lights DATSUN B110 1973 Service Repair Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1973, Model line: B110, Model: DATSUN B110 1973Pages: 513, PDF Size: 28.74 MB

Page 7 of 513

AUTOMATIC

TRANSMISSION

Manual

linkage

The

hand

lever

motion

The

hand

lever

is

located

in

the

driver

s

com

part

men

mechanically

transmitted

from

the

remote

control

linkage

is

further

transmitted

to

the

inner

manual

lever

in

the

transmission

case

from

the

range

selector

lever

in

the

right

center

poc

tion

of

the

transmission

case

through

the

manual

shaft

The

inner

manual

lever

is

thereby

turned

A

pin

installed

on

the

bottom

of

the

inner

manual

lever

slides

the

manu

al

valve

spool

of

the

control

valve

and

thus

the

spool

is

appropriately

posi

lioned

opposing

to

each

select

position

The

parking

rod

pin

is

held

in

the

groove

on

the

top

of

the

inner

manual

plate

The

parking

rod

pin

operates

the

rod

at

p

range

and

operates

the

mechanical

lock

system

Moreover

the

above

described

manual

shaft

is

equipped

with

an

inhibitor

switch

A

rotor

inside

the

inhibitor

switch

rotates

in

response

to

each

range

When

the

range

is

selected

at

p

or

N

the

rotor

closes

the

starter

magnet

circuit

so

that

the

engine

can

be

started

When

the

range

is

selected

at

R

the

rotor

closes

the

back

up

lamp

circuit

and

the

back

up

lamp

lights

Vacuum

diaphragm

The

vacuum

diaphragm

is

installed

un

the

left

center

portion

of

the

transmission

case

The

internal

con

struction

of

the

vacuum

diaphragm

is

as

follows

A

rubber

diaphragm

forms

a

partition

in

the

center

The

engine

intake

manifold

negative

pressure

led

through

vacuum

tube

and

spring

force

are

applied

to

the

front

surface

of

the

rubber

diaphragm

and

atmospheric

pressure

is

applied

to

the

back

surface

A

difference

between

pressure

applied

to

the

front

and

back

surfaces

be

comes

a

vacuum

reaction

and

thus

the

throttle

valve

of

the

control

valve

inside

the

transmission

case

is

op

erated

When

accelerator

pedal

is

fully

de

pressed

and

the

carburetor

is

fully

upened

but

the

engine

speed

is

not

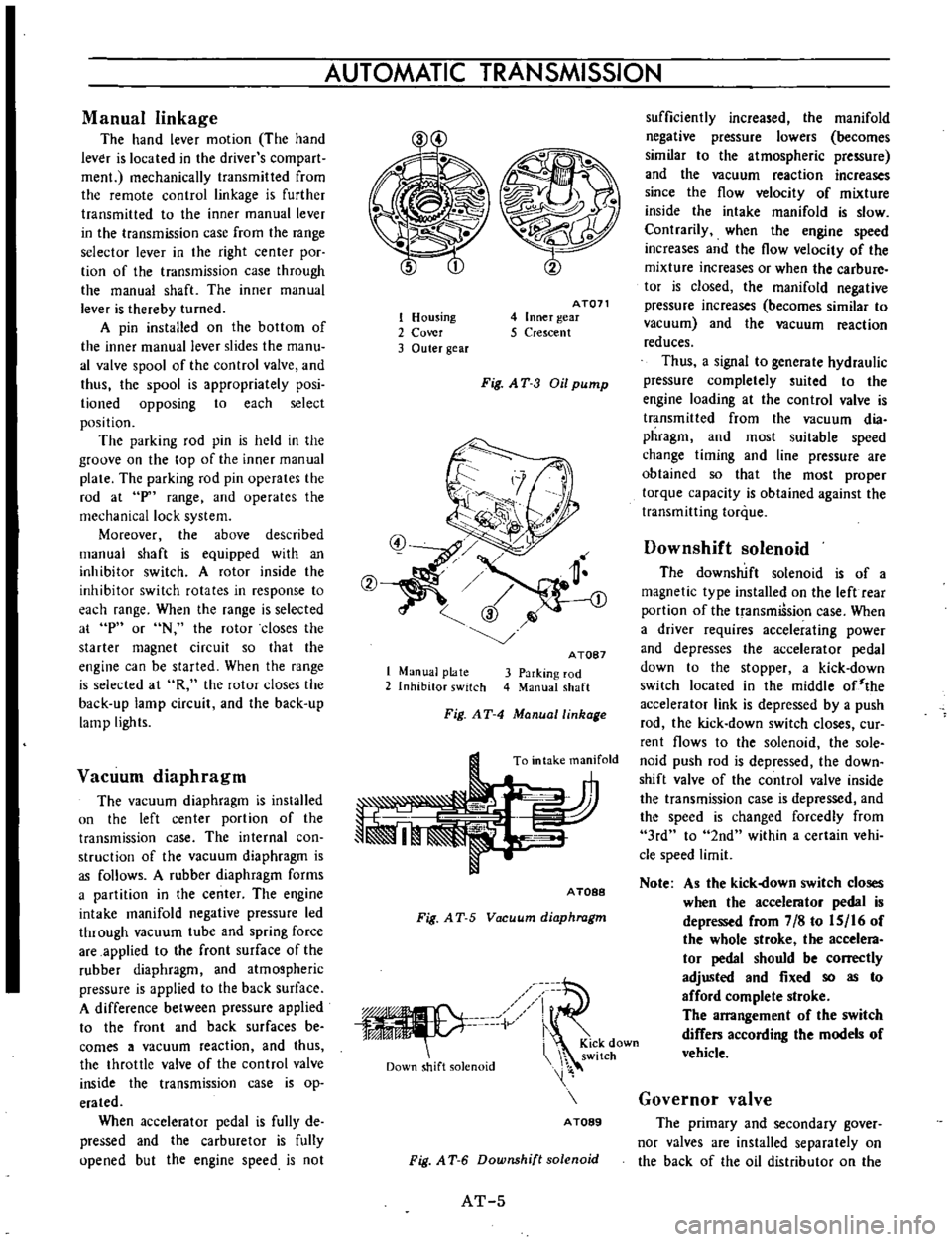

1

Housing

2

Cover

3

Outer

gear

AT071

4

Inner

gear

5

Crescent

Fig

AT

3

Oil

pump

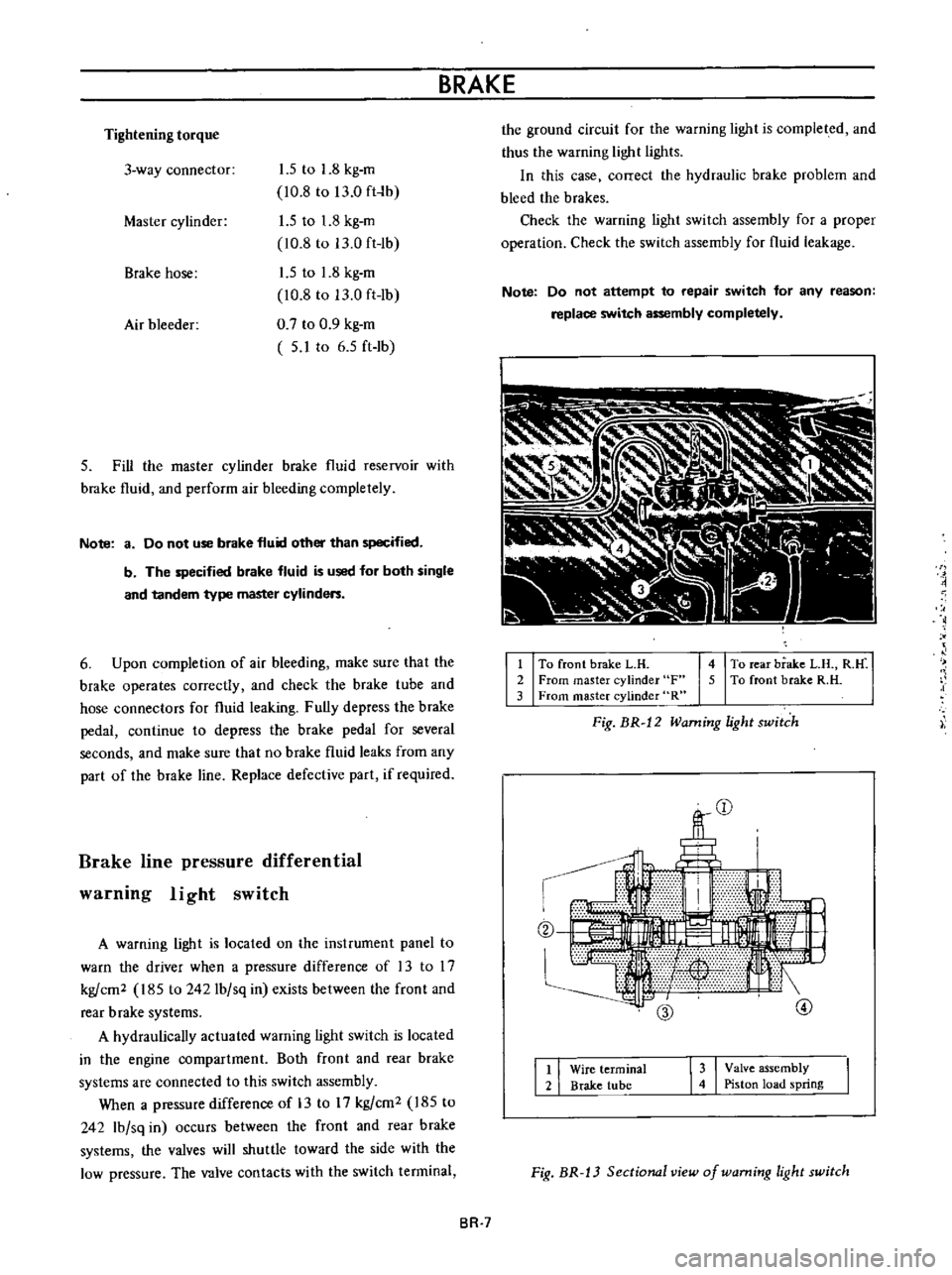

1

Manual

plate

2

Inhibitor

switch

A

TOB7

3

Parking

rod

4

Manual

shaft

Fig

AT

4

Manuallinhage

To

intake

manifold

A

TOBB

Fig

A

T

5

Vacuum

diaphragm

iV

Down

shift

solenoid

i

KiCk

down

switch

A

TOB9

Fig

A

T

6

Downshift

solenoid

AT

5

sufficiently

increased

the

manifold

negative

pressure

lowers

becomes

similar

to

the

atmospheric

pressure

and

the

vacuum

reaction

increases

since

the

flow

velocity

of

mixture

inside

the

intake

manifold

is

slow

Contrarily

when

the

engine

speed

increases

and

the

flow

velocity

of

the

mixture

increases

or

when

the

carbure

tor

is

closed

the

manifold

negative

pressure

increases

becomes

similar

to

vacuum

and

the

vacuum

reaction

reduces

Thus

a

signal

to

generate

hydraulic

pressure

completely

suited

to

the

engine

loading

at

the

control

valve

is

transmitted

from

the

vacuum

dia

phragm

and

most

suitable

speed

change

timing

and

line

pressure

are

obtained

so

that

the

most

proper

torque

capacity

is

obtained

against

the

transmitting

torque

Downshift

solenoid

The

downshift

solenoid

is

of

a

magnetic

type

installed

on

the

left

rear

portion

of

the

transmiSsion

case

When

a

driver

requires

accelerating

power

and

depresses

the

accelerator

pedal

down

to

the

stopper

a

kick

down

switch

located

in

the

middle

of

the

accelerator

link

is

depressed

by

a

push

rod

the

kick

down

switch

closes

cur

rent

flows

to

the

solenoid

the

sole

noid

push

rod

is

depressed

the

down

shift

valve

of

the

control

valve

inside

the

transmission

case

is

depressed

and

the

speed

is

changed

forcedly

from

3rd

to

2nd

within

a

certain

vehi

cle

speed

limit

Note

As

the

kick

own

switch

closes

when

the

accelerator

pedal

is

depressed

from

7

8

to

IS

16

of

the

whole

stroke

the

accelera

tor

pedal

should

be

correctly

adjusted

and

fixed

so

as

to

afford

complete

stroke

The

arrangement

of

the

switch

differs

according

the

models

of

vehicle

Governor

valve

The

primary

and

secondary

gover

nor

valves

are

installed

separately

on

the

back

of

the

oil

distributor

on

the

Page 131 of 513

Tightening

torque

3

way

connector

1

5

to

1

8

kg

m

10

8

to

13

0

ft

lh

1

5

to

1

8

kg

m

10

8

to

13

0

ft

lh

1

5

to

1

8

kg

m

10

8

to

13

0

ft

lb

0

7

to

0

9

kg

m

5

1

to

6

5

ft

1b

Master

cylinder

Brake

hose

Air

bleeder

5

Fill

the

master

cylinder

brake

fluid

reservoir

with

brake

fluid

and

perform

air

bleeding

complele1y

Note

a

Do

not

use

brake

fluid

other

than

specified

b

The

specified

brake

fluid

is

used

for

both

single

and

tandem

type

master

cylinders

6

Upon

completion

of

air

bleeding

make

sure

that

the

brake

operates

correctly

and

check

the

brake

tube

and

hose

connectors

for

fluid

leaking

Fully

depress

the

brake

pedal

continue

to

depress

the

brake

pedal

for

several

seconds

and

make

sure

that

no

brake

fluid

leaks

from

any

part

of

the

brake

line

Replace

defective

part

if

required

Brake

line

pressure

differential

warning

light

switch

A

warning

light

is

located

on

the

instrument

panel

to

warn

the

driver

when

a

pressure

difference

of

13

to

17

kg

cm2

185

to

2421bJsq

in

exists

between

the

front

and

rear

b

rake

systems

A

hydraulically

actuated

warning

light

switch

is

located

in

the

engine

compartment

Both

front

and

rear

brake

systems

are

connected

to

this

switch

assembly

When

a

pressure

difference

of

13

to

17

kgJcm2

185

to

242

lbJsq

in

occurs

between

the

front

and

rear

brake

systems

the

valves

will

shuttle

toward

the

side

with

the

low

pressure

The

valve

contacts

with

the

switch

terminal

BRAKE

the

ground

circuit

for

the

warning

light

is

completed

and

thus

the

warning

light

lights

In

this

case

correct

the

hydraulic

brake

problem

and

bleed

the

brakes

Check

the

warning

light

switch

assembly

for

a

proper

operation

Check

the

switch

assembly

for

fluid

leakage

Note

Do

not

attempt

to

repair

switch

for

any

reason

replace

switch

assembly

completely

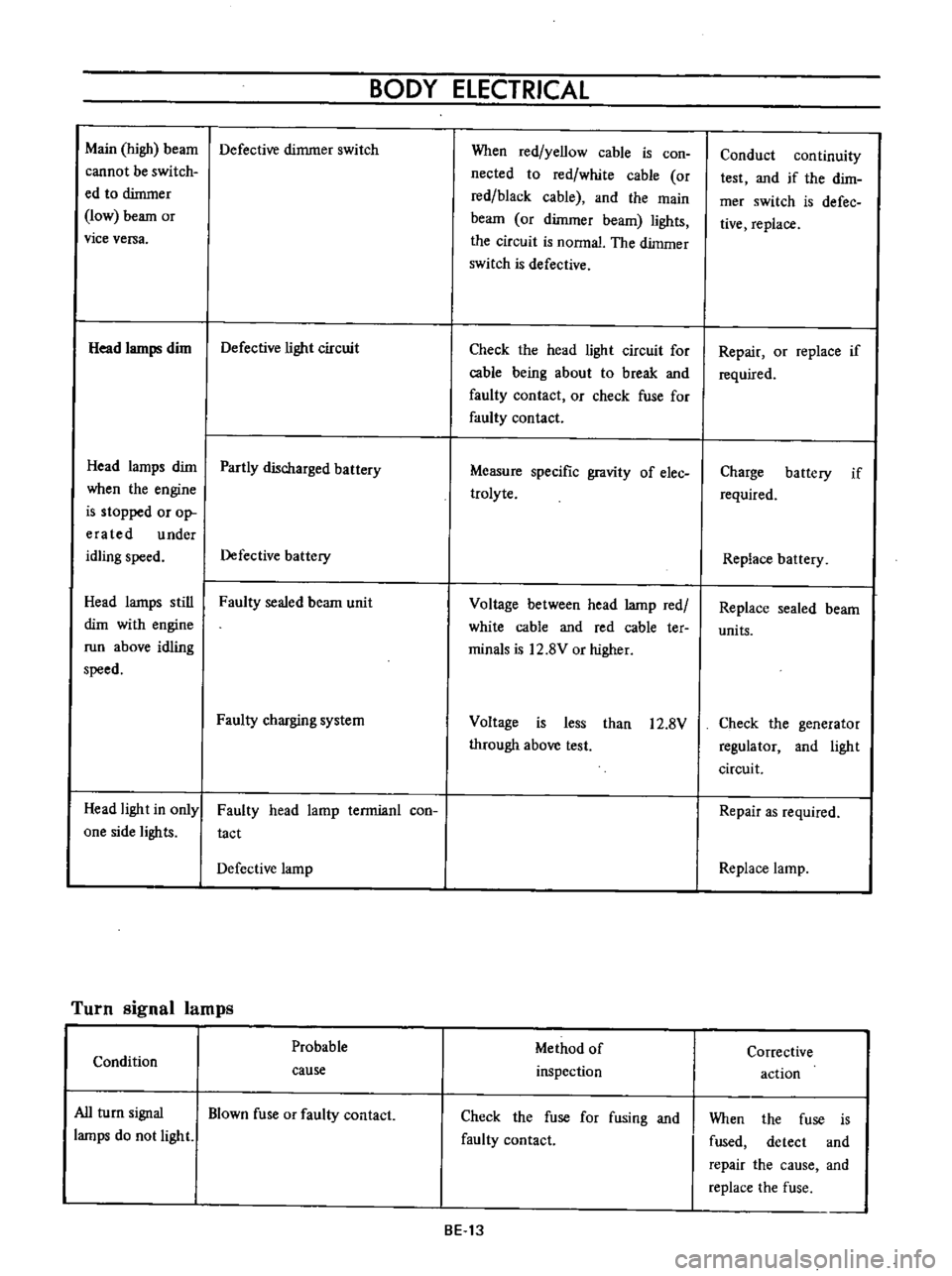

1

To

front

brake

L

H

2

From

master

cylinder

F

3

From

master

cylinder

R

4

To

rear

brake

L

B

R

M

5

To

front

brake

R

H

Fig

BR

12

Warning

light

switch

r

I

@

I

I

3

I

Valve

assembly

4

Piston

load

spring

Wire

terminal

Brake

tube

Fig

BR

13

Sectional

view

of

warning

light

switch

BR

7

Page 248 of 513

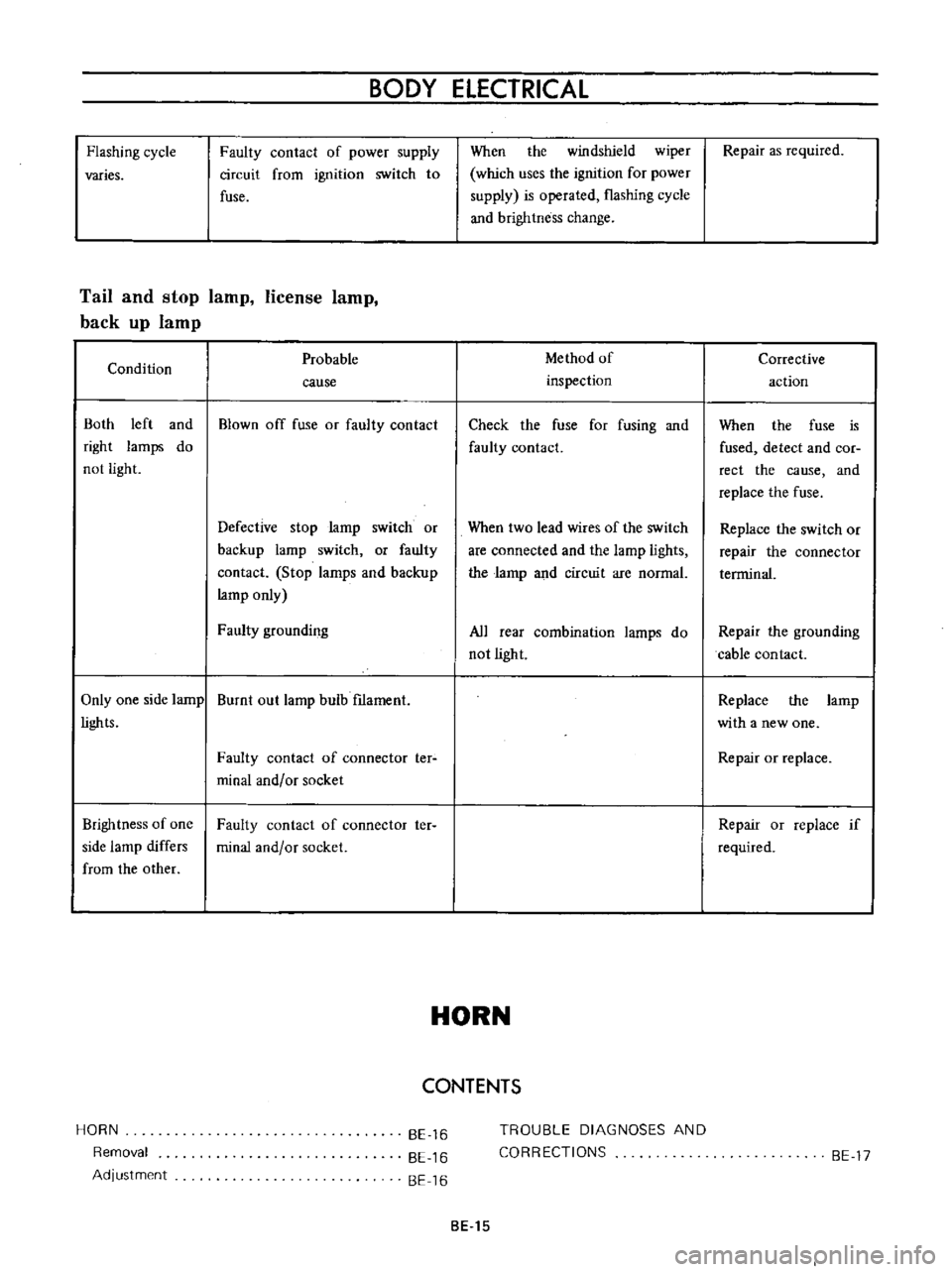

BODY

ELECTRICAL

Main

high

beam

Defective

dimmer

switch

cannot

be

switch

ed

to

dimmer

low

beam

or

vice

versa

Head

lamps

dim

Defective

light

circuit

Head

lamps

dim

Partly

discharged

battery

when

the

engine

is

stopped

or

op

era

ted

under

idling

speed

Defective

battery

Head

lamps

still

Faulty

sealed

beam

unit

dim

with

engine

run

above

idling

speed

Faulty

charging

system

Head

light

in

only

one

side

lights

Faulty

head

lamp

terrnianl

con

tact

Defective

lamp

Turn

signal

lamps

Probable

Condition

cause

All

turn

signal

Blown

fuse

or

faulty

contact

lamps

do

not

light

When

red

yellow

cable

is

con

nected

to

red

white

cable

or

red

black

cable

and

the

main

beam

or

dimmer

beam

lights

the

circuit

is

nonnal

The

dimmer

switch

is

defective

Check

the

head

light

circuit

for

cable

being

about

to

break

and

faulty

contact

or

check

fuse

for

faulty

contact

Measure

specific

gravity

of

elec

trolyte

Voltage

between

head

lamp

red

white

cable

and

red

cable

ter

minals

is

12

8V

or

higher

Voltage

is

less

than

12

8V

through

above

test

Method

of

inspection

Check

the

fuse

for

fusing

and

faulty

contact

BE

13

Conduct

continuity

test

and

if

the

dirn

mer

switch

is

defec

tive

replace

Repair

or

replace

if

required

Charge

battery

if

required

Replace

battery

Replace

sealed

beam

units

Check

the

generator

regulator

and

light

circuit

Repair

as

required

Replace

lamp

Corrective

action

When

the

fuse

is

fused

detect

and

repair

the

cause

and

replace

the

fuse

Page 250 of 513

Flashing

cycle

varies

BODY

ELECTRICAL

Faulty

contact

of

power

supply

circuit

from

ignition

switch

to

fuse

Tail

and

stop

lamp

license

lamp

back

up

lamp

Condition

Both

left

and

right

lamps

do

not

light

Probable

cause

Blown

off

fuse

or

faulty

contact

Defective

stop

larnp

switch

or

backup

lamp

switch

or

faulty

contact

Stop

larnps

and

backup

lamp

only

Faulty

grounding

Only

one

side

lamp

Burnt

out

lamp

bulb

f1lament

lights

Brightness

of

one

side

lamp

differs

from

the

other

HORN

Removal

Adjustment

Faulty

contact

of

connector

ter

minal

and

or

socket

Faulty

contact

of

connector

ter

minal

and

or

socket

BE

16

BE

16

BE

16

When

the

windshield

wiper

which

uses

the

ignition

for

power

supply

is

operated

flashing

cycle

and

brightness

change

Method

of

inspection

Check

the

fuse

for

fusing

and

faulty

contact

When

two

lead

wires

of

the

switch

are

connected

and

the

lamp

lights

the

larnp

and

circuit

are

normal

All

rear

combination

lamps

do

not

light

HORN

CONTENTS

TROUBLE

DIAGNOSES

AND

CORRECTIONS

BE

15

Repair

as

required

Corrective

action

When

the

fuse

is

fused

detect

and

COf

rect

the

cause

and

replace

the

fuse

Replace

the

switch

or

repair

the

connector

terrninal

Repair

the

grounding

cable

contact

Replace

the

larnp

with

a

new

one

Repair

or

replace

Repair

or

replace

if

required

BE

17

Page 256 of 513

BODY

ElECTRICAL

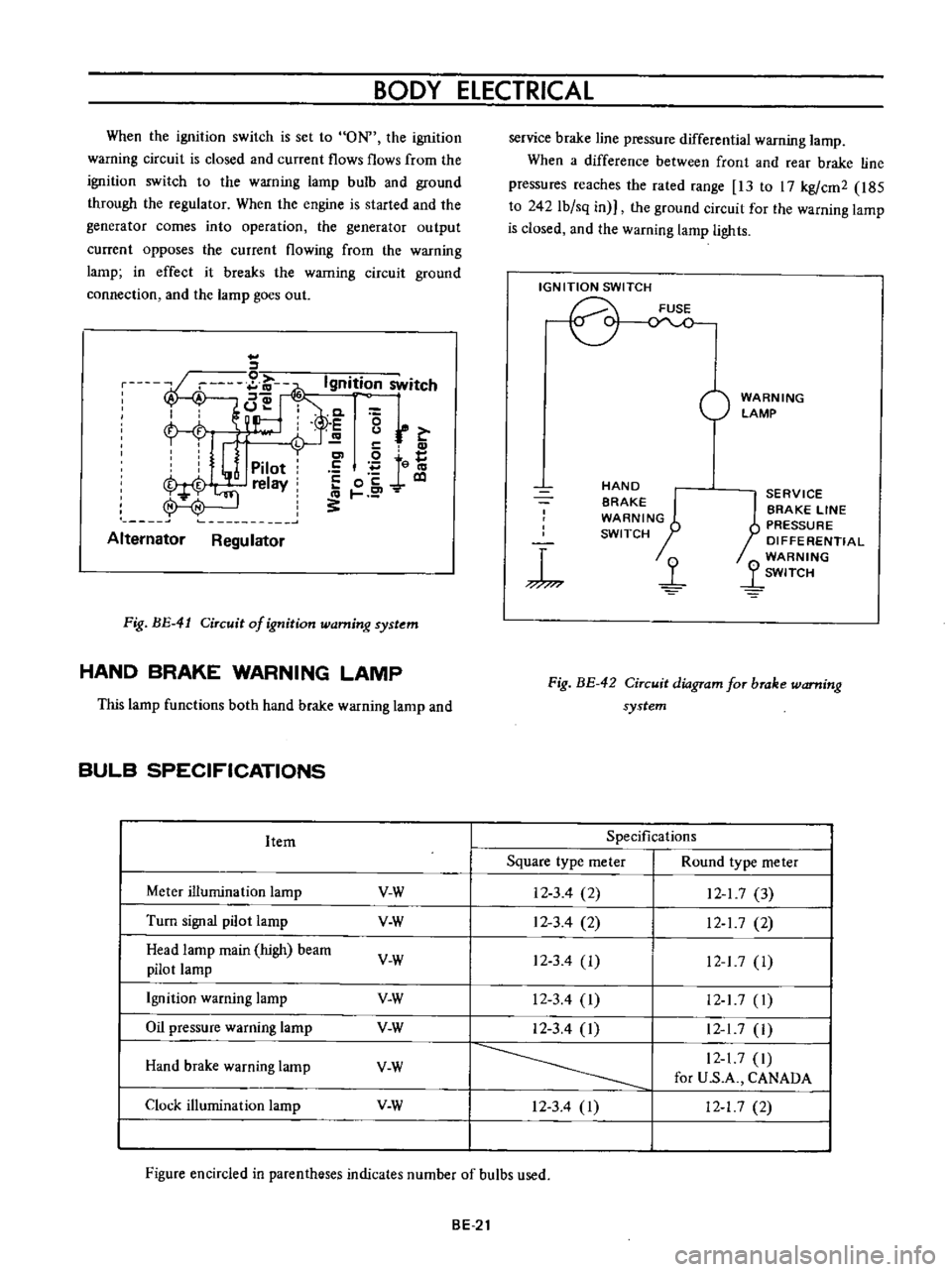

When

the

ignition

switch

is

set

to

ON

the

ignition

wa

rning

circuit

is

closed

and

current

flows

flows

from

the

ignition

switch

to

the

warning

lamp

bulb

and

ground

through

the

regulator

When

the

engine

is

started

and

the

generator

comes

into

operation

the

generator

output

current

opposes

the

current

flowing

from

the

warning

lamp

in

effect

it

breaks

the

warning

circuit

ground

connection

and

the

lamp

goes

out

l

r

hffi

u

z

Ignition

switch

I

Q

6

I

0

c

M

1

E

8

ca

i

L

g

PI

lot

c

P

I

j

co

rt

0

relay

E

0

5

y

y

1

N

N

3

Alternator

Regulator

Fig

BE

41

Circuit

of

ignition

warning

system

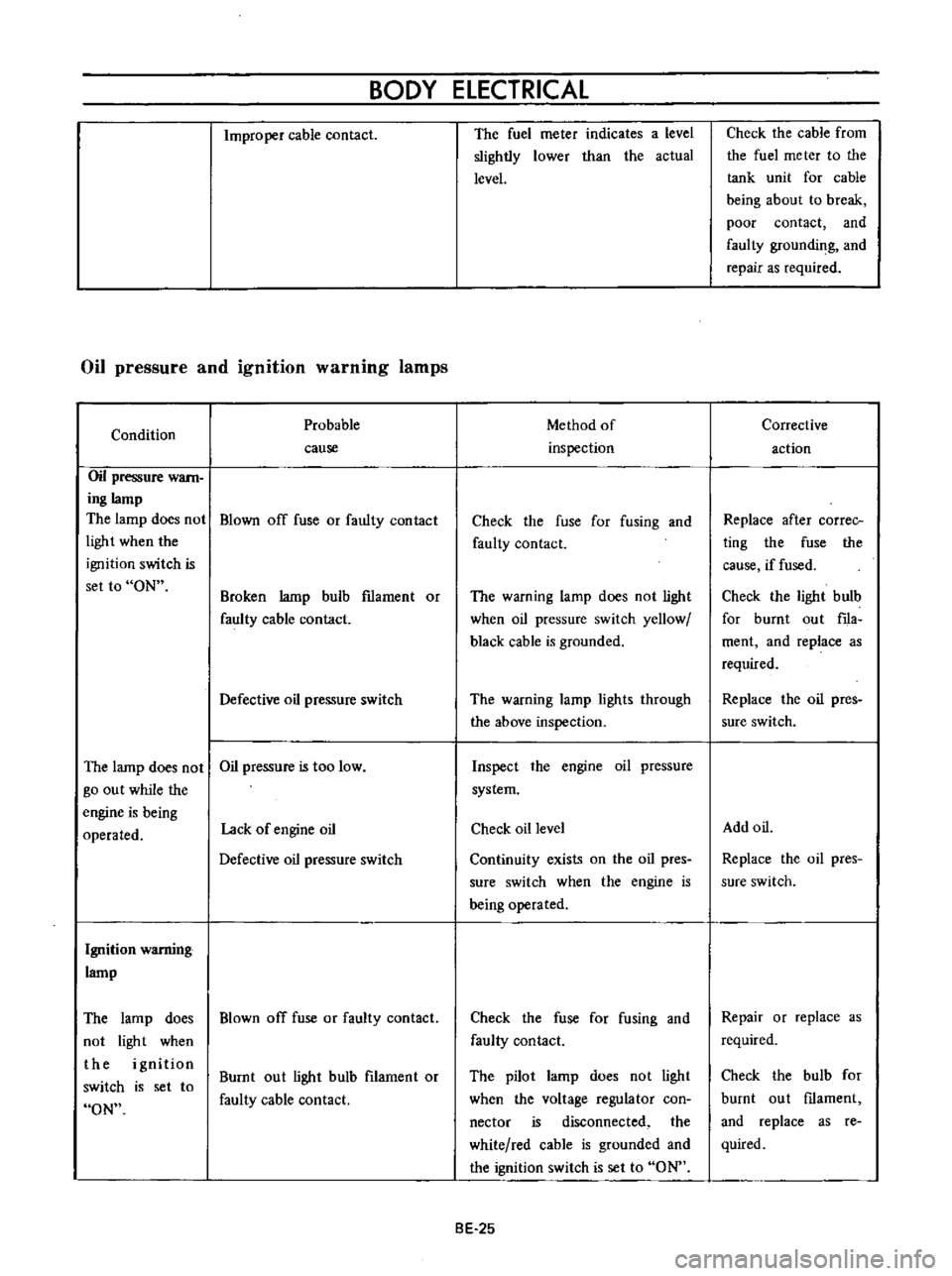

HAND

BRAKE

WARNING

LAMP

This

lamp

functions

both

hand

brake

warning

larnp

and

BULB

SPECIFICATIONS

service

brake

line

pressure

differential

warning

lamp

When

a

difference

between

front

and

rear

brake

line

pressures

reaches

the

rated

range

13

to

17

kgfcm2

185

to

242

lb

sq

in

the

ground

circuit

for

the

warning

lamp

is

closed

and

the

warning

lamp

lights

IGNITION

SWITCH

WARNING

LAMP

L

E

WARNING

SWITCH

1

SERVICE

BRAKE

LINE

PRESSU

R

E

DIFFERENTIAL

WARNING

J

SWITCH

Fig

BE

42

Circuit

diagram

for

brake

warning

system

tern

Specifications

Square

type

meter

Round

type

meter

Meter

illumination

larnp

VoW

12

3

4

2

12

1

7

3

Turn

signal

pilot

lamp

VoW

12

3

4

2

12

1

7

2

Head

lamp

main

high

beam

VoW

12

3

4

I

12

17

1

pilot

lamp

Ignition

warning

lamp

VoW

123

4

I

12

17

1

Oil

pressure

warning

lamp

VoW

12

3

4

1

12

1

7

1

Hand

brake

warning

lamp

VoW

12

1

7

1

for

U

S

A

CANADA

Clock

illumination

lamp

VoW

123

4

I

12

17

2

Figure

encircled

in

parentheses

indicates

number

of

bulbs

used

BE

21

Page 260 of 513

BODY

ELECTRICAL

Improper

cable

contact

Oil

pressure

and

ignition

warning

lamps

Condition

Oil

pressure

Want

ing

lamp

The

lamp

does

not

ligh

t

when

the

ignition

switch

is

set

to

ON

Probable

cause

Blown

off

fuse

or

faulty

contact

Broken

lamp

bulb

fIlarnent

or

faulty

cable

contact

Defective

oil

pressure

switch

The

lamp

does

not

Oil

pressure

is

too

low

go

out

while

the

engine

is

being

operated

Lack

of

engine

oil

Defective

oil

pressure

switch

Ignition

warning

lamp

The

lamp

does

not

light

when

the

ignition

switch

is

set

to

ON

Blown

off

fuse

or

faulty

contact

Burnt

out

light

bulb

filarnent

or

faulty

cable

contact

The

fuel

rneter

indicates

a

level

slightly

lower

than

the

actual

level

Method

of

inspection

Check

the

fuse

for

fusing

and

faulty

contact

The

warning

lamp

does

not

light

when

oil

pressure

switch

yellow

black

cable

is

grounded

The

warning

lamp

lights

through

the

above

inspection

Inspect

the

engine

oil

pressure

system

Check

oil

level

Continuity

exists

on

the

oil

pres

sure

switch

when

the

engine

is

being

operated

Check

the

fuse

for

fusing

and

faulty

contact

The

pilot

lamp

does

not

light

when

the

voltage

regulator

con

nector

is

disconnected

the

white

red

cable

is

grounded

and

the

ignition

switch

is

set

to

ON

BE

25

Check

the

cable

from

the

fuel

meter

to

the

tank

unit

for

cable

being

about

to

break

poor

contact

and

faulty

grounding

and

repair

as

required

Corrective

action

Replace

after

corree

ting

the

fuse

the

cause

if

fused

Check

the

light

bulb

for

burnt

out

fIla

ment

and

replace

as

required

Replace

the

oil

pres

sure

switch

Add

oil

Replace

the

oil

pres

sure

switch

Repair

or

replace

as

required

Check

the

bulb

for

burnt

out

fIlament

and

replace

as

re

quired

Page 442 of 513

ENGINE

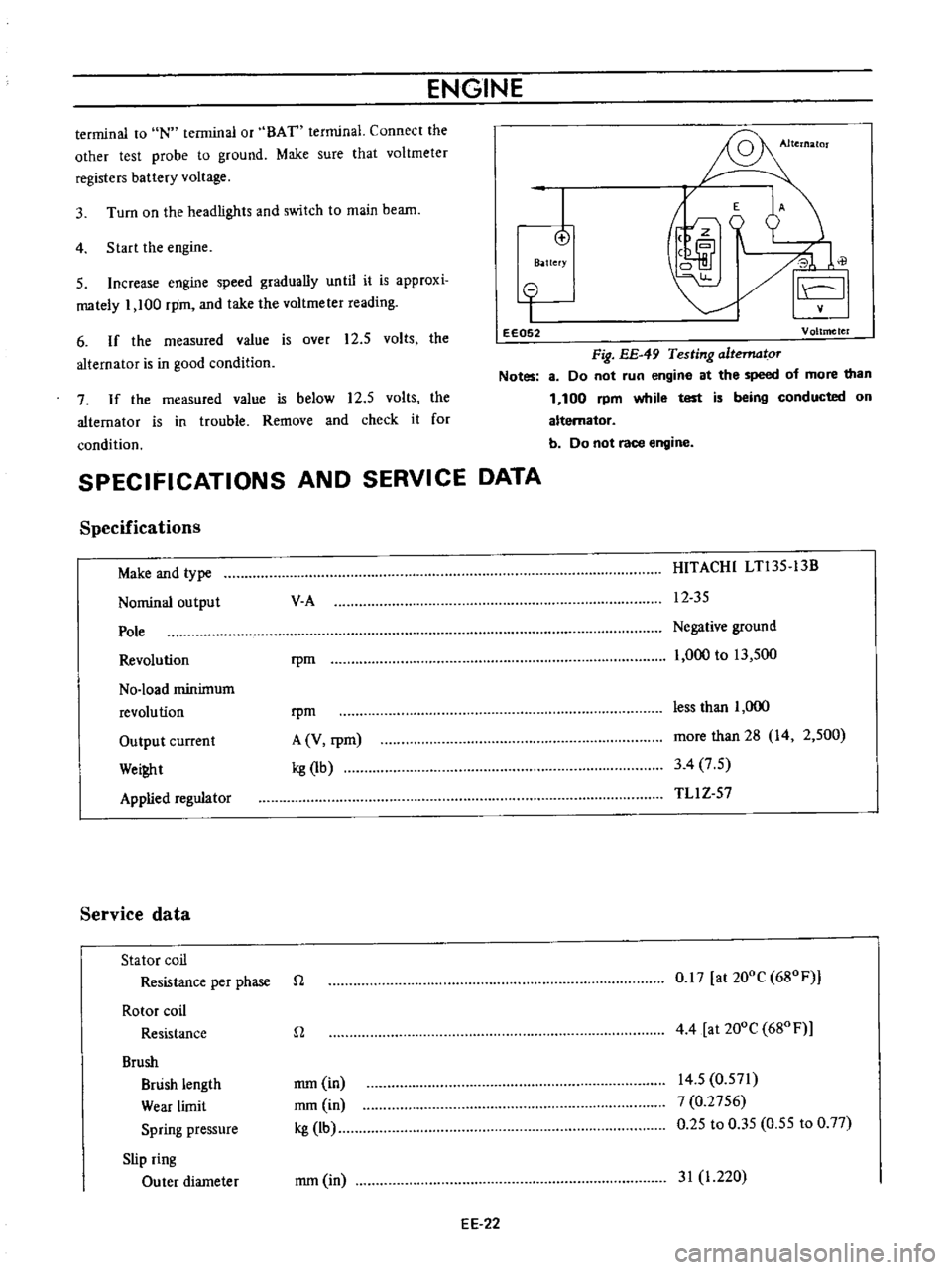

terminal

to

IN

terminal

or

BAT

terminal

Connect

the

other

test

probe

to

ground

Make

sure

that

voltmeter

registers

battery

voltage

4

Start

the

engine

3

Turn

on

the

headlights

and

switch

to

main

beam

I

o

B

ttefY

E

A

J

0

il

I

5

Increase

engine

speed

gradually

until

it

is

approxi

mately

1

100

rpm

and

take

the

voltmeter

reading

6

If

the

measured

value

is

over

12

5

volts

the

alternator

is

in

good

condition

o

I

eE052

Voltmeter

Fig

EE

49

Testing

altematoT

Notes

8

Do

not

run

engine

at

the

speed

of

more

than

1

100

rpm

while

test

is

being

conducted

on

alternator

b

Do

not

race

engine

7

If

the

measured

value

is

below

12

5

volts

the

alternator

is

in

trouble

Remove

and

check

it

for

condition

SPECIFICATIONS

AND

SERVICE

DATA

Specifications

Make

and

type

Nominal

output

Pole

Revolution

No

load

minimum

revolution

Output

current

Wei

t

Applied

regulator

Service

data

Stator

coil

Resistance

per

phase

Rotor

coil

Resistance

Brush

Brush

length

Wear

limit

Spring

pressure

Slip

ring

Outer

diameter

V

A

HITACHI

LTl35

13B

12

35

rpm

Negative

ground

1

000

to

13

500

rpm

A

V

rpm

kg

1b

less

than

1

000

more

than

28

14

2

500

3

4

7

5

TLl

Z

57

n

0

17

at

200C

680F

n

4

4

at

200e

680

F

mm

in

mm

in

kg

lb

14

5

0

571

7

0

2756

0

25

to

0

35

0

55

to

0

77

mm

in

31

1

220

EE

22