heater DATSUN B110 1973 Service User Guide

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1973, Model line: B110, Model: DATSUN B110 1973Pages: 513, PDF Size: 28.74 MB

Page 309 of 513

ENGINE

Checking

cooling

system

hoses

and

connections

Check

cooling

system

hoses

and

fiHings

for

loose

connections

and

deterioration

Retighten

or

replace

as

necessary

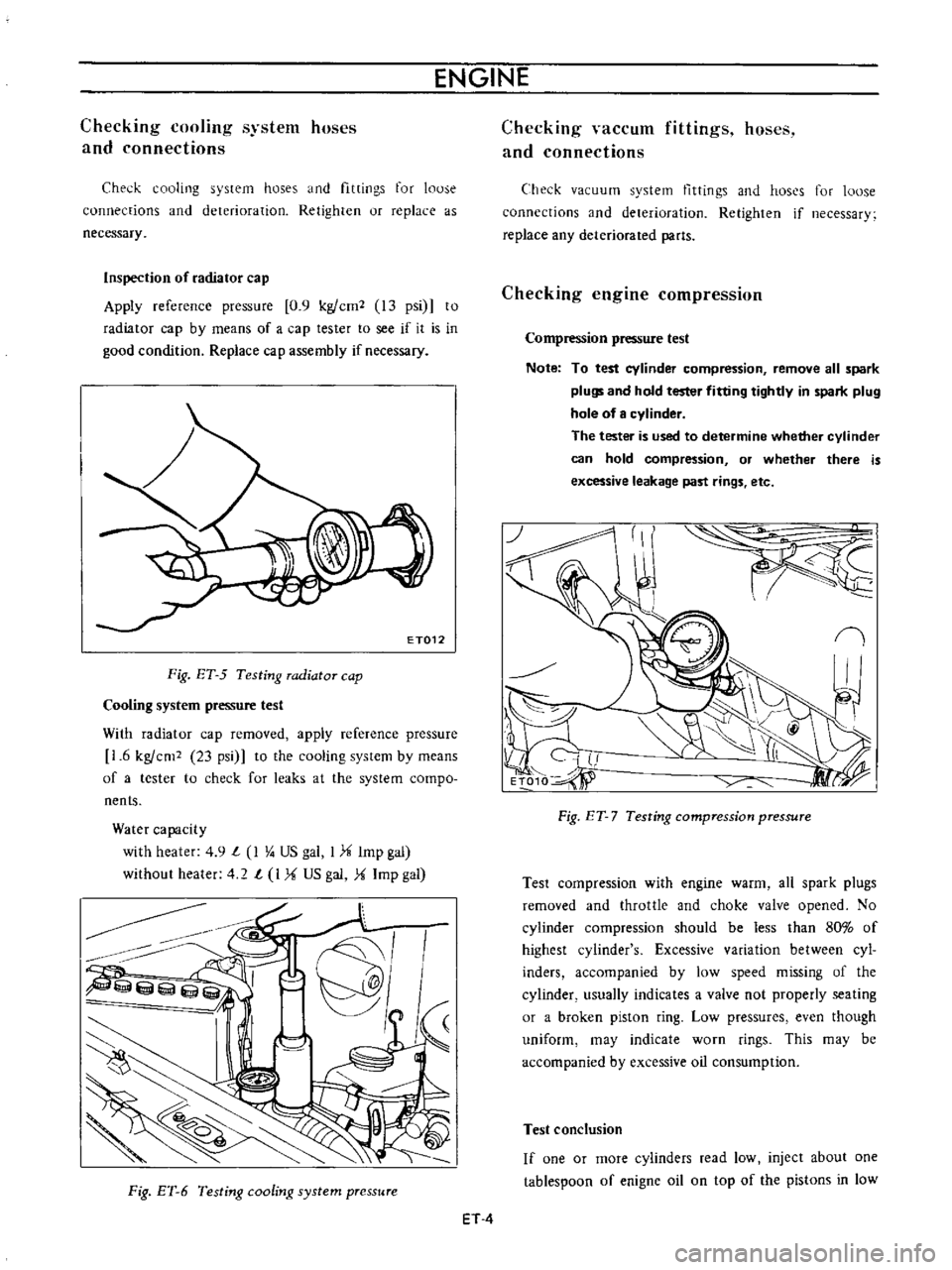

Inspection

of

radiator

cap

Apply

reference

pressure

0

9

kg

cm1

13

psi

to

radiator

cap

by

means

of

a

cap

tester

to

see

if

it

is

in

good

condition

Replace

cap

assembly

if

necessary

ET012

Fig

ET

5

Testing

radiator

cap

Cooling

system

pressure

test

With

radiator

cap

removed

apply

reference

pressure

1

6

kg

cm1

23

psi

to

the

cooling

system

bv

means

of

a

tester

to

check

for

leaks

at

the

system

compo

nents

Water

capacity

with

heater

4

9

l

I

Y

US

gal

l

i

Imp

gal

without

heater

4

2

l

I

i

US

gal

i

Imp

gal

Fig

ET

6

Testing

cooling

system

pressure

Checking

vaccum

fittings

hoses

and

connections

Check

vacuum

system

fittings

and

hoses

for

loose

connections

and

deterioration

Retighten

if

necessary

replace

any

deteriorated

parts

Checking

engine

compression

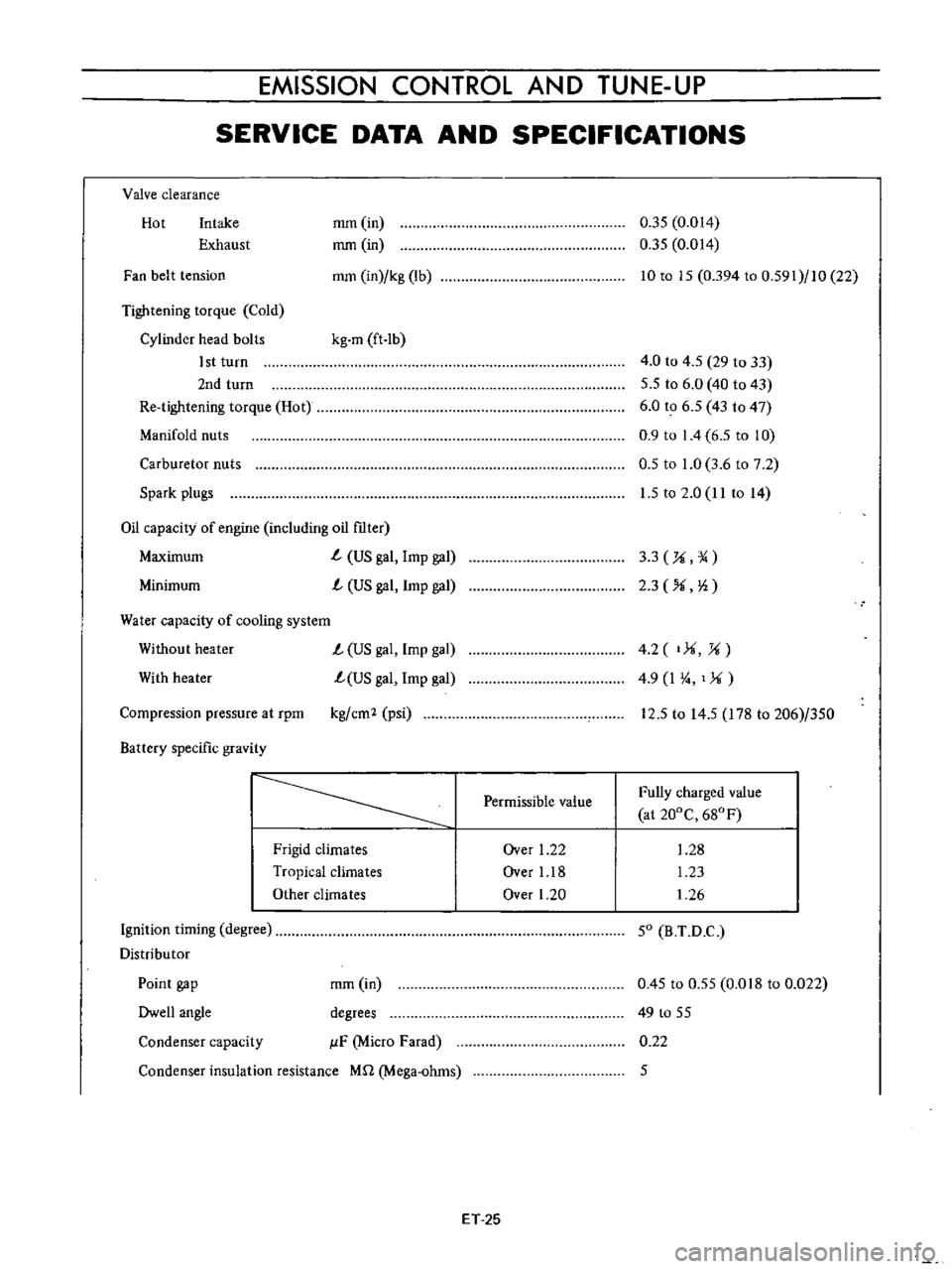

Compression

pressure

test

Note

To

test

cylinder

compression

remove

all

spark

plugs

and

hold

tester

fitting

tightly

in

spark

plug

hole

of

cylinder

The

tester

is

used

to

determine

whether

cylinder

can

hold

compression

or

whether

there

is

excessive

leakage

past

rings

etc

I

Td10

l

y

Fig

ET

7

Testing

compression

pressure

Test

compression

with

engine

warm

all

spark

plugs

removed

and

throttle

and

choke

valve

opened

No

cylinder

compression

should

be

less

than

80

of

highest

cylinder

s

Excessive

variation

between

cyl

inders

accompanied

by

low

speed

missing

of

the

cylinder

usually

indicates

a

valve

not

properly

seating

or

a

broken

piston

ring

Low

pressures

even

though

uniform

may

indicate

worn

rings

This

may

be

accompanied

by

excessive

oil

consumption

Test

conclusion

If

one

or

more

cylinders

read

low

inject

about

one

tablespoon

of

enigne

oil

on

top

of

the

pistons

in

low

ET

4

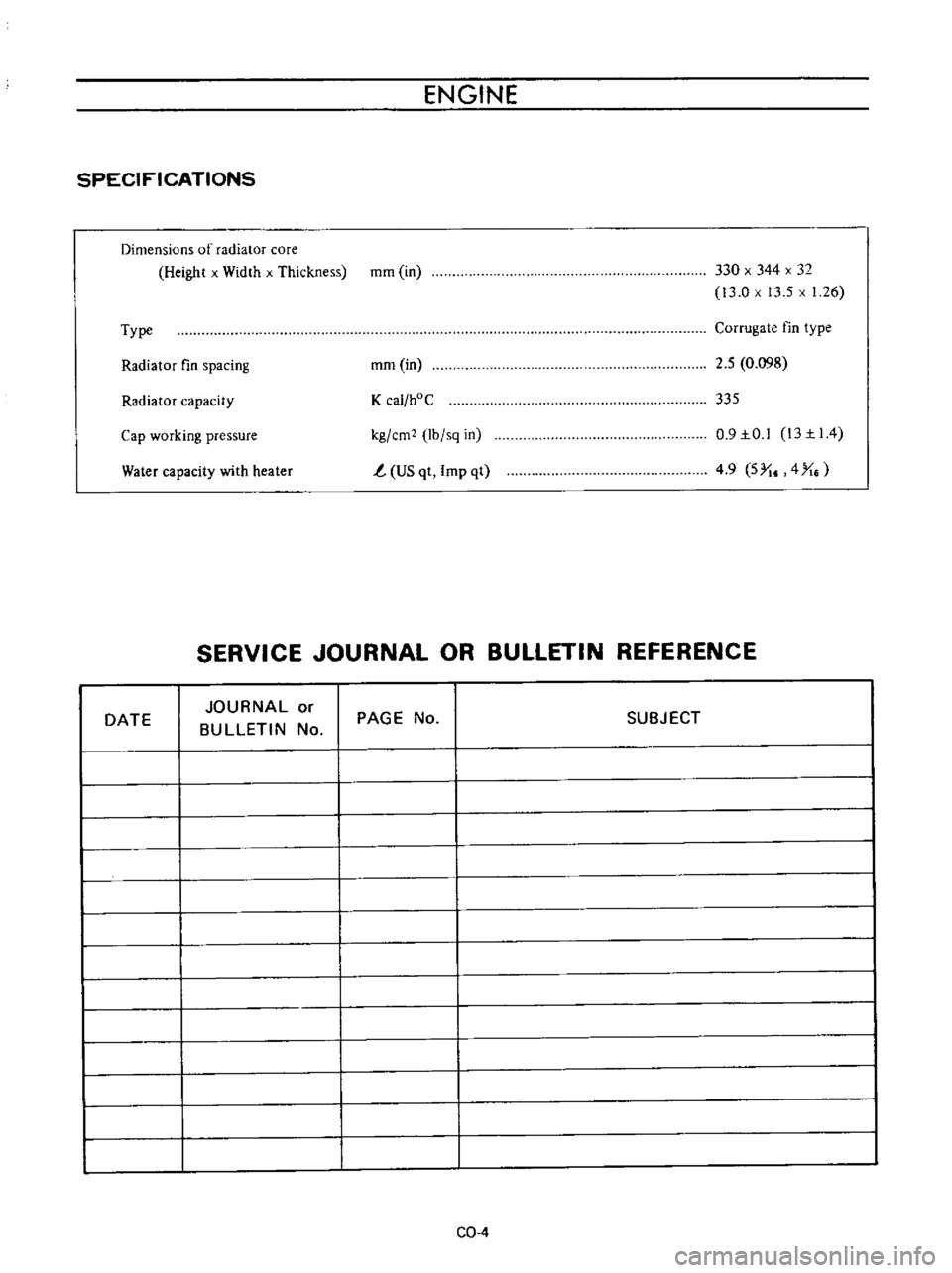

Page 330 of 513

EMISSION

CONTROL

AND

TUNE

UP

SERVICE

DATA

AND

SPECIFICATIONS

Valve

clearance

Hot

Intake

Exhaust

mm

in

rom

in

rom

in

kg

lb

0

35

0

014

0

35

0

014

10

to

15

0

394

to

0

591

10

22

Fan

belt

tension

Tightening

torque

Cold

Cylinder

head

bolts

kg

m

ft

lb

1st

turn

2nd

turn

Re

tightening

torque

Hot

Manifold

nuts

Carburetor

nuts

4

0

to

4

5

29

to

33

5

5

to

6

0

40

to

43

6

0

to

6

5

43

to

47

0

9

to

I

4

6

5

to

10

0

5

to

1

0

3

6

to

7

2

1

5

to

2

0

II

to

14

Spark

plugs

Oil

capacity

of

engine

including

oil

ftIter

Maximum

L

US

gal

Imp

gal

L

US

gal

Imp

gal

3

3

U

14

2

3

Ii

Minimum

Water

capacity

of

cooling

system

Without

heater

L

US

gal

Imp

gal

With

heater

L

US

gal

Imp

gal

4

2

1

U

4

9

I

4

11

12

5

to

14

5

I78

to

206

350

Compression

pressure

at

rpm

kg

em

psi

Battery

specific

gravity

Permissible

value

Fully

charged

value

at

200C

680F

Frigid

climates

Tropical

climates

Other

elima

tes

Over

1

22

Over

1

18

Over

1

20

1

28

1

23

1

26

Ignition

timing

degree

Distributor

50

B

T

D

C

Condenser

capacity

mm

in

degrees

IlF

Micro

Farad

0

45

to

0

55

0

018

to

0

022

49

to

55

0

22

5

Point

gap

Dwell

angle

Condenser

insulation

resistance

Mil

Mega

ohms

ET

25

Page 390 of 513

ENGINE

SPECIFICATIONS

Dimensions

of

radiator

core

Height

x

Width

x

Thickness

mm

in

330

x

344

x

32

13

0

x

13

5

x

1

26

Type

Corrugate

fin

type

Radiator

fin

spacing

mm

in

2

5

0

098

Radiator

capacity

K

cal

hoC

335

Water

capacity

with

heater

kg

em

lb

sq

in

t

US

qt

Imp

qt

0

9IO

l

13II4

4

9

5

I

4

X

Cap

working

pressure

SERVICE

JOURNAL

OR

BULLETIN

REFERENCE

DATE

JOURNAL

or

BULLETIN

No

PAGE

No

SUBJECT

CQ

4

Page 403 of 513

ENGINE

Step

system

The

construction

of

this

system

corresponds

to

the

idling

and

slow

system

of

the

primary

system

This

system

aims

at

the

power

filling

up

of

the

gap

when

fuel

supply

is

transferred

from

the

primary

system

to

the

secondary

system

The

step

port

is

located

near

the

auxiliary

valve

in

its

fully

closed

state

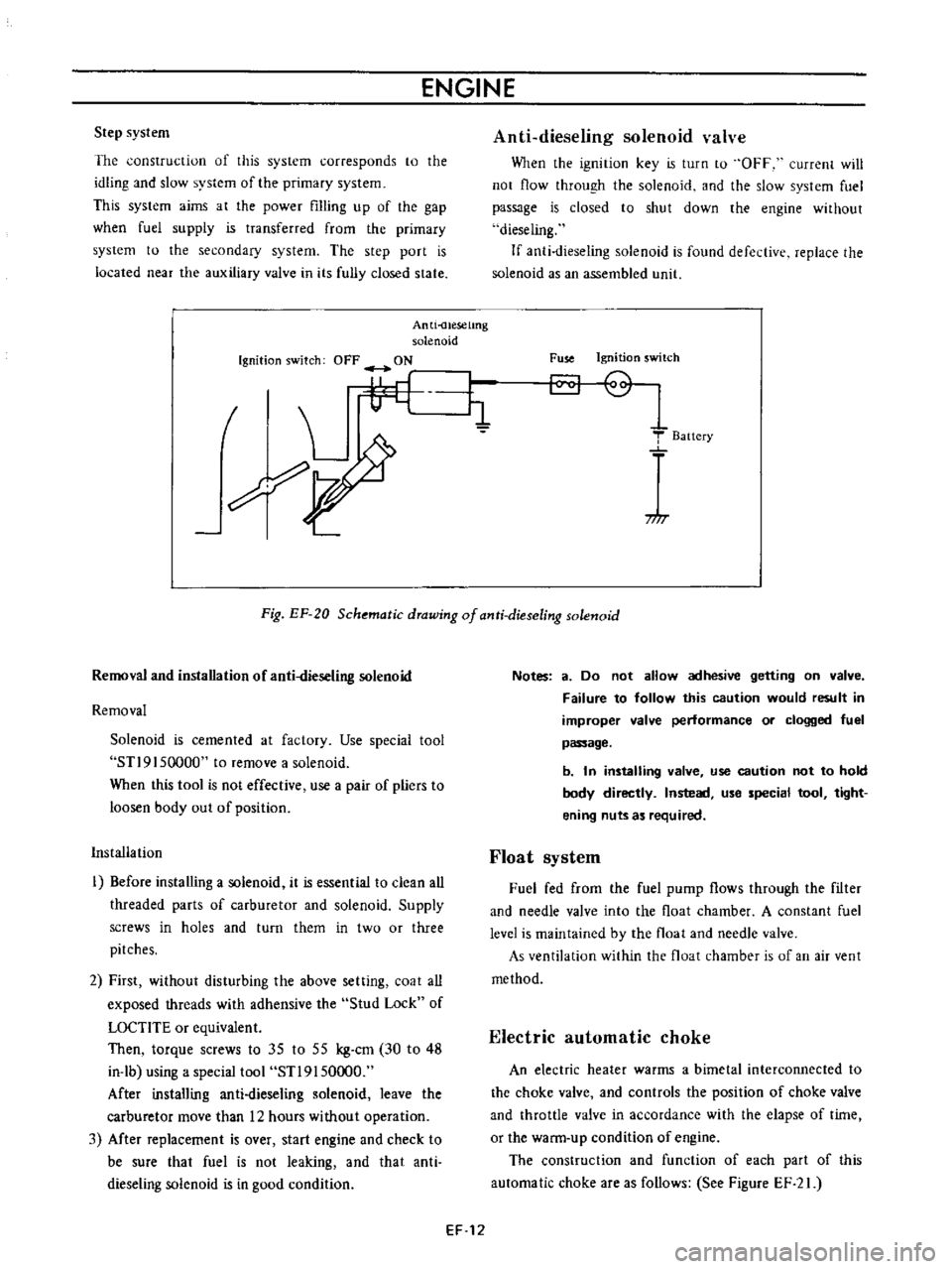

Anti

uesetmg

solenoid

Ignition

switch

OFF

ON

I

L

i1

7

I

Anti

dieseling

solenoid

valve

When

the

ignition

key

is

turn

to

OFF

current

will

not

flow

through

the

solenoid

and

the

slow

system

fuel

passage

is

closed

to

shut

down

the

engine

without

dieseling

If

anti

dieseling

solenoid

is

found

defective

replace

the

solenoid

as

an

assembled

llnit

Fuse

Ignition

switch

T

Baitery

717

Fig

EF

20

Schematic

drawing

of

anti

dieseling

solenoid

Removal

and

installation

of

anti

dieseling

solenoid

Removal

Solenoid

is

cemented

at

factory

Use

special

tool

STl9

I

50000

to

remove

a

solenoid

When

this

tool

is

not

effective

use

a

pair

of

pliers

to

loosen

body

out

of

position

Installation

I

Before

installing

a

solenoid

it

is

essential

to

clean

all

threaded

parts

of

carburetor

and

solenoid

Supply

screws

in

holes

and

turn

them

in

two

or

three

pitches

2

First

without

disturbing

the

above

setting

coat

all

exposed

threads

with

adhensive

the

Stud

Lock

of

LOCTlTE

or

equivalent

Then

torque

screws

to

35

to

55

kg

cm

30

to

48

in

lb

using

a

special

tool

STl9150000

After

installing

anti

dieseling

solenoid

leave

the

carburetor

move

than

12

hours

without

operation

3

Mter

replacement

is

over

start

engine

and

check

to

be

sure

that

fuel

is

not

leaking

and

that

anti

dieseling

solenoid

is

in

good

condition

Notes

a

Do

not

allow

adhesive

getting

on

valve

Failure

to

follow

this

caution

would

result

in

improper

valve

performance

or

clogged

fuel

passage

b

In

installing

valve

use

caution

not

to

hold

body

directly

Instead

use

special

tool

tight

ening

nuts

as

required

Float

system

Fuel

fed

from

the

fuel

pump

flows

through

the

filter

and

needle

valve

into

the

float

chamber

A

constant

fuel

level

is

maintained

by

the

float

and

needle

valve

As

ventilation

within

the

float

chamber

is

of

an

air

vent

method

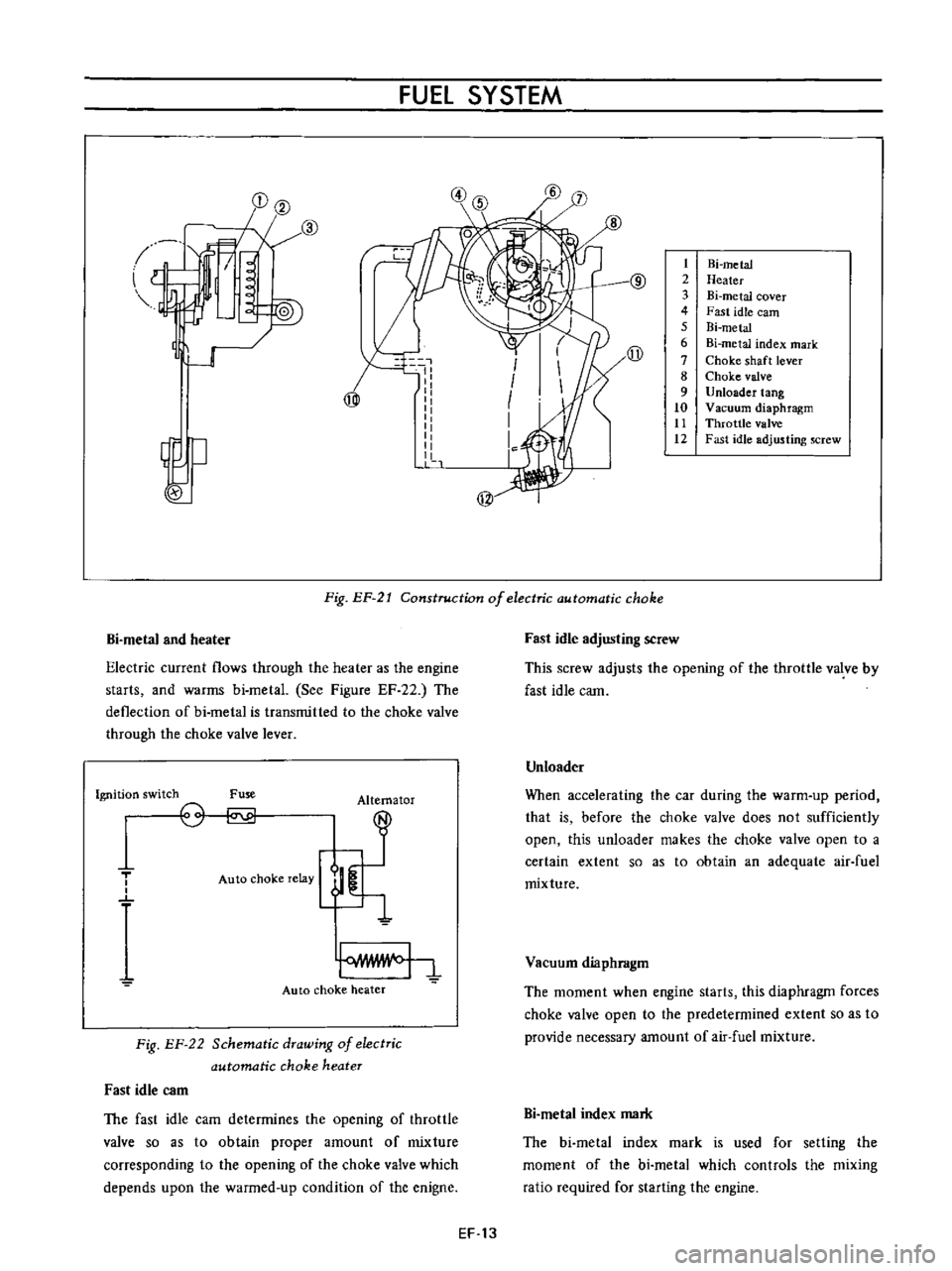

Electric

automatic

choke

An

electric

heater

warms

a

bimetal

interconnected

to

the

choke

valve

and

controls

the

position

of

choke

valve

and

throttle

valve

in

accordance

with

the

elapse

of

time

or

the

warm

up

condition

of

engine

The

construction

and

function

of

each

part

of

this

automatic

choke

are

as

follows

See

Figure

EF

21

EF

12

Page 404 of 513

FUEl

SYSTEM

l

I

@

1J

w

I

I

I

I

1

1

1

t

2

3

4

5

6

7

8

9

10

tt

12

Hi

metal

Heater

Bi

metal

cover

Fast

idle

earn

Bi

metal

Bi

metal

index

mark

Choke

shaft

lever

Choke

valve

Unloader

tang

Vacuum

diaphragm

Throttle

valve

Fast

idle

adjusting

screw

j

@

Fig

EP

21

Construction

of

electric

automatic

choke

Bi

metal

and

heater

Electric

current

flows

through

the

heater

as

the

engine

starts

and

warms

bi

metal

See

Figure

EF

22

The

deflection

of

bi

metal

is

transmitted

to

the

choke

valve

through

the

choke

valve

lever

Ignition

switch

Fuse

Alternator

T

o

o

Auto

choke

relay

Auto

choke

heater

Fig

EF

22

Schematic

drawing

of

electric

automatic

choke

heater

Fast

idle

C3m

The

fast

idle

cam

determines

the

opening

of

throttle

valve

so

as

to

obtain

proper

amount

of

mixture

corresponding

to

the

opening

of

the

choke

valve

which

depends

upon

the

warmed

up

condition

of

the

enigne

Fast

idle

adjusting

screw

This

screw

adjusts

the

opening

of

the

throttle

valve

by

fast

idle

cam

Unloader

When

accelerating

the

car

during

the

warm

up

period

that

is

before

the

choke

valve

does

not

sufficiently

open

this

unloader

makes

the

choke

valve

open

to

a

certain

extent

so

as

to

obtain

an

adequate

air

fuel

mixture

Vacuum

diaphragm

The

moment

when

engine

starts

this

diaphragm

forces

choke

valve

open

to

the

predetermined

extent

so

as

to

provide

necessary

amount

of

air

fuel

mixture

Bi

metaI

index

mark

The

bi

metal

index

mark

is

used

for

setting

the

moment

of

the

bi

metal

which

controls

the

mixing

ratio

required

for

starting

the

engine

EF

13

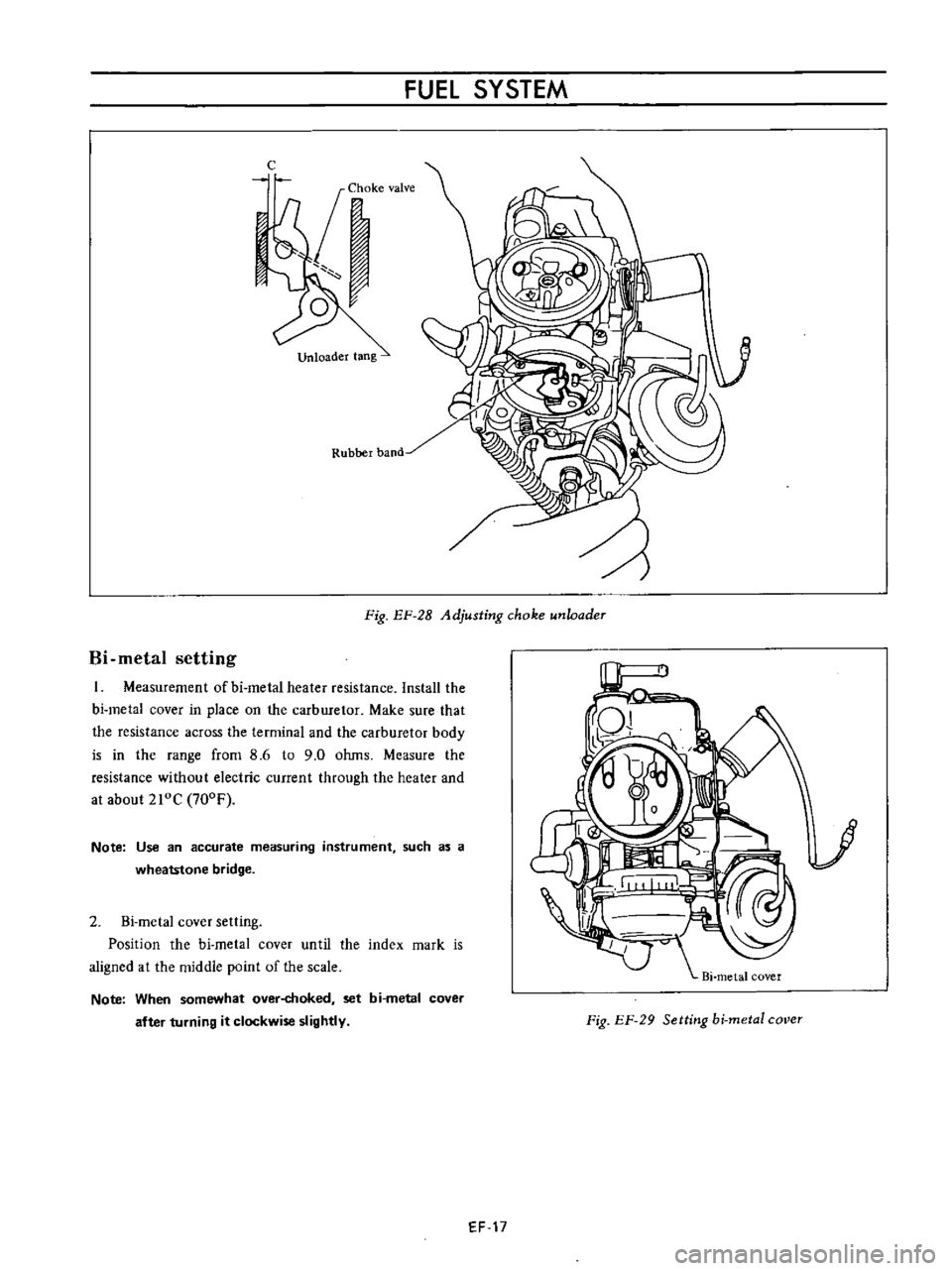

Page 408 of 513

FUEL

SYSTEM

c

Oke

valve

1

Or

Rubber

band

Fig

EF

2B

Adjusting

choke

unloadeT

Hi

metal

setting

Measurement

of

bi

metal

heater

resistance

Install

the

bi

metal

cover

in

place

on

the

carburetor

Make

sure

that

the

resistance

across

the

terminal

and

the

carburetor

body

is

in

the

range

from

8

6

to

9

0

ohms

Measure

the

resistance

without

electric

current

through

the

heater

and

at

about

210e

700F

Note

Use

an

accurate

measuring

instrument

such

as

a

wheatstone

bridge

2

Bi

metal

cover

setting

Position

the

hi

metal

cover

until

the

index

mark

is

aligned

at

the

middle

point

of

the

scale

Note

When

somewhat

over

choked

set

bi

metal

cover

after

turning

it

clockwise

slightly

Fig

EF

29

Setting

hi

metal

cover

EF

17

Page 467 of 513

CHASSIS

ENGINE

REMOVAL

AND

INSTALLATION

CONTENTS

PR

ECAUTIONS

REMOVAL

ERA

ERA

PRECAUTIONS

Be

sure

to

use

fender

cover

so

that

the

body

is

not

damaged

2

When

lifting

the

engine

or

when

jacking

up

the

engine

pay

attention

for

safety

and

carry

out

operation

correctly

so

that

the

parts

are

not

damaged

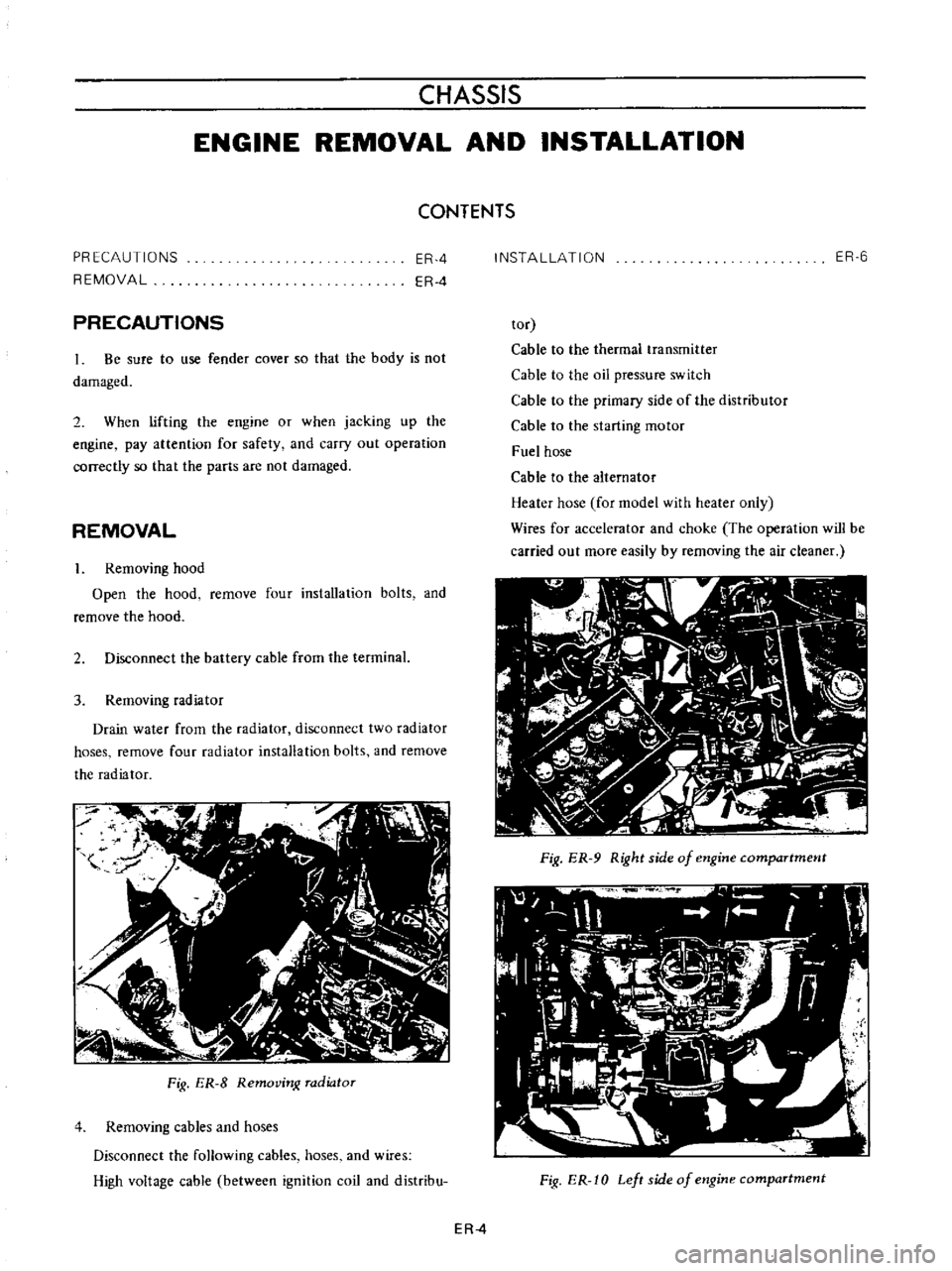

REMOVAL

I

Removing

hood

Open

the

hood

remove

four

installation

bolts

and

remove

the

hood

2

Disconnect

the

battery

cable

from

the

terminal

3

Removing

radiator

Drain

water

from

the

radiator

disconnect

two

radiator

hoses

remove

four

radiator

installation

bolts

and

remove

the

radiator

Fig

ER

8

Removin

radiator

4

Removing

cables

and

hoses

Disconnect

the

following

cables

hoses

and

wires

High

voltage

cable

between

ignition

coil

and

distribu

INSTAllATION

ER

6

tor

Cable

to

the

thermal

transmitter

Cable

to

the

oil

pressure

switch

Cable

to

the

primary

side

of

the

distributor

Cable

to

the

starting

motor

Fuel

hose

Cable

to

the

alternator

Heater

hose

for

model

with

heater

only

Wires

for

accelerator

and

choke

The

operation

will

be

carried

out

more

easily

by

removing

the

air

cleaner

Fig

ER

9

Right

side

of

engine

compartment

Fig

ER

10

Left

side

of

engine

compartment

ERA