

raised

a

little

it

is

an

indication

that

attaching

bolts

are

loosened

calling

for

retightening

Governor

Disassembly

l

Separate

governor

from

oil

dis

tributor

by

unscrewing

attaching

bolts

2

To

disassemble

secondary

gover

nor

remove

spring

seat

spring

and

secondary

governor

valve

from

valve

body

in

this

written

order

as

shown

in

Figure

AT

95

3

If

primary

governor

is

to

be

dis

assembled

for

any

purpose

remove

spring

seat

primary

governor

valve

spring

and

spring

eal

CHASSIS

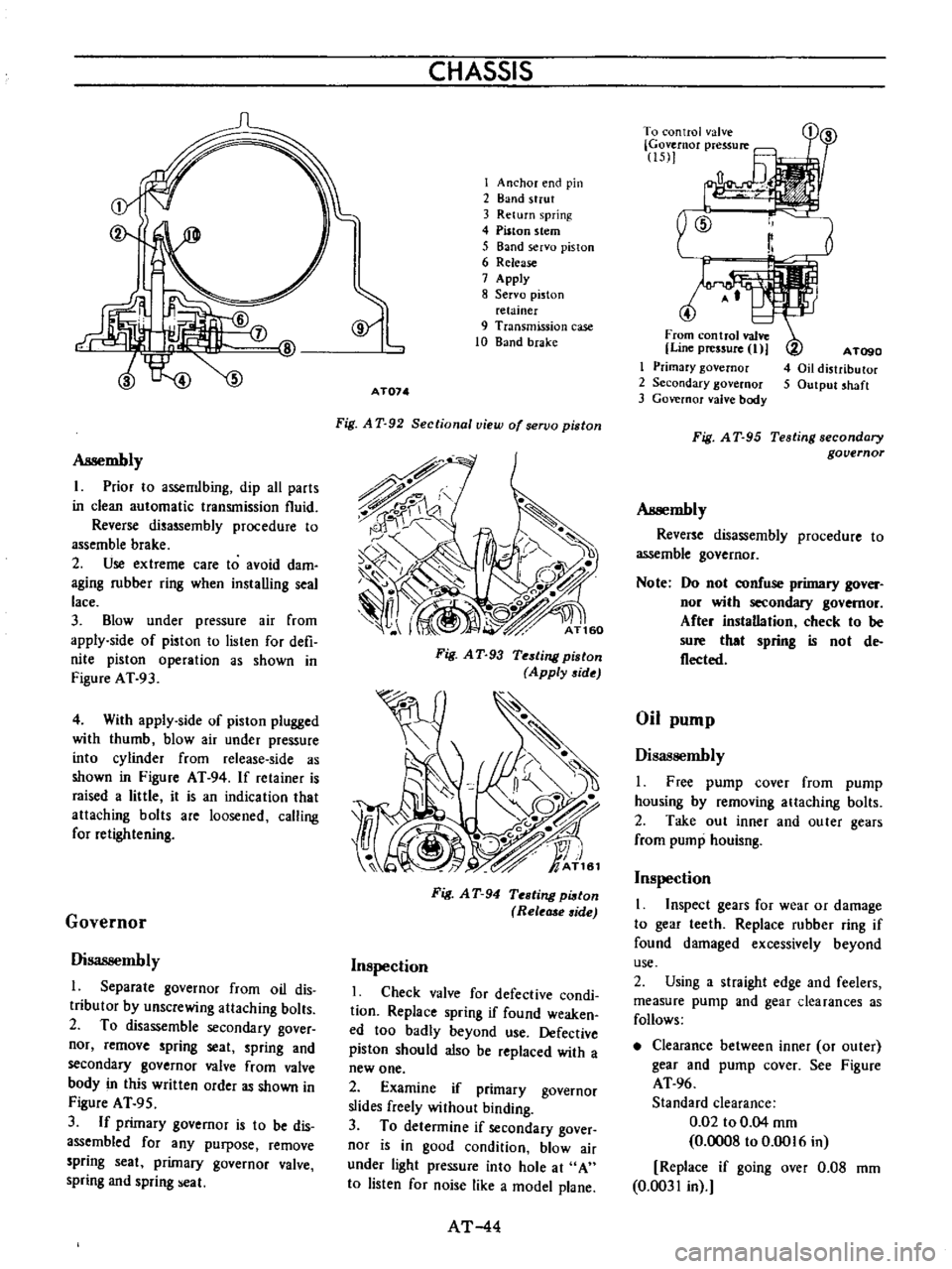

I

Anchor

end

pin

2

Band

strut

3

Return

spring

4

Piston

stem

5

Band

servo

piston

6

Release

7

Apply

8

Servo

piston

relainer

9

Transmission

case

10

Band

brake

AT074

Fig

A

T

92

Sectional

view

of

servo

piston

Fig

A

T

93

Testing

piston

Apply

side

Fig

A

T

94

Testing

pi8ton

Rele

side

Inspection

I

Check

valve

for

defective

condi

tion

Replace

spring

if

found

weaken

ed

too

badly

beyond

use

Defective

piston

should

also

be

replaced

with

a

new

one

2

Examine

if

primary

governor

slides

freely

without

binding

3

To

determine

if

secondary

gover

nor

is

in

good

condition

blow

air

under

light

pressure

into

hole

at

A

to

listen

for

noise

like

a

model

plane

AT

44

r

To

control

valve

Governor

pressure

15

1

4

From

control

valve

Line

pressure

I

I

Primary

governor

2

Secondary

governor

3

Governor

valve

body

A

TogO

4

Oil

distributor

5

Output

shaft

Fig

A

T

95

Testing

secondary

governor

Assembly

Reverse

disassembly

procedure

to

assemble

governor

Note

Do

nol

confuse

primary

gover

nor

wilh

secondary

governor

After

instaDation

check

to

be

sure

that

spring

is

nol

de

flecled

Oil

pump

Disassembly

I

Free

pump

cover

from

pump

housing

by

removing

attaching

bolts

2

Take

out

inner

and

outer

gears

from

pump

houisng

Inspection

1

Inspect

gears

for

wear

or

damage

to

gear

leeth

Replace

rubber

ring

if

found

damaged

excessively

beyond

use

2

Using

a

straight

edge

and

feelers

measure

pump

and

gear

clearances

as

follows

Clearance

between

inner

or

outer

gear

and

pump

cover

See

Figure

AT

96

Standard

clearance

0

02

to

0

04

mm

0

0008

to

0

0016

in

Replace

if

going

over

0

08

mm

0

0031

in

Page 73 of 513

CHASSIS

4

Remove

the

side

bearing

caps

and

take

out

the

differential

case

assembly

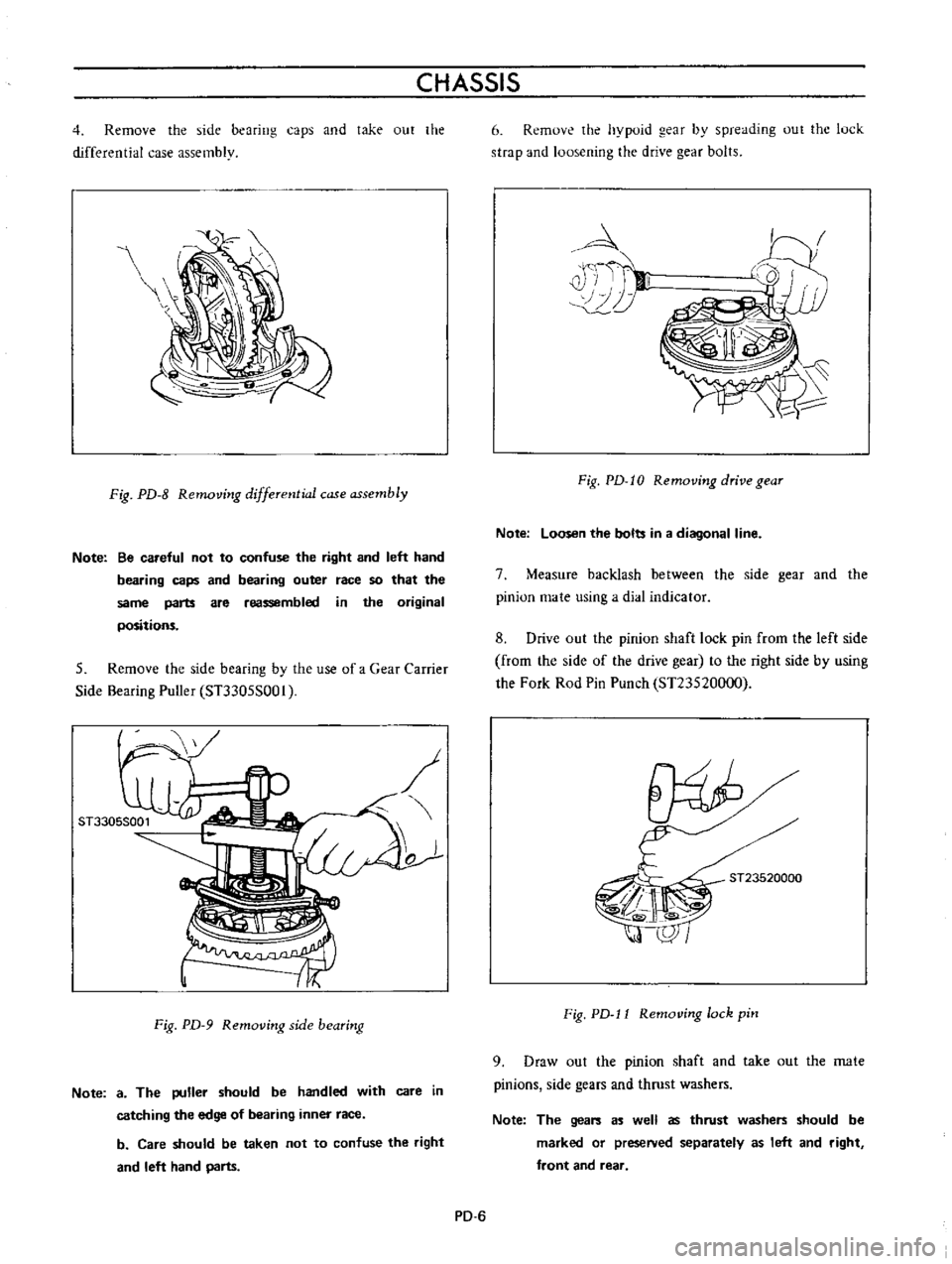

Fig

PD

8

Removing

differential

case

assembly

Note

Be

careful

not

to

confuse

the

right

and

left

hand

bearing

caps

and

bearing

outer

race

so

that

the

same

parts

are

reassembled

in

the

original

positions

5

Remove

the

side

bearing

by

the

use

of

a

Gear

Carrier

Side

Bearing

Puller

ST3305S001

o

Fig

PD

9

Removing

side

bearing

Note

a

The

puller

should

be

handled

with

care

in

catching

the

edge

of

bearing

inner

race

b

Care

should

be

taken

not

to

confuse

the

right

and

left

hand

parts

6

Remove

the

hypoid

gear

by

spreading

out

the

luck

strap

and

loosening

the

drive

gear

bolts

4

i

T

II

10

Fig

PD

I0

Removing

drive

gear

Note

Loosen

the

bolts

in

a

diagonal

line

7

Measure

backlash

between

the

side

gear

and

the

pinion

mate

using

a

dial

indicator

8

Drive

out

the

pinion

shaft

lock

pin

from

the

left

side

from

the

side

of

the

drive

gear

to

the

right

side

by

using

the

Fork

Rod

Pin

Punch

ST23520000

ST23520000

Fig

PD

l1

Removing

lock

pin

9

Draw

out

the

pinion

shaft

and

take

out

the

mate

pinions

side

gears

and

thrust

washers

Note

The

gears

as

well

as

thrust

washers

should

be

marked

or

preseNed

separately

as

left

and

right

front

and

rear

PD

6

Page 80 of 513

PROPELLER

SHAFT

DIFFERENTIAL

CARRIER

C

DMark

Unit

mm

in

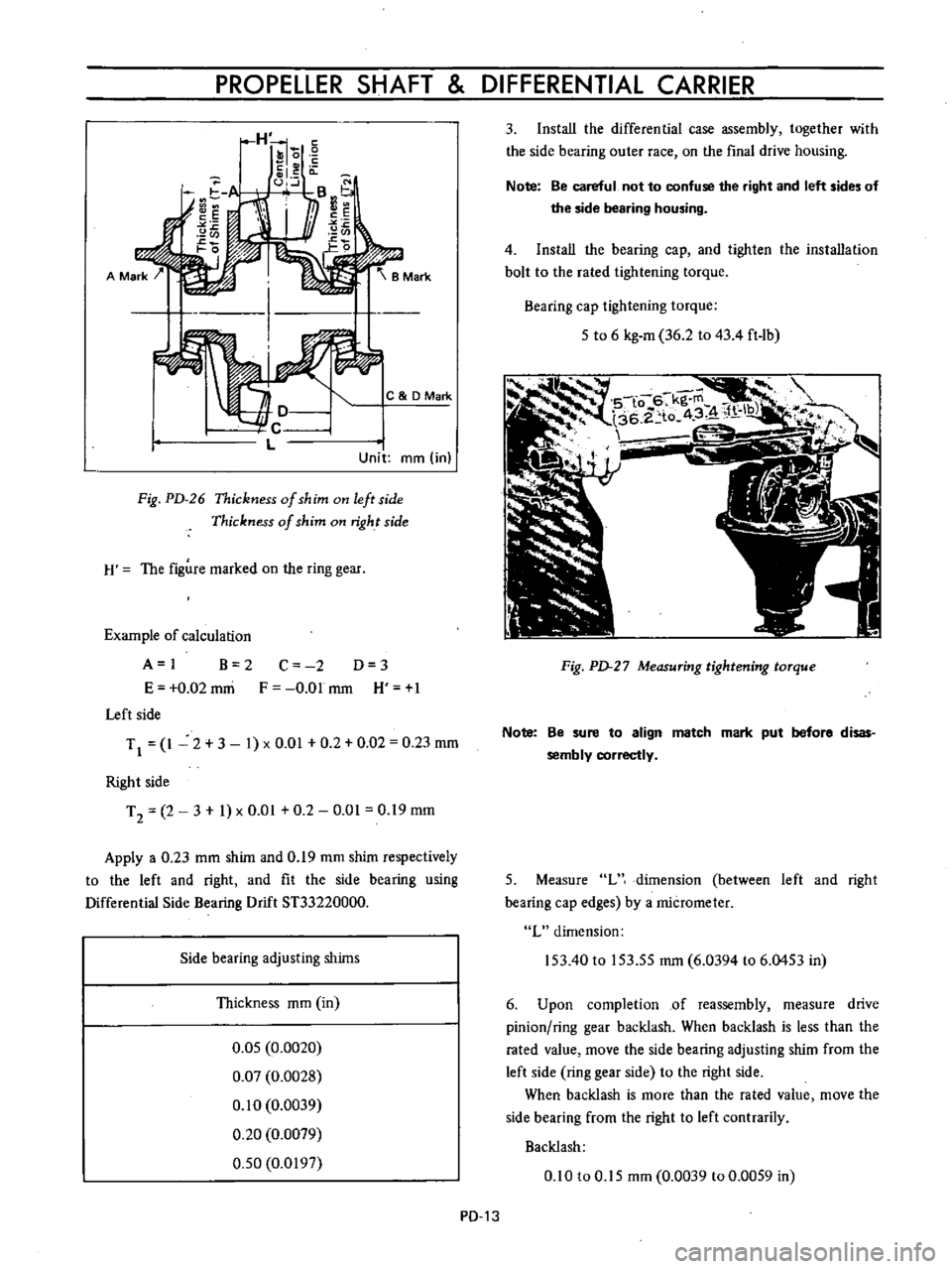

Fig

PD

26

Thickness

of

shim

on

left

side

Thickness

of

shim

on

right

side

H

The

figure

marked

on

the

ring

gear

Example

of

calculation

A

I

B

2

E

0

02

mni

Left

side

C

2

D

3

F

O

Olmm

H

1

TJ

1

2

3

1

xO

01

0

2

0

02

0

23

mm

Right

side

T

2

2

3

1

x

0

01

0

2

0

01

0

19

mm

Apply

a

0

23

mm

shim

and

0

19

mm

shim

respectively

to

the

left

and

right

and

fit

the

side

bearing

using

Differential

Side

Bearing

Drift

ST33220000

Side

bearing

adjusting

shims

Thickness

mm

in

0

05

0

0020

0

07

0

0028

0

10

0

0039

0

20

0

0079

0

50

0

0197

PD

13

3

Install

the

differential

case

assembly

together

with

the

side

bearing

outer

race

on

the

final

drive

housing

Note

Be

careful

not

to

confuse

the

right

and

left

sides

of

the

side

bearing

housing

4

Install

the

bearing

cap

and

tighten

the

installation

bolt

to

the

rated

tightening

torque

Bearing

cap

tightening

torque

5

to

6

kg

m

36

2

to

43

4

ft

1b

Fig

PD

27

Measuring

tightening

torque

Note

Be

sure

to

align

match

mark

put

before

disas

sembly

correctly

5

Measure

L

dimension

between

left

and

right

bearing

cap

edges

by

a

micrometer

L

dimension

153

40

to

153

55

mm

6

0394

to

6

0453

in

6

Upon

completion

of

reassembly

measure

drive

pinion

ring

gear

backlash

When

backlash

is

less

than

the

rated

value

move

the

side

bearing

adjusting

shim

from

the

left

side

ring

gear

side

to

the

right

side

When

backlash

is

more

than

the

rated

value

move

the

side

bearing

from

the

right

to

left

contrarily

Backlash

0

10

to

0

15

mm

0

0039

to

0

0059

in

Page 138 of 513

CHASSIS

Note

When

cleaning

rubber

parts

use

alcohol

or

brake

fluid

If

rubber

parts

are

cleaned

with

mineral

oil

they

will

be

deteriorated

1

Calipers

If

the

cylinder

wall

is

damaged

or

worn

replace

If

the

cylinder

wall

is

rusted

or

foreign

matters

are

accumu

lated

on

the

cylinder

wall

carefully

polish

with

fine

emery

paper

so

that

the

cylinder

wall

is

not

damaged

If

rusted

or

roughened

excessively

replace

2

Pad

See

paragraph

covering

replacement

of

pad

3

Piston

Replace

if

unevenly

worn

damaged

and

or

rusted

Note

The

piston

sliding

surface

is

plated

Thus

do

not

use

emery

paper

although

rusted

or

foreign

matters

are

Slicked

on

the

sliding

surface

4

Seals

Primarily

replace

both

piston

and

dust

seals

whenever

overhauling

Note

The

piston

seal

affects

not

only

leaking

but

also

piston

return

For

this

reason

replace

the

piston

seal

even

if

the

damage

is

minor

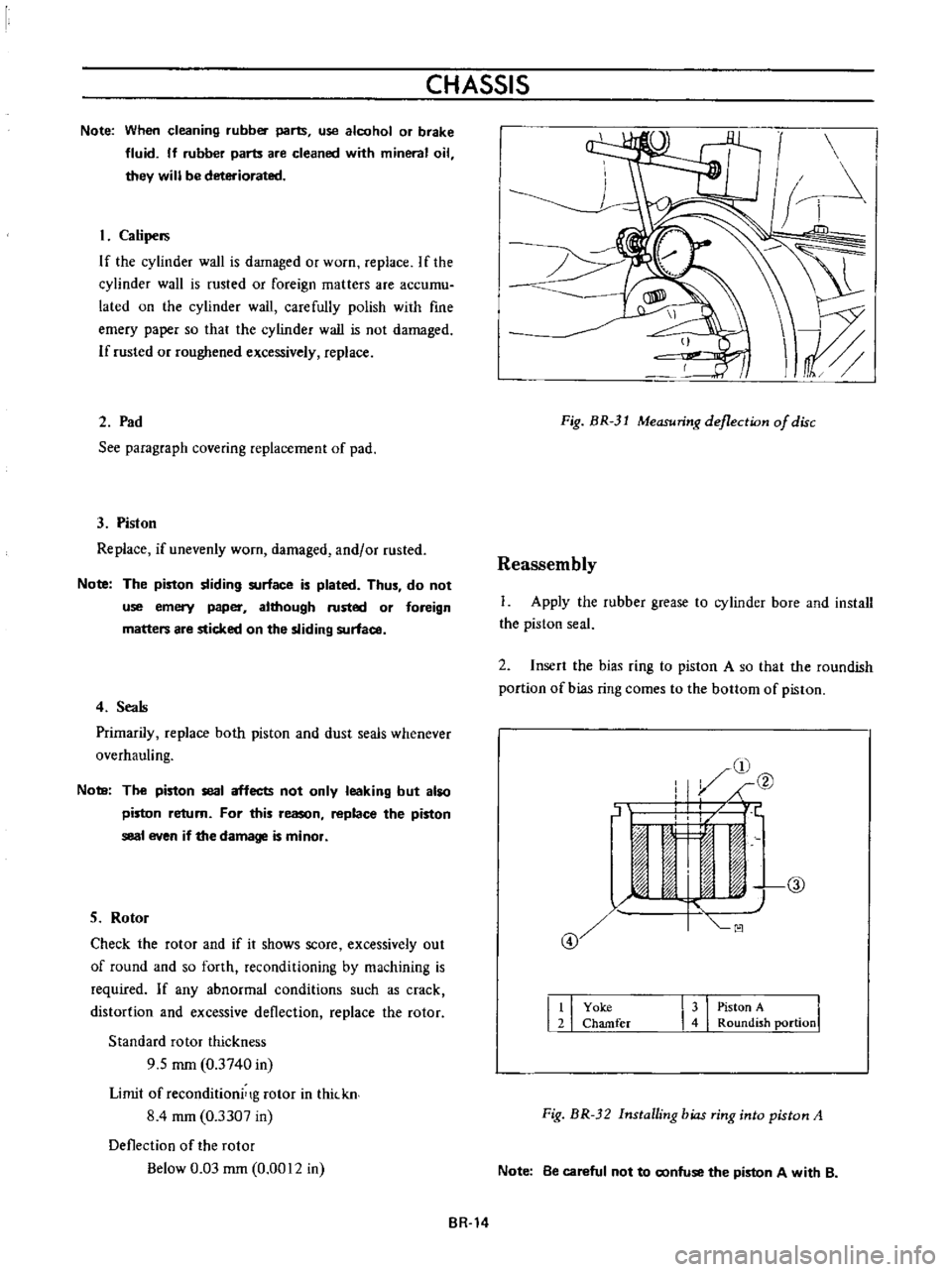

S

Rotor

Check

the

rotor

and

if

it

shows

score

excessively

out

of

round

and

so

forth

reconditioning

by

machining

is

required

If

any

abnormal

conditions

such

as

crack

distortion

and

excessive

deflection

replace

the

rotor

Standard

rotor

thickness

9

5

mm

0

3740

in

Limit

of

reconditionillg

rotor

in

thkkn

8

4

mm

0

3307

in

Deflection

of

the

rotor

Below

0

03

mm

0

0012

in

I

I

I

I

ri

U

h

J

r

Fig

BR

1

Measuring

deflection

of

disc

Reassembly

Apply

the

rubber

grease

to

cylinder

bore

and

install

the

piston

seal

2

Insert

the

bias

ring

to

piston

A

so

that

the

roundish

portion

of

bias

ring

comes

to

the

bottom

of

piston

1

ilY

f@

I

I

C

I

1

n

tL

c

ffi

1

1

fJ

u

IZ

@

I

I

Yoke

Chamfer

13

PistonA

I

4

Roundish

portion

Fig

BR

32

Installing

bias

ring

into

piston

A

Note

Be

careful

not

to

confuse

the

piston

A

with

B

BR

14

Page 200 of 513

pointer

used

at

the

rearward

lut

atiol1

With

the

proper

scttings

the

tram

bar

will

be

on

a

piane

parallel

to

that

of

the

body

The

exception

to

this

would

be

wht

n

one

of

the

reterence

locations

is

induded

in

the

misaligned

area

then

the

parallel

plane

between

the

body

and

the

tram

bar

may

not

prevail

After

completiun

of

the

repairs

the

tram

gauge

should

be

set

at

the

specitled

dimension

to

check

the

accuracy

of

the

repair

operation

CAR

PREPARATION

Preparing

the

car

for

the

underbody

alignment

check

involves

the

following

Place

the

car

on

a

level

surface

2

The

weight

of

the

car

should

be

supported

at

the

wheel

locations

3

A

visual

damage

inspection

should

be

made

to

eliminate

unnecessary

measuring

Obviously

damaged

or

misaligned

areas

may

often

be

located

visually

BODY

TRAMMING

SEQUENCE

The

tramming

sequence

will

varv

depending

upon

the

nature

and

IOl

atiun

uf

the

misaligned

area

Priur

to

performing

any

tramming

uperation

the

h

uracy

of

refereJlce

points

to

be

used

must

be

determined

A

measurement

that

originates

from

a

reference

point

included

in

a

damaged

area

will

produce

untrue

results

and

confuse

the

evaluation

of

the

underbody

condition

Unlike

the

conventional

type

of

frame

design

the

unitized

type

of

body

construction

seldom

develops

the

condition

of

diamond

in

the

floor

pan

area

as

a

result

of

front

or

rear

end

collision

Therefore

underbody

alignment

checking

can

usually

originate

from

the

body

floor

pan

area

If

inspection

indicates

that

these

locations

have

been

disturbed

and

are

not

suitable

for

measuring

one

of

the

undamaged

suspension

locations

should

be

used

as

an

initial

reference

point

If

a

rare

situation

should

exist

where

all

of

these

lucalions

are

not

suitable

as

reference

points

repair

operations

should

begin

with

the

body

floor

pan

area

All

other

underbody

components

should

be

aligned

progressively

from

this

area

MEMO

BF

10

Page 235 of 513

DATSUN

1200

MODEL

B

11

0

SERIES

I

NISSAN

I

NISSAN

MOTOR

CO

LTD

TOKYO

JAPAN

SECTION

BE

BODY

ELECTRICAL

WIRING

FUSE

LIGHTING

SYSTEM

HORN

METERS

AND

GAUGES

WINDSHIELD

WIPER

AND

WASHER

IGNITION

SWITCH

AND

STEERING

LOCK

CLOCK

RADIO

HEATER

BE

1

BE

6

BE

7

BE

15

BE

18

BE

26

BE

29

BE

31

BE

32

BE

34

Page 241 of 513

INSPECTION

Referring

to

the

wiring

diagram

check

the

wiring

harness

for

connection

with

electrical

equipment

and

connector

for

conned

ion

and

installation

When

checking

the

wiring

harness

note

the

following

matters

Connected

unit

should

not

be

loose

rusted

or

contaminated

2

Cable

insulator

cover

should

not

be

damaged

crack

ed

or

insulating

material

should

not

be

deteriorated

3

For

those

parts

which

are

grounded

through

the

installation

bolts

the

bolts

should

be

in

contact

with

the

body

completely

so

that

continuity

is

provided

in

between

the

body

and

bolts

4

Terminals

of

unit

through

which

current

flows

should

not

come

into

contact

with

other

metal

parts

5

No

erroneous

connection

should

be

present

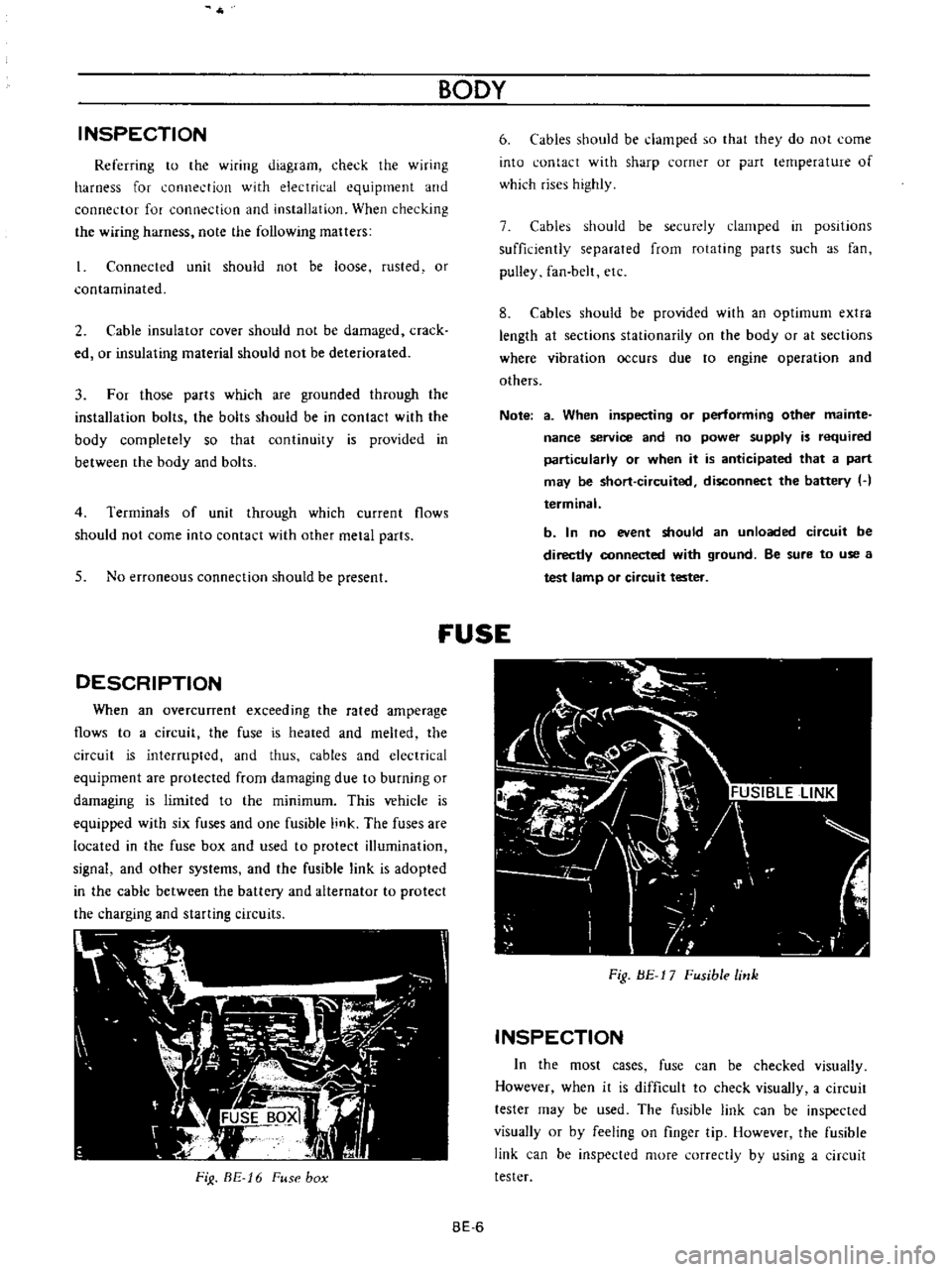

DESCRIPTION

When

an

overcunent

exceeding

the

rated

amperage

flows

to

a

circuit

the

fuse

is

heated

and

melted

the

circuit

is

interrupted

and

thus

cables

and

electrical

equipment

are

protected

from

damaging

due

to

burning

or

damaging

is

limited

to

the

minimum

This

vehicle

is

equipped

with

six

fuses

and

one

fusible

link

The

fuses

are

located

in

the

fuse

box

and

used

to

protect

illumination

signal

and

other

systems

and

the

fusible

link

is

adopted

in

the

cable

between

the

battery

and

alternator

to

protect

the

charging

and

starting

circuits

FiJ

BE

16

Fuse

box

BODY

6

Cables

should

be

damped

so

that

they

do

not

come

into

contact

with

sharp

corner

or

part

lernperature

of

which

rises

highly

7

Cables

should

be

securely

clamped

in

posItions

sufficiently

separated

from

rotating

parts

such

as

fan

pulley

fan

belt

etc

8

Cables

should

be

provided

with

an

optimum

extra

length

at

sections

stationarity

on

the

body

or

at

sections

where

vibration

occurs

due

to

engine

operation

and

others

Note

a

When

inspecting

or

performing

other

mainte

nance

service

and

no

power

supply

is

required

particularly

or

when

it

is

anticipated

that

a

part

may

be

short

circuited

disconnect

the

battery

H

terminal

b

In

no

event

should

an

unloaded

circuit

be

directly

connected

with

ground

Be

sure

to

use

a

test

lamp

or

circuit

tester

fUSE

Fig

BE

17

Fusible

link

INSPECTION

In

the

most

cases

fuse

can

be

checked

visually

However

when

it

is

difficult

to

check

visually

a

circuit

tester

may

be

used

The

fusible

link

can

be

inspected

visually

or

by

feeling

on

finger

tip

However

the

fusible

link

can

be

inspected

more

correctly

by

using

a

circuit

tester

BE

6

Page 242 of 513

BODY

ELECTRICAL

Note

8

When

a

fuse

is

blown

off

be

sure

to

correct

the

cause

before

installing

new

fuse

b

Be

sure

to

use

fuse

having

the

rated

capacity

Do

not

use

fuse

having

larger

capacity

i

e

20A

JOA

etc

c

Particularly

when

the

fusible

link

is

fused

replace

with

a

designated

fusible

link

Green

color

link

for

model

8110

In

comparison

with

fuse

much

higher

current

flows

through

the

fusible

link

Moreover

it

is

important

to

eliminate

the

cause

of

blown

off

fusible

link

before

replacing

d

When

fuse

is

connected

incorrectly

and

the

contact

is

loose

voltage

drops

and

heat

are

gener

ated

resulting

abnormally

operated

electrical

equip

ment

Remove

dust

or

when

oxidized

polish

with

a

fine

emery

paper

so

that

the

contact

is

improved

LlGHTING

SYSTEM

CONTENTS

HEAD

LAMP

Descri

ption

Sealed

beam

replacement

Aiming

adjustment

FRONT

PARKING

AND

TURN

SIGNAL

SIDE

FLASHER

IMARKER

LAMP

AN

D

LICENSE

LAMP

REAR

COMBINATION

LAMPS

BULB

SPECIFICATIONS

TURN

SIGNAL

AND

DIMMER

COMBINATION

SWITCH

BE

7

BE

7

BE

7

BE

8

LAMP

BE

8

BE

9

BE10

BE10

HEAD

LAMP

Description

All

weather

type

sealed

beam

2

light

system

front

lamps

are

adopted

Each

lamp

of

both

side

head

lamps

is

provided

with

high

beam

filament

for

long

range

SOW

and

low

beam

filarnent

for

dipping

40W

In

other

words

the

lamp

is

of

a

double

filament

type

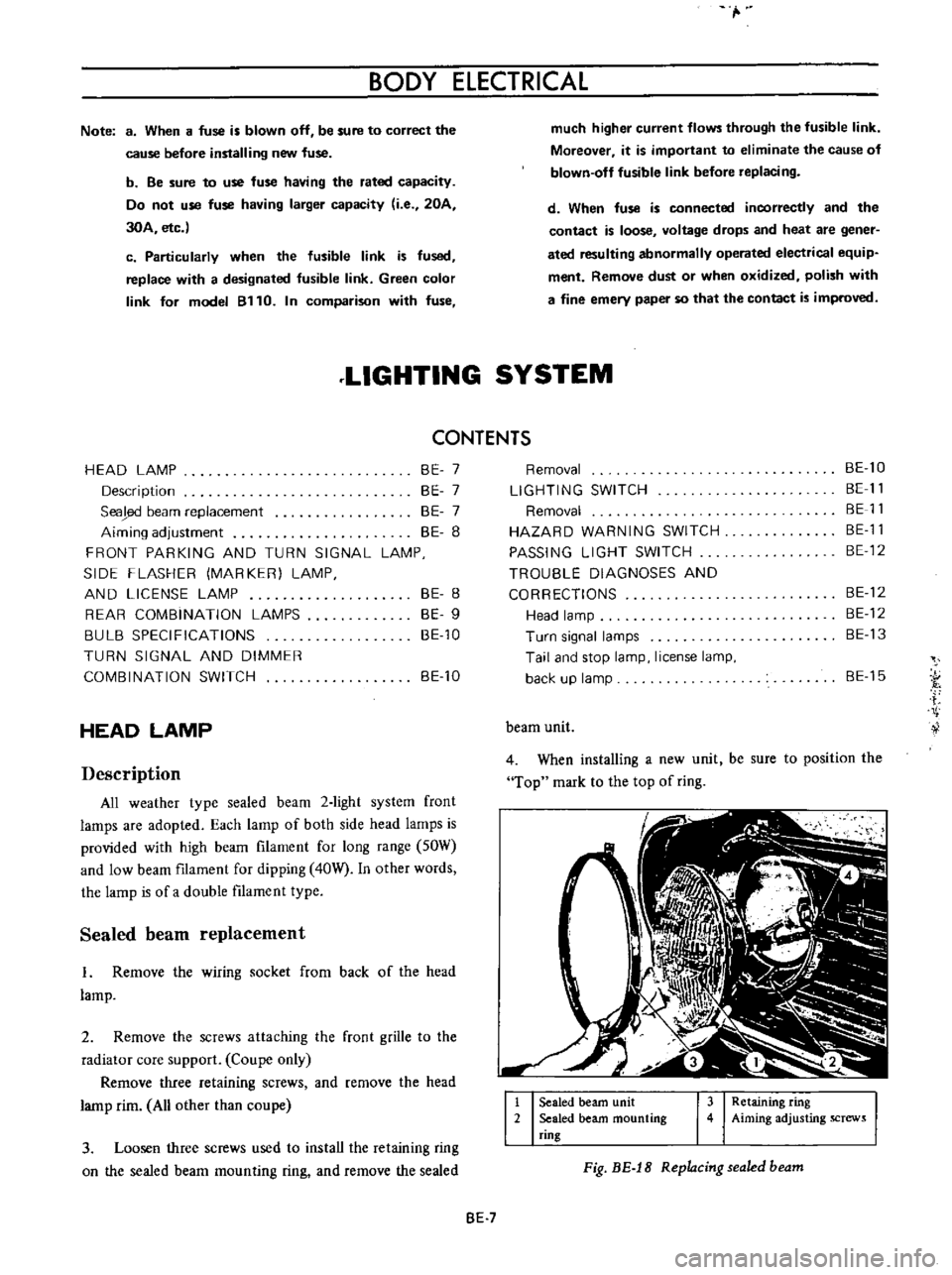

Sealed

beam

replacement

I

Rernove

the

wiring

socket

from

back

of

the

head

lamp

2

Remove

the

screws

attaching

the

front

grille

to

the

radiator

core

support

Coupe

only

Remove

three

retaining

screws

and

remove

the

head

lamp

rim

All

other

than

coupe

3

Loosen

three

screws

used

to

install

the

retaining

ring

on

the

sealed

bearn

mounting

ring

and

remove

the

sealed

Removal

LIGHTING

SWITCH

Removal

HAZARD

WARNING

SWITCH

PASSING

LIGHT

SWITCH

TROUBLE

DIAGNOSES

AND

CORRECTIONS

Head

lamp

Turn

signal

lamps

Tail

and

stop

lamp

license

lamp

back

up

lamp

BE

10

BE

11

BE

11

BE

11

BE

12

BE

12

BE

12

BE

13

BE

15

i

Ii

beam

unit

4

When

installing

a

new

unit

be

sure

to

position

the

Top

mark

to

the

top

of

ring

1

2

Sealed

beam

unit

Sealed

beam

mounting

ring

3

Retaining

ring

4

Aiming

adjusting

screws

Fig

BE

18

Replacing

sealed

beam

BE

7

Page 247 of 513

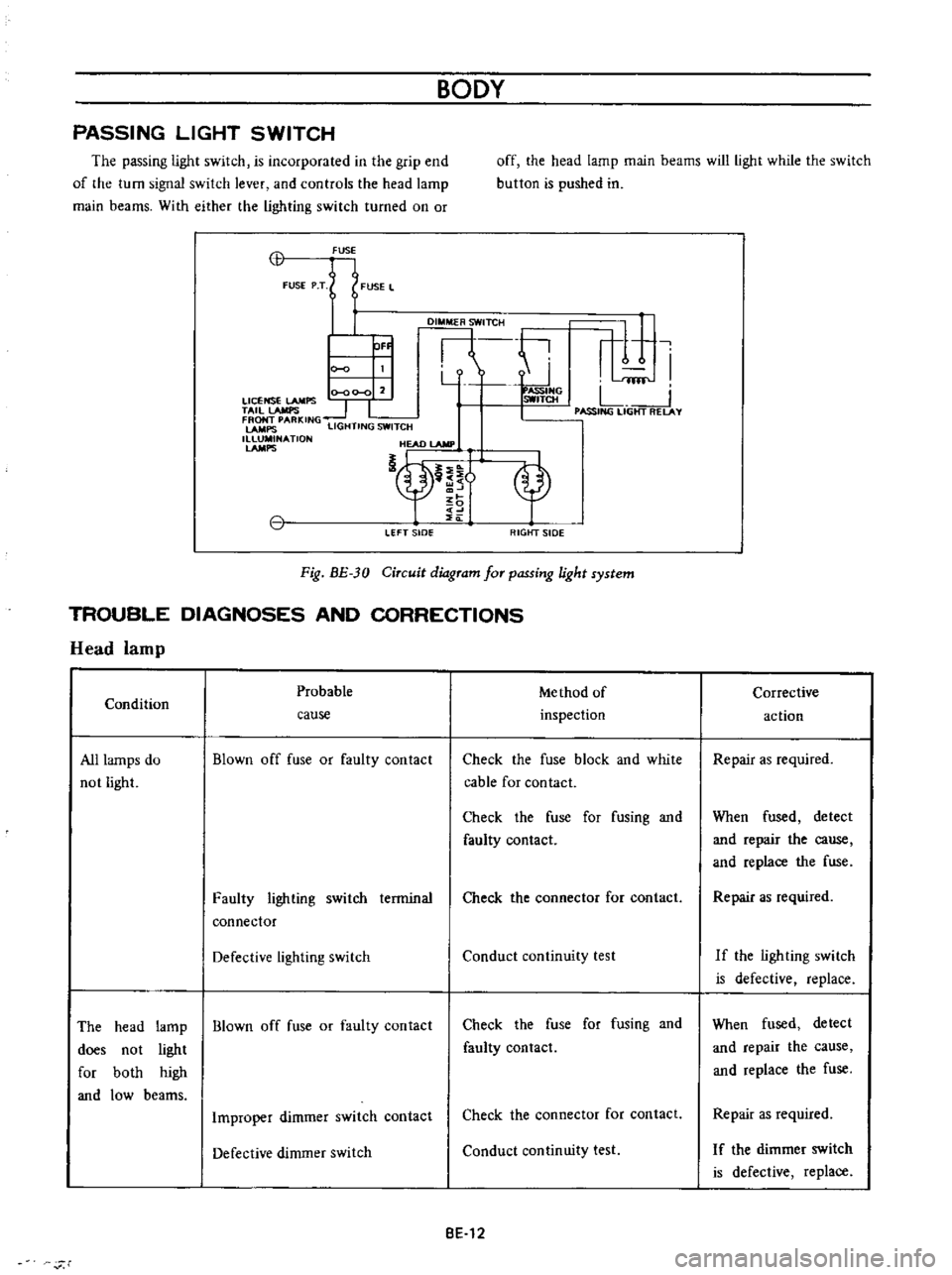

BODY

PASSING

LIGHT

SWITCH

The

passing

light

switch

is

incorporated

in

the

grip

end

of

the

turn

signal

switch

lever

and

controls

the

head

lamp

main

beams

With

either

the

lighting

switch

turned

on

or

off

the

head

lamp

main

beams

will

light

while

the

switch

button

is

pushed

in

CB

FUSE

FUSE

P

T

FUSE

L

DI

TCH

ti

r

1

I

Y

fflf

0

00

0

2

ASSIHG

LICENSE

LAMPS

SWITCH

L

TAil

lAMPS

1

I

I

PASSING

LIGHT

RELAY

FRONT

PARKING

LAMPS

LIGHTING

SWITCH

1

NATlON

HEAD

lAMP

nt

OF

LEFT

sIDe

RIGtfT

SIDE

Fig

BE

30

Circuit

diagram

for

passing

light

system

TROUBLE

DIAGNOSES

AND

CORRECTIONS

Head

lamp

Probable

Me

thod

of

Condition

inspection

cause

All

lamps

do

not

light

Blown

off

fuse

or

faulty

contact

Check

the

fuse

block

and

white

cable

for

contact

Check

the

fuse

for

fusing

and

faulty

contact

Faulty

lighting

switch

terminal

connector

Check

the

connector

for

contact

Defective

lighting

switch

Conduct

continuity

test

The

head

lamp

Blown

off

fuse

or

faulty

contact

does

not

light

for

both

high

and

low

beams

Check

the

fuse

for

fusing

and

faulty

contact

Improper

dimmer

switch

contact

Check

the

connector

for

contact

Defective

dimmer

switch

Conduct

continuity

test

BE

12

r

Corrective

action

Repair

as

required

When

fused

detect

and

repair

the

cause

and

replace

the

fuse

Repair

as

required

If

the

ligh

ting

swi

tch

is

defective

replace

When

fused

detect

and

repair

the

cause

and

replace

the

fuse

Repair

as

required

I

f

the

dimmer

switch

is

defective

replace

Page 248 of 513

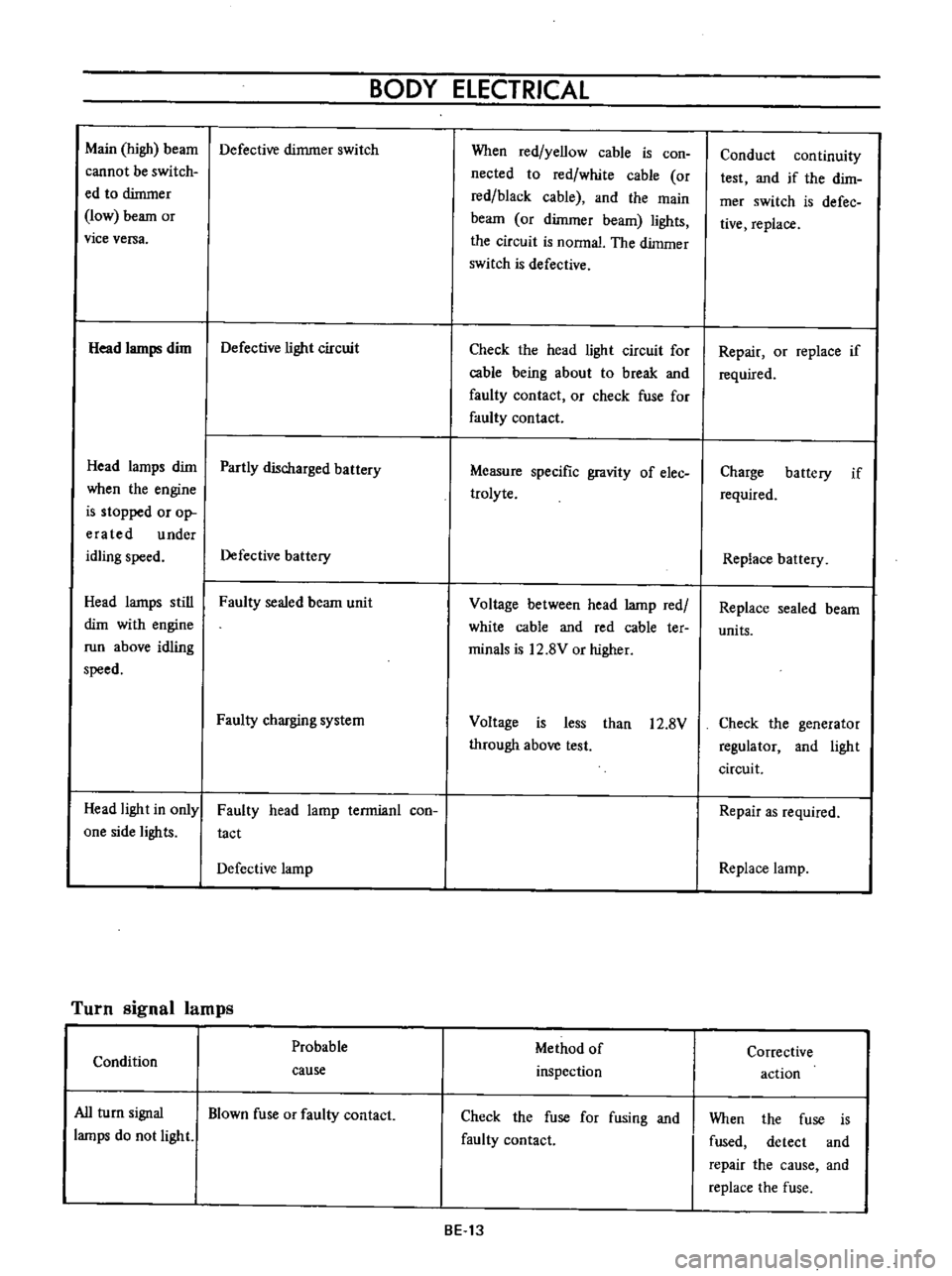

BODY

ELECTRICAL

Main

high

beam

Defective

dimmer

switch

cannot

be

switch

ed

to

dimmer

low

beam

or

vice

versa

Head

lamps

dim

Defective

light

circuit

Head

lamps

dim

Partly

discharged

battery

when

the

engine

is

stopped

or

op

era

ted

under

idling

speed

Defective

battery

Head

lamps

still

Faulty

sealed

beam

unit

dim

with

engine

run

above

idling

speed

Faulty

charging

system

Head

light

in

only

one

side

lights

Faulty

head

lamp

terrnianl

con

tact

Defective

lamp

Turn

signal

lamps

Probable

Condition

cause

All

turn

signal

Blown

fuse

or

faulty

contact

lamps

do

not

light

When

red

yellow

cable

is

con

nected

to

red

white

cable

or

red

black

cable

and

the

main

beam

or

dimmer

beam

lights

the

circuit

is

nonnal

The

dimmer

switch

is

defective

Check

the

head

light

circuit

for

cable

being

about

to

break

and

faulty

contact

or

check

fuse

for

faulty

contact

Measure

specific

gravity

of

elec

trolyte

Voltage

between

head

lamp

red

white

cable

and

red

cable

ter

minals

is

12

8V

or

higher

Voltage

is

less

than

12

8V

through

above

test

Method

of

inspection

Check

the

fuse

for

fusing

and

faulty

contact

BE

13

Conduct

continuity

test

and

if

the

dirn

mer

switch

is

defec

tive

replace

Repair

or

replace

if

required

Charge

battery

if

required

Replace

battery

Replace

sealed

beam

units

Check

the

generator

regulator

and

light

circuit

Repair

as

required

Replace

lamp

Corrective

action

When

the

fuse

is

fused

detect

and

repair

the

cause

and

replace

the

fuse